Anti-carbon deposition anode film material and method for producing the same

An anode film and carbon deposition technology, applied in battery electrodes, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of anode carbon deposition electrode performance, many processes, and high costs, to improve electrochemical performance, improve microscopic Structure, the effect of easy large-area production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

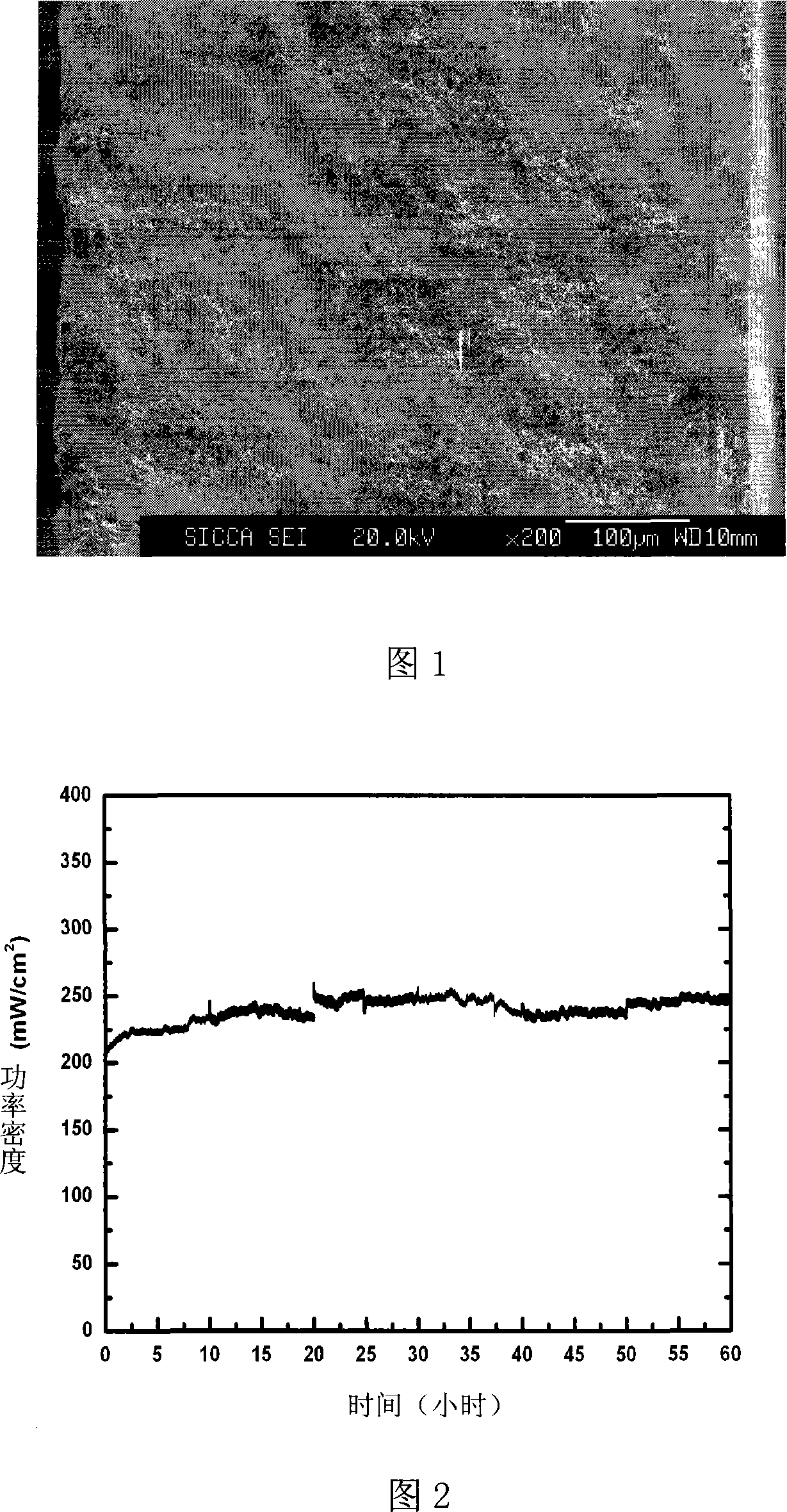

[0033] Preparation of Large Area Carbon Deposition Resistant Cu-CeO 2 / NiO-YSZ composite anode membrane material

[0034] Take YSZ (8mol%Y 2 o 3 Stable ZrO 2 ) 25g, nickel oxide 25g, ammonium oxalate 20g, ETOH24g, MEK48g, TEA3.5g, zirconia grinding ball 180g, add in the polytetrafluoroethylene ball mill jar, ball mill 1 hour on the planetary ball mill; Add PVB10g in the above-mentioned slurry, DOP4.7g, PEG4.7g, continue ball milling for 1 hour to obtain anode support body slurry.

[0035] Vacuumize the anode support slurry for 2 minutes, cast it on a tape casting machine with a knife height of 1.7 mm, dry it at room temperature for 20 hours, and then remove the film.

[0036] Raise the temperature of the anode blank film to 600°C to debinding and remove the pore-forming agent at a heating rate of 0.5°C / min, keep it warm for 2 hours, then raise the temperature to 1400°C for sintering for 4 hours at a heating rate of 2°C / min. Prepare a porous anode support membrane.

[003...

Embodiment 2

[0040] Preparation of large-area anode-supported dense ScSZ membranes

[0041] Take 25g of YSZ, 25g of NiO, 20g of ammonium oxalate, 24g of ETOH, 48g of MEK, 3.5g of TEA, 180g of zirconia grinding balls, add them into a polytetrafluoroethylene ball mill jar, and mill them on a planetary ball mill for 1 hour; add PVB10g, DOP4. 7g, PEG4.7g, continue ball milling for 1 hour to obtain anode slurry. Take ScSZ (8mol%Sc 2 o 3 Stable ZrO 2 ) 20g, ETOH6g, MEK12g, TEA0.6g, zirconia ball 50g, add in the polytetrafluoroethylene ball mill tank, ball mill 1 hour on the planetary ball mill; Add PVB1.0g, DOP1.5g, PEG1. 5 g, and continued ball milling for 1 hour to obtain electrolyte slurry.

[0042] After evacuating the electrolyte slurry for 2 minutes, cast it on a tape casting machine with a knife height of 250 μm, and dry it at room temperature for 2 hours; vacuumize the anode slurry for 2 minutes, cast it on the electrolyte membrane with a knife height of 1.7 mm, and dry it at room te...

Embodiment 3

[0047] Preparation of Cu-CeO 2 / NiO-YSZ / ScSZ / Pr 0.7 Ca 0.3 MnO 3 (PCM) planar SOFC cell

[0048] According to the method of Case 2, a large-area anode-supported dense ScSZ membrane was prepared, and a disc with a diameter of 3 cm was cut.

[0049]Take 0.5g of PCM and 0.35g of the above-mentioned terpineol solution, grind them fully in an agate mortar, screen-print the obtained slurry on the electrolyte membrane side of the composite membrane, and then sinter at 1200°C for 3 hours to finally obtain Cu- CeO 2 / NiO-YSZ / ScSZ / PCM planar SOFC cell.

[0050] Battery Power Generation Experiment

[0051] Platinum grids are coated on the anode side of the single cell to collect current, and Pt wires are drawn at the two poles to collect electricity and sealed with glass rings.

[0052] After reducing CuO and NiO in the anode at 800 °C, hydrogen and ethanol were used as fuels to conduct power generation experiments. The results show that the single cell has good performance. 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com