Process for preparing high-purity diketene

A technology for the preparation of diketene, which is applied in the field of preparation of high-purity diketene, can solve the problems of high content of acetic acid in the residual liquid, low product purity, and many side reactions, and achieve the effects of low operating cost, high purity, and long stability time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

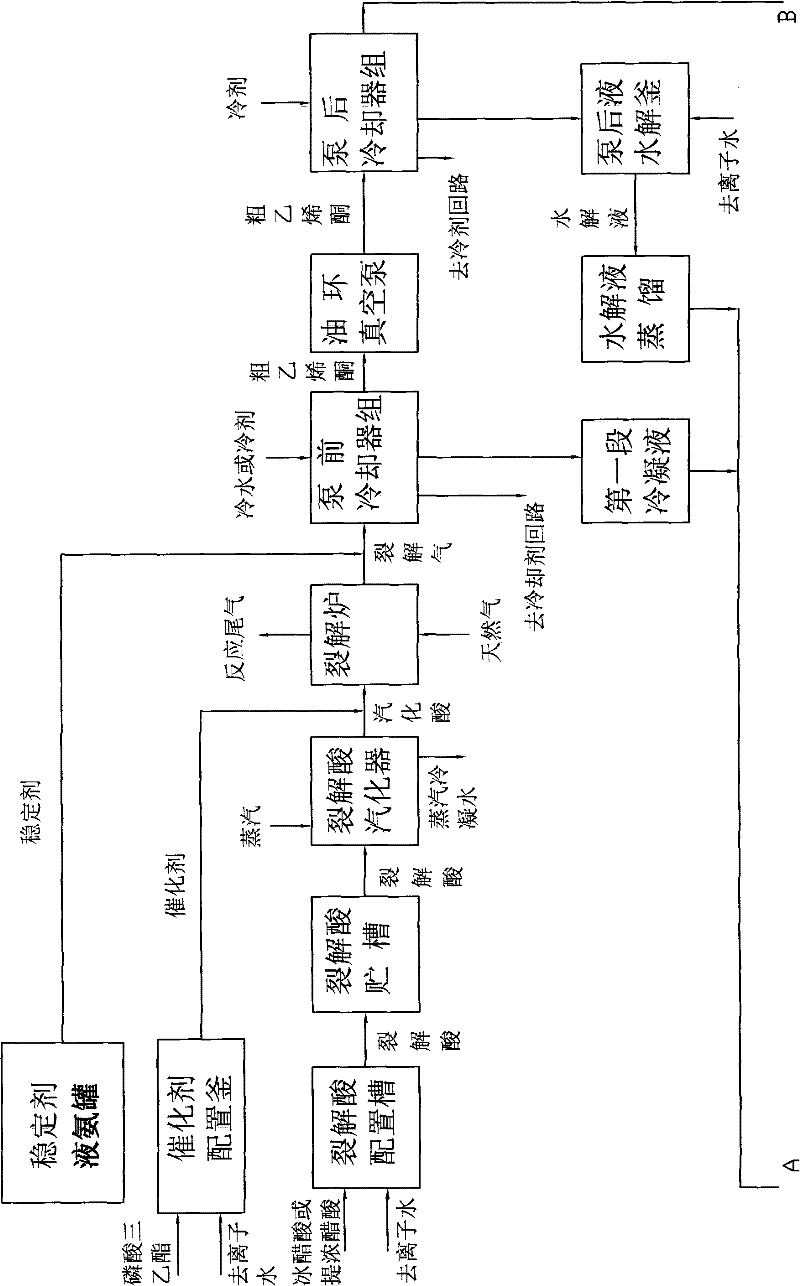

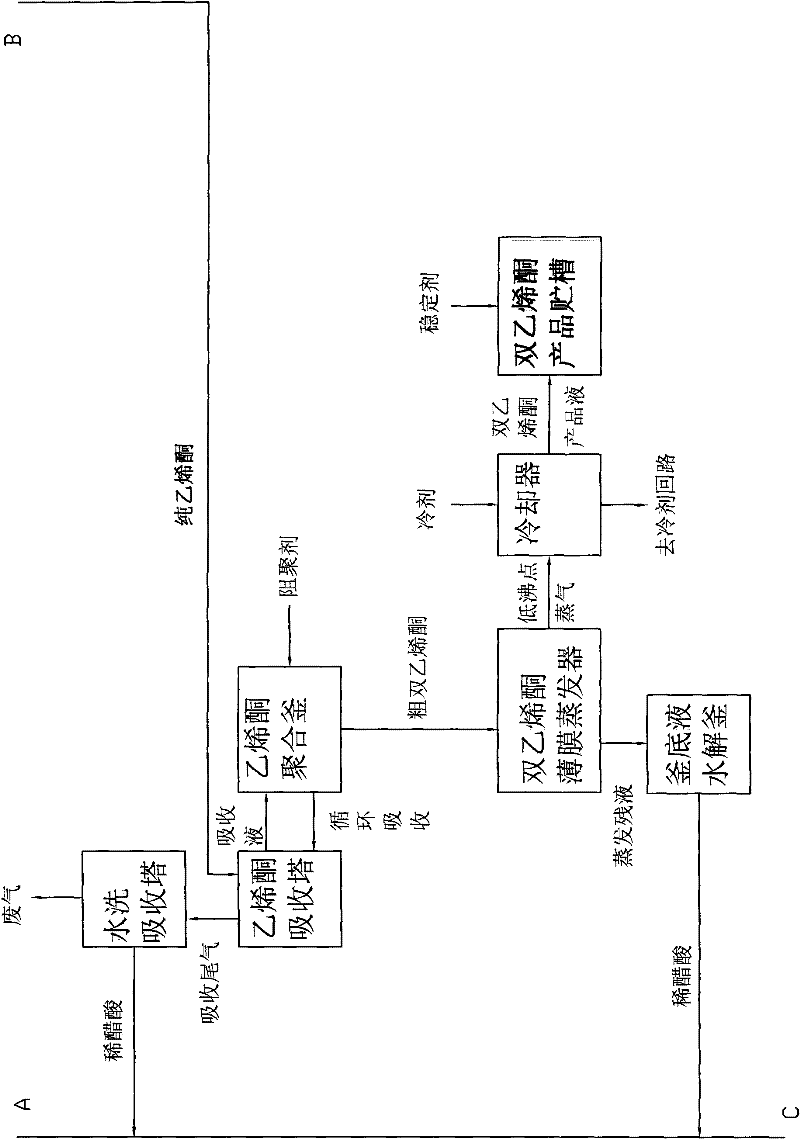

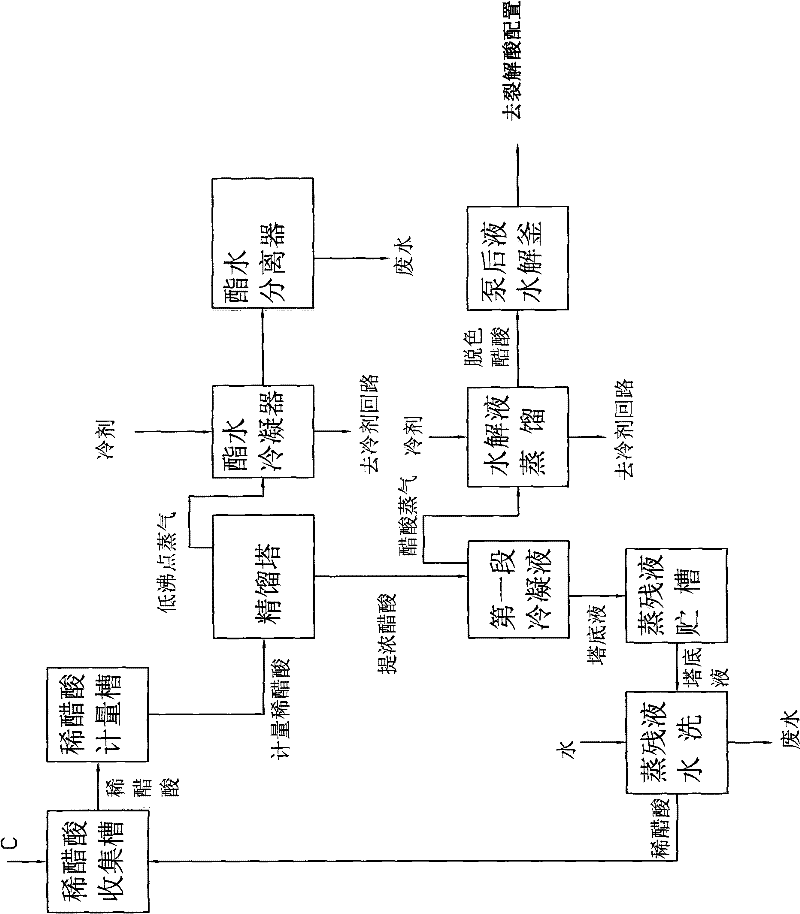

[0056] Such as Figure 1 to Figure 3 As shown, the preparation process of high-purity diketene includes acetic acid cracking process, diketene synthesis process, dilute acetic acid concentration process.

[0057] The acetic acid cracking process includes:

[0058] The > 80% acetic acid and 99% glacial acetic acid obtained from dilute acetic acid enrichment process are prepared into 92% acetic acid solution; the acetic acid solution is vaporized into acetic acid vapor and the prepared triethyl phosphate solution catalyst is acetic acid per unit time 0.3% of the feeding amount enters the cracking tube at 740°C at the same time and undergoes high-temperature cracking under the negative pressure of 12kPa. The acetic acid is thermally cracked into a mixed cracking gas containing ketene, water and side reaction products; in order to prevent the reverse reaction and polymerization of ketene, mix 0.3% liquid ammonia according to the feeding amount of acetic acid is fed into the crack...

Embodiment 2

[0065] Acetic acid cracking and freezing impurity removal process operate according to the following process, and all the other are with embodiment 1:

[0066] (1) The high-temperature catalyst used in the cracking reaction of acetic acid is triethyl phosphate. The> 80% acetic acid obtained from the dilute acetic acid enrichment process, the concentrated> 80% acetic acid and 99% glacial acetic acid are prepared into a 91% acetic acid solution, and the 91% acetic acid solution is vaporized, and the acetic acid vapor and mass Triethyl phosphate with a percentage of about 8% enters the cracking tube at 730°C and 10kPa negative pressure at the same time at a ratio of 100:2 for high-temperature cracking, and acetic acid is thermally cracked into mixed cracking gas containing ketene, water and by-products ;

[0067] (2) In order to prevent the reverse reaction and polymerization of ketene in the mixed cracking gas, the mixed cracking gas and the 0.3% liquid ammonia added according ...

Embodiment 3

[0070] Acetic acid cracking and freezing impurity removal process operate according to the following process, and all the other are with embodiment 1:

[0071] (1) acetic acid cracking reaction adopts high-temperature catalyst to be ammonium dihydrogen phosphate, will come from the> 80% acetic acid that dilute acetic acid enrichment operation obtains, will concentrate> 80% acetic acid and 99% glacial acetic acid to be mixed with 95% acetic acid solution, The 95% acetic acid solution is gasified, and the acetic acid vapor and the ammonium dihydrogen phosphate with a mass percentage of about 12% are simultaneously entered into the cracking tube at 750°C and 15kPa negative pressure in a ratio of 100:4 for high-temperature cracking, and the acetic acid is Thermal cracking into mixed cracked gas containing ketene, water and side reaction products;

[0072] (2) The mixed cracked gas is rapidly cooled to below -20°C through the cooler group before the pump, and the water in the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com