Lithium lanthanum bismuthate-based solid electrolyte material and preparation method thereof

A solid-state electrolyte and lithium-based technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problem of electrolytes that are not suitable for all-solid-state lithium-ion batteries, titanium, lanthanum and lithium components are not easy to control, and the temperature of preparation and synthesis is oxidized Lithium loss and other problems, to achieve the effect of easy, convenient and accurate doping process, easy control of components, and improvement of total conductivity at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

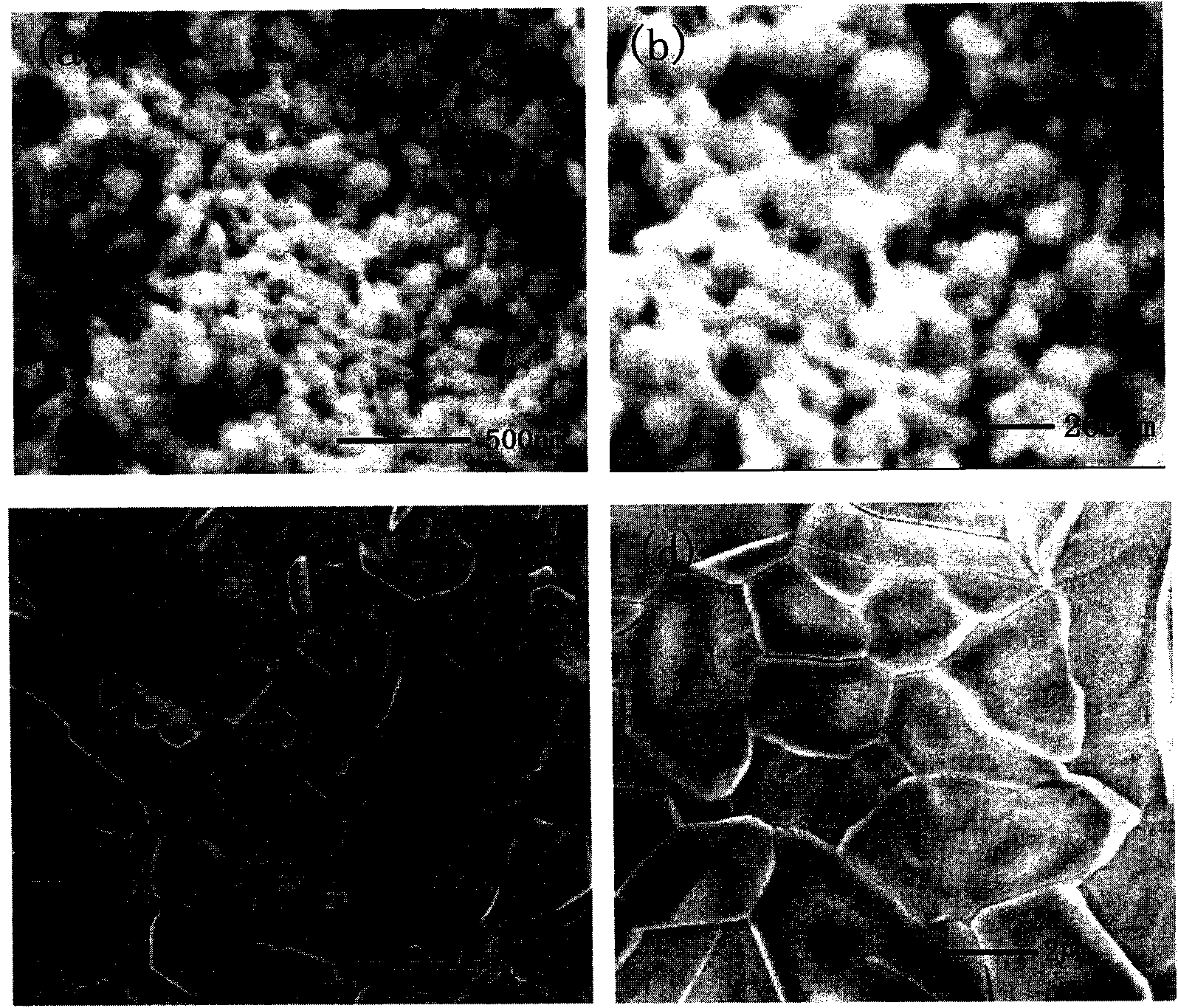

Image

Examples

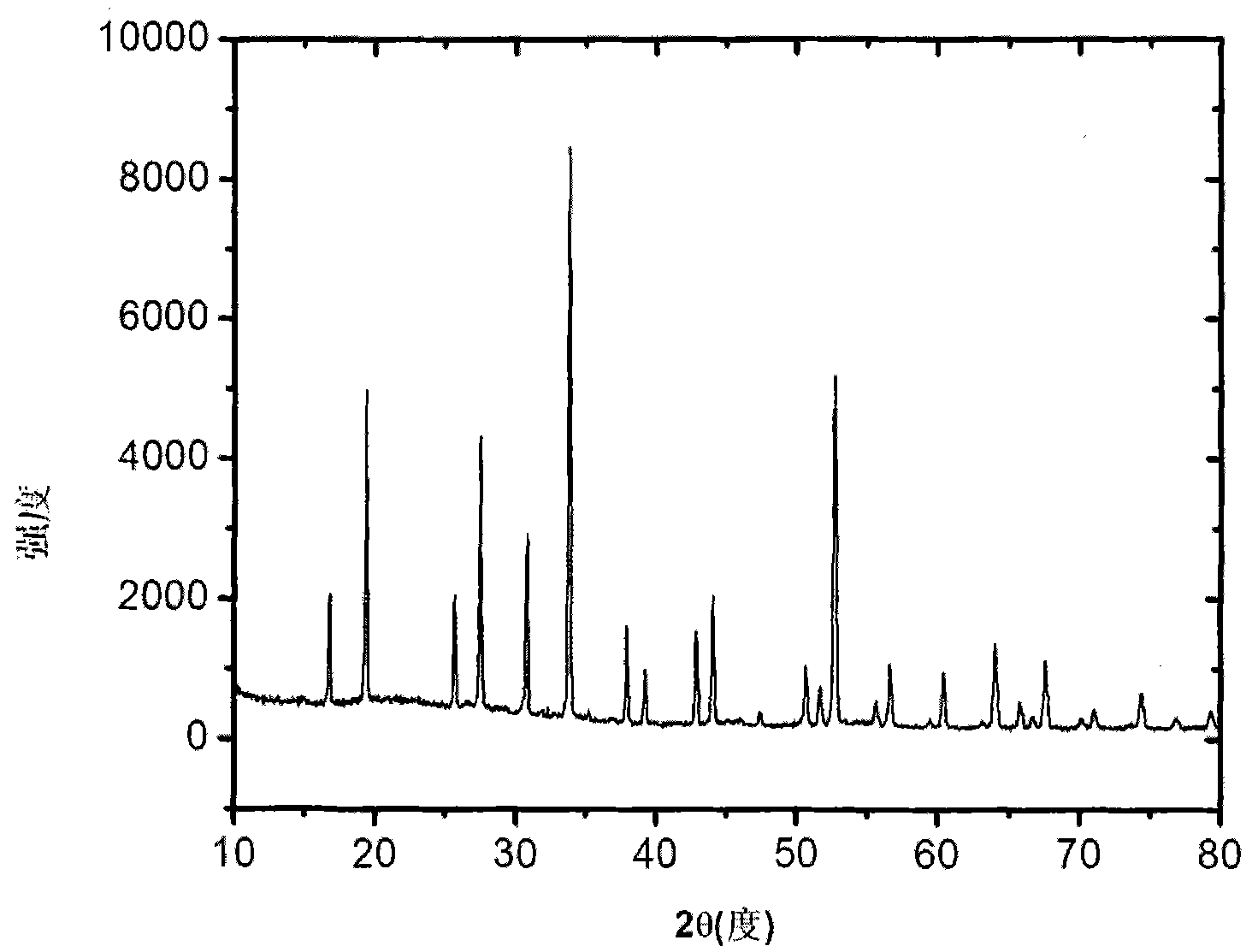

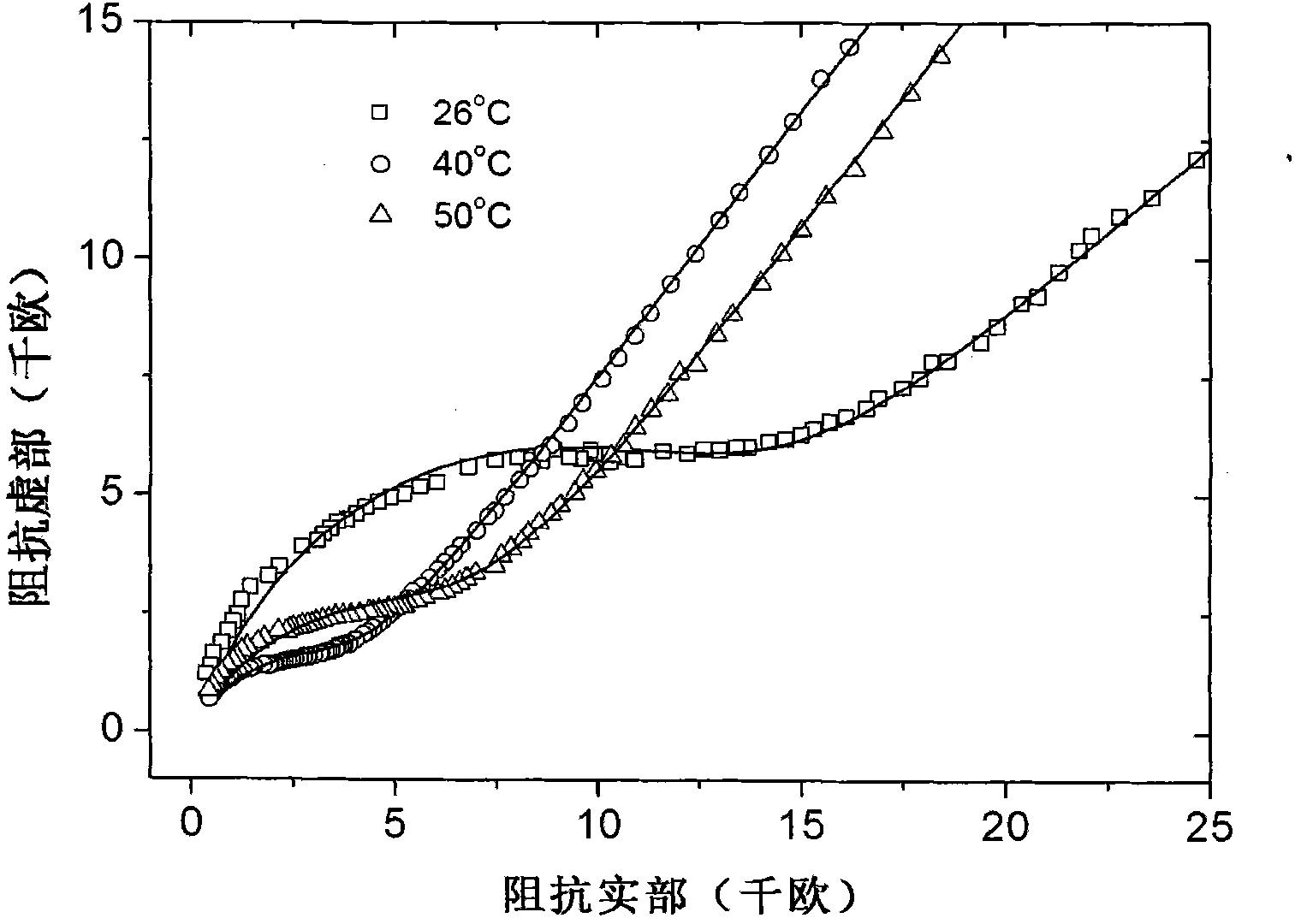

Embodiment 1

[0023] The concrete steps of preparation are:

[0024] Step 1, according to La 3-X A X Li 5+δ Bi 2-Y B Y o 12The composition ratio, wherein x is 0, y is 1.25, weigh the corresponding amount of nitrate or carbonate or chloride or acetate or alkoxide of lithium, lanthanum, bismuth and bismuth dopant or soluble oxides in the medium, and add them to the solvent to prepare corresponding solutions; among them, lithium, lanthanum, bismuth and bismuth dopants are their nitrates, specifically lithium nitrate, lanthanum nitrate, bismuth nitrate and indium nitrate, the solvent is water, and the corresponding solution is the corresponding clear solution. First add the lanthanum salt solution, the bismuth salt solution and the bismuth dopant solution dropwise to the lithium salt solution placed at 30°C under stirring, wherein the lithium salt solution is lithium nitrate solution, the lanthanum salt solution is lanthanum nitrate solution, bismuth The salt solution is a bismuth nitrat...

Embodiment 2

[0028] The concrete steps of preparation are:

[0029] Step 1, according to La 3-X A X Li 5+δ Bi 2-Y B Y o 12 The composition ratio, wherein x is 0.1, y is 0.8, weigh the corresponding amount of lithium, lanthanum, bismuth, nitrate or carbonate or chloride or acetate of lanthanum dopant and bismuth dopant Or alkoxides or oxides soluble in acid, and add them to the solvent to prepare the corresponding solutions; among them, lithium, lanthanum, bismuth, lanthanum dopant and bismuth dopant are its nitric acid Salts, in particular lithium nitrate, lanthanum nitrate, bismuth nitrate, calcium nitrate and indium nitrate, the solvent is water, and the corresponding solutions are the corresponding clear solutions. First, add lanthanum salt solution, bismuth salt solution, lanthanum dopant solution and bismuth dopant solution dropwise to the lithium salt solution placed at 50°C under stirring, wherein the lithium salt solution is lithium nitrate solution, lanthanum salt solution ...

Embodiment 3

[0033] The concrete steps of preparation are:

[0034] Step 1, according to La 3-X A X Li 5+δ Bi 2-Y B Y o 12 The composition ratio, wherein x is 0.5, y is 0, weigh the corresponding amount of nitrate or carbonate or chloride or acetate or alkoxide of lithium, lanthanum, bismuth and lanthanum dopant or soluble oxides, and add them to the solvent to prepare the corresponding solution; among them, lithium, lanthanum, bismuth and lanthanum dopant are their nitrates, specifically lithium nitrate, lanthanum nitrate, bismuth nitrate and calcium nitrate, the solvent is water, and the corresponding solution is the corresponding clear solution. First add the lanthanum salt solution, the bismuth salt solution and the lanthanum dopant solution dropwise to the lithium salt solution placed at 65°C under stirring, wherein the lithium salt solution is lithium nitrate solution, the lanthanum salt solution is lanthanum nitrate solution, bismuth The salt solution is a bismuth nitrate sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com