Efficient condensing heat exchange pipe

A technology of condensing heat exchangers and heat exchange tubes, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve problems such as energy waste, and achieve the effects of improving durability, uniform strength, and increasing heat generation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

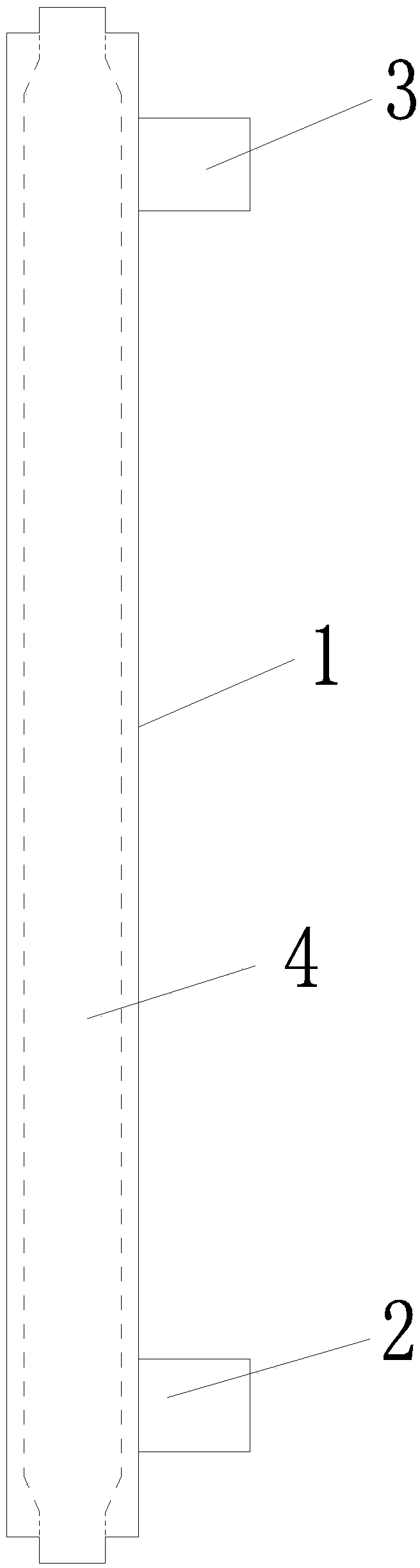

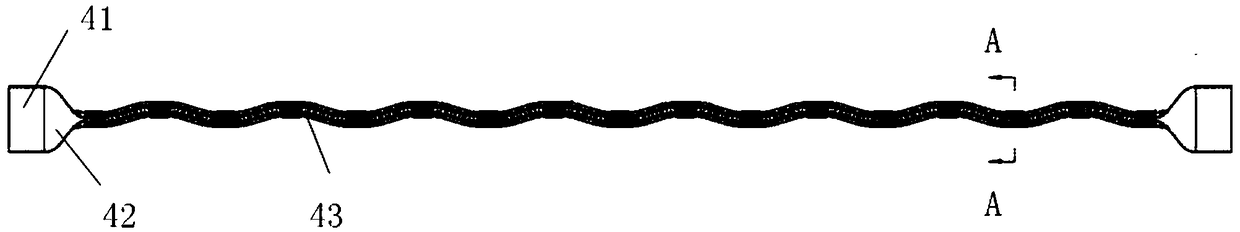

[0022] Such as Figure 1 to Figure 3 As shown, a high-efficiency condensing heat exchange tube includes: a water pipe 1 and a condensing heat exchanger 4, the condensing heat exchanger 4 is located inside the water pipe 1, the lower end of the water pipe 1 is provided with a water pipe inlet port 2, and the water pipe 1 The upper end is provided with a water pipe outlet port 3, and the condensing heat exchanger 4 includes a heat exchanger connecting pipe head 41, a heat exchanger flexible connecting pipe 42 and a plurality of condensing heat exchanger fins 43, and the heat exchanger connecting pipe hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com