Mirror silver coating, mirror silver resin forming mirror silver coating, and preparation methods for mirror silver coating and mirror silver resin

A mirror-surface silver resin and technology of mirror-surface silver, which are applied in the preparation of mirror-surface silver coatings and composite mirror-surface silver resins, mirror-surface silver coatings, and the field of composite mirror-surface silver resins, can solve the problem of not meeting the requirements of wet-on-wet process spraying and losing the paint film Protective effect, poor paint film compactness and other problems, to achieve excellent coating film high transparency, improve chemical resistance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

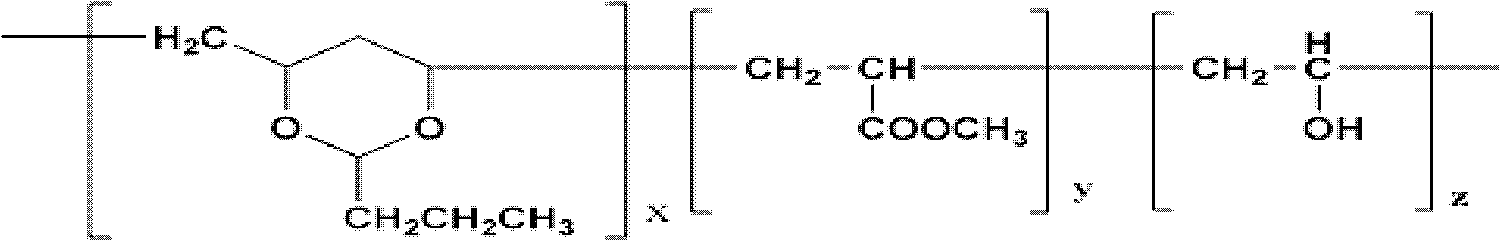

[0060] 1. Preparation of mirror silver resin

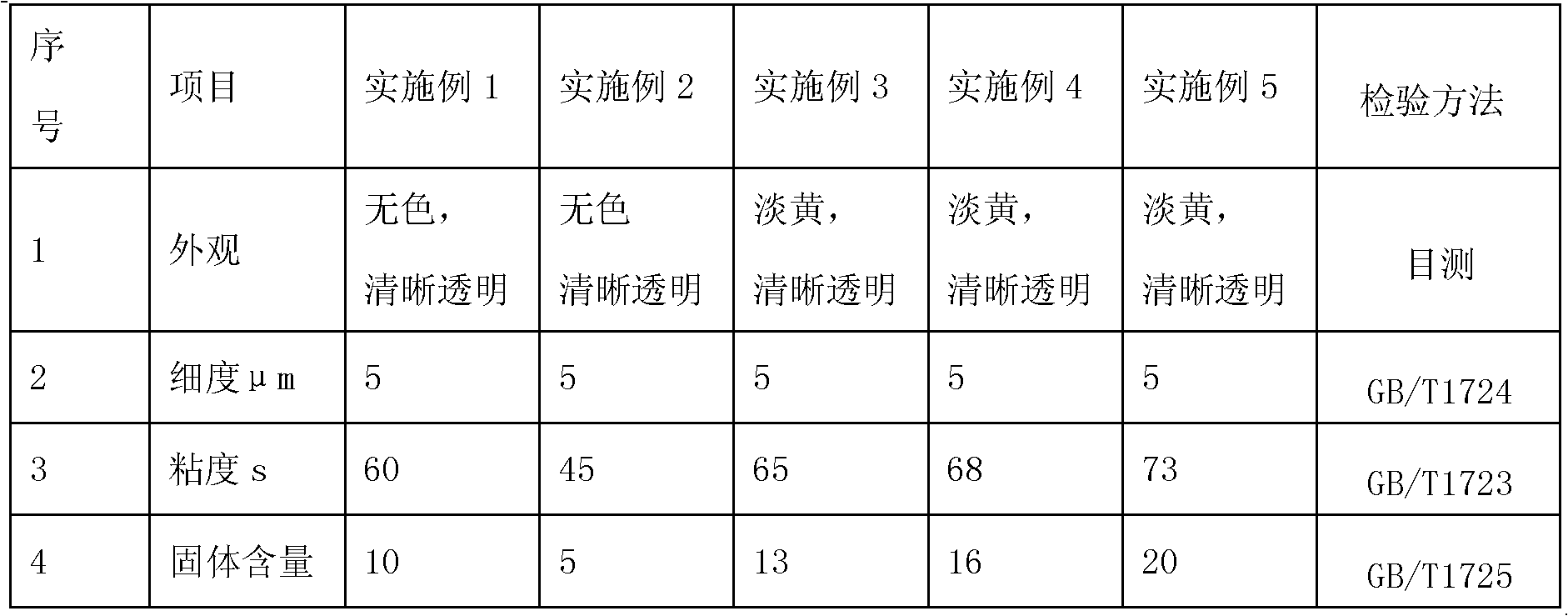

[0061] The formula of the mirror silver resin prepared in each embodiment is shown in Table 1:

[0062] Table 1: The formula mass parts of mirror silver resin are calculated by mass parts

[0063] Example 1

Example 2

Example 3

Example 4

Example 5

10

5

13

16

20

50

60

45

40

30

20

20

30

19

20

20

15

12

25

30

[0064] (2) Preparation steps

[0065] According to the production volume, choose equipment and tools such as dispersing cylinder and dispersing machine, and choose the power of the machine. In principle, the higher the power, the easier the dispersion of materials, and to ensure that it is clean and trouble-free.

[0066] (1) Add butanol to the paint mixing tank, adjust the speed to 200r / min, add polyvinyl butyral under stirring, and dissolve uniformly;

[0067] (2) Under stirring, add xylene and butyl acetate in order. After the additio...

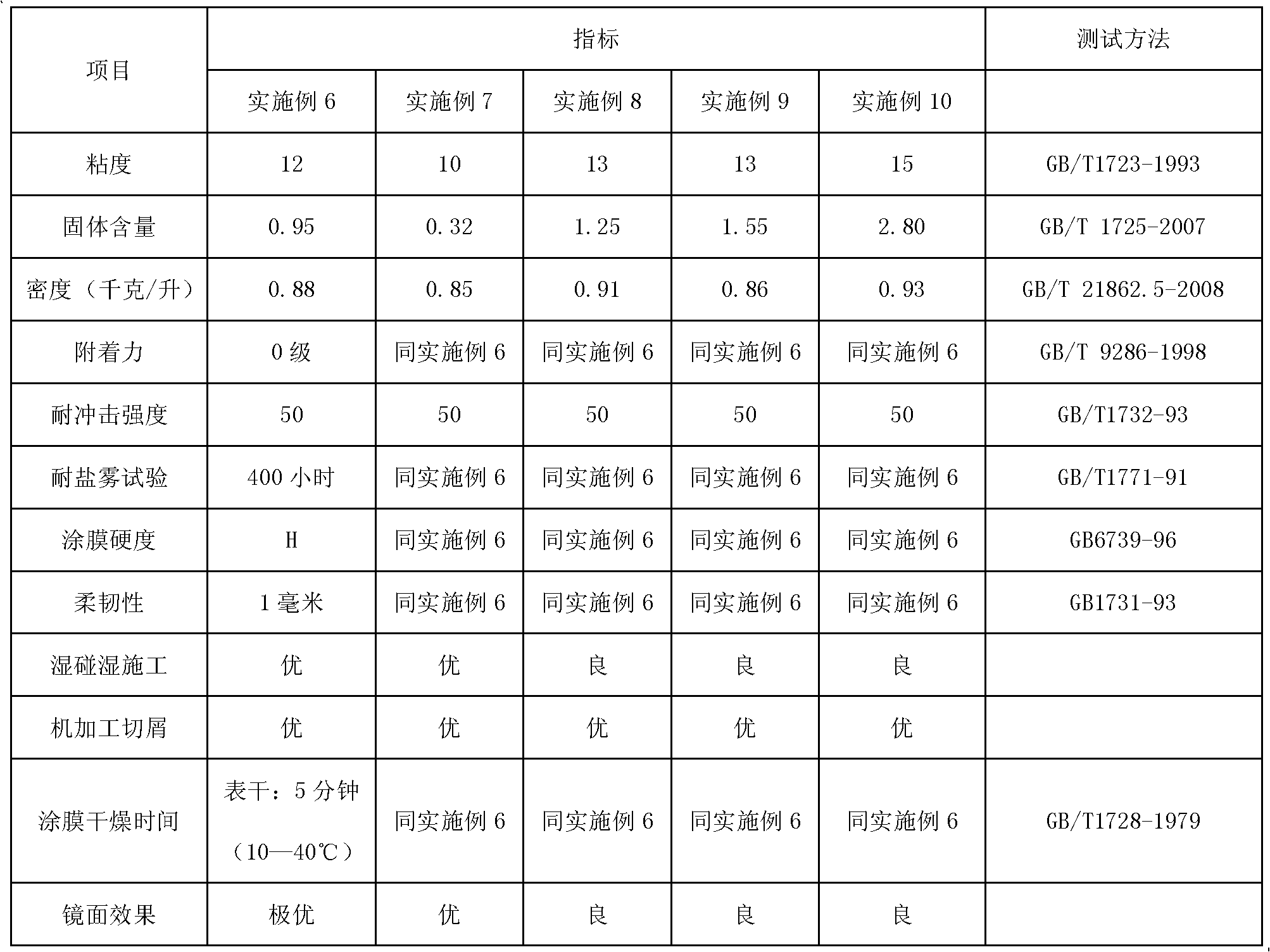

Embodiment 6

[0074] (1) Paint formula

Embodiment 1

[0075] The mirror silver resin prepared in Example 1 8kg;

[0076] Butanol 15kg;

[0078] Ethyl acetate 43.5kg;

[0079] Butyl acetate 15kg;

[0080] Propylene glycol methyl ether acetate 9kg;

[0081] Electroplating silver paste 1.5kg.

[0082] (2) Preparation steps

[0083] According to the production volume, choose equipment and tools such as dispersing cylinder and dispersing machine, and choose the power of the machine. In principle, the higher the power, the easier the dispersion of materials, and to ensure that it is clean and trouble-free.

[0084] (1) At room temperature, add butanol and isopropanol to the paint mixing tank, and adjust the speed to 200r / min. Under stirring, add the mirror silver resin prepared in Example 1 and dissolve uniformly to obtain a uniform solution A for use. ;

[0085] (2) Take the uniform solution A obtained in step (1), add ethyl acetate and butyl acetate under stirring, and after the addition is complete, continue to sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com