Method for preparing recombinant glossy ganoderma immunomodulatory protein

A technology of immunoregulatory protein and Ganoderma lucidum, which is applied in the field of fermentation engineering, can solve the problems of small production scale and low yield, and achieve the effects of reduced electrical conductivity, rich nutrition, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Construction of engineering bacteria

[0015] 1. Experimental materials

[0016] Pichia pastoris host strain GS115 and plasmid pPIC9K were purchased from Invitrogen, and yeast integrated expression vector p819 was constructed by the Chinese Center for Disease Control and Prevention.

[0017] Yeast Nitrogen Base (without amino acid), D-Biotin and Casein (Acid hydrolysates) are imported reagents from Sigma, and G418 is a product of GIBCOBRL.

[0018] 2. Experimental methods and results

[0019] 2.1 Construction of α-rLZ-8 fusion gene

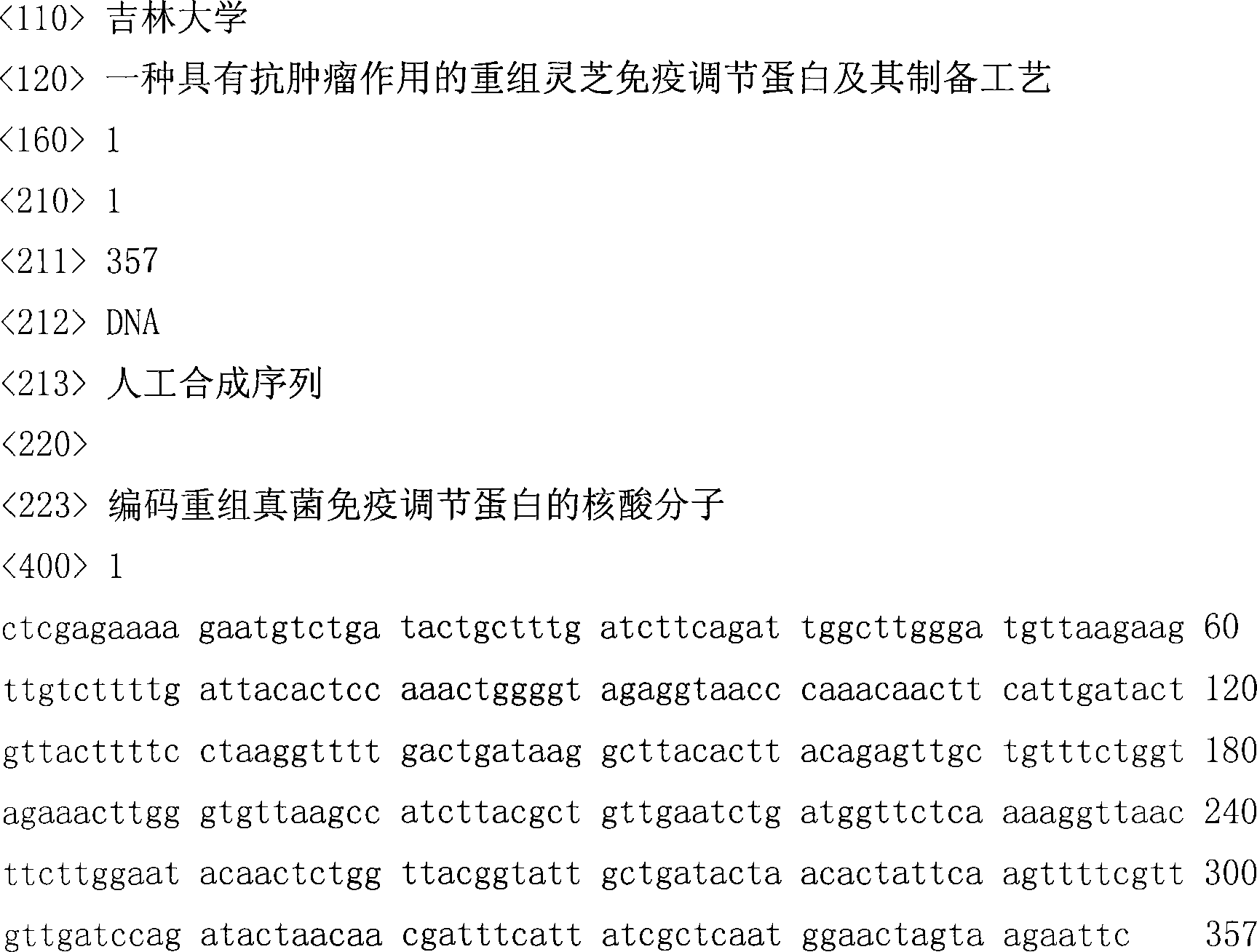

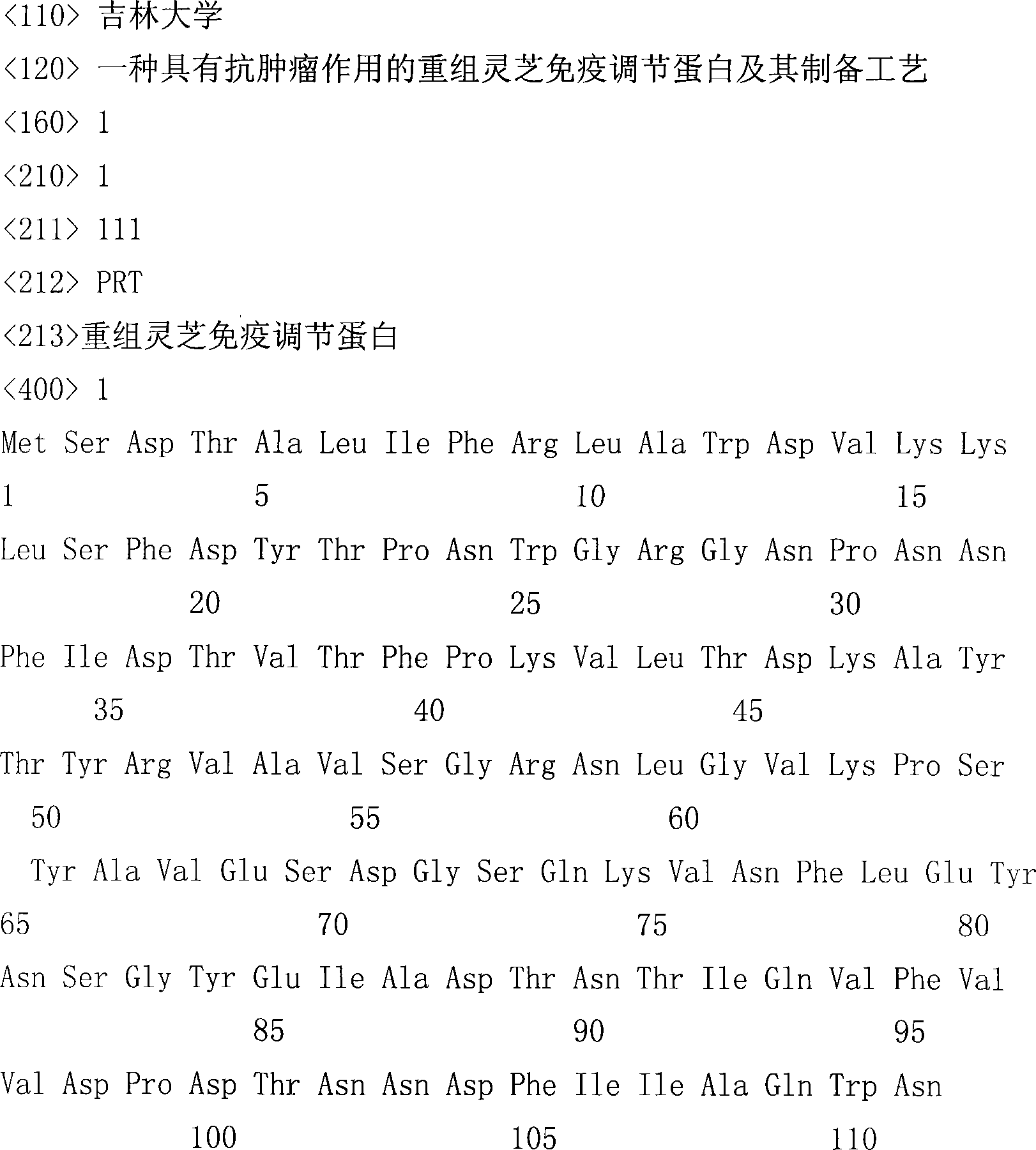

[0020] 1) According to the preference of the genetic code of Pichia pastoris, redesign the base sequence encoding LZ-8, and commission Shanghai Shenggong Biotechnology Service Co., Ltd. to synthesize the full sequence of Ganoderma lucidum immunomodulatory protein gene. The synthesized recombinant plasmid is named pUC57-rLZ -8. The redesigned rLZ-8 gene is as follows:

[0021] CTCGAG AAAAGAATGTCTGATACTGCTTTGATCTTCAGATTGGCTTGGGATGTTA...

Embodiment 2

[0045] Example 2: Fermentation process under the scale of 100L fermentor

[0046] Fermentation pilot test result: the output of rLZ-8 reached 800mg·L -1 , About 10 times the expression in the shake flask, the wet weight of the bacteria is 420g·L -1 . The specific process is as follows:

[0047] 1. Equipment and equipment

[0048] Digital display peristaltic pump (7523-47), fermentation tank (BioFlo-5000), low temperature centrifuge (Microfuge R), low temperature centrifuge (Allegra 6R), constant temperature shaker (Scientific Allegra 6), biological safety cabinet (Scientific Model 1205A) ), gel analysis system (Biotech), ultra-low temperature refrigerator, UV spectrophotometer (DU7400), incubator (Scientific Model 3111), chromatography UV detection system (REC 112), 3K hollow fiber column, cation exchange resin (SP Sepharose XL), three-foot sedimentation centrifuge (SSC-600-NG), tubular separator (GQLB-105), vertical electrophoresis apparatus (OYC-40B), transfer electrophoresis ap...

Embodiment 3

[0121] Example 3: Purification process

[0122] The purification process is designed according to the characteristics of rLZ-8, the main process is as follows:

[0123] Fermentation broth separator centrifugation (3000rpm)→Using the supernatant with a tubular separator (16000rpm)→Ultrafiltration (30000-5000Da)→Anion exchange purification column (Q Sepharose Fast Flow)→Hydrophobic interaction purification column (PhenylSepharose 6 Fast Flow) )→Ultrafiltration to remove salt→High performance liquid phase (gel chromatography) to prepare the target protein.

[0124] 1. Ion Exchange Chromatography

[0125] Use the chromatographic column Q sepharose HP (1ml) to explore the chromatographic conditions and find the best pH value for purification. Mobile phase A: A1 liquid is 0.07M Bis-Tris and 0.05M Tris, A2 liquid is 0.1M HCl. The effective buffer range of the buffer is pH=6.0-9.0. Mobile phase B phase: B1 is pure water, B2 is 2M NaCl solution. The instrument automatically adjusts the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com