Yaw brake block and preparation method thereof

A technology of brake pads and yaw, which is applied in the field of yaw brake pads and its preparation, can solve the problems of dual aggressiveness, easy-to-rust linings, windmill accidents, etc., and achieve excellent flexibility and flexure, high resistance Compression and shear strength, reducing aggressiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

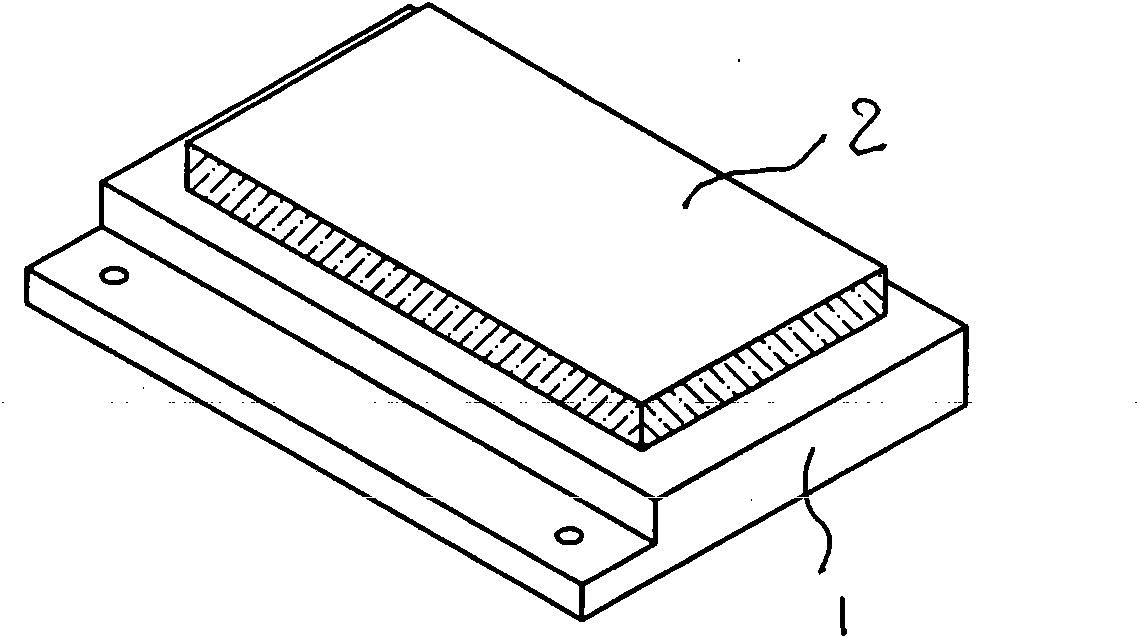

Image

Examples

Embodiment 1

[0033] (1) Ingredients: get 9 kg of nitrile modified phenolic resin, 5 kg of polyvinyl butyral, 6 kg of glass fiber, 2 kg of aramid fiber and 10 kg, 10 kg, and 10 kg respectively Fiber material composed of limestone, talc powder and coke powder mineral fiber, 15 kg of precipitated barium sulfate with stable friction coefficient, 20 kg of potassium titanate spar with sound-absorbing and noise-reducing properties, 5 kg of barite, 2 kg of Molybdenum disulfide with high-temperature friction-increasing properties is mixed with 6 kg of flake graphite, a conventional friction material;

[0034] (2) Mixing: The above-mentioned prepared binder, reinforcing material, friction performance modifier and lubricating anti-friction material are fully stirred and mixed for 20 minutes by mixing equipment;

[0035] (3) Compression molding: the mixed mixture and the steel back coated with adhesive are pressed for 15 minutes at a temperature of 160°C and 195kgf / cm to form a yaw brake pad. blank; ...

Embodiment 2

[0042] (1) Ingredients: Take 10 kg of nitrile modified phenolic resin, 4 kg of polyvinyl butyral, 5 kg of glass fiber, 3 kg of aramid fiber and 10 kg, 5 kg, and 5 kg respectively Fiber material composed of phosphate flakes, corundum and dolomite mineral fibers, 18 kg of precipitated barium sulfate with stable friction coefficient, 22 kg of potassium titanate spar with sound-absorbing and noise-reducing properties, 10 kg of barite, 3.5 kg Molybdenum disulfide with high-temperature friction-increasing properties is mixed with 12 kg of conventional friction material flake graphite;

[0043] (2) Mixing: The above prepared binder, reinforcing material, friction performance modifier and lubricating antifriction material are fully stirred and mixed for 25 minutes by mixing equipment;

[0044] (3) Compression molding: the mixed mixture and the steel back coated with adhesive are pressed for 15 minutes at a temperature of 155°C and 200kgf / cm to form a yaw brake pad. blank;

[0045] (...

Embodiment 3

[0051] (1) Ingredients: get 8 kg of nitrile modified phenolic resin, 6 kg of polyvinyl butyral, 8 kg of glass fiber, 4 kg of aramid fiber and 5 kg of fluorinated graphite, potassium Fiber material composed of feldspar and graphite mineral fiber, 12 kg of precipitated barium sulfate with stable friction coefficient characteristics, 18 kg of potassium titanate spar with sound absorption and noise reduction characteristics, 8 kg of barite, 4 kg with high temperature friction increasing characteristics Molybdenum disulfide and 10 kg of conventional friction material flake graphite are mixed together;

[0052] (2) Mixing: The above prepared binder, reinforcing material, friction performance modifier and lubricating antifriction material are fully stirred and mixed for 25 minutes by mixing equipment;

[0053] (3) Compression molding: the mixed material and the steel back coated with adhesive are pressed for 10 minutes at a temperature of 170°C and 210kgf / cm by a mold to form a yaw b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com