Pyrite nano mineral material and preparation method thereof

A mineral material, pyrite technology, applied in nanotechnology, sulfur preparation/purification, iron sulfide, etc., can solve the problems of catalyst poisoning, high cost, low efficiency of wastewater, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

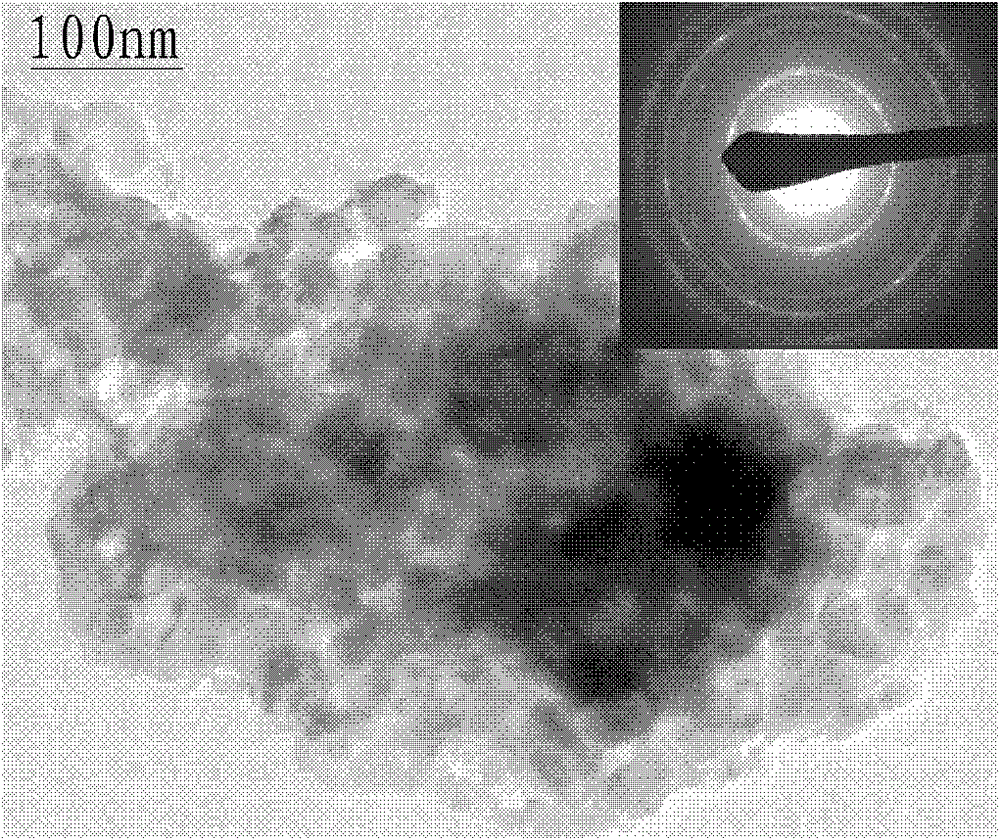

[0027] In this embodiment, 5 g of 200-mesh sulfur concentrate powder with a pyrite mass percentage content of not less than 95% is selected, put into a tube furnace with a supporting layer of quartz glass wool, and heated to 500° C. with nitrogen gas, and kept for 30 minutes, turn off the tube furnace power supply, and cool to room temperature under a nitrogen protective atmosphere to get the finished product ( figure 1 ). According to the chemical analysis results of Fe and S content, the ratio of Fe / S in the product pyrrhotite is 0.87-0.90:1

Embodiment 2

[0029] In this embodiment, 100 g of 200 mesh sulfur concentrate powder with pyrite mass percentage content not less than 95% is selected, and 8 g of water glass is added to form pellets with a particle diameter of 1-3 mm. In the tube furnace on the cotton supporting layer, pass nitrogen gas, heat to 600°C, keep warm for 30 minutes, turn off the power of the tube furnace, and cool to room temperature under nitrogen protection atmosphere to obtain the finished product. According to the chemical analysis results of Fe and S content, the ratio of Fe / S in the product pyrrhotite composition is 0.88-0.94:1

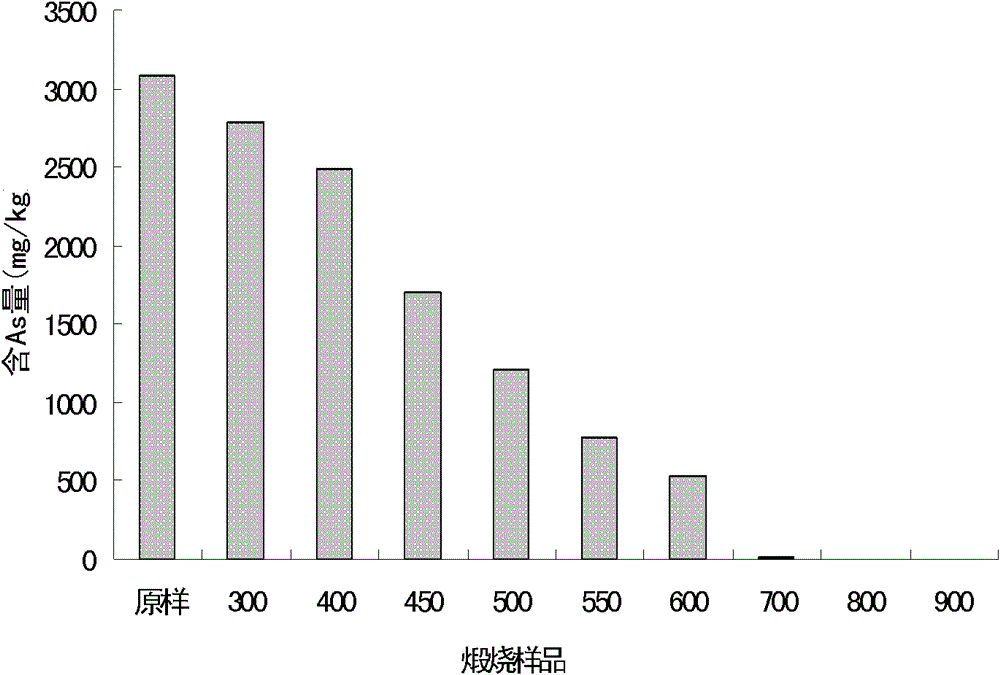

[0030] The content of pyrrhotite in the nano mineral material prepared by the present embodiment is greater than 95% ( figure 2 ), the arsenic content is less than 600mg / kg ( image 3 ), the magnetic susceptibility is greater than 3000SI ( Figure 4 ).

Embodiment 3

[0032] This embodiment selects pyrite ore (the rest is quartz and sericite) with pyrite mass percentage content not less than 80%, crushing and screening to obtain pellets with a particle size of 0.1-0.5mm, and putting the gained pellets into a belt In a tube furnace with a supporting layer of quartz glass wool, pass nitrogen gas, heat to 700°C, keep warm for 30 minutes, turn off the power of the tube furnace, and cool to room temperature under nitrogen protection atmosphere to obtain the finished product. According to the chemical analysis results of Fe and S content, the ratio of Fe / S in the product pyrrhotite composition is 0.88-0.94:1

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com