Pleuromutilin solvent extraction process

A technology of pleuromutilin and extraction process, which is applied in the field of solvent extraction process of pleuromutilin, can solve the problems of endangering the health of production environment operators, high toxicity and irritation, large solvent consumption and the like, and achieves industrial application prospects Good, low water solubility, low solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0018] 1. Experimental materials and instruments

[0019] The whole fermentation broth of pleuromutilin was prepared according to the literature method (Hu C, et al.Effect of soybean oil on the production of mycelial biomass and pleuromutilin in the shake-flask culture of Pleurotus mutilis.World J Microb Biot, 2009, 25(10): 1705-1711) were produced by fermentation of the producer Pleurotus mutilis-04.

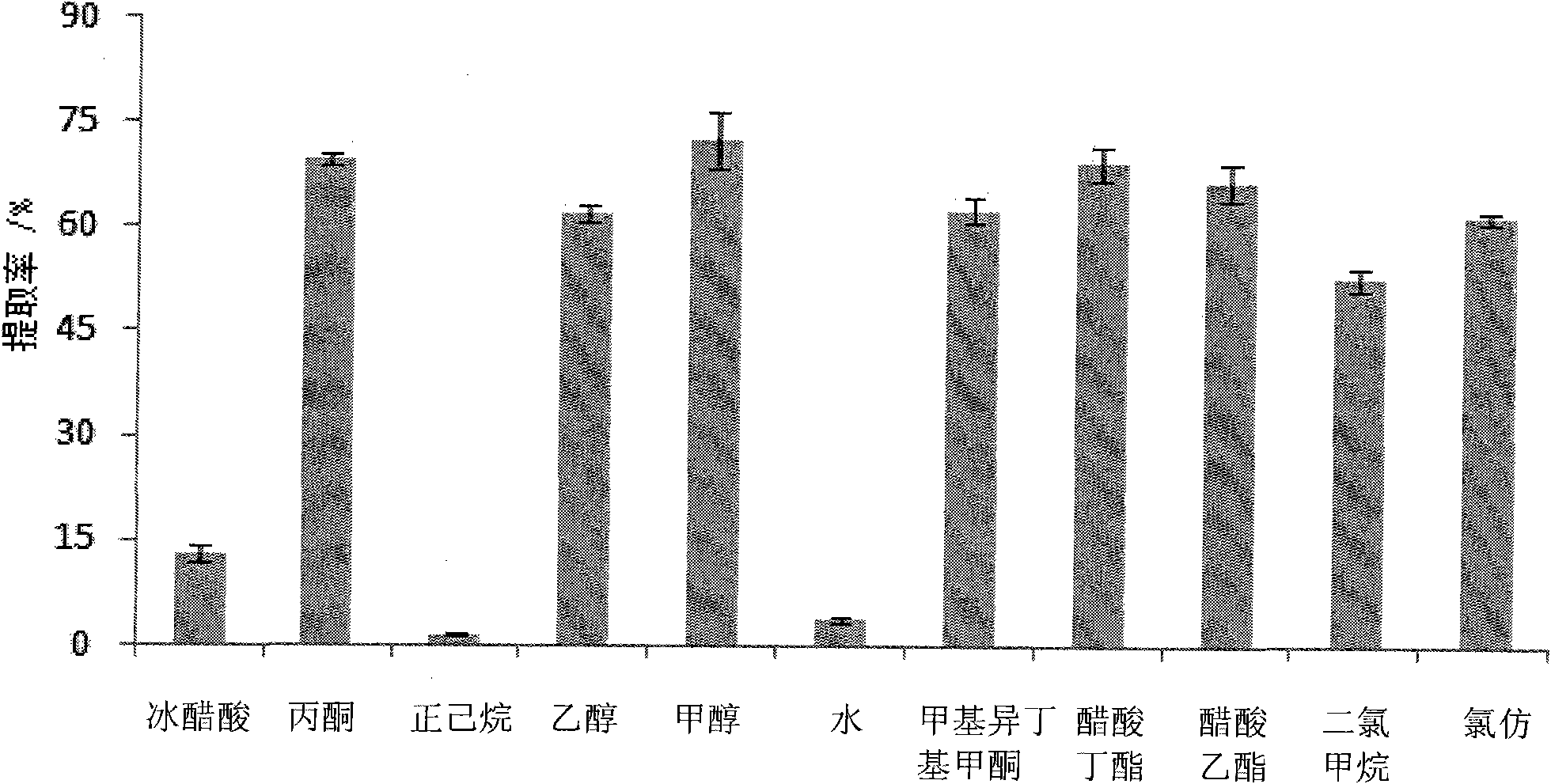

[0020] Solvents such as butyl acetate, methanol, glacial acetic acid, acetone, n-hexane, absolute ethanol, methyl isobutyl ketone, ethyl acetate, dichloromethane, and chloroform were all of domestic analytical grade, and chromatographic grade methanol was purchased from Fisher Scientific in the United States.

[0021] FUS-50L fermenter (Shanghai Guoqiang Biochemical Engineering Equipment Co., Ltd.), JA2003A electronic balance (Shanghai J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com