Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Torque transmitted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

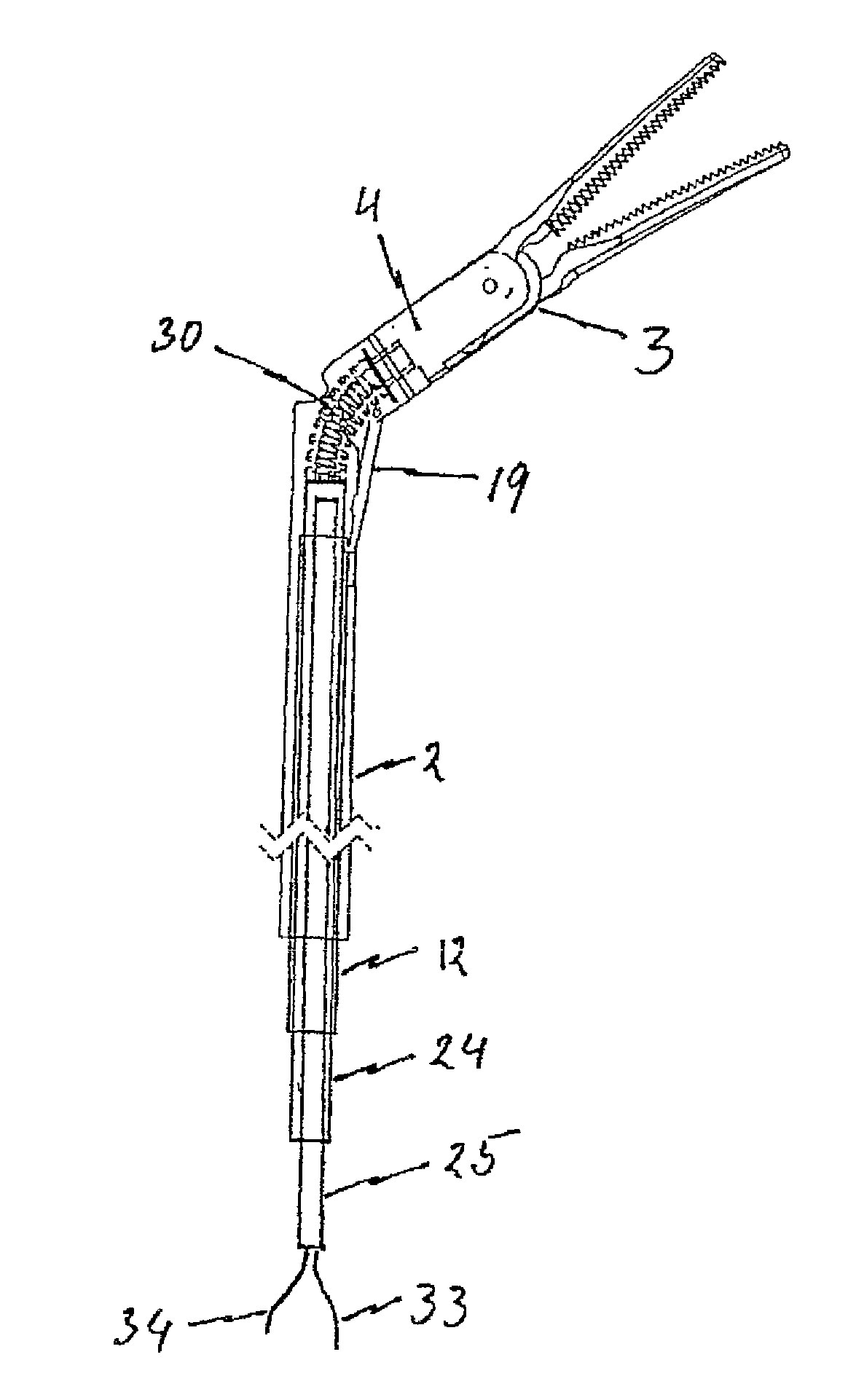

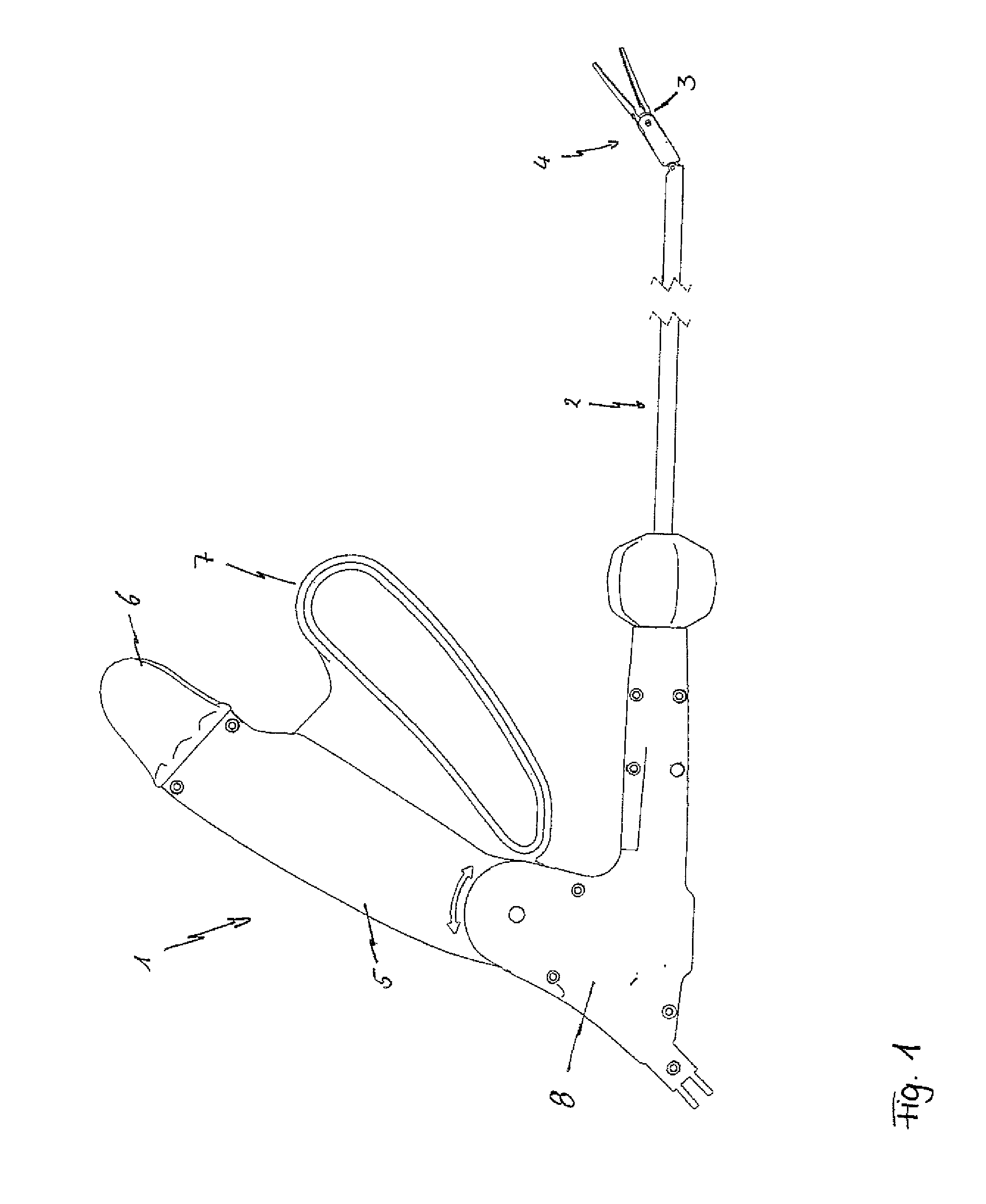

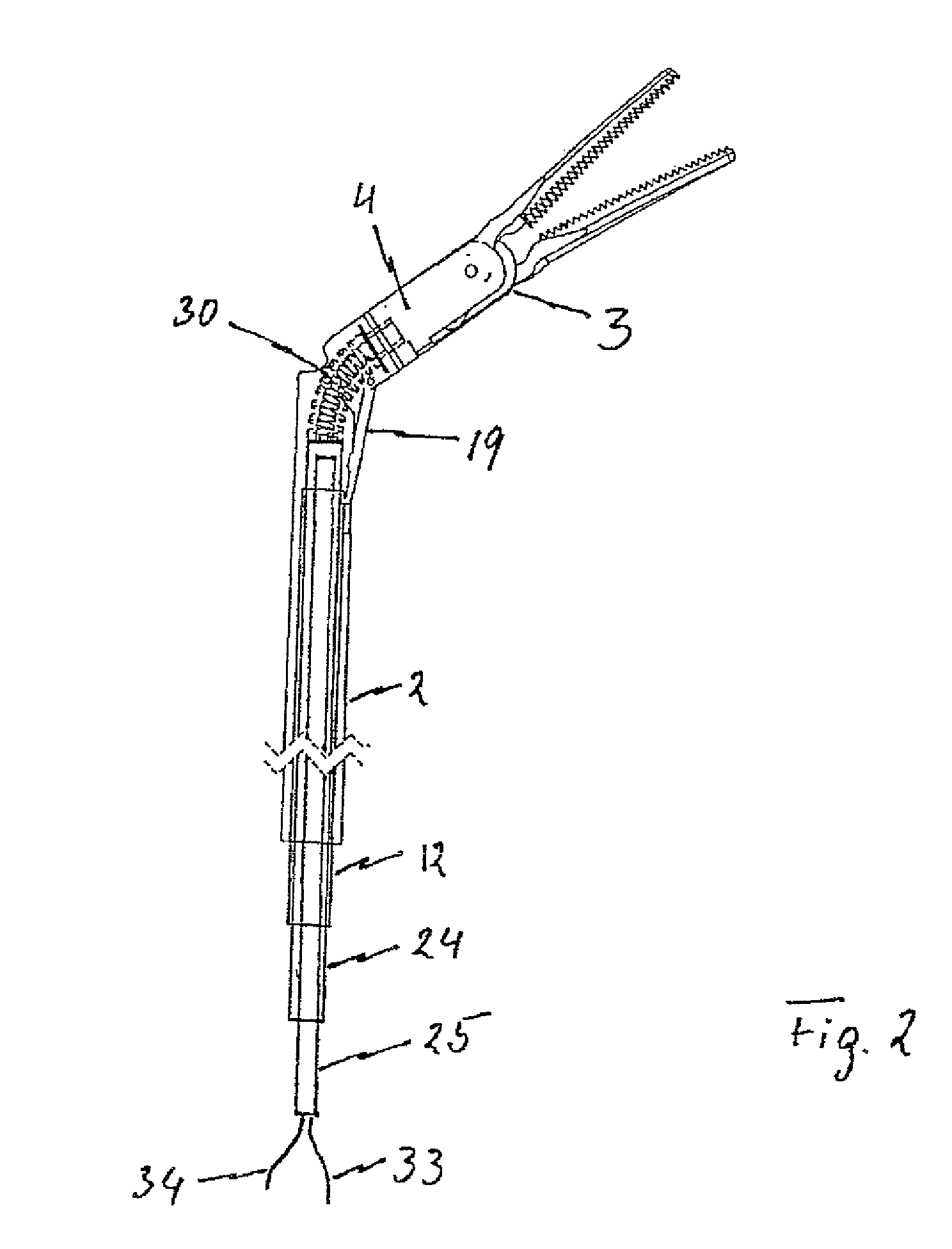

Surgical instrument with elastically movable instrument head

ActiveUS8876858B2More working spaceSufficient torqueSurgical instruments for heatingSurgical forcepsEngineeringSurgical device

Disclosed is a surgical instrument comprising an instrument handle, an instrument shaft shaft having a distal end and a proximal end at which the instrument handle is linked, an instrument head, pivotally linked to the distal end of the instrument shaft via a hinge shaft or pins and comprising an effector rotatably supported in said instrument head around its longitudinal axis as well as a surgical tool held by said effector, and a mechanical transmission system at least partially arranged within said instrument shaft transmitting mechanical operation signals from said instrument handle to said instrument head at least for pivoting and / or rotating motions. A bending flexible as well as rotating rigid, hollow spindle is arranged bypassing said hinge shaft or pins and directly connecting said effector with the mechanical transmission system for transmitting at least rotating signals via said spindle to said effector.

Owner:TUEBINGEN SCI MEDICAL

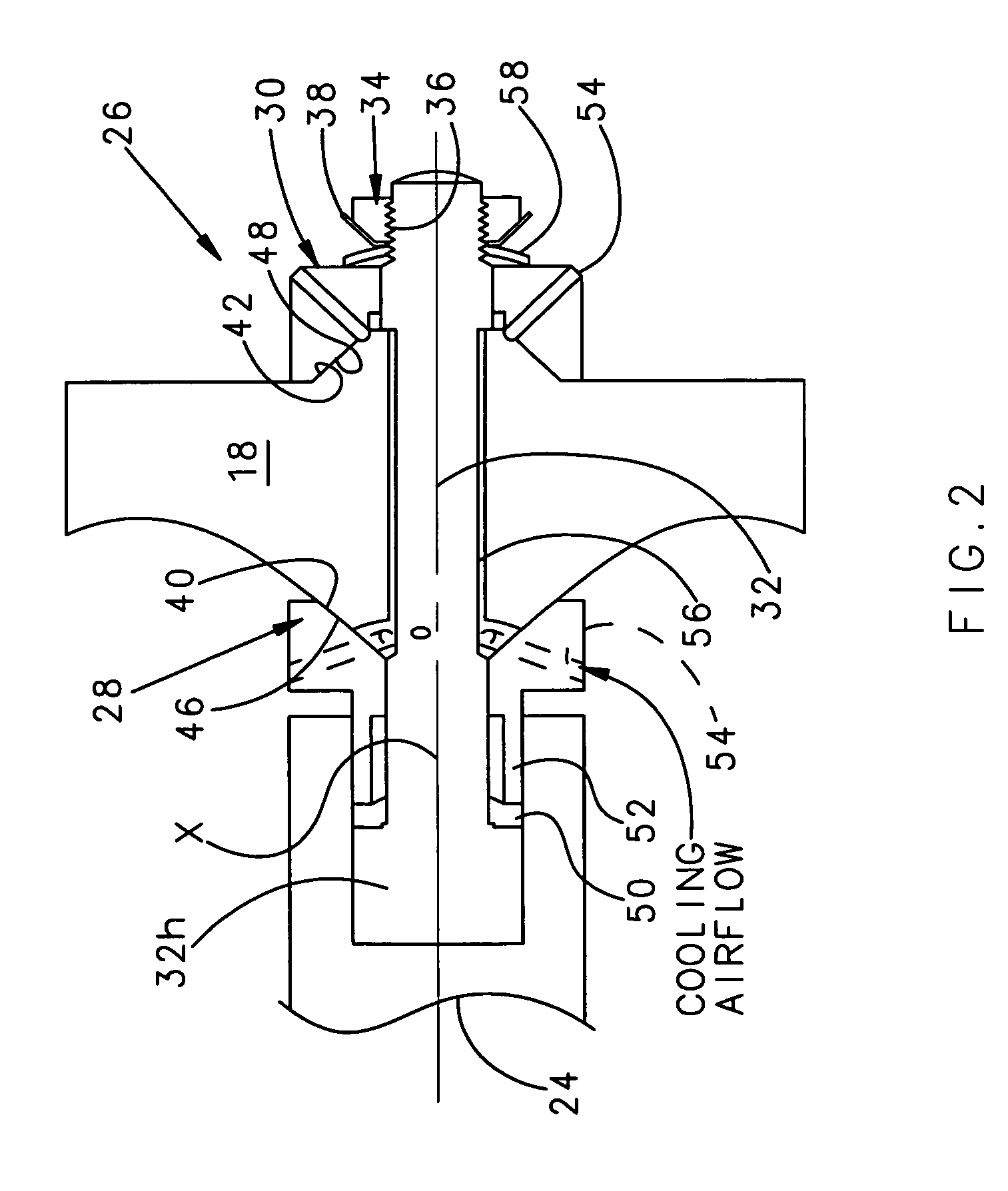

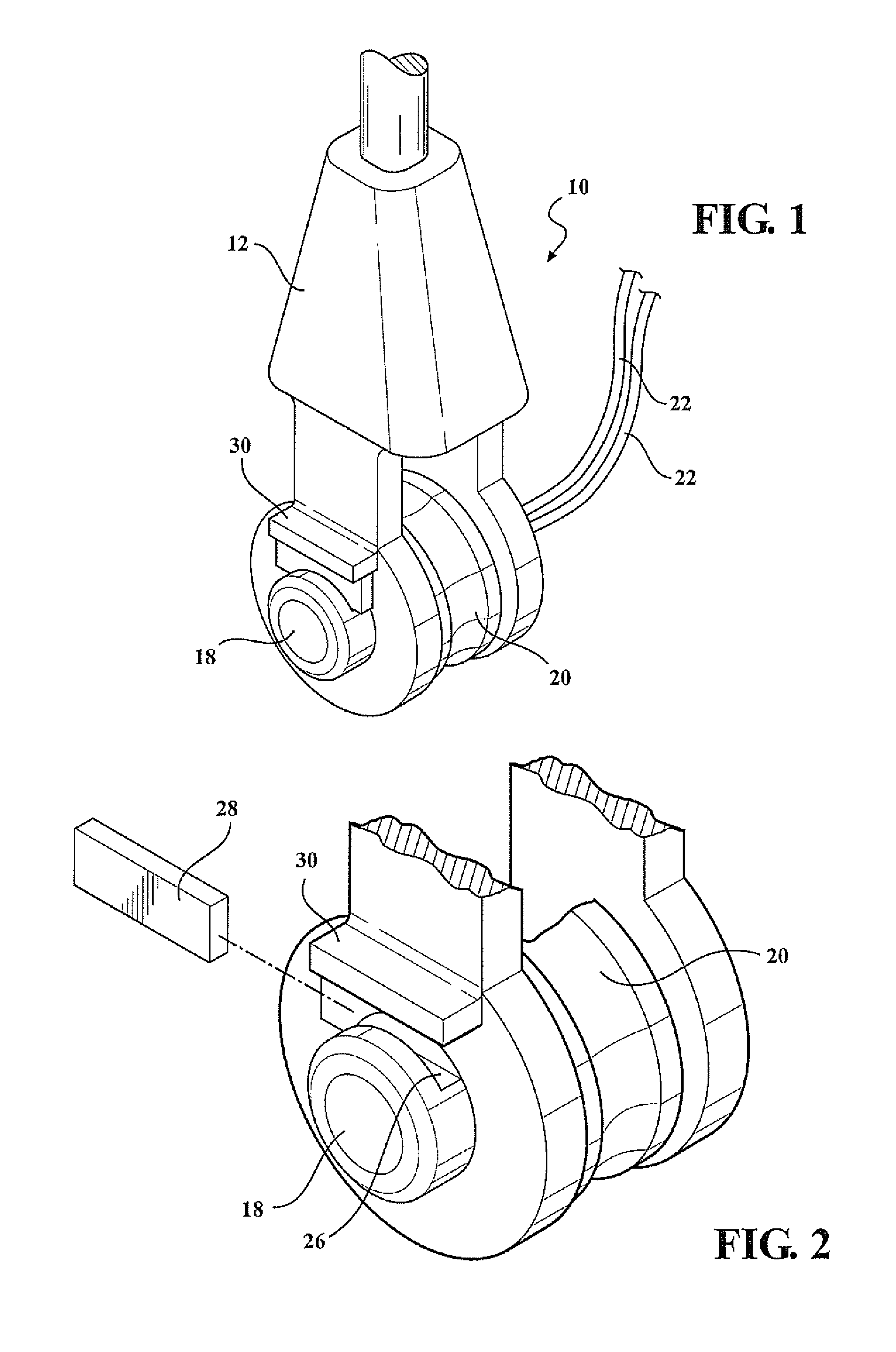

Mechanical coupling for a rotor shaft assembly of dissimilar materials

A mechanical coupling for coupling a ceramic disc member to a metallic shaft includes a first wedge clamp and a second wedge clamp. A fastener engages a threaded end of a tie-bolt to sandwich the ceramic disc between the wedge clamps. An axial spring is positioned between the fastener and the second wedge clamp to apply an axial preload along the longitudinal axis. Another coupling utilizes a rotor shaft end of a metallic rotor shaft as one wedge clamp. Still another coupling includes a solid ceramic rotor disc with a multiple of tie-bolts radially displaced from the longitudinal axis to exert the preload on the solid ceramic rotor disc.

Owner:HAMILTON SUNDSTRAND CORP

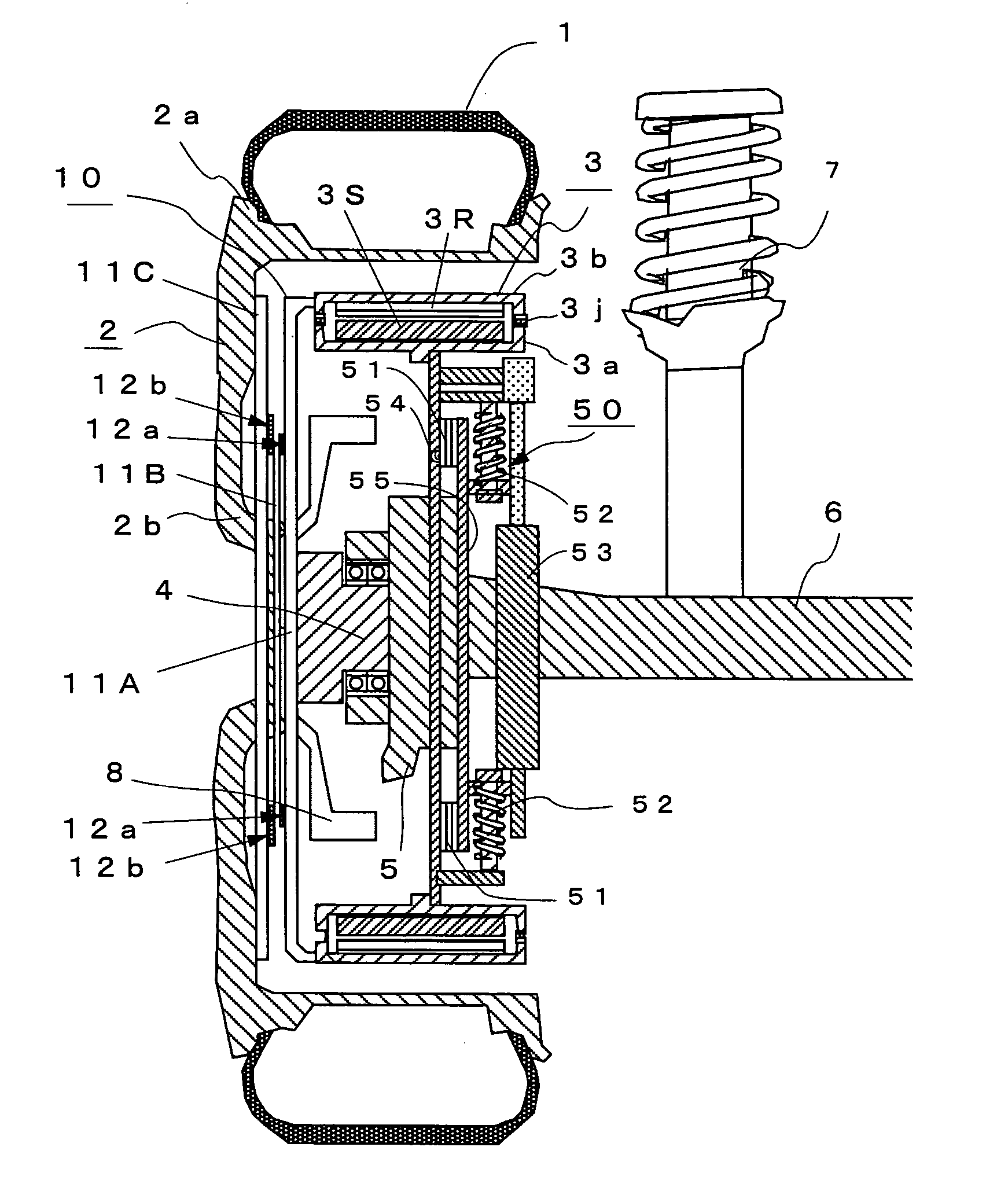

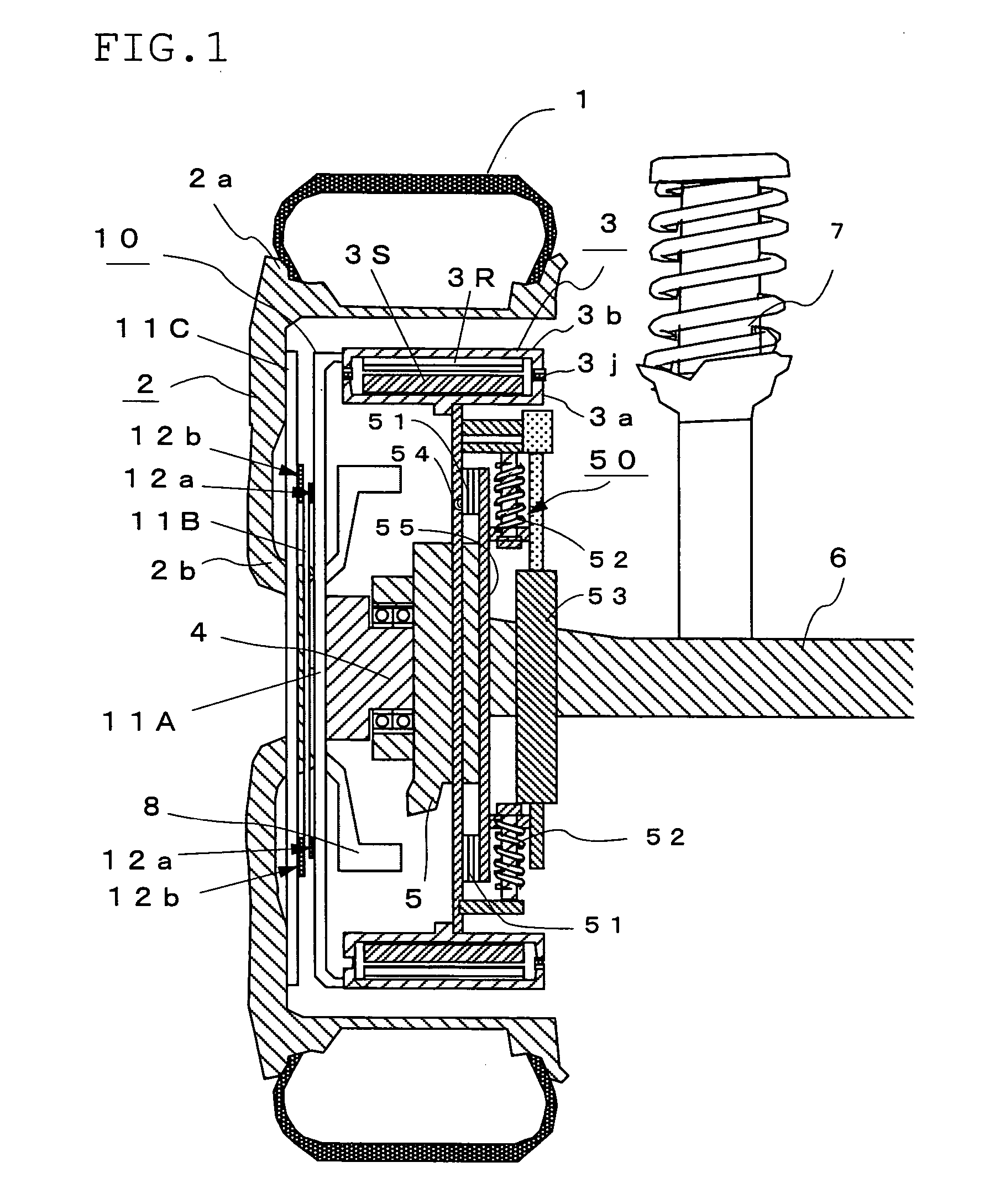

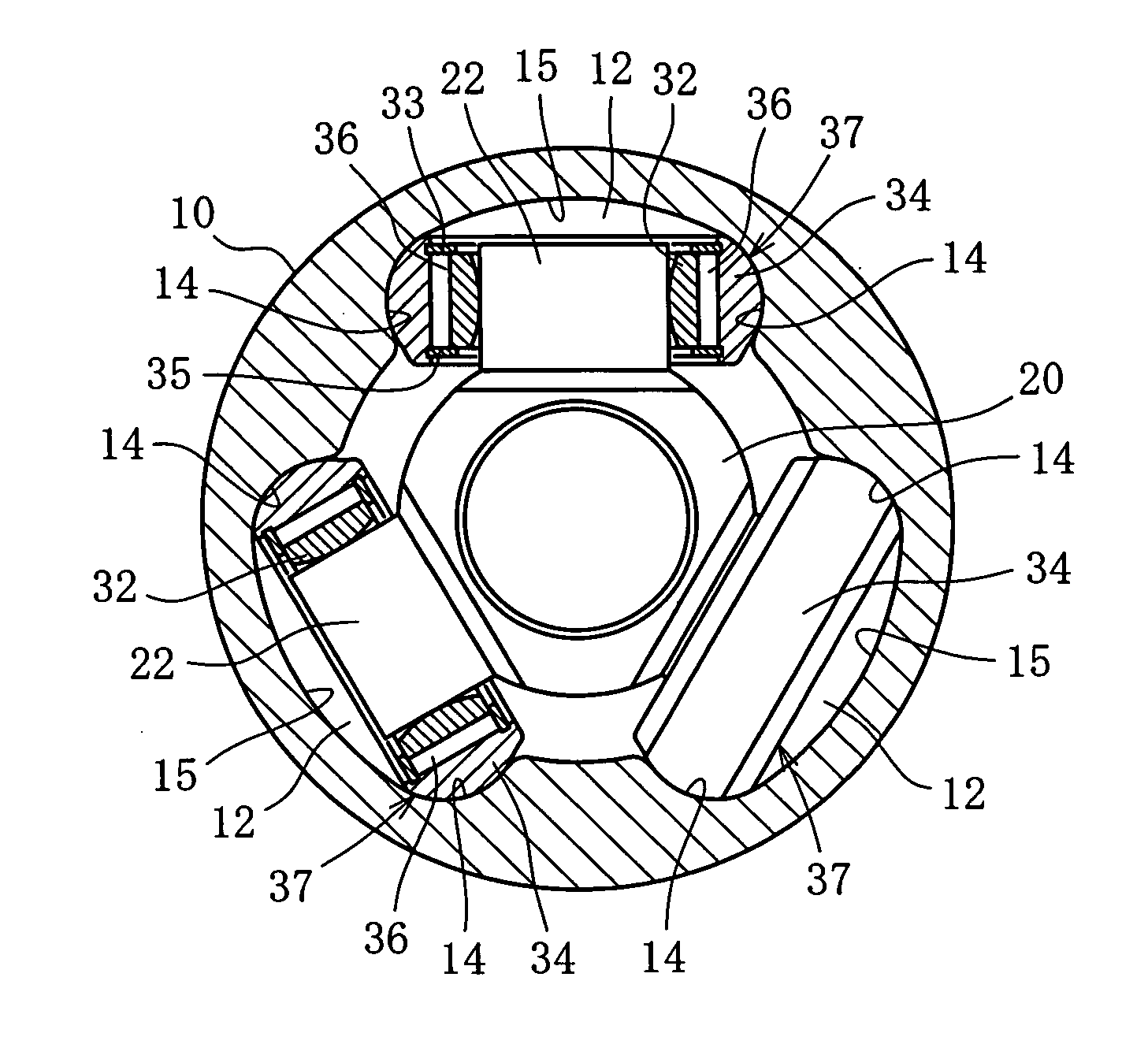

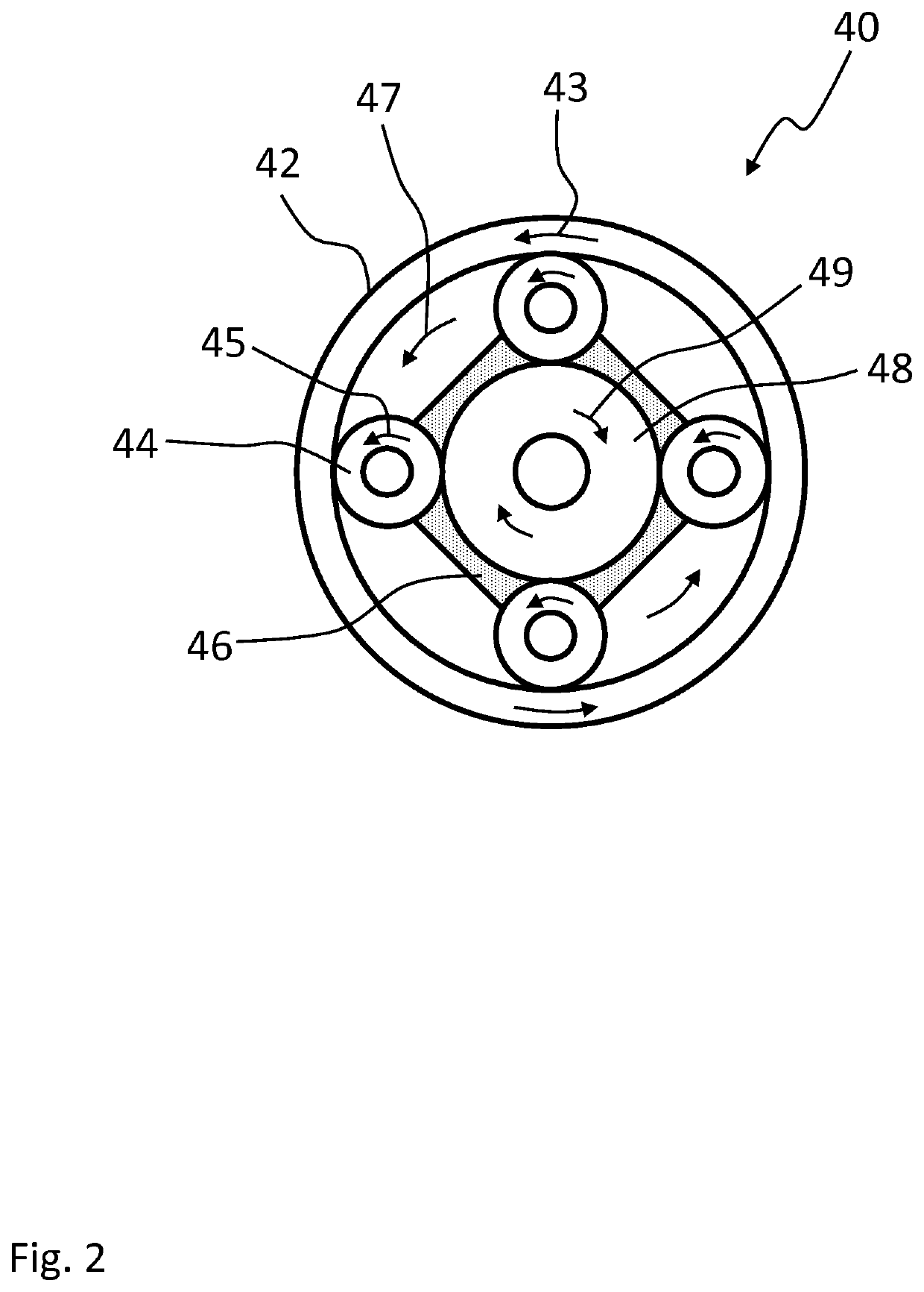

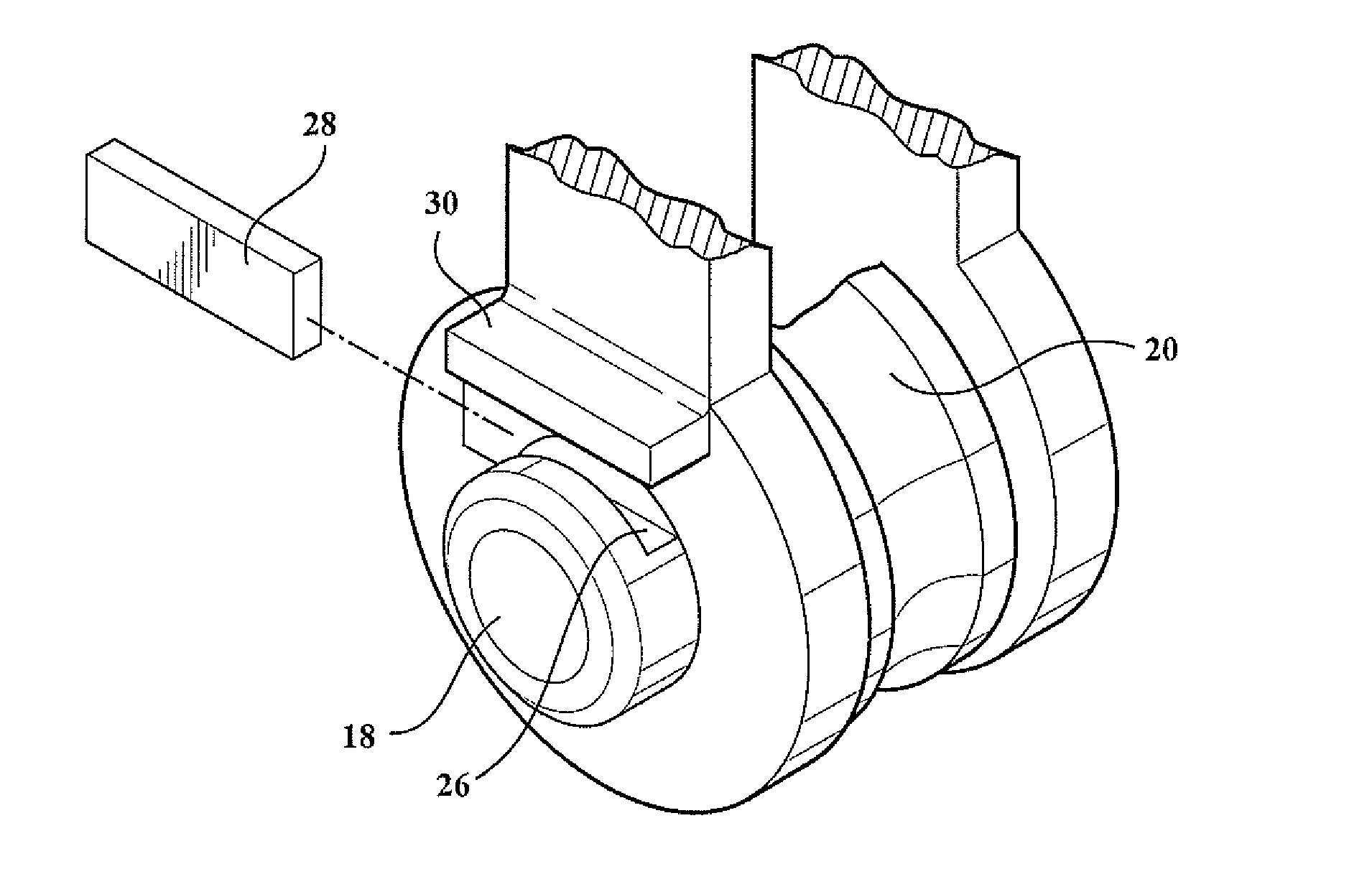

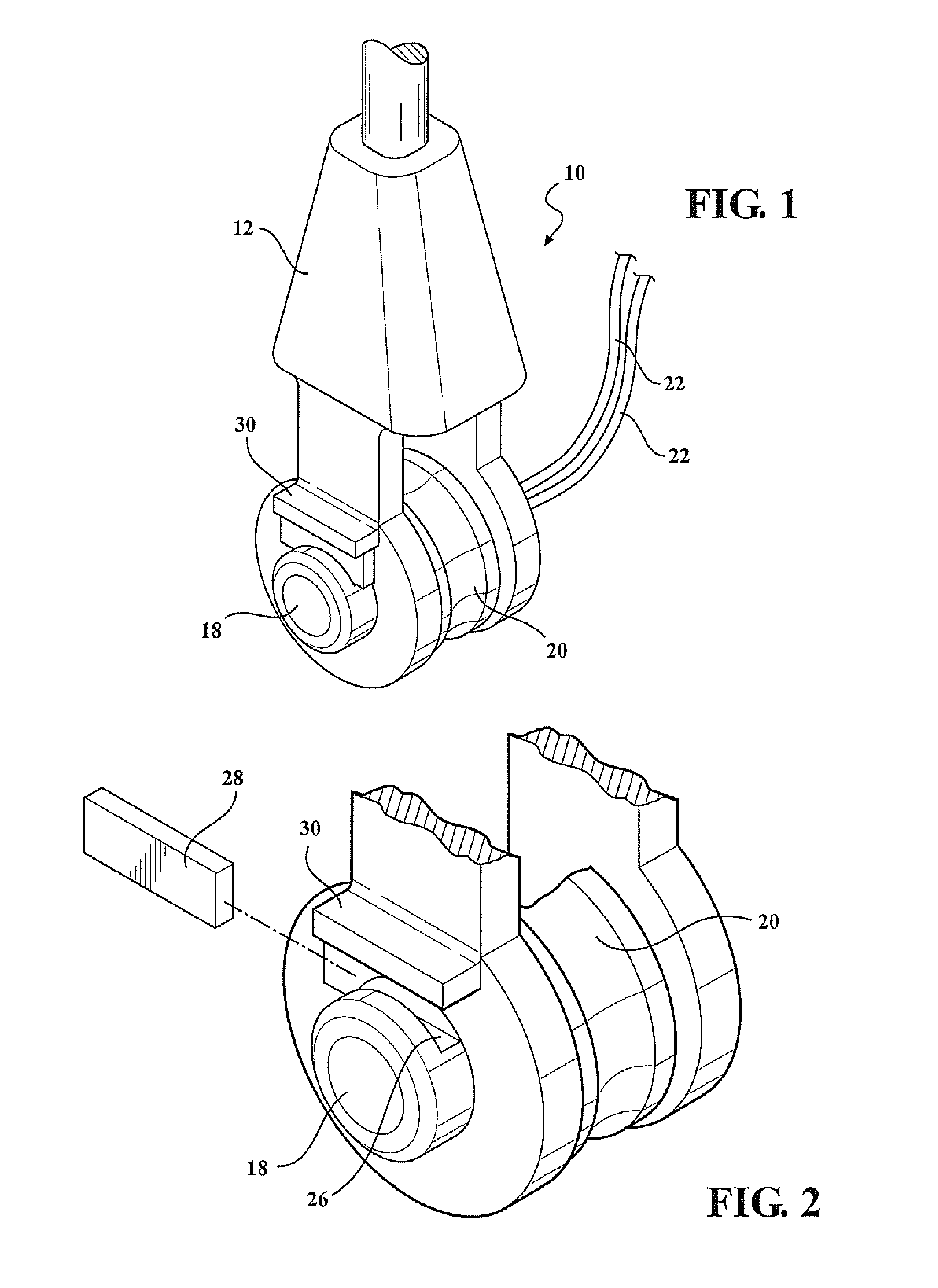

In-wheel motor system

InactiveUS20070107959A1Easy to assembleImprove work efficiencyYielding couplingSpringsCouplingEngineering

An in-wheel motor system having a flexible coupling for transmitting the drive torque of a motor to a wheel. The flexible coupling 10 simple in structure and easily assembled comprises a motor-side plate (11A) mounted to the rotating side case of the motor, a wheel-side plate (11C) mounted to the wheel or a hub, an intermediate plate (11B) disposed between these two plates (11A) and (11C), a first rubber member (12a) of generally rectangular shape in plan view which connects the motor-side plate (11A) to the intermediate plate (11B) in such a manner that they can move relative to each other in a direction (direction B) orthogonal to their connection direction (direction A), and a second rubber member (12b) formed in the same manner as the first rubber member (12a) which connects the intermediate plate (11B) to the wheel side plate (11C) in such a manner that they can move relative to each other in the direction A orthogonal to the direction B.

Owner:BRIDGESTONE CORP

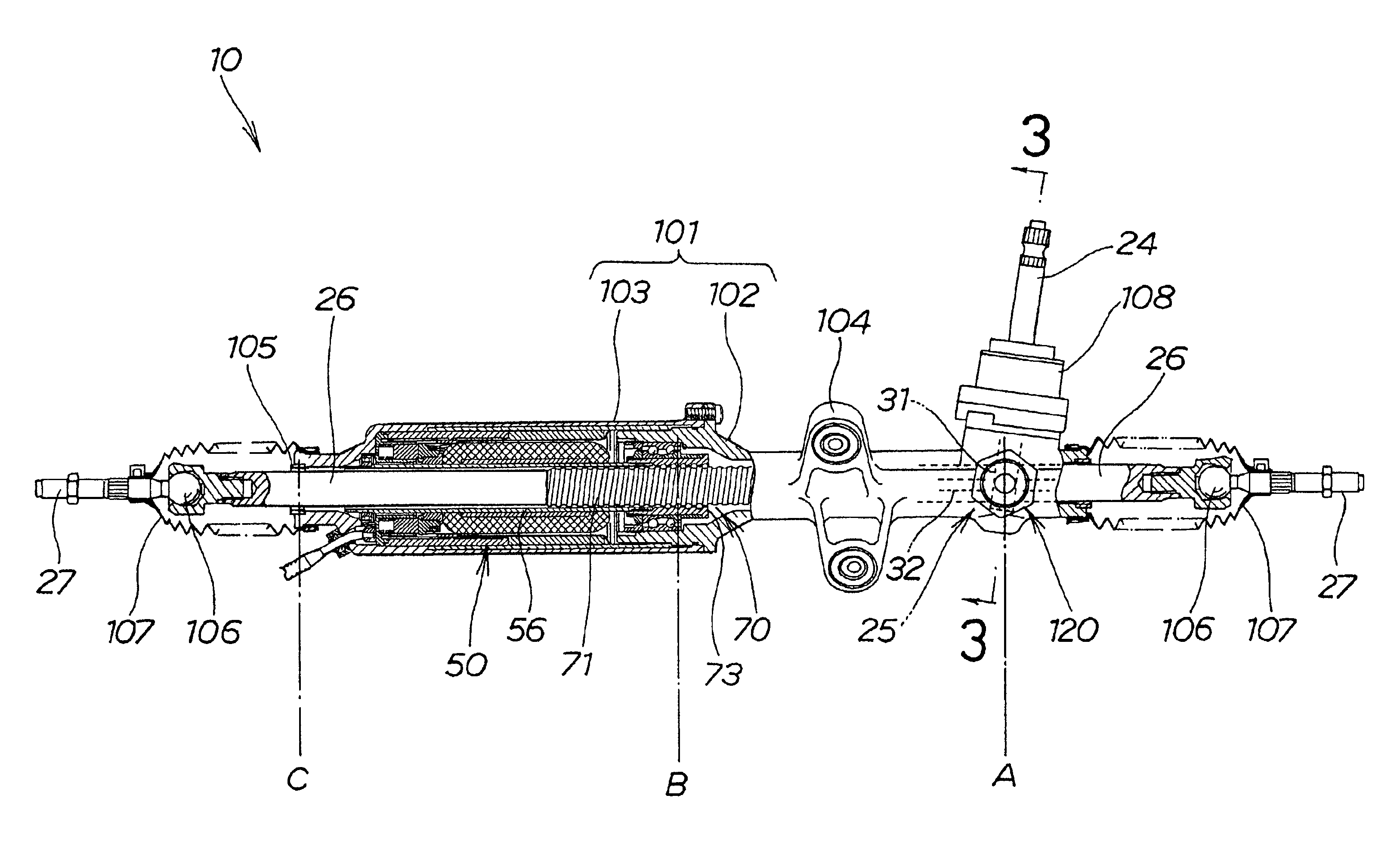

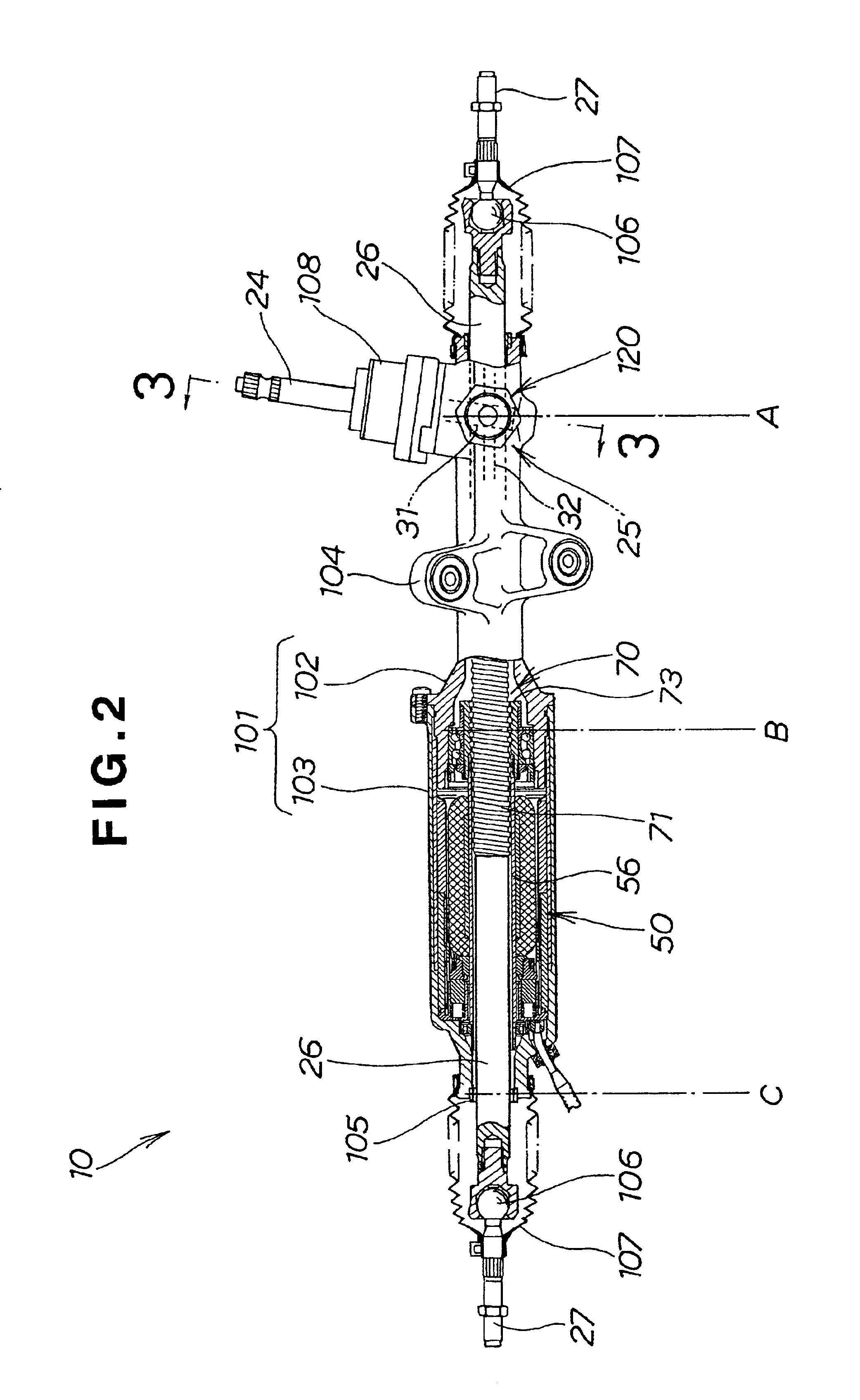

Electric power steering apparatus

InactiveUS6848534B2Improve assembly efficiencyImproved steering toughSteering linkagesGearingElectric power steeringGear tooth

An electric power steering apparatus for a vehicle includes a rack shaft having a rack of gear teeth formed at one end portion thereof and an externally threaded screw formed at a portion thereof excluding the toothed one end portion, a pinion meshing with the rack, a ball-screw mechanism having a nut threadedly engaged with the screw via balls, and an electric motor having a hollow motor shaft extending around the rack shaft and connected to the nut such that an assist torque generated by the electric motor is transmitted from the motor shaft via the nut to the rack shaft. The nut is disposed between the rack and the electric motor. This arrangement ensures that the electric motor and the electric power steering apparatus can be assembled easily and efficiently.

Owner:HONDA MOTOR CO LTD

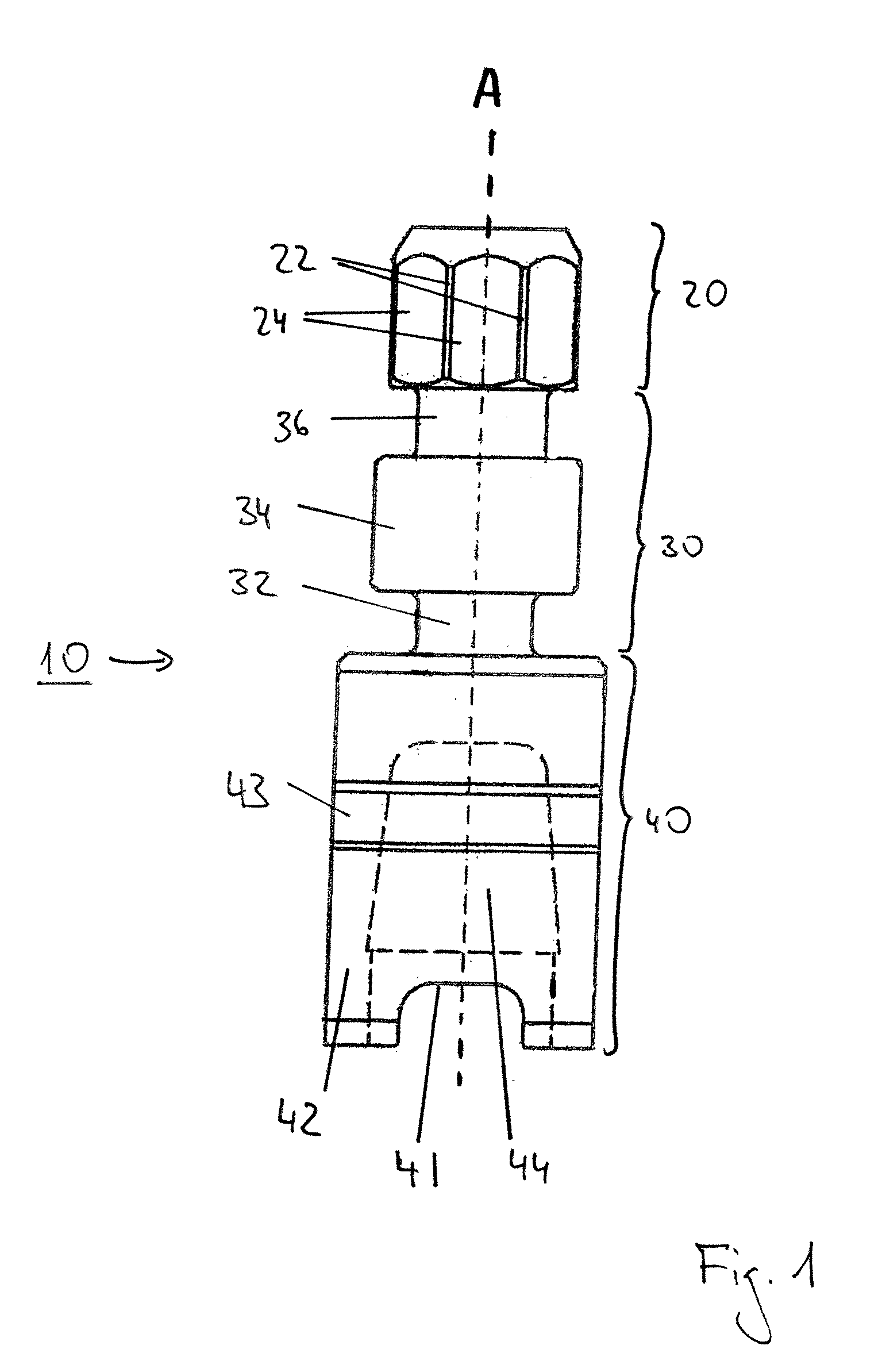

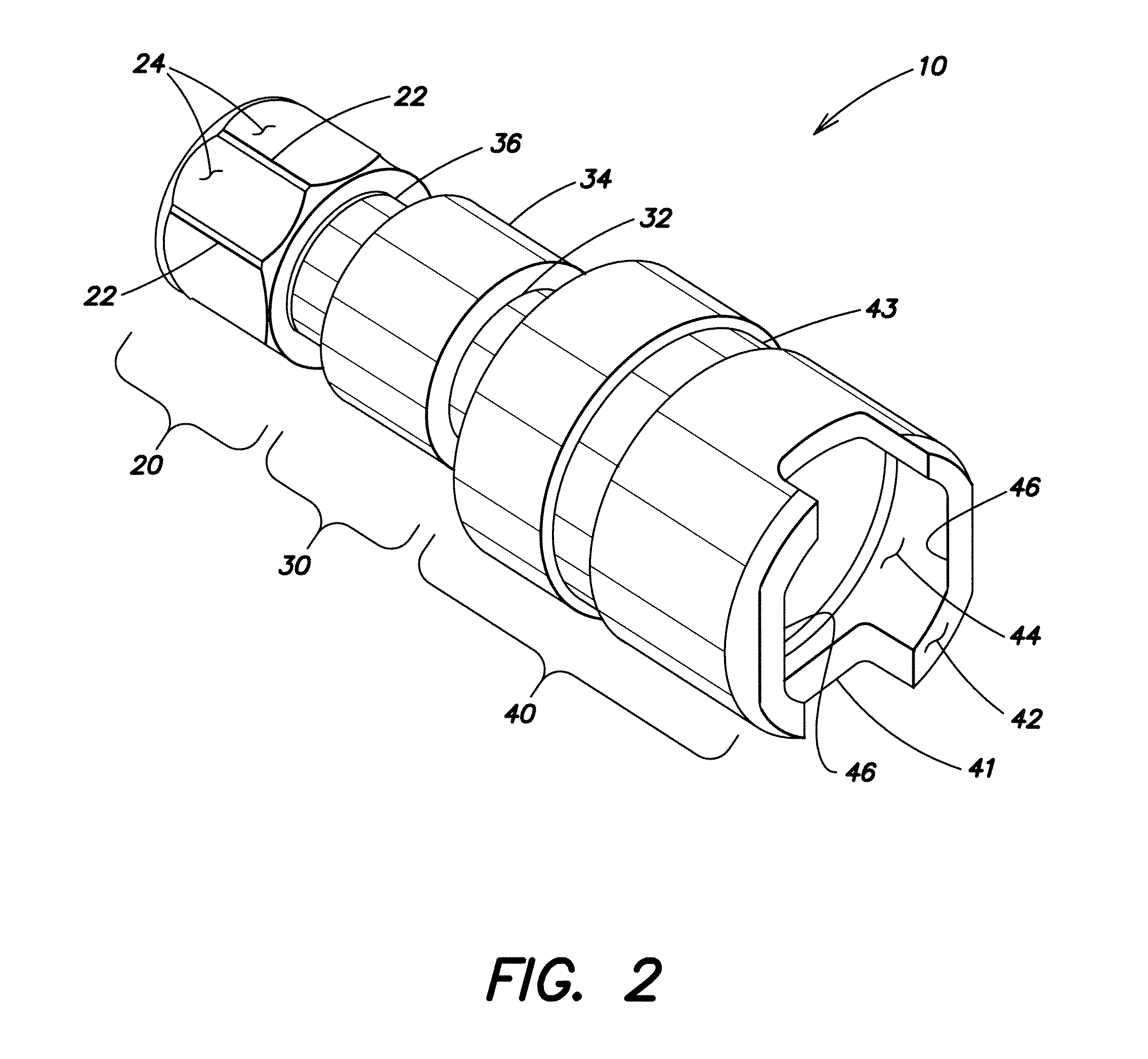

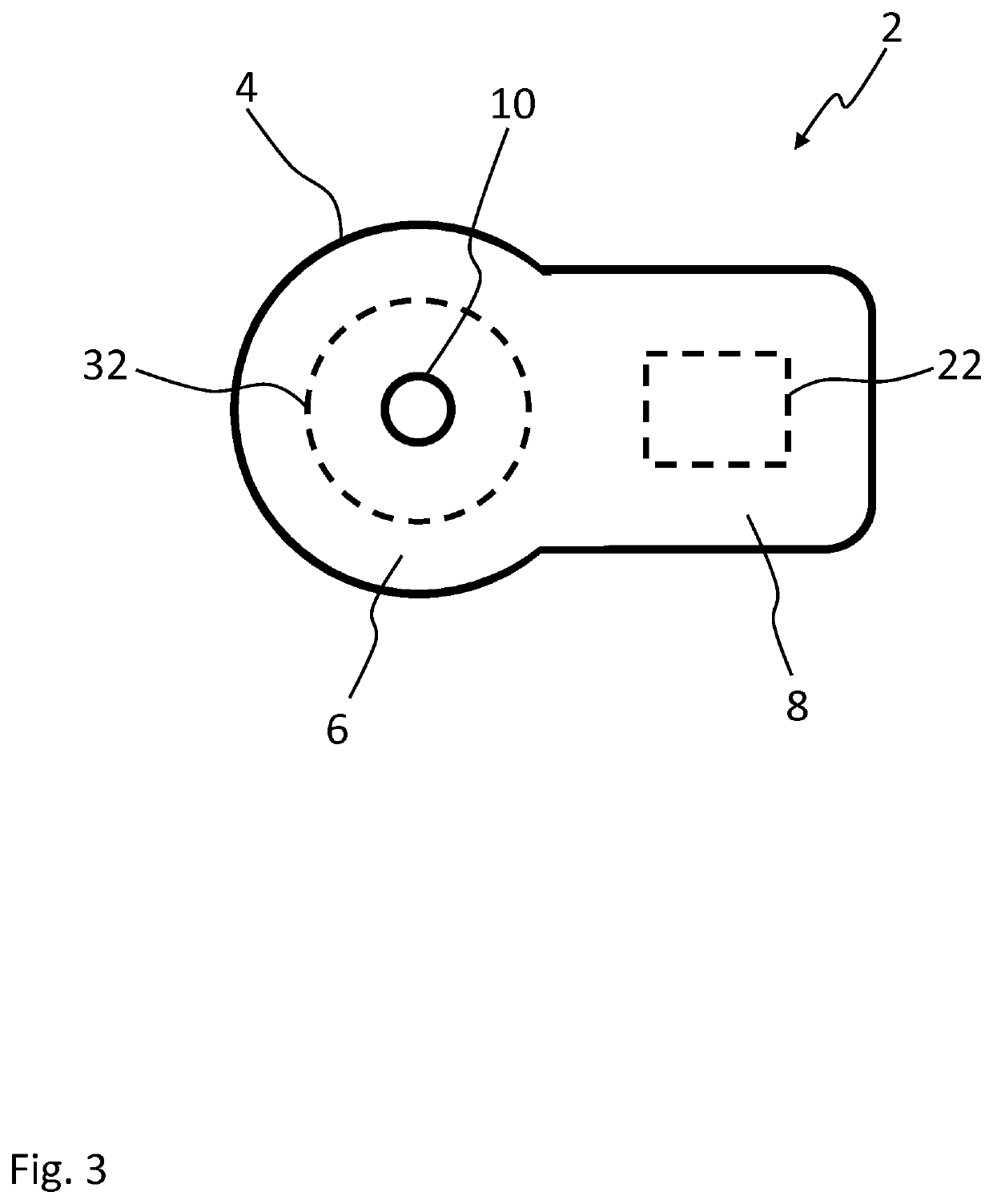

Adapter for transmitting a torque to the mounting part of a dental implant

Adapter (10, 110) for transmitting a torque from a screwing instrument to a mounting part of a dental implant, in particular for screwing the dental implant into a bone or for screwing the mounting part into an anchoring part. The adapter (10, 110) has a head portion (20, 120), which can engage with the screwing instrument, and a receiving portion (40, 140). The receiving portion (40, 140) can be connected releasably to the mounting part of the dental implant. The adapter (10, 110) has at least one zone of weakness (32, 50, 132) and, above a predetermined torque Tdeform, deforms in the area of the zone of weakness (32, 50, 132).

Owner:STRAUMANN HLDG AG

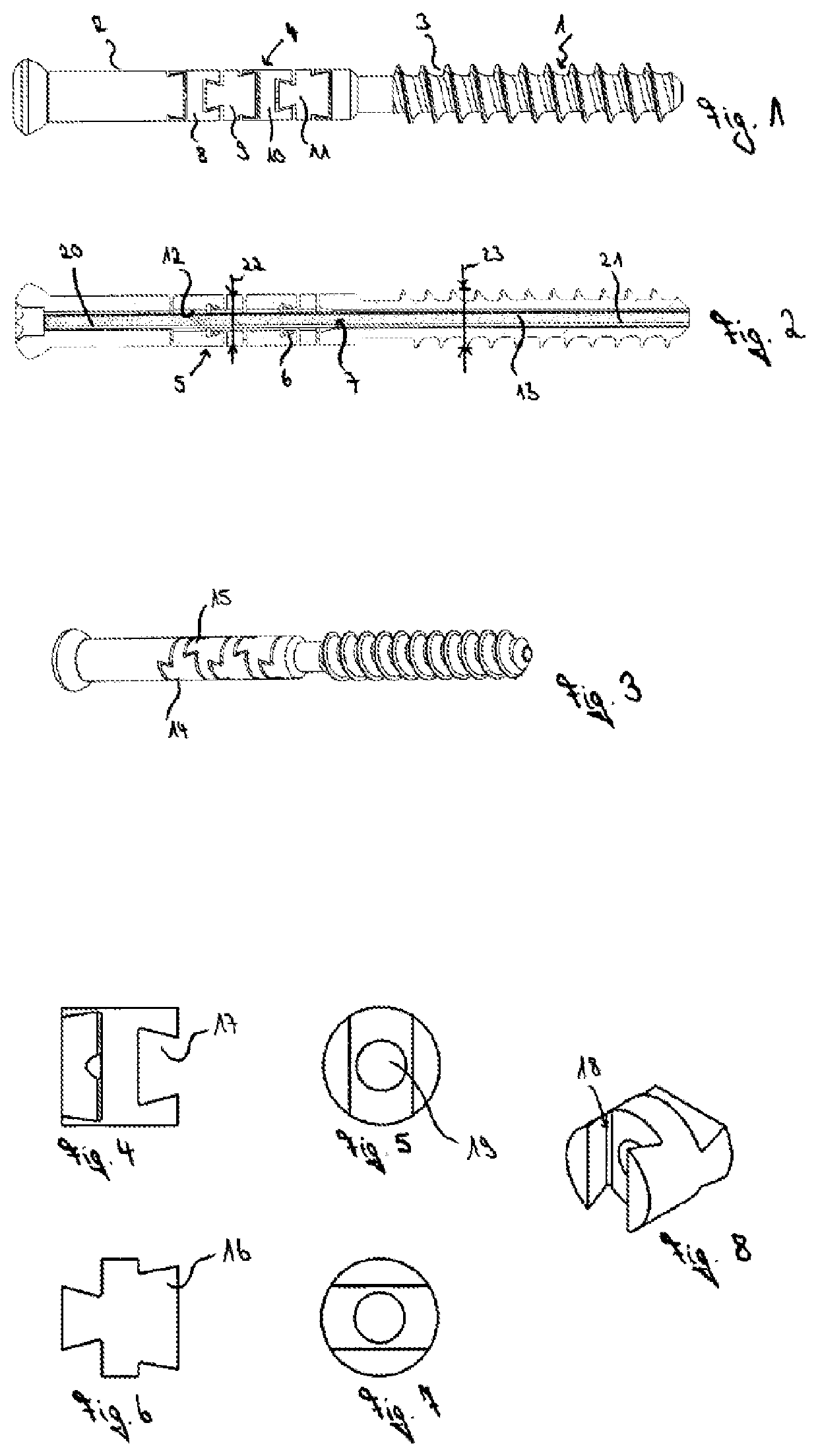

Screw

ActiveUS20180092681A1Set compactTorque transmittedInternal osteosythesisLoad modified fastenersEngineeringScrew thread

Owner:BLUEWATER MEDICAL GMBH

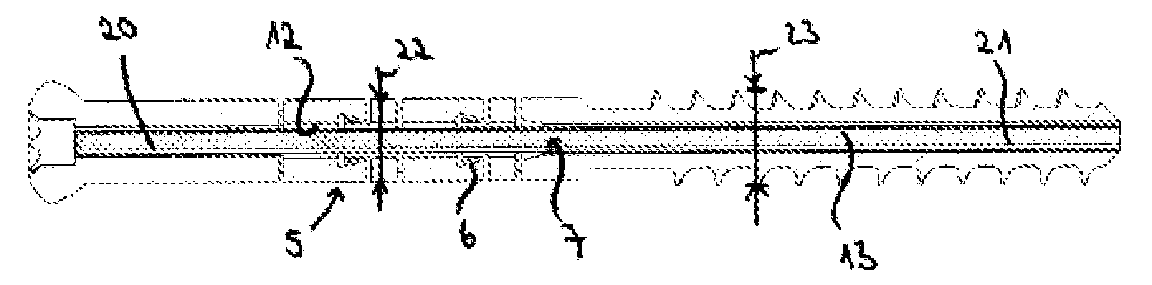

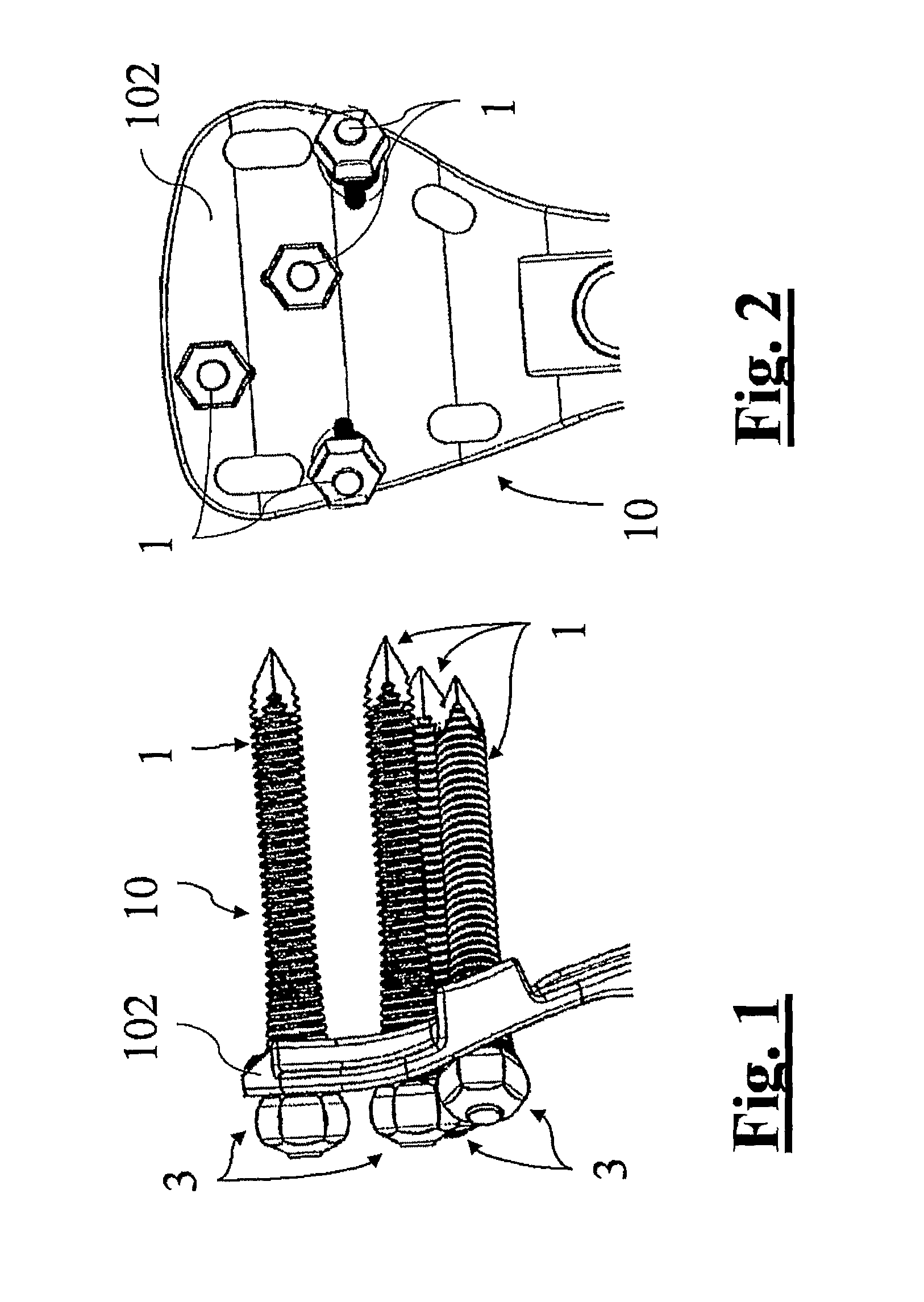

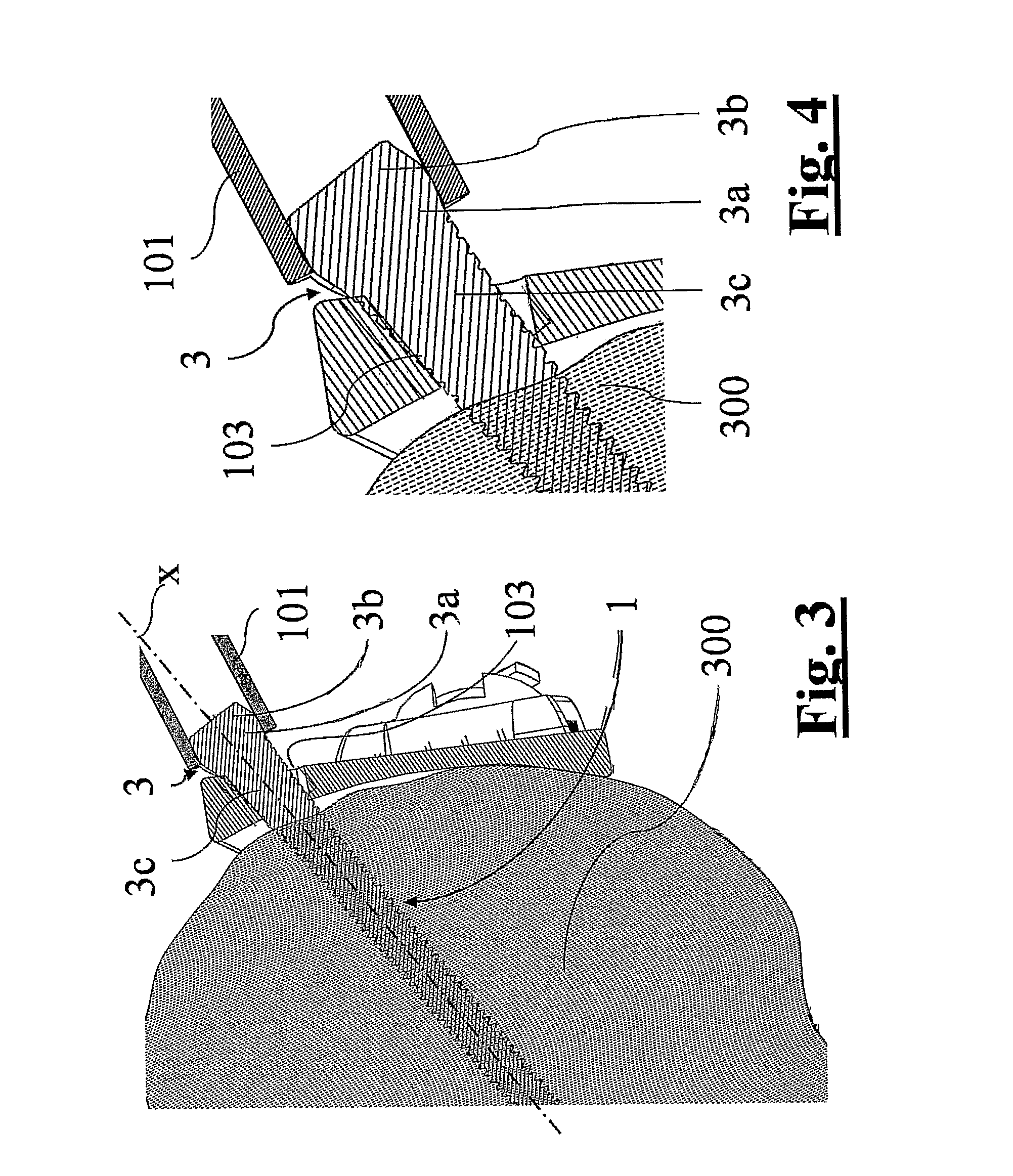

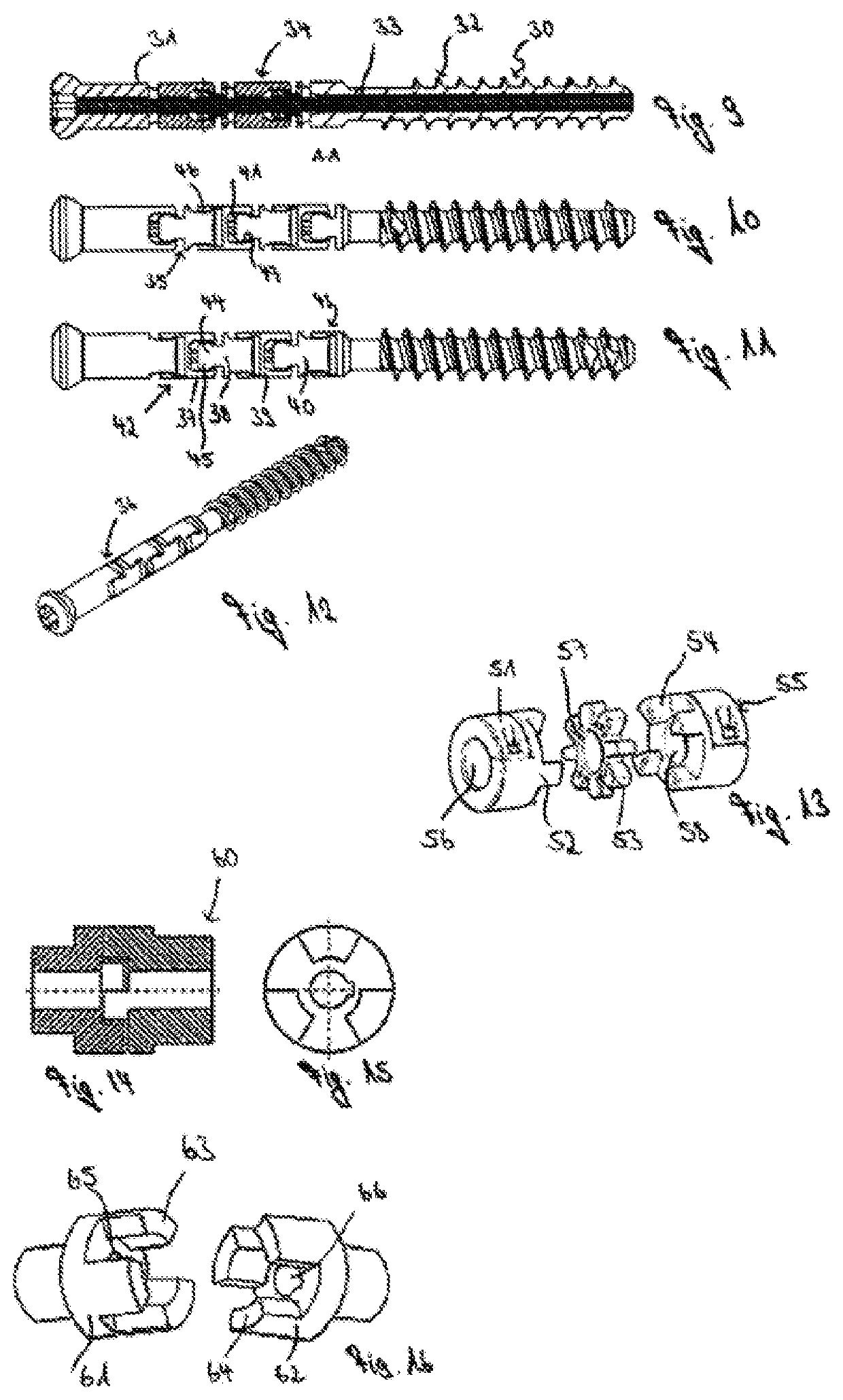

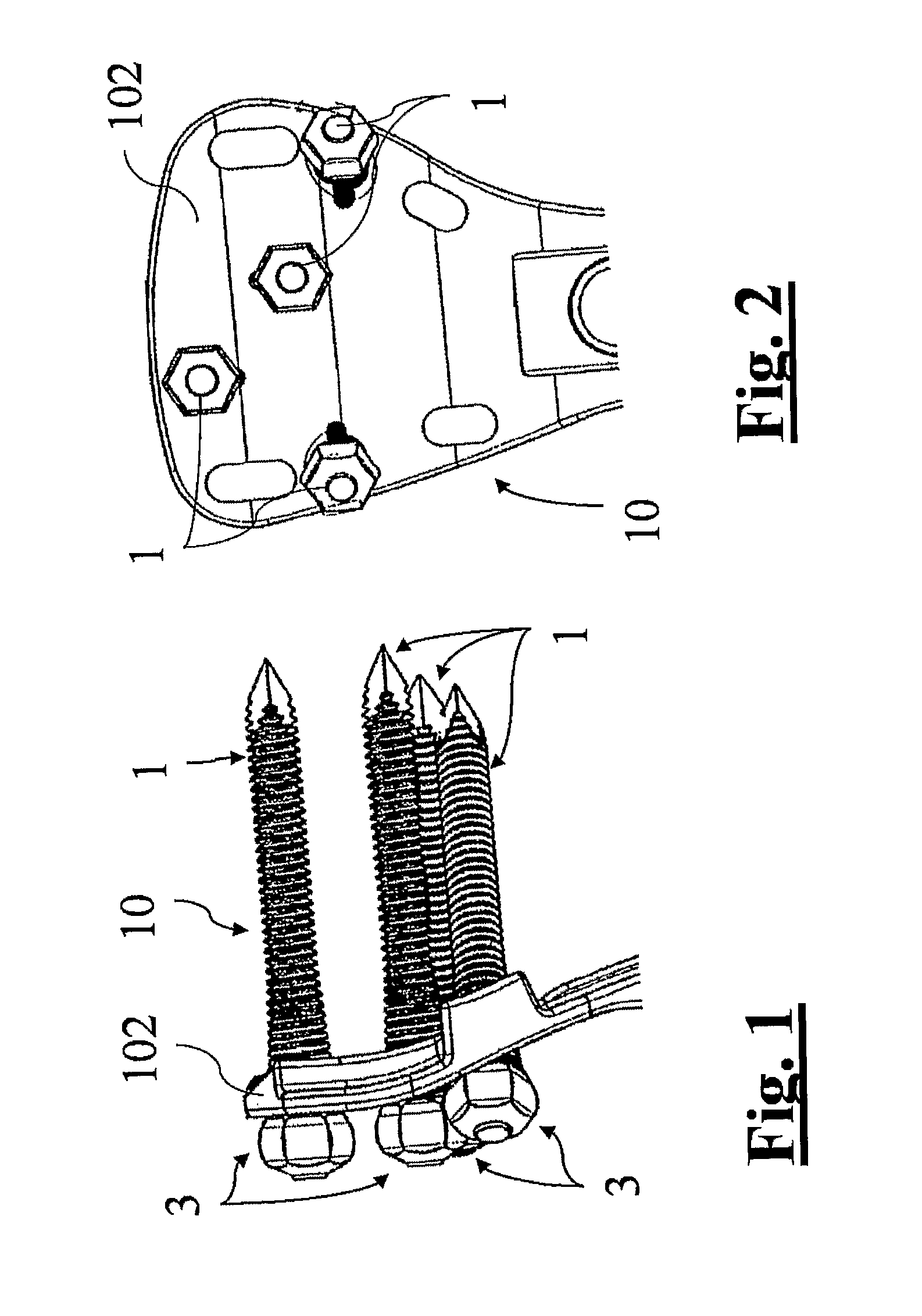

Endosseous screws and orthopaedic device to assist the rigid osteosynthesis of fractures

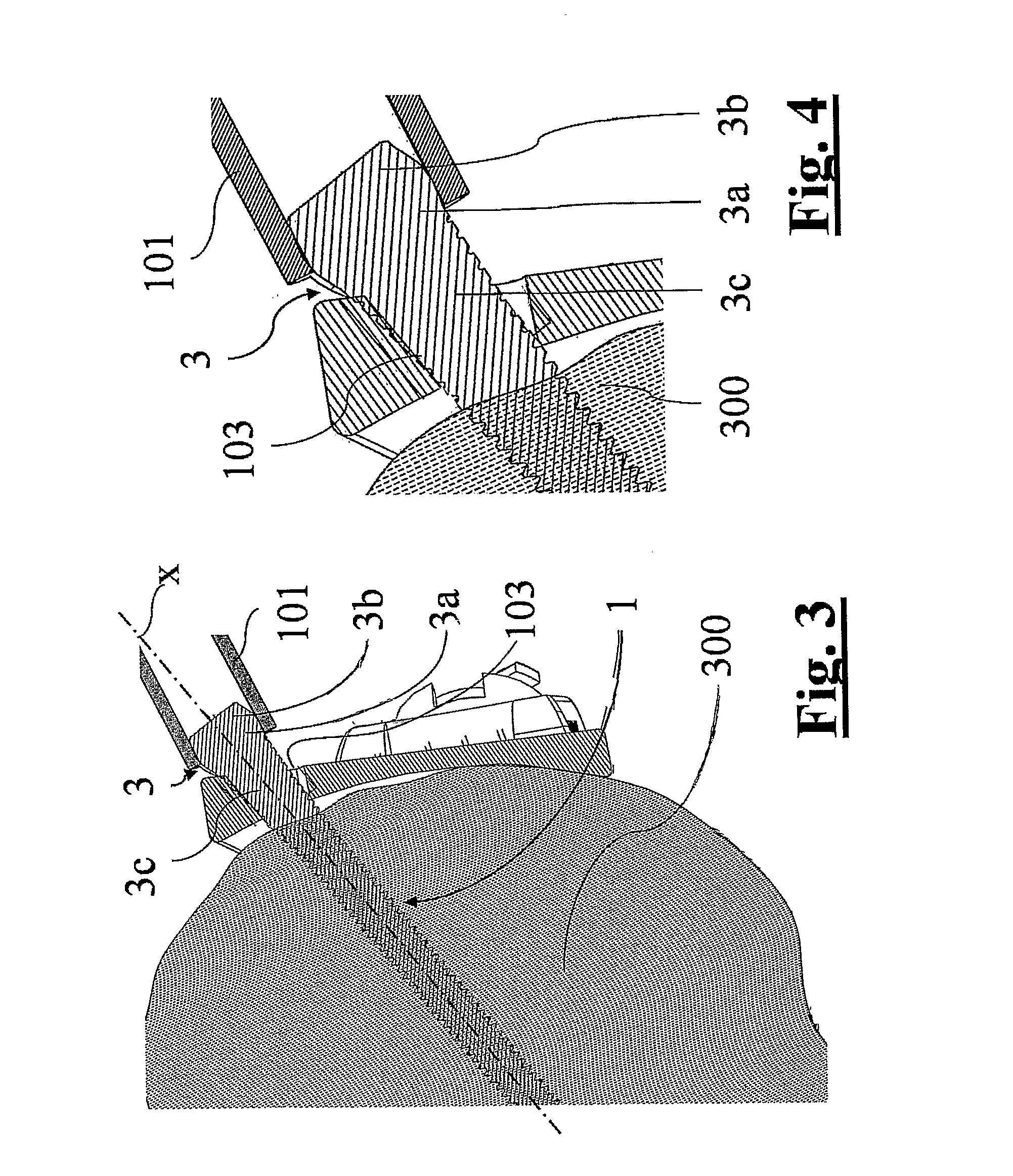

ActiveUS8852252B2Easily inserted into manipulating wrenchEasy to disassembleSuture equipmentsDiagnosticsOrthopaedic deviceCoupling

Endosseous screw (1) for fixing a plate (102) to a bone site (300), comprising an at least partially threaded shaft (2), insertion means for inserting the screw into a bone site and a distal portion (33) provided for engaging said plate to fasten it to said bone site and comprising a head (3) having facets (30) defining an external peripheral profile provided for engagement with a tubular manipulating wrench, to allow the screw (1) to be extracted from the bone site (300) into which it has been inserted, wherein the facets (30) are curvilinear and the external peripheral profile defined by same facets (30) has a convex barrel-like shape, in order to allow a stable coupling between the tubular manipulating wrench and said profile, which is maintained during the untightening phase of screw from plate, even when said tubular manipulating wrench is oriented in an inclined direction with respect to a longitudinal axis (x) of the endosseous screw (1).

Owner:ORTHOFIX SRL

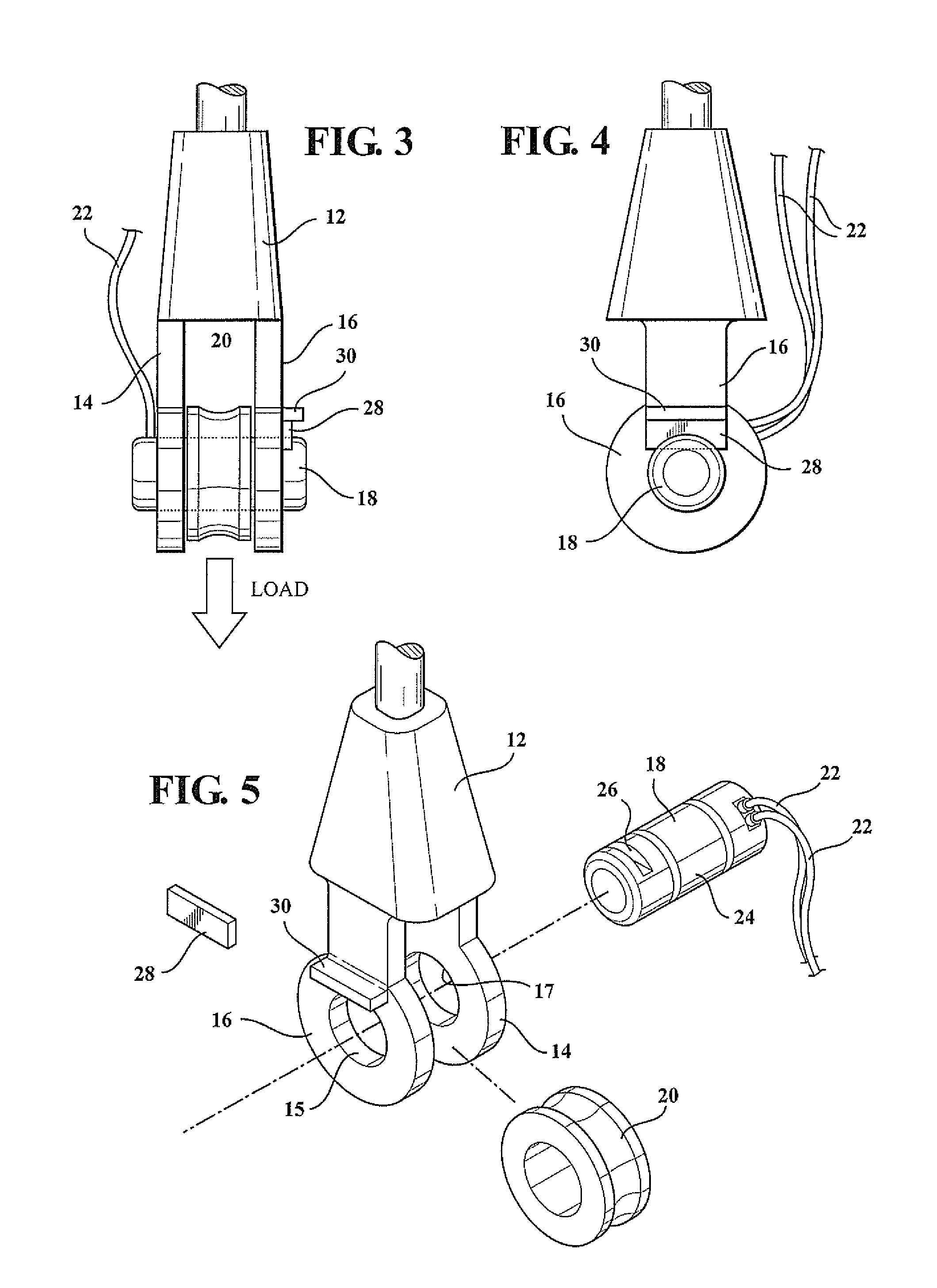

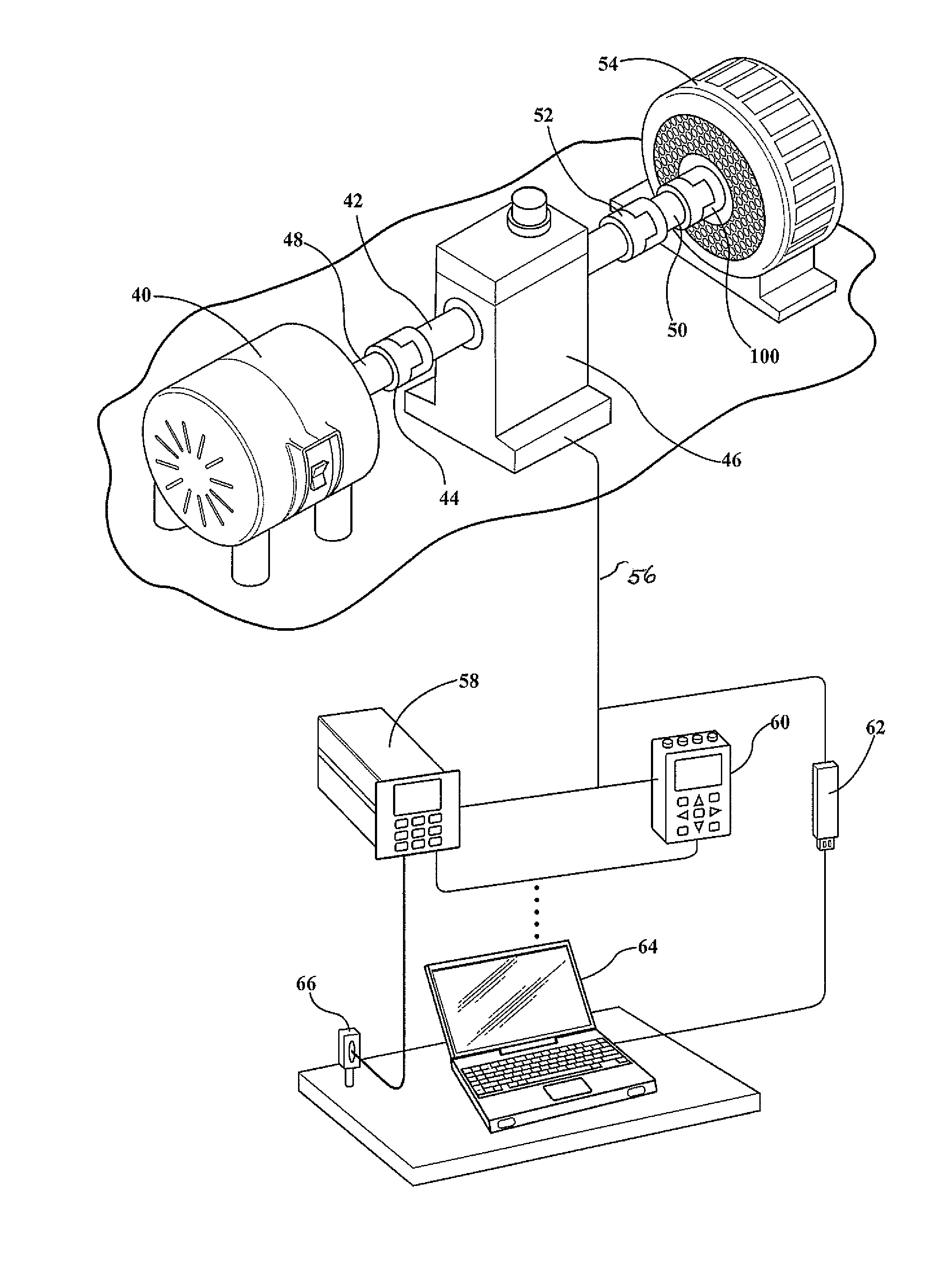

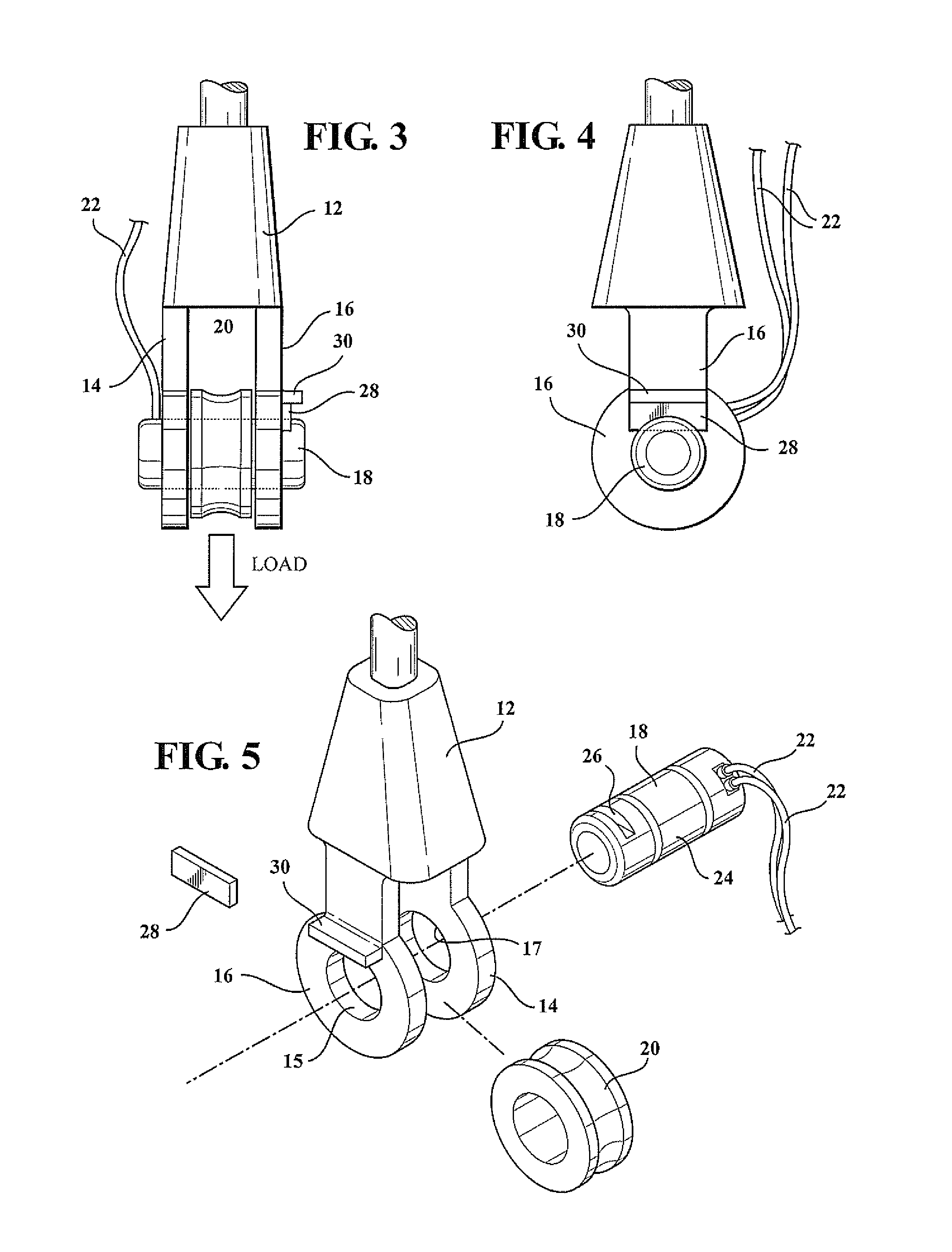

Load and torque sensing systems utilizing magnetic key for mechanical engagement

Two forms of load bearing or transmitting structures are disclosed wherein each uses magnetism to hold a key in one of two bodies to prevent movement therebetween. One embodiment is a clevis, wherein the clevis pin is instrumented as a load cell and a magnetic key resides in a slot in a portion of the clevis pin which protrudes outside of one of the clevis legs. In another embodiment, torque is transmitted between a shaft and a coupling by means of keys that are held in keyways by magnetism thereby to provide a torque coupling between the shaft and coupling members.

Owner:FUTEK ADVANCED SENSOR TECH

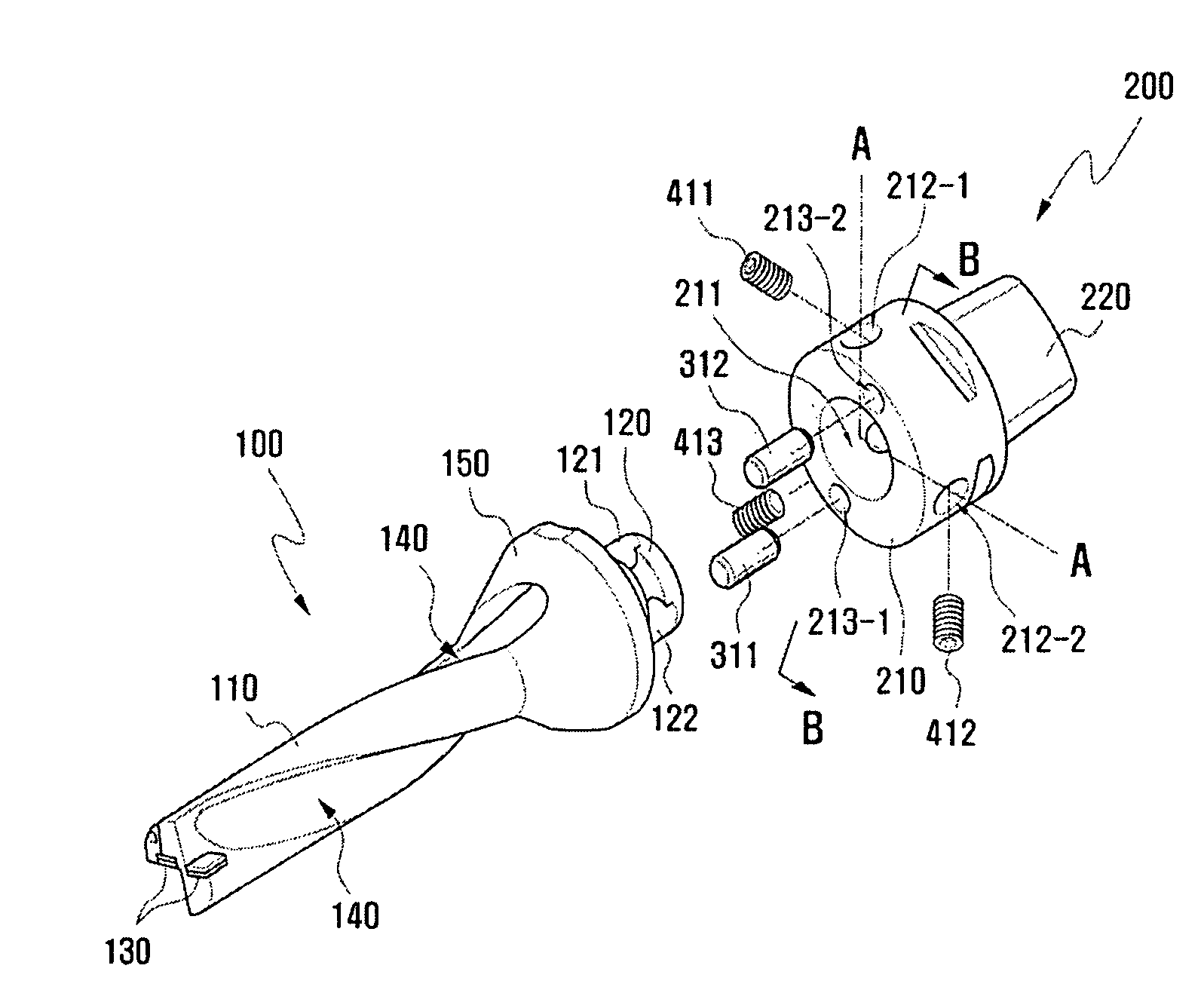

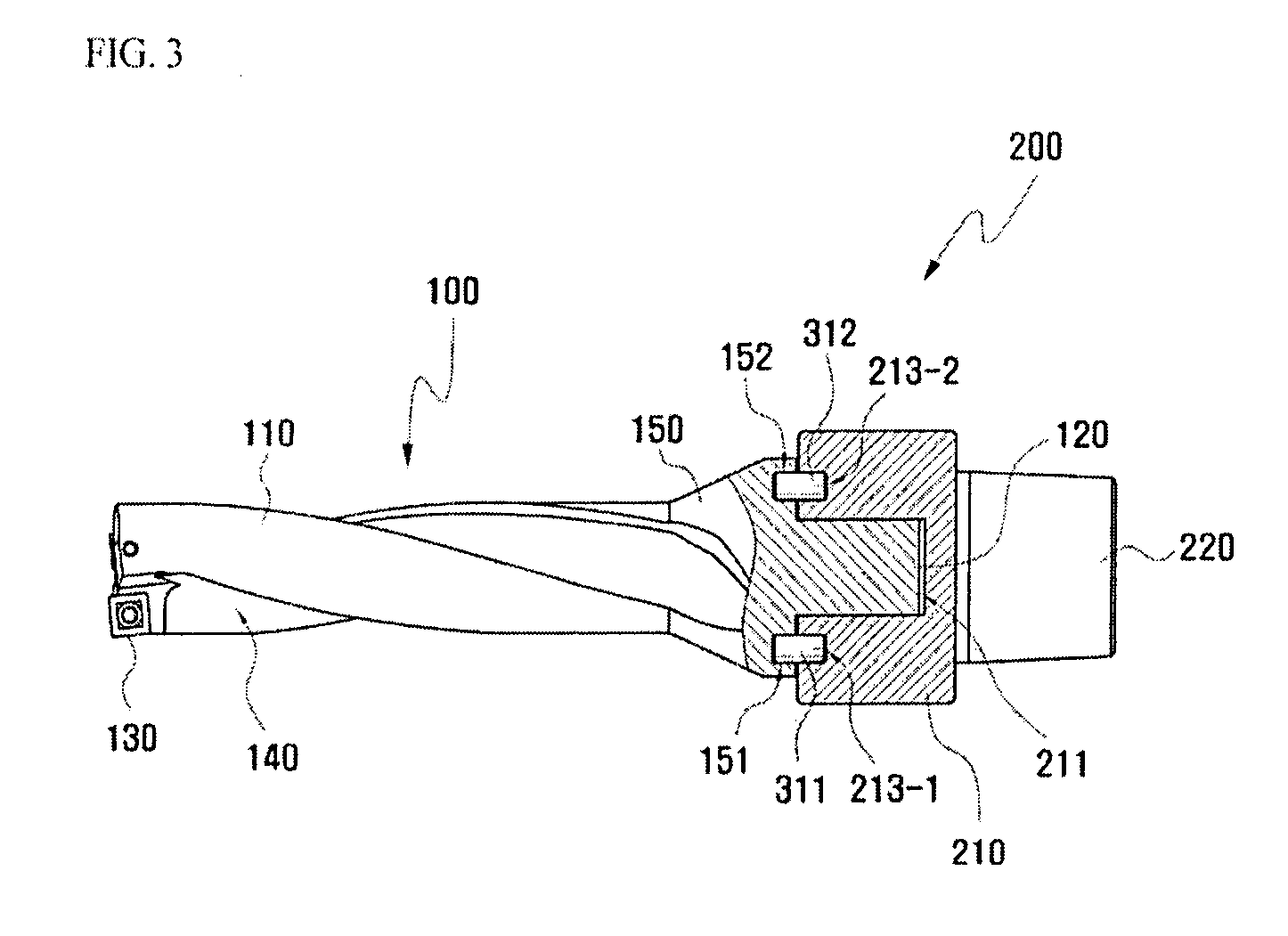

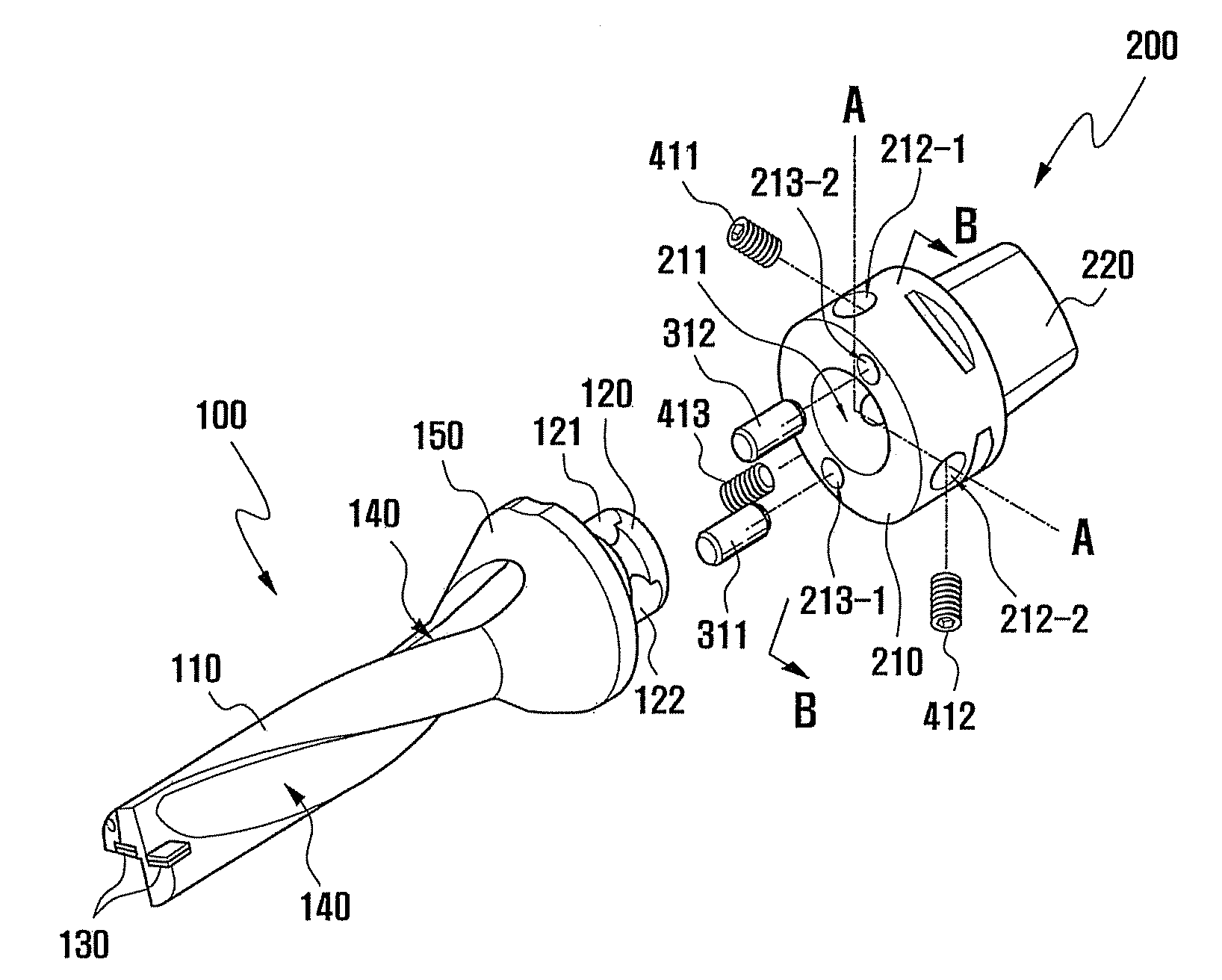

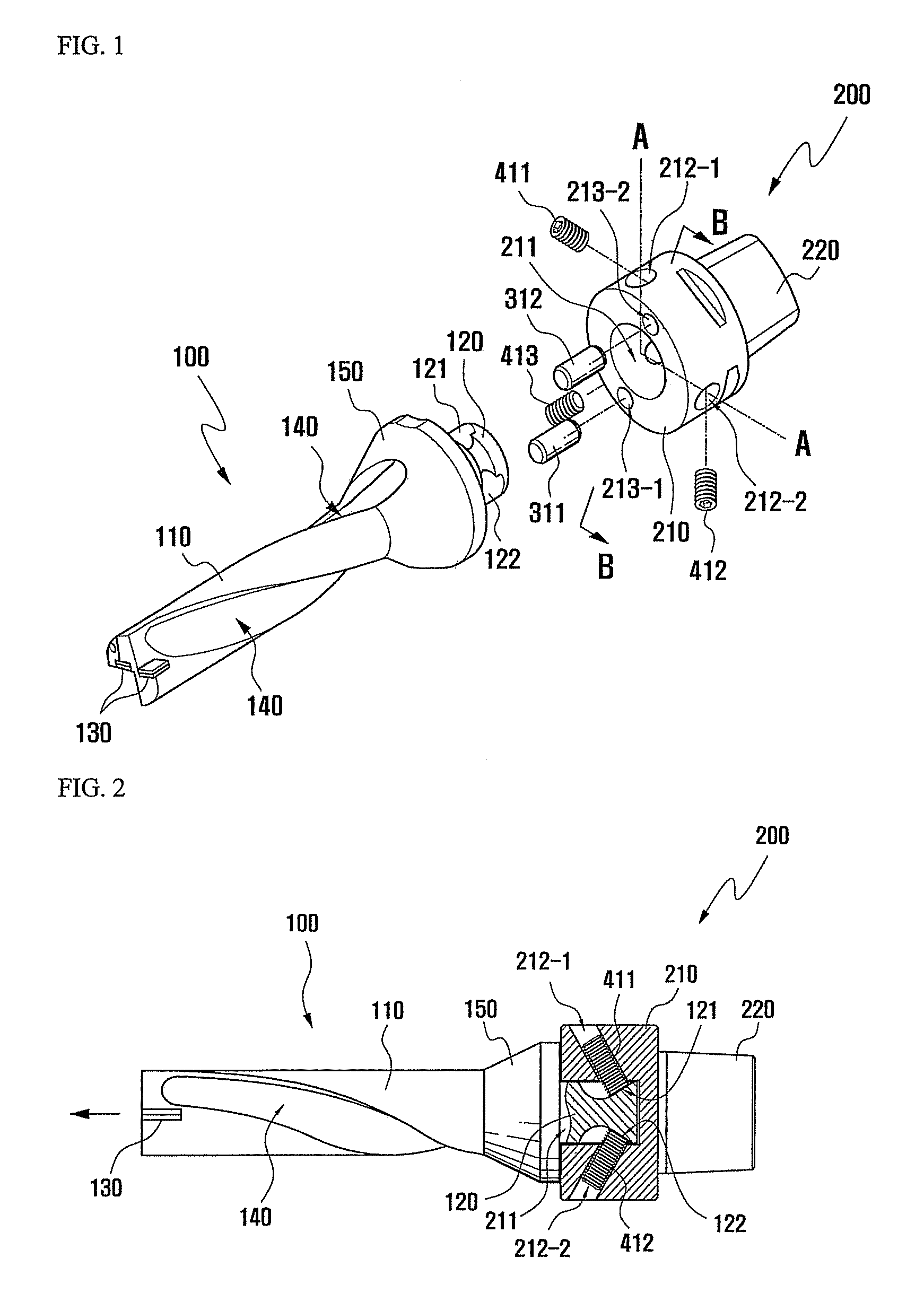

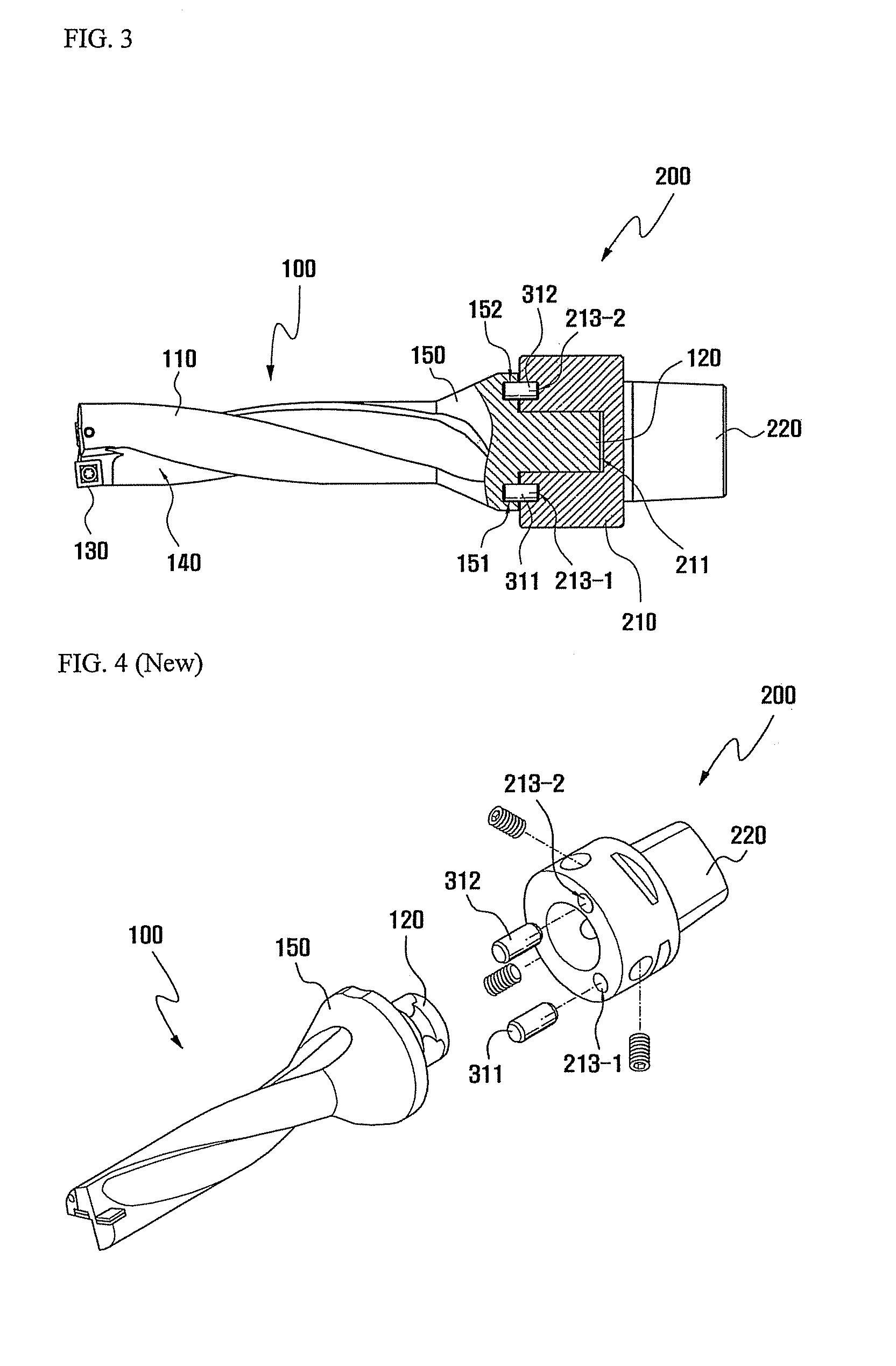

Tool assembly

InactiveUS20080279645A1Reduce working lengthSecure couplingThread cutting toolsTransportation and packagingCouplingEngineering

The present invention discloses a tool assembly being capable of reducing considerably an axial length of a working member (tool), in particular, a length of a male spigot to be coupled with a coupling member and transmitting a torque to a working member without generating a loss by means of a secure coupling between a male spigot of a working member (tool) having a short length and a coupling member. A tool assembly according to the present invention comprises a tool including a head to be approached to a work-piece, a male spigot extended from a rear end of the head and a flange formed at a border portion between the head and the male spigot and having a ring shaped flat rear surface; and a coupling member consisting of a first section having a cavity formed on a central portion of a front side thereof for receiving the male spigot and a second section formed at a rear side of the first section and connected to a driving means. The male spigot has a tapered surface formed on a side thereof, a through hole communicated with the cavity is formed on a side of the first section of the coupling member, and an end of a coupling screw coupled with the through holes is capable of pressurizing the tapered surface of the male spigot received in the cavity.

Owner:TAEGUTEC

Screw

ActiveUS10610276B2Torque transmittedInternal osteosythesisLoad modified fastenersEngineeringScrew thread

Owner:BLUEWATER MEDICAL GMBH

Tool Assembly

InactiveUS7520704B2Reduce working lengthSecure couplingThread cutting toolsTransportation and packagingCouplingFlange

Owner:TAEGUTEC

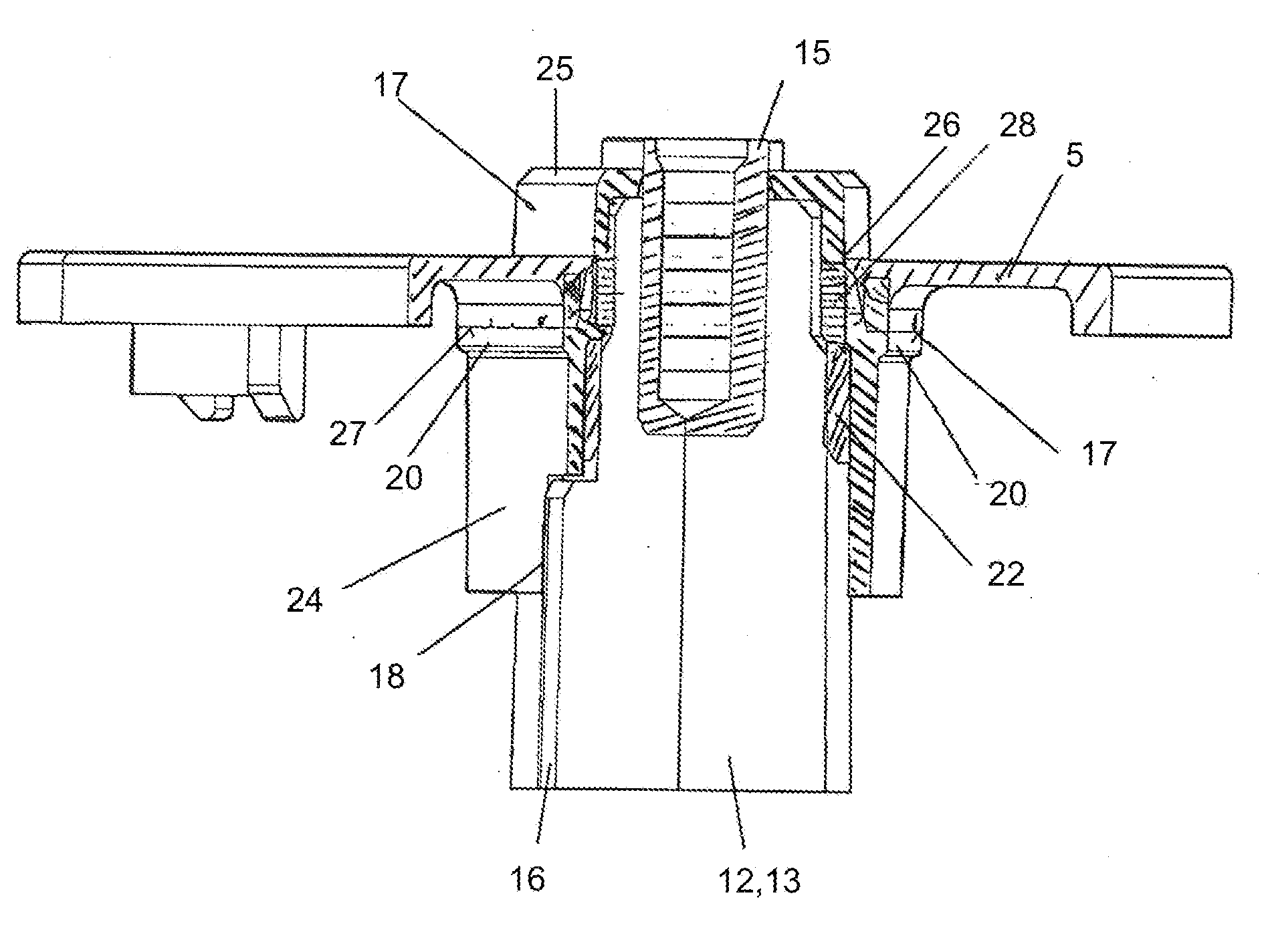

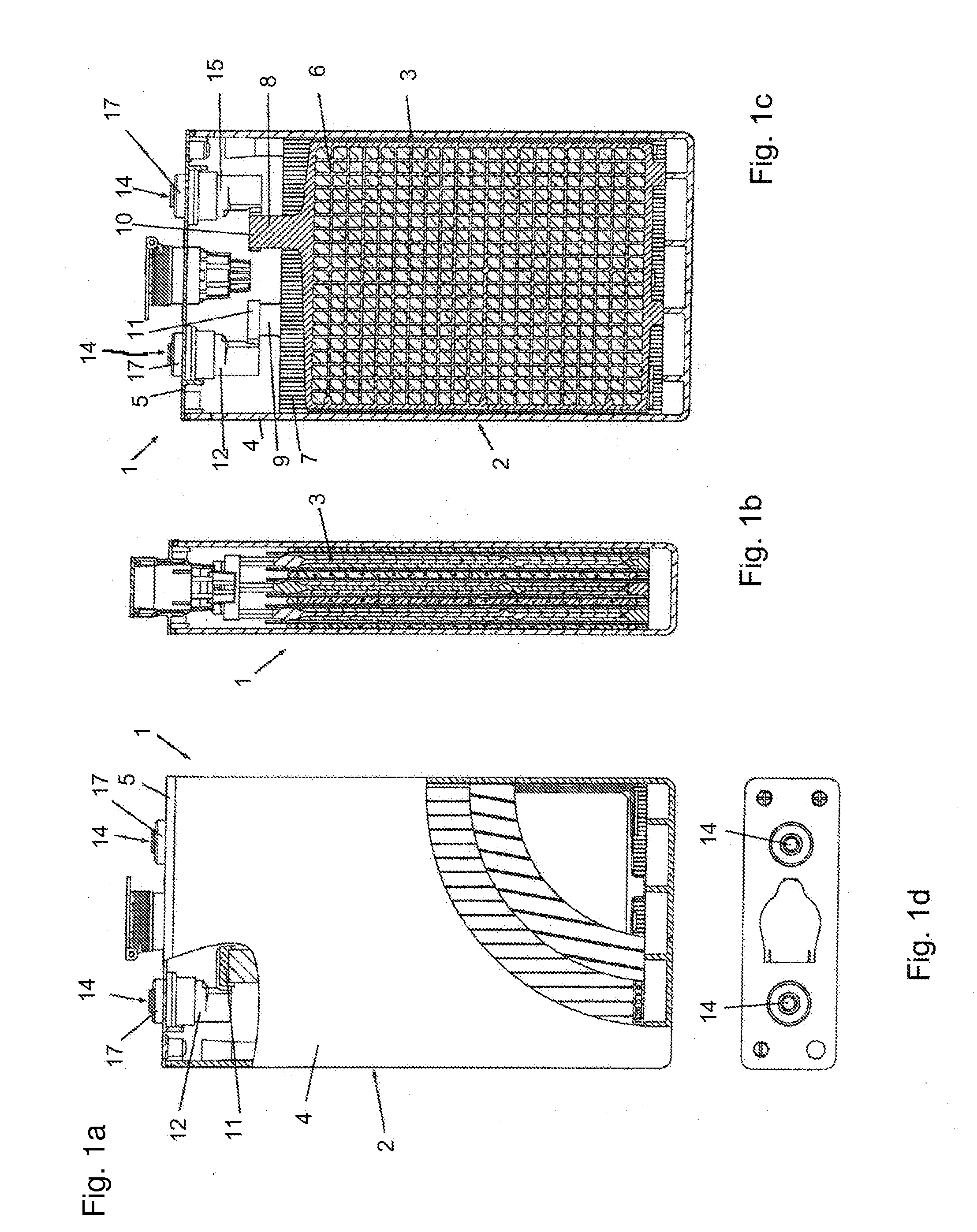

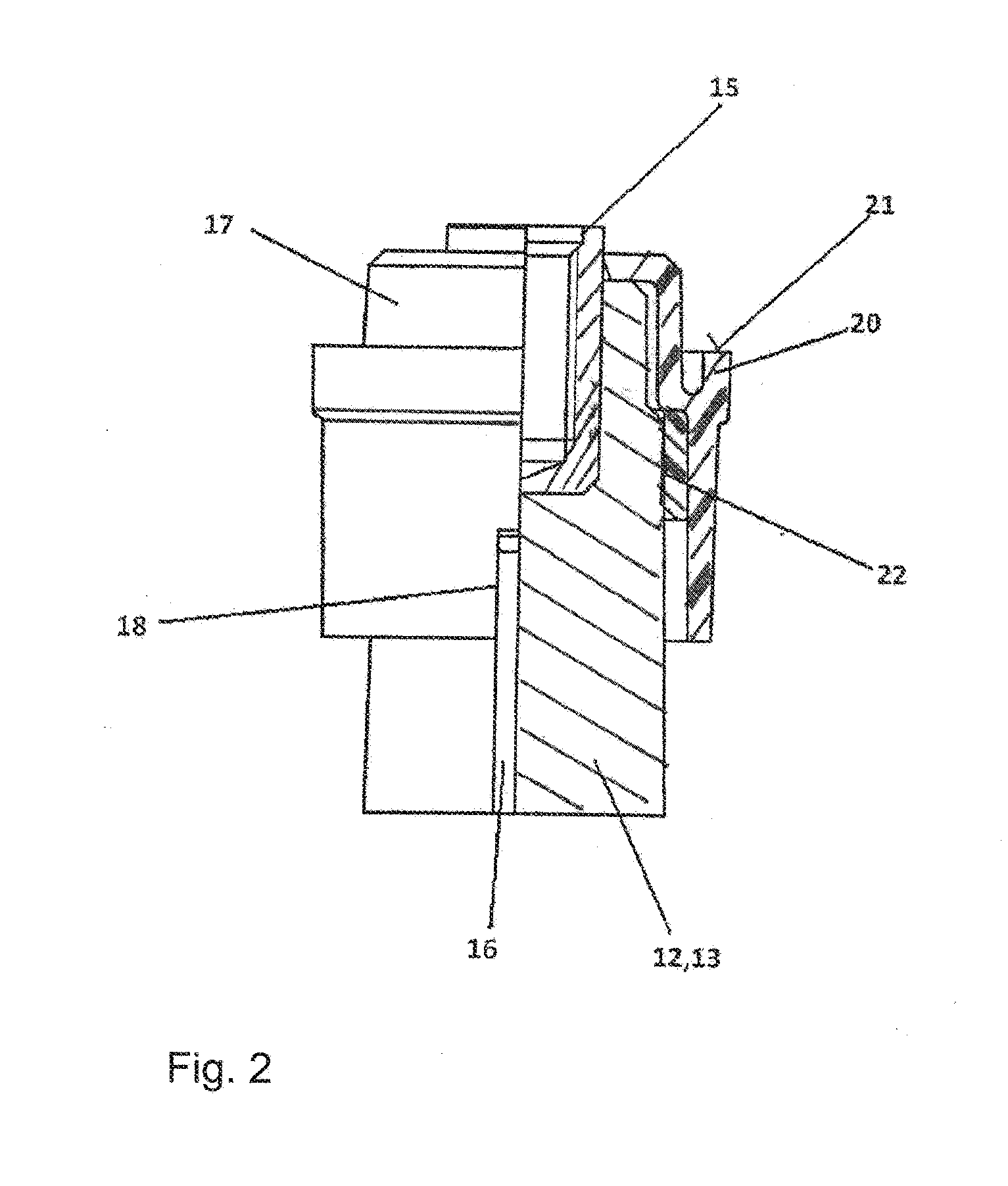

Battery Cell for a Battery, Especially for a Traction Battery

ActiveUS20160020440A1Relieve stressEliminate riskPrimary cell to battery groupingCurrent conducting connectionsPlastic materialsNonferrous metal

A battery cell has an electrode plate pack arranged in a casing and provided with a terminal of lead material that extends through a cover opening of the casing cover of the casing. A plastic material cap is placed onto the terminal. The cap has an inner side provided with a circumferentially extending shoulder and an exterior side provided with a circumferentially extending support web. A sealing element is arranged at the inner side of the cap between cap and terminal and is positionally fixed by the circumferentially extending shoulder. The casing cover rests on the circumferentially extending support web. Cap and casing cover are welded to each other. A threaded sleeve of nonferrous metal is embedded in the lead material of the terminal and is aligned with an insertion opening of the cap. The threaded sleeve receives a connecting screw to be passed through the insertion opening.

Owner:HOPPECKE BATTERIEN

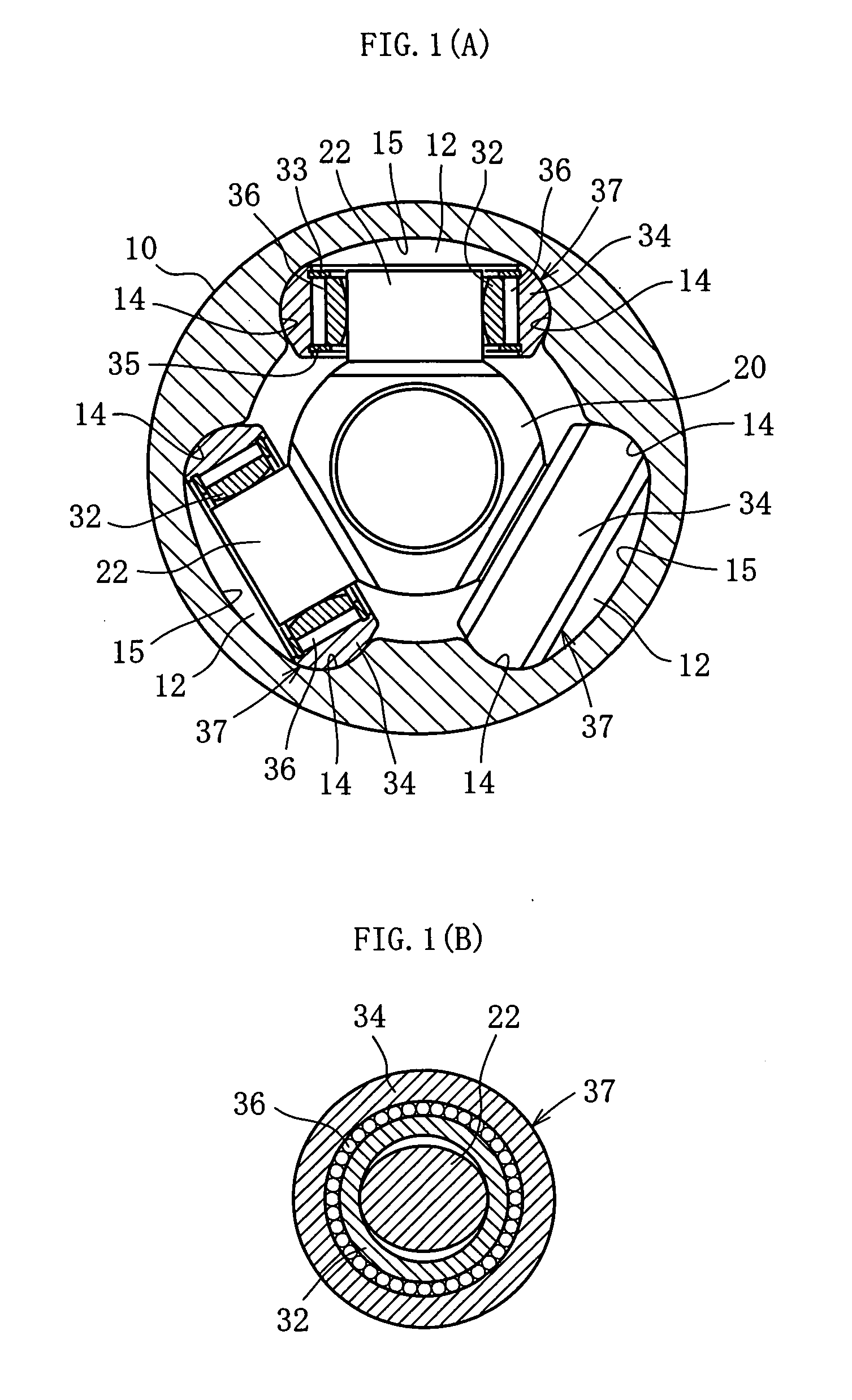

Constant velocity universal joint

ActiveUS20050014565A1Torque transmittedExtended service lifeYielding couplingRotary machine partsUniversal jointCoupling

In a no-flange type outer joint member, the amount of abrasion in a large inner diameter portion formed for a track groove is intended to be restrained. In a tripod type constant velocity universal joint including: a no-flange type outer joint member; and a roller assembly including a roller, being attached to a trunnion so as to be capable of oscillating, hardened layers are formed on portions of a large inner diameter portion of the outer joint member, which are in contact with an inclined roller assembly. In this case, a value of F / D is set equal to or less than 0.45, where a distance from a center of the track groove of the outer joint member to the ends of both the hardened layers on the side of the center of the track groove is F, and a diameter of an outer circumference of the roller assembly is D.

Owner:NTN CORP

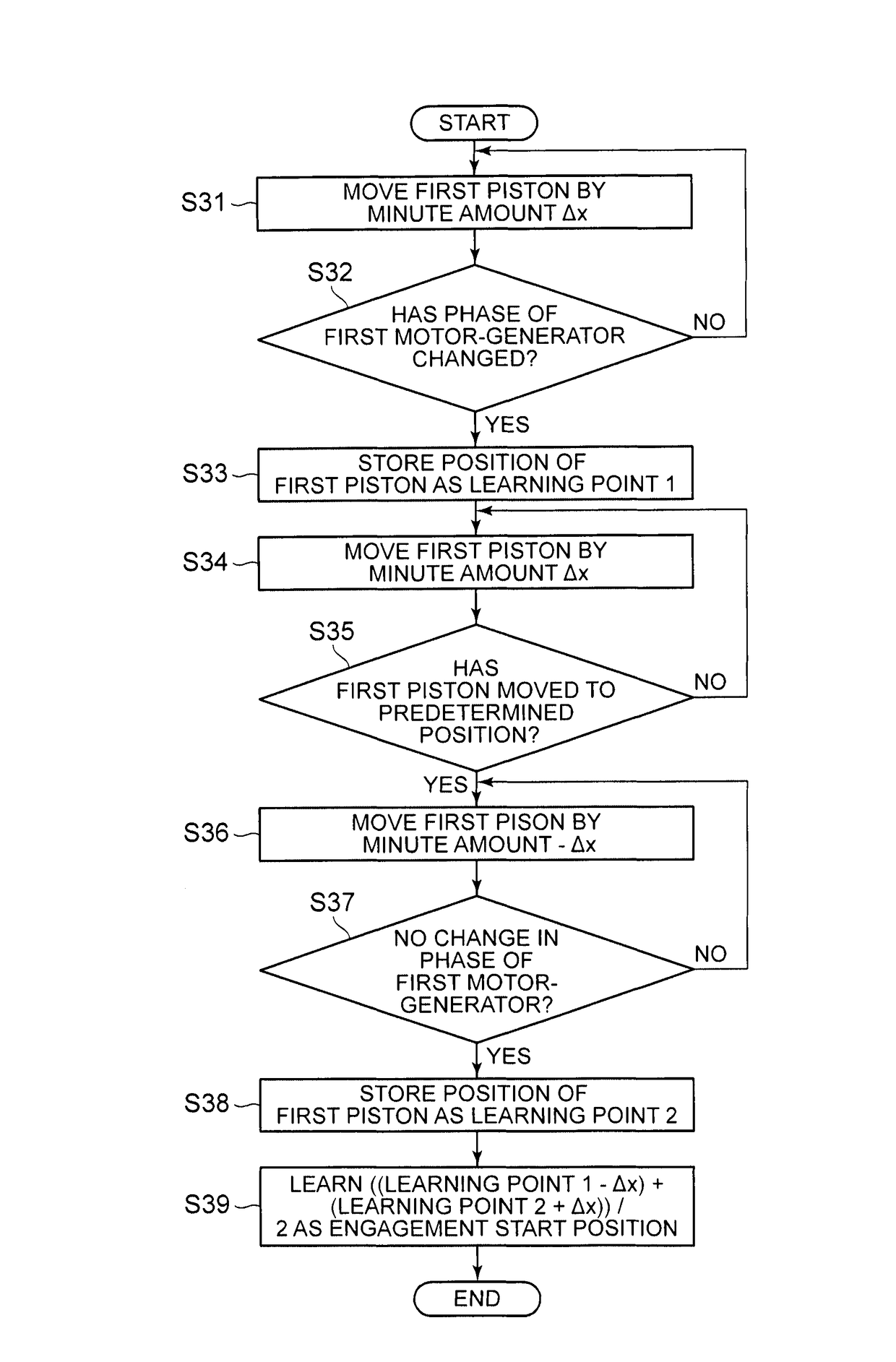

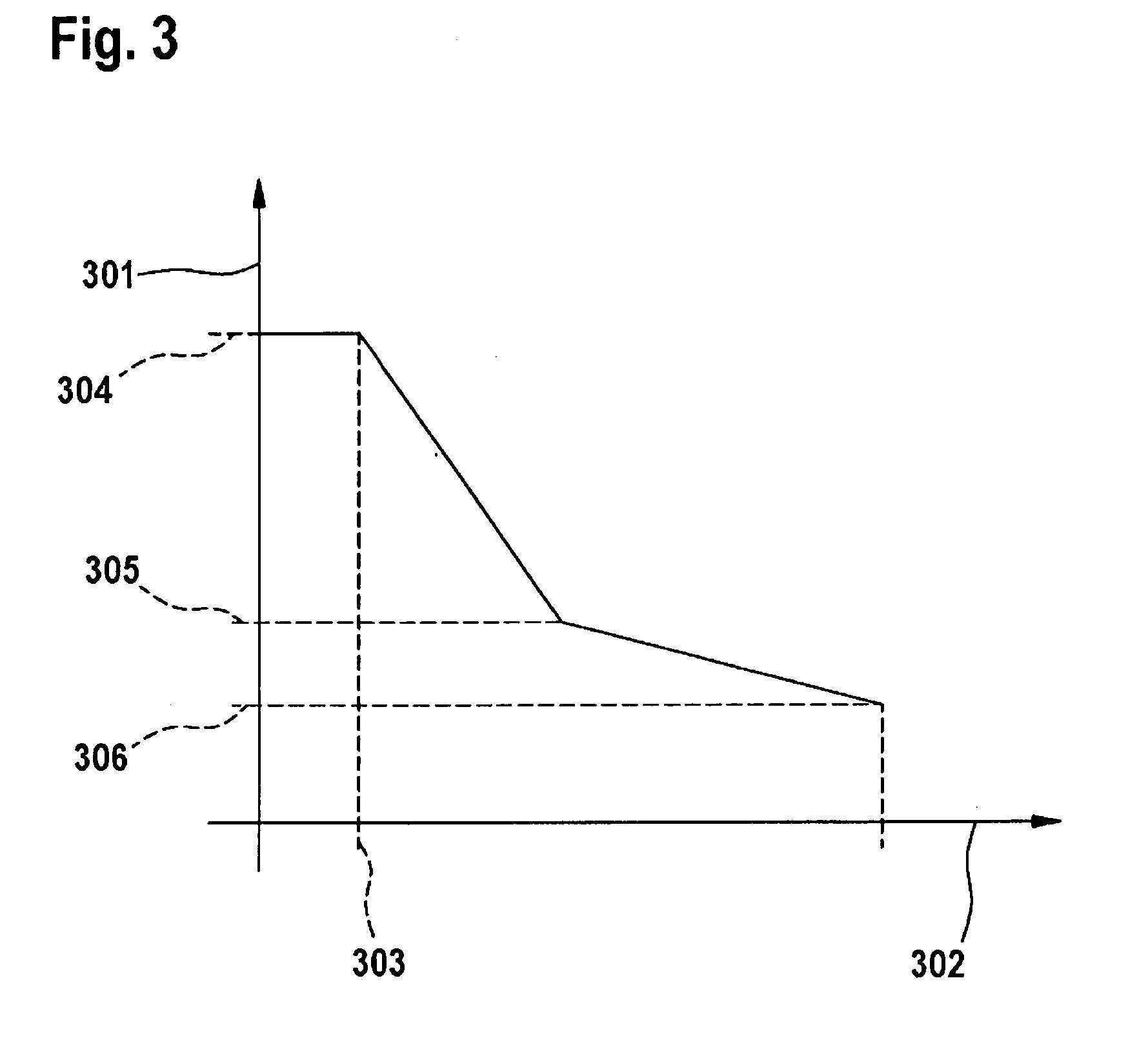

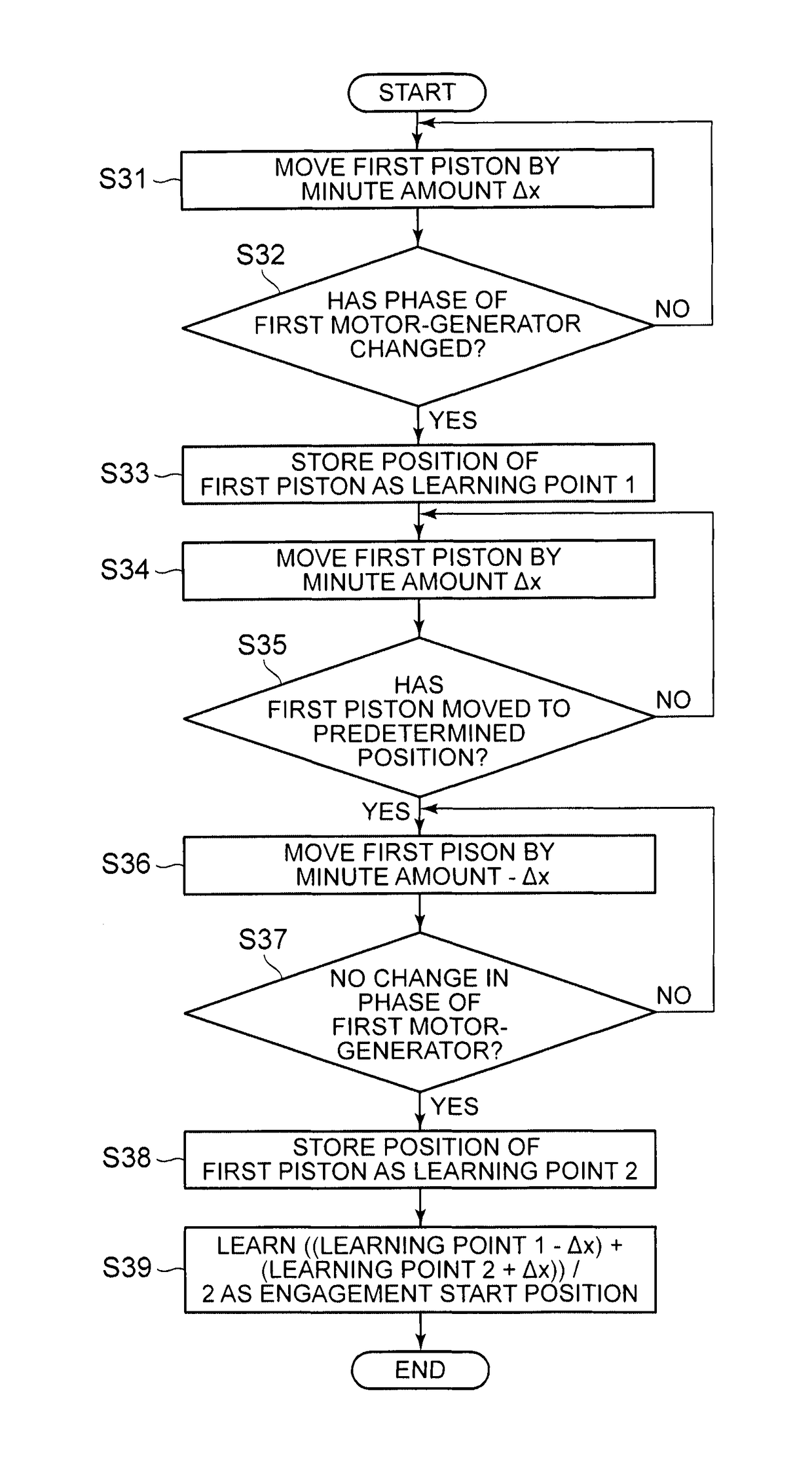

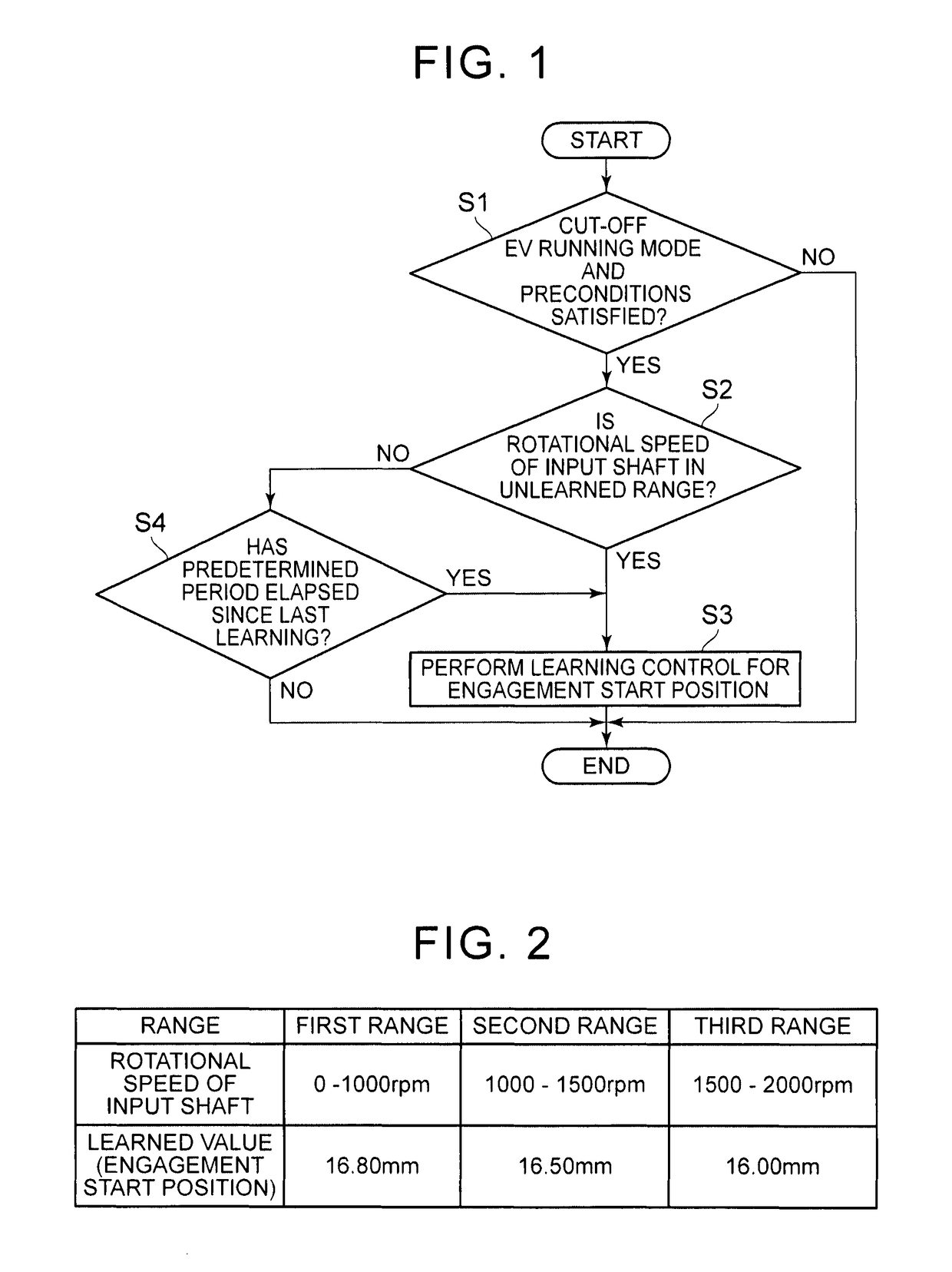

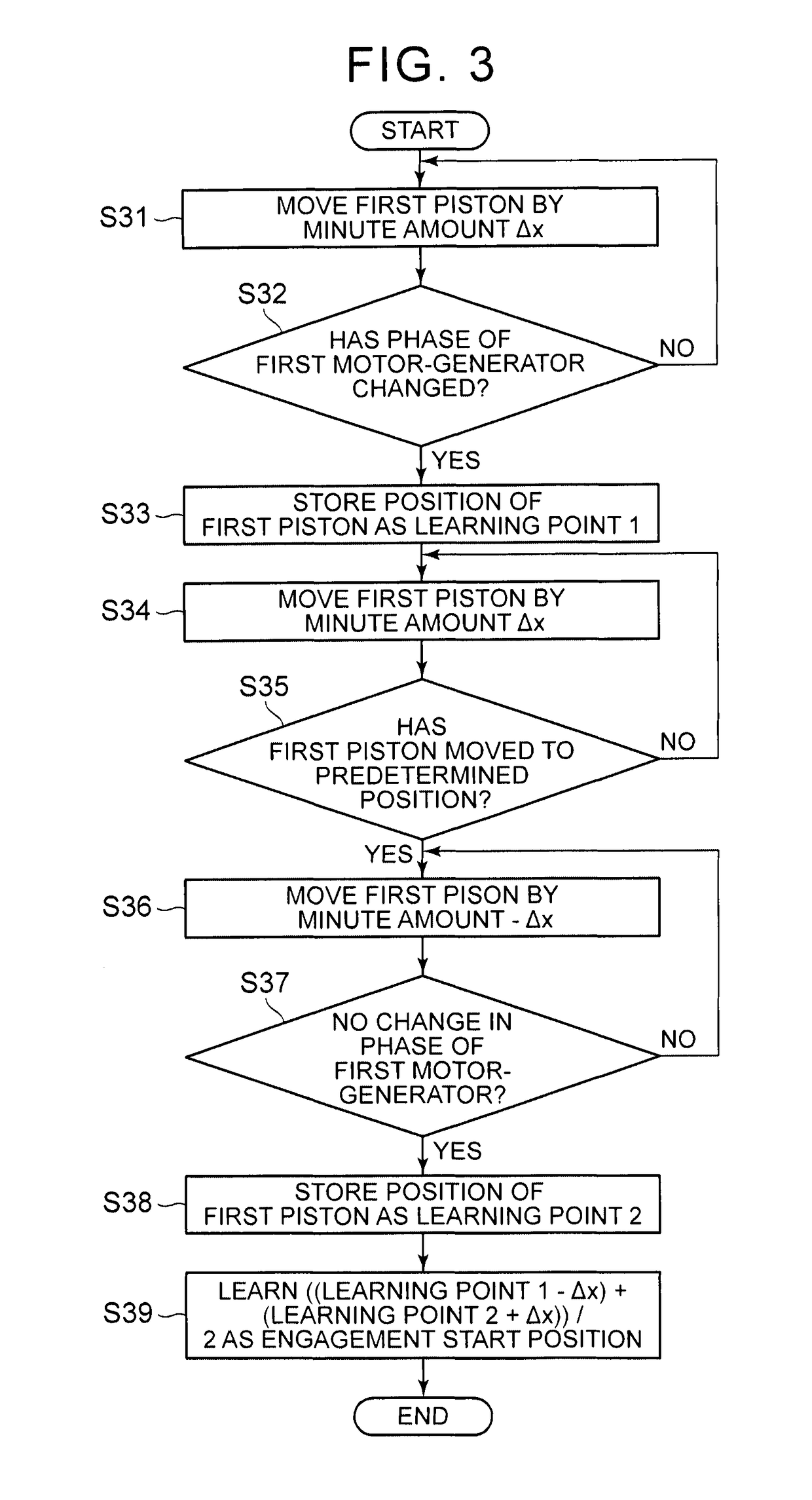

Control system for clutch

ActiveUS20170089412A1Reduce frequencyReduce controlFluid actuated clutchesPistonElectronic control unit

A control system is for a clutch mechanism. The clutch mechanism includes a first engaging element, a second engaging element, and a piston. The first engaging element is configured to be moved according to change of a position of the piston. The first engaging element and the second engaging element are coupled to each other such that torque can be transmitted from the first engaging element to the second engaging element. The control system comprises an electronic control unit. The electronic control unit is configured to learn an engagement start position, according to a rotational speed of one of the first engaging element and the second engaging element. The engagement start position is a position of the first engaging element at the time when the first engaging element and the second engaging element start contacting with each other.

Owner:TOYOTA JIDOSHA KK

Endosseous screws and orthopaedic device to assist the rigid osteosynthesis of fractures

ActiveUS20110245882A1Easily inserted into manipulating wrenchEasy to disassembleSuture equipmentsDiagnosticsOrthopaedic deviceCoupling

Endosseous screw (1) for fixing a plate (102) to a bone site (300), comprising an at least partially threaded shaft (2), insertion means for inserting the screw into a bone site and a distal portion (33) provided for engaging said plate to fasten it to said bone site and comprising a head (3) having facets (30) defining an external peripheral profile provided for engagement with a tubular manipulating wrench, to allow the screw (1) to be extracted from the bone site (300) into which it has been inserted, wherein the facets (30) are curvilinear and the external peripheral profile defined by same facets (30) has a convex barrel-like shape, in order to allow a stable coupling between the tubular manipulating wrench and said profile, which is maintained during the untightening phase of screw from plate, even when said tubular manipulating wrench is oriented in an inclined direction with respect to a longitudinal axis (x) of the endosseous screw (1).

Owner:ORTHOFIX SRL

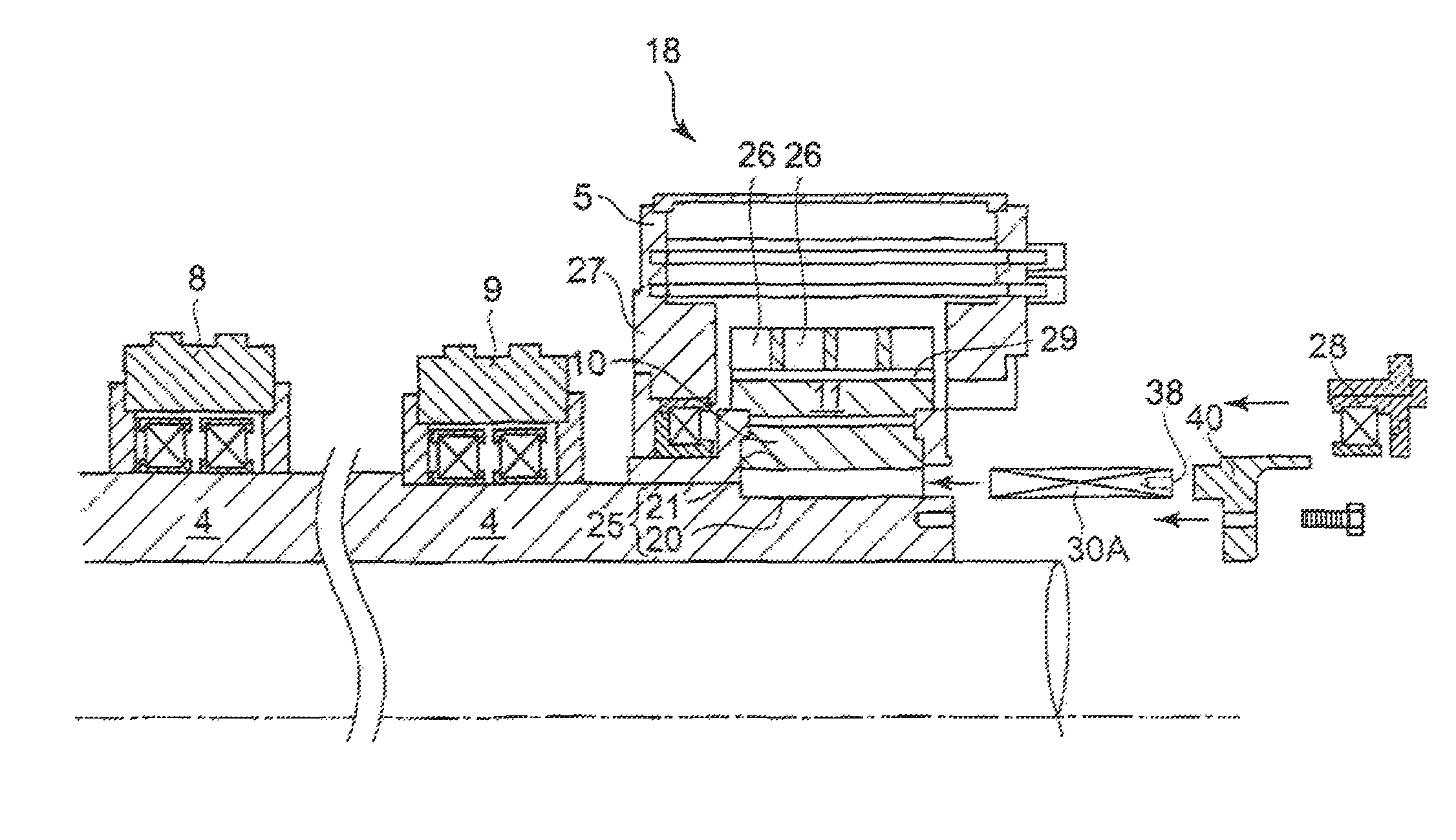

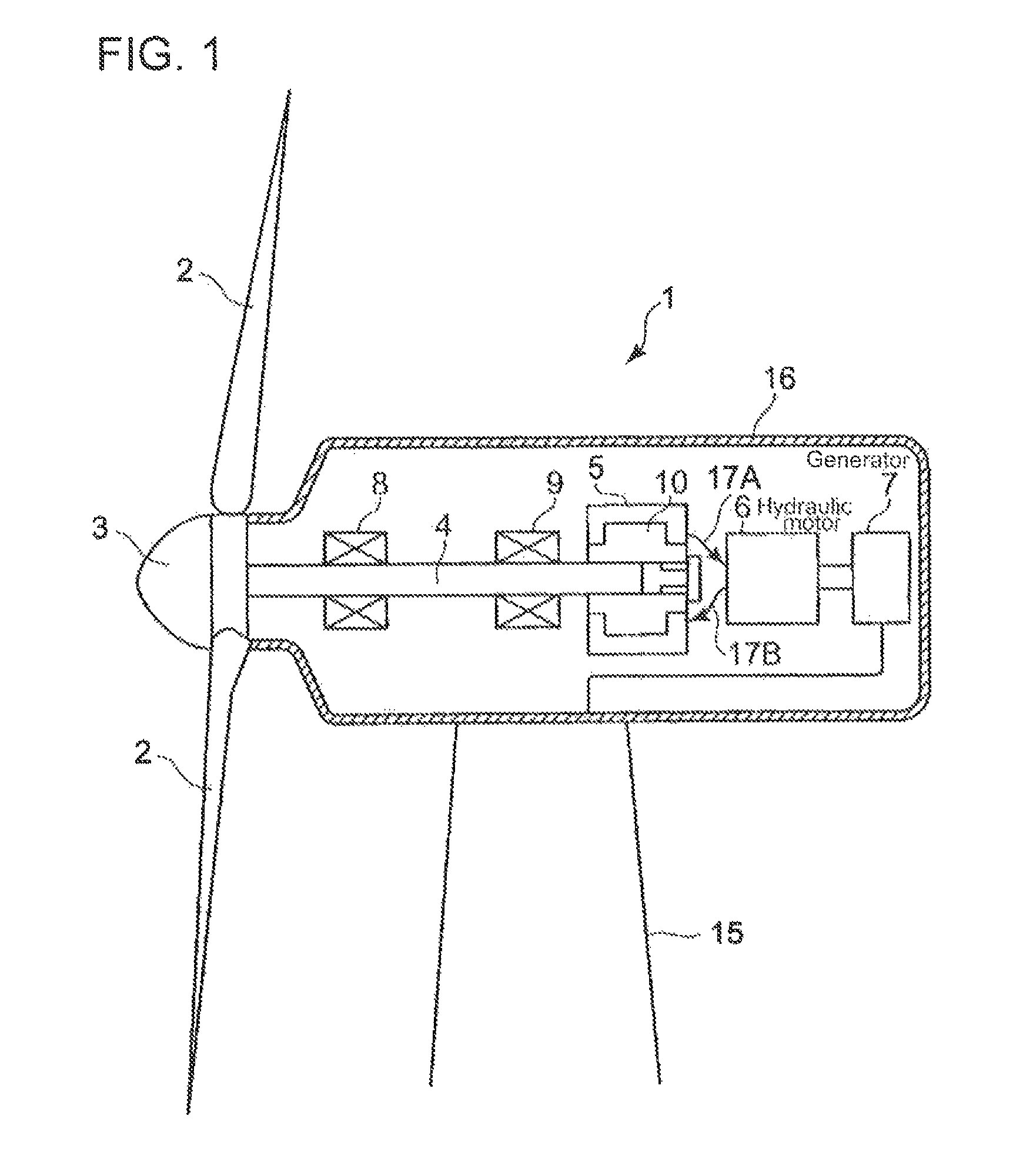

Power generating apparatus of renewable energy type and method for installing hydraulic pump

InactiveUS8497596B2Structure fixing structure with easeLow costEngine fuctionsWind energy generationHydraulic pumpEngineering

It is intended to provide a power generating apparatus of renewable energy type which can transmit large torque and has a low-cost and readily processable structure of fixing a hydraulic pump to the main shaft and a method of mounting the hydraulic pump. A plurality of key slots 25 are formed at an end on the back-end side of the main shaft 4. A plurality of keys 30A, 30B are inserted in the key slots 25. The keys 30A, 30B include a reference key 30A to be inserted in one of the key slots and a split key 30B to be inserted in the other of the key slots. The split key 30B is separated into a first key piece 34 having a projection to be inserted in a first groove formed in the main shaft and a second key piece 36 having a depression to be inserted in a second groove formed in the cylindrical member. The pair of key pieces 34, 36 are arranged so that the projection and the depression engage with each other. The projection and the depression of the first and second key pieces have side surfaces 34A, 34B, 36A and 36B formed along a radial direction of the main shaft 4. The side surfaces 34A, 34B, 36A and 36B are contact surfaces of the first and second key pieces 36 and incline with respect to the axial direction of the main shaft.

Owner:MITSUBISHI HEAVY IND LTD

Load and torque sensing systems utilizing magnetic key for mechanical engagement

ActiveUS20160116000A1Easy to assembleEasy loadingDrilling rodsRopes and cables for vehicles/pulleyCouplingEngineering

Torque is transmitted by way of a shaft having an axial groove formed as a keyway therein and a key held in the groove by means of a coin-shaped magnet located in a pocket formed in the floor of the groove. A second element, such as a coupling, is configured to receive the shaft and key therein and has a matching keyway.

Owner:FUTEK ADVANCED SENSOR TECH

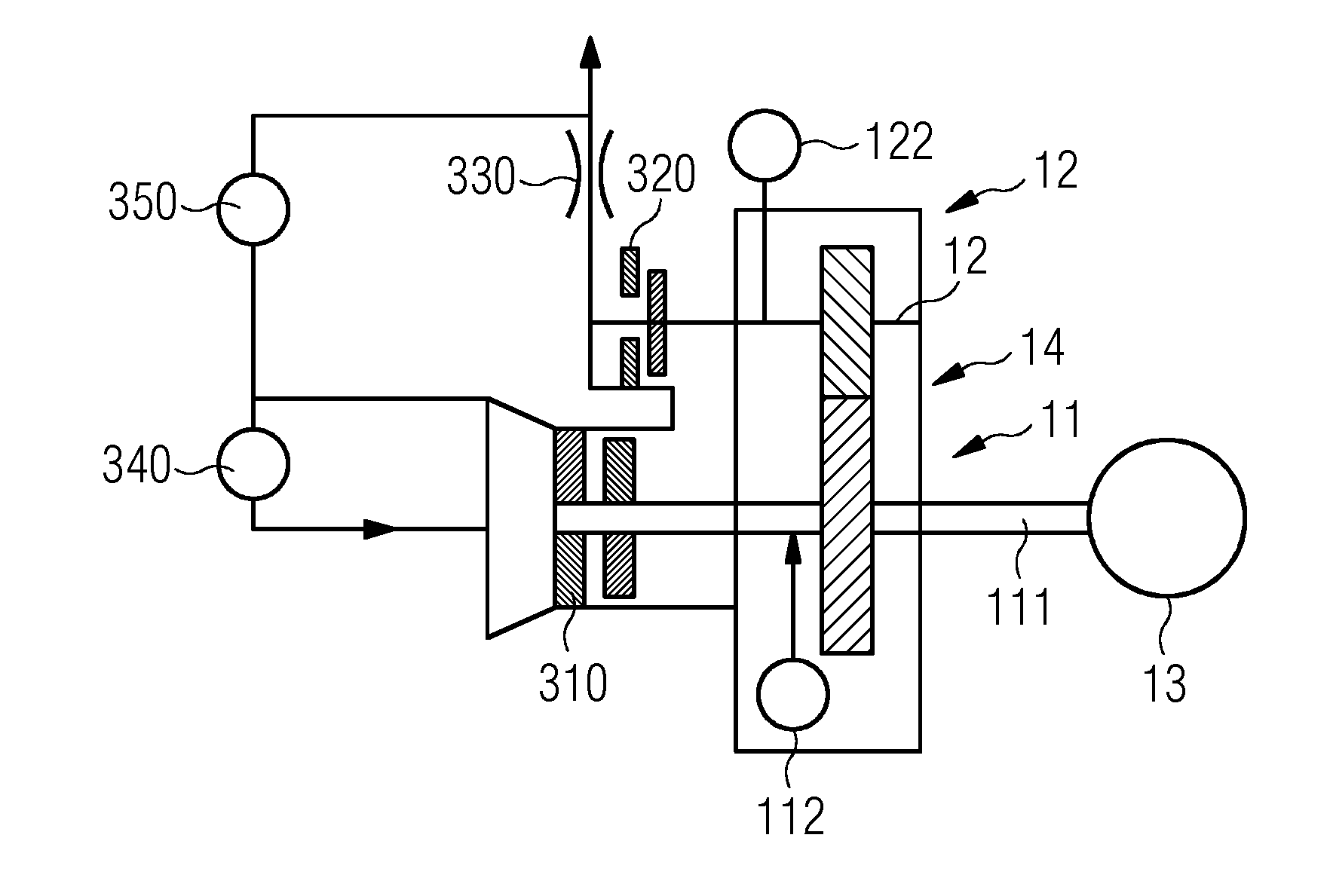

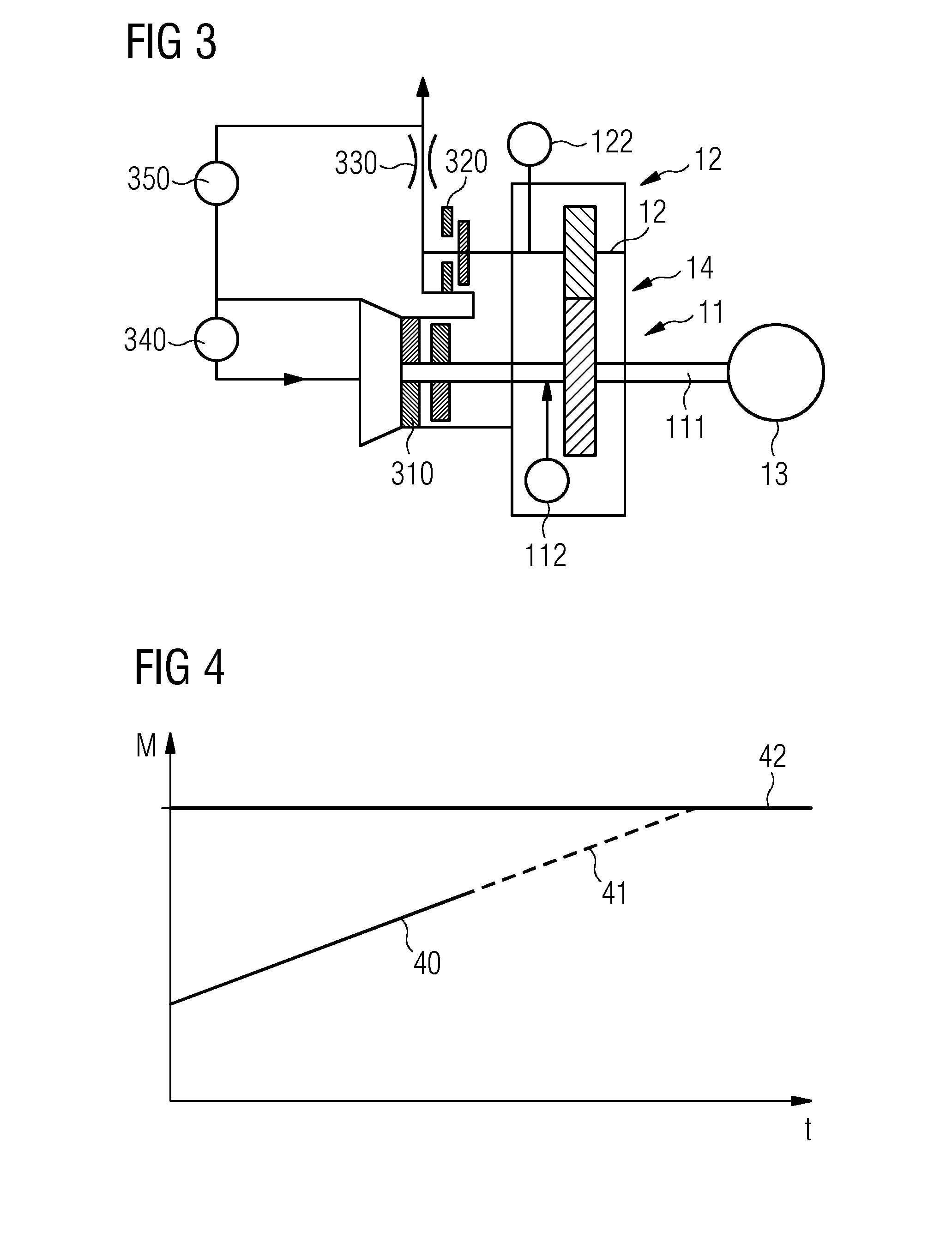

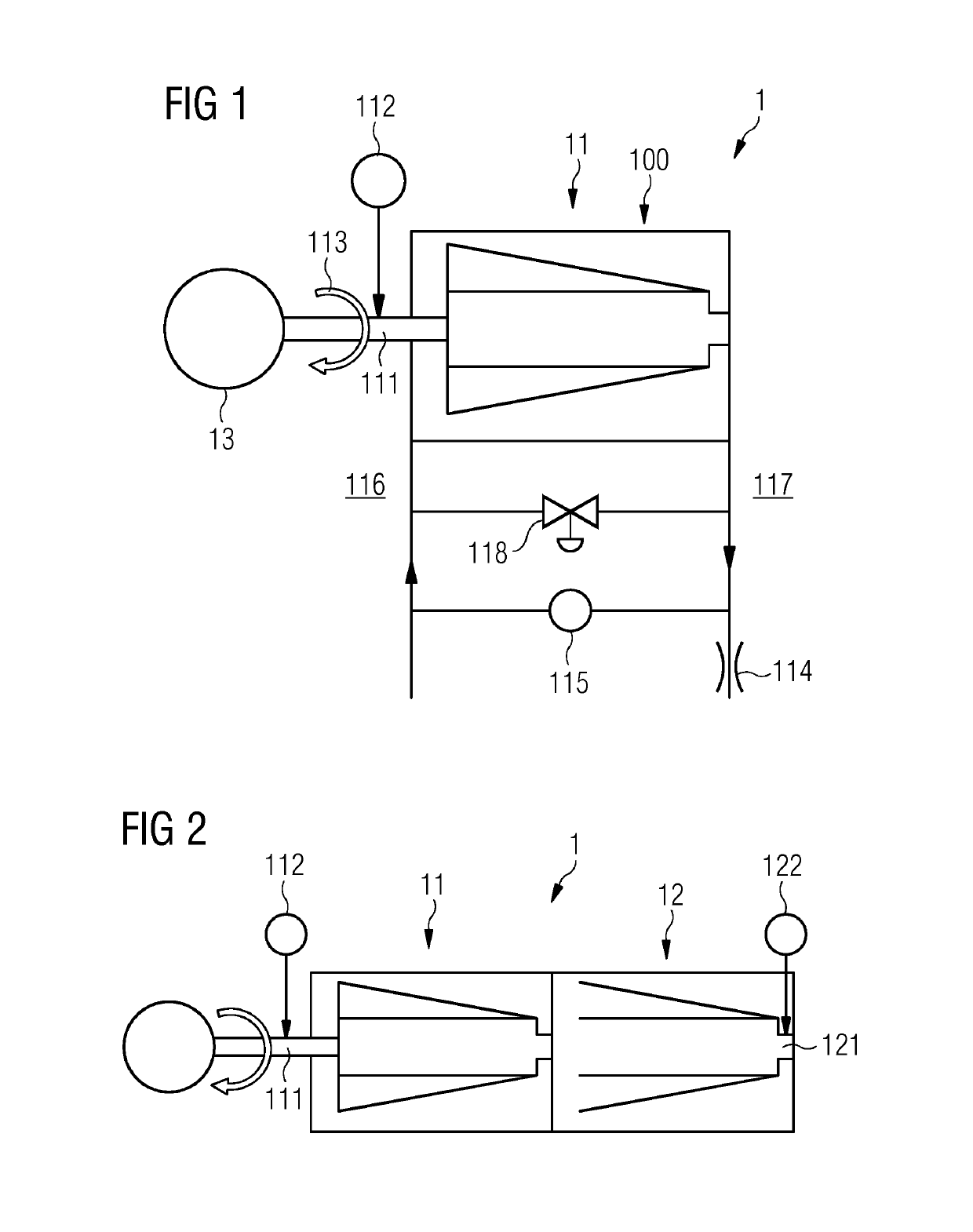

Method for operating a turbo-machine having overload protection and turbo-machine comprising a device for carrying out said method

ActiveUS20160230591A1Simple mannerTorque transmittedPump componentsWork measurementMagnetoRotational axis

A turbo-machine is provided having at least one turbo-machine stage, wherein overload protection of the rotating shaft is provided by the method and, to protect the rotating shaft against overload, a measurement of a torsional stress of the rotating shaft is carried out during operation of the rotating shaft. The torsional stress is measured via a measurement of the torque of the rotating shaft. The torque is preferably measured magneto-elastically. By using the measured torque of the rotating shaft, the development of the torque is forecast. On the basis of the forecast produced, the turbo-machine stage or operating parameters of the turbo-machine is / are regulated. Further to a turbo-machine is provided comprising at least one turbo-machine stage which has at least one rotating shaft, wherein the turbo-machine has a device for carrying out the method.

Owner:SIEMENS ENERGY BV

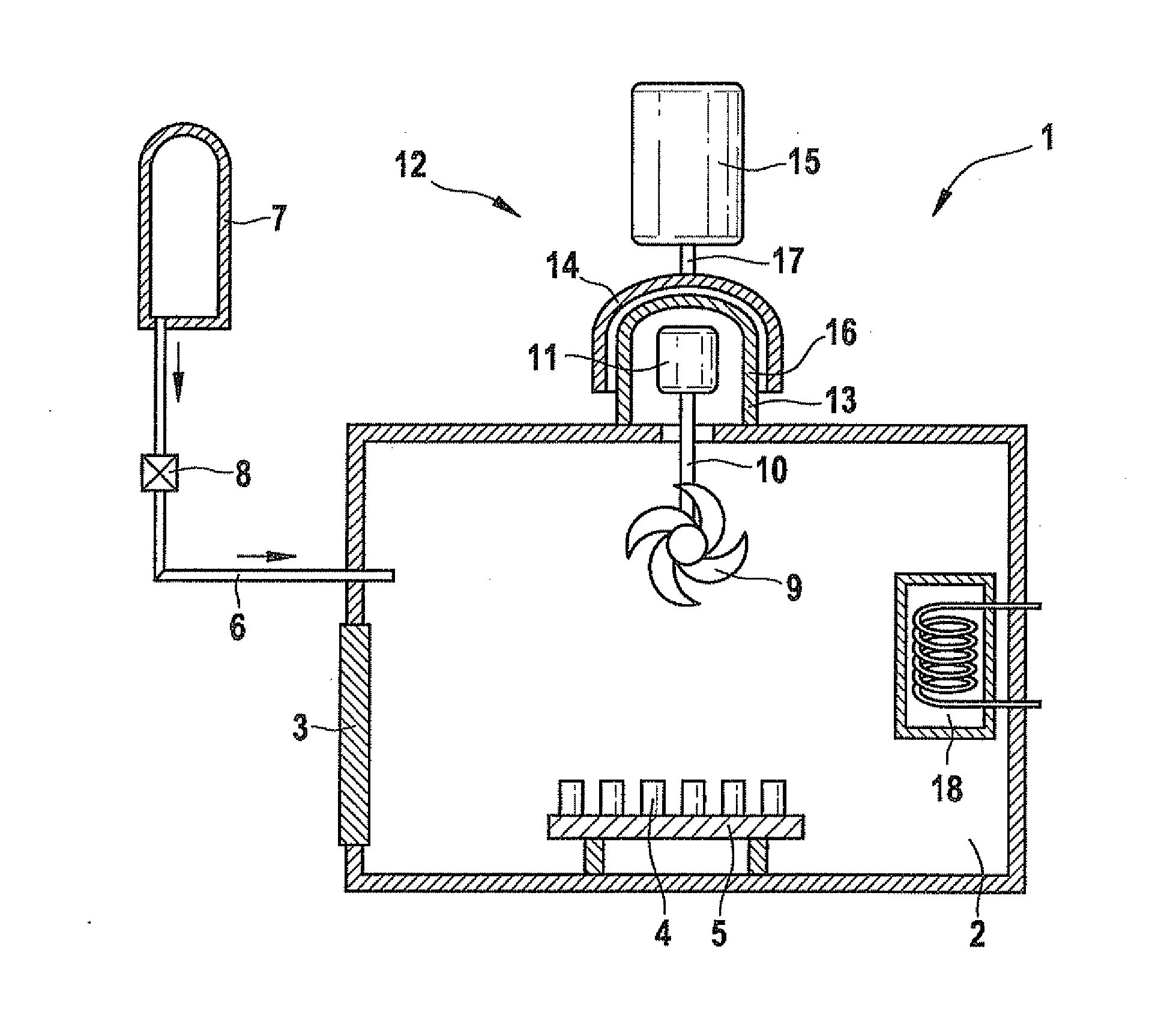

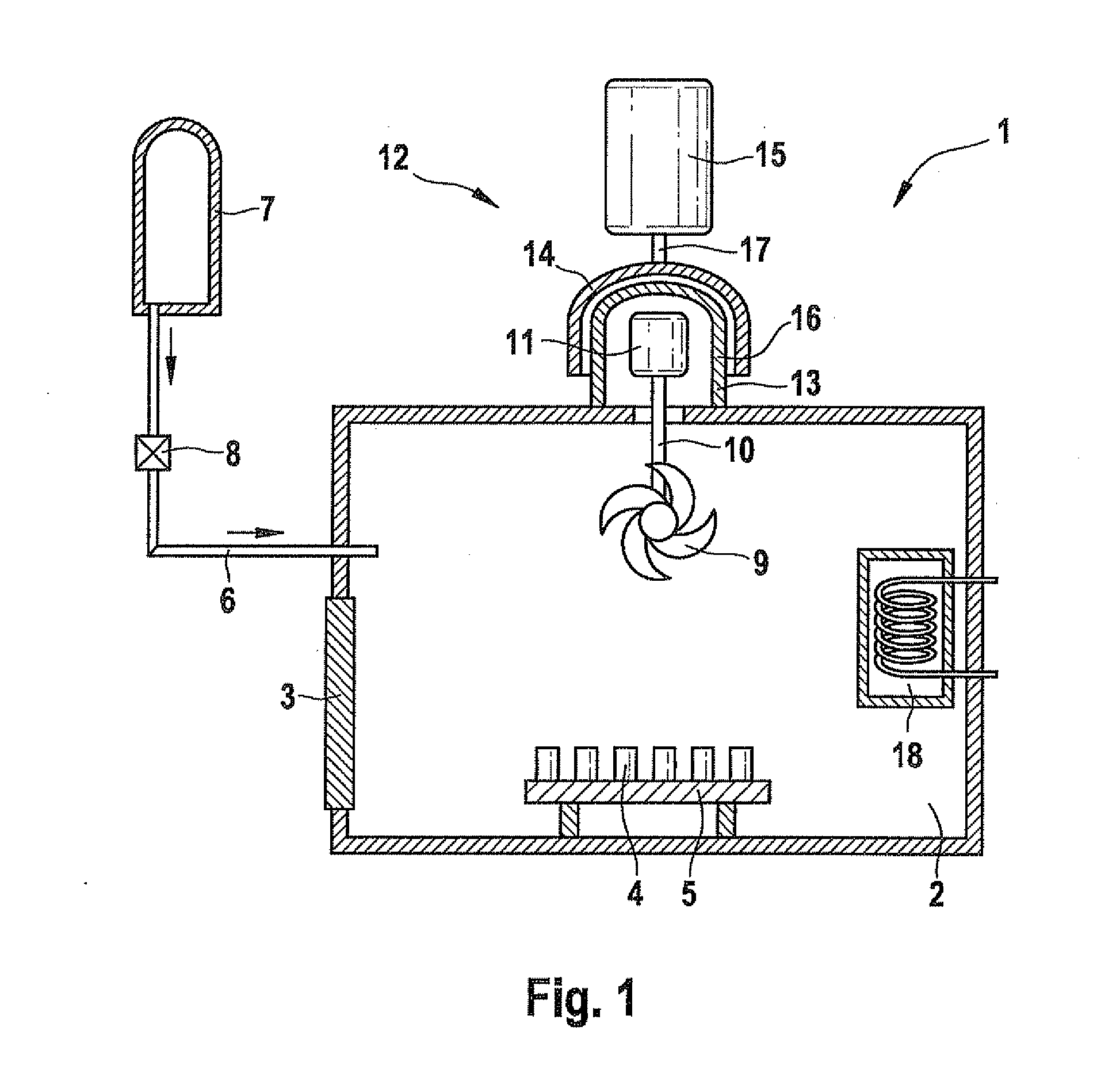

Quenching device and quenching method

InactiveUS20120067467A1Avoid problemsStarting is possibleFurnace typesQuenching agentsCouplingDrive motor

A quenching device is described that includes at least one chamber that can be filled with quenching gas and that has a blower wheel for circulating quenching gas, in particular a quenching chamber and / or a flow channel, a drive motor, situated outside the chamber, for driving the blower being allocated to the blower wheel. The drive motor is coupled to the blower wheel so as to transmit torque via a coupling that operates in contactless fashion. Also described is a related quenching method.

Owner:ROBERT BOSCH GMBH

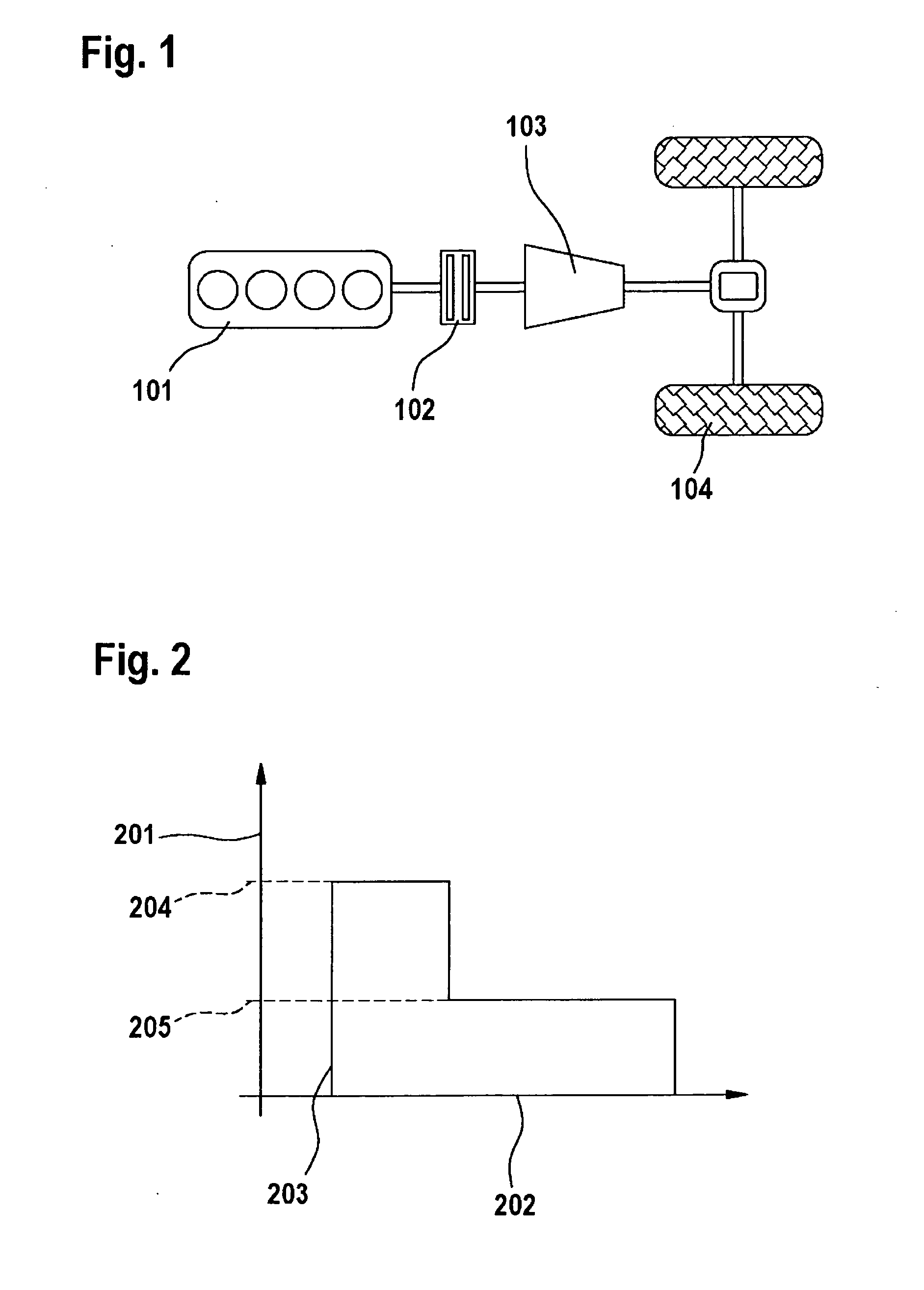

Method and device for engaging a clutch

InactiveUS20110093175A1Shortened methodShorten speedClutchesDigital data processing detailsControl theoryClutch

Owner:ROBERT BOSCH GMBH

Power unit and method

PendingUS20220258832A1Limited transmission of torqueImprove power efficiencyWheel based transmissionToothed gearingsGear wheelTorque transmission

A power unit for a pedal vehicle includes a pedal shaft, an output shaft arranged to transfer torque to a vehicle wheel, a main epicyclic gear set arranged to control transmission ratio between the pedal shaft and the output shaft, an assist motor connected to an assist gear of the main epicyclic gear set, and a control motor connected to a control gear of the main epicyclic gear set. The control motor and the control gear form a control assembly of the power unit. The power unit includes a one-way clutch provided to the control assembly of the power unit and arranged to transmit rotation in only a first rotation direction.

Owner:REVONTE OY

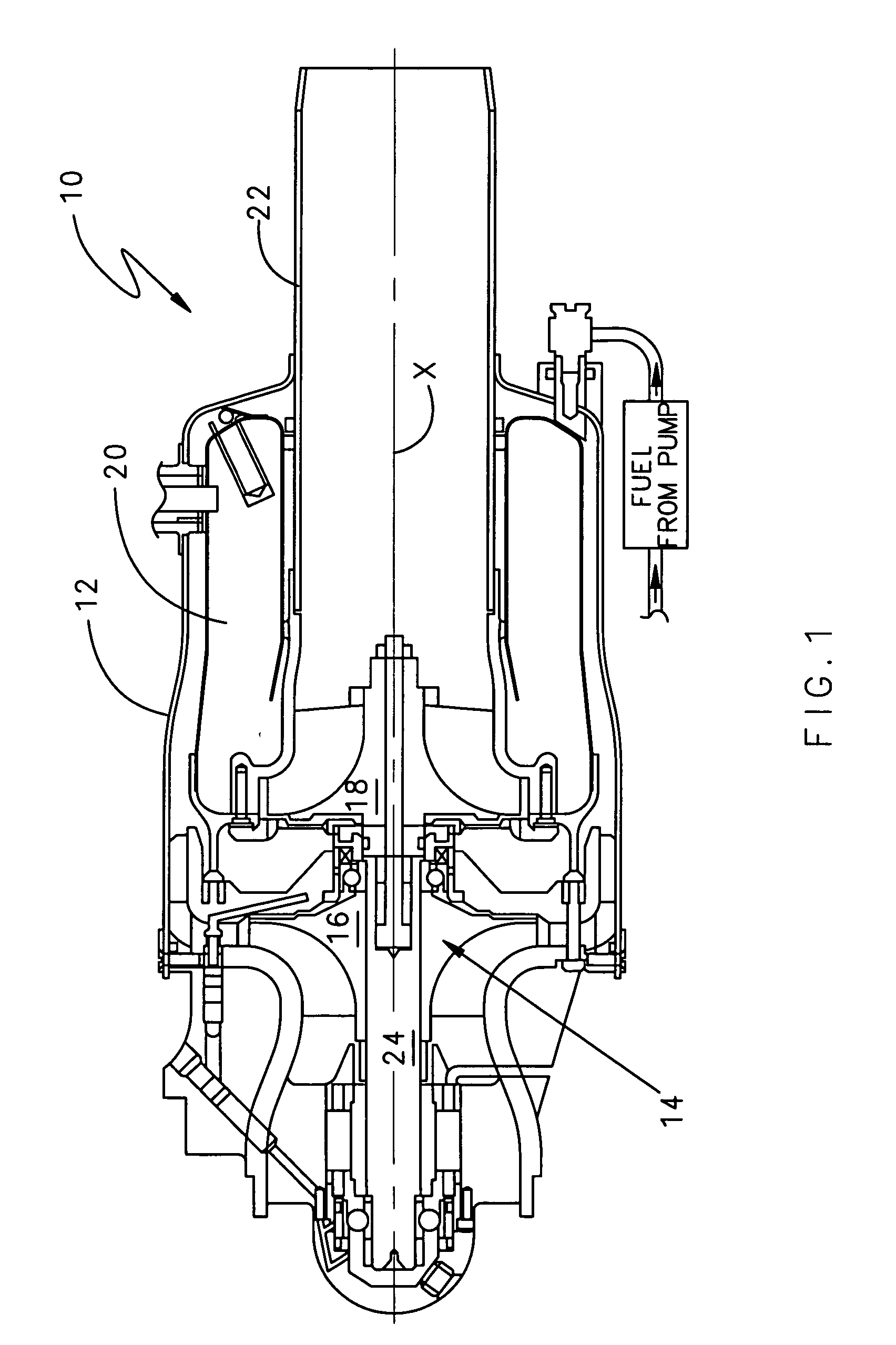

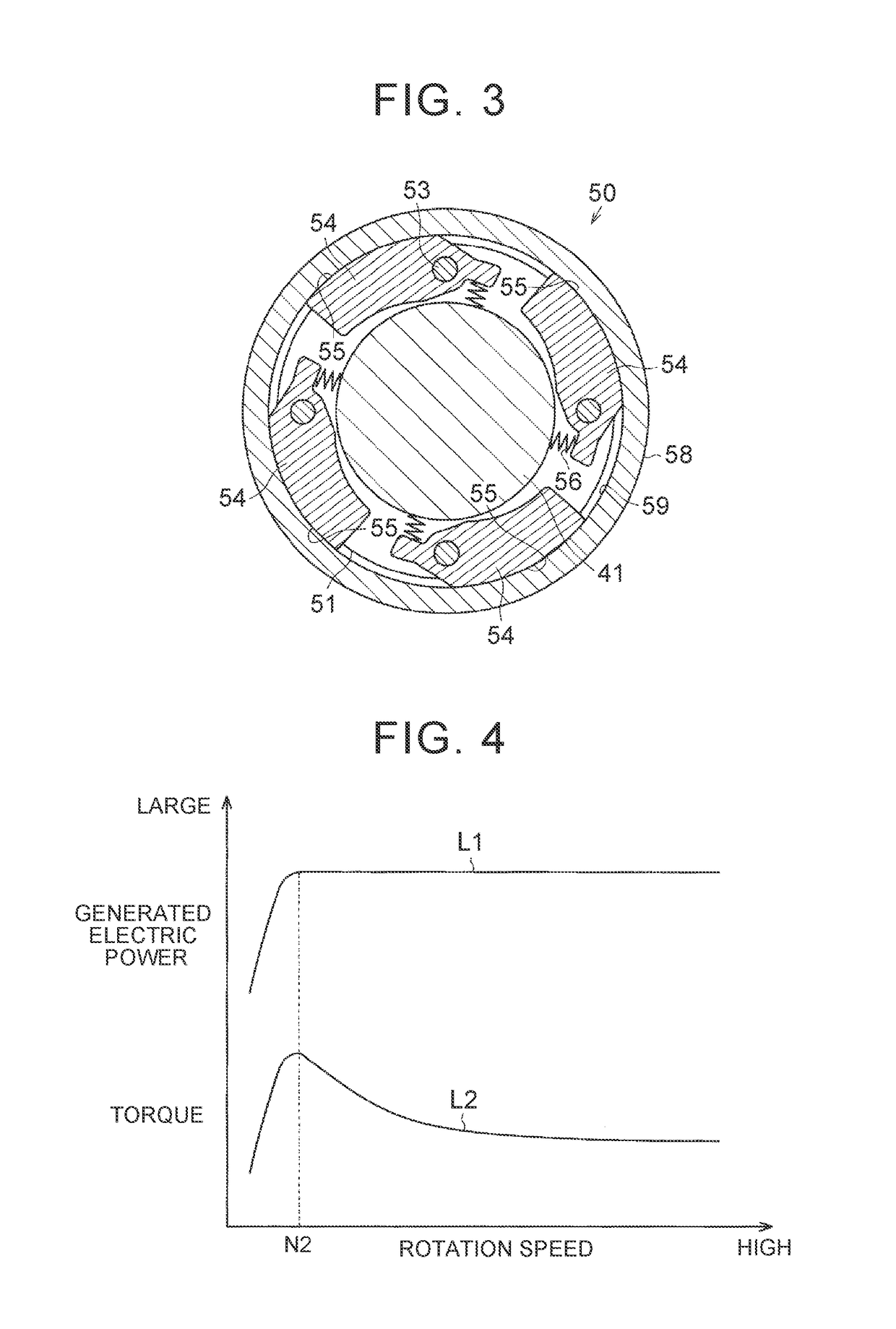

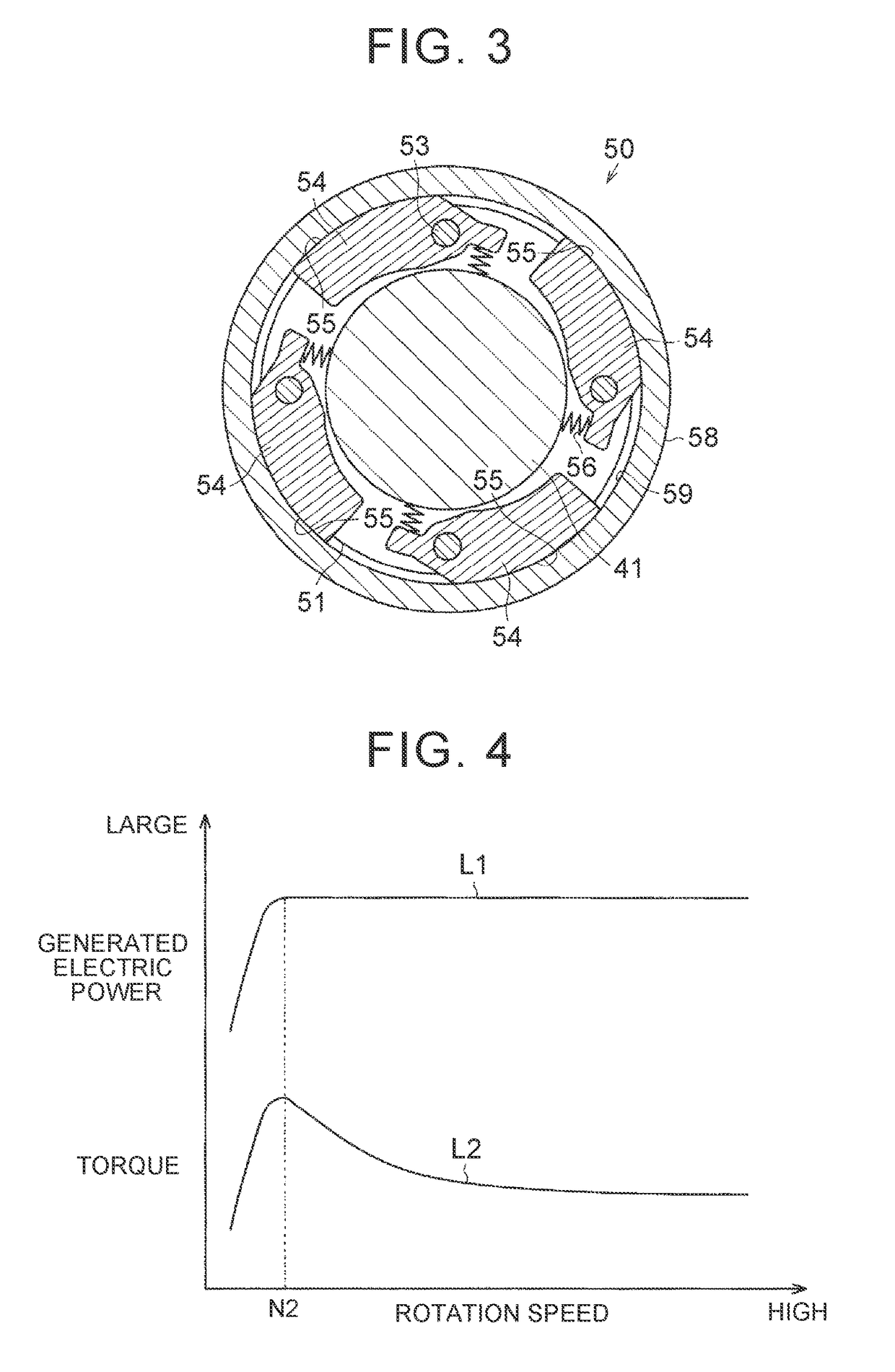

Fuel supply apparatus for internal combustion engine

InactiveUS20170074202A1Easy to getIncrease rotation speedElectrical controlDC motor speed/torque controlRotational axisExternal combustion engine

A fuel supply apparatus for an internal combustion engine includes a motor, a fuel pump, an alternator, a centrifugal clutch, and an electronic control unit. The centrifugal clutch is configured to, when the rotation speed of the output shaft of the motor is higher than or equal to an engaging rotation speed, connect the output shaft of the motor with the rotary shaft of the alternator. The engaging rotation speed is a rotation speed higher than a rotation speed of the rotary shaft at which torque that acts on the rotary shaft as a result of generation of electric power by the alternator becomes maximum and is a rotation speed lower than a rotation speed at which torque for driving the high-pressure fuel pump cannot be provided by only the motor at the time when the motor is driven at rated output power.

Owner:TOYOTA JIDOSHA KK

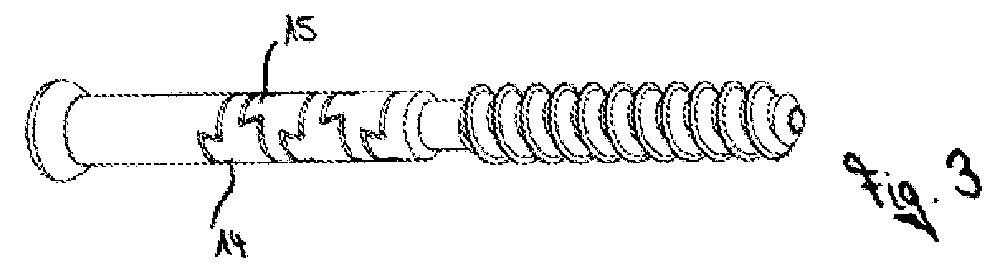

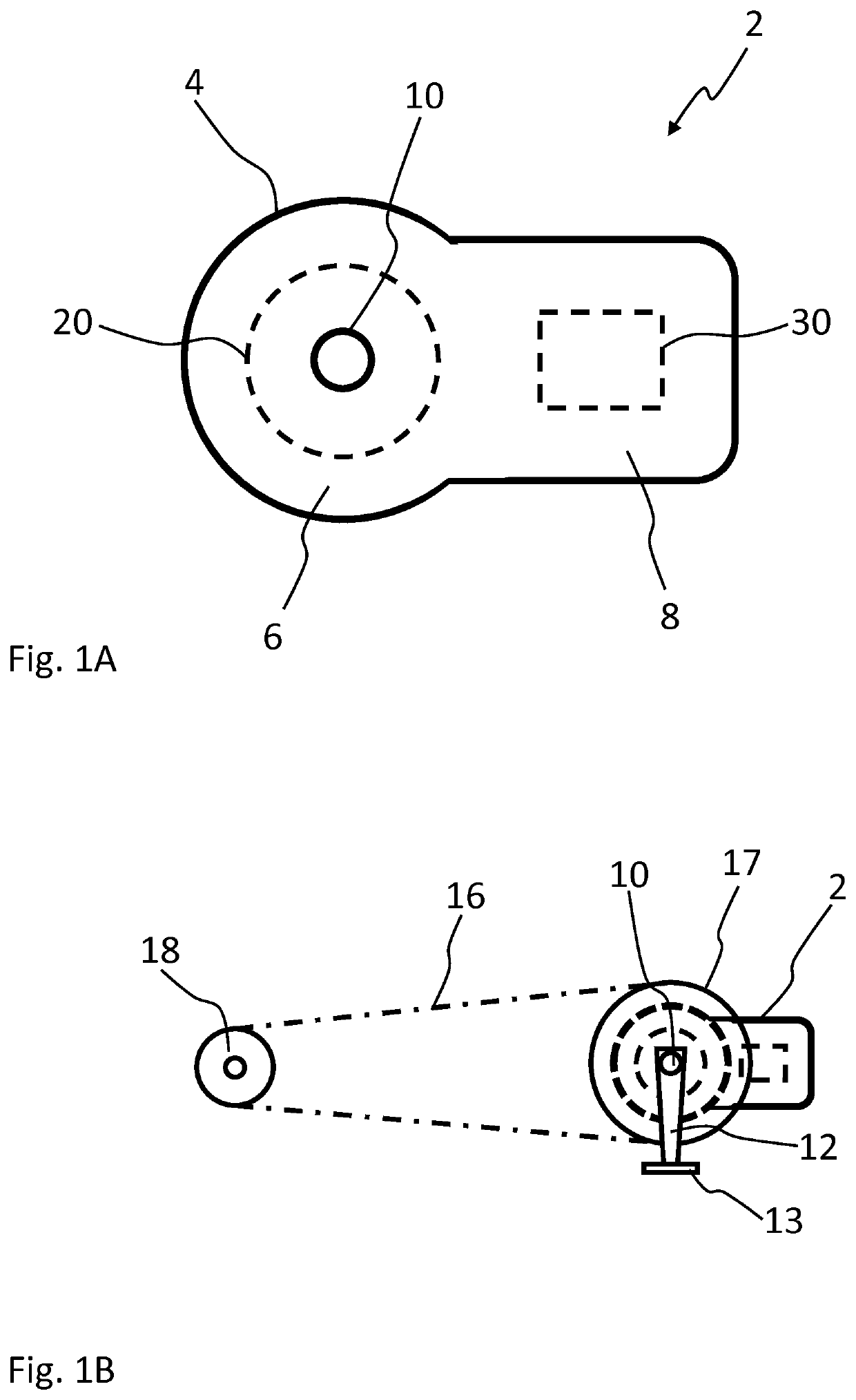

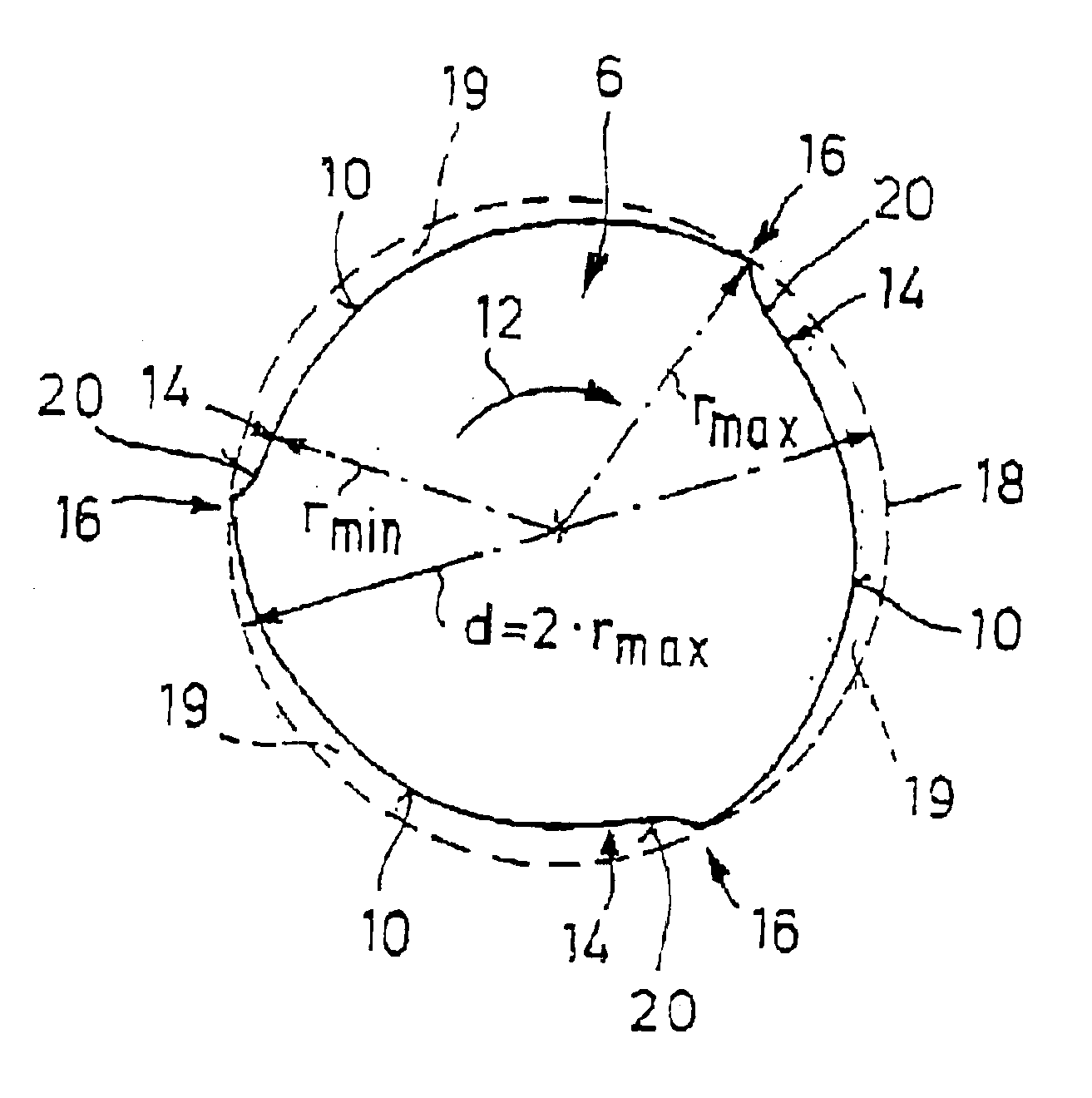

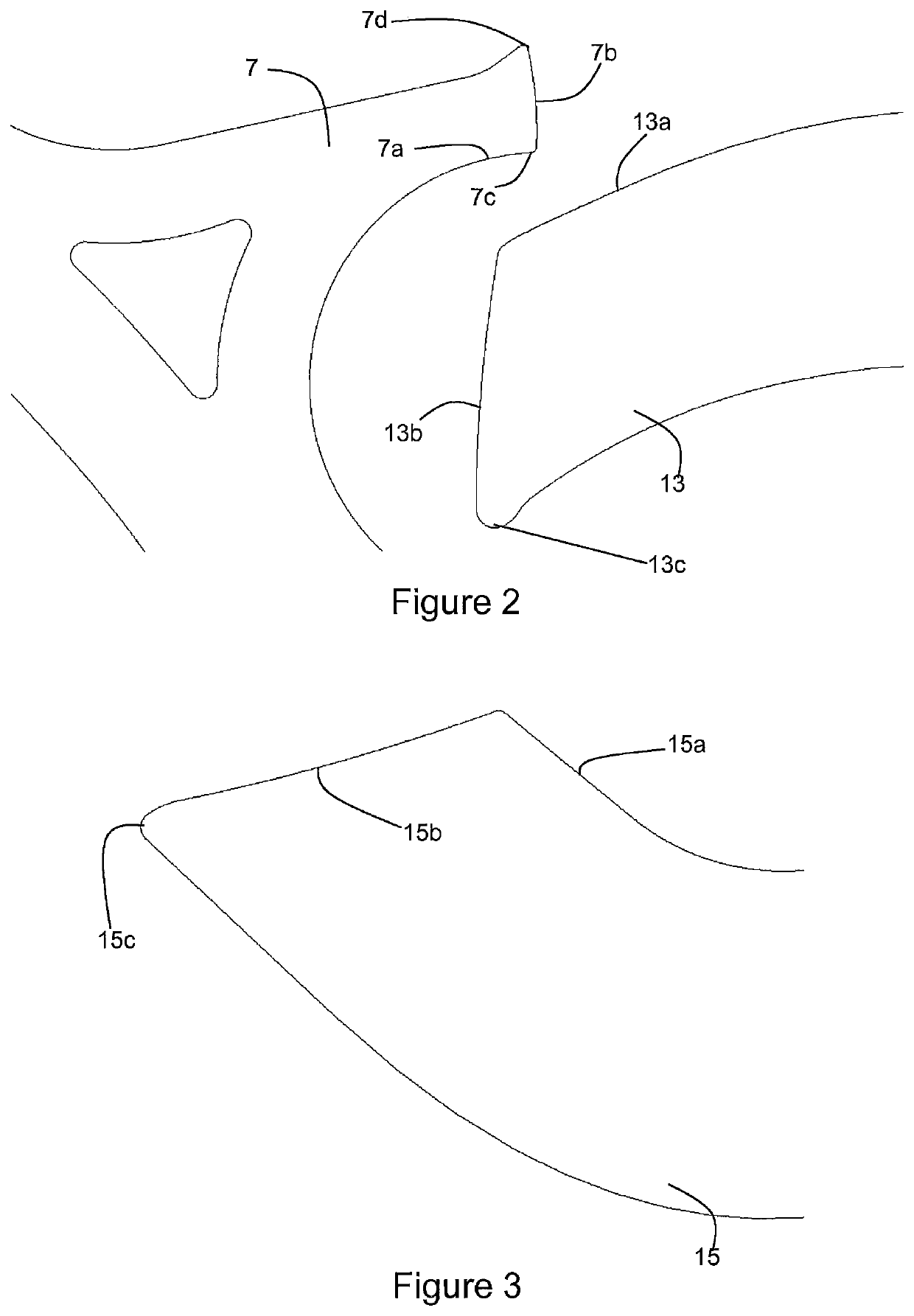

Adaptor for an Axle

InactiveUS20080038052A1Reduce deformationTorque transmittedCouplings for rigid shaftsMetal-working hand toolsCentre of rotationEngineering

An adaptor (8) for an axle where the axle defines the centre of rotation for transmission of the rotational movement to at least one access or attachment point (6), which is eccentric with the axis of rotation, where the adaptor (8) is disc-shape with an outer perimeter (7) and an inner perimeter (9), where the inner perimeter (9) has a shape which fits the axle, and furthermore where the adaptor (8) includes securing means for securing the adaptor (8) to the axle. This adaptor (8) is distinctive by a cut-out (10) connects the inner perimeter (9) with the outer perimeter (7), and the securing means consist of a shank portion (15) and a tread portion (14) where the shank portion (15) is larger than the tread portion (14). Hereby reducing the permanent deformation of the adaptor (8) as well as the axle as the shank portion (15) will provide most of the elasticity for the clamping force rendering it possible to transmit torque as well as reduce angle deformation.

Owner:MARTIN PROFESSIONAL

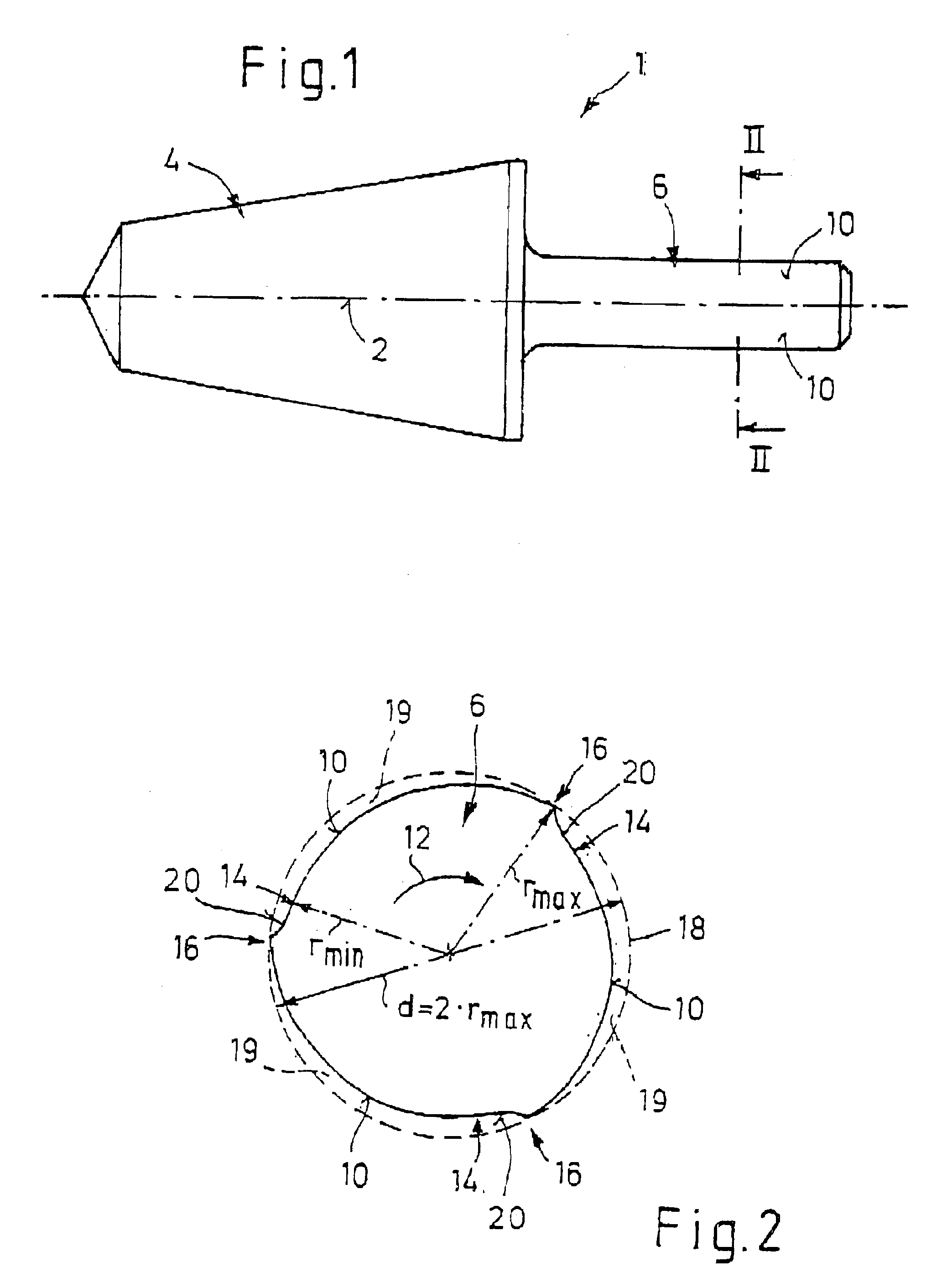

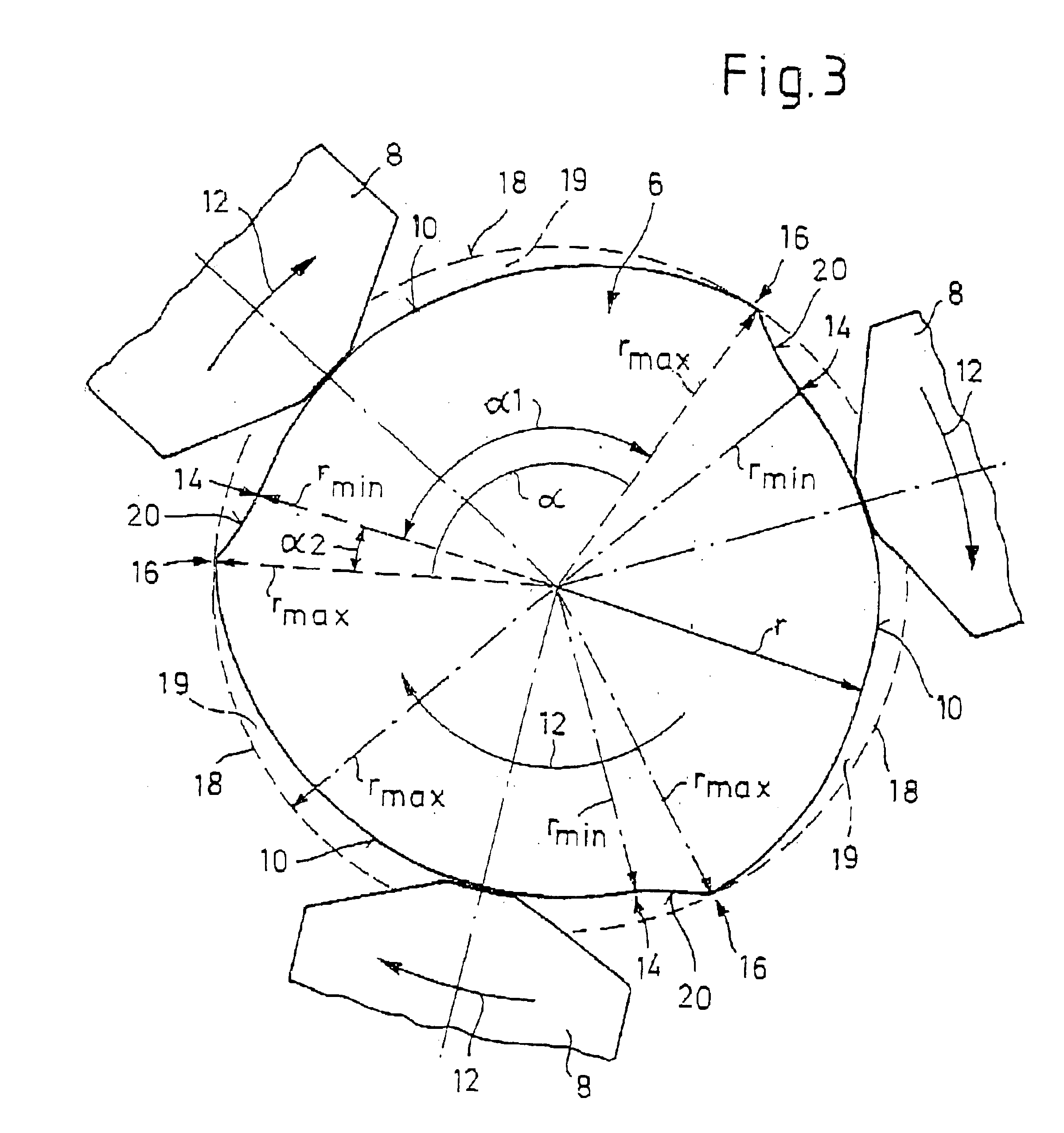

Rotating tool with a clamping shank

InactiveUS7175373B2Easy clamping operationSufficient clampingWood turning toolsTransportation and packagingCountersinkEngineering

A rotating tool such as a drill, a milling cutter, a countersink, a deburrer and the like, including a working part, which is driven in rotation about an axis of rotation for cutting machining, and also including an axially adjoining clamping shank for insertion into a clamping chuck of a drive machine. The clamping shank is provided with a number of clamping surfaces on its outer circumference for supporting a clamping jaw of the clamping chuck. The clamping shank has a shank radius in the region of each clamping surface which, as seen in a predetermined direction of rotation of the tool, rises from a minimum shank radius to a maximum shank radius as it passes over a range of angle of rise.

Owner:REINER QUANZ

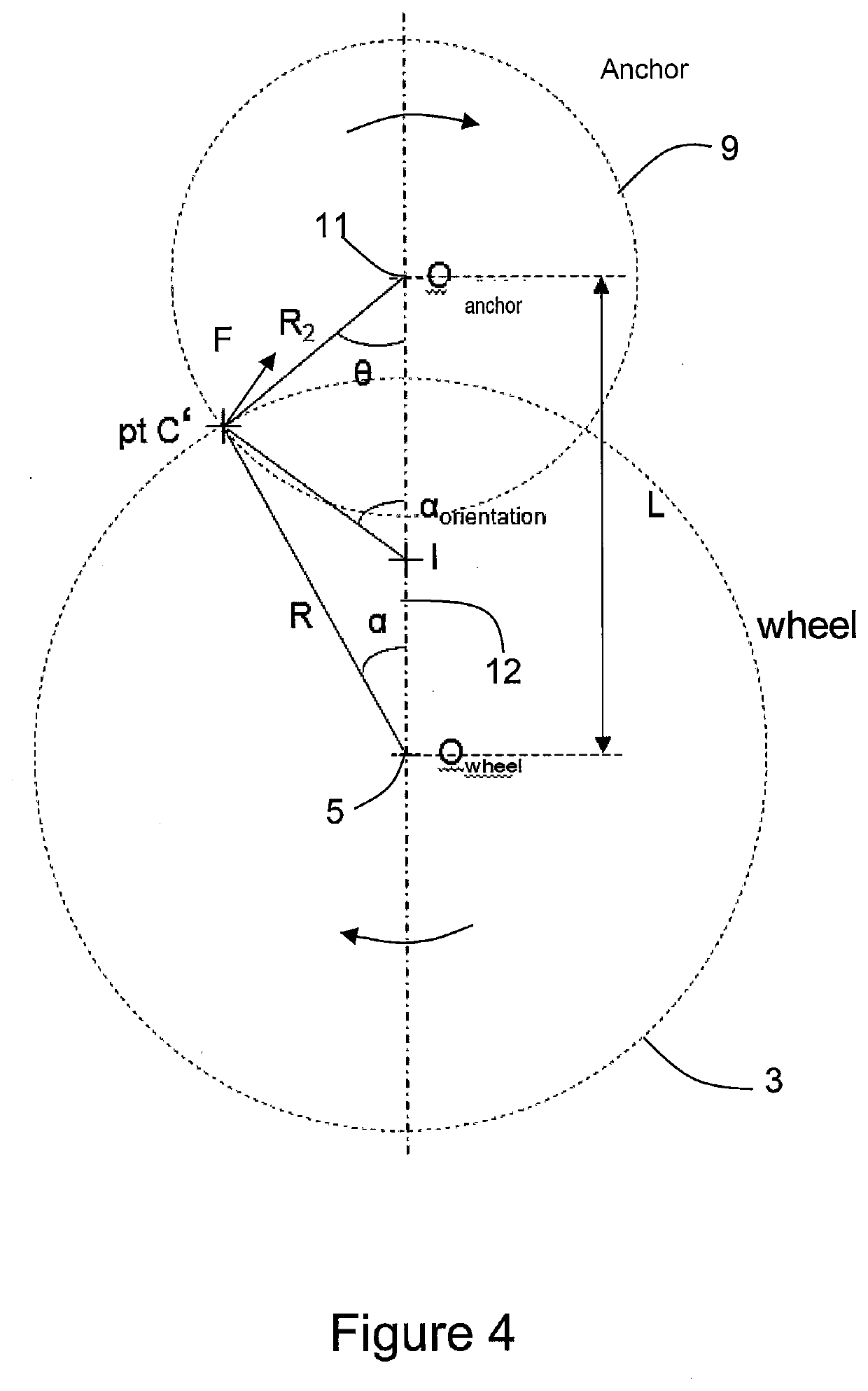

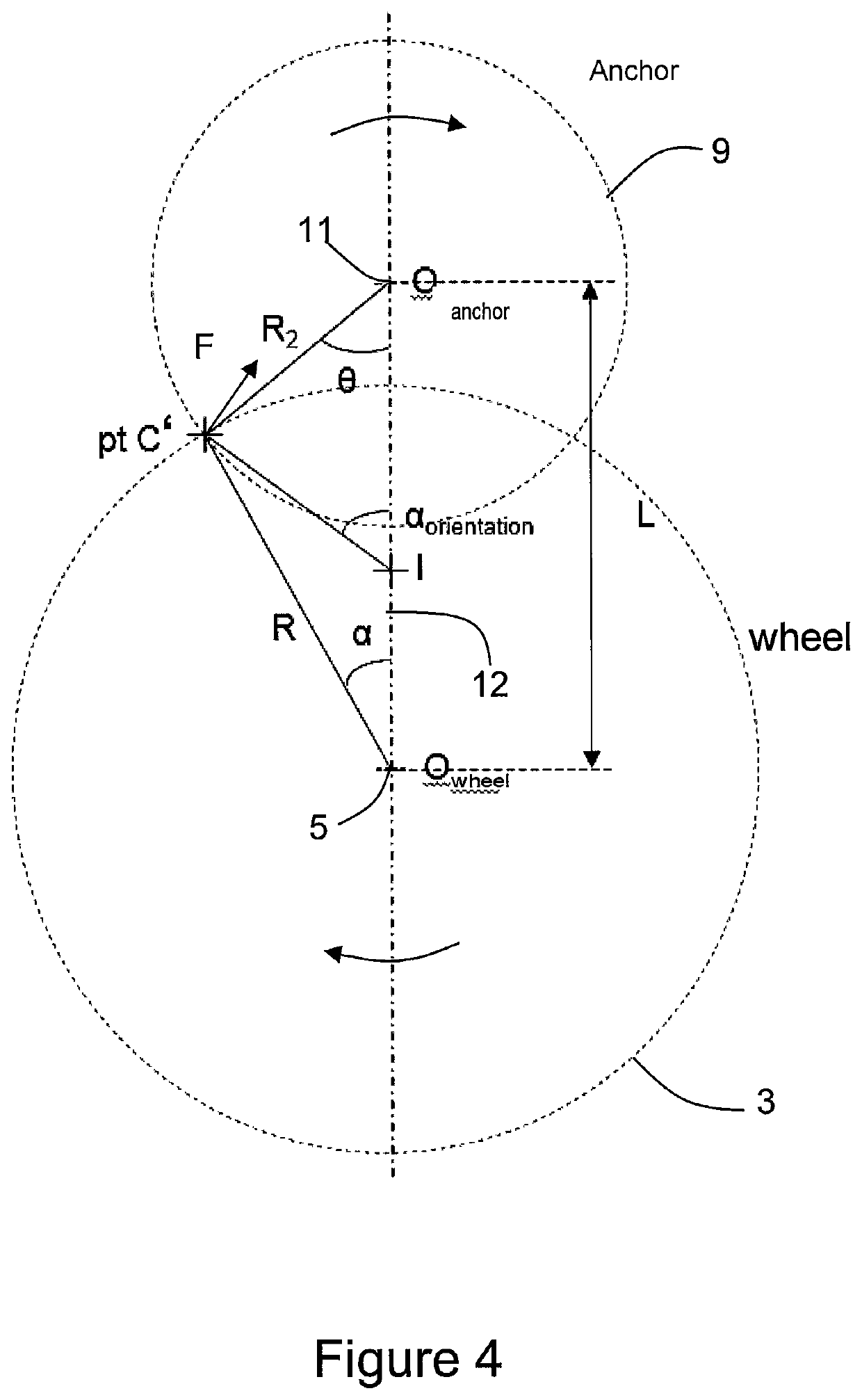

Escapement for a timepiece with optimized torque transmission

ActiveUS20200064776A1Constant transmissionSmooth transitionEscapementsRotational axisControl engineering

An escapement for a timepiece, comprising: —an escapement wheel pivotally mounted around a corresponding axis of rotation and intended to be driven by a drive source, said escapement wheel comprising a plurality of teeth; —a pallet fork pivotably mounted around a corresponding axis of rotation, said pallet fork comprising an entry pallet and an exit pallet, each pallet comprising a rest face arranged to block the escapement wheel, as well as a pulse face arranged to interact with the escapement wheel in order to transmit the pulses received from the latter to a regulating member arranged to perform oscillations, said pallet fork being arranged to free the escapement wheel periodically under the control of the regulating member, characterized in that at least one of the pulse faces is shaped in such a way that, on at least one portion of the pulse face, and considered at each point of contact (C′) between the escapement wheel and the pulse face, the tangent of the pulse face intersects the center-to-center distance between the escapement wheel and the pallet fork according to an angle (αorientation) that observes a particular relation.

Owner:RICHEMONT INT

Method for operating a turbo-machine having overload protection and turbo-machine comprising a device for carrying out said method

InactiveUS10415422B2Torque transmittedPump componentsWork measurementMagnetic tension forceEngineering

A turbo-machine is provided having at least one turbo-machine stage, wherein overload protection of the rotating shaft is provided by the method and, to protect the rotating shaft against overload, a measurement of a torsional stress of the rotating shaft is carried out during operation of the rotating shaft. The torsional stress is measured via a measurement of the torque of the rotating shaft. The torque is preferably measured magneto-elastically. By using the measured torque of the rotating shaft, the development of the torque is forecast. On the basis of the forecast produced, the turbo-machine stage or operating parameters of the turbo-machine is / are regulated. Further a turbo-machine is provided comprising at least one turbo-machine stage which has at least one rotating shaft, wherein the turbo-machine has a device for carrying out the method.

Owner:SIEMENS ENERGY BV

Load and torque sensing systems utilizing magnetic key for mechanical engagement

ActiveUS9267856B2Easy to assemblePrevent movementPortable liftingWork measurementMagnetic tension forceCoupling

Owner:FUTEK ADVANCED SENSOR TECH

Fuel supply apparatus for internal combustion engine

InactiveUS9840979B2Increase rotation speedTorque transmittedElectrical controlDC motor speed/torque controlRotational axisExternal combustion engine

A fuel supply apparatus for an internal combustion engine includes a motor, a fuel pump, an alternator, a centrifugal clutch, and an electronic control unit. The centrifugal clutch is configured to, when the rotation speed of the output shaft of the motor is higher than or equal to an engaging rotation speed, connect the output shaft of the motor with the rotary shaft of the alternator. The engaging rotation speed is a rotation speed higher than a rotation speed of the rotary shaft at which torque that acts on the rotary shaft as a result of generation of electric power by the alternator becomes maximum and is a rotation speed lower than a rotation speed at which torque for driving the high-pressure fuel pump cannot be provided by only the motor at the time when the motor is driven at rated output power.

Owner:TOYOTA JIDOSHA KK

Escapement for a timepiece with optimized torque transmission

ActiveUS11480923B2Improve performanceMinimize disturbanceEscapementsRotational axisControl engineering

An escapement for a timepiece, comprising: —an escapement wheel pivotally mounted around a corresponding axis of rotation and intended to be driven by a drive source, said escapement wheel comprising a plurality of teeth; —a pallet fork pivotably mounted around a corresponding axis of rotation, said pallet fork comprising an entry pallet and an exit pallet, each pallet comprising a rest face arranged to block the escapement wheel, as well as a pulse face arranged to interact with the escapement wheel in order to transmit the pulses received from the latter to a regulating member arranged to perform oscillations, said pallet fork being arranged to free the escapement wheel periodically under the control of the regulating member, characterized in that at least one of the pulse faces is shaped in such a way that, on at least one portion of the pulse face, and considered at each point of contact (C′) between the escapement wheel and the pulse face, the tangent of the pulse face intersects the center-to-center distance between the escapement wheel and the pallet fork according to an angle (αorientation) that observes a particular relation.

Owner:RICHEMONT INT

Control system for clutch

ActiveUS9933025B2Reduce controlTorque transmittedFluid actuated clutchesClutch controlControl system

A control system is for a clutch mechanism. The clutch mechanism includes a first engaging element, a second engaging element, and a piston. The first engaging element is configured to be moved according to change of a position of the piston. The first engaging element and the second engaging element are coupled to each other such that torque can be transmitted from the first engaging element to the second engaging element. The control system comprises an electronic control unit. The electronic control unit is configured to learn an engagement start position, according to a rotational speed of one of the first engaging element and the second engaging element. The engagement start position is a position of the first engaging element at the time when the first engaging element and the second engaging element start contacting with each other.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com