Halogen-free flame retardant thermoplastic polyester resin composition

A thermoplastic polyester and resin composition technology, applied in the field of fiber-reinforced halogen-free flame-retardant thermoplastic polyester resin composition, can solve the problem of reducing the mechanical properties of PBT or PET composites, low tensile strength and bending strength, and reducing the composition Mechanical properties and other issues, to achieve high flame retardancy, simple operation, and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

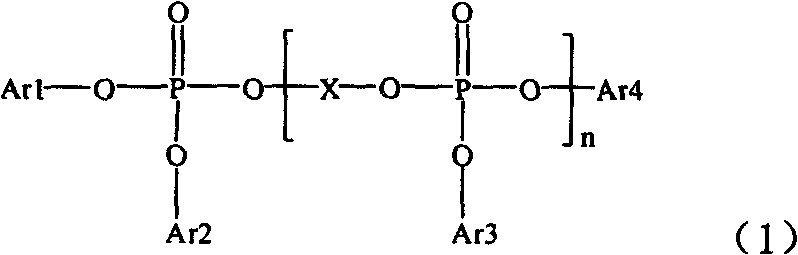

Method used

Image

Examples

Embodiment 1

[0101] Weigh thermoplastic polyester resin PBT, phosphoric acid ester PX200, melamine cyanurate MC4000 and flame retardant synergistic enhancer mica respectively according to the ratio shown in Table 2, and pre-mix evenly with a high-speed mixing and stirring device at room temperature. The hopper, the chopped glass fiber ECS303H is quantitatively transported to the TEX30α co-rotating twin-screw extruder (made by Japan Steel) through the side feeding device for melt extrusion, the extrusion temperature is 250 ° C, the speed is 200 rpm, and the extrusion After being cooled in a water tank, the pellets were cut into pellets with a length of about 3 mm. After the pellets were air-dried at 120°C for 4 hours, they were injected into standard splines with a NEX1000 injection molding machine (manufactured by Nissei Corporation of Japan), and subjected to UL94 and mechanical tests. The measurement of performance, its result is shown in table 2.

Embodiment 2

[0103] The talcum powder is surface-treated with silane coupling agent KH560 first, and the thermoplastic polyester resin PBT, melamine cyanurate MC4000 and surface-treated talcum powder are weighed according to the ratio shown in Table 2, and mixed and stirred at a high speed at room temperature The device is pre-mixed evenly, the mixed material is from the main hopper, the chopped glass fiber ECS303H passes through the side feeding device, and at the same time, the phosphate ester RDP and BDP are quantitatively transported to the TEX30α co-rotating twin-screw extruder (made in Japan) by a special liquid feeding device Steel) for melt extrusion, the extrusion temperature is 230 ° C, the rotation speed is 200 rpm, the extruded strands are cooled in a water tank, and then cut into pellets with a length of about 3 mm by a pelletizer. The pellets are air-dried at 120 ° C for 4 Hours later, use NEX1000 injection molding machine (produced by Nissei Co., Ltd., Japan) to inject into a...

Embodiment 3

[0105] Weigh thermoplastic polyester resin PBT, phosphate ester PX200, melamine cyanurate MC4000, flame retardant synergistic enhancer glass flakes and PTFE respectively according to the ratio shown in Table 2, pre-mix evenly with a high-speed mixing and stirring device at room temperature, and mix From the main hopper, the chopped basalt fiber CBF13-6 is quantitatively transported to the TEX30α co-rotating twin-screw extruder (made by Japan Steel) through the side feeding device for melt extrusion. The extrusion temperature is 250°C and the rotation speed is 200rpm. The extruded strands are cooled in a water tank and then cut into pellets with a length of about 3mm by a pelletizer. After the pellets are air-dried at 120°C for 4 hours, they are injection molded into standard splines with a NEX1000 injection molding machine (manufactured by Nissei Corporation of Japan). , for the determination of UL94 and mechanical properties, the results are shown in Table 2.

[0106] Compara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com