Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Uneven inhibitory concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

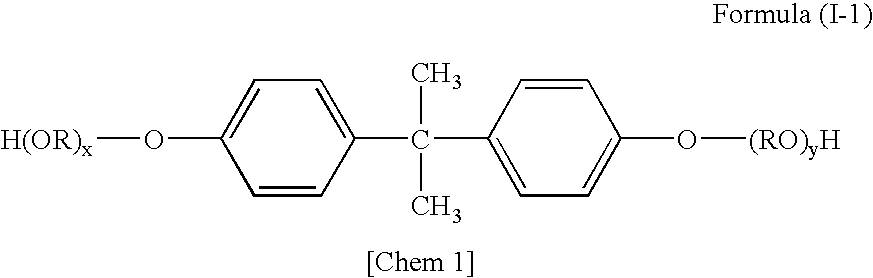

Magnetic toner

ActiveUS7544455B2Improve development performanceHigh blacknessDevelopersDielectric lossAqueous solution

A magnetic toner having magnetic toner particles each containing at least a binder resin and a magnetic iron oxide particle, in which: when a solution is prepared by dissolving the magnetic iron oxide particles in an acidic aqueous solution and an Fe element amount in a solution in which all the magnetic iron oxide particles are dissolved is defined as a total Fe element amount, a ratio X of the amount of Fe(2+) in a solution in which the magnetic iron oxide particles are dissolved to a state where 10 mass % of the total Fe element amount is present in the solution (solution having an Fe element-dissolving ratio of 10 mass %) to an Fe element amount in the solution having a specific Fe element-dissolving ratio; and the dielectric loss tangents of the magnetic toner measured at a temperature of 40° C. satisfy specific conditions.

Owner:CANON KK

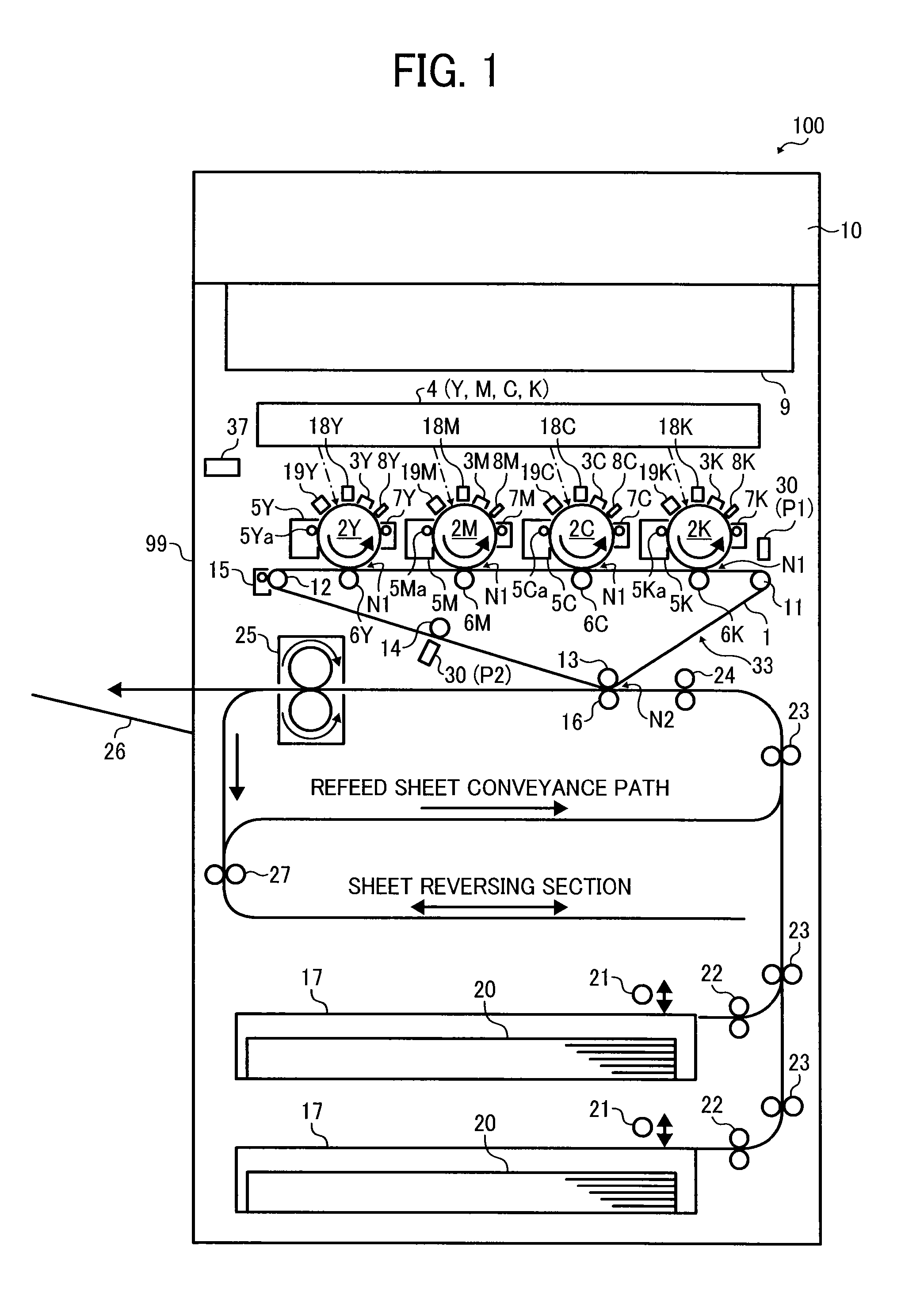

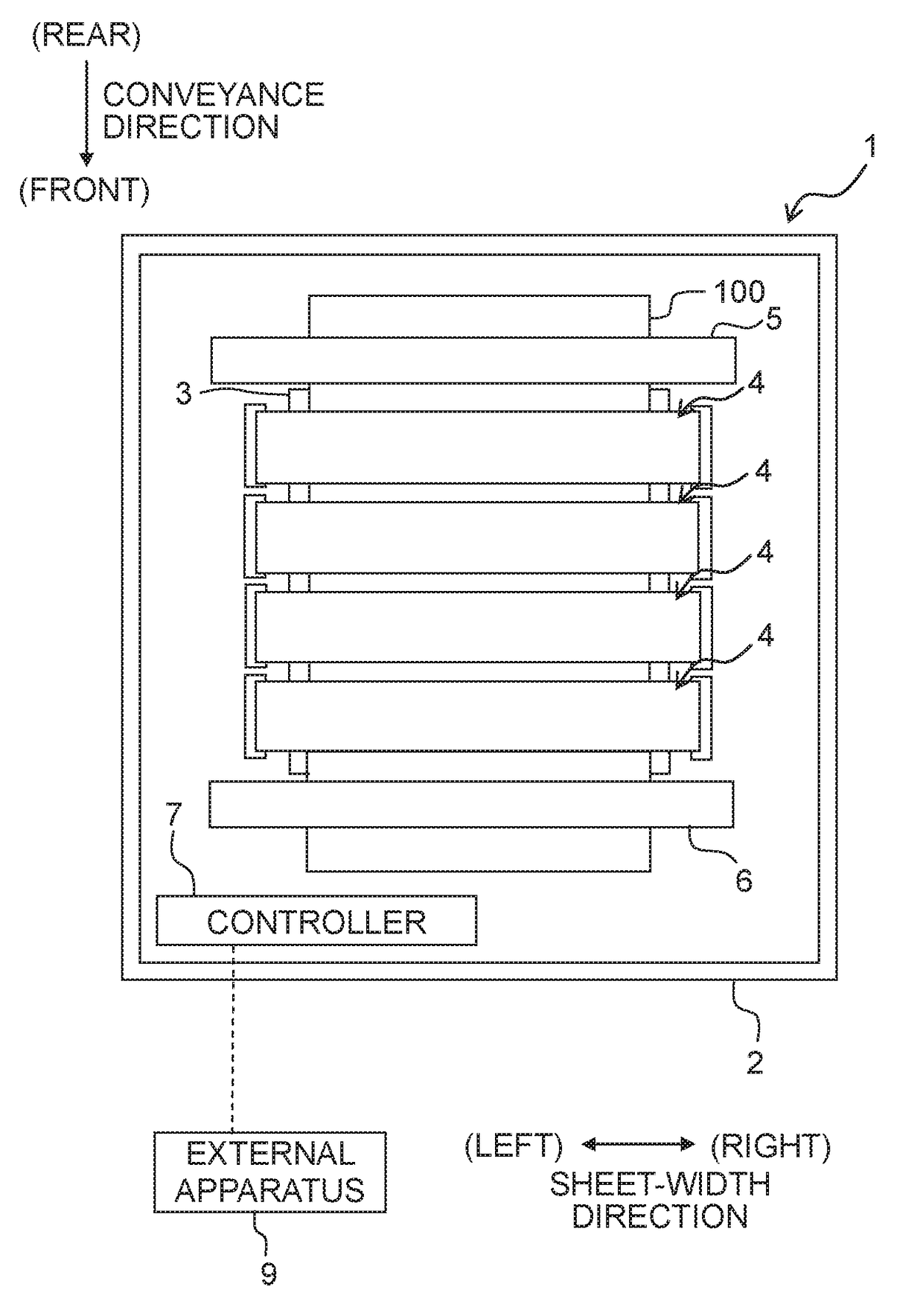

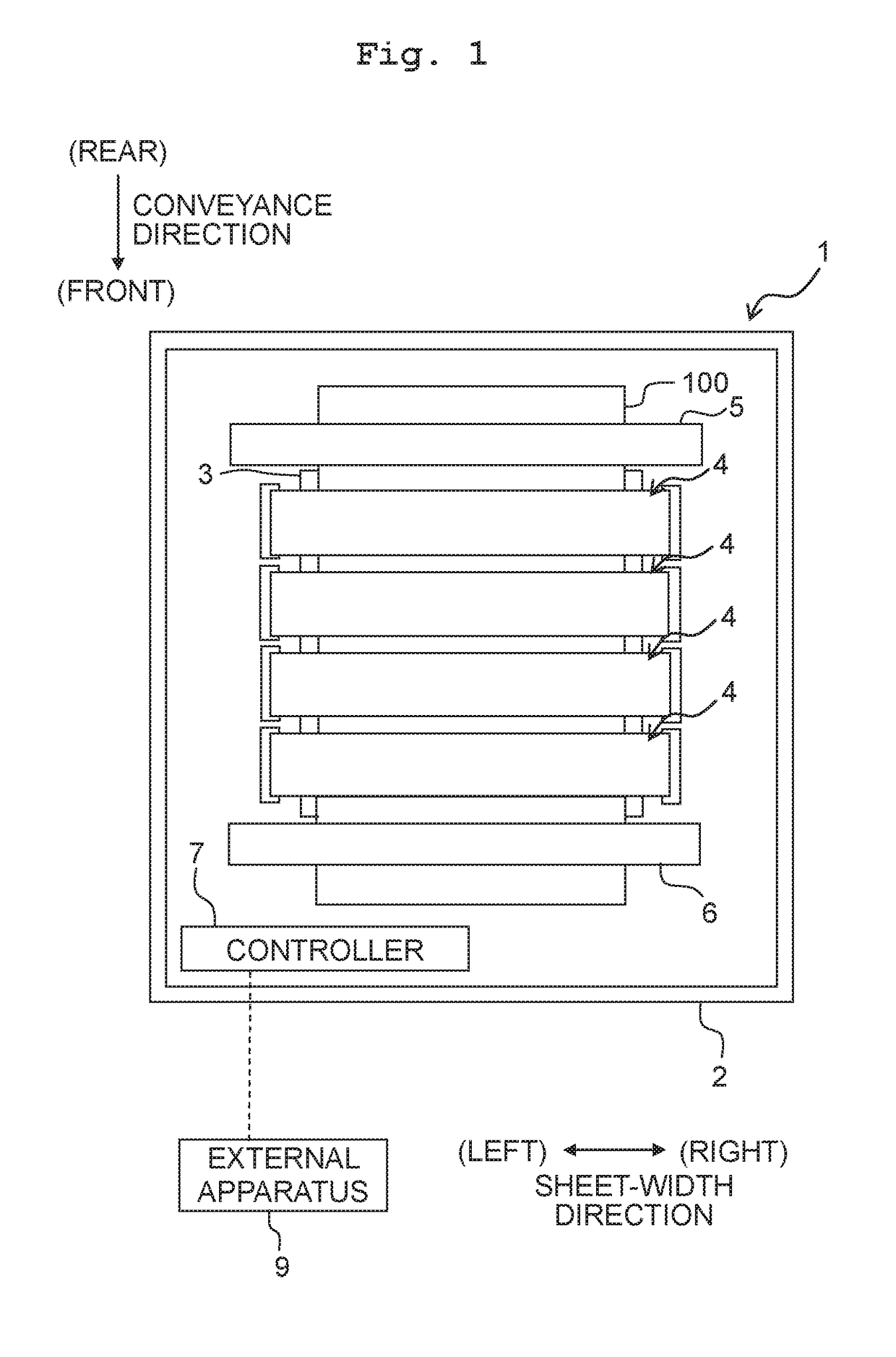

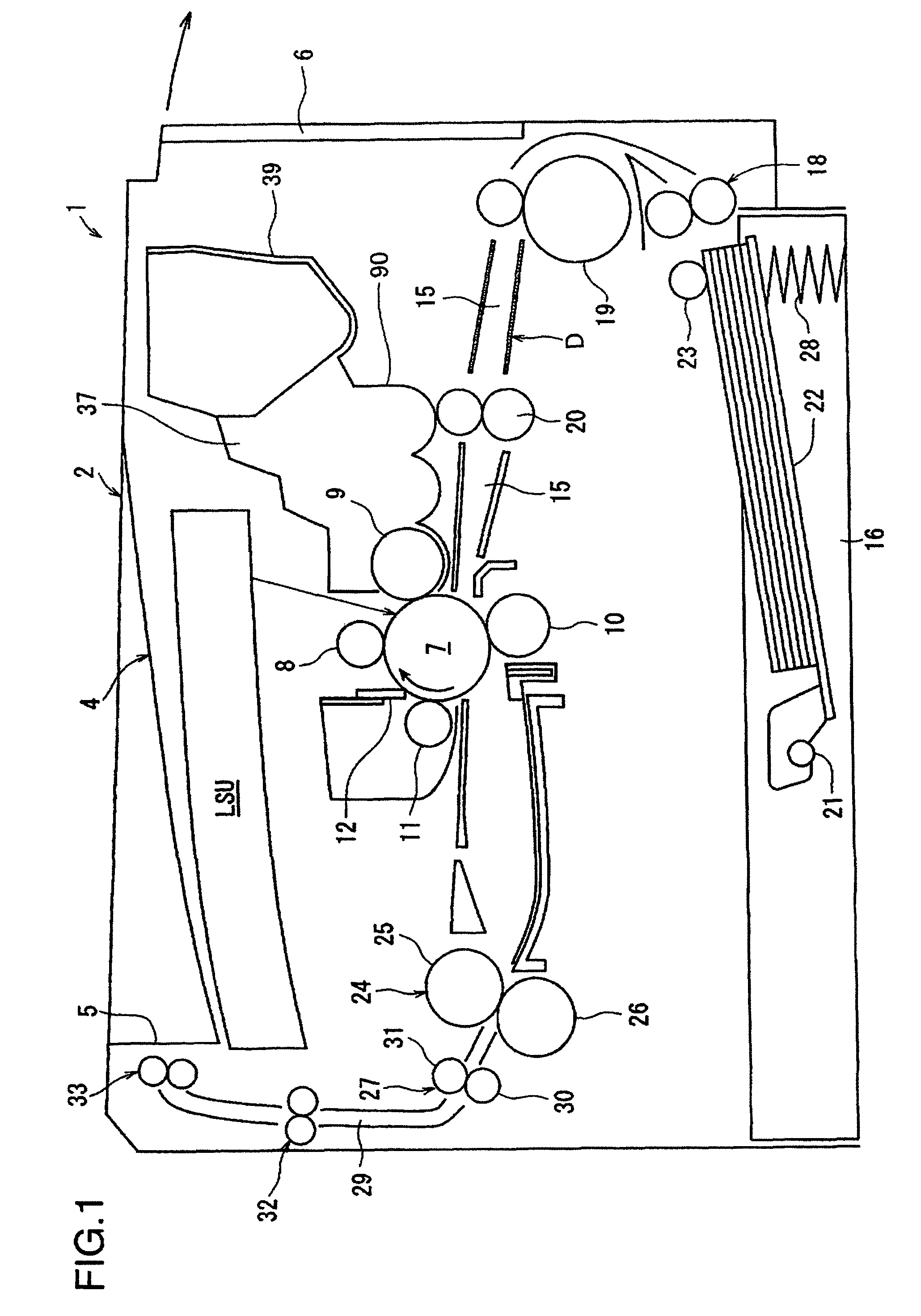

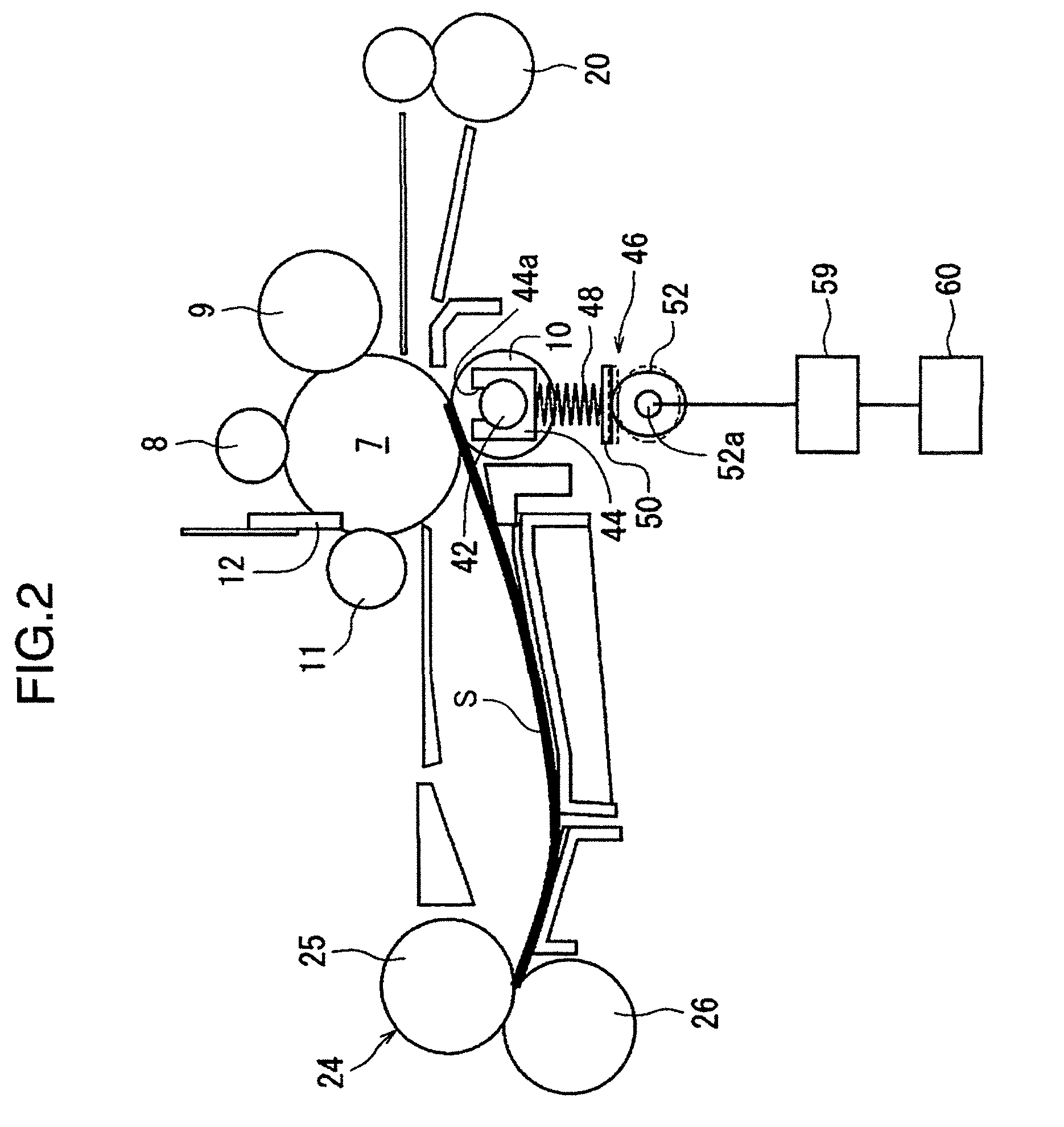

Image forming apparatus and image forming method

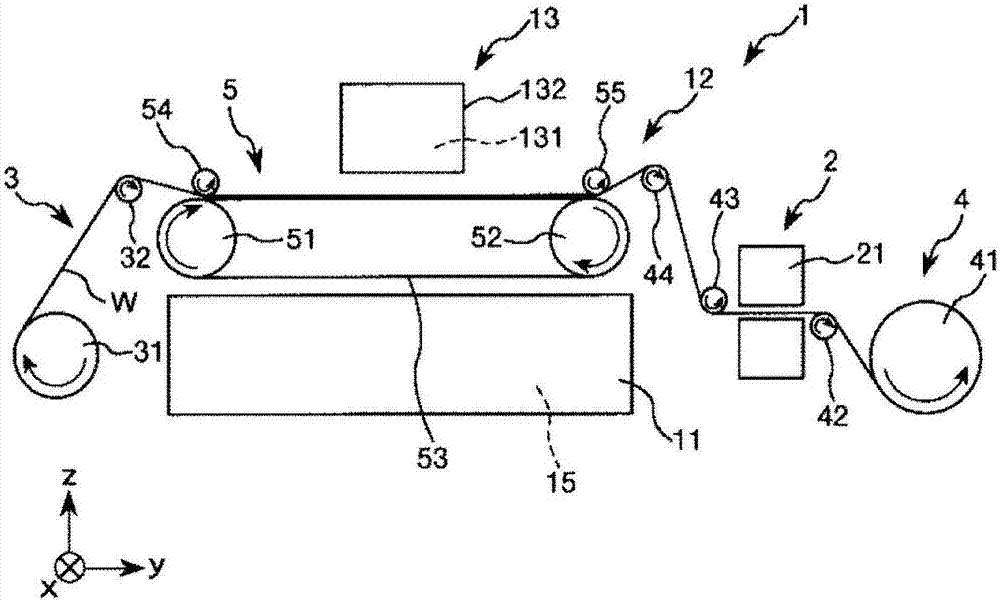

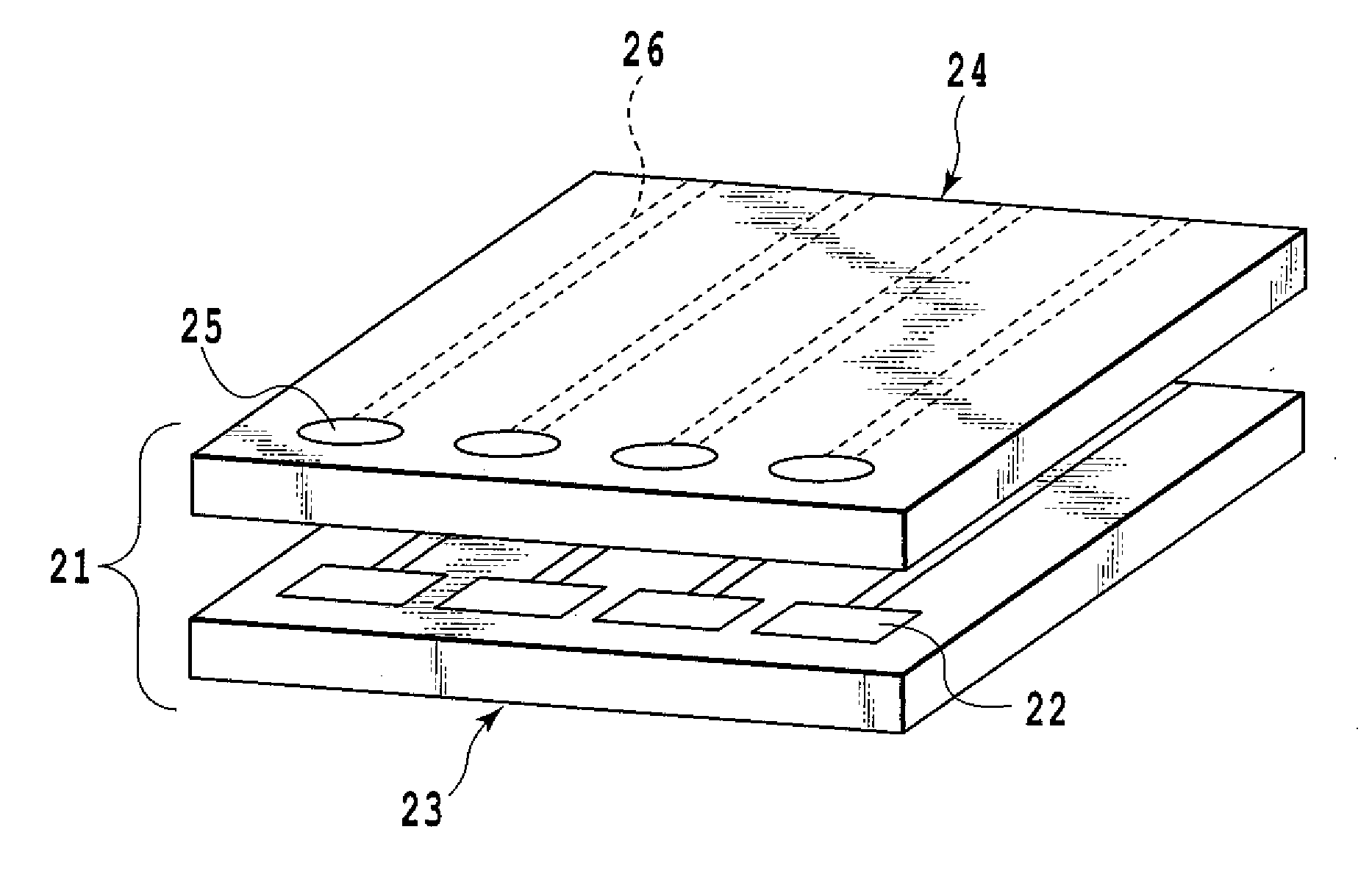

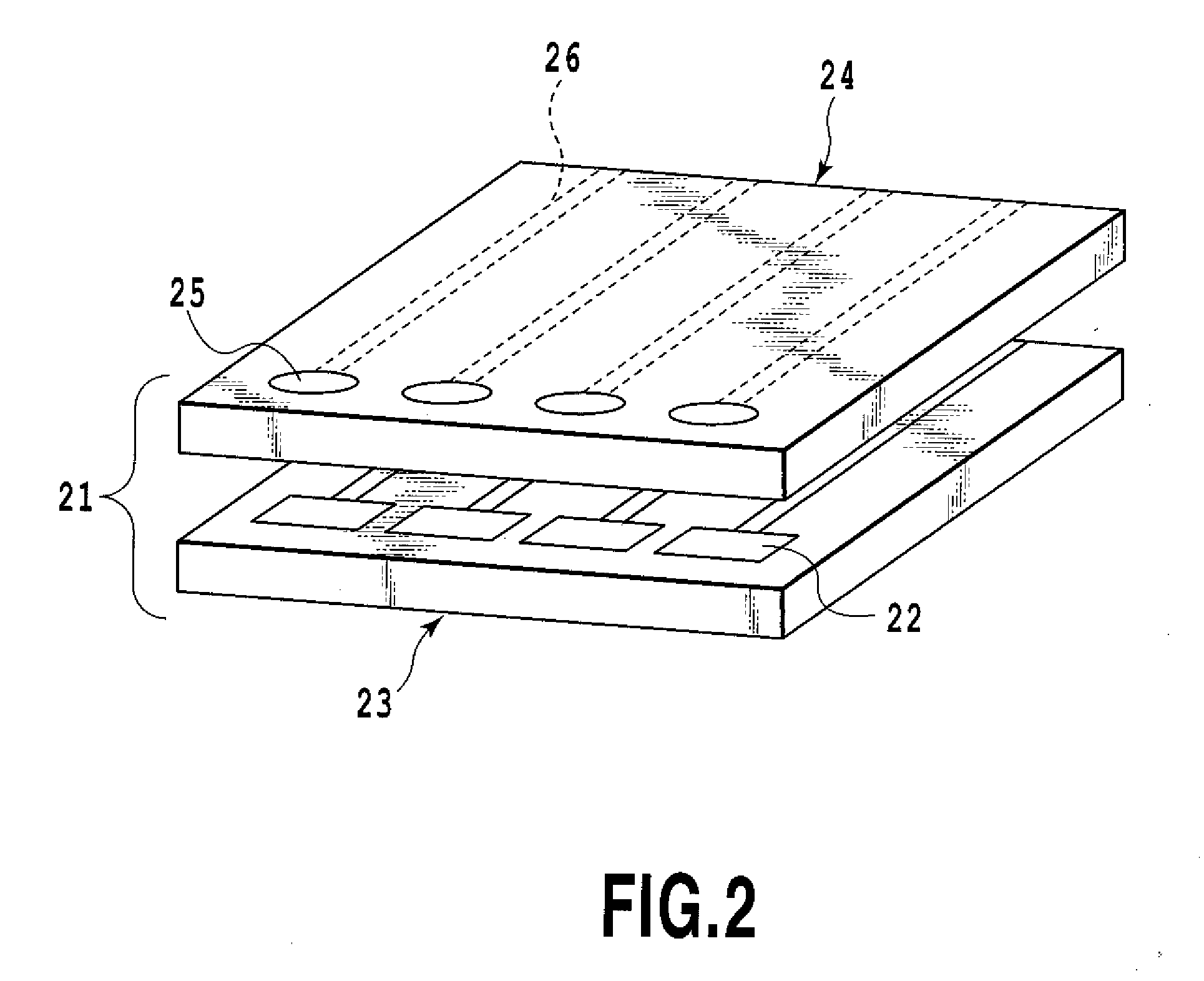

ActiveUS20140268242A1Uneven inhibitory concentrationAccurate dataVisual representation by electrographic printingElectrographic process apparatusDevice formImage pattern

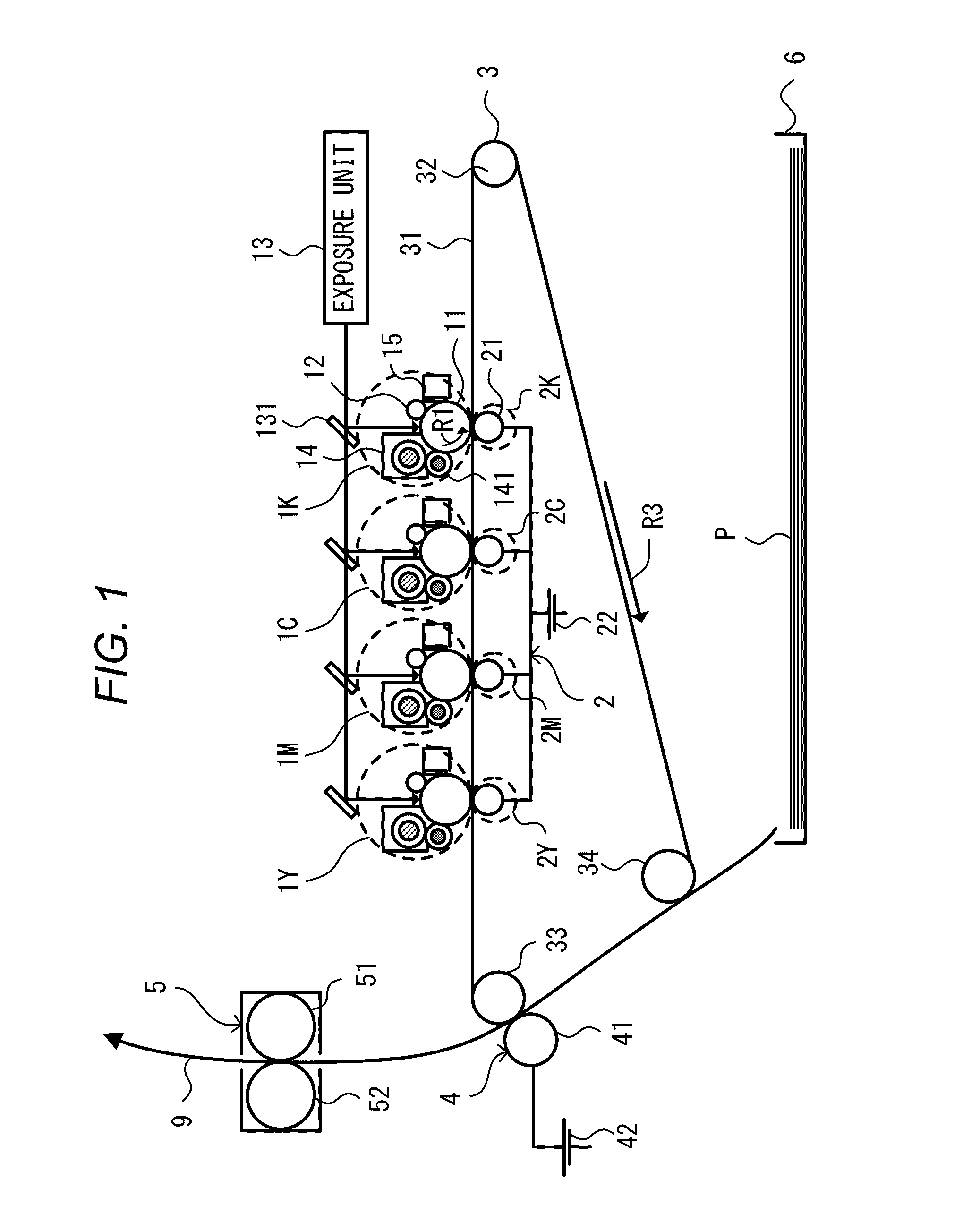

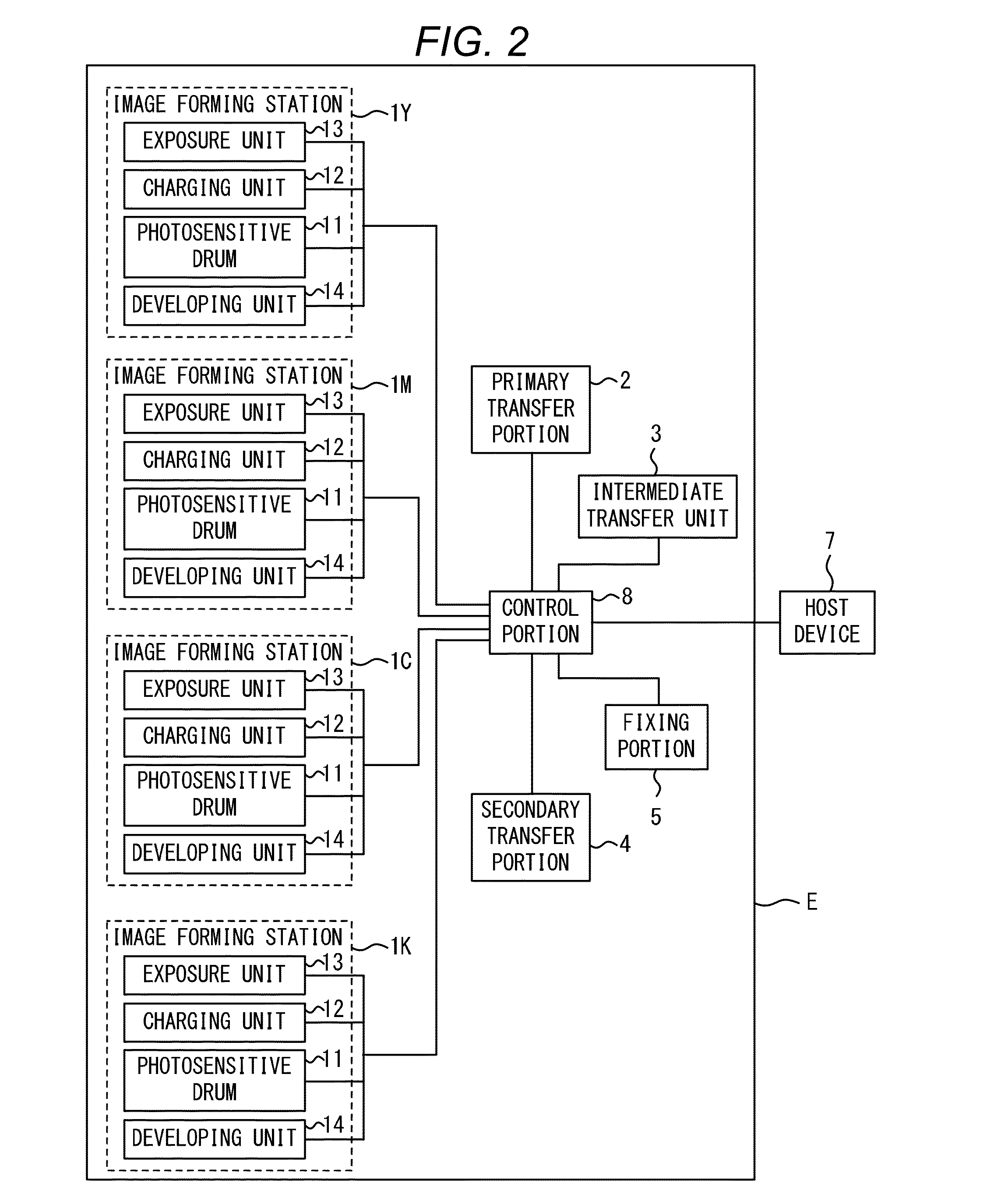

An image forming apparatus includes an image density detector, an image forming device, a rotator, an image density controller, and a timing correction data obtainer. The image density detector detects a toner density of an image formed on an image bearing member. An image forming device forms the image using a density adjustable element that adjusts the density of the image. The rotator forms an image pattern while the density adjustable element is changed, and a density thereof is detected by the image density detector. The image density controller controls the image forming device using a density correction data for the density adjustable element corresponding to a rotational period of the rotator. The timing correction data obtainer obtains timing correction data for correction of driving timing of the image forming device based on a change in the density of the image pattern detected by the image density detector.

Owner:RICOH KK

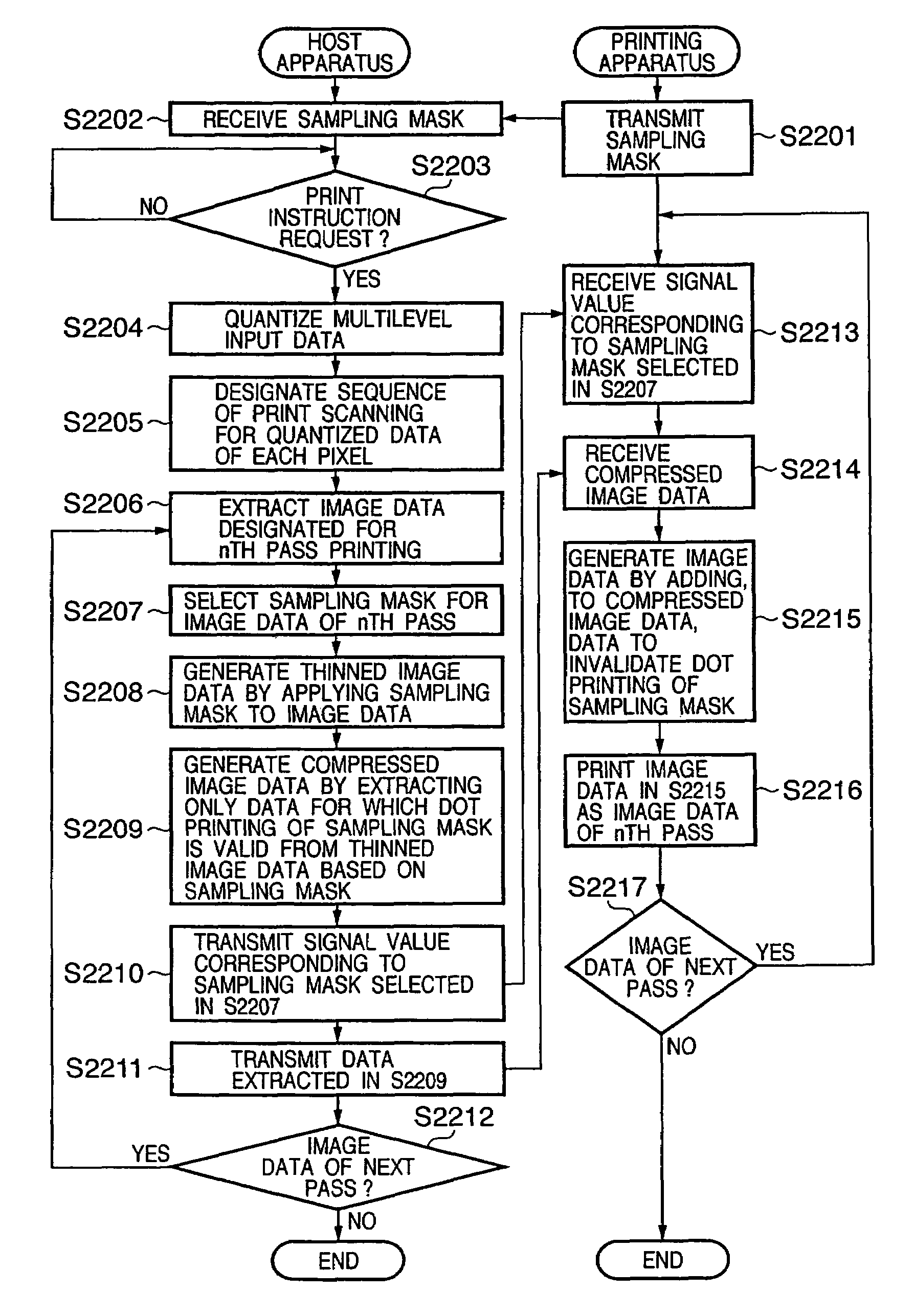

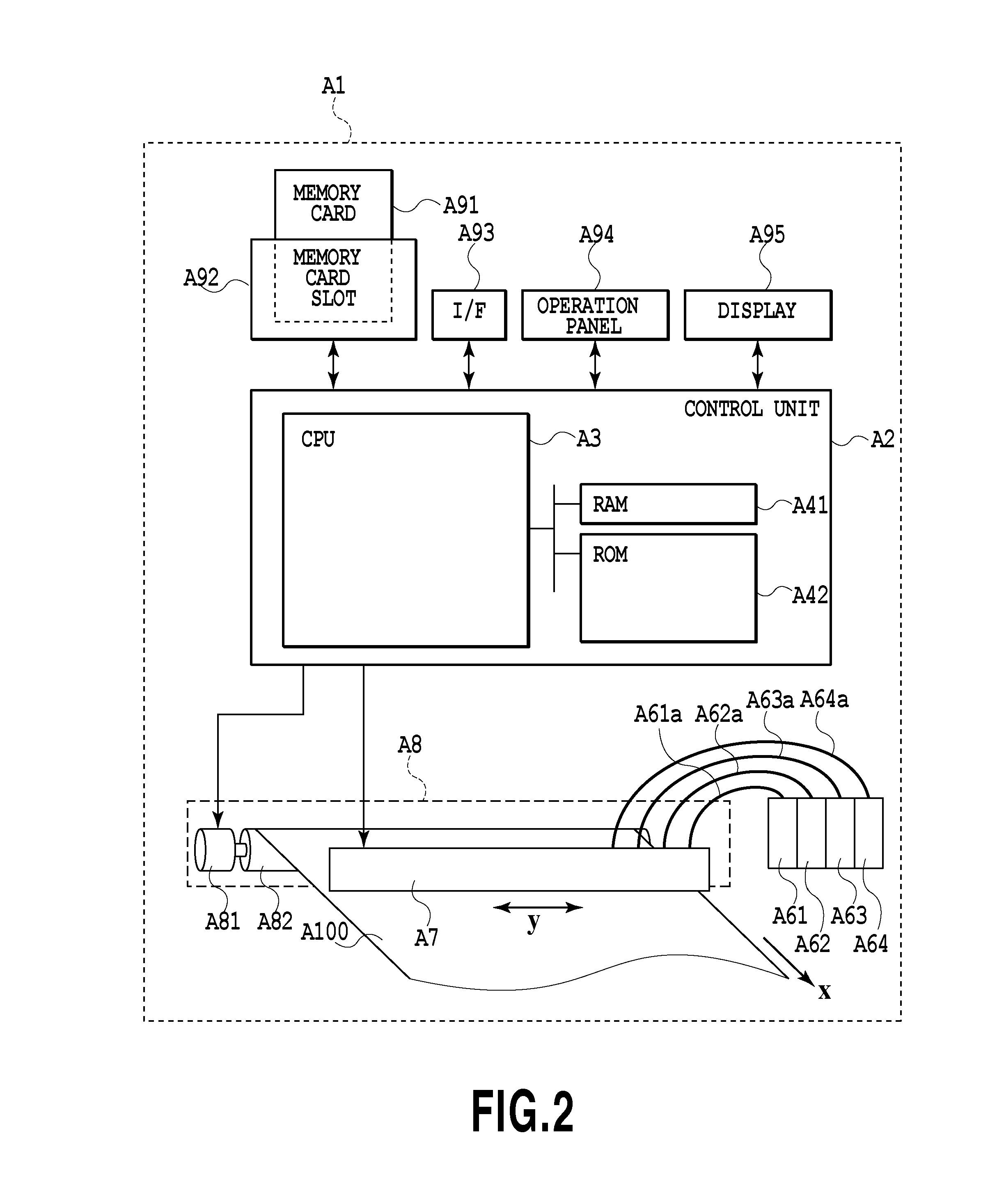

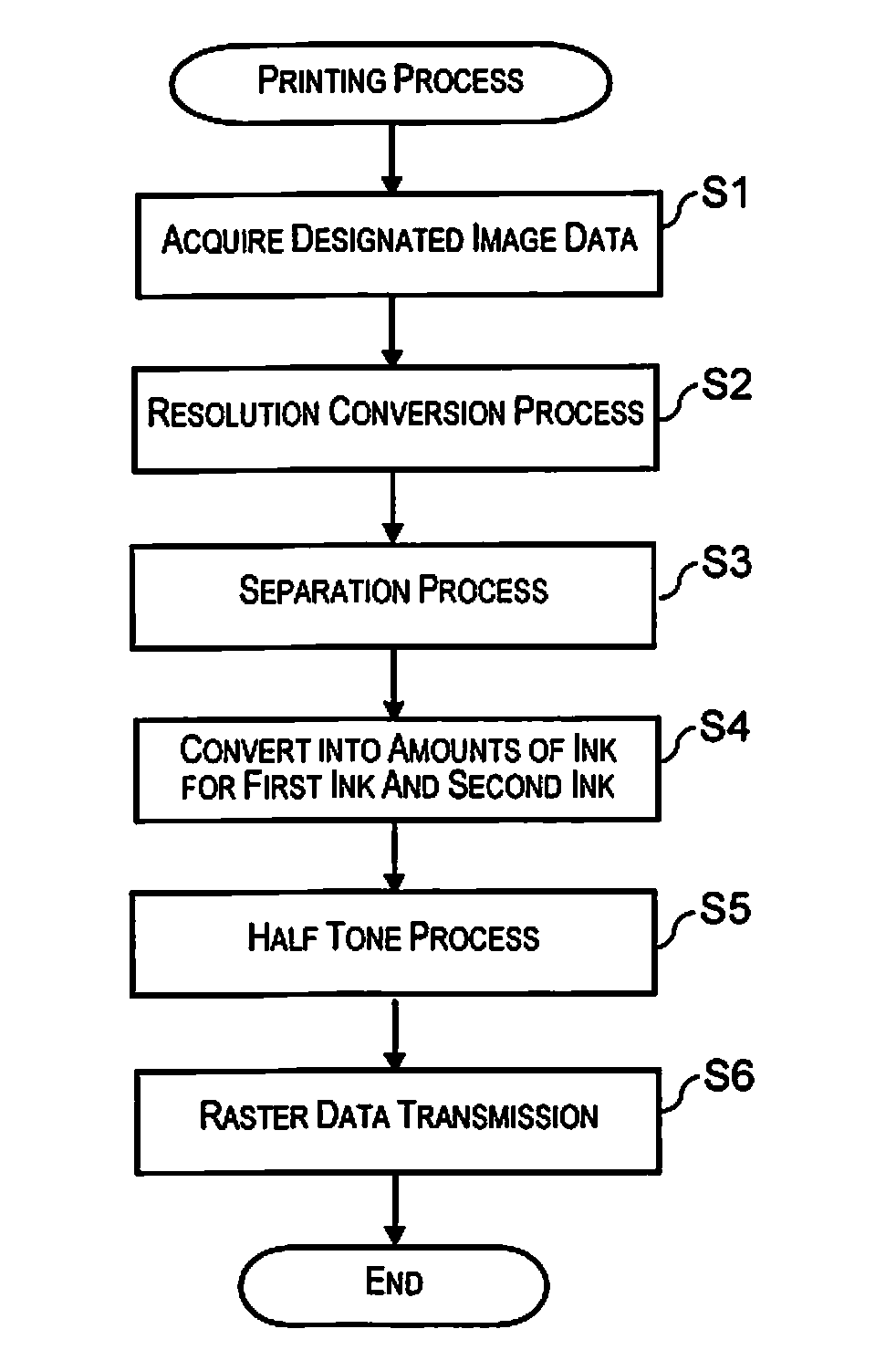

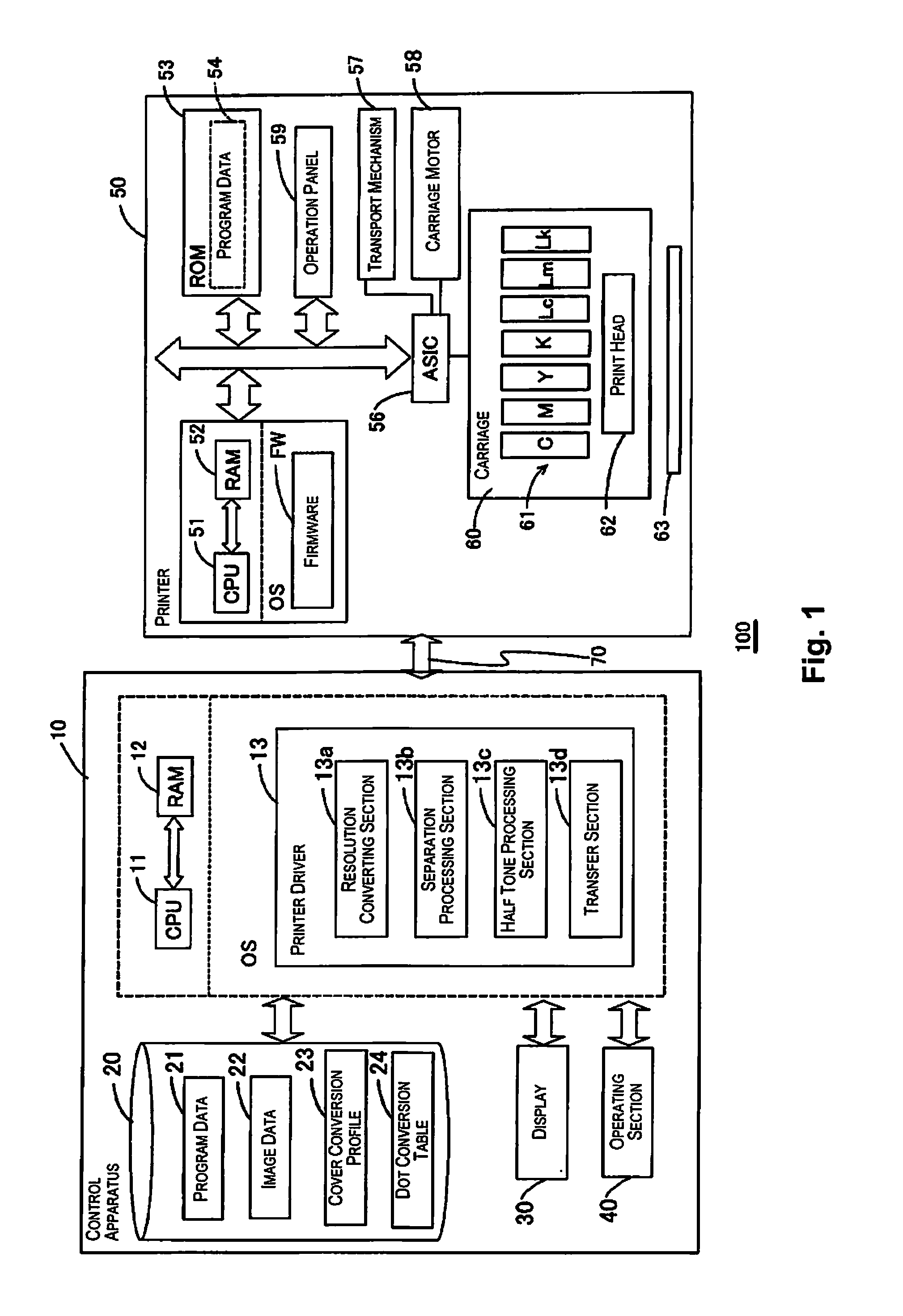

Data processing method, printing apparatus, host apparatus, and printing system

InactiveUS7706023B2Reduce the amount of data transferredUneven inhibitory concentrationDigitally marking record carriersDigital computer detailsEngineeringData transmission

Owner:CANON KK

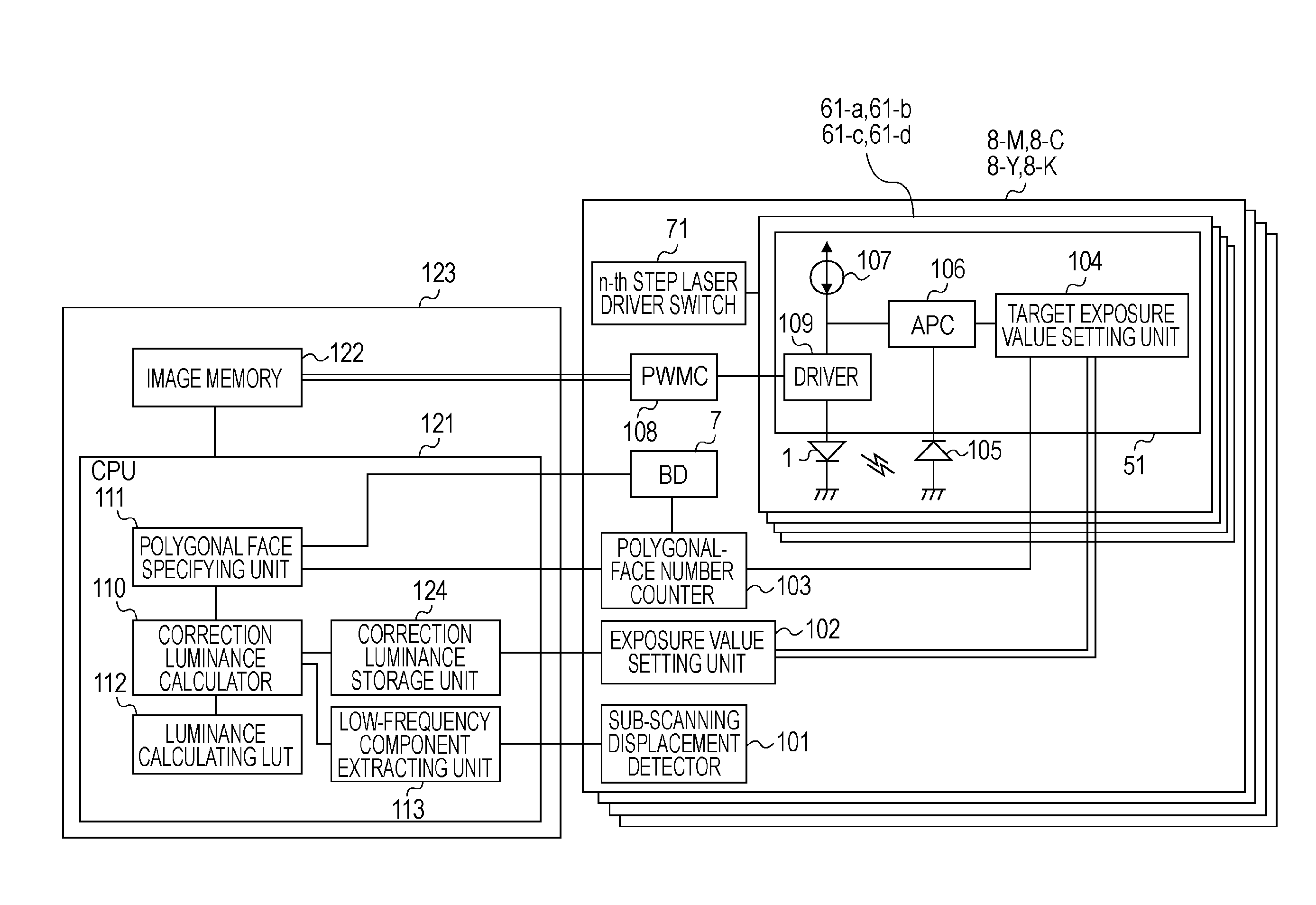

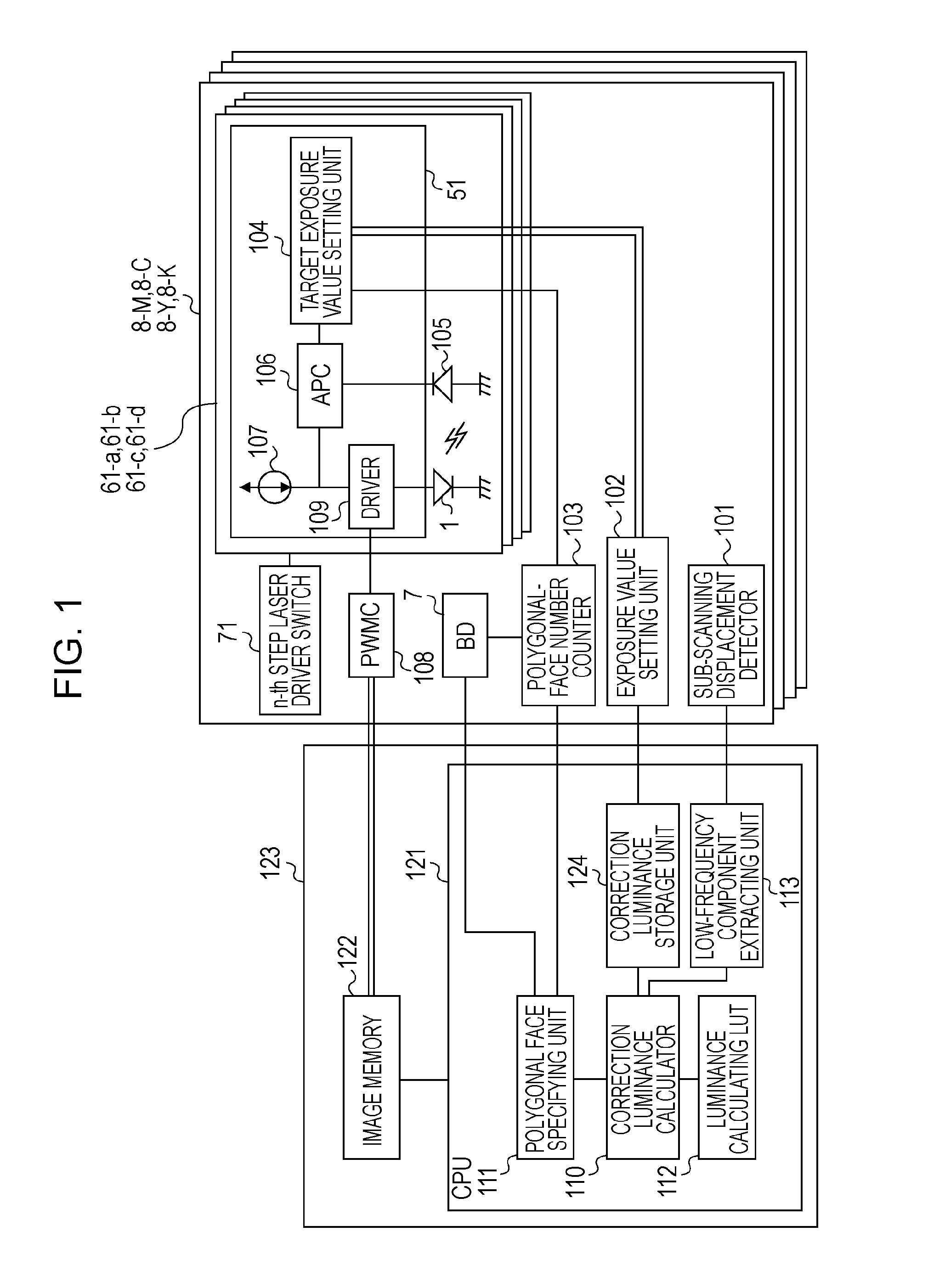

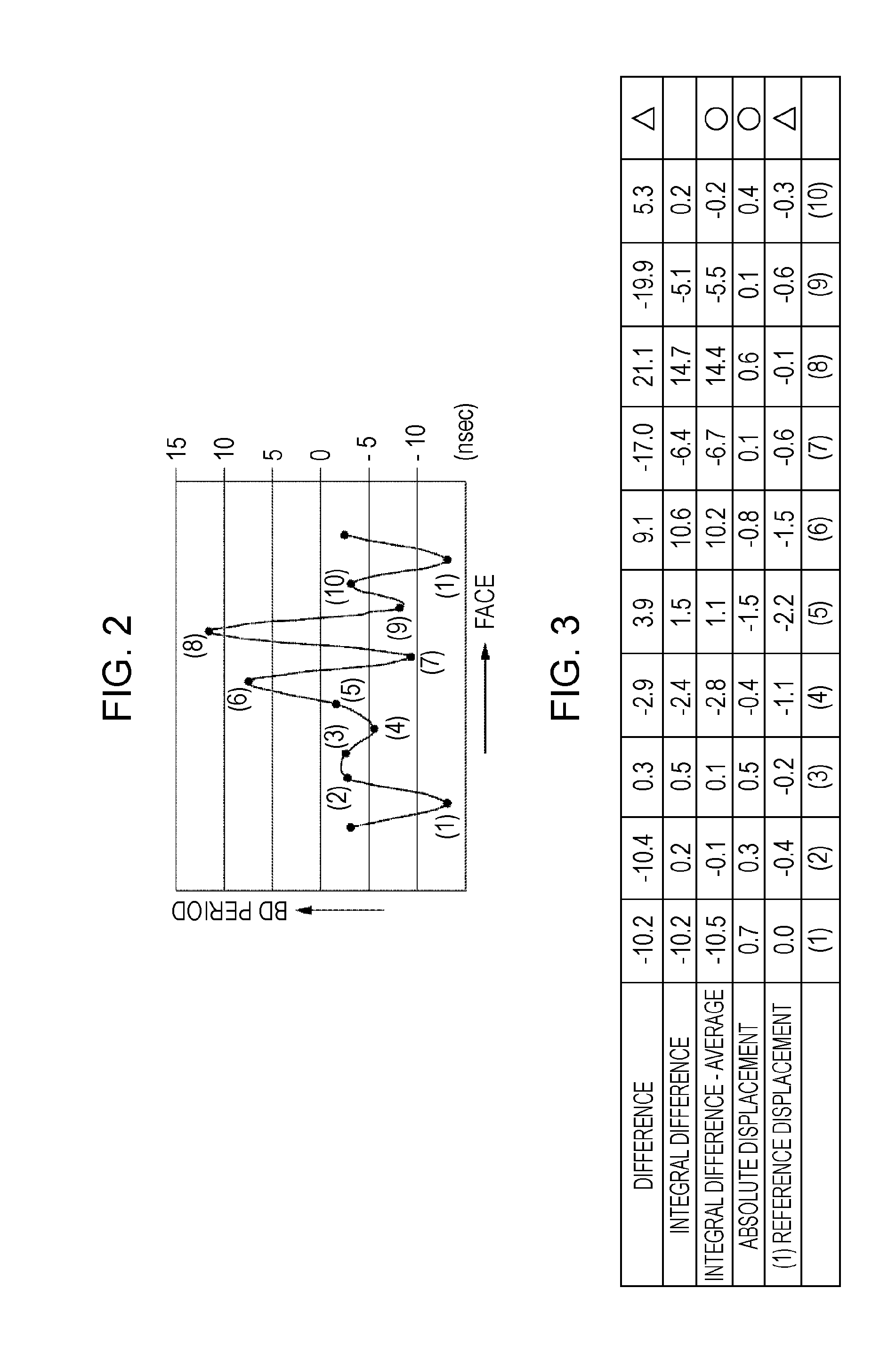

Image forming apparatus and control method

InactiveUS20090003862A1Suppress color unevennessSuppressing color density unevennessElectrographic process apparatusPrintingVisibilityImage formation

For suppressing color density unevenness due to a polygonal face tangle, laser luminance is controlled so as to maintain the color density unevenness with a spatial frequency sensitive to human visibility substantially constant.

Owner:CANON KK

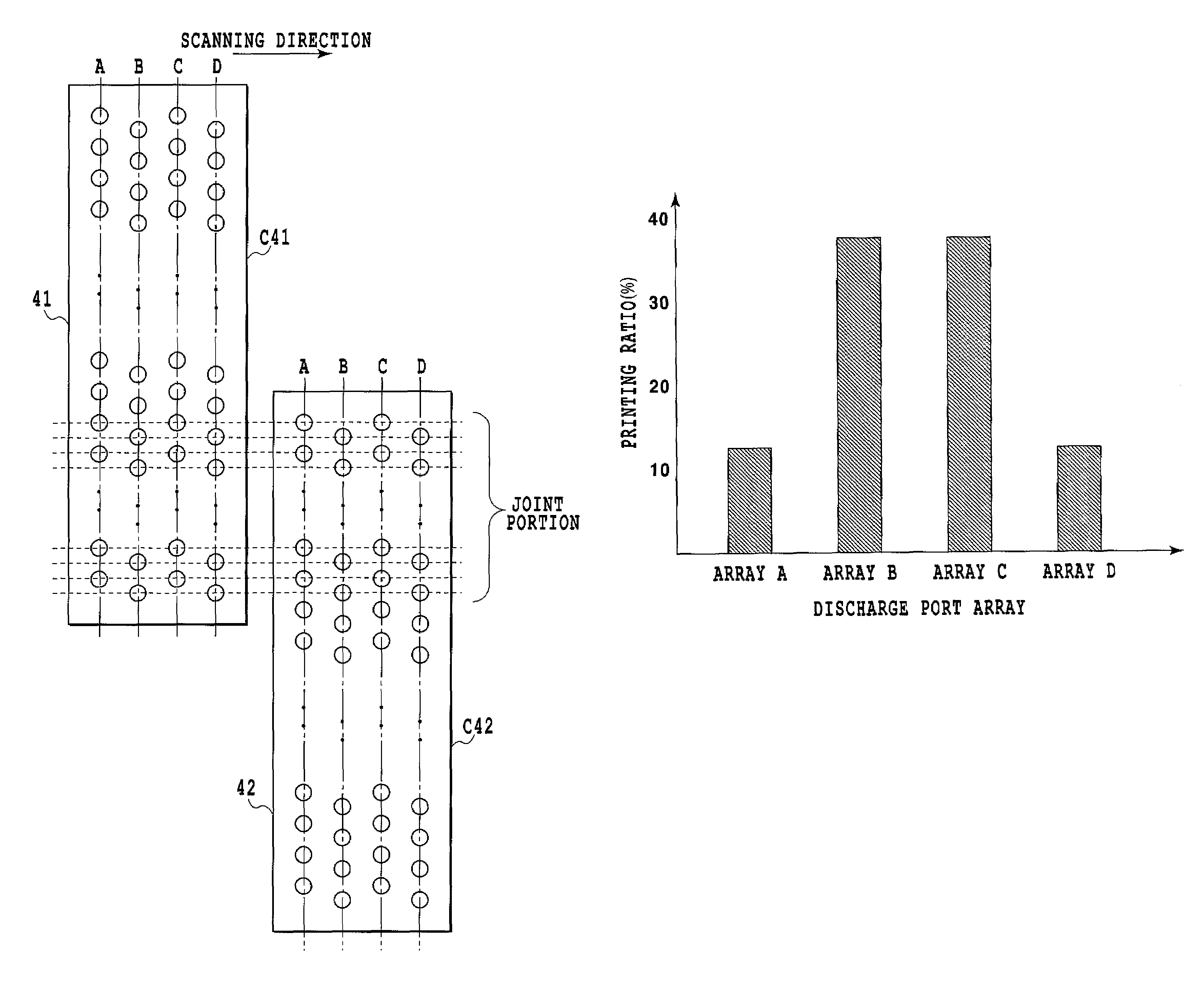

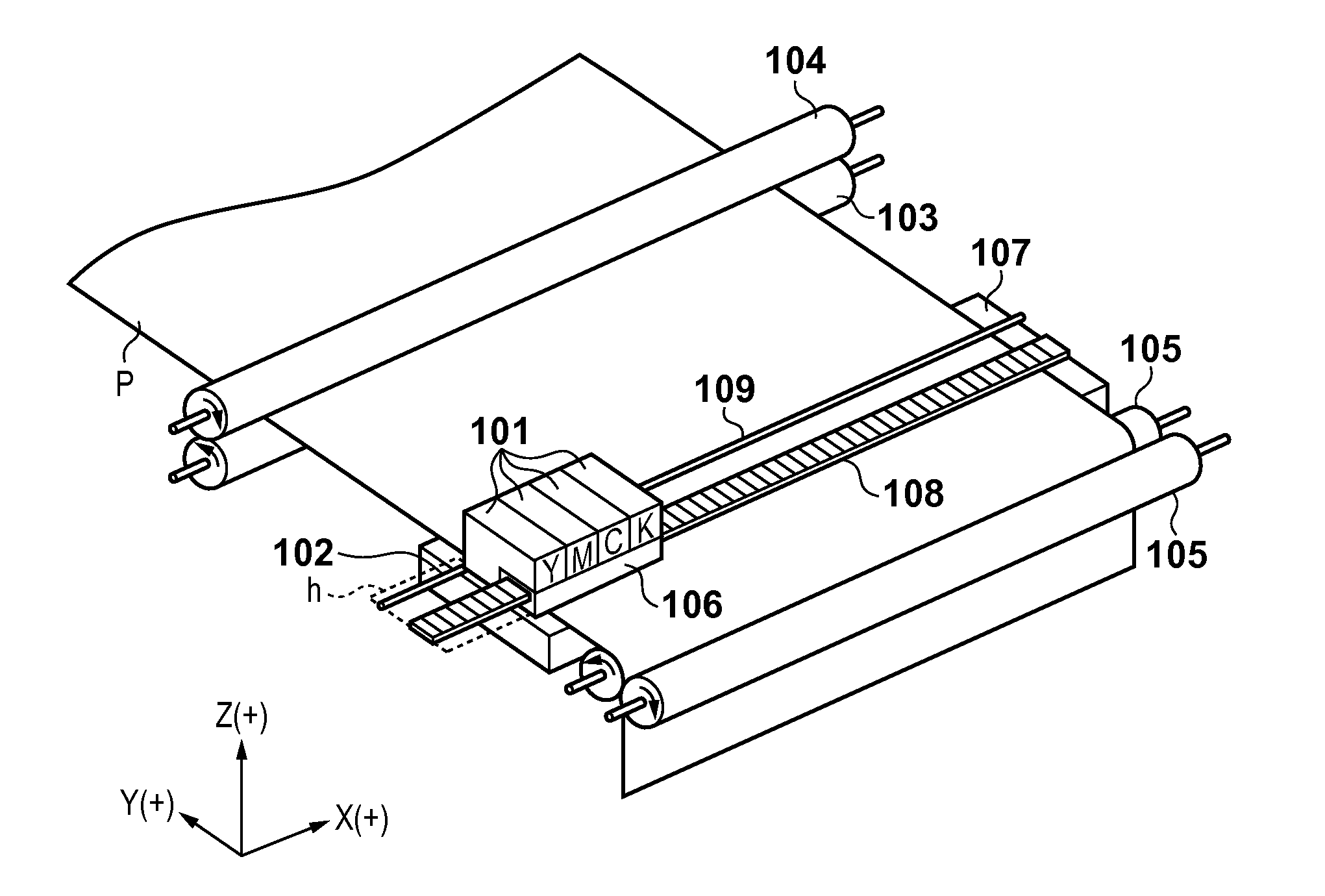

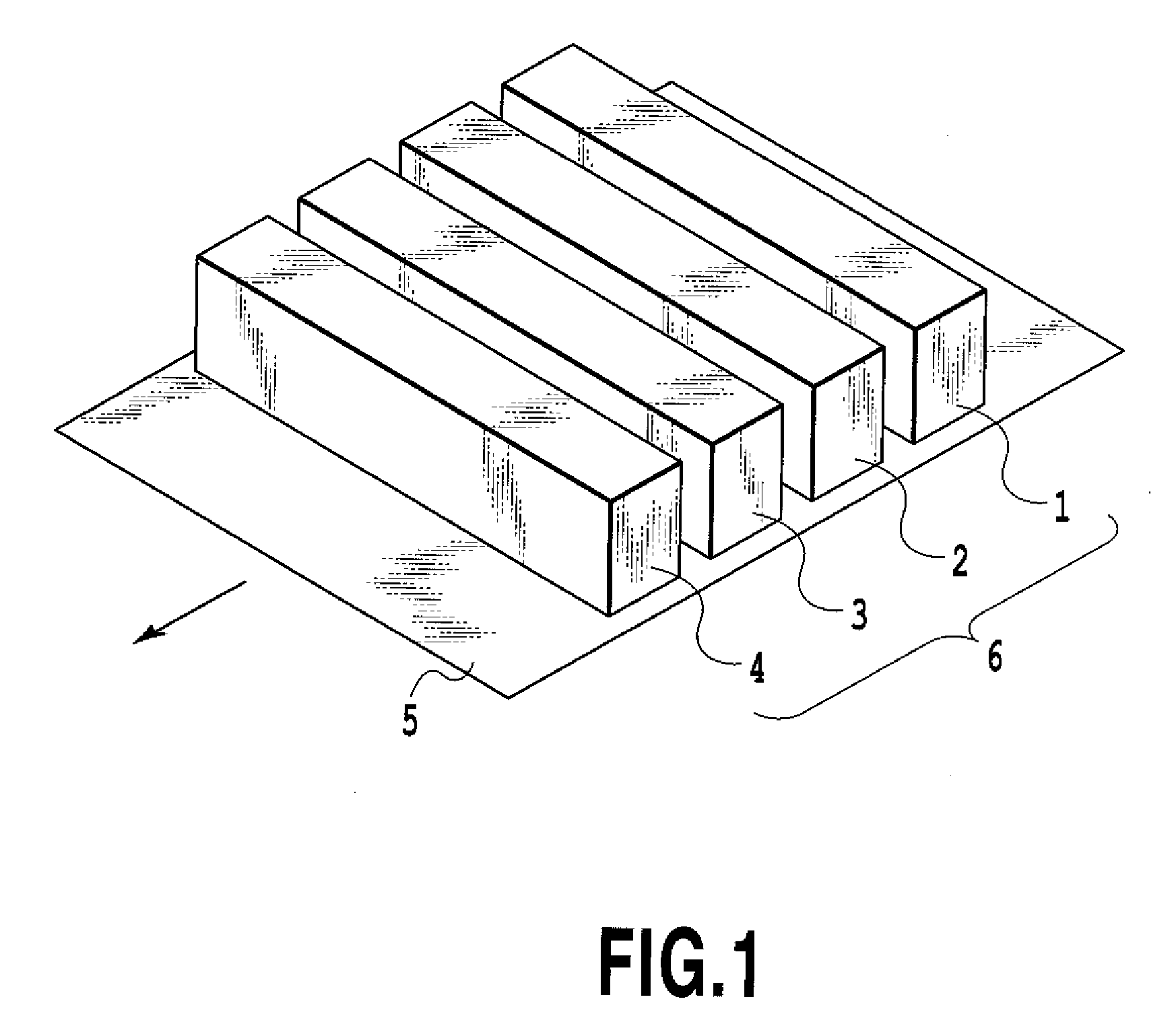

Ink jet printing apparatus and ink jet printing method

InactiveUS7585039B2Quality improvementUneven inhibitory concentrationOther printing apparatusVolumetric Mass DensityMechanical engineering

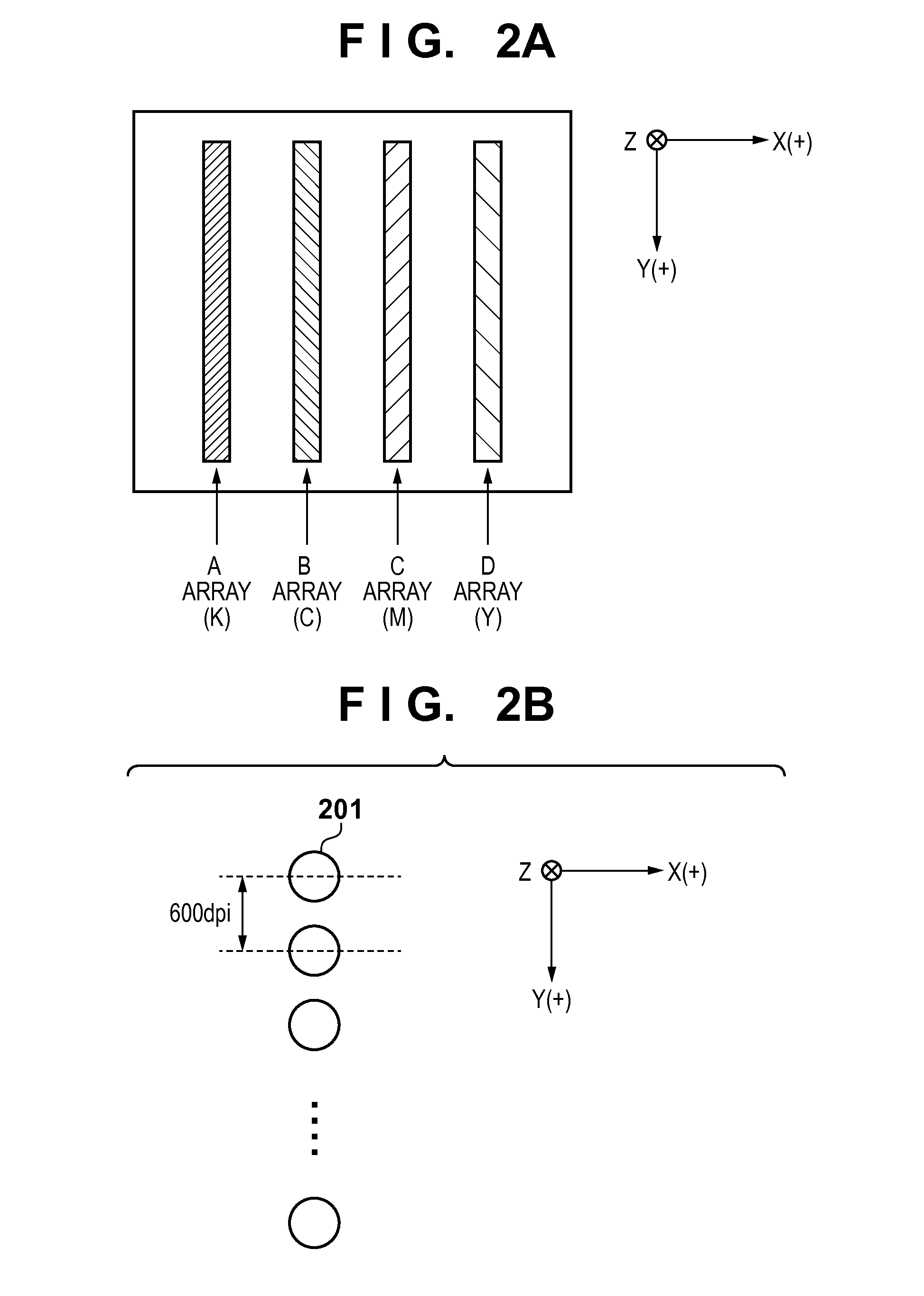

An ink jet printing apparatus and an ink jet printing method are provided which use a printing head having a plurality of ejection opening arrays and enable high quality printing without causing uneven density in a conveying direction. For this purpose, by providing a plurality of ejection opening arrays to chips constituting the printing head and changing data assigning ratio of each ejection opening array, deviation in impact positions depending on the distance between the ejection opening arrays becomes inconspicuous.

Owner:CANON KK

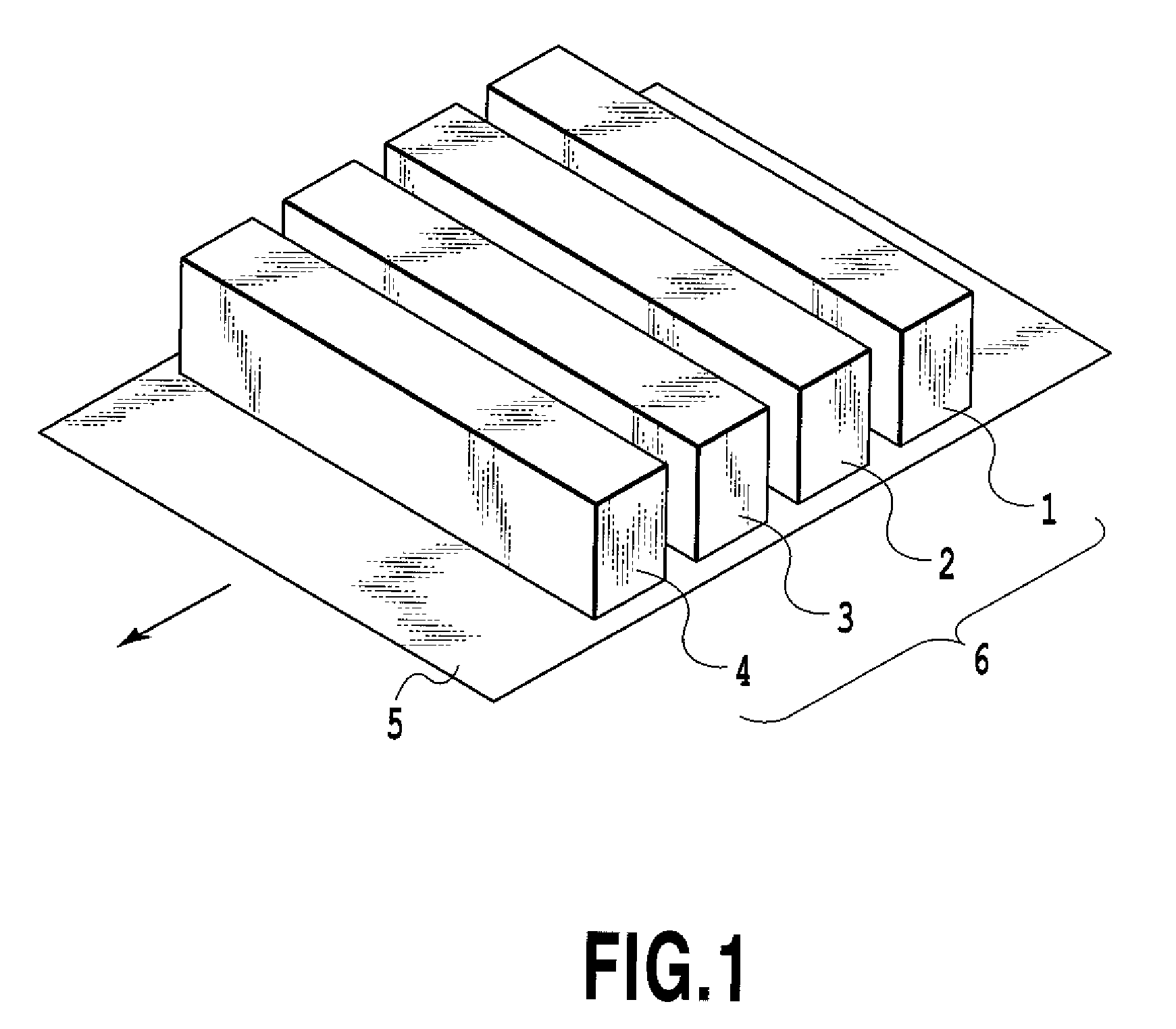

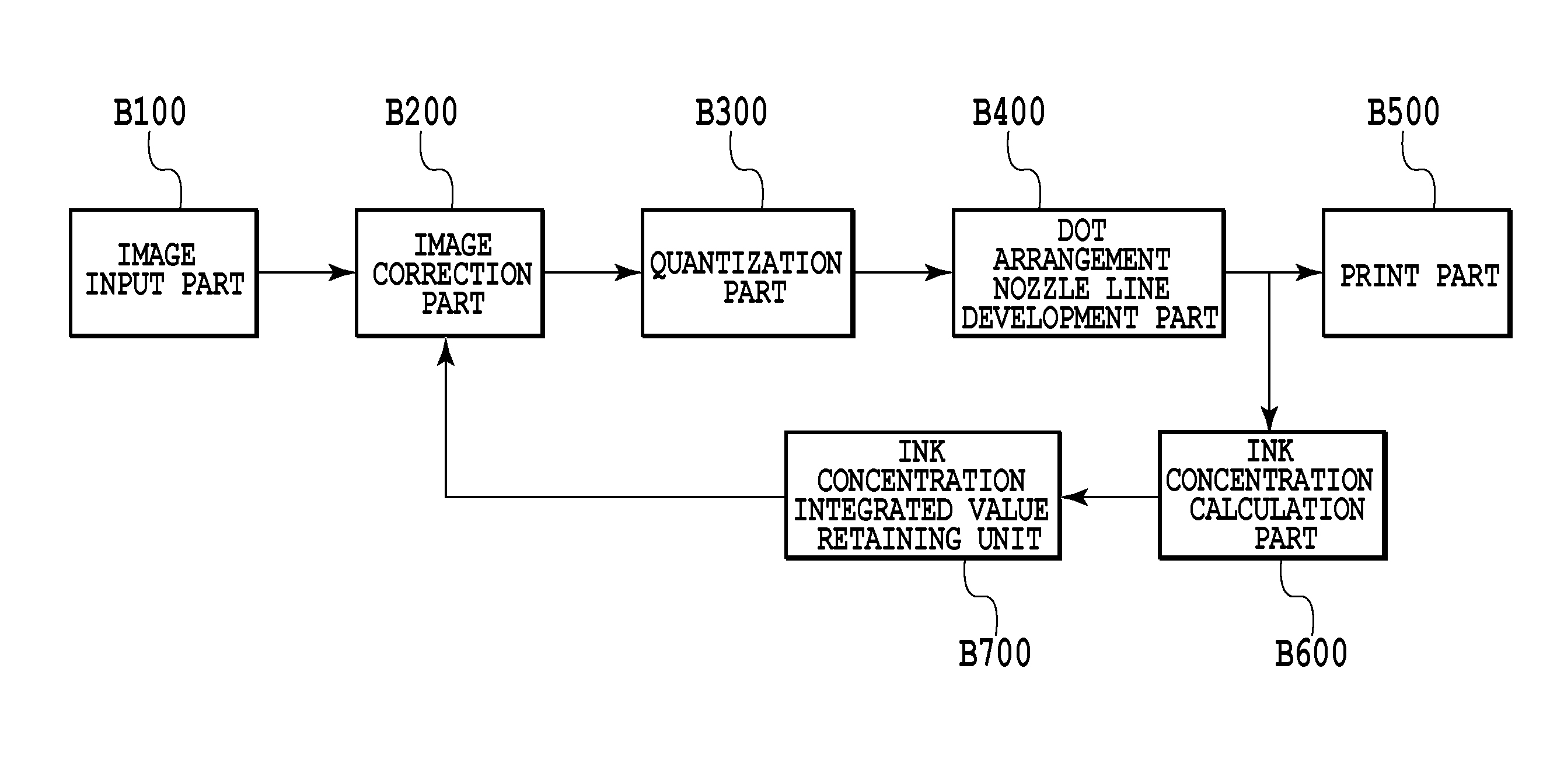

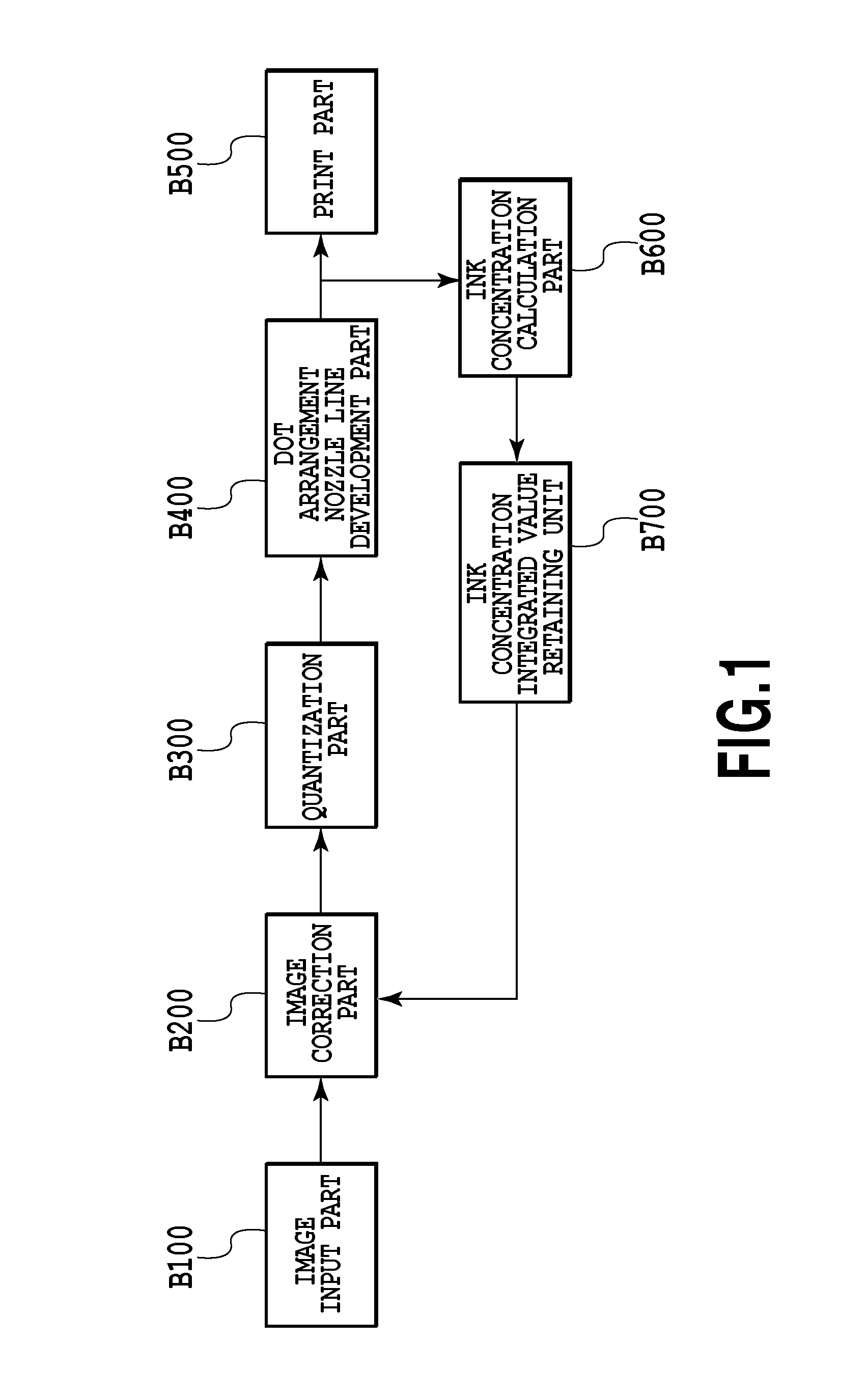

Image processing method and image processor

ActiveUS8979238B2Uneven inhibitory concentrationHighly and accurately performVisual representation by matrix printersOther printing apparatusImaging processingComputer science

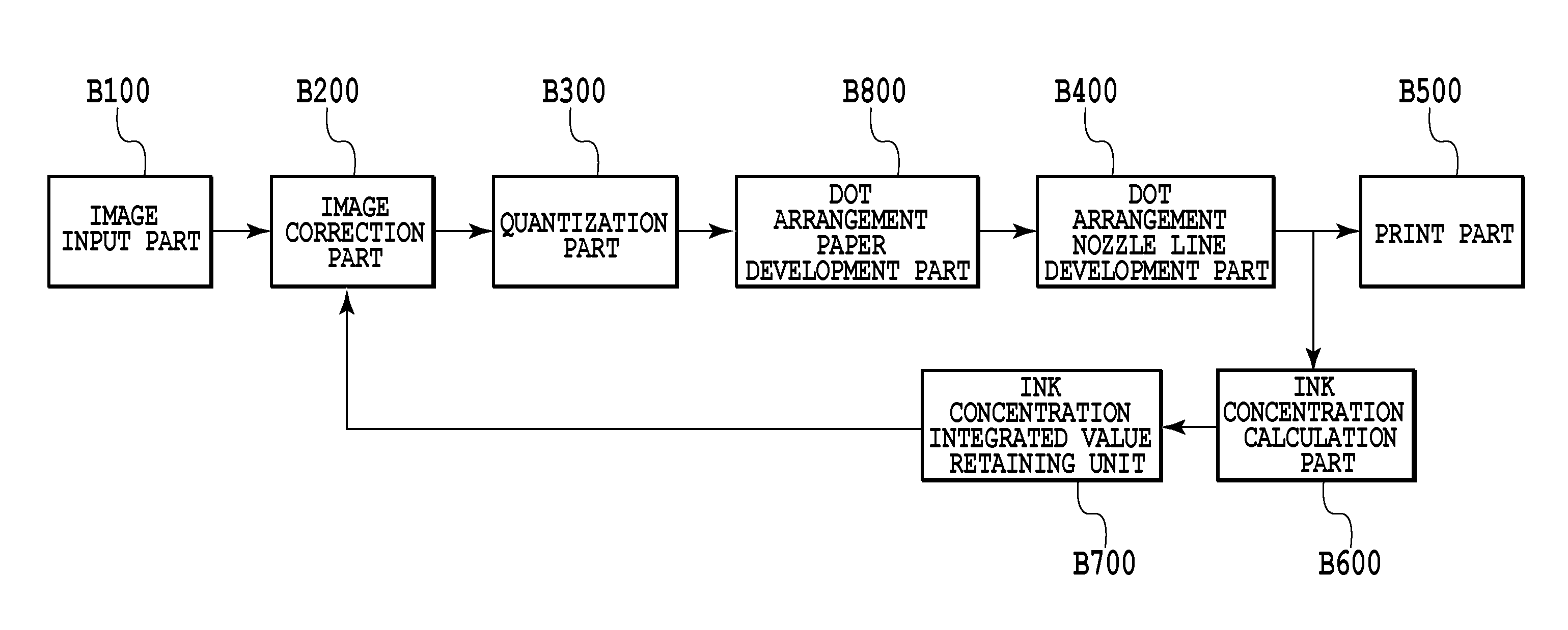

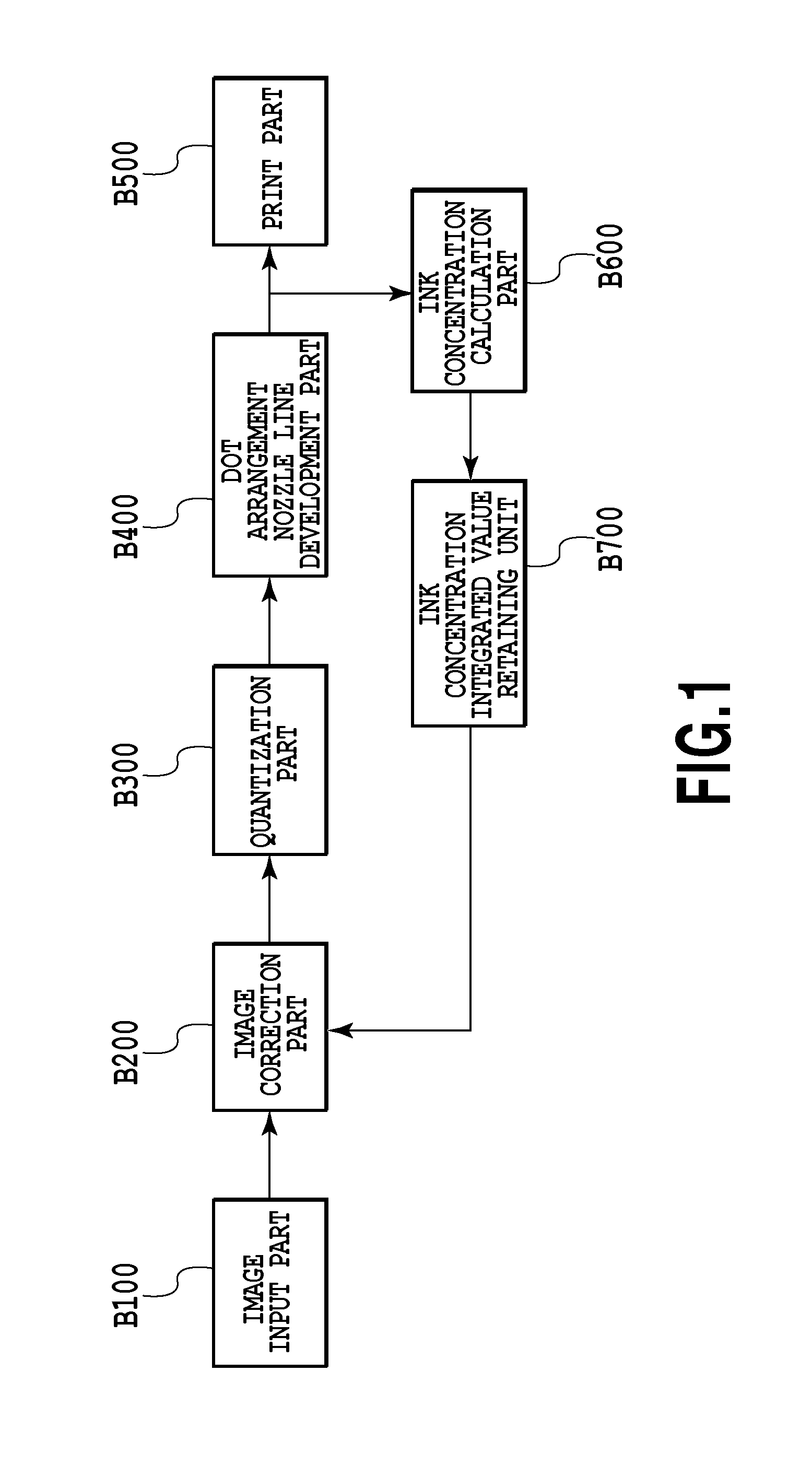

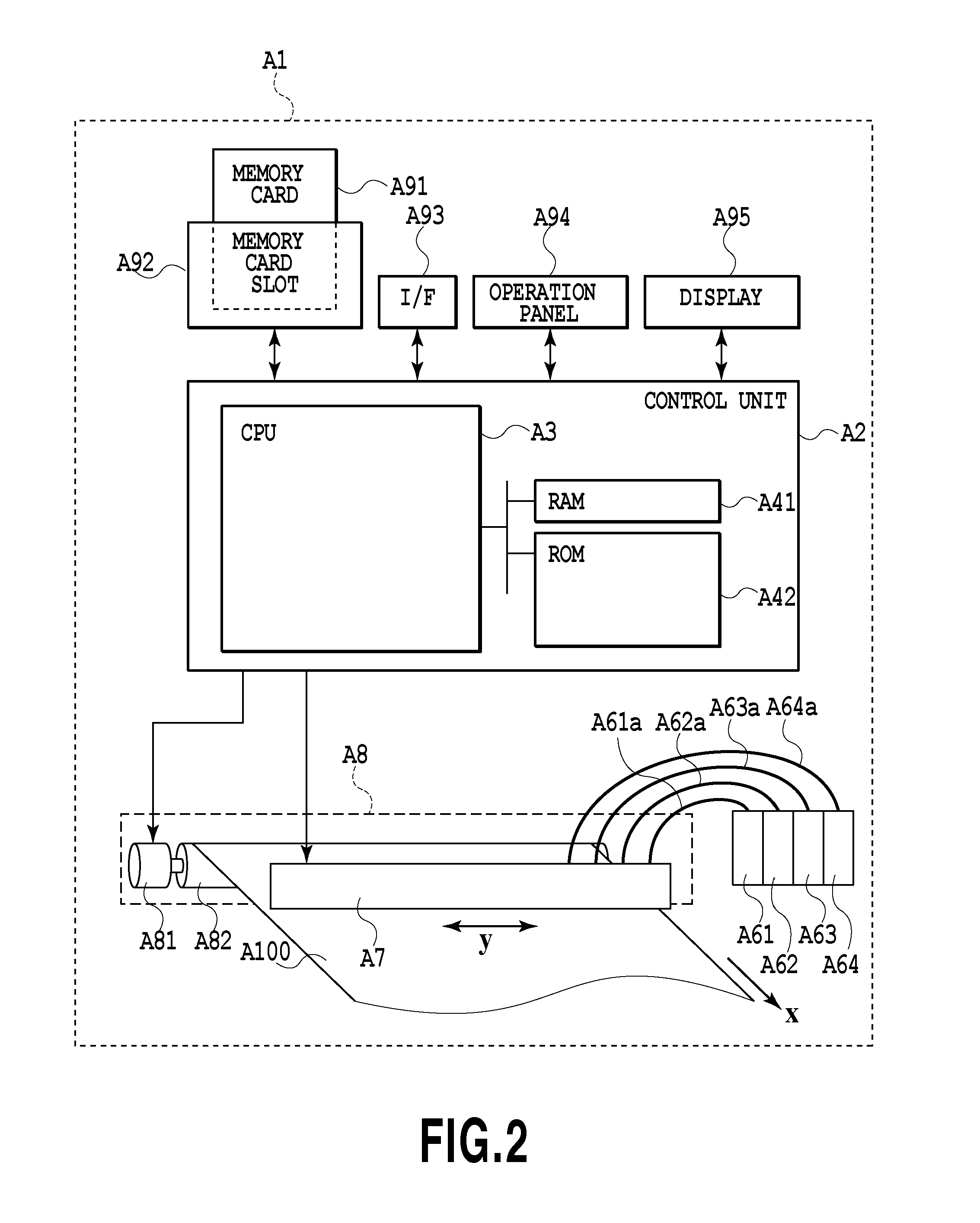

Provided are an inkjet printing apparatus and inkjet printing method that can, regardless of an ejection frequency of a print head, stabilize density of an image expressed on a print medium. For this purpose, an ink concentration integrated value is obtained according to the ejection history of each nozzle so as to be increased by data indicating non-ejection of the nozzle or decreased by data indicating ejection. Then, image data on the target pixel is corrected such that density of the target pixel is further reduced as the pixel is subjected to printing by a nozzle having a higher ink concentration integrated value.

Owner:CANON KK

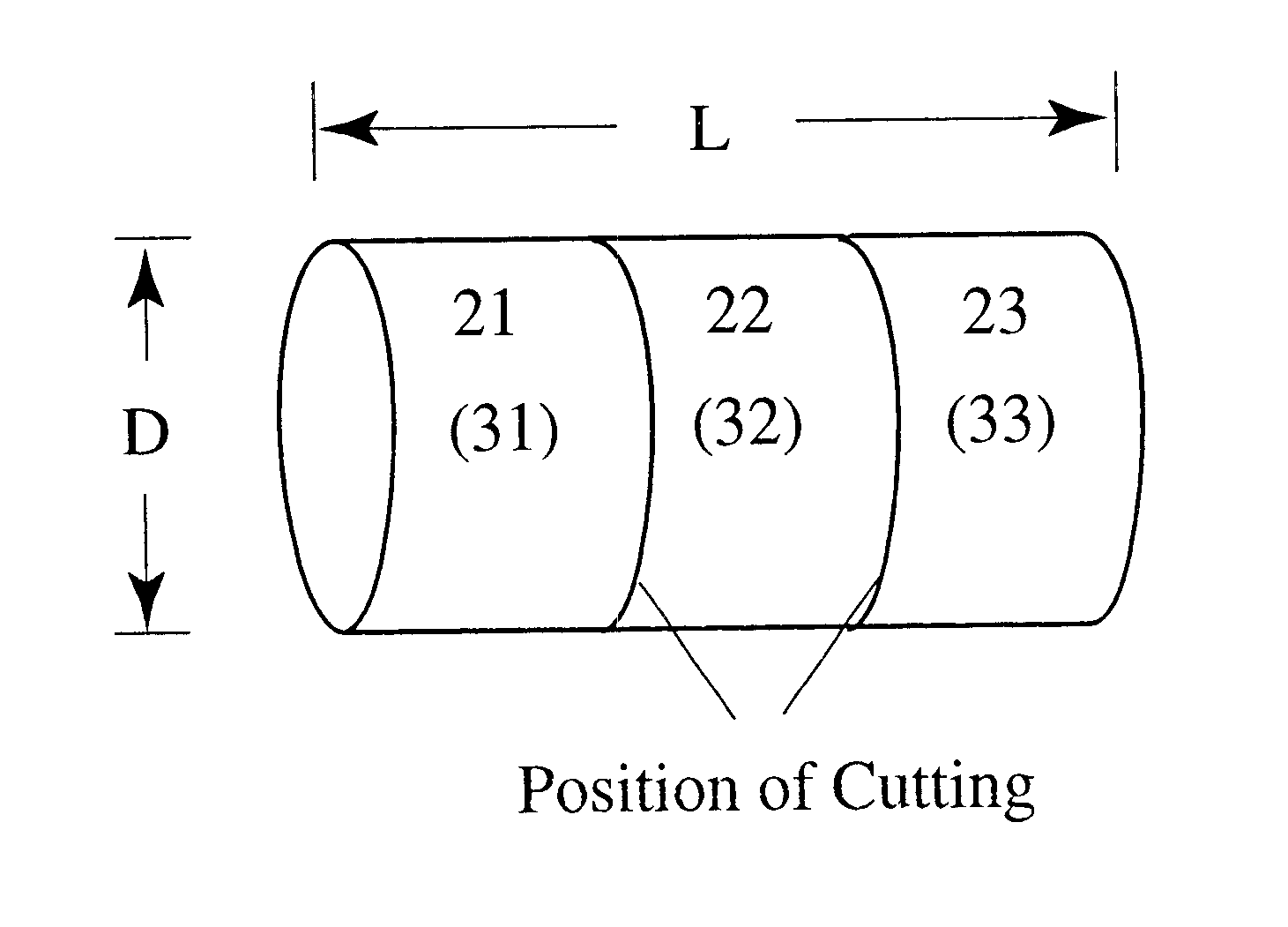

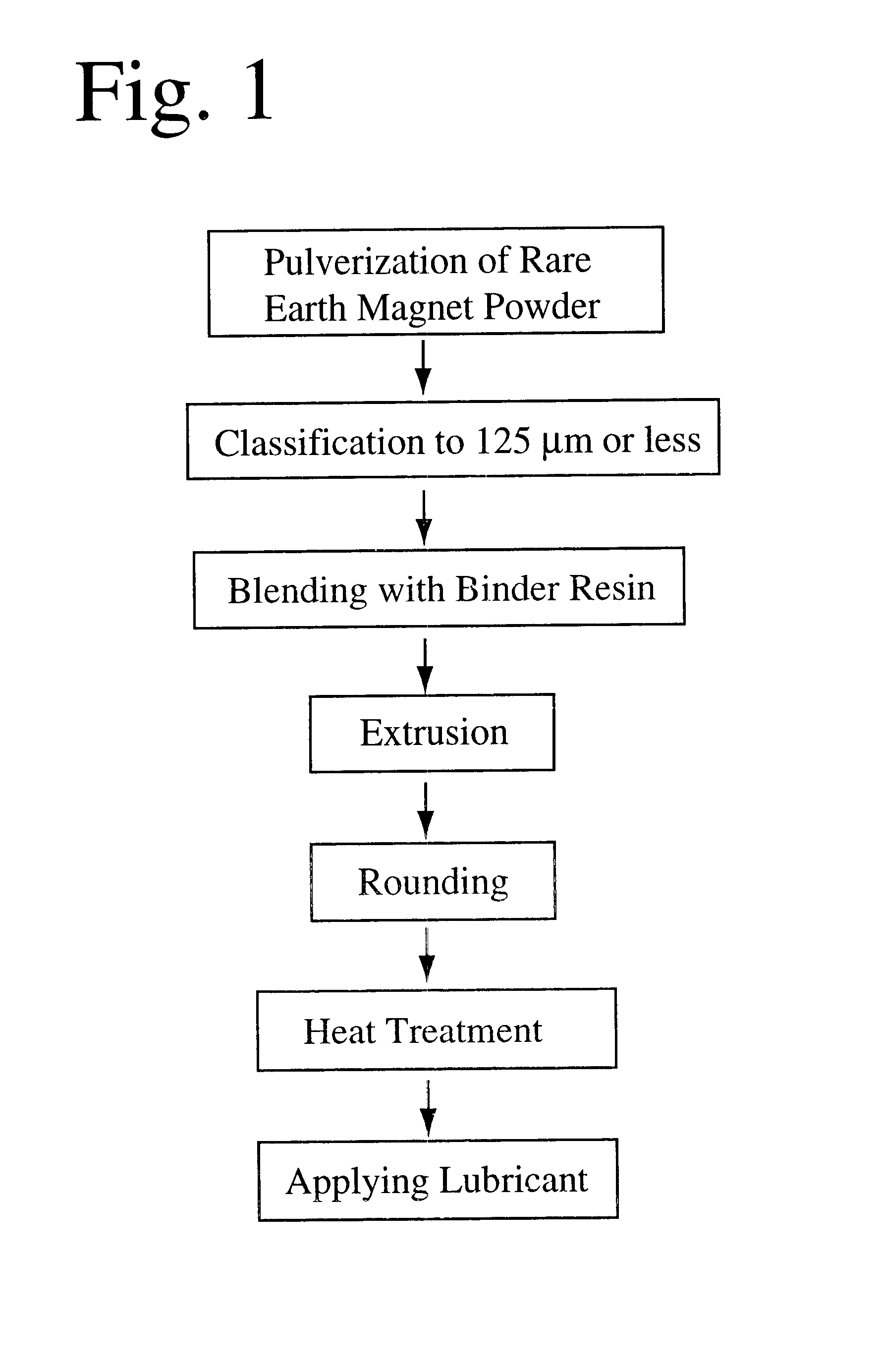

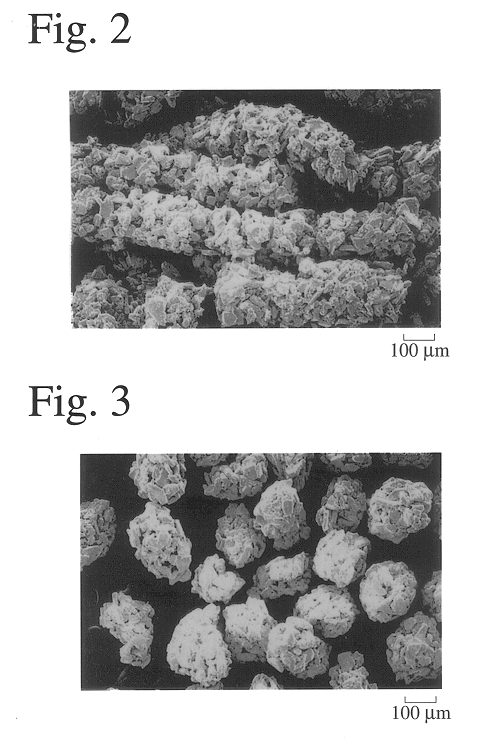

Magnet powder-resin compound particles, method for producing such compound particles and resin-bonded rare earth magnets formed therefrom

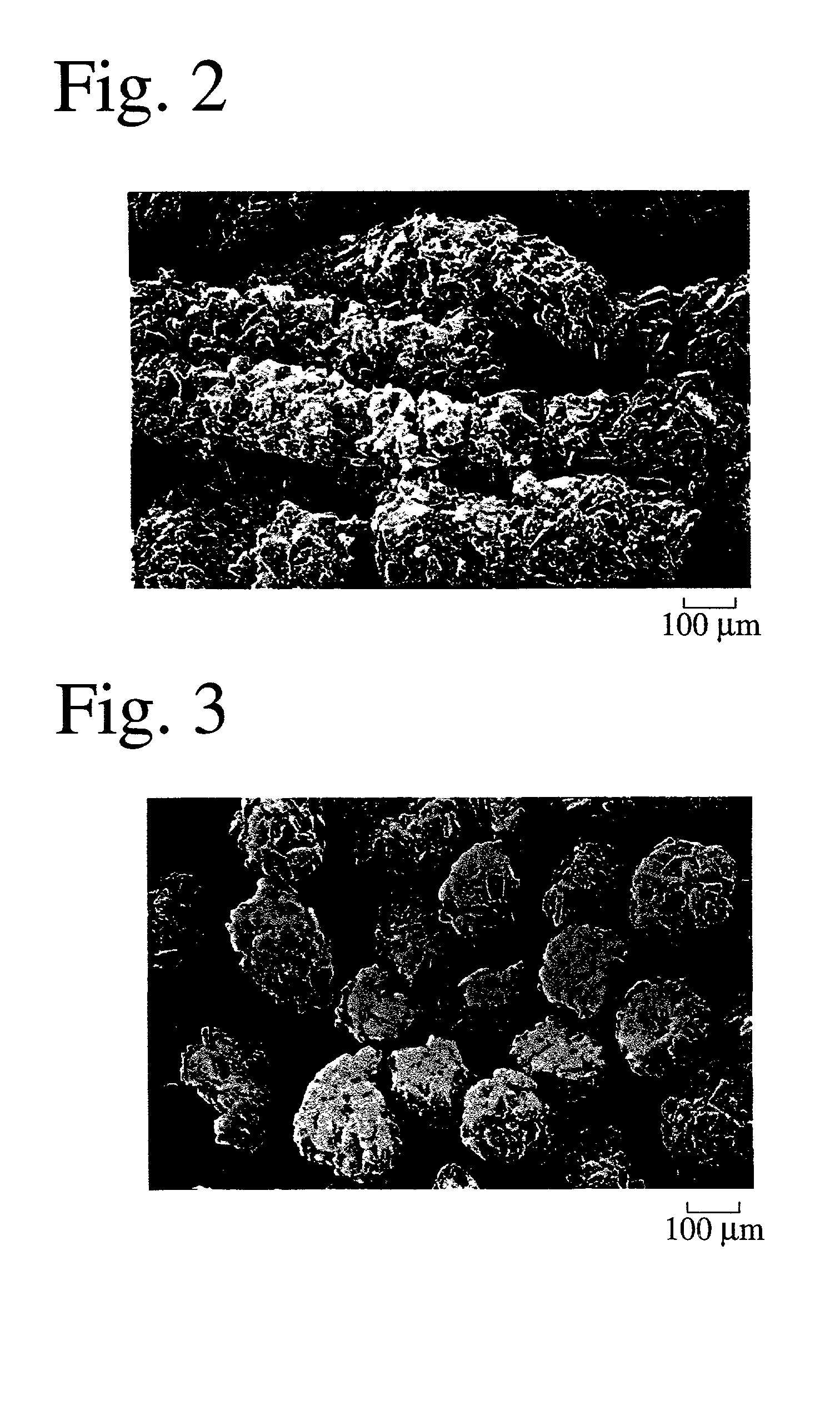

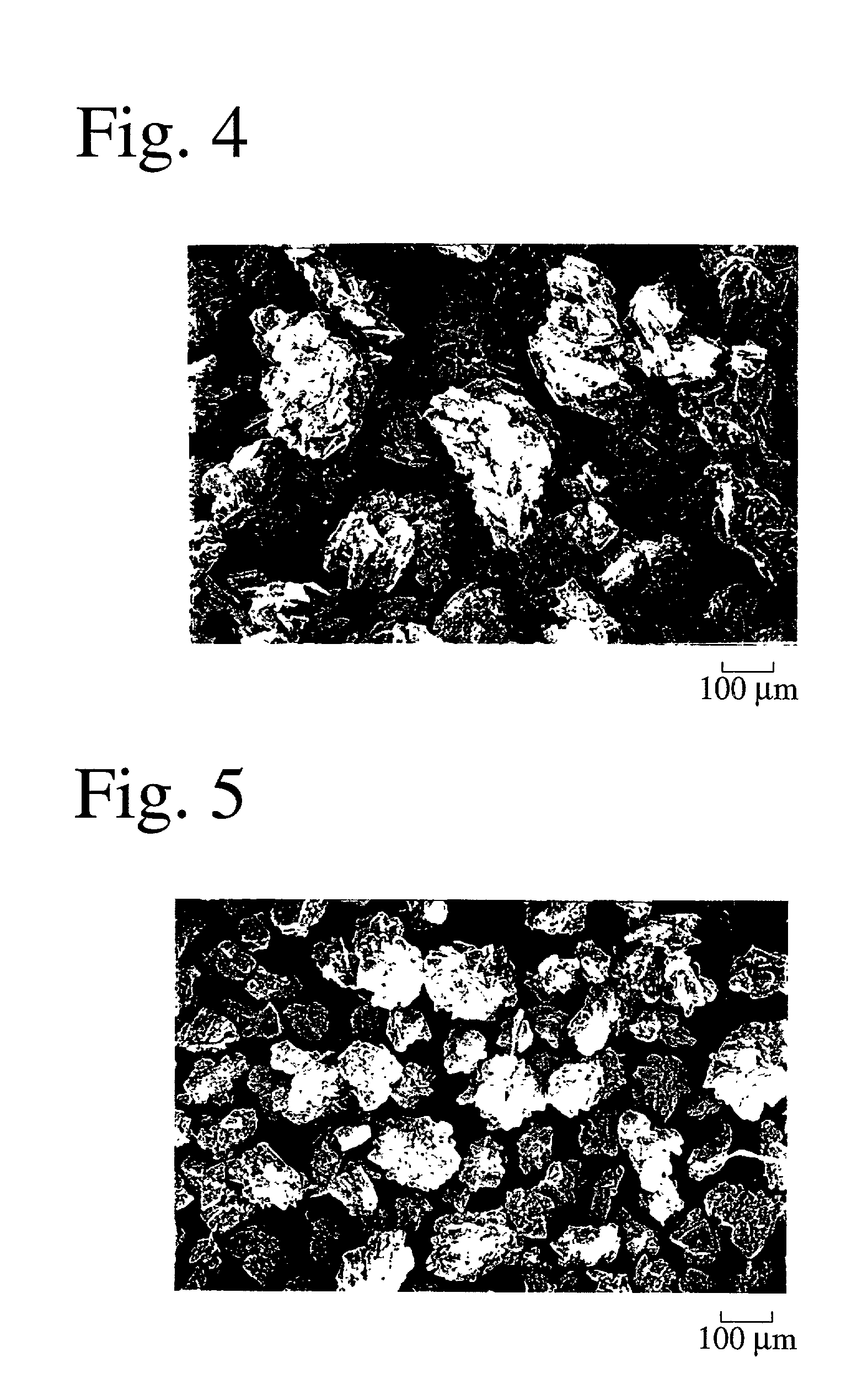

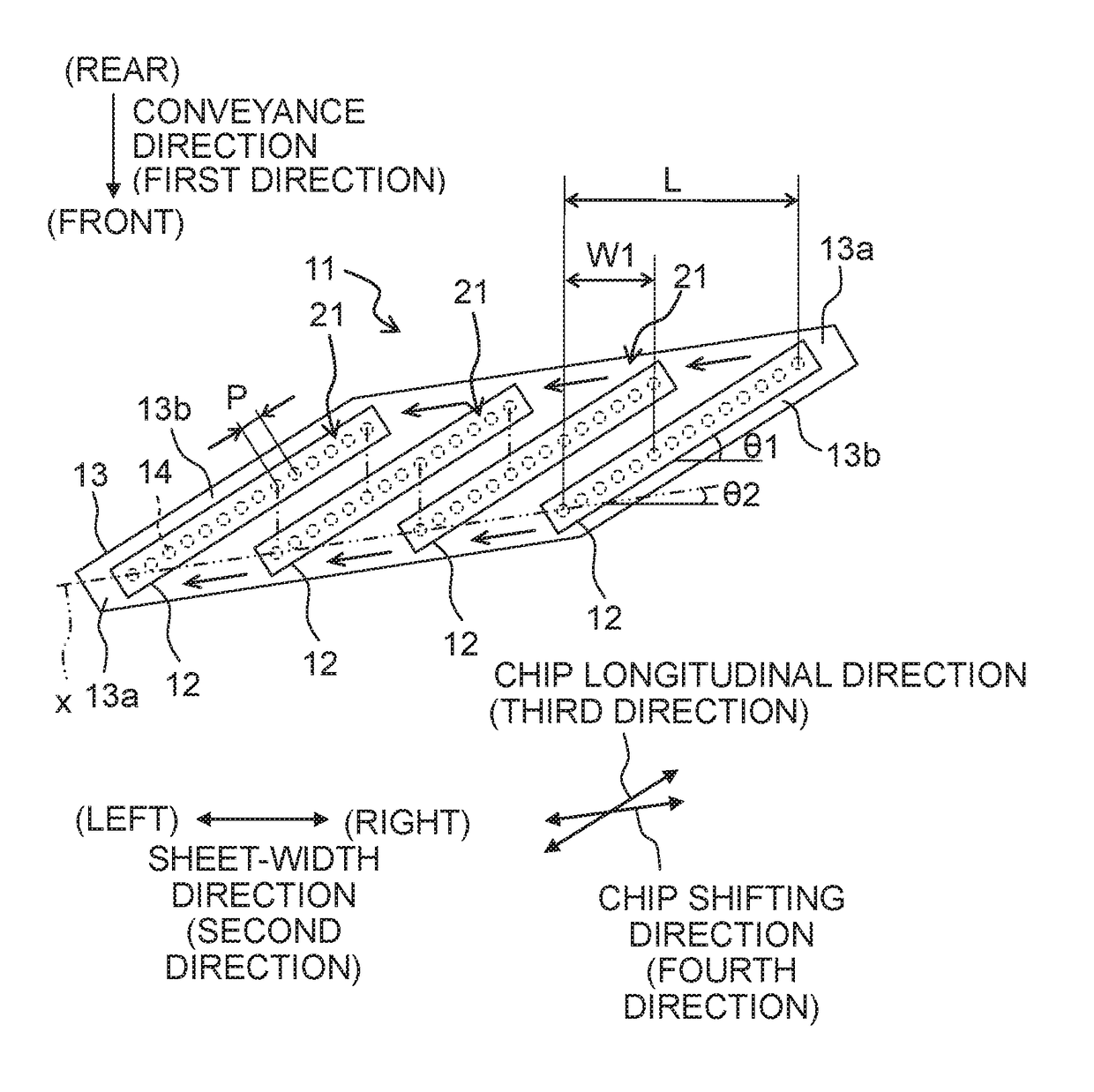

InactiveUS6423386B2High dimensional accuracyImprove magnetic propertiesEnvelopes/bags making machinerySynthetic resin layered productsMetallurgyRare-earth magnet

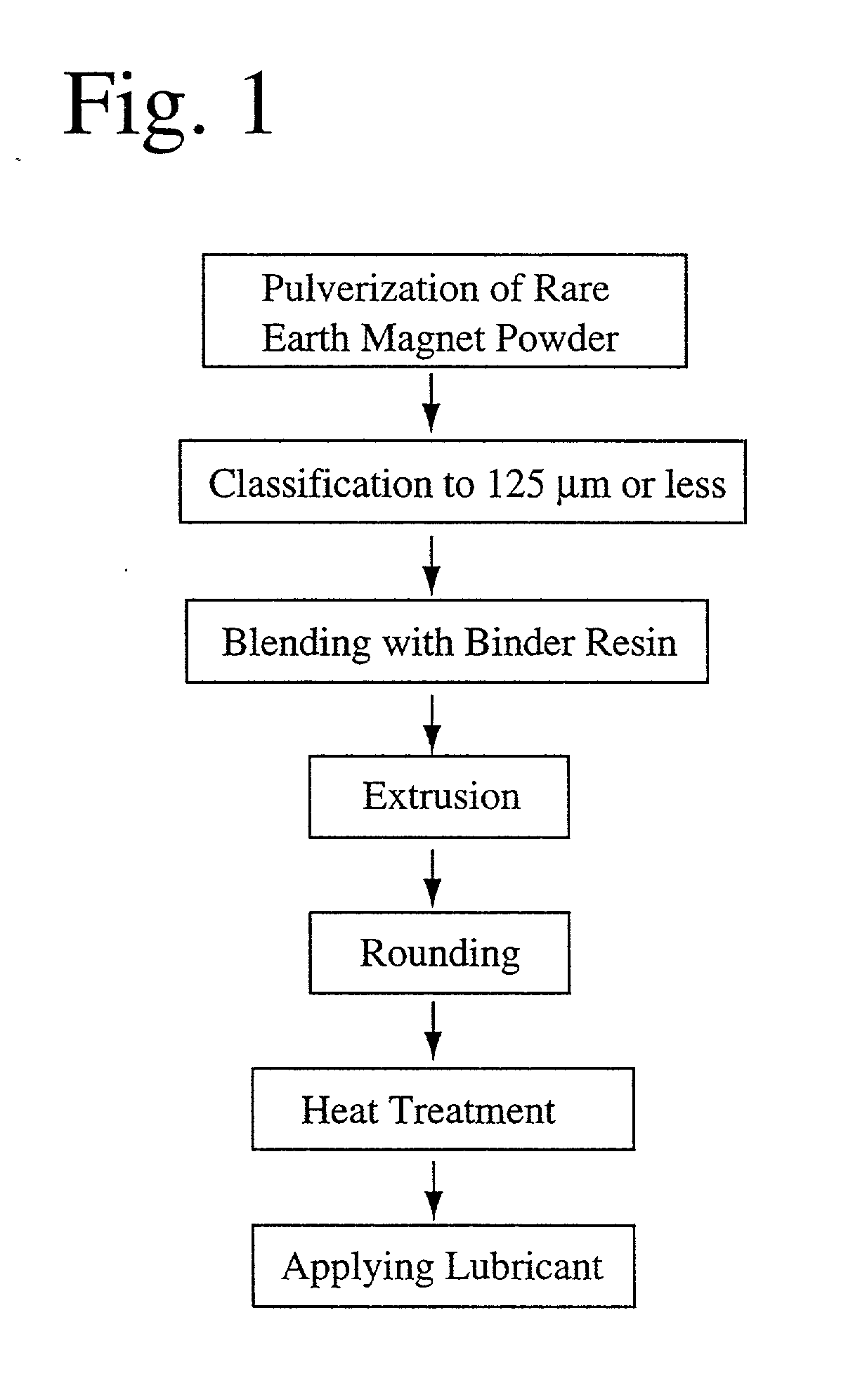

The magnet powder-resin compound particles substantially composed of rare earth magnet powder and a binder resin are in such a round shape that a ratio of the longitudinal size a to the transverse size b (a / b) is more than 1.00 and 3 or less, and that an average particle size defined by (a / b) / 2 is 50-300 mum. They are produced by charging a mixture of rare earth magnet powder and a binder resin into an extruder equipped with nozzle orifices each having a diameter of 300 mum or less; extruding the mixture while blending under pressure though the nozzle orifices to form substantially cylindrical, fine pellets; and rounding the pellets by rotation.

Owner:HITACHI METALS LTD

Liquid jetting apparatus

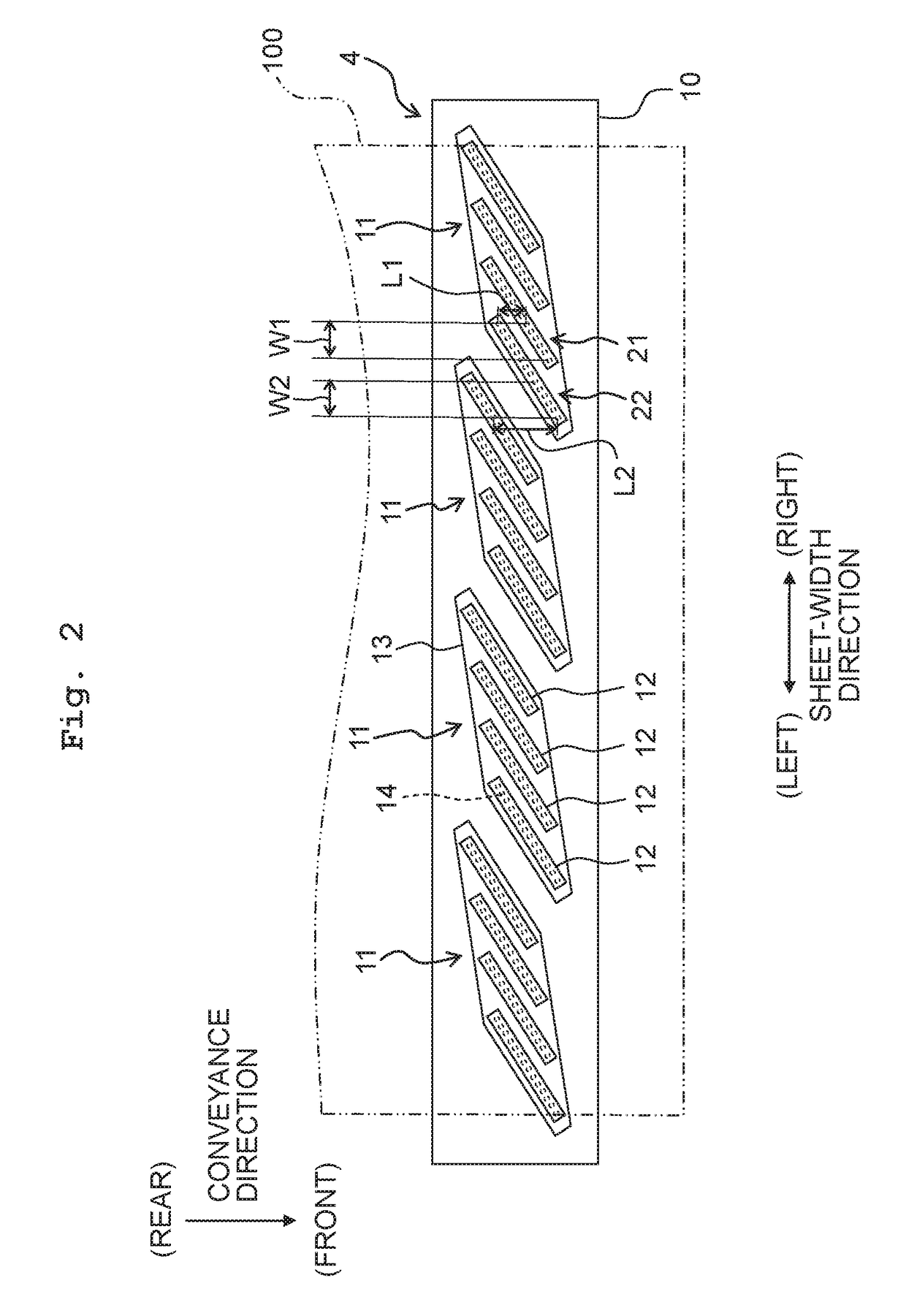

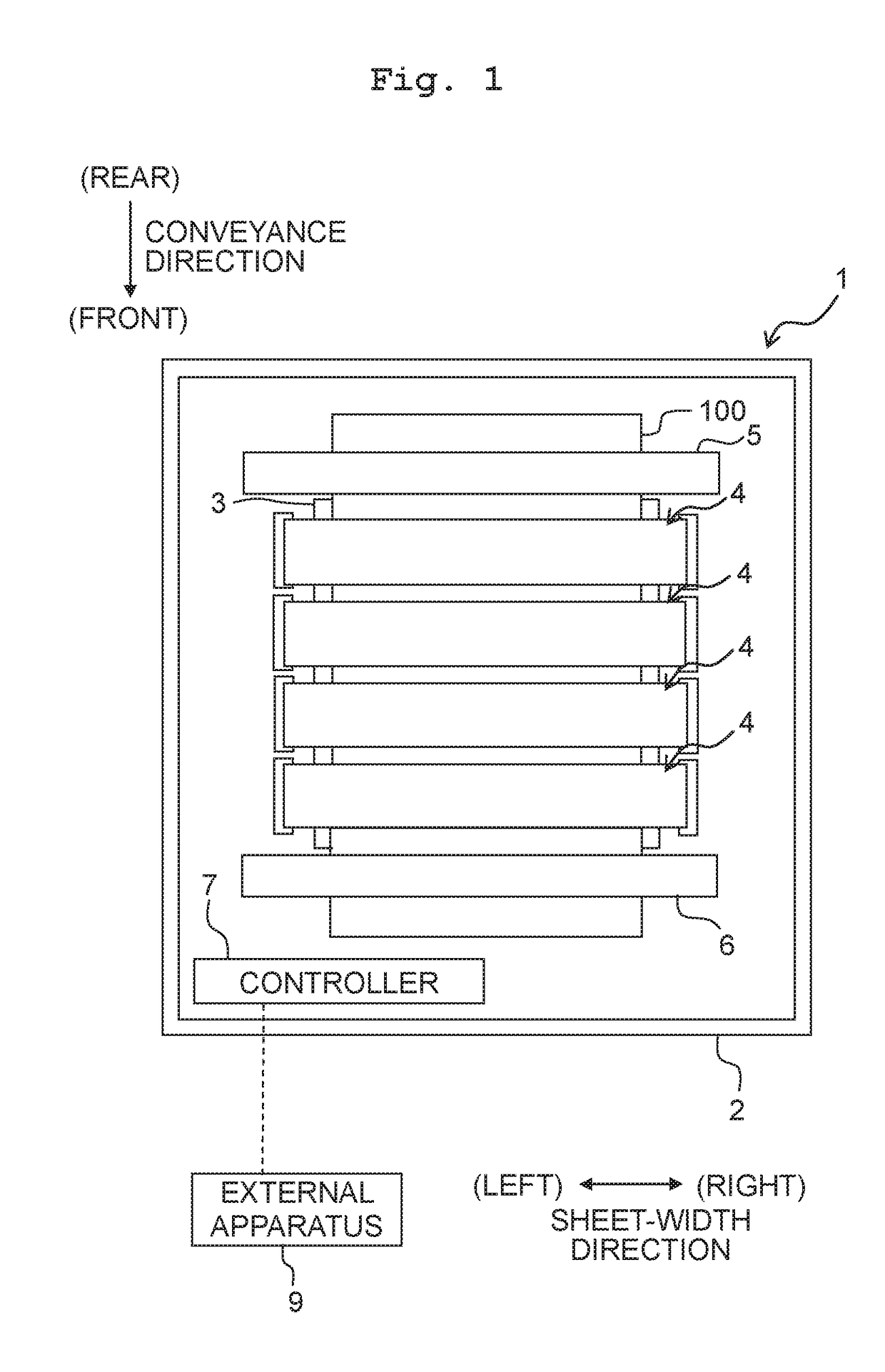

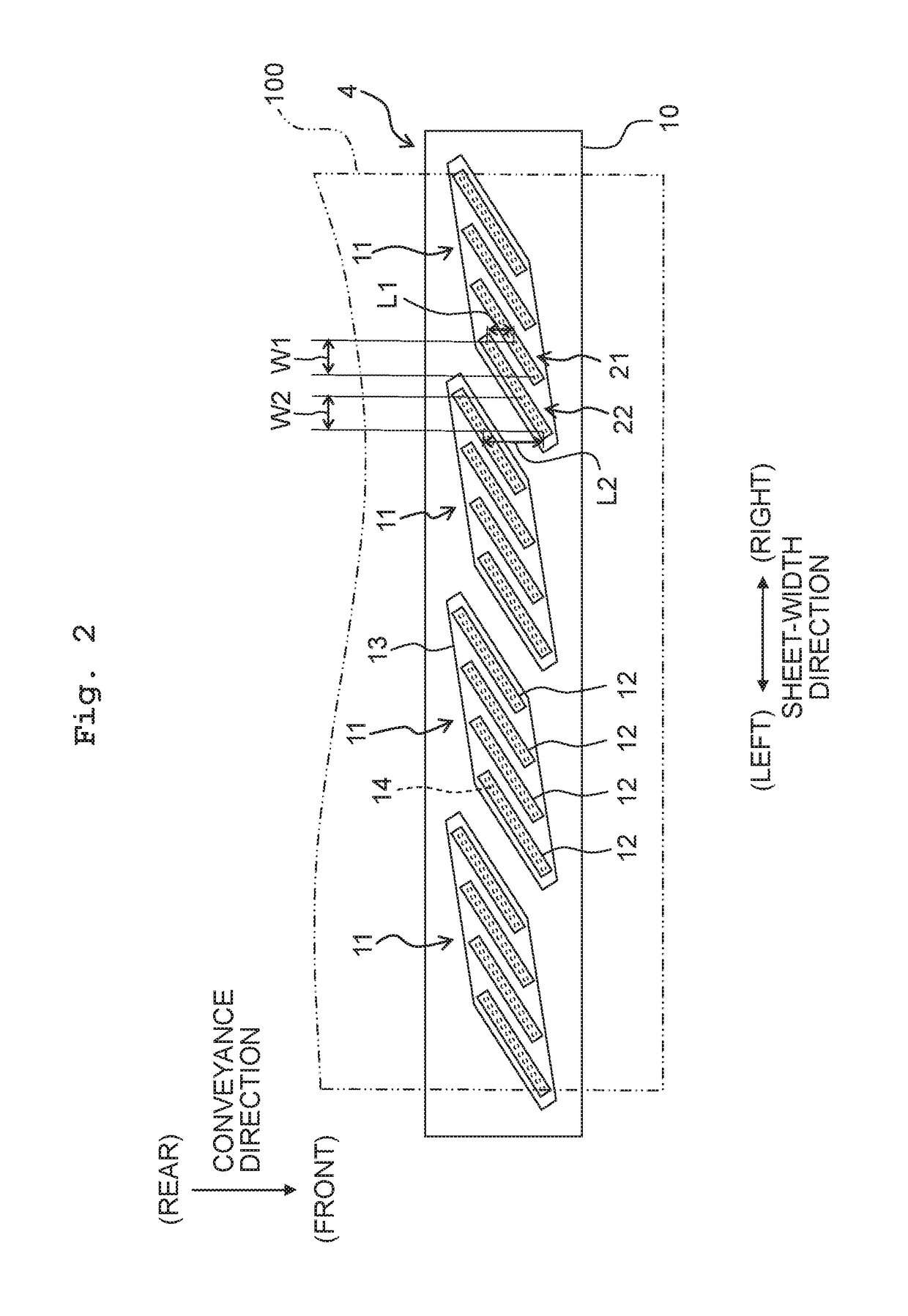

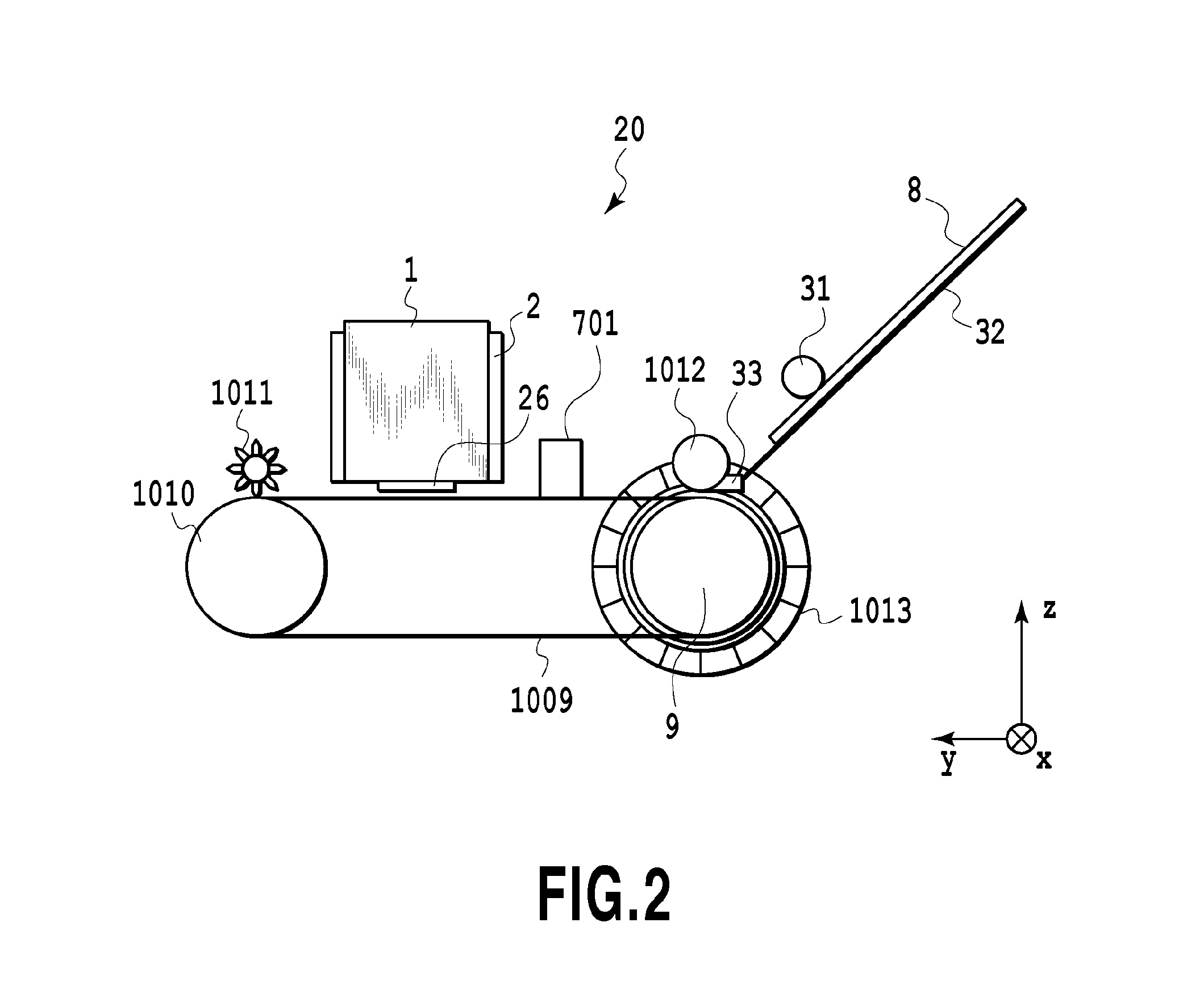

ActiveUS20170282562A1Unevenness in density can be lessUneven inhibitory concentrationInking apparatusLiquid jetEngineering

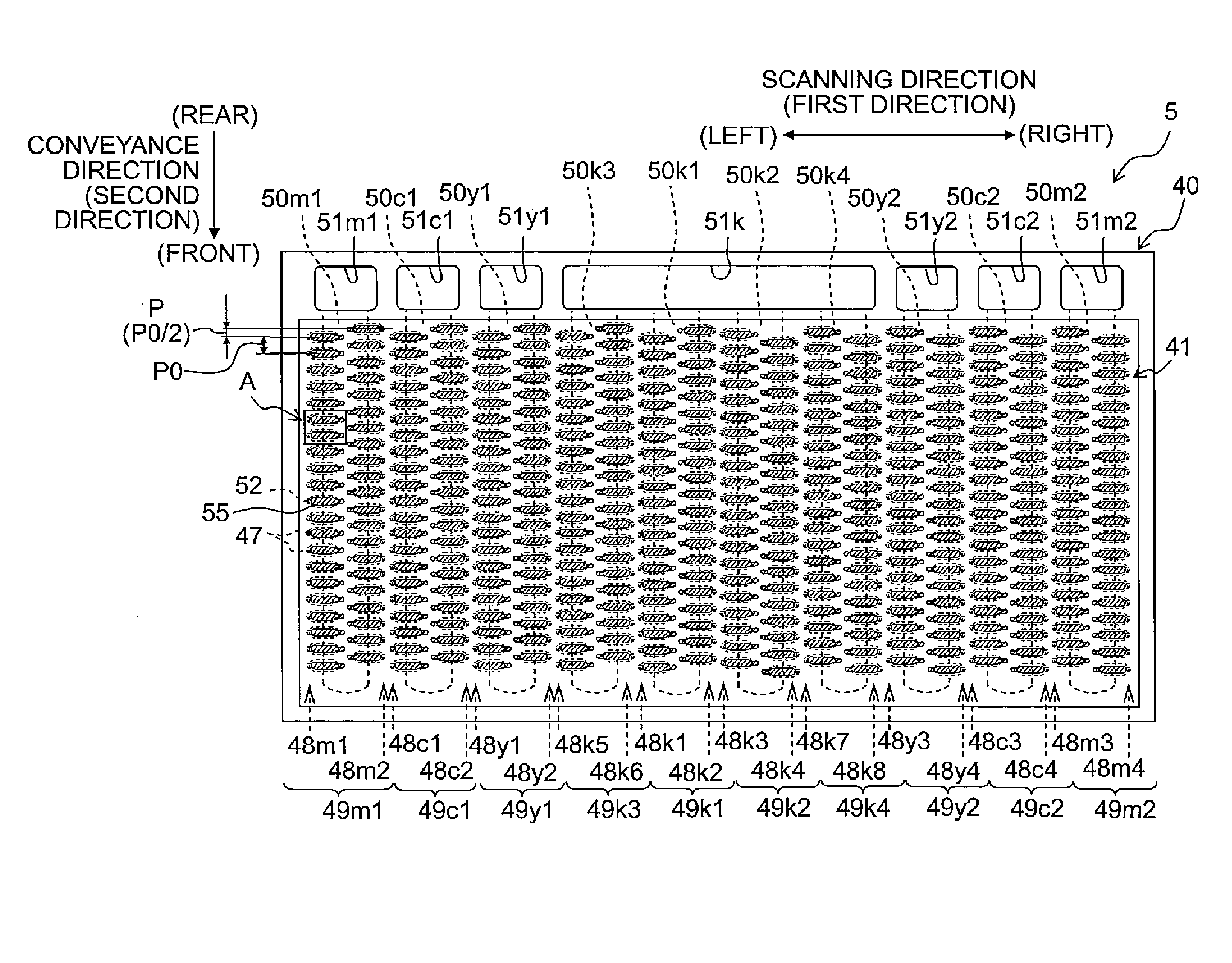

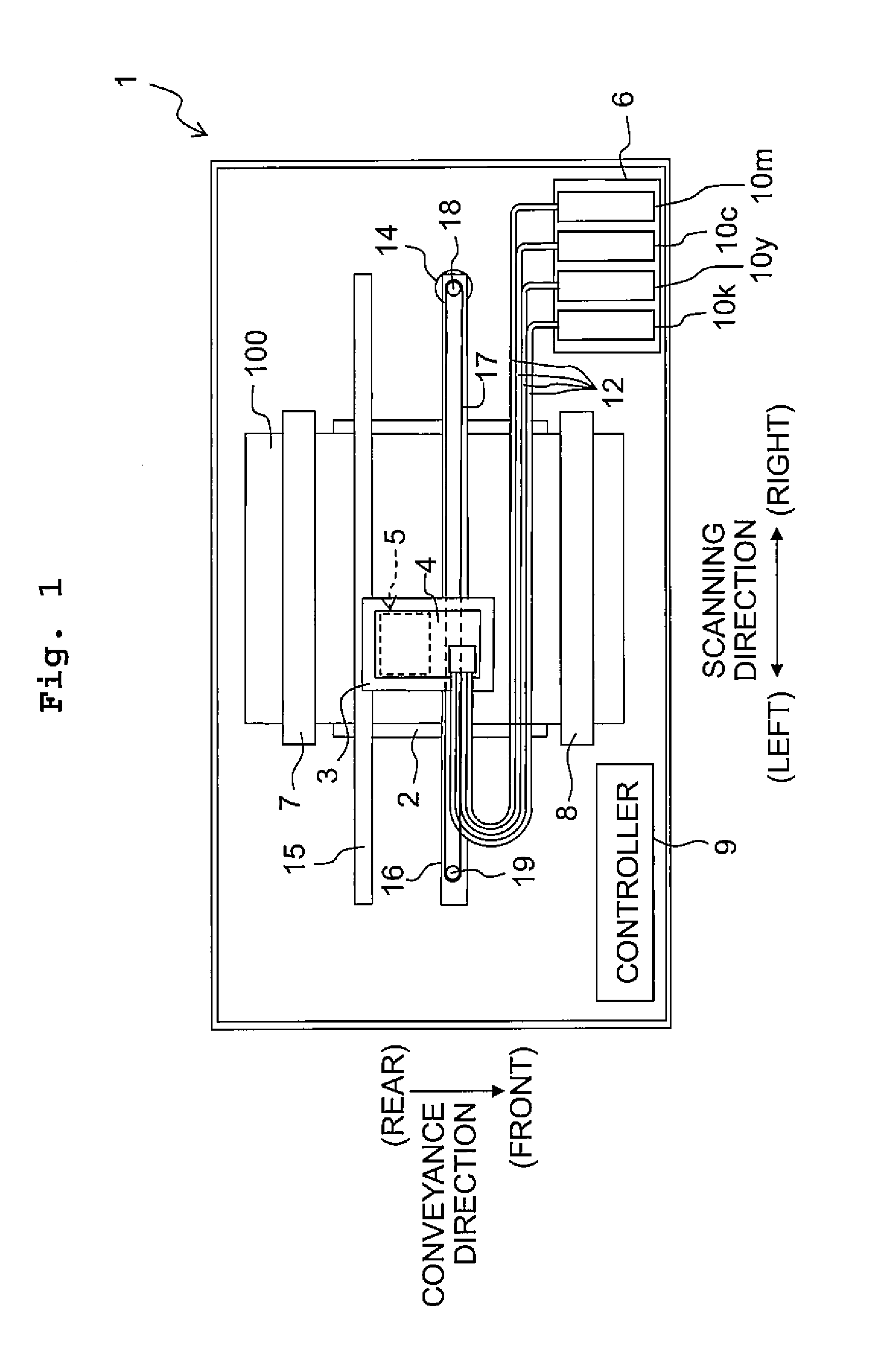

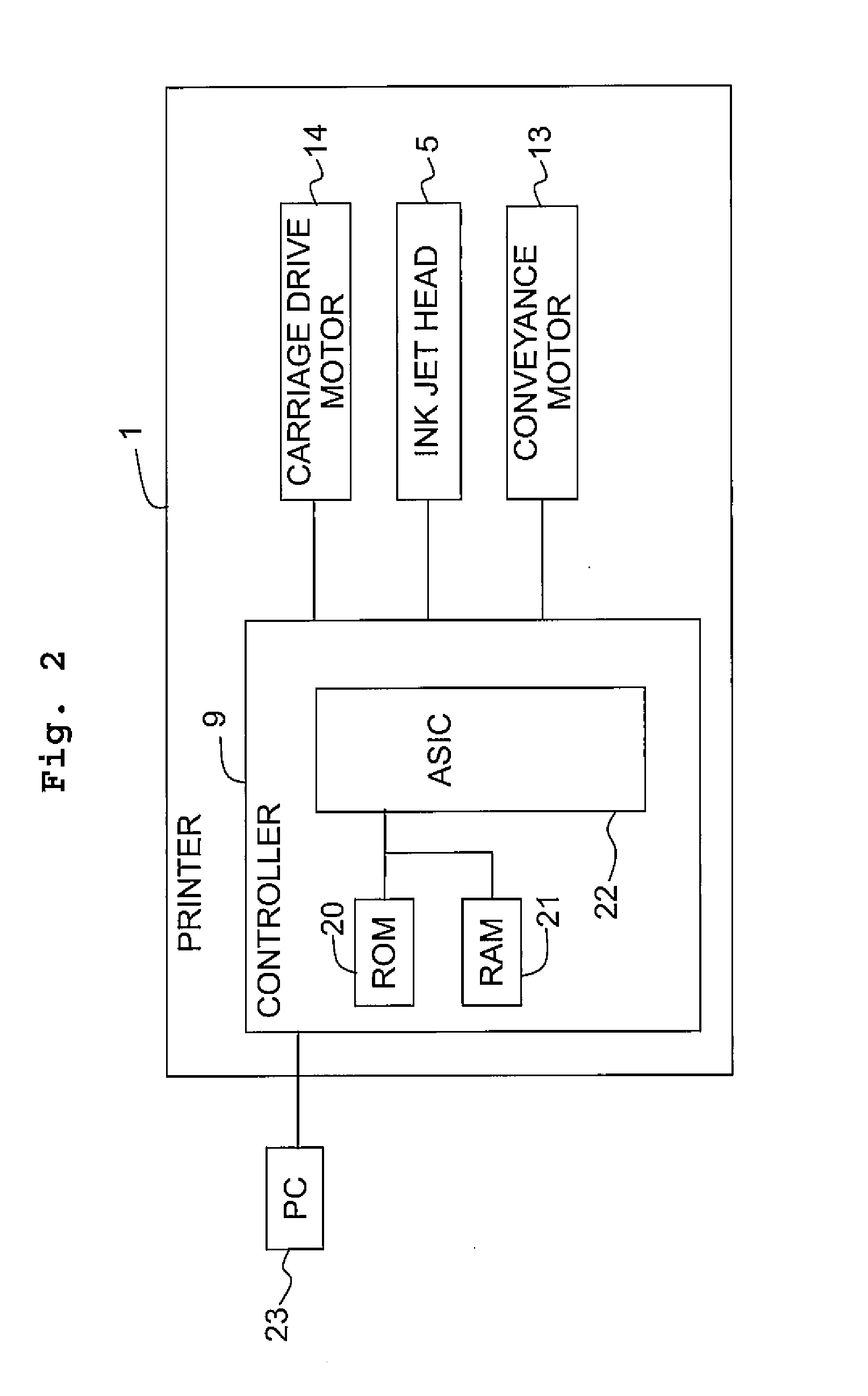

A liquid jetting apparatus jetting a liquid onto a recording medium conveyed in a first direction includes head units arranged in a second direction orthogonal to the first direction. One head unit includes nozzle chips; one nozzle chip has a nozzle arrangement area wherein nozzles are aligned in a third direction crossing the first and second directions. The nozzle chip is arranged to be shifted relative to another nozzle chip in a direction crossing the first and second directions and different from the third direction. The head unit has a first overlapping portion wherein nozzle arrangement areas of first and second nozzle chips included in the nozzle chips partially overlap with each other in the first direction. The liquid jetting apparatus has a second overlapping portion wherein nozzle arrangement areas of third and fourth nozzle chips included in the head units partially overlap with each other in the first direction.

Owner:BROTHER KOGYO KK

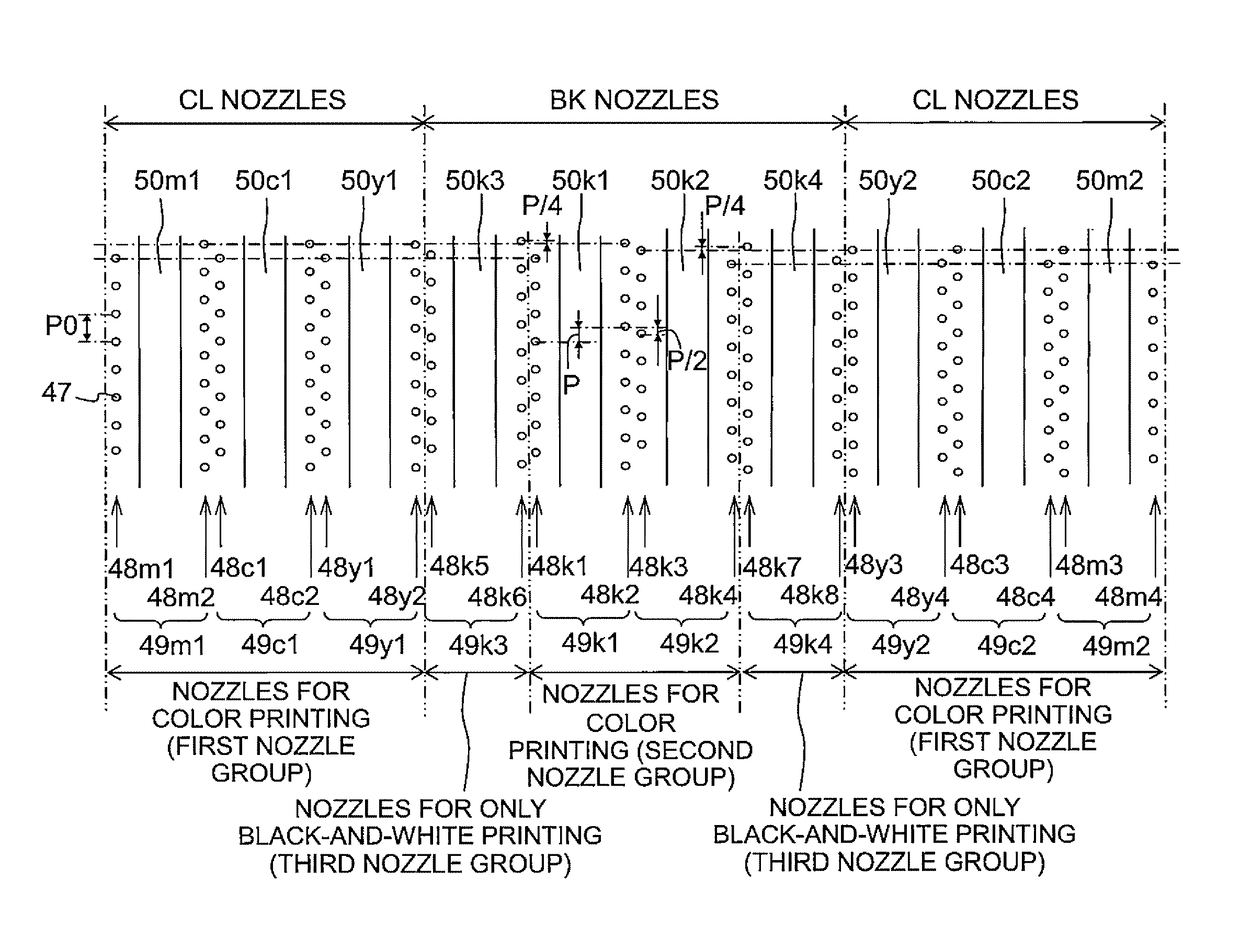

Ink jet printer and ink jet head

There is provided an ink jet primer including a carriage, and an ink jet head. The ink jet head has two first nozzle groups to jet a first ink, two second nozzle groups to jet a second ink, and two third nozzle groups to jet the second ink. Each of the first, second and third nozzle groups includes a plurality of nozzles arrayed at a pitch P along a second direction. The second nozzle groups accord respectively with the first nozzle groups in terms of nozzle position in the second direction, the third nozzle groups are dislocated respectively from the second nozzle groups in terms of nozzle position in the second direction, and any two groups selected from the first and second nozzle groups are arranged respectively on two opposite sides of each of the third nozzle groups in the first direction.

Owner:BROTHER KOGYO KK

Magnet powder-resin compound particles, method for producing such compound particles and resin-bonded rare earth magnets formed therefrom

InactiveUS20010051246A1High dimensional accuracyImprove magnetic propertiesEnvelopes/bags making machinerySynthetic resin layered productsMetallurgyRare-earth magnet

The magnet powder-resin compound particles substantially composed of rare earth magnet powder and a binder resin are in such a round shape that a ratio of the longitudinal size a to the transverse size b (a / b) is more than 1.00 and 3 or less, and that an average particle size defined by (a / b) / 2 is 50-300 mum. They are produced by charging a mixture of rare earth magnet powder and a binder resin into an extruder equipped with nozzle orifices each having a diameter of 300 mum or less; extruding the mixture while blending under pressure though the nozzle orifices to form substantially cylindrical, fine pellets; and rounding the pellets by rotation.

Owner:HITACHI METALS LTD

Liquid jetting apparatus

A liquid jetting apparatus jetting a liquid onto a recording medium conveyed in a first direction includes head units arranged in a second direction orthogonal to the first direction. One head unit includes nozzle chips; one nozzle chip has a nozzle arrangement area wherein nozzles are aligned in a third direction crossing the first and second directions. The nozzle chip is arranged to be shifted relative to another nozzle chip in a direction crossing the first and second directions and different from the third direction. The head unit has a first overlapping portion wherein nozzle arrangement areas of first and second nozzle chips included in the nozzle chips partially overlap with each other in the first direction. The liquid jetting apparatus has a second overlapping portion wherein nozzle arrangement areas of third and fourth nozzle chips included in the head units partially overlap with each other in the first direction.

Owner:BROTHER KOGYO KK

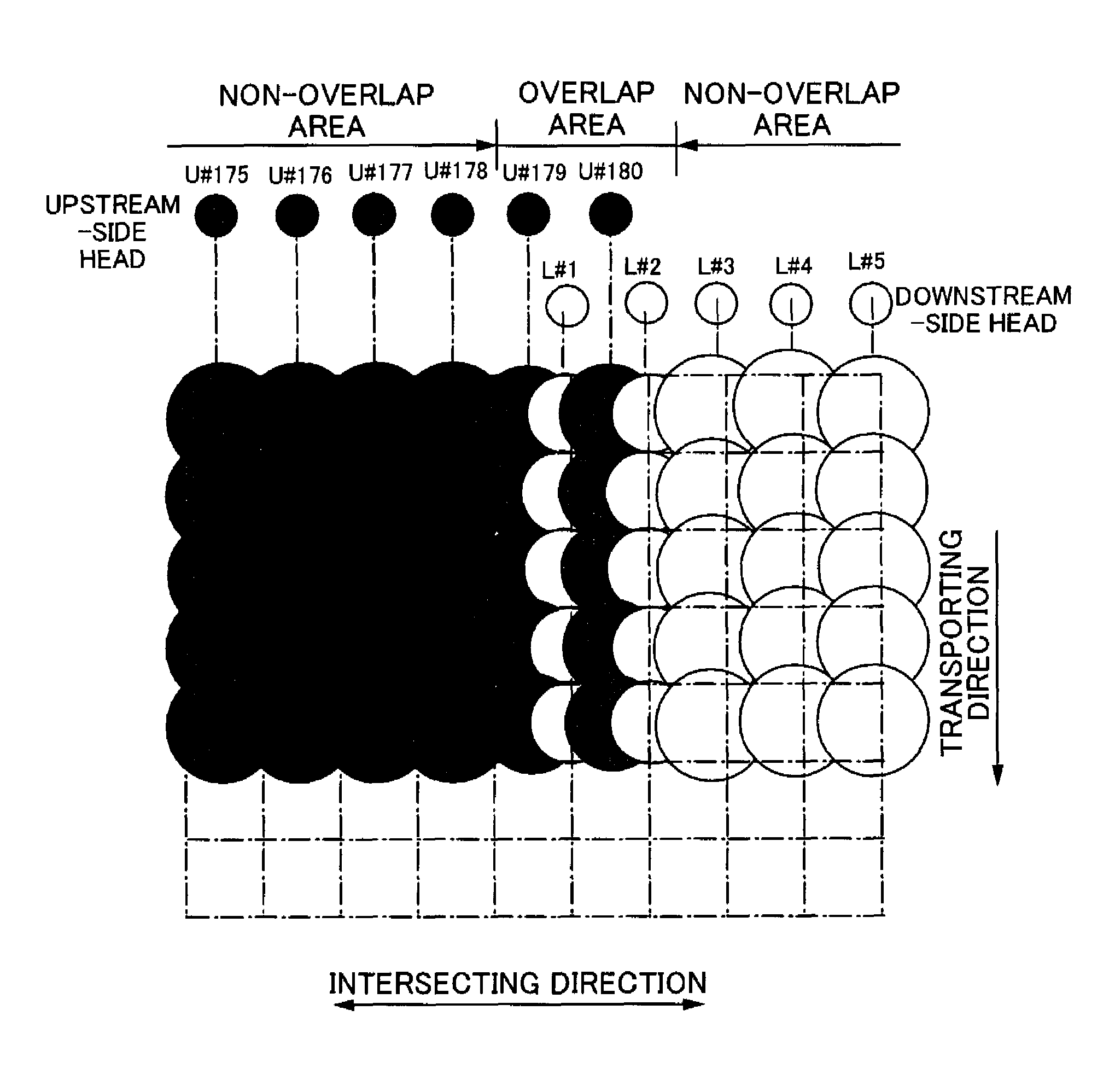

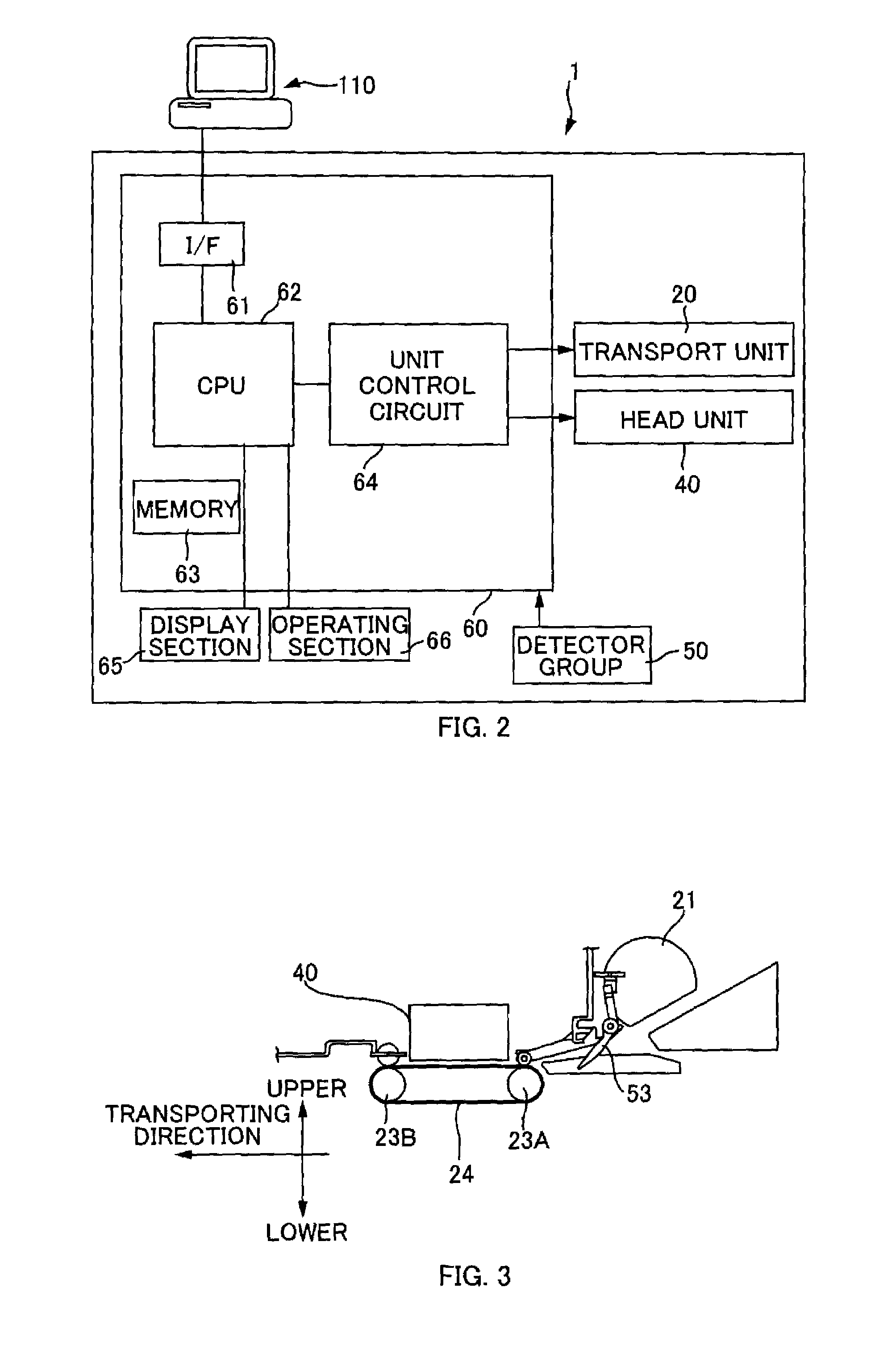

Method of determining ink ejection method, printing apparatus, and method of manufacturing printing apparatus

ActiveUS7484821B2Uneven inhibitory concentrationInking apparatusOther printing apparatusVolumetric Mass DensityEngineering

Density unevenness caused in an image formed with an overlap portion of nozzles is suppressed. For this purpose, a method of determining an ink ejection method includes: transporting a medium in a transporting direction; forming an image with a nozzle unit having a plurality of nozzle rows in which a plurality of nozzles for ejecting ink are arranged at a predetermined interval in an intersecting direction intersecting the transporting direction, wherein the plurality of nozzle rows are arranged parallel to each other, one end side in the intersecting direction in a particular nozzle row and the other end side in the intersecting direction in another nozzle row are overlapped with each other in the transporting direction so as to form an overlap area, and in the overlap area, the nozzle in the particular nozzle row and the nozzle in the other nozzle row are at different positions in the intersecting direction; and determining an ink ejection method from the nozzles in the overlap area, based on a density of the image.

Owner:SEIKO EPSON CORP

Image forming apparatus and image forming method

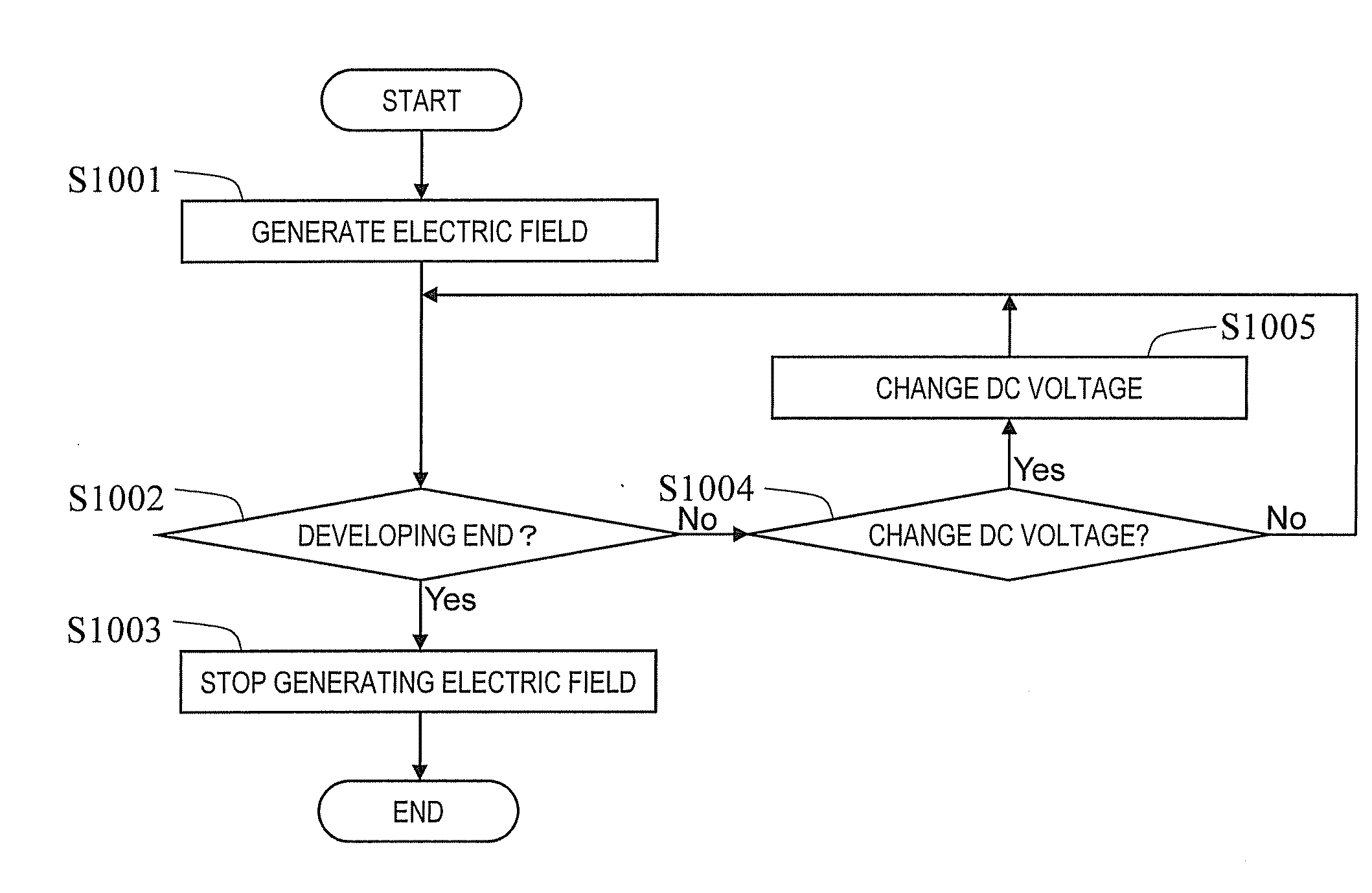

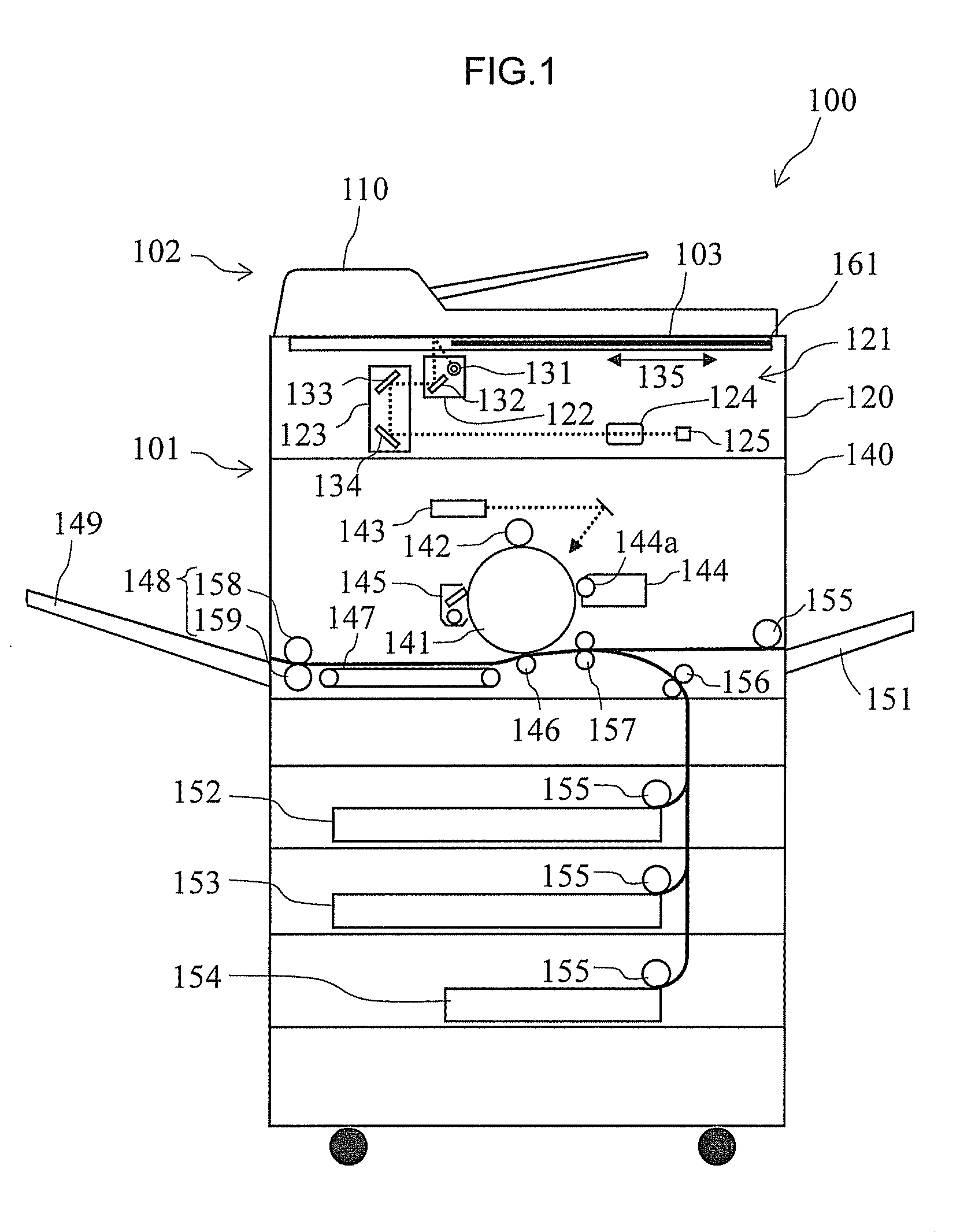

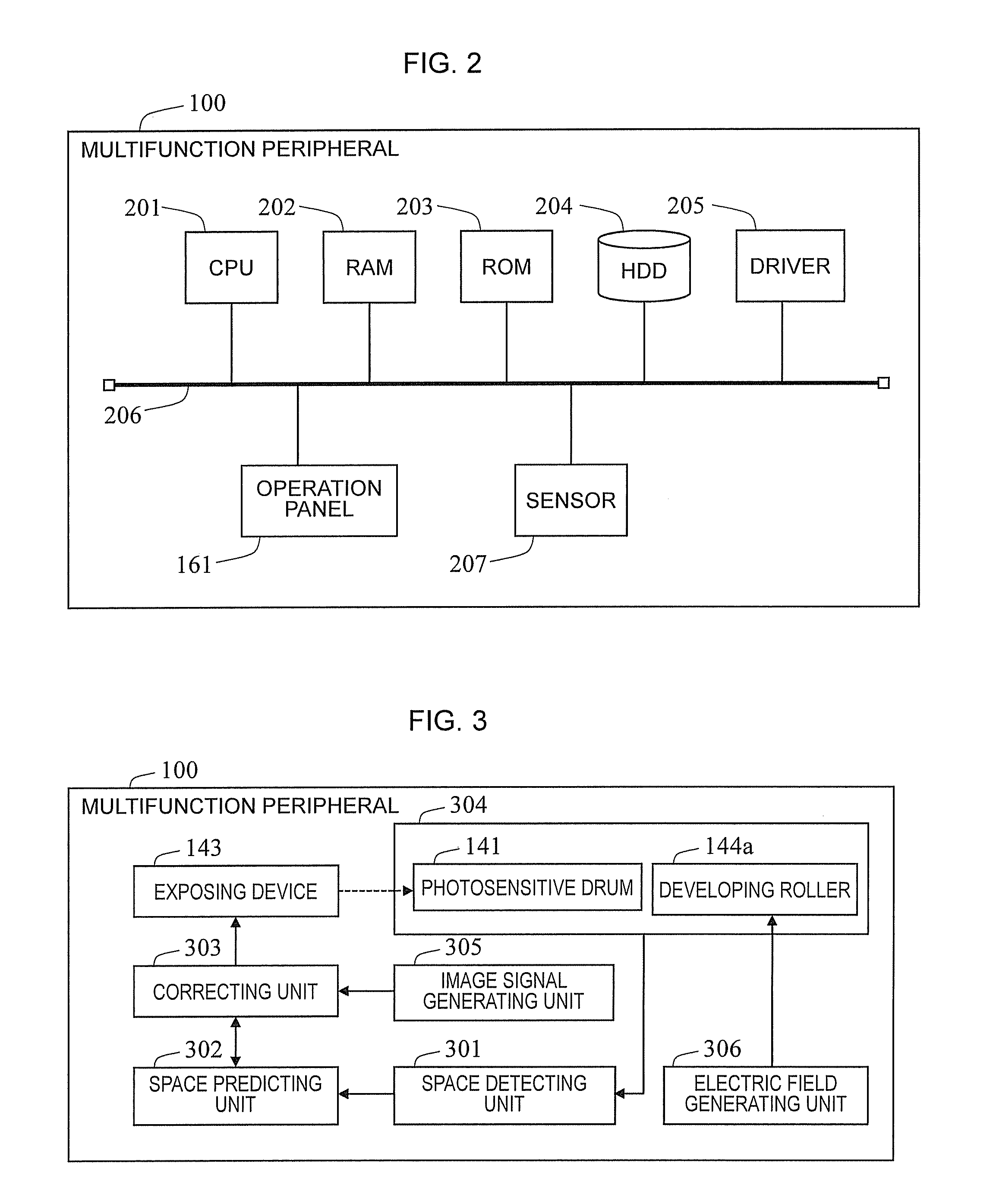

ActiveUS20150338762A1Uneven inhibitory concentrationReduce light intensityElectrographic process apparatusLatent imageImage transfer

In the image forming apparatus, the space detecting unit detects the space between the image carrying surface and the developer carrying surface. The correcting unit corrects the intensity of the development field for developing the electrostatic latent image on the image carrying surface based on the acquired correspondence relation and the space detected by the space detecting unit, for example. In this case, the correspondence relation is a relation between the image density of the visible image transferred from the image carrying surface to the transferred medium and the development filed for suppressing the density unevenness of the visible image.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Magnetic toner

ActiveUS20080286676A1Improve development performanceFog suppressionDevelopersDielectric lossAqueous solution

A magnetic toner having magnetic toner particles each containing at least a binder resin and a magnetic iron oxide particle, in which: when a solution is prepared by dissolving the magnetic iron oxide particles in an acidic aqueous solution and an Fe element amount in a solution in which all the magnetic iron oxide particles are dissolved is defined as a total Fe element amount, a ratio X of the amount of Fe(2+) in a solution in which the magnetic iron oxide particles are dissolved to a state where 10 mass % of the total Fe element amount is present in the solution (solution having an Fe element-dissolving ratio of 10 mass %) to an Fe element amount in the solution having a specific Fe element-dissolving ratio; and the dielectric loss tangents of the magnetic toner measured at a temperature of 40° C. satisfy specific conditions.

Owner:CANON KK

Printing apparatus and printing method

InactiveUS20150077449A1Suppressing bleedingUneven inhibitory concentrationPrintingPictoral communicationEngineeringImaging data

A printing apparatus includes a first processing section configured to convert input values that are specified for each pixel in image data into amounts of ink for inks of each color, and a second processing section configured to generate half tone data from the image data that is converted. The second processing section is further configured to convert an amount of ink for a first ink, which is in a range of a first amount of ink where it is easy for density unevenness to be generated, into an amount of ink for the first ink and an amount of ink for a second ink that is the same color as the first ink and has a high brightness compared to the first ink. An increase in the amount of the first ink that is set in the range of the first amount of ink is large.

Owner:SEIKO EPSON CORP

Image processing method and image processor

ActiveUS20120287191A1Uneven inhibitory concentrationHighly and accurately performVisual presentationOther printing apparatusImaging processingComputer science

Provided are an inkjet printing apparatus and inkjet printing method that can, regardless of an ejection frequency of a print head, stabilize density of an image expressed on a print medium. For this purpose, an ink concentration integrated value is obtained according to the ejection history of each nozzle so as to be increased by data indicating non-ejection of the nozzle or decreased by data indicating ejection. Then, image data on the target pixel is corrected such that density of the target pixel is further reduced as the pixel is subjected to printing by a nozzle having a higher ink concentration integrated value.

Owner:CANON KK

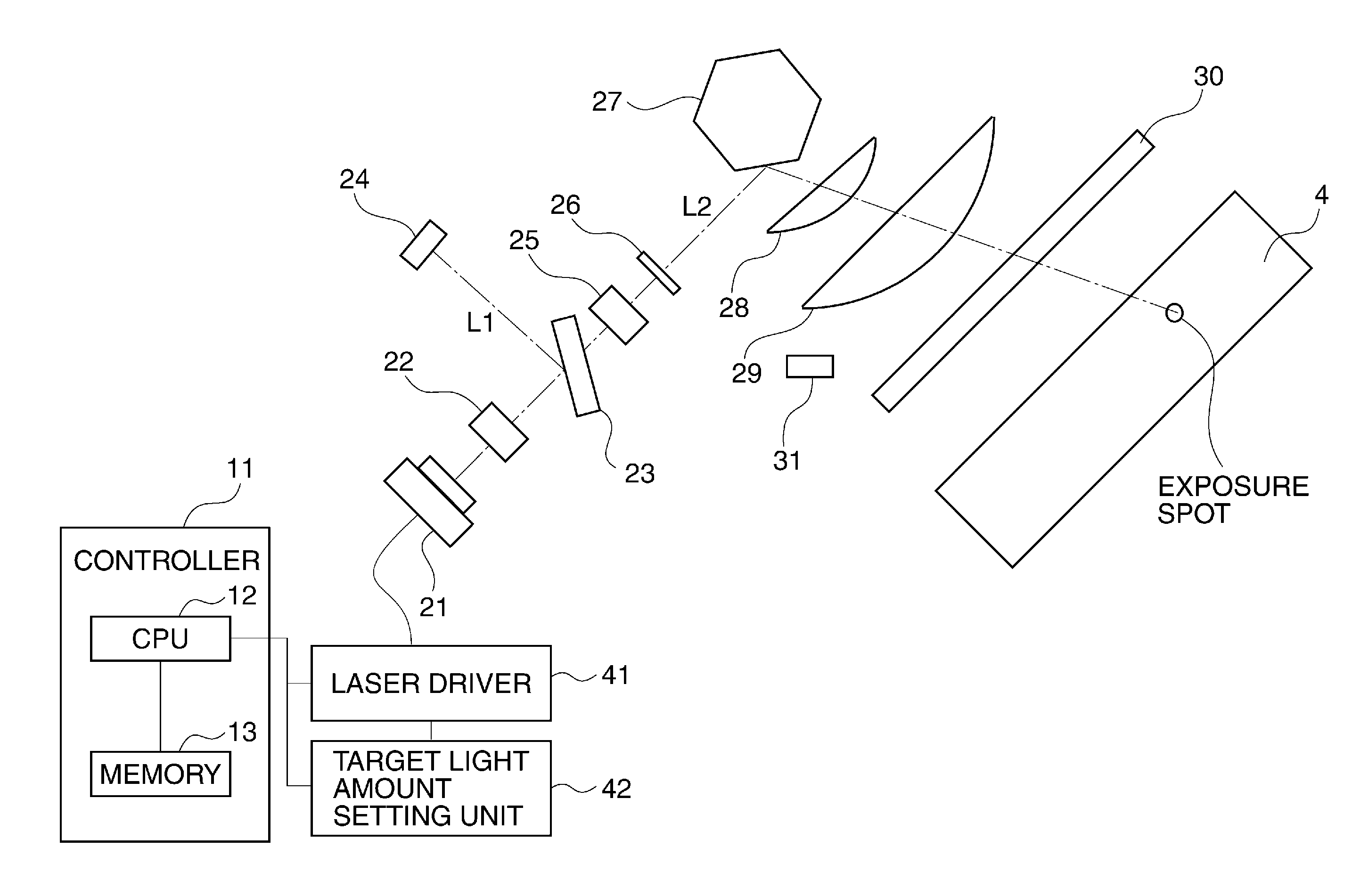

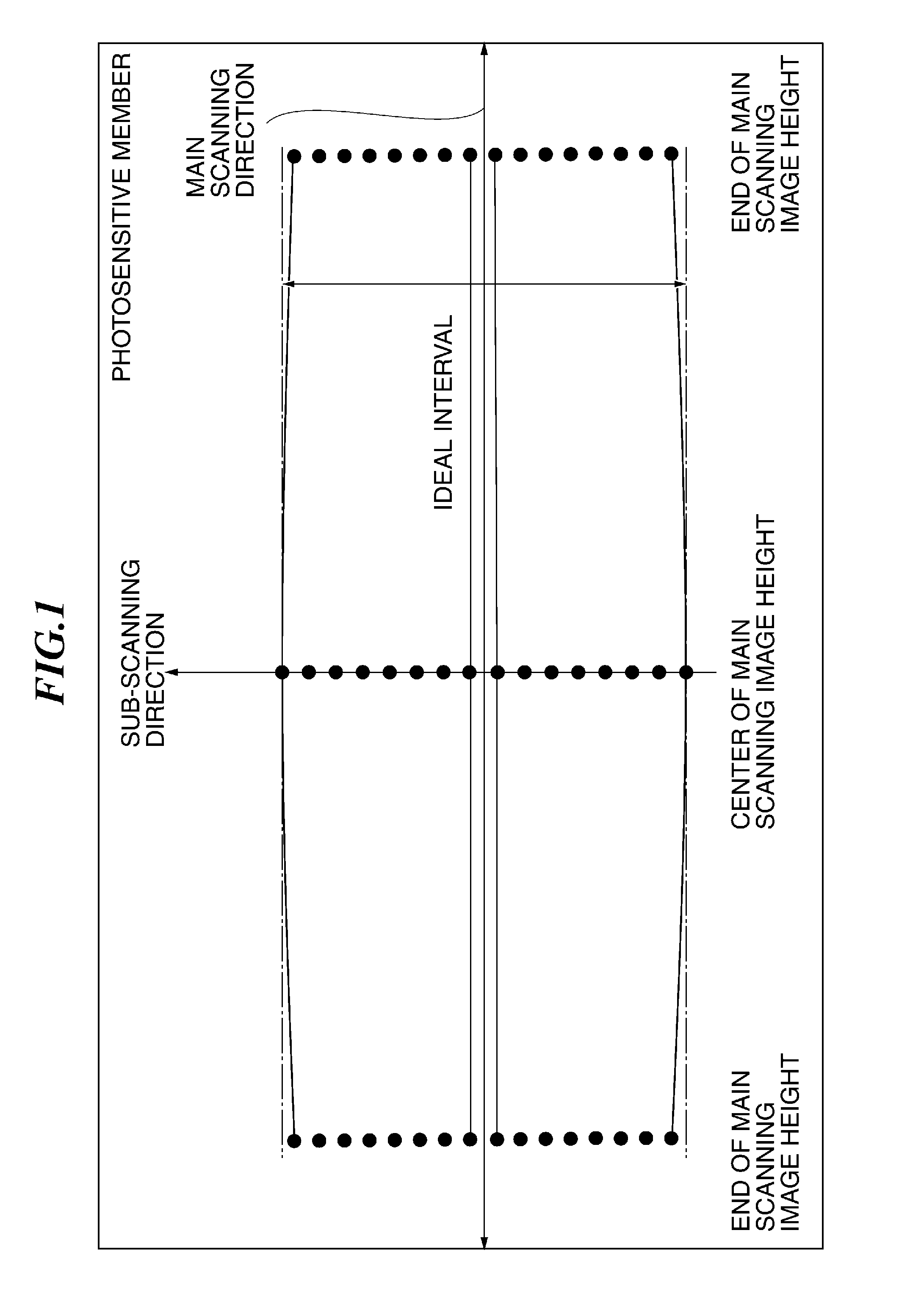

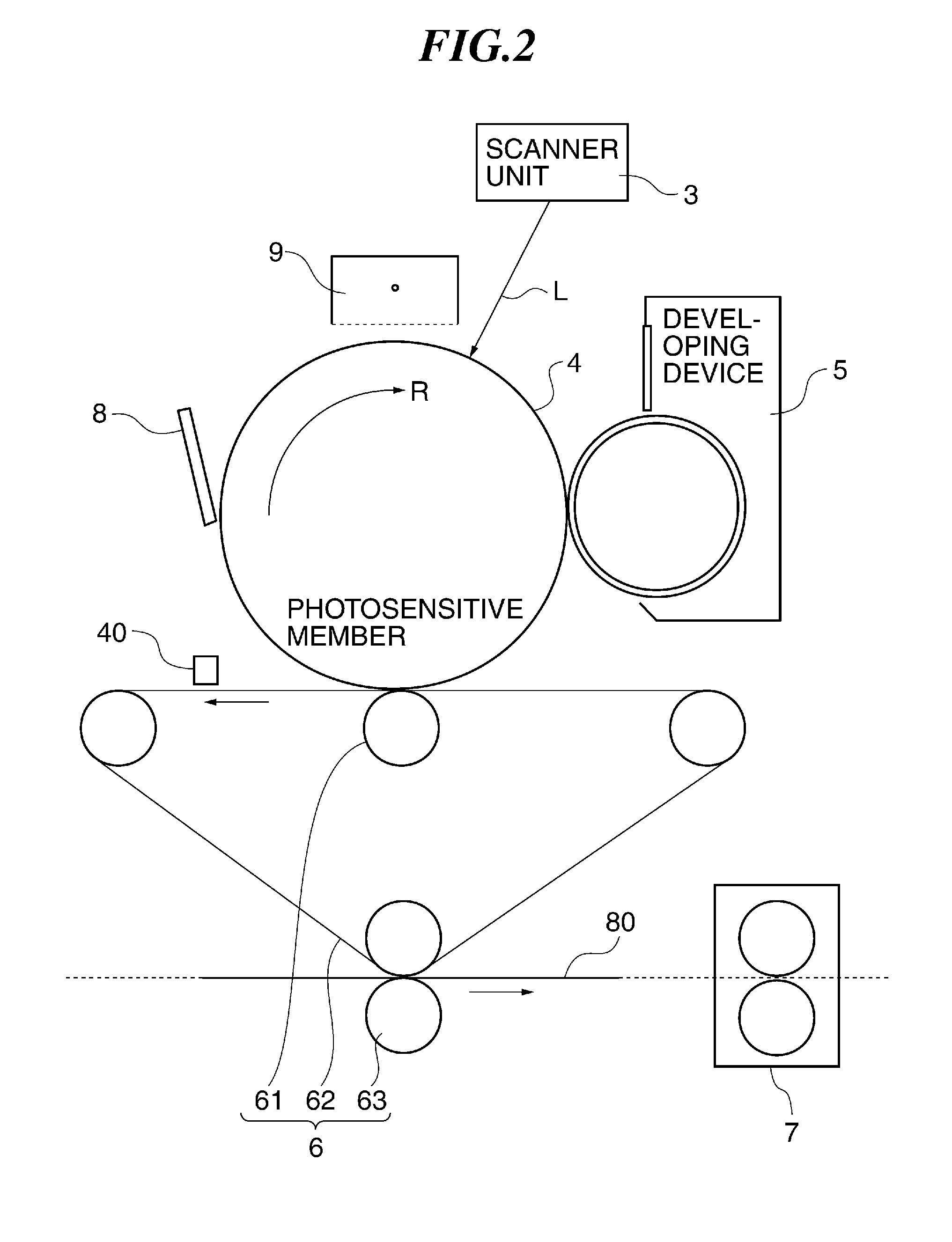

Image forming apparatus having photosensitive member exposed to plural beams, and control apparatus for light source of image forming apparatus

ActiveUS20140036020A1Suppress density unevennessUneven inhibitory concentrationRecording apparatusElectrographic process apparatusLight sourceEngineering

An image forming apparatus capable of suppressing density unevenness of a toner image formed on a photosensitive member. A light amount of a light beam that exposes an end portion of the photosensitive member is made different from a light amount of a light beam that exposes a central portion thereof in order to suppress a density difference between a toner image density at the central portion of the photosensitive member and that at the end portion thereof in a scanning direction of the light beams.

Owner:CANON KK

Printing apparatus and printing control method thereof

ActiveUS20130201238A1Density unevennessSuppress relative position shiftOther printing apparatusEngineeringImaging data

Owner:CANON KK

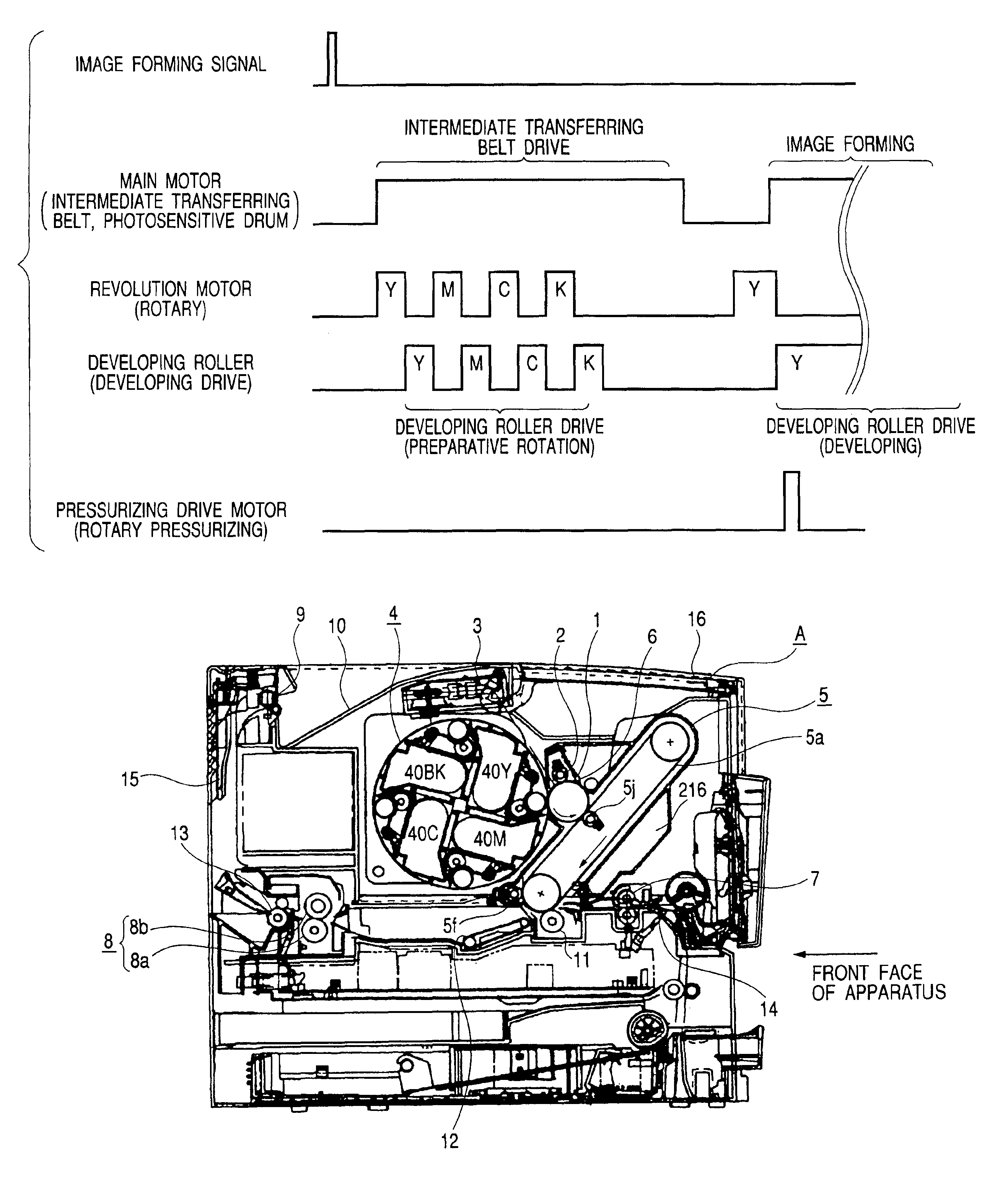

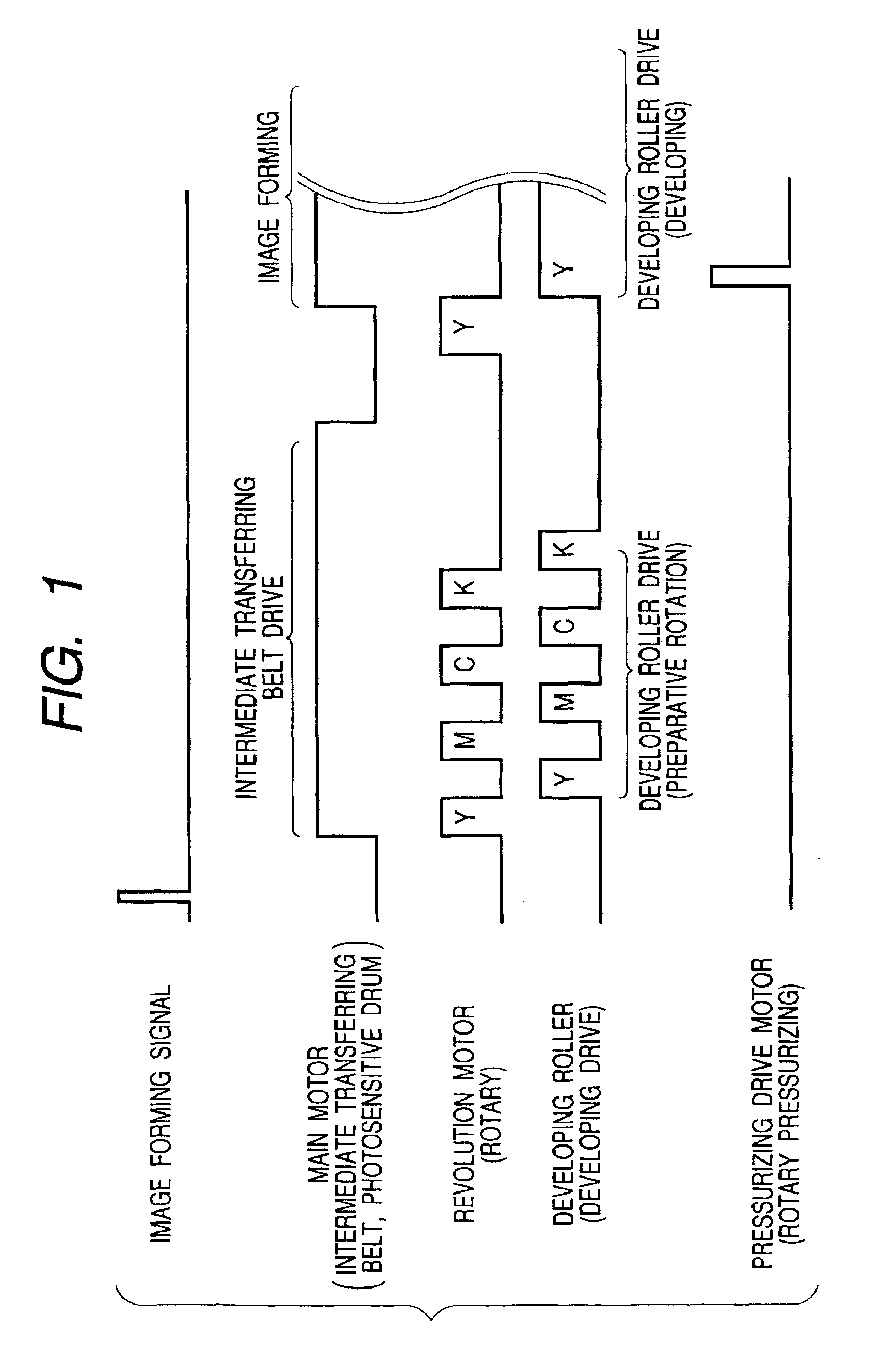

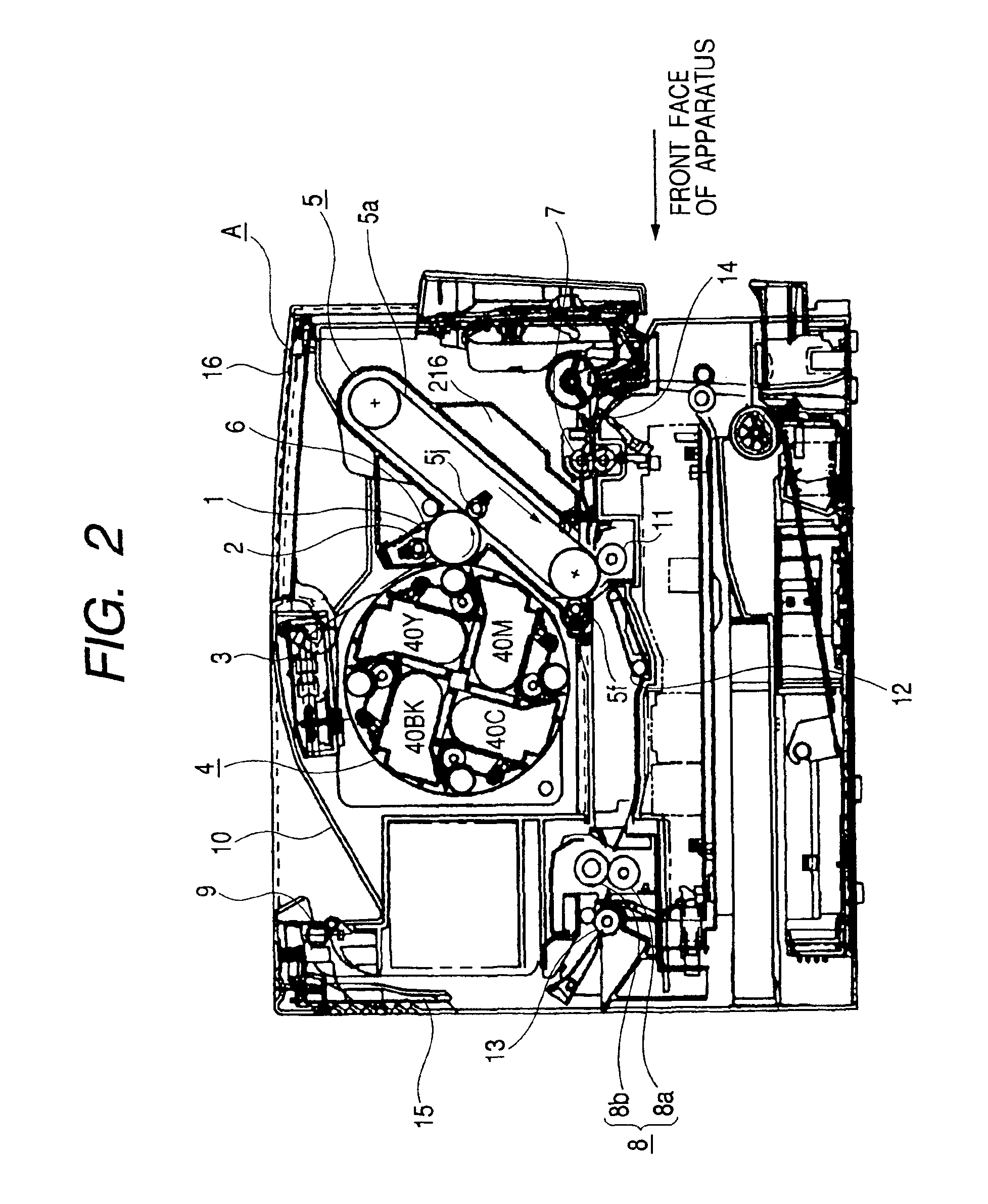

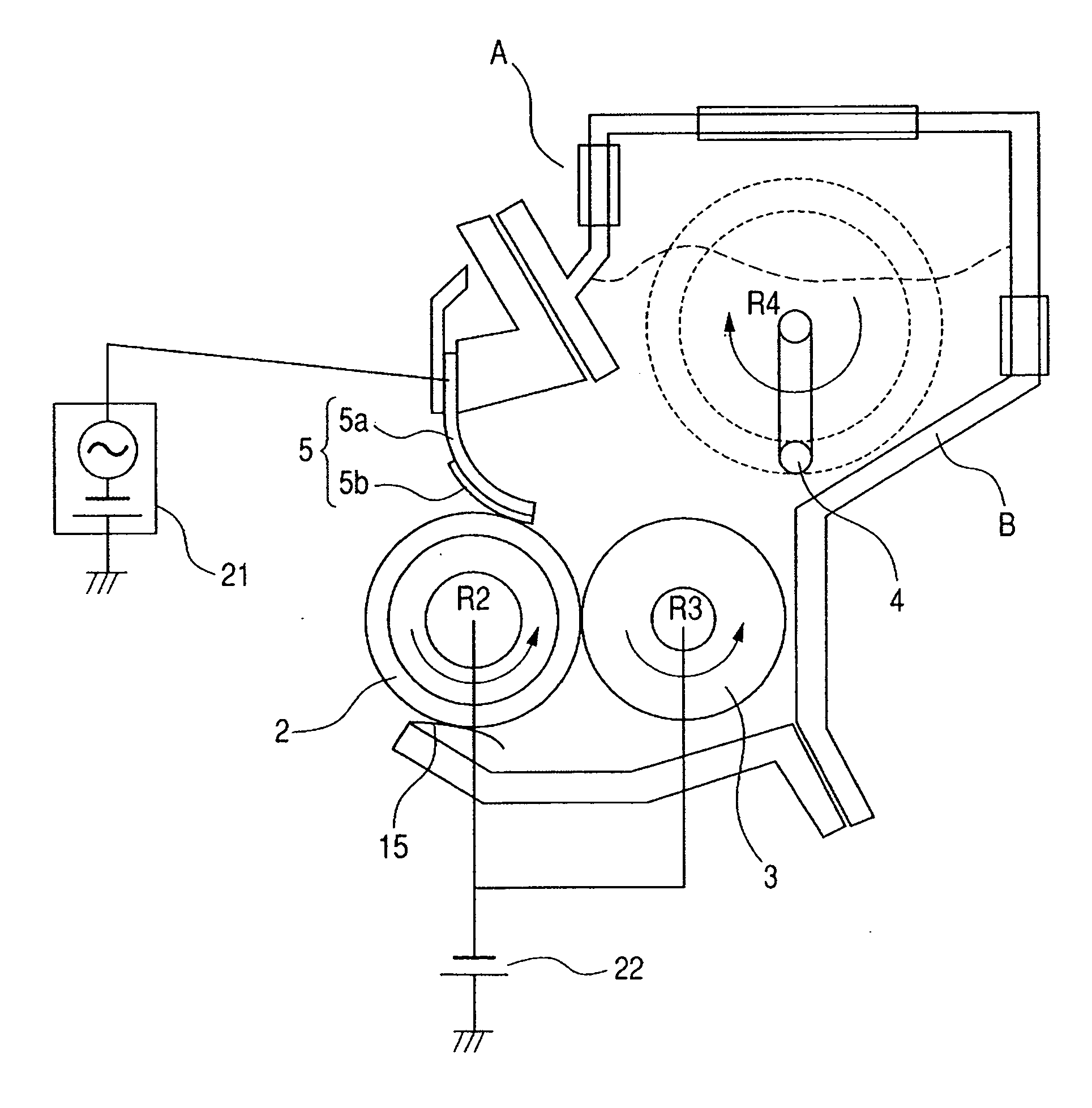

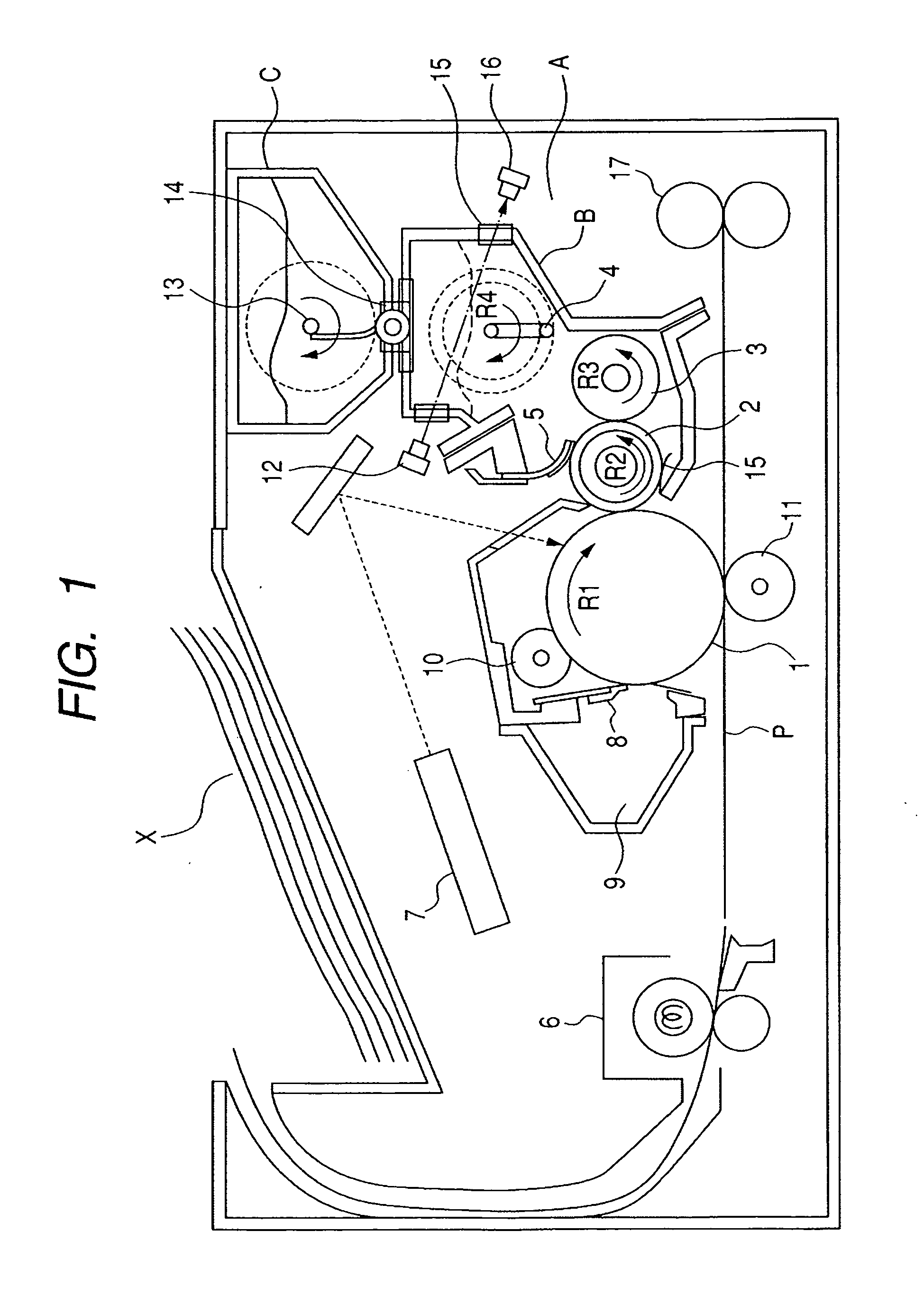

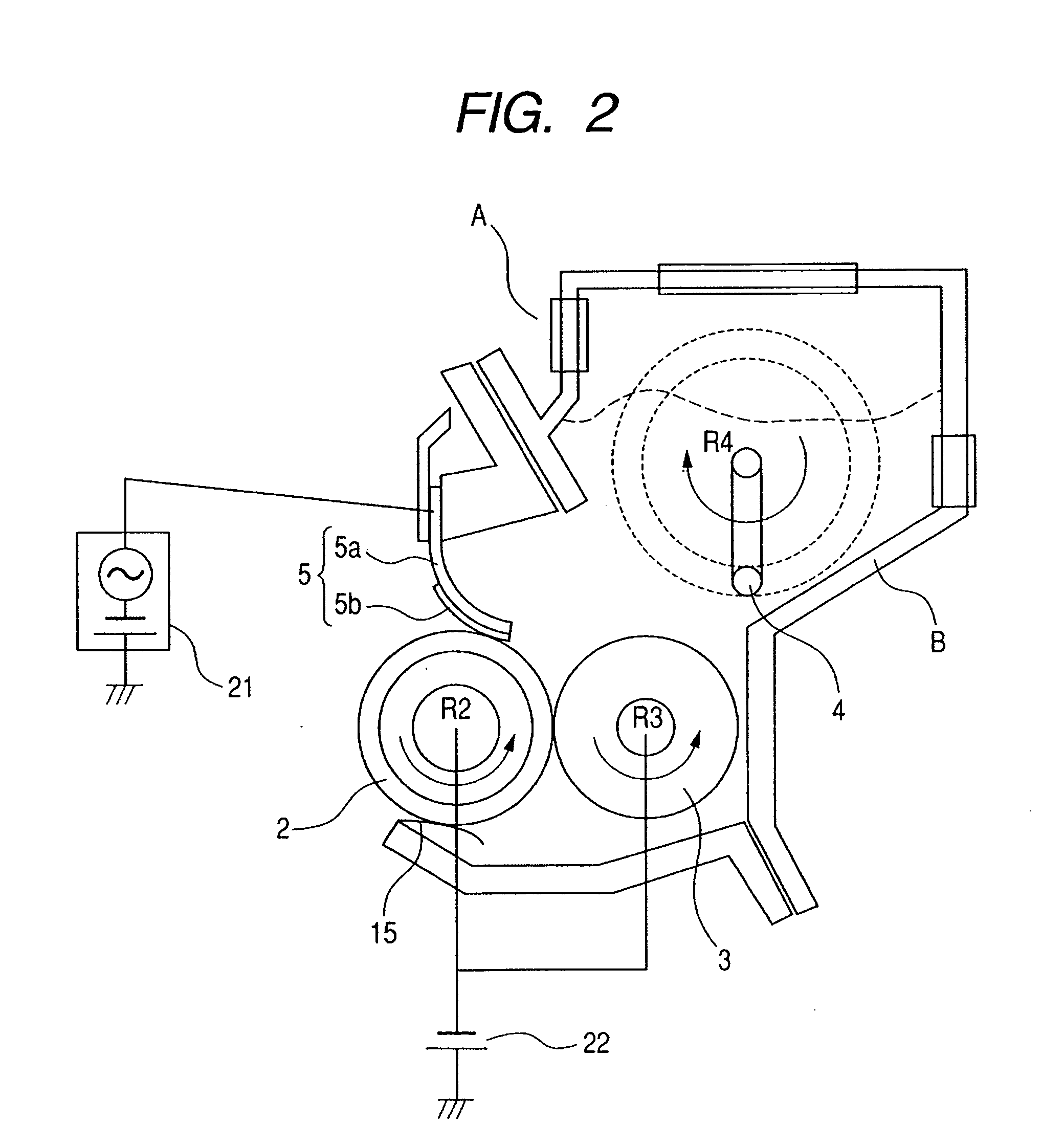

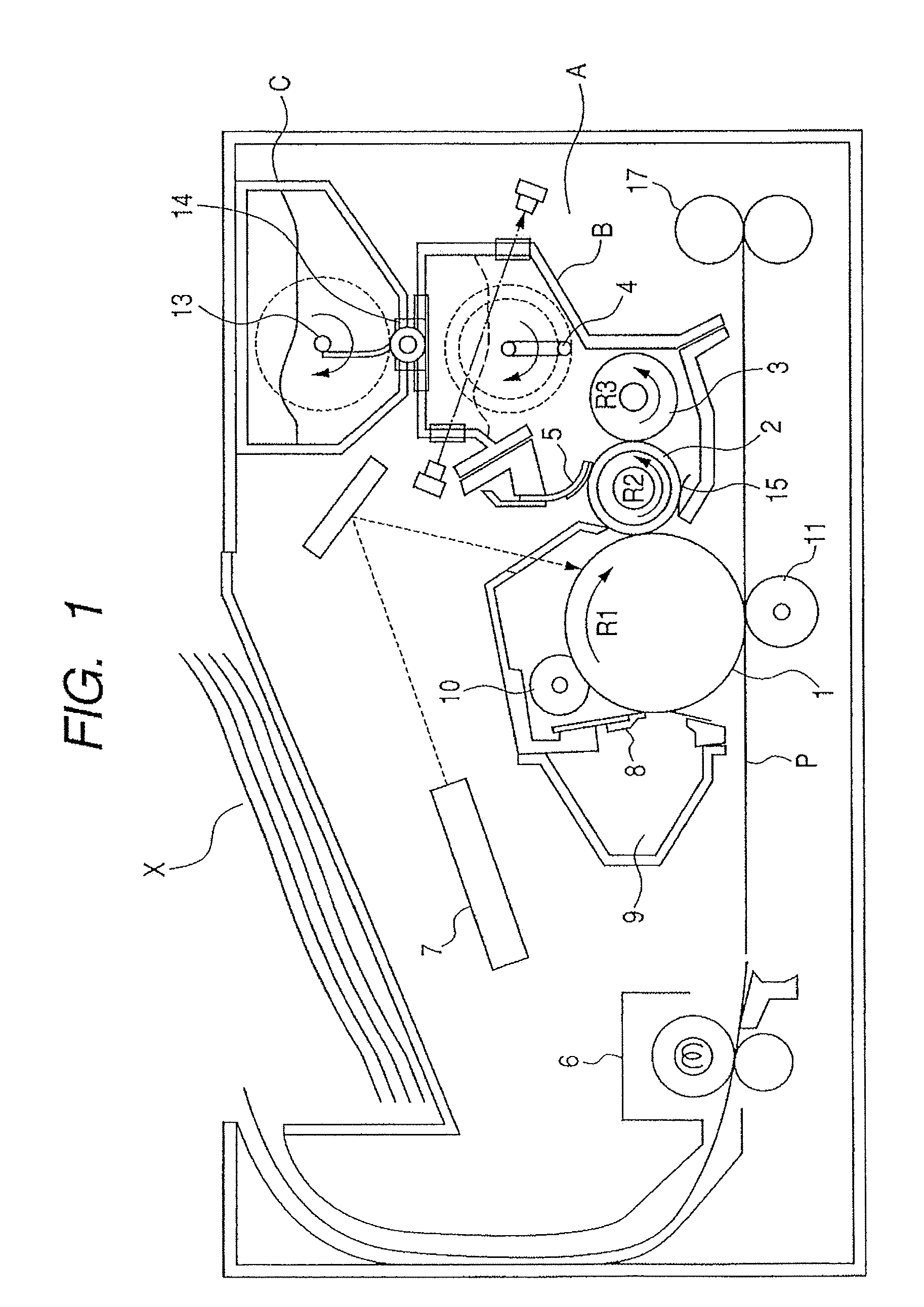

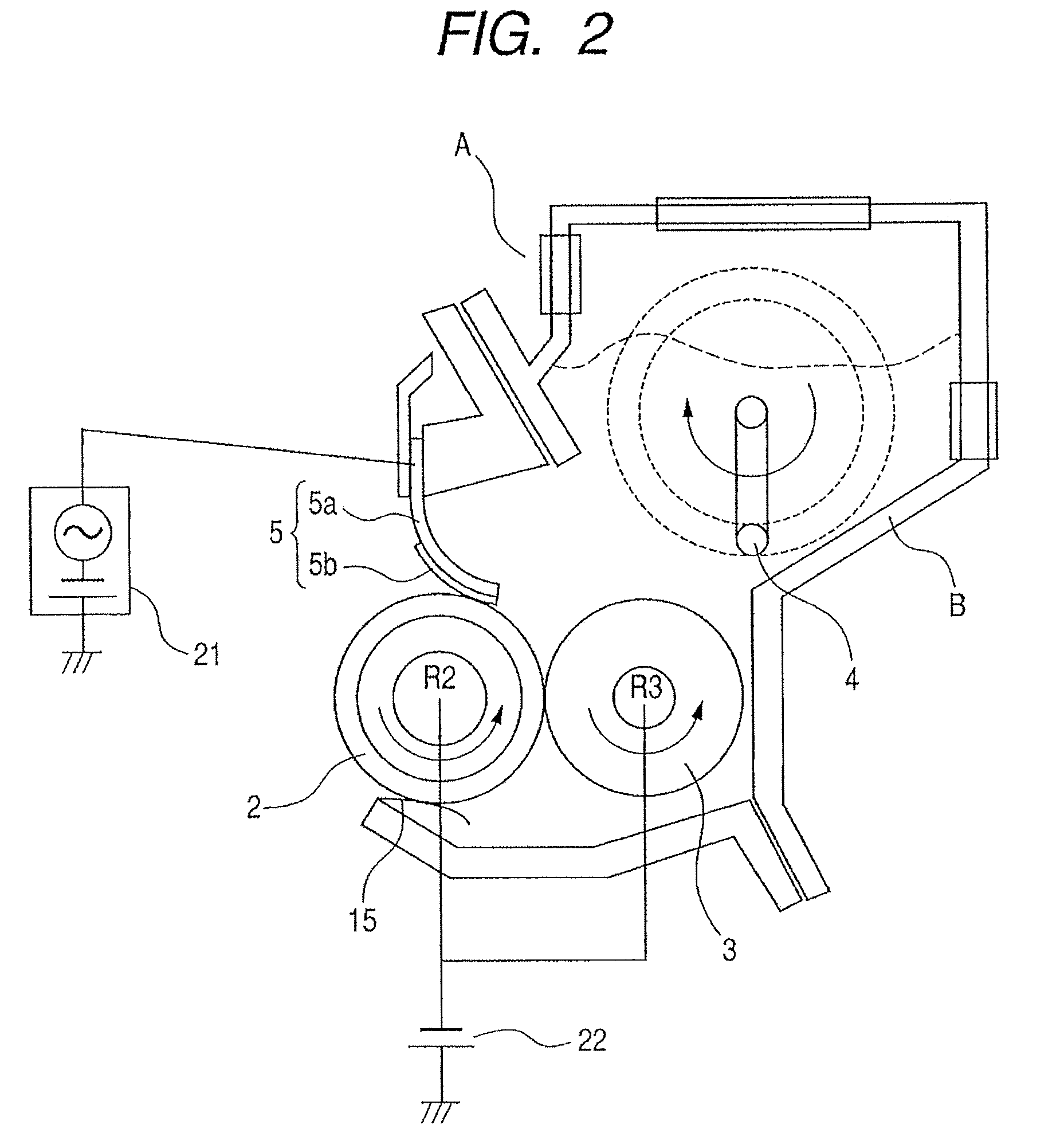

Image forming apparatus having rotary unit for holding multiple developing devices

InactiveUS6941097B2Uneven inhibitory concentrationShorten the overall cycleElectrographic process apparatusLatent imageImage formation

In order to suppress uneven densities in an image, an image forming apparatus includes an image bearing member; a first developing unit, including a first developer carrying member, for developing a first latent image formed on the image bearing member; a second developing unit, including a second developer carrying member, for developing a second latent image formed on the image bearing member after the first developing unit has developed the first latent image; and a rotary unit, for holding the first and the second developing units and for moving the first and the second developing unit to positions opposite said image bearing member. Upon the reception of an image forming signal at the image forming apparatus, the first and the second developer carrying members are rotated before the first latent image on the image bearing member is developed.

Owner:CANON KK

Image forming apparatus

ActiveUS20070177907A1Uneven inhibitory concentrationAvoid it happening againElectrographic process apparatusImage formationElectrical polarity

The invention realizes a uniform toner coating on a developing roller, thereby preventing a density unevenness and a toner dripping and suppressing a developing roller set mark image in a contact developing method, by conditions that the DC voltage applied to the developer regulating member is the same as the DC voltage applied to the developer carrying member or at a side of a charging polarity of the developer with respect to the DC voltage applied to the developer carrying member; and a frequency f (Hz) and a peak electric field strength E (V / m) of the AC electric field formed by the AC voltage between the developer regulating member and the developer carrying member, and a peripheral speed v (m / s) of the image bearing member satisfies conditions: 4.2×v≦f≦2500 and 2.2×106≦E≦5.2×106.

Owner:CANON KK

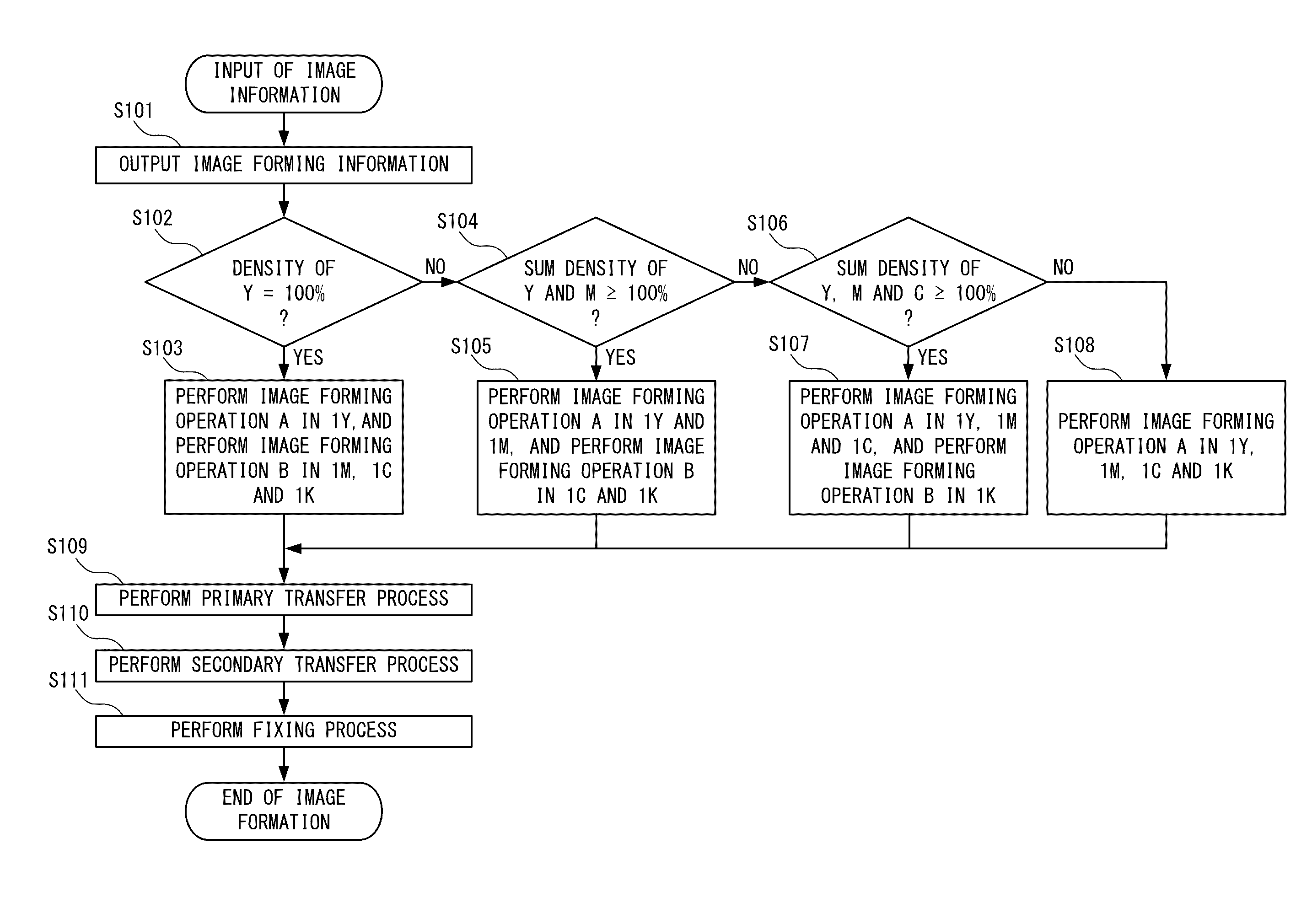

Image forming apparatus

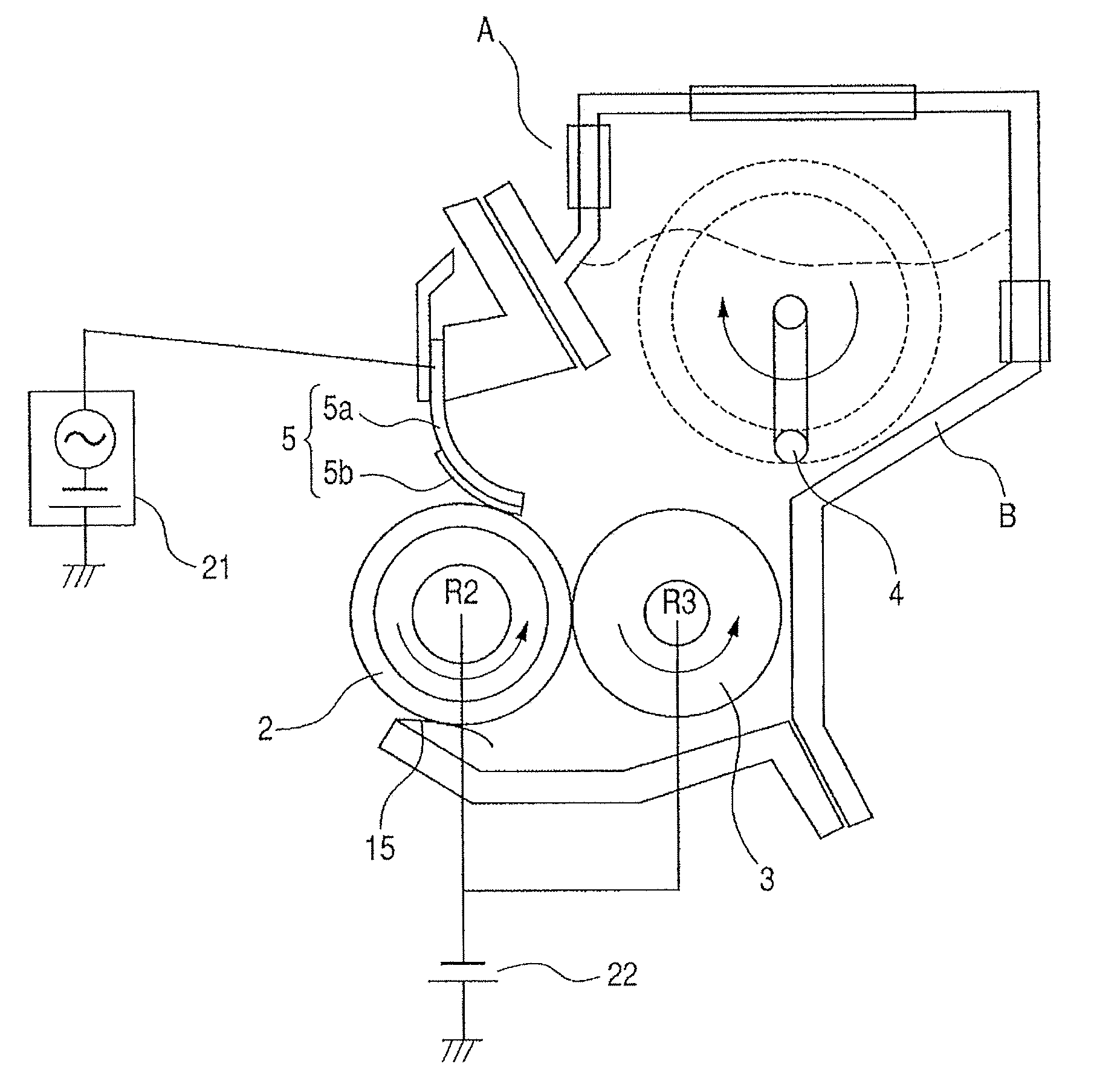

ActiveUS20140169815A1Uneven inhibitory concentrationSuppress deterioration of a photosensitive drumElectrographic process apparatusCorona dischargeImage transferImage formation

An image forming apparatus including: a plurality of image forming stations; and a control portion configured to control an image forming operation, each of the image forming stations includes: an image bearing member configured to form a toner image on a surface thereof; and a charging device configured to charge the image bearing member, wherein the toner images formed on the image bearing members of the image forming stations are sequentially transferred to a transfer incurring member to be superimposed, wherein the control portion sets a voltage applied to the charging device in forming an image in an image forming station which performs the transfer later based on image density information of the toner image transferred to the transfer incurring member by an image forming station which performs the transfer earlier in a sequence of the image forming operations.

Owner:CANON KK

Image forming apparatus with a developer regulating member

ActiveUS7346301B2Uneven inhibitory concentrationAvoid drippingElectrographic process apparatusElectrical polarityImage formation

The invention realizes a uniform toner coating on a developing roller, thereby preventing a density unevenness and a toner dripping and suppressing a developing roller set mark image in a contact developing method, by conditions that the DC voltage applied to the developer regulating member is the same as the DC voltage applied to the developer carrying member or at a side of a charging polarity of the developer with respect to the DC voltage applied to the developer carrying member; and a frequency f (Hz) and a peak electric field strength E (V / m) of the AC electric field formed by the AC voltage between the developer regulating member and the developer carrying member, and a peripheral speed v (m / s) of the image bearing member satisfy conditions:4.2×v≦f≦2500 and2.2×106≦E≦5.2×106.

Owner:CANON KK

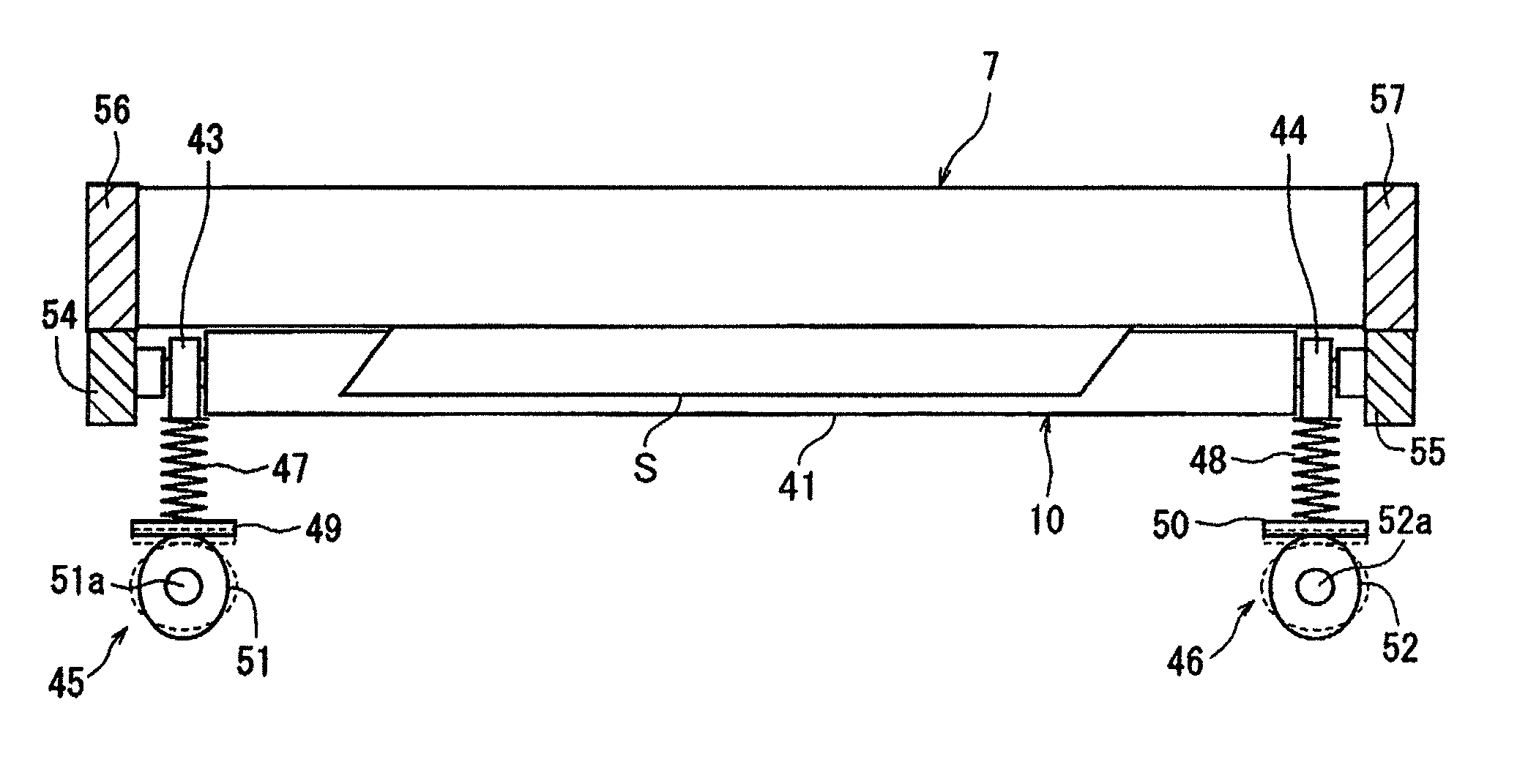

Image forming apparatus provided with transfer roller

InactiveUS8213835B2Inhibition formationUneven inhibitory concentrationElectrographic process apparatusImage formationMechanical engineering

An image forming apparatus has an image bearing member on which a toner image is to be formed. A transfer roller contacts a surface of the image bearing member for transferring a toner image on the image bearing member to one side of a transfer medium by applying a voltage having a polarity opposite to that of the toner image on the image bearing member from the other side of the transfer medium. A biasing member biases the transfer roller toward the image bearing member. The transfer roller is shaped such that the outer diameter of a first part corresponding to the width of a specified sheet size is constant and the outer diameters of second parts located closer to opposite ends of the transfer roller than the first part are gradually increased toward the outer sides in an axial direction.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

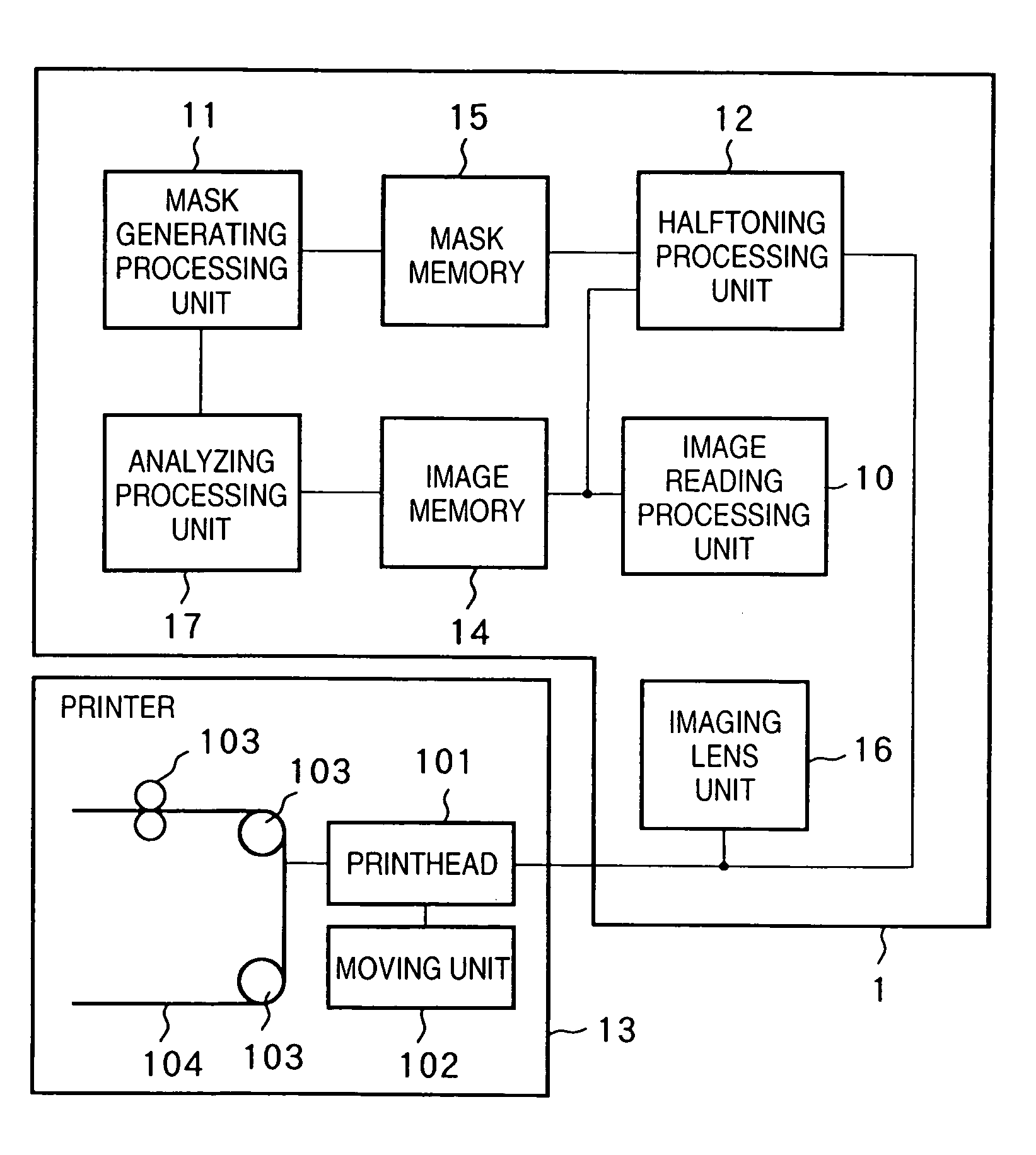

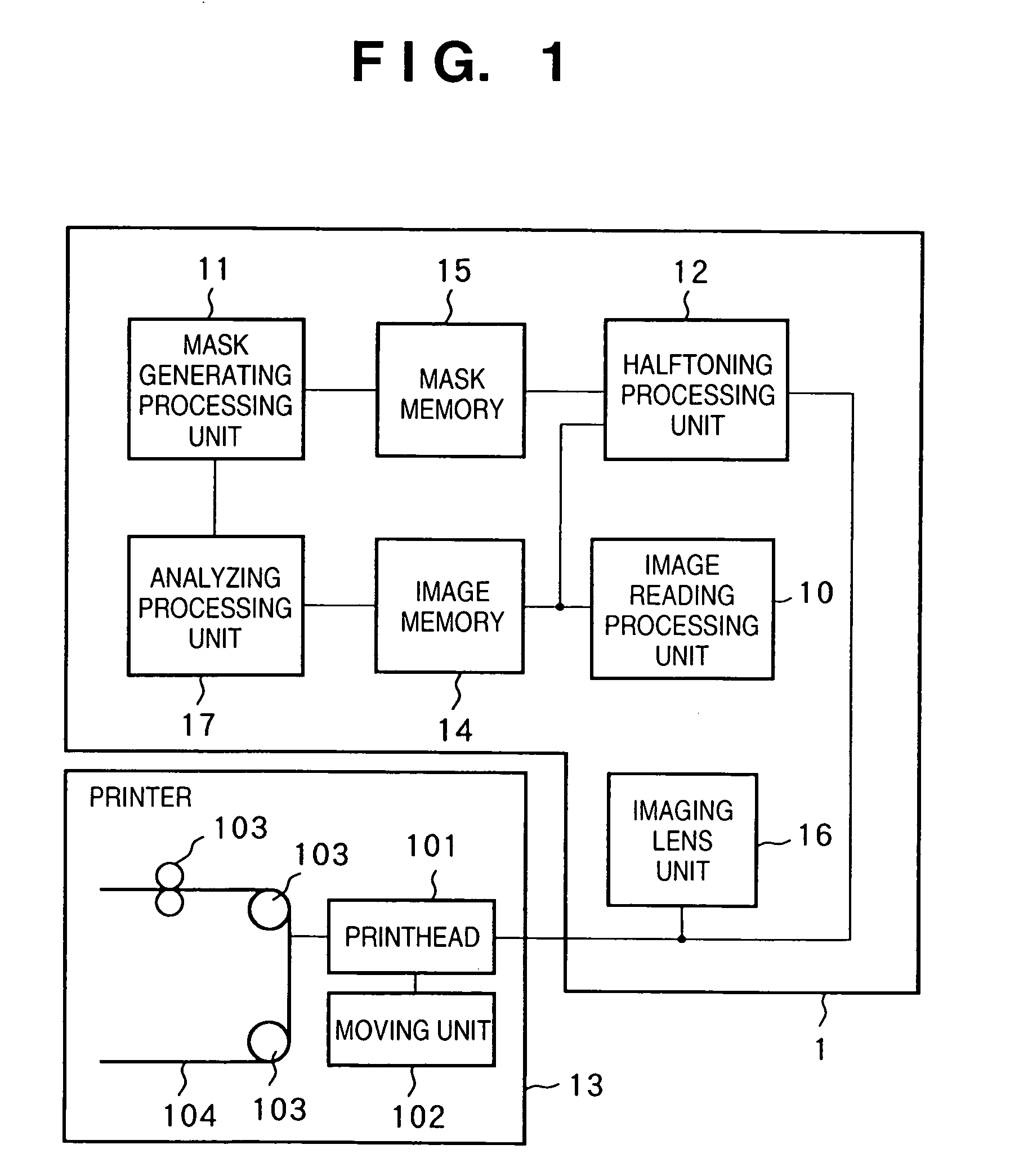

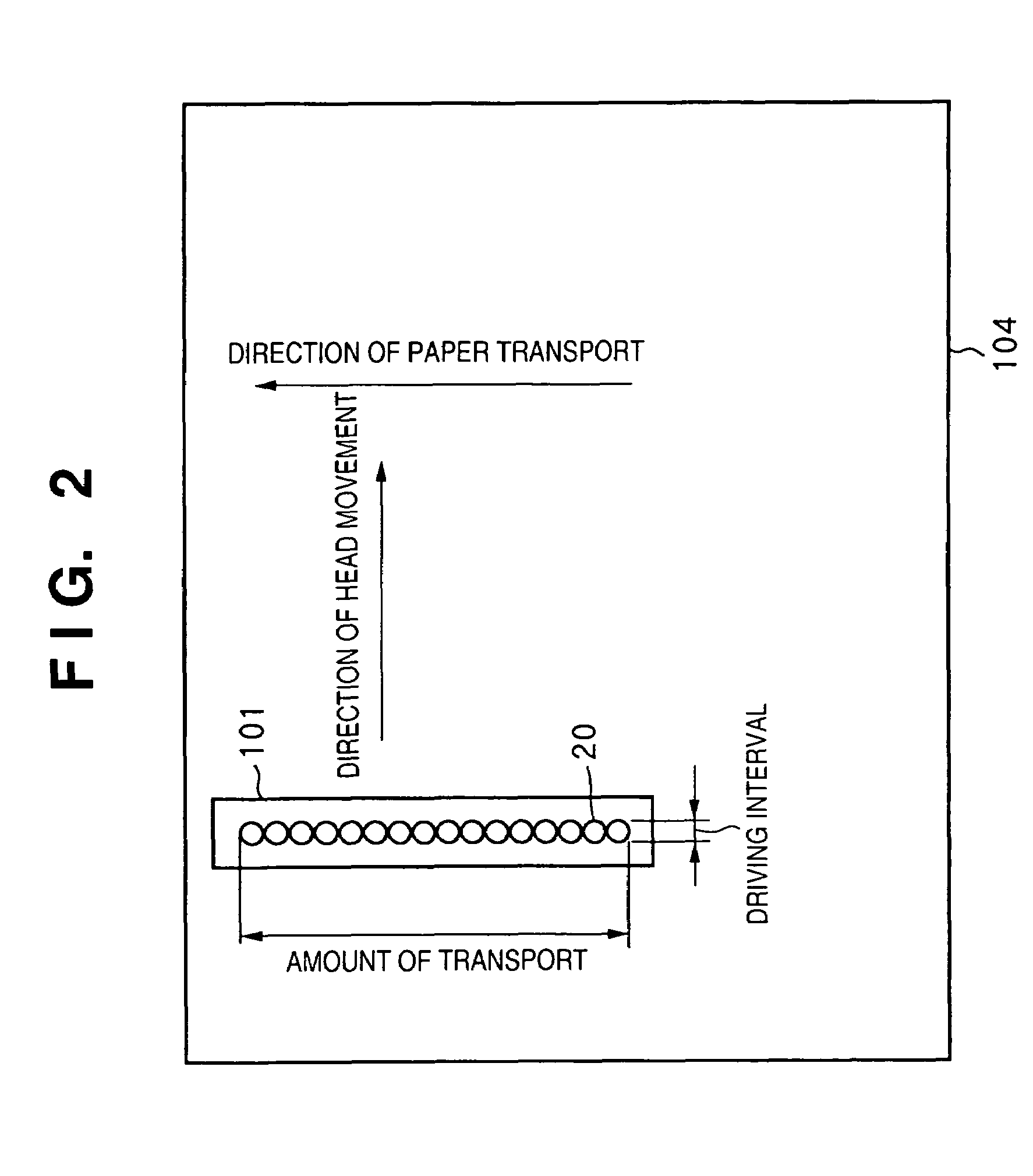

Image processing apparatus and method for correcting print data so as to reduce density unevenness, and image forming system

InactiveUS6970270B1Uneven inhibitory concentrationSimple wayDigitally marking record carriersDigital computer detailsImaging processingVolumetric Mass Density

Disclosed are an image processing apparatus and method in which it is possible to suppress density unevenness in the output of an image forming apparatus in a simple manner. A test image is printed out by a printer (13), the printout is read by an image reading processing unit (10), and an analyzing processing unit (17) detects the output characteristic (density unevenness, printing position deviation, etc.) of each of a plurality of print elements possessed by the printhead of the printer. A mask generating processing unit (11) generates a threshold-value mask which reflects the output characteristics detected by the analyzing processing unit and stores the mask in a mask memory (15). A halftoning processing unit (12) outputs image data to the printer after the image data is subjected to halftoning utilizing the threshold-value map that has been stored in the mask memory.

Owner:CANON KK

Ink jet printer and ink jet head

Owner:BROTHER KOGYO KK

Printing apparatus and printing method

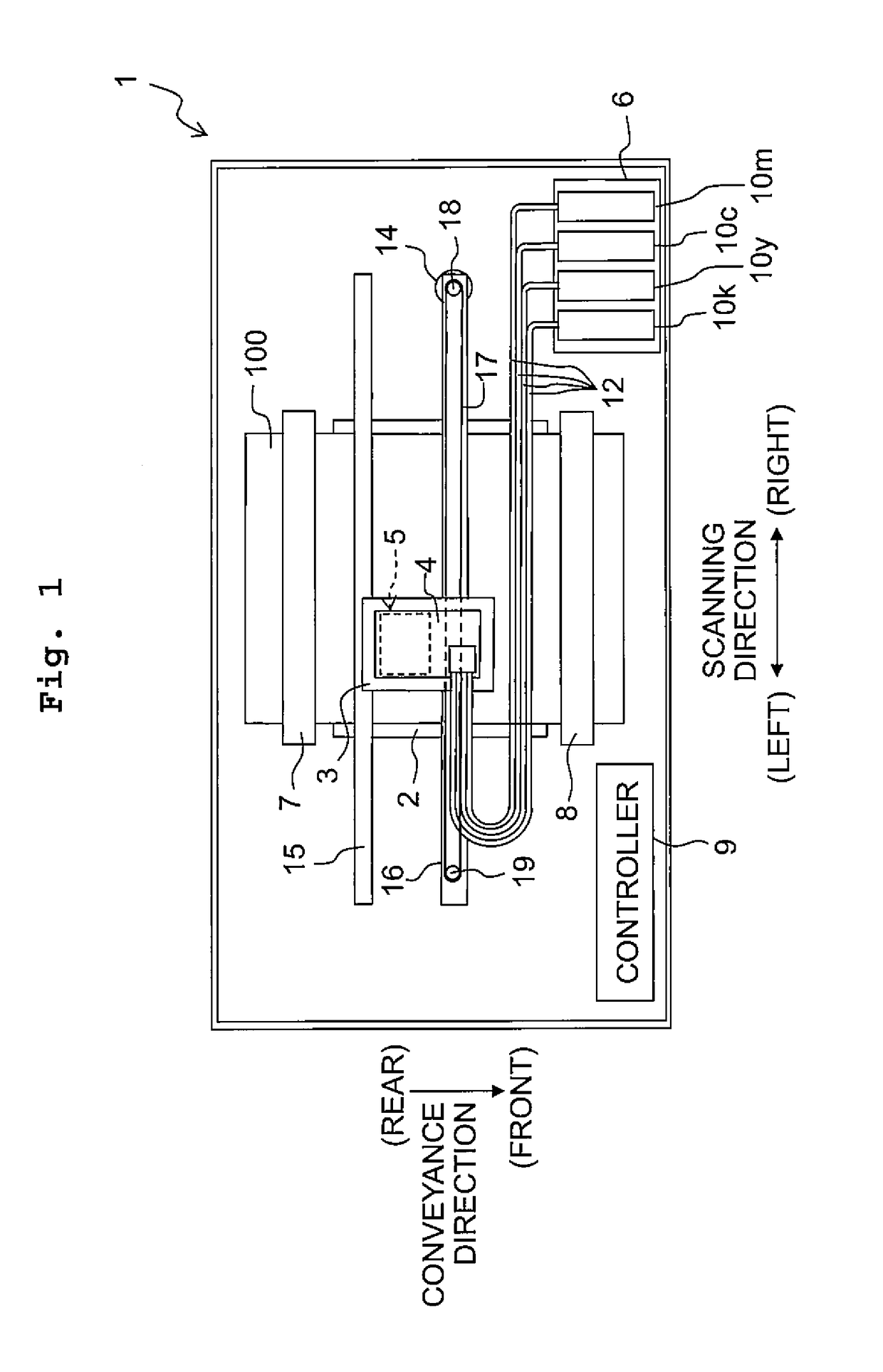

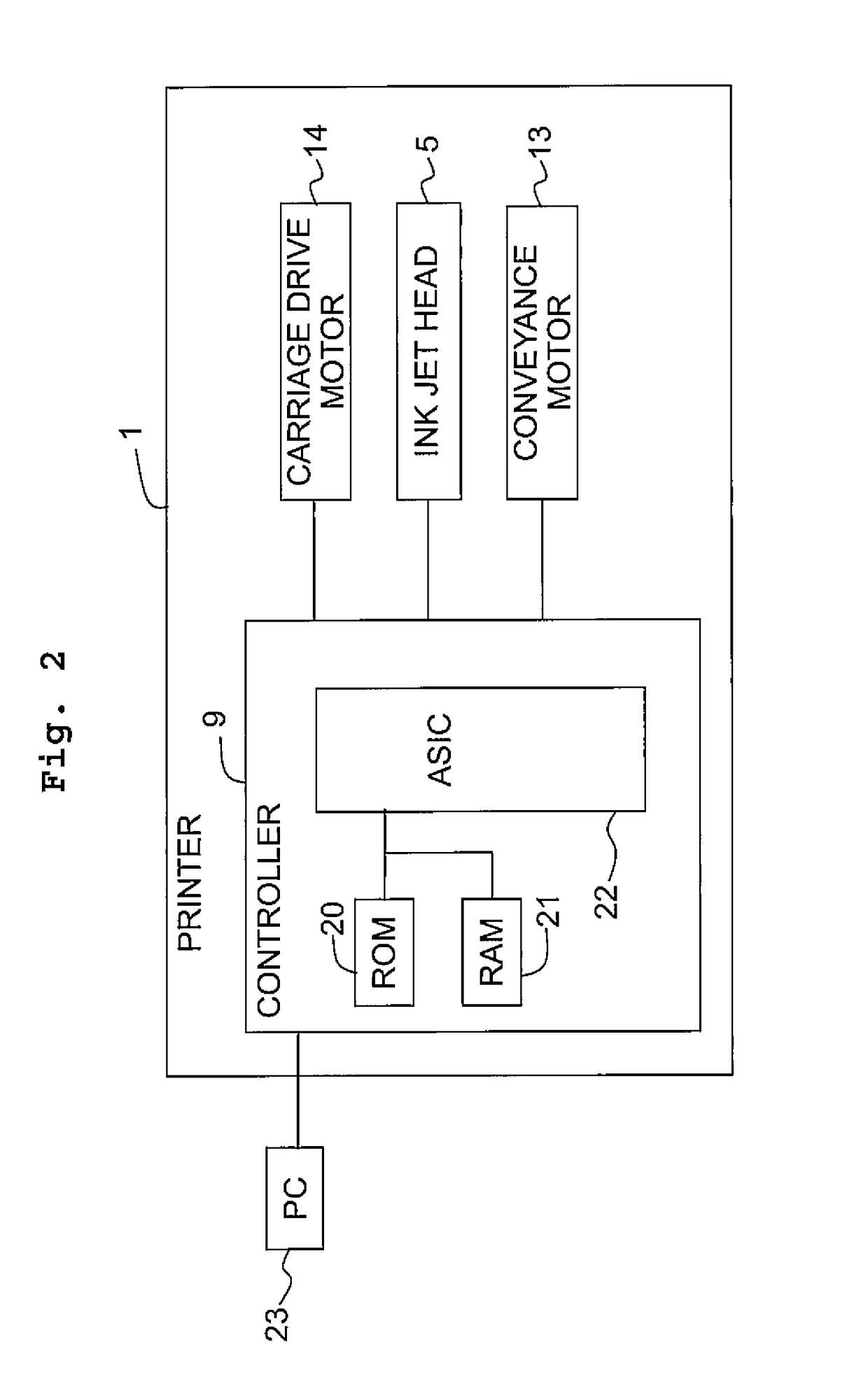

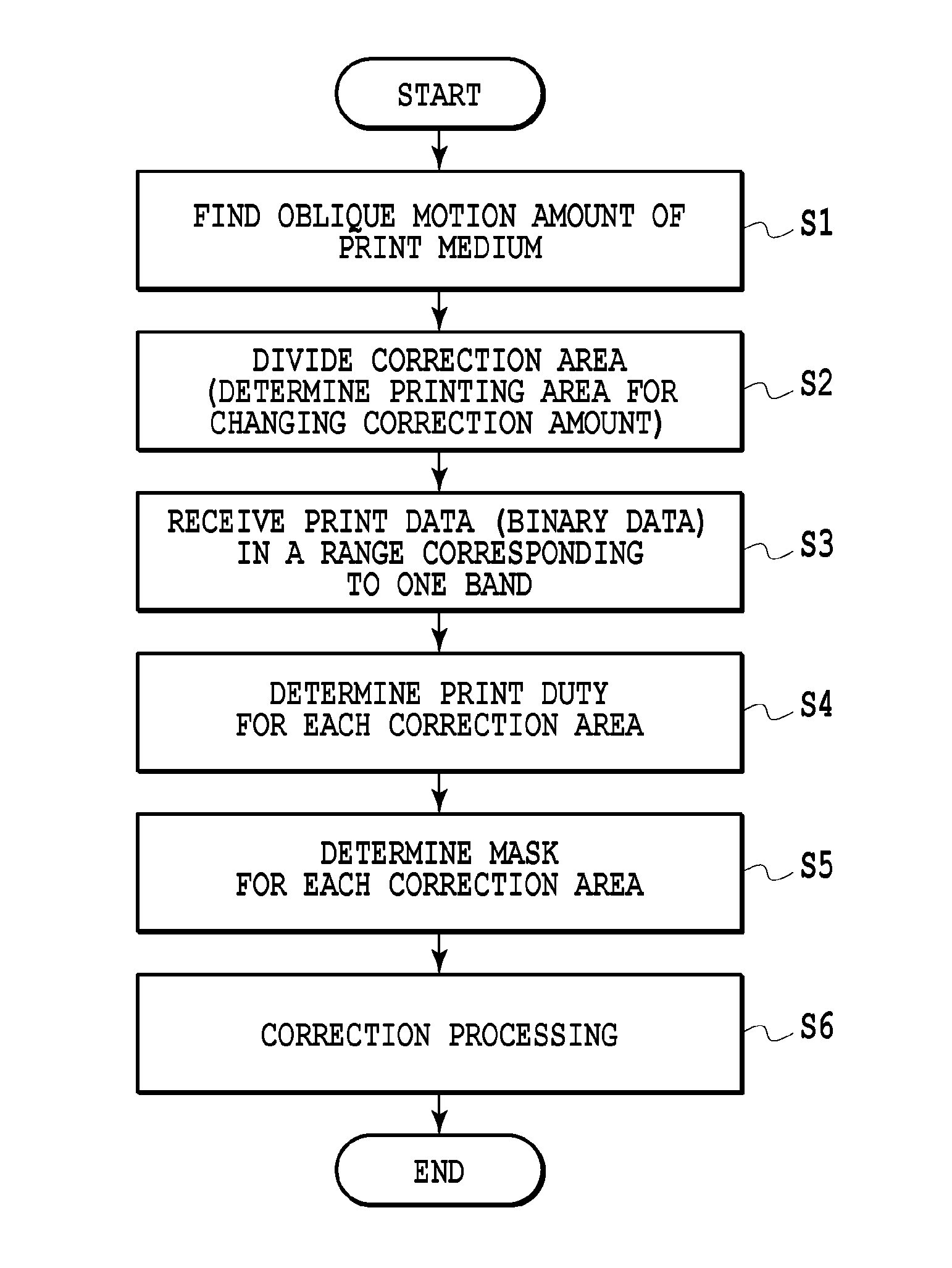

ActiveUS20150054877A1InhibitionUneven inhibitory concentrationSpacing mechanismsOther printing apparatusEngineeringMechanical engineering

A printing apparatus includes: a print head for applying ink on a print medium; a print control unit configured to control the print head; a conveying unit; an obtaining unit configured to obtain information regarding a conveyance error of conveyance of the print medium in a conveying direction crossing a predetermined direction by the conveying unit with respect to each of a plurality of areas of the print medium that are in positions different from each other in the predetermined direction; and an adjusting unit configured to divide a predetermined area of the print medium in accordance with a conveyance error amount indicated by the information in each of the plurality of areas obtained by the obtaining unit into a plurality of correction areas, and to adjust the amount of ink to be applied onto each of the plurality of correction areas lining up in the predetermined direction.

Owner:CANON KK

Pipe type circulation-based reaction apparatus

InactiveCN102917789AIncrease contact areaProduction rate suppressionFlow mixersTransportation and packagingEngineeringFluid supply

Disclosed is a pipe type circulation-based reaction apparatus which comprises two or more fluid supply passages formed by a multi-layered tube for supplying two or more types of fluids to be used for reaction; a reaction flow passage which has an annular cross section and is capable of reacting said fluids while causing the same to circulate; and a fluid discharge passage for discharging resection products. In order that the fluid supply passages may communicate with the inlet to the reaction flow passage, the fluid supply passages are connected along a circumferential tangent direction of the annular reaction flow passage or along a direction intersecting the circumferential surface thereof at right angles. Furthermore, the fluid discharge passage is connected to the outlet of the reaction flow passage in such a way as to establish communication.

Owner:NISSO ENG

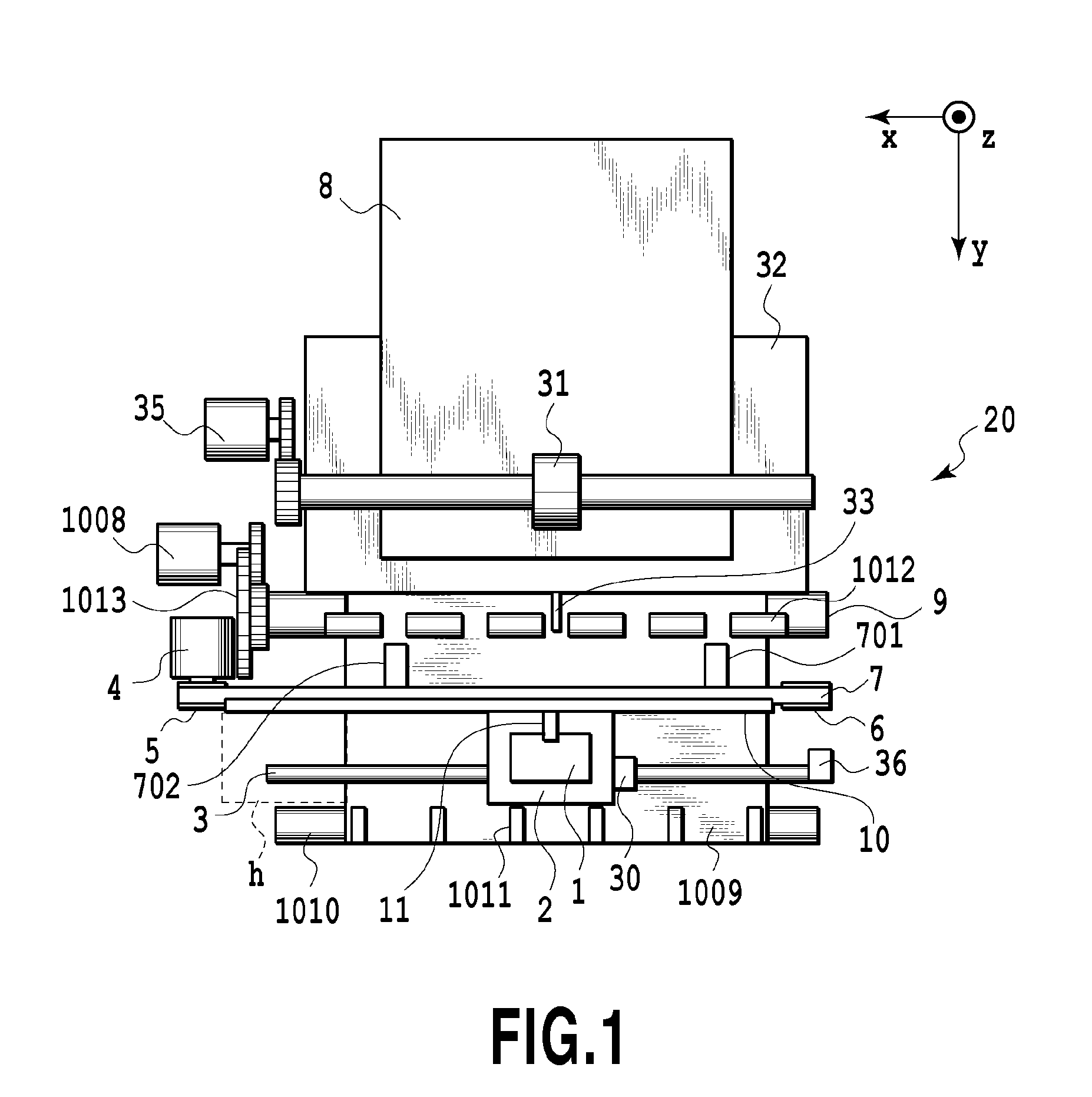

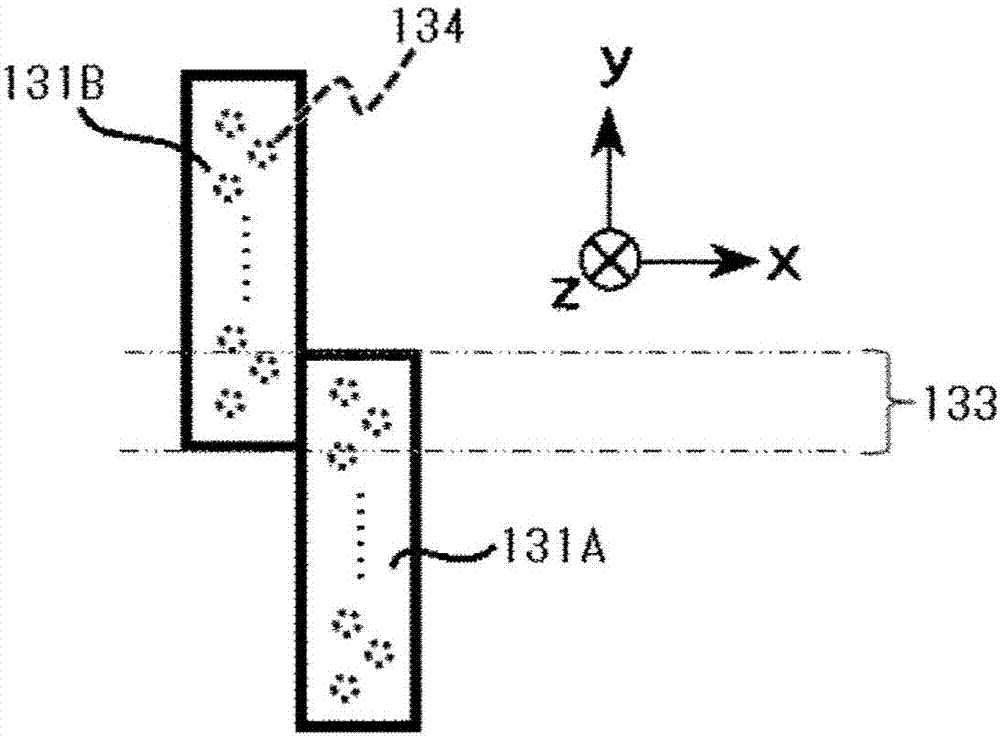

Printing apparatus and printing method

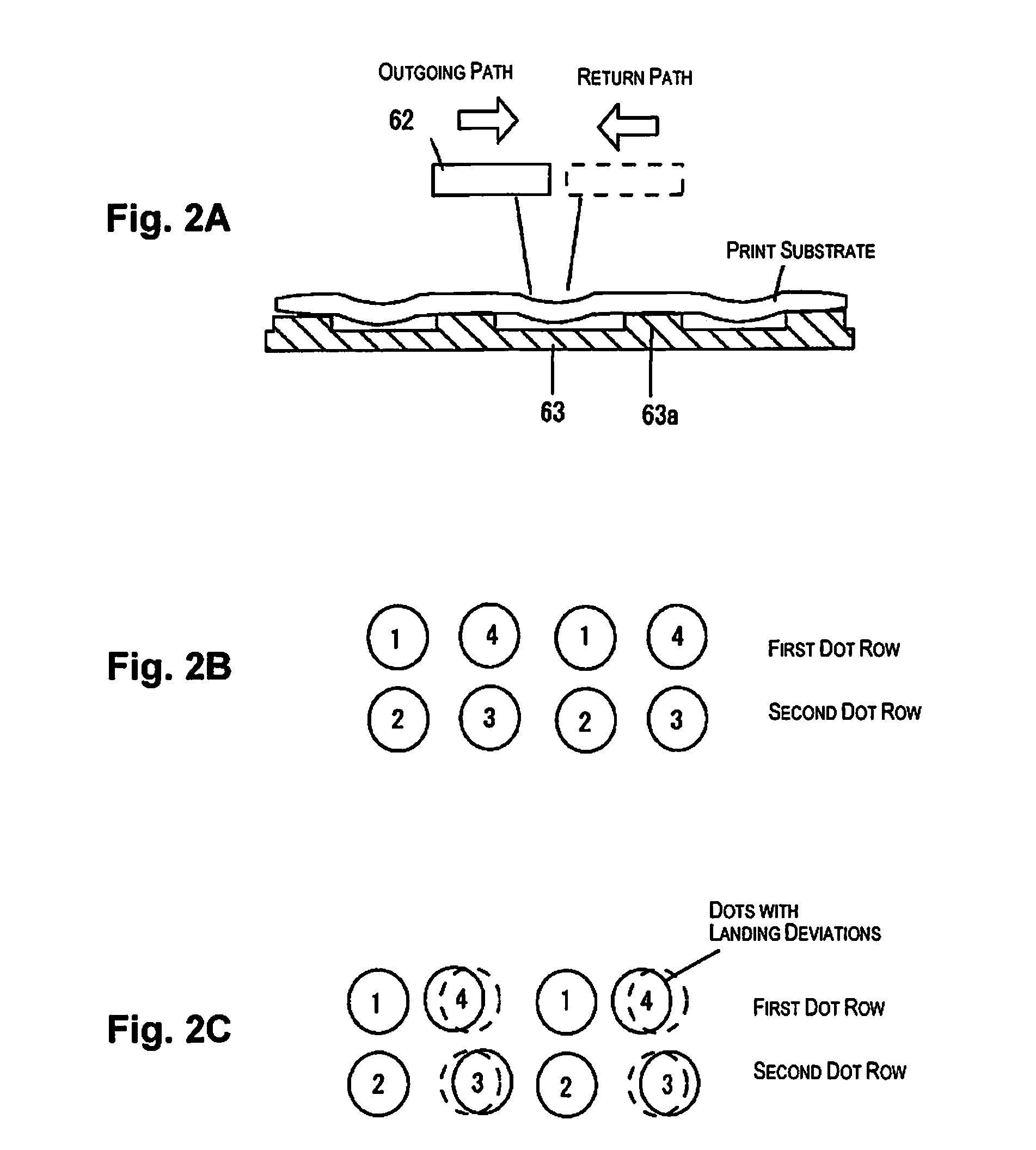

ActiveCN106985522AUneven inhibitory concentrationSpacing mechanismsPower drive mechanismsReciprocating motionRecording media

The invention provides a printing apparatus and a printing method that can sufficiently suppress the occurrence of variations in density due to the shifting of landing positions. A printing apparatus includes a carriage unit, and carries out printing on a recording medium while transporting the recording medium. The carriage unit includes a first head that discharges an ink and a second head that discharges an ink of the same color, and the second head is disposed so as to be adjacent to the first head in an x axis direction, and to overlap with the first head in a y axis direction. In an outgoing path in the reciprocation of the carriage unit, a printing density of a first image, which the first head prints, gradually decreases toward a downstream side in a transport direction of the recording medium, and the first image includes a dot group, in which at least two dots formed using the ink from the first nozzles are linked to one another in the x axis direction. In addition, in a return path in the reciprocation of the carriage unit, the second nozzles print a second image, which supplements a decrease in the printing density of the first image.

Owner:SEIKO EPSON CORP

Ink jet printing apparatus and ink jet printing method

InactiveUS20090219340A1Quality improvementUneven inhibitory concentrationDigitally marking record carriersDigital computer detailsVolumetric Mass DensityEngineering

An ink jet printing apparatus and an ink jet printing method are provided which use a printing head having a plurality of ejection opening arrays and enable high quality printing without causing uneven density in a conveying direction. For this purpose, by providing a plurality of ejection opening arrays to chips constituting the printing head and changing data assigning ratio of each ejection opening array, deviation in impact positions depending on the distance between the ejection opening arrays becomes inconspicuous.

Owner:CANON KK

Print control device and program

ActiveUS20130278670A1Density irregularityPrecise positioningOther printing apparatusGratingSpray nozzle

A plurality of test patterns that are disposed in a predetermined direction are printed using dot arrays formed along an intersecting direction interesting with the predetermined direction using nozzles included in an overlapping portion of a first nozzle array and a second nozzle array, a plurality of rules lined in the predetermined direction are printed so as to be adjacent to the test patterns using nozzles included in the first nozzle array and the second nozzle array, density correction values are computed according to density of each of raster lines of the test patterns, and the positions of nozzles specified from the positions of rules are associated with the positions of the raster lines for which density correction values are computed.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com