Multi-passage direction selecting flow-injection quick analysis system for hexavalent chromium water quality

A flow injection, rapid analysis technology, applied in the fields of chemical analysis and water environment monitoring and analysis, can solve the problems of not being widely used, expensive instruments, difficult to popularize and use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

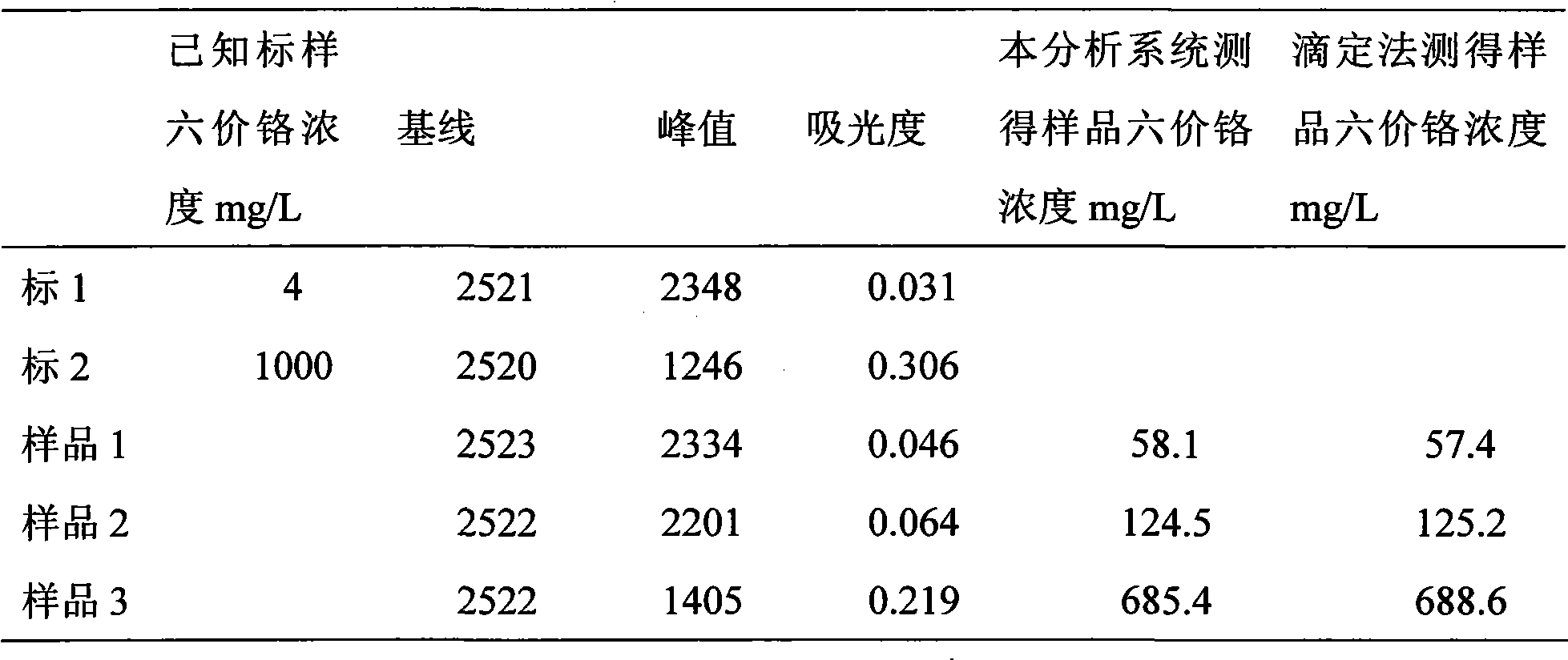

[0015] The embodiment structure and testing process of the flow injection rapid analysis system for hexavalent chromium will be described below with reference to the accompanying drawings.

[0016] The pipelines of the following examples are polytetrafluoroethylene capillaries with an inner diameter of 0.8 mm and an outer diameter of 2.5 mm;

[0017] figure 1 The multi-channel check valve V is provided with a selection interface 0 and six circumferential distribution interfaces 1~6, the selection interface 0 is set on the valve cover, and can be changed by the internal groove (shown as a dotted line) that rotates with the valve cover. The connection relationship with the valve seat interface 1~6. The ceramic constant flow syringe pump P1 is connected to the direction selection interface 0 through the capillary storage tube L1. The interface 1 of the multi-channel directional valve V is connected to the reaction tube F and the photoelectric flow cell G in sequence, the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com