Method for producing double embedded structure

A dual damascene structure and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as heavy impact and thermal stress, simplify the process, reduce the impact of thermal stress, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

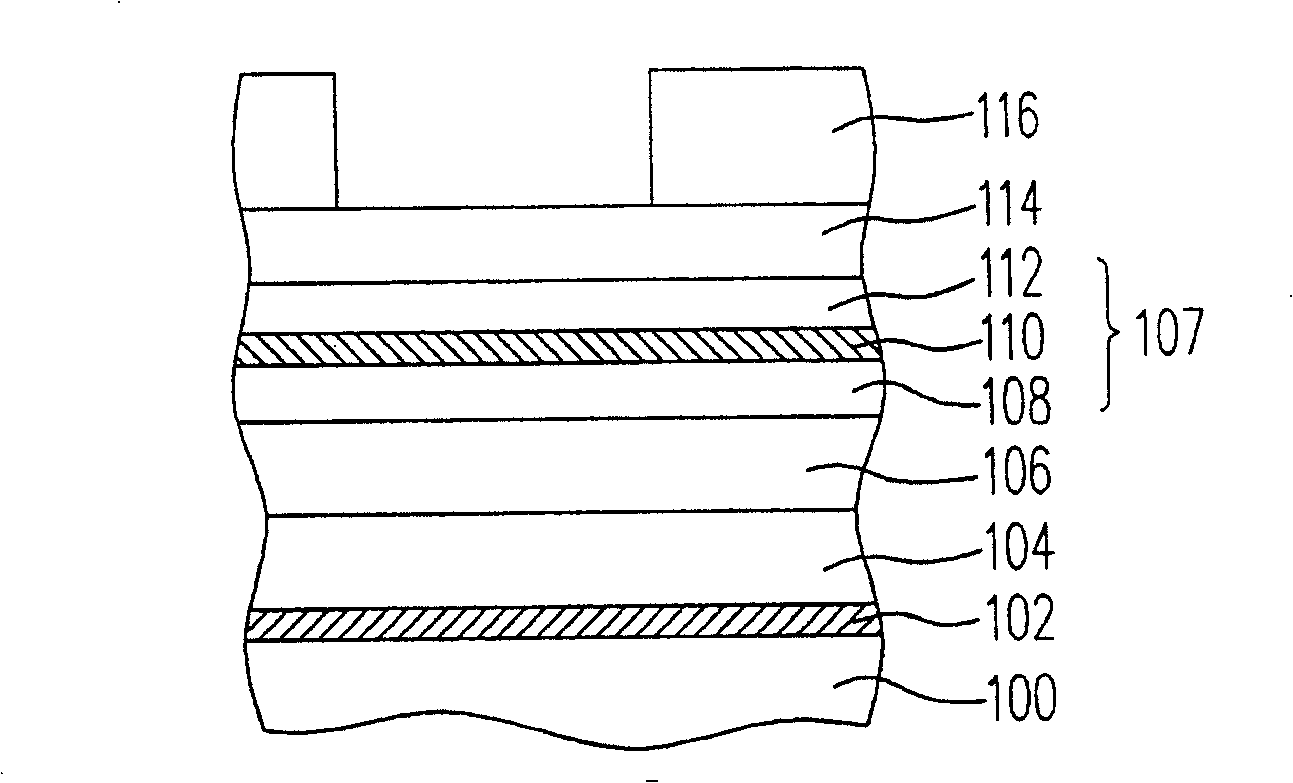

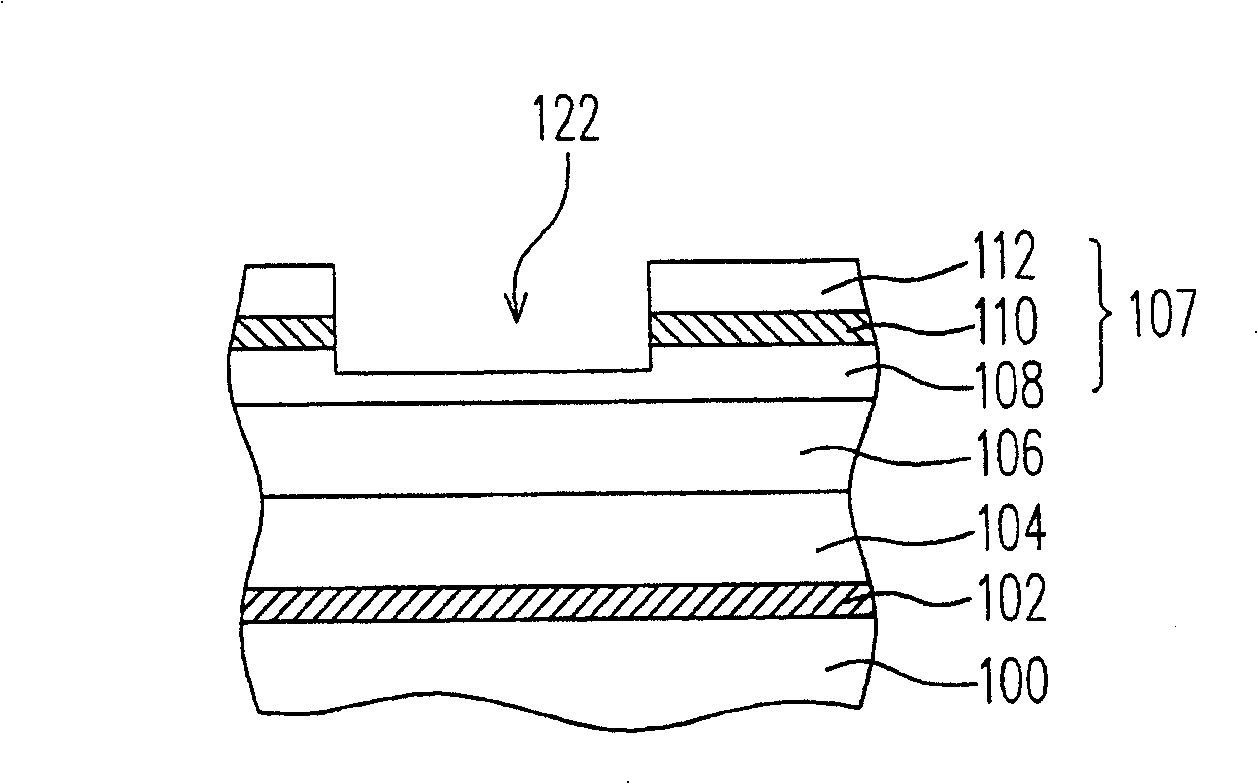

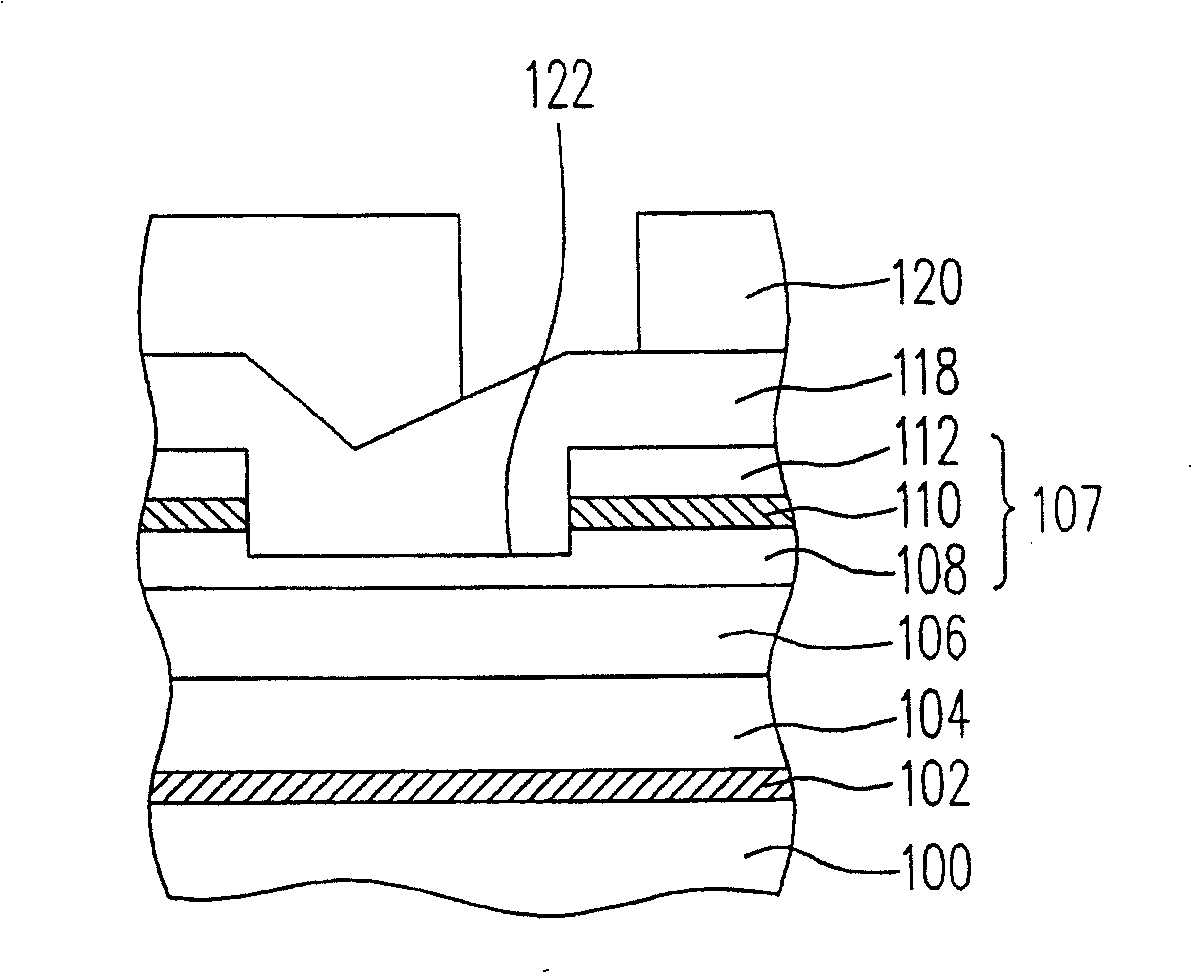

[0051] Figure 1A to Figure 1I It is a cross-sectional view showing the process of a method for manufacturing a dual damascene structure according to a preferred embodiment of the present invention. First, please refer to Figure 1A, forming a barrier layer 102 on the substrate 100 . Wherein, the material of the barrier layer 102 is, for example, one of silicon nitride, silicon carbide, and silicon carbonitride. Next, a first dielectric layer 104, a second dielectric layer 106, a multilayer mask layer 107, a first bottom anti-reflection layer 114, and a first photoresist layer (not shown) are sequentially formed on the barrier layer 102 drawn). Wherein, the multi-layer mask layer 107 is composed of, for example, a cover layer 108 , a metal-containing hard mask layer 110 , and a dielectric hard mask layer 112 . In another embodiment, the multi-layer mask layer may also be composed of a cover layer and a metal-containing hard mask layer. In addition, the material of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com