Preparation method of cerium oxide microspheres

A technology of ceria and microspheres, applied in the field of nanomaterials, to achieve the effects of easy control, mild reaction conditions, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

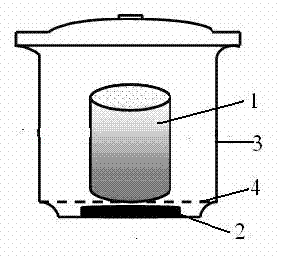

Method used

Image

Examples

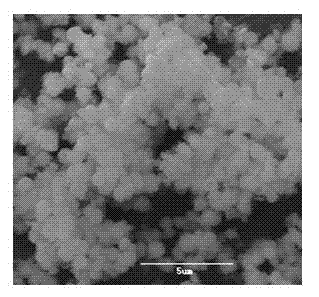

Embodiment 1

[0035] (1) Dissolve industrial cerium carbonate with nitric acid to obtain cerium nitrate, remove impurities and filter to obtain 282.62g / L cerium nitrate mother liquor with high purity.

[0036] Take 42.6ml of cerium nitrate mother liquor in a beaker filled with 457.4ml of water, stir evenly with a glass rod, then vibrate with an ultrasonic wave for 5min; in addition, dissolve 0.5g / L polyelectrolyte PSS in 500ml of water, stir evenly with a glass rod, Also use ultrasonic vibration for 5 minutes; then slowly pour the PSS aqueous solution into the cerium nitrate aqueous solution, adjust the pH to 4, continue stirring until uniform, use ultrasonic vibration for 15 minutes, seal the mouth of the beaker with plastic wrap, and pierce 3 holes on the plastic wrap ,stand-by;

[0037] (2) Take 20.2 g of ground ammonium carbonate, put it into a petri dish, seal it with plastic wrap, and make 3 holes.

[0038] (3) Put the petri dish containing ammonium carbonate in (2) into the bottom o...

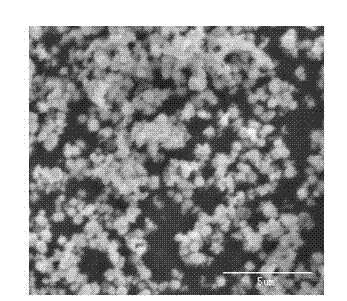

Embodiment 2

[0042] (1) Dissolve industrial cerium carbonate with nitric acid to obtain cerium nitrate, remove impurities and filter to obtain 282.62g / L cerium nitrate mother liquor with high purity. Take 9.74ml of cerium nitrate mother liquor in a beaker containing 491.26ml of water, stir evenly with a glass rod, then oscillate with ultrasonic wave for 5min; dissolve 0.5g / L PAH in 500ml of water, stir evenly with a glass rod, Ultrasonic oscillation for 5 minutes; then slowly pour the polyelectrolyte PAH aqueous solution into the cerium nitrate aqueous solution, adjust the pH to 4, continue stirring until uniform, use ultrasonic oscillation for 15 minutes, seal the mouth of the beaker with plastic wrap, and pierce 3 holes on the plastic wrap ,stand-by;

[0043] (2) Take 3.8g of ground ammonium bicarbonate, put it into a petri dish, seal it with plastic wrap, and make 3 holes.

[0044] (3) Put the petri dish containing ammonium bicarbonate in (2) into the bottom of the desiccator, add a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com