Preparation method for barium strontium titanate (BST) thick film material

A technology of strontium barium titanate and thick film, which is applied in the field of preparation of thick film materials, can solve the problems of poor electrical properties, achieve high density, uniform particle size, and improve electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1, 1 mol of strontium hydroxide was added to 300 ml of glacial acetic acid, heated and dissolved in a water bath at 80° C. with stirring. After the solution turns into a clear solution, add 1.5 mol of barium acetate. Then add 600ml ethylene glycol methyl ether solution as a solvent, and stir for 10min. Weigh 7.5 mol of tetra-n-butyl titanate and add it dropwise into the solution. After stirring for 30 min, slowly add 150 ml of acetylacetone. Then heated and stirred for 3h. Finally, add 50ml of deionized water, stir and heat to obtain BST gel. The obtained BST gel was dried at 120°C, ground and sieved, and then heat-treated at 800°C for 3 hours at a heating rate of 1°C / min to synthesize a pure-phase BST nanopowder. Weigh 60 g of the obtained barium strontium titanate powder, add 10 g of ethanol as a solvent, 20 g of xylene and 1 g of glyceryl trioleate as a dispersant, and then ball mill and mix the slurry after ball milling for 24 hours, then add 2.35 g of it...

Embodiment 2

[0018] Example 2, 1 mol of strontium hydroxide was added to 300 ml of glacial acetic acid, heated and dissolved in a 75° C. water bath with stirring. After the solution turns into a clear solution, add 1.5 mol of barium acetate. Then add 600ml ethylene glycol methyl ether solution as a solvent, and stir for 5min. Weigh 7.5 mol of tetra-n-butyl titanate and add it dropwise into the solution. After stirring for 20 min, slowly add 150 ml of acetylacetone. Then heated and stirred for 1 h. Finally, add 50ml of deionized water, stir and heat to obtain BST gel. The obtained BST gel was dried at 100°C, ground and sieved, and then heat-treated at 750°C for 2 hours at a heating rate of 2°C / min to synthesize a pure-phase BST nanopowder. Weigh 60 g of the obtained barium strontium titanate powder, add 10 g of ethanol as a solvent, 20 g of xylene and 1 g of glyceryl trioleate as a dispersant, then ball mill and mix the slurry after 20 h of ball milling, and then add 2.35 g of it as a vi...

Embodiment 3

[0019] Example 3, 1 mol of strontium hydroxide was added to 300 ml of glacial acetic acid, heated and dissolved in a water bath at 85° C. while stirring. After the solution turns into a clear solution, add 1.5 mol of barium acetate. Then add 600ml ethylene glycol methyl ether solution as a solvent, and stir for 8min. Weigh 7.5 mol of tetra-n-butyl titanate and add it dropwise into the solution, and after stirring for 25 min, slowly add 150 ml of acetylacetone. Then heated and stirred for 2h. Finally, add 50ml of deionized water, stir and heat to obtain BST gel. The obtained BST gel was dried at 110°C, ground and sieved, and then heat-treated at 850°C for 4 hours at a heating rate of 3°C / min to synthesize a pure-phase BST nanopowder. Weigh 60 g of the obtained barium strontium titanate powder, add 10 g of ethanol as a solvent, 20 g of xylene and 1 g of triolein as a dispersant, and then ball mill and mix the slurry after ball milling for 26 hours, then add 2.35 g of it as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

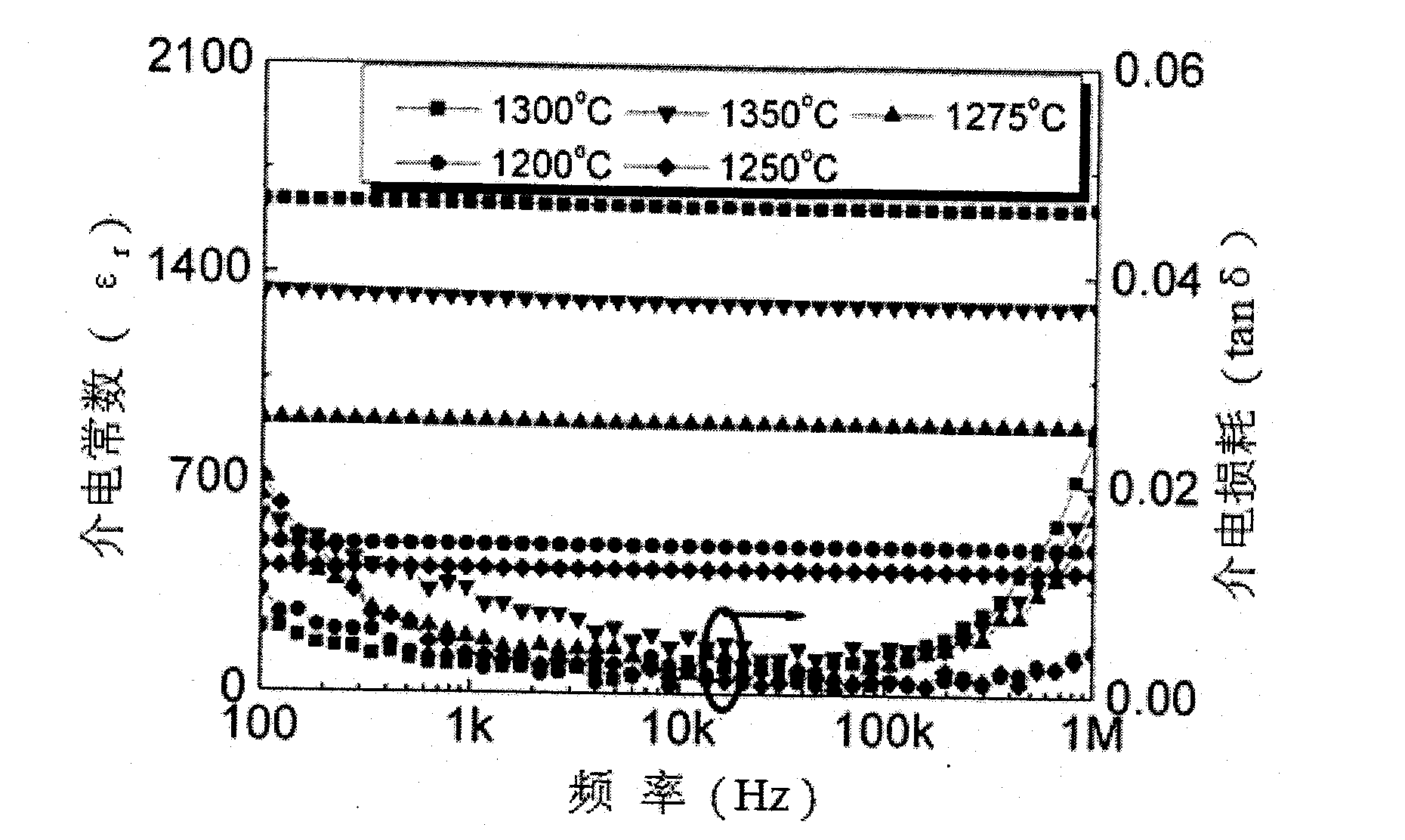

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com