Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Stretch out smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

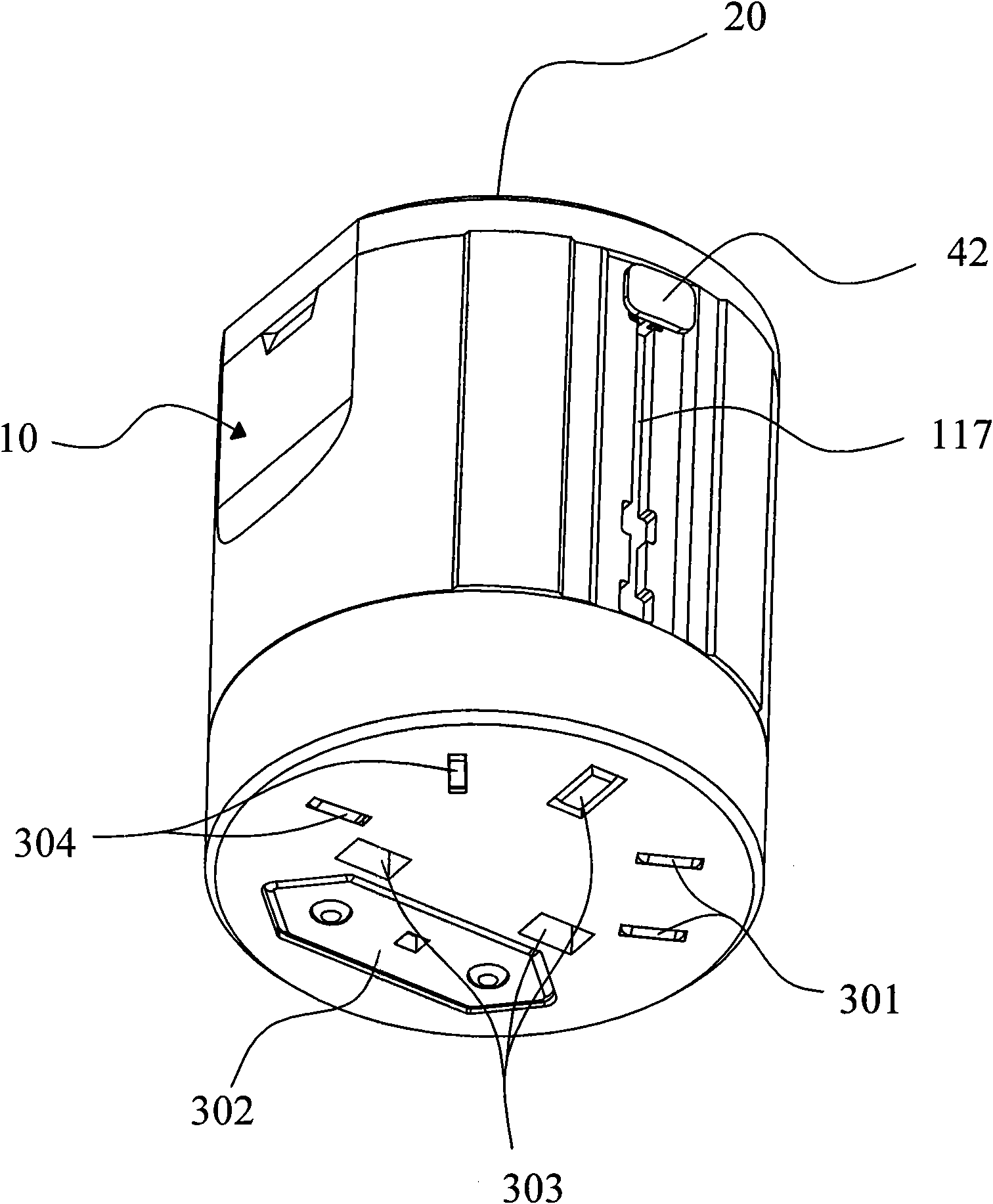

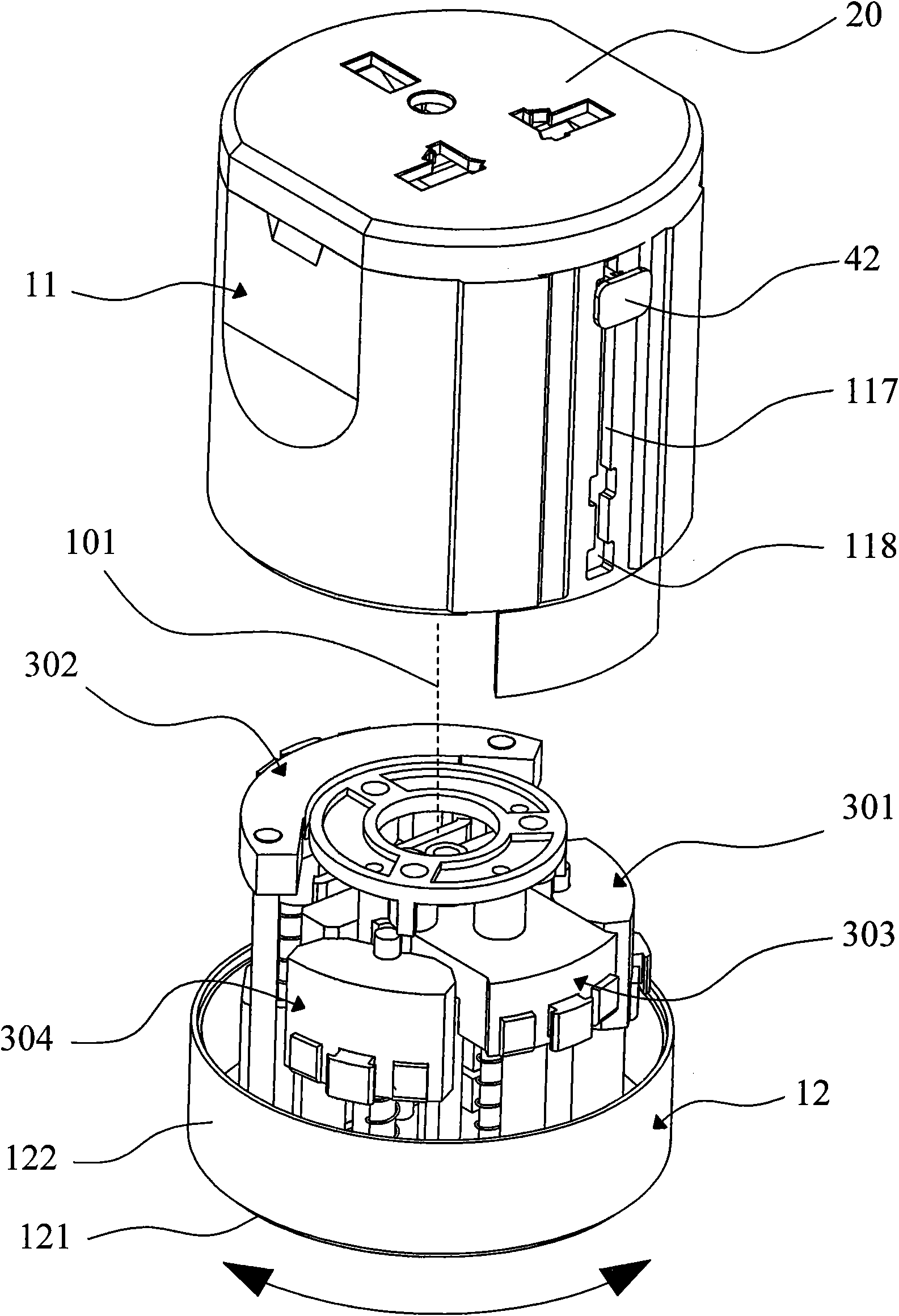

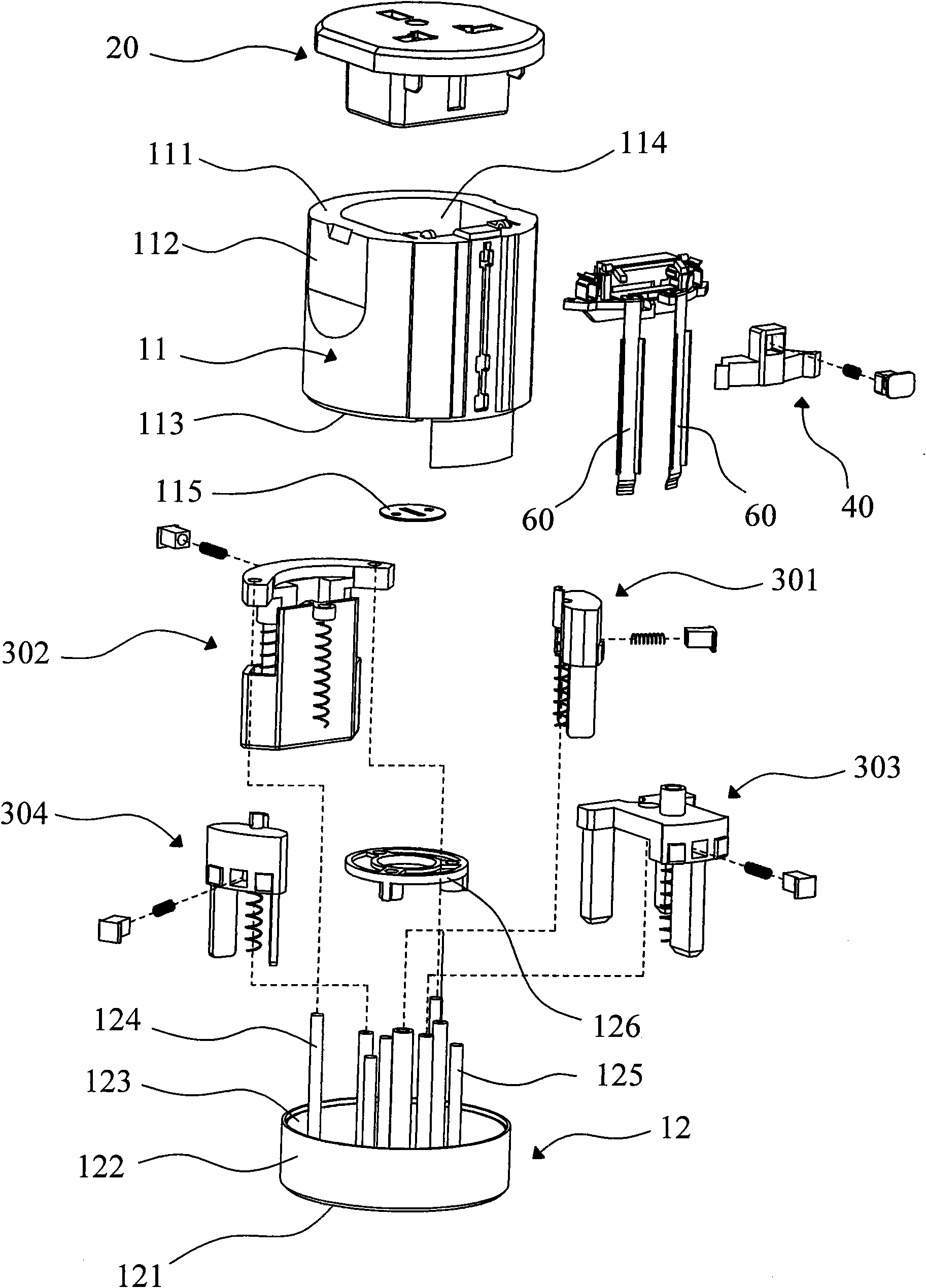

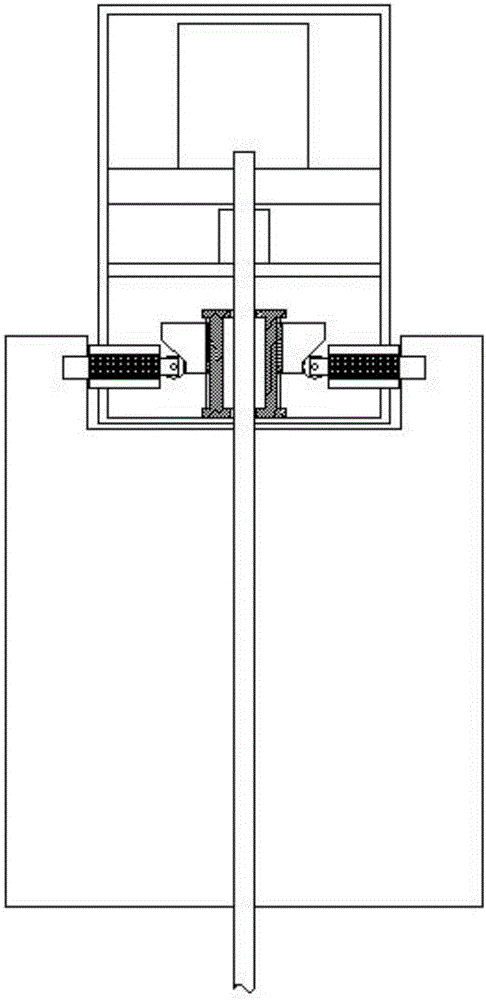

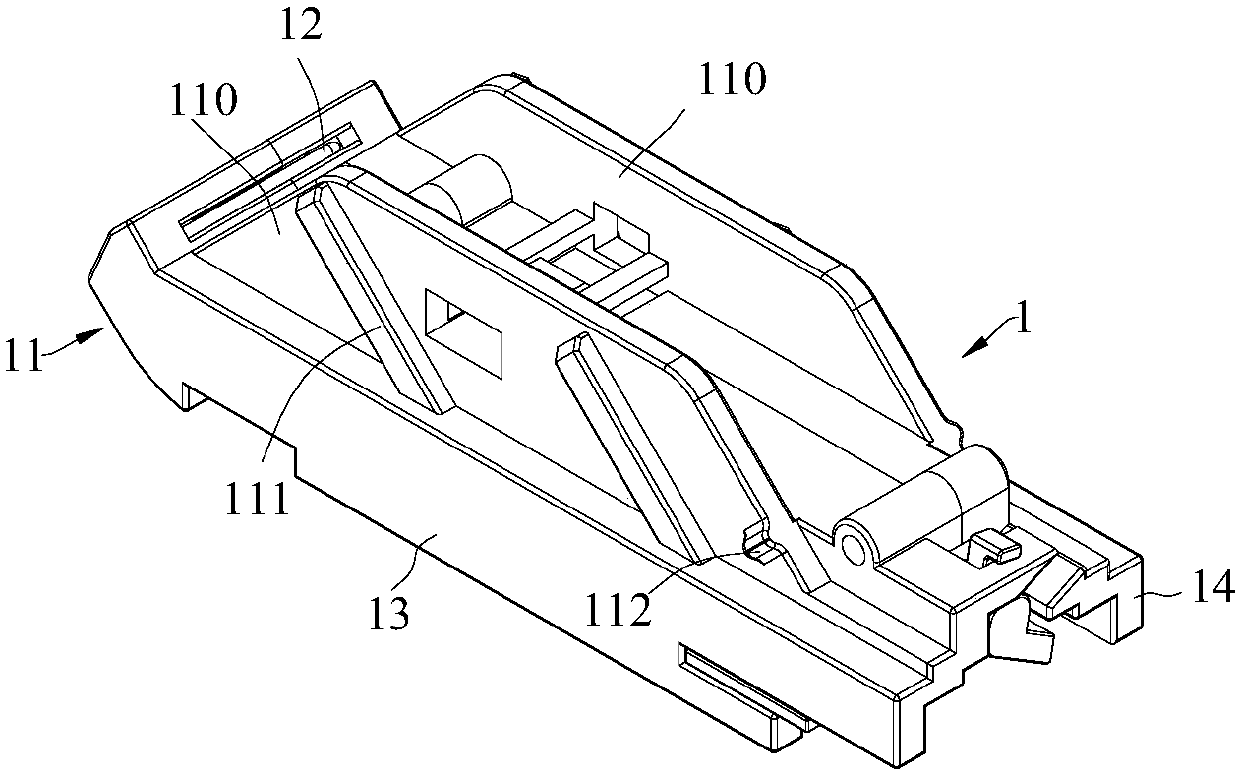

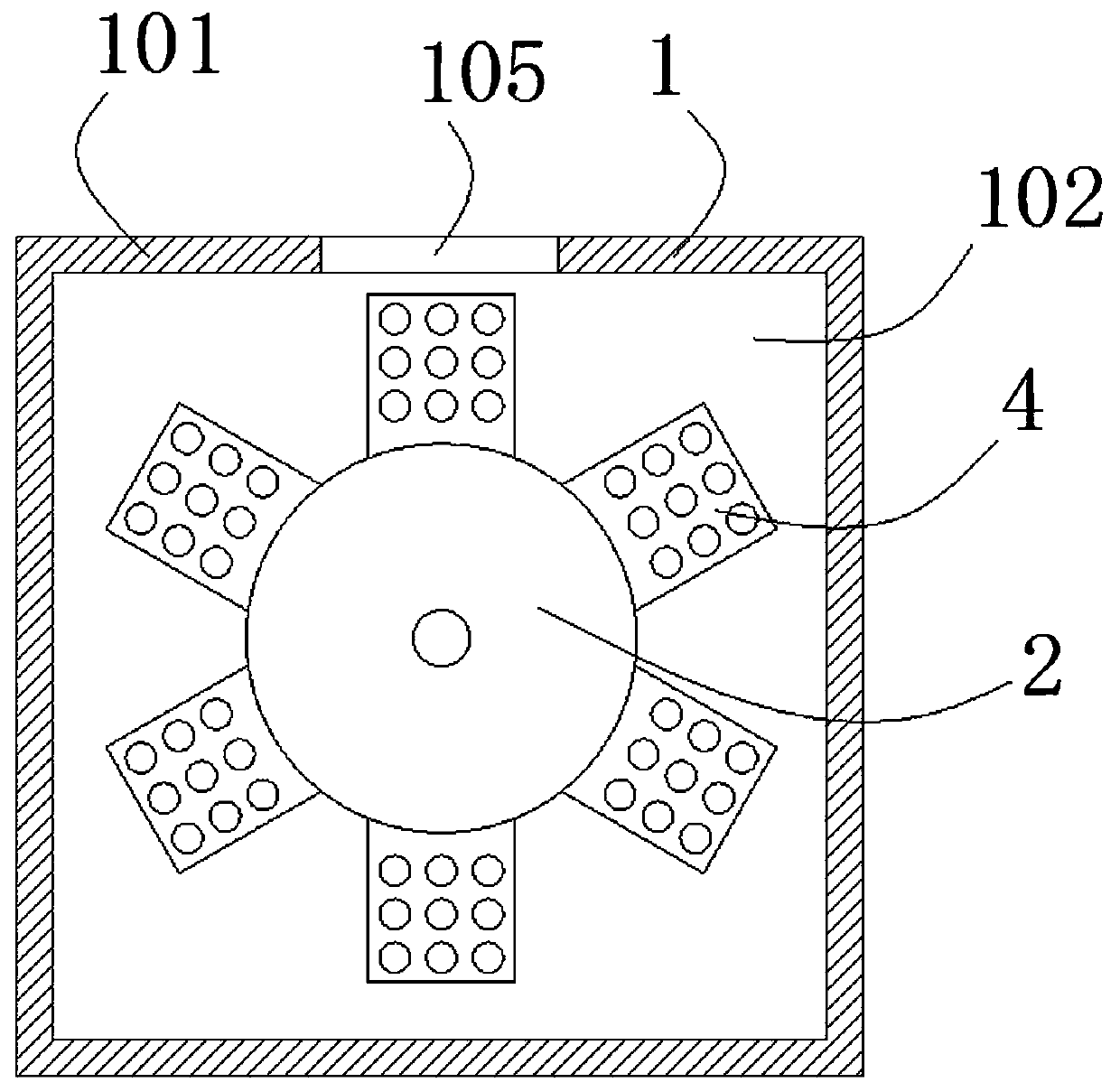

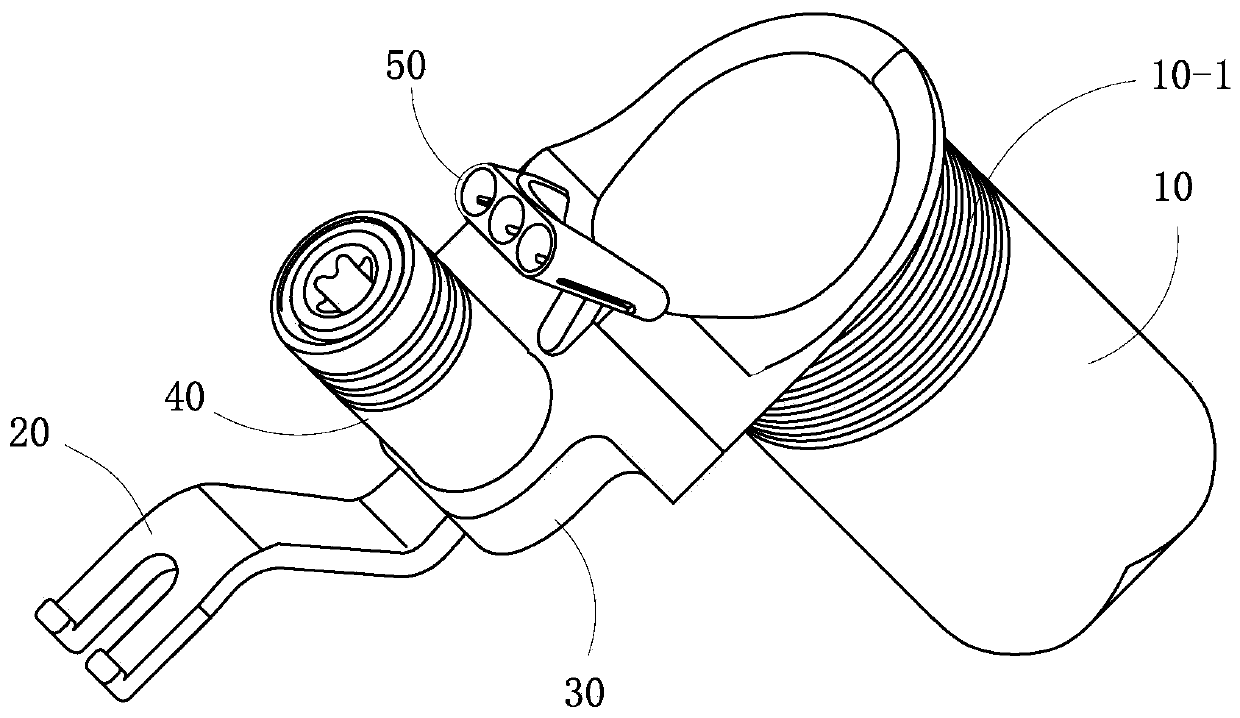

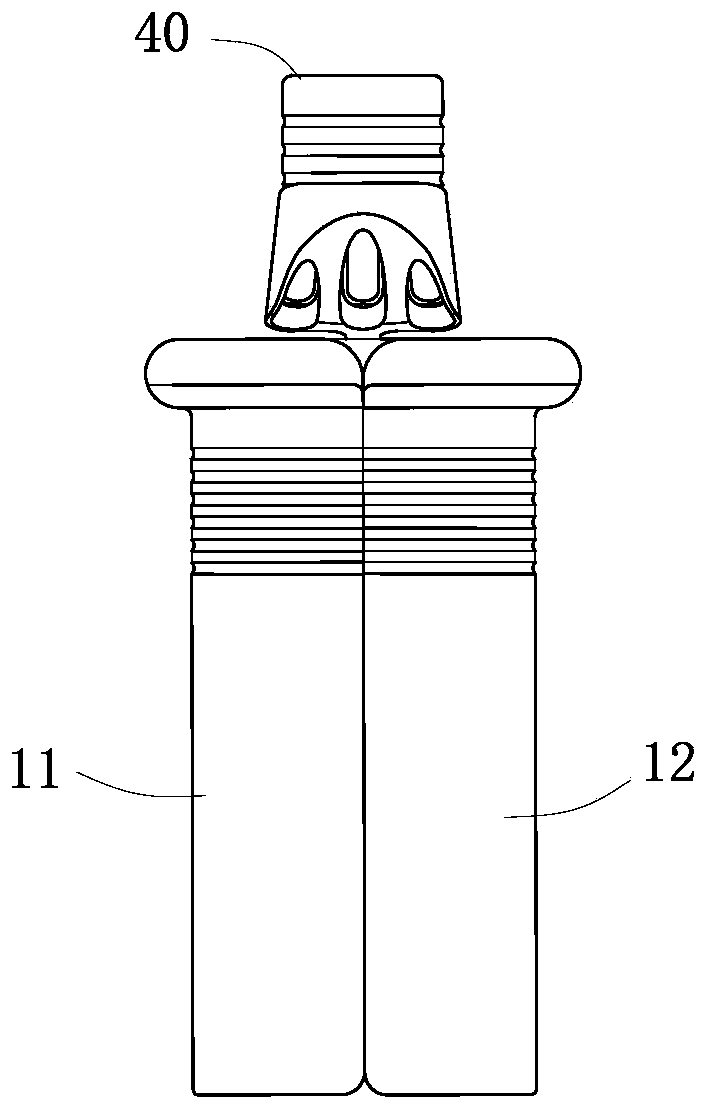

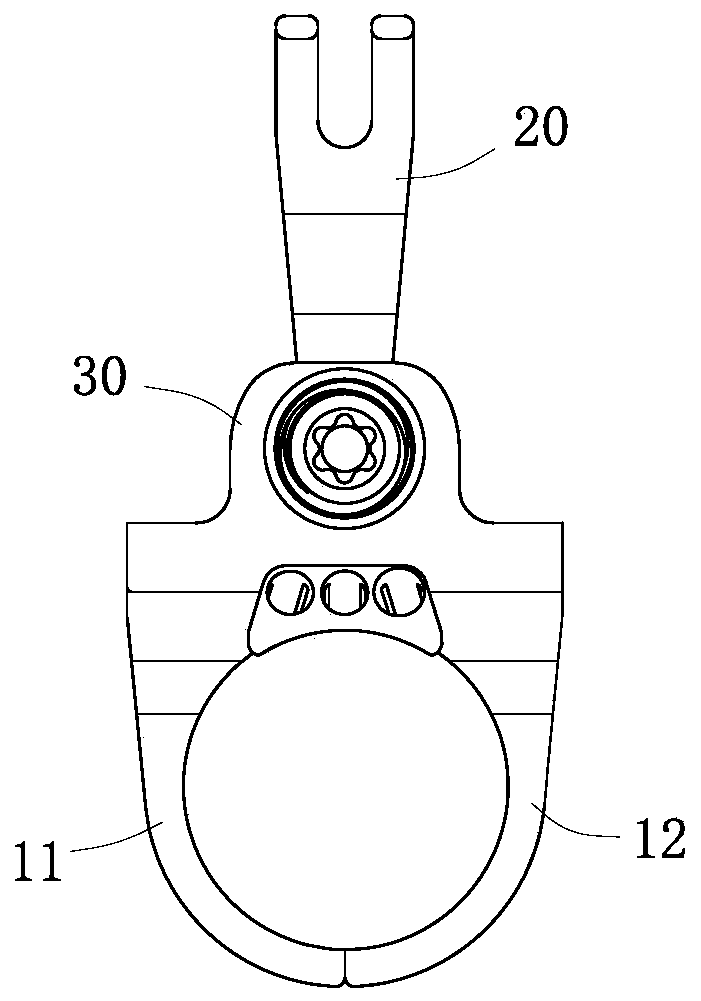

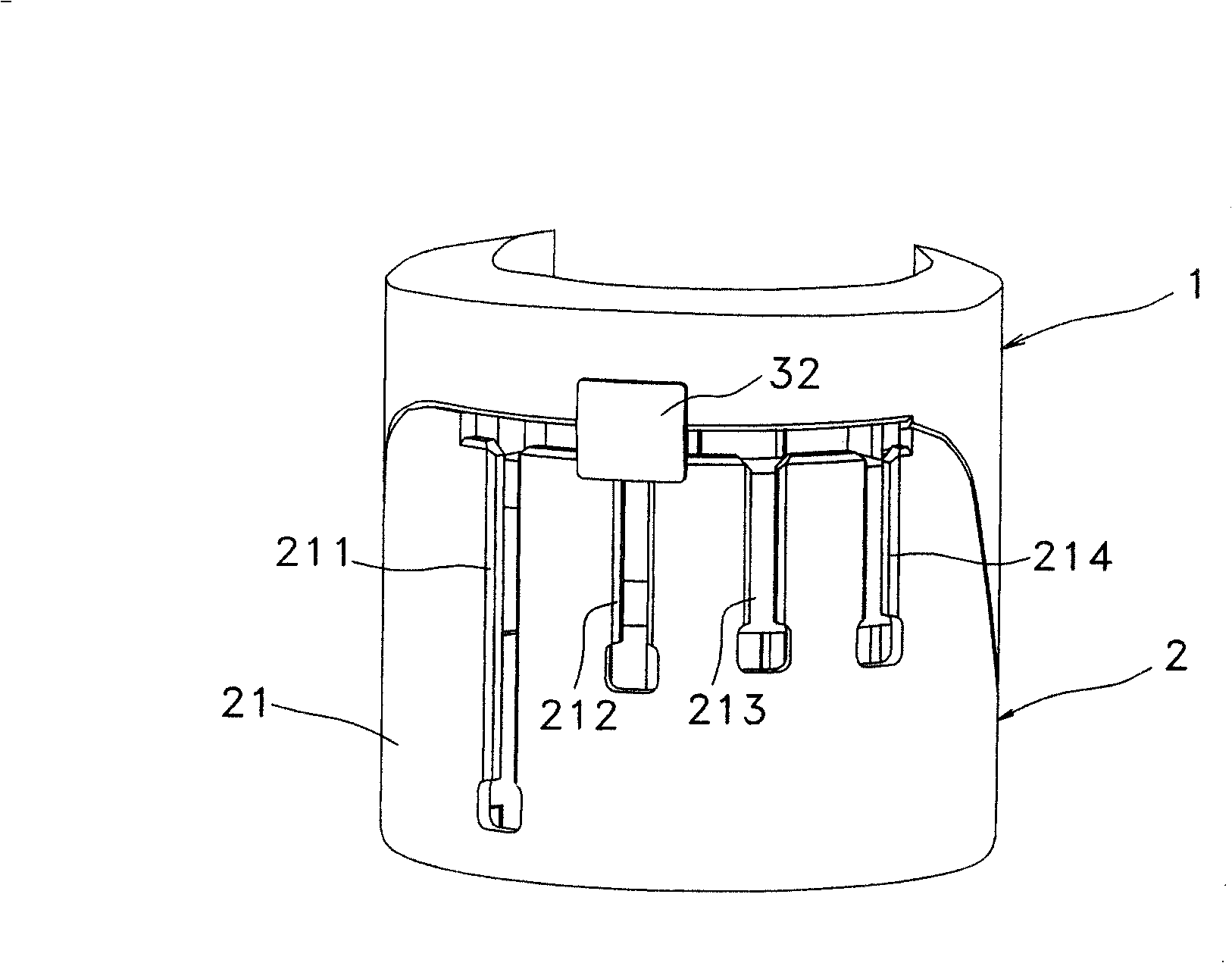

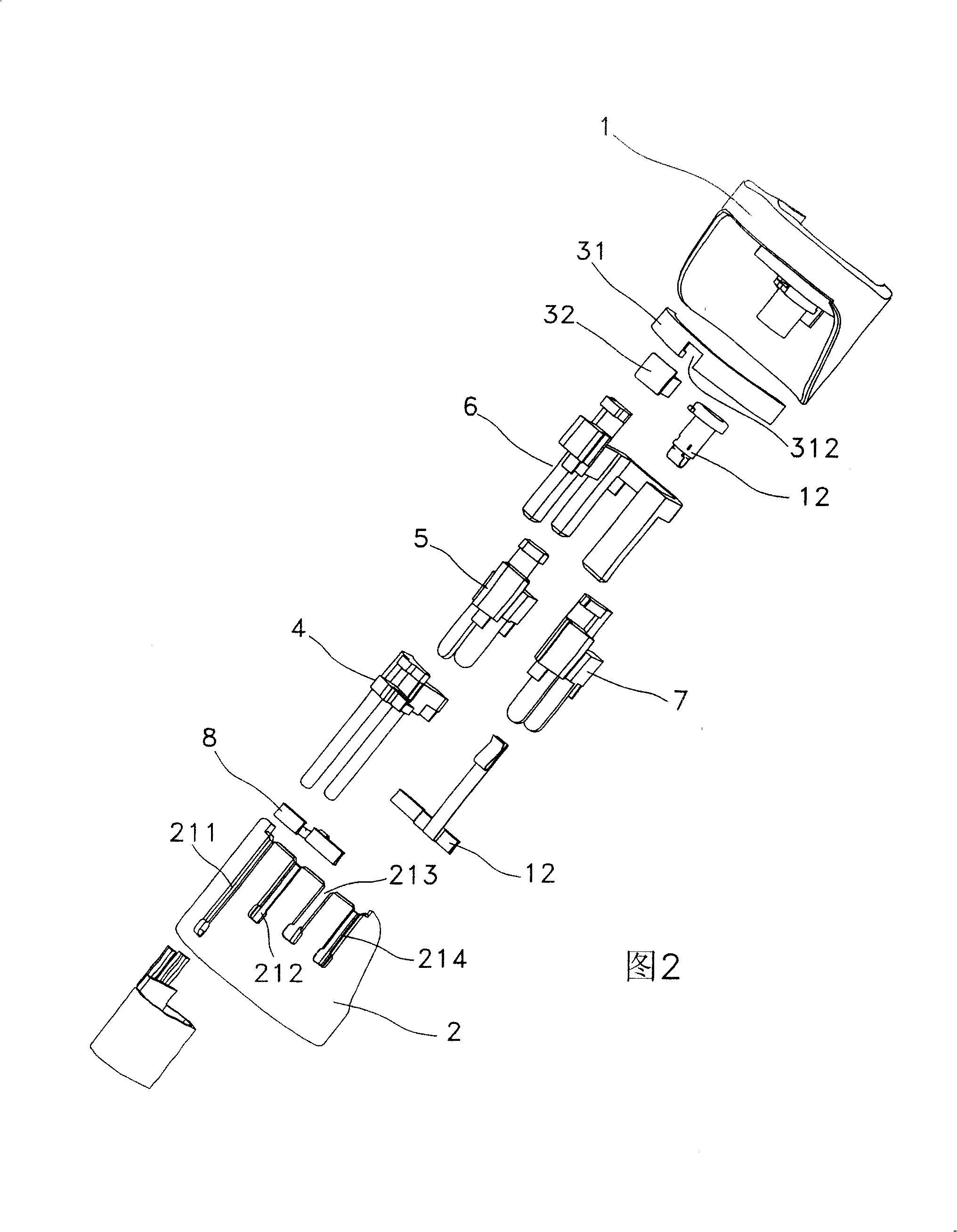

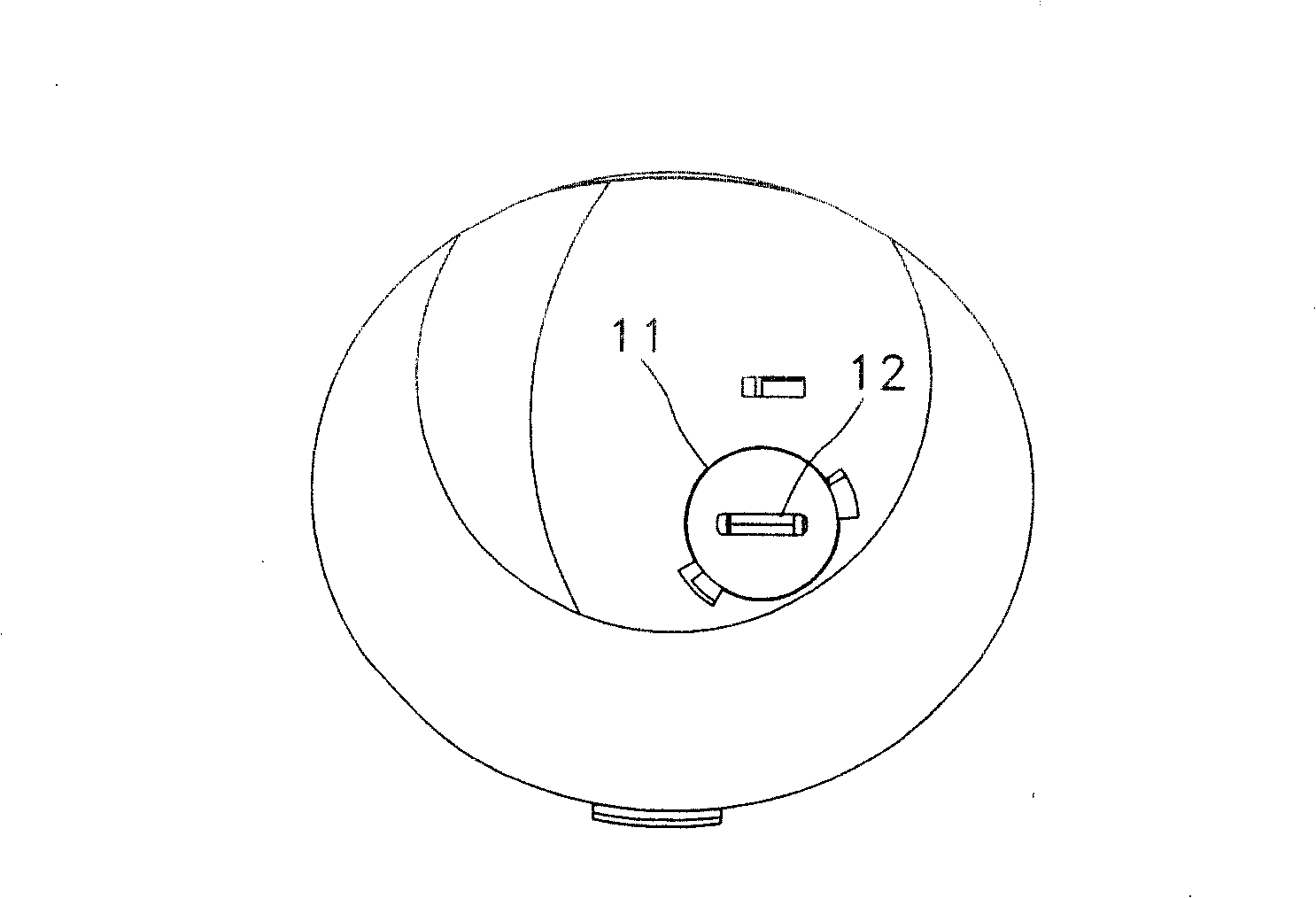

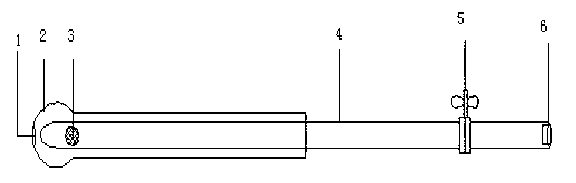

Rotatable and selectable push type multinational power source adapter

InactiveCN101872911AStretch out smoothlySimple and fast operationCoupling contact membersMechanical engineeringEngineering

Owner:GENERAL JACK TECH

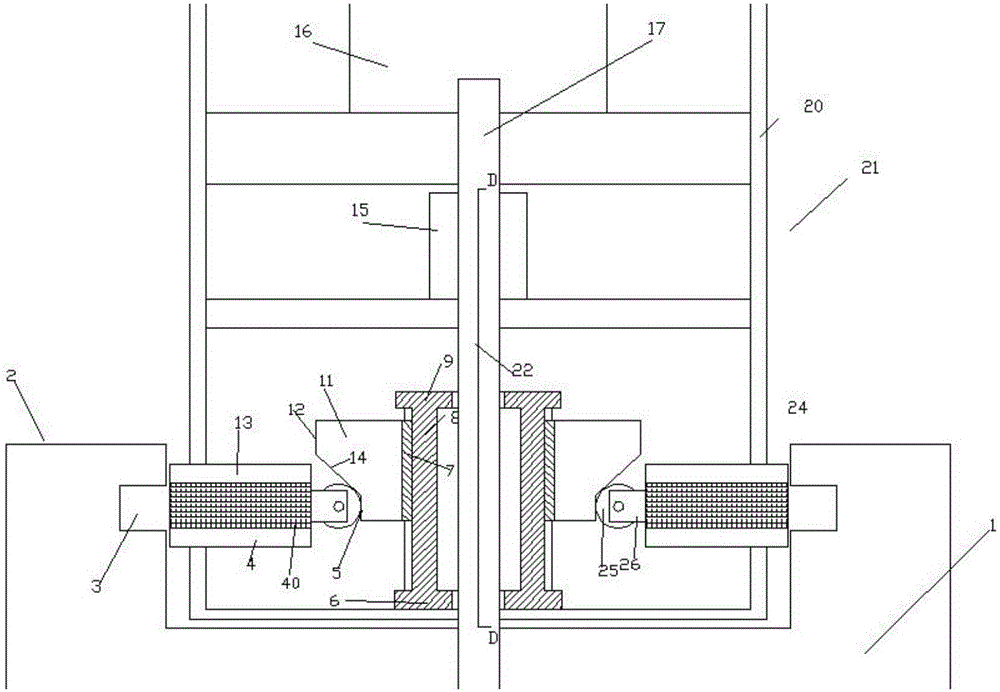

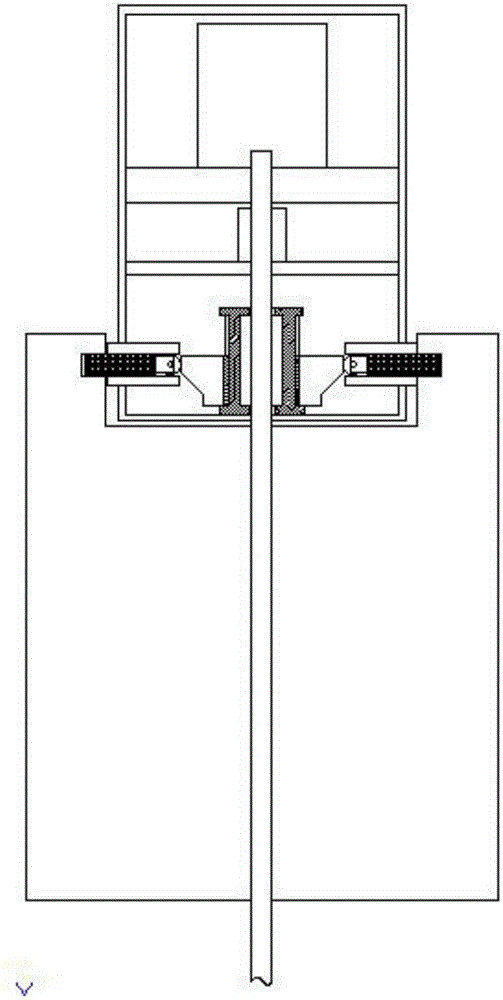

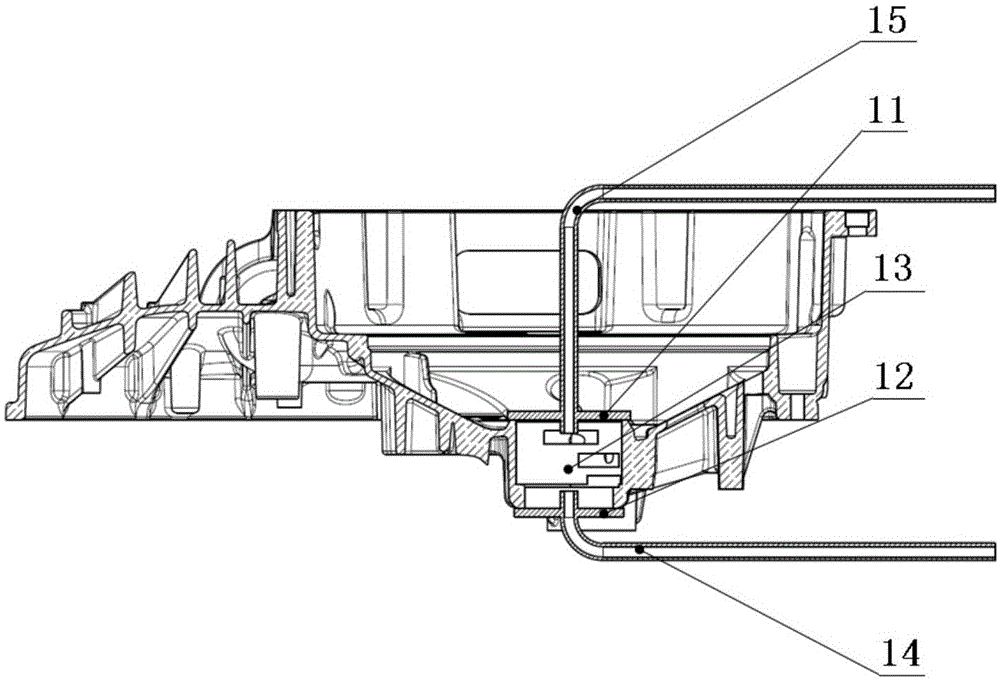

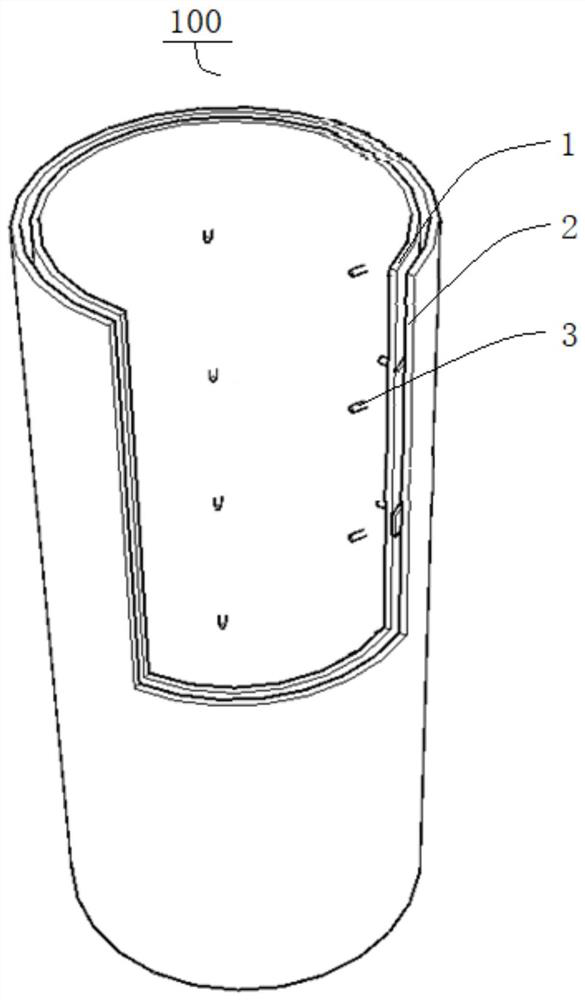

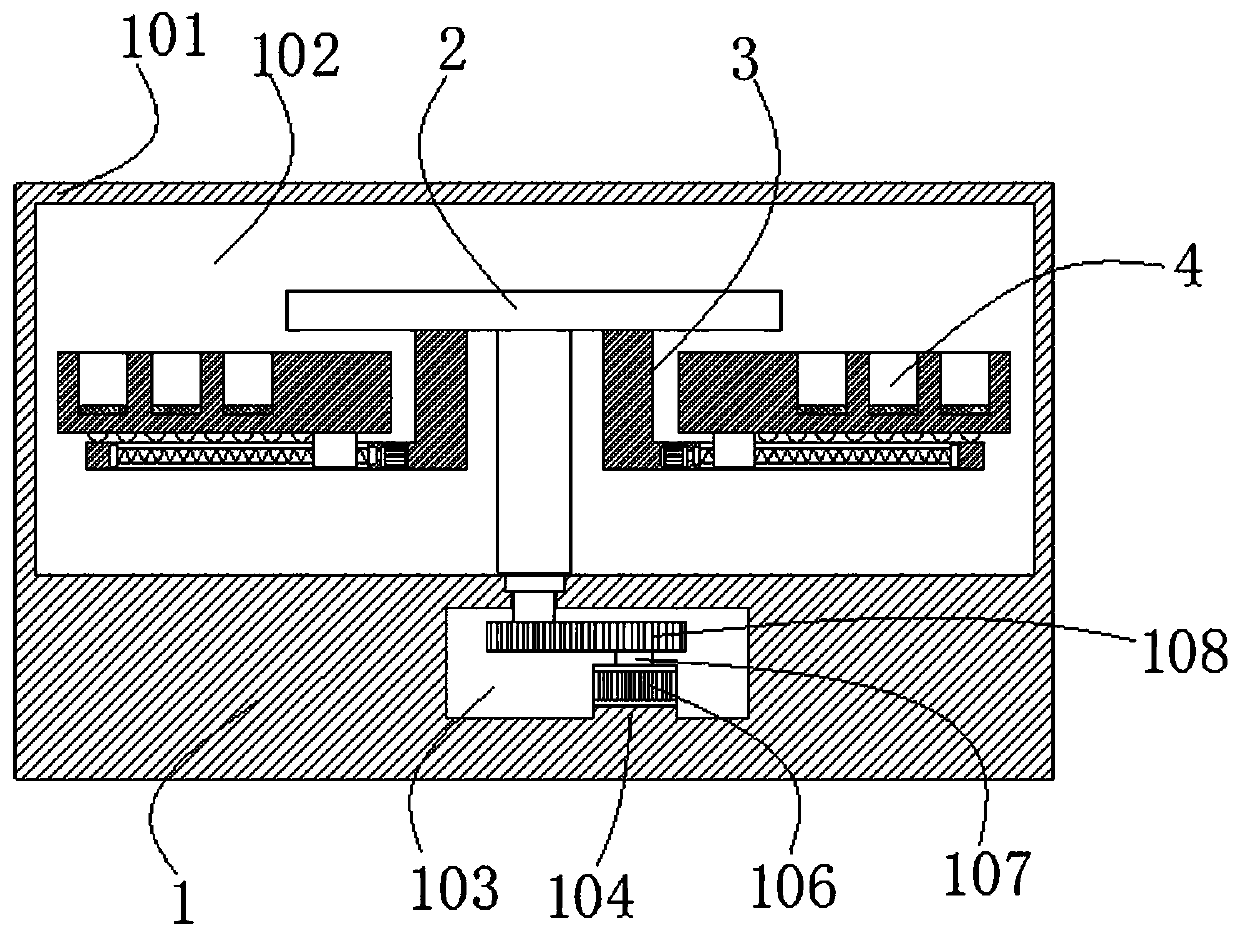

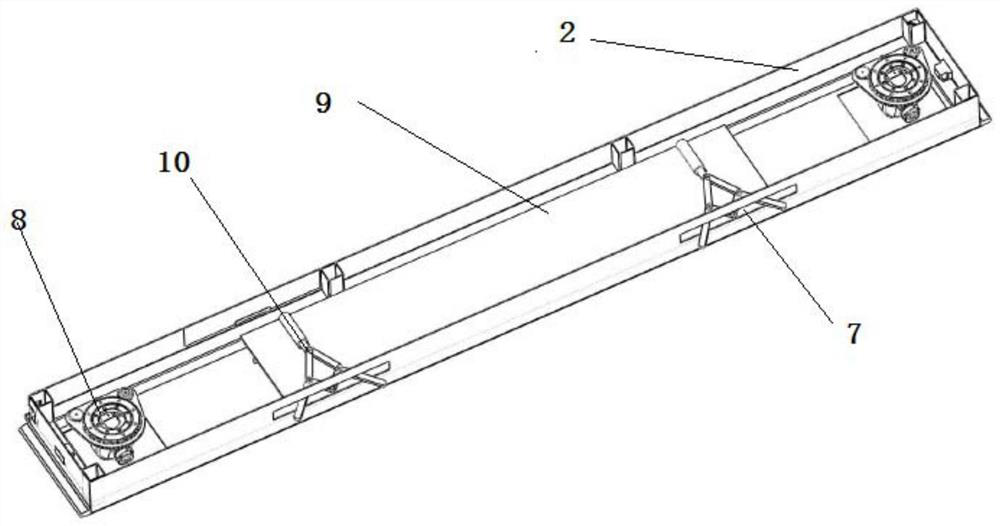

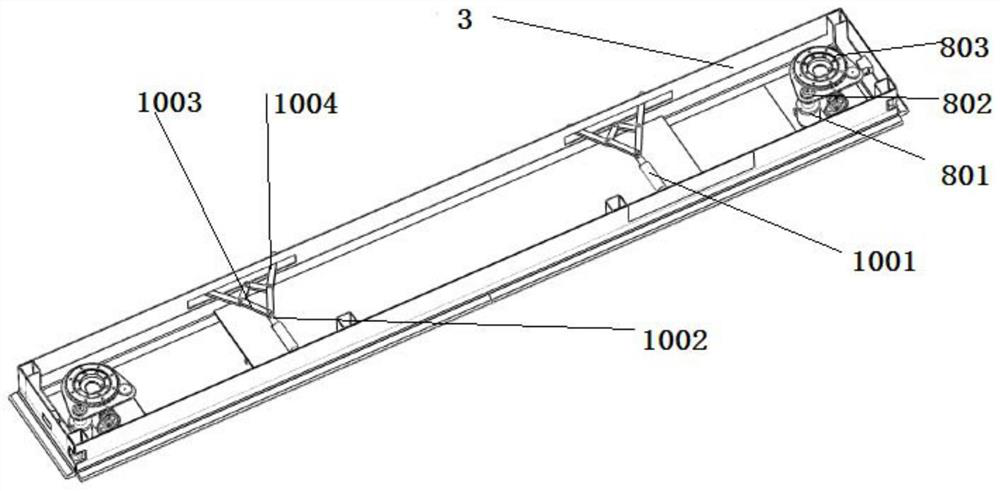

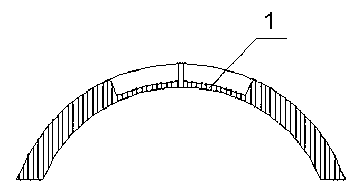

Application method of lift type door plank device using single screw to achieve automatic locking

InactiveCN105840036AReduce usageReduce distractionsBarrages/weirsPower-operated mechanismProtruding shouldersDrive motor

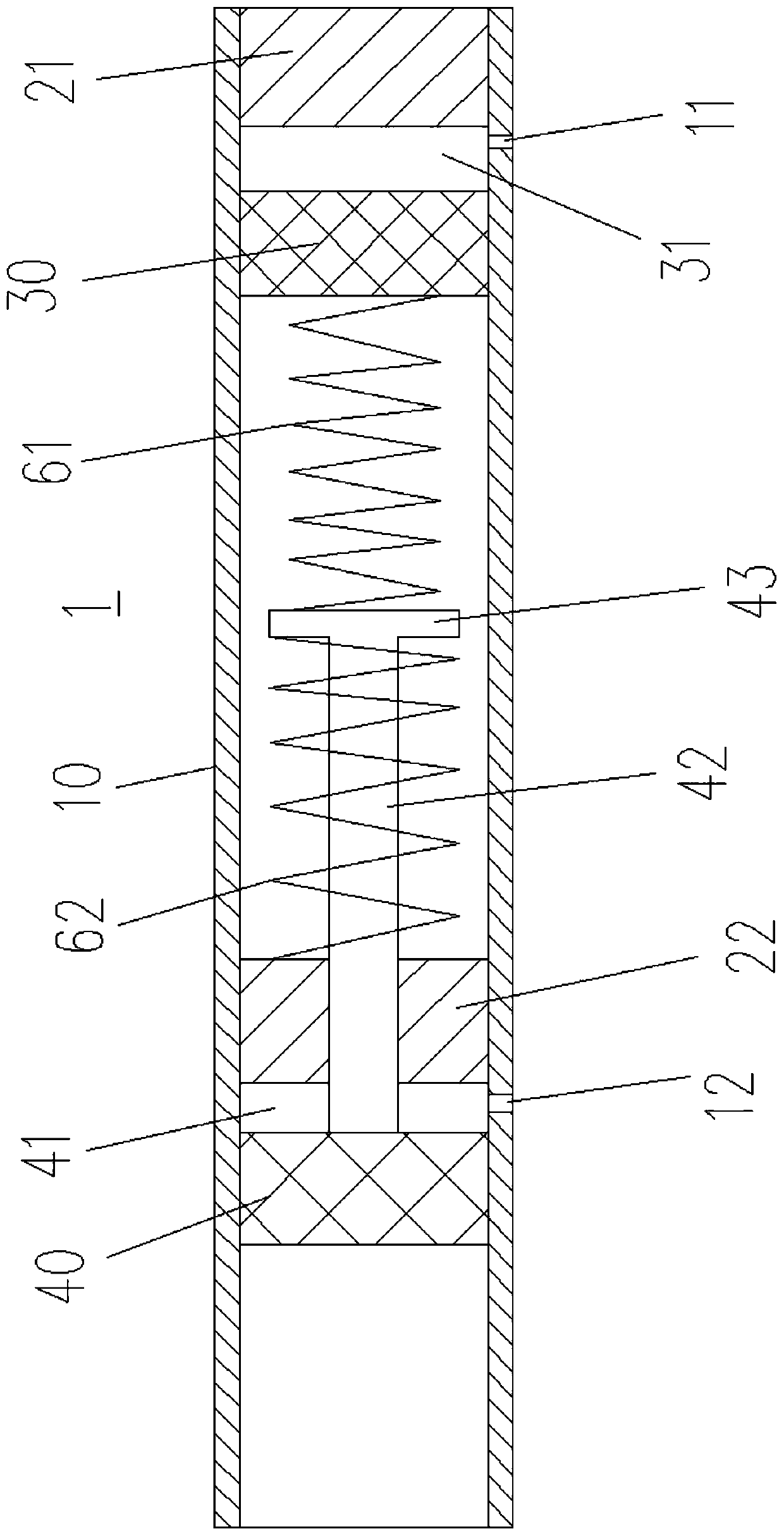

The invention discloses an application method of a lift type door plank device using a single screw to achieve automatic locking. The lift type door plank device comprises a door plank (1) and a door plank lift driving unit (21). The door plank lift driving unit (21) comprises a shell (20) which is fixed to a supporting substrate. A door plank lift driving motor (16) is fixed in the shell (20) and is in power connection with upper end of a door plank lift driving lead screw (17). The door plank lift driving lead screw (17) is in screw-thread fit with a screw hole in the door plank (1). The two sides of the upper edge of the door plank (1) are each provided with a protruding shoulder (2). The inner side faces of the two protruding shoulders (2) are provided with locking holes (3) which are open towards the middle of the door plank (1) and extend in the direction perpendicular to the door plank lift driving lead screw (17).

Owner:项智锋

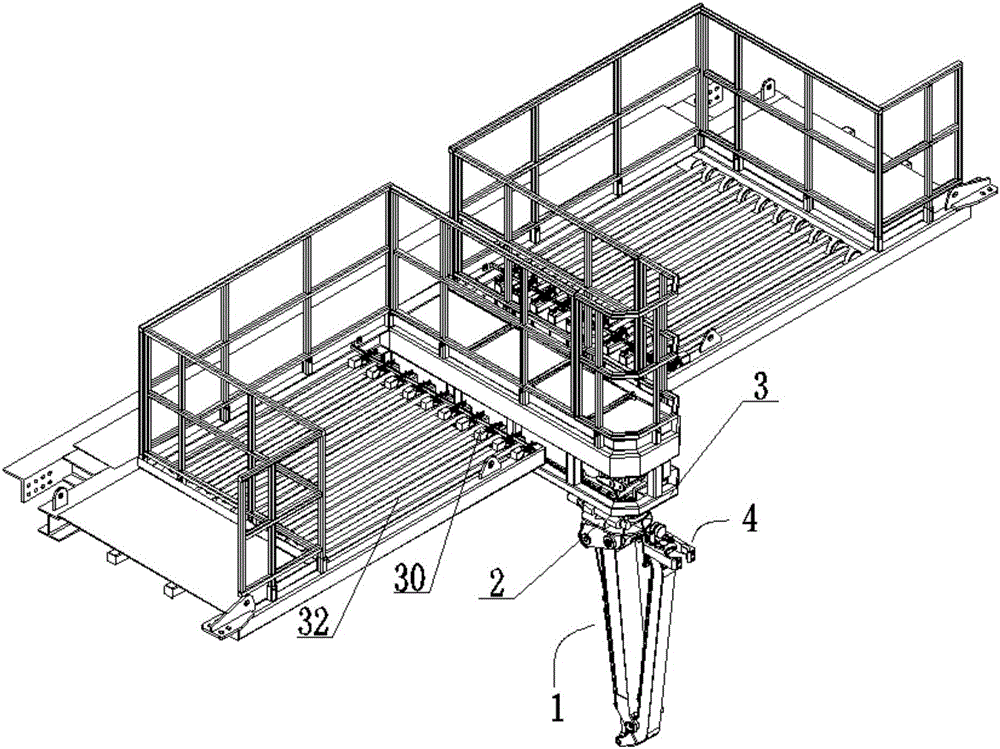

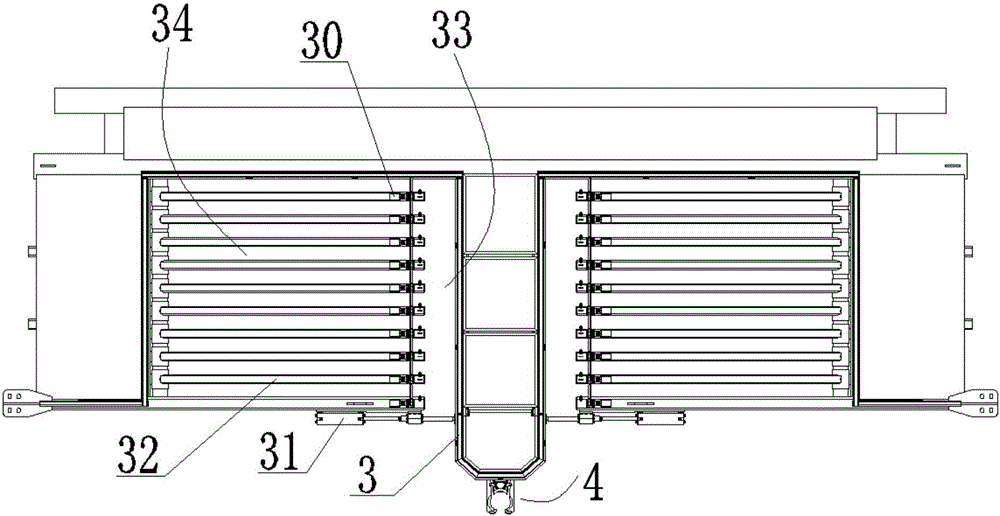

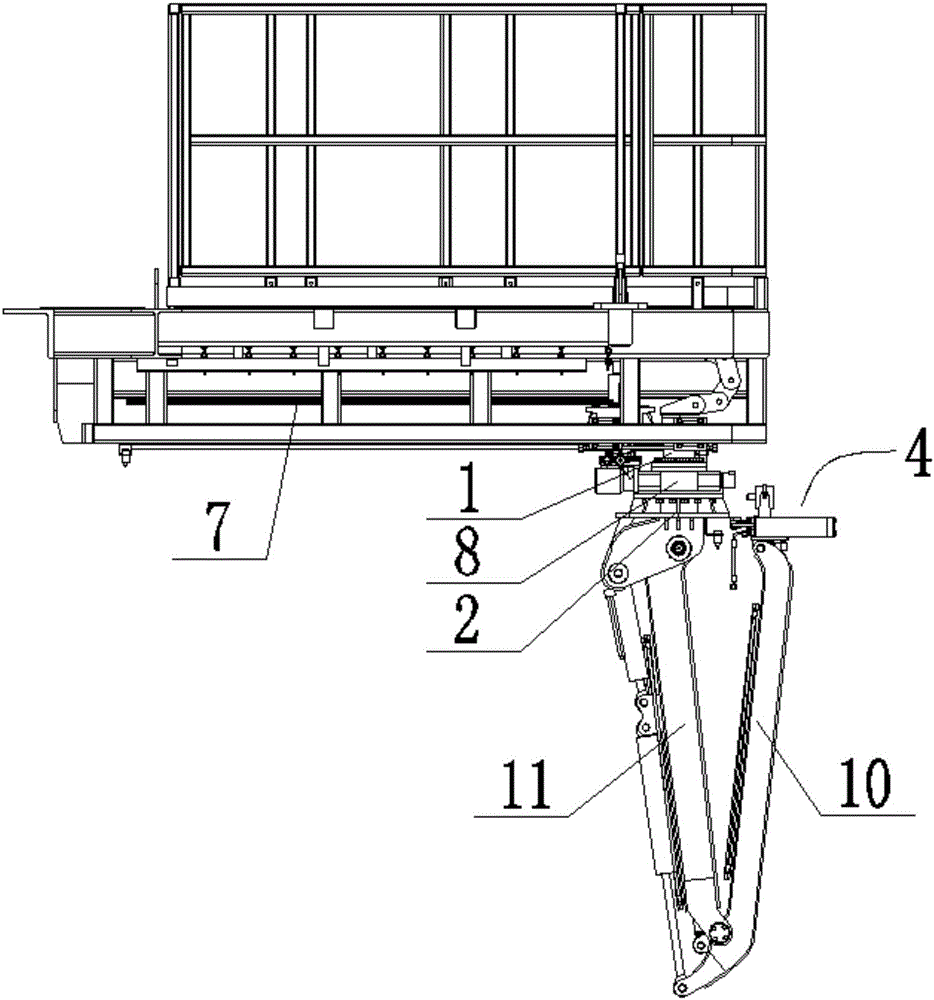

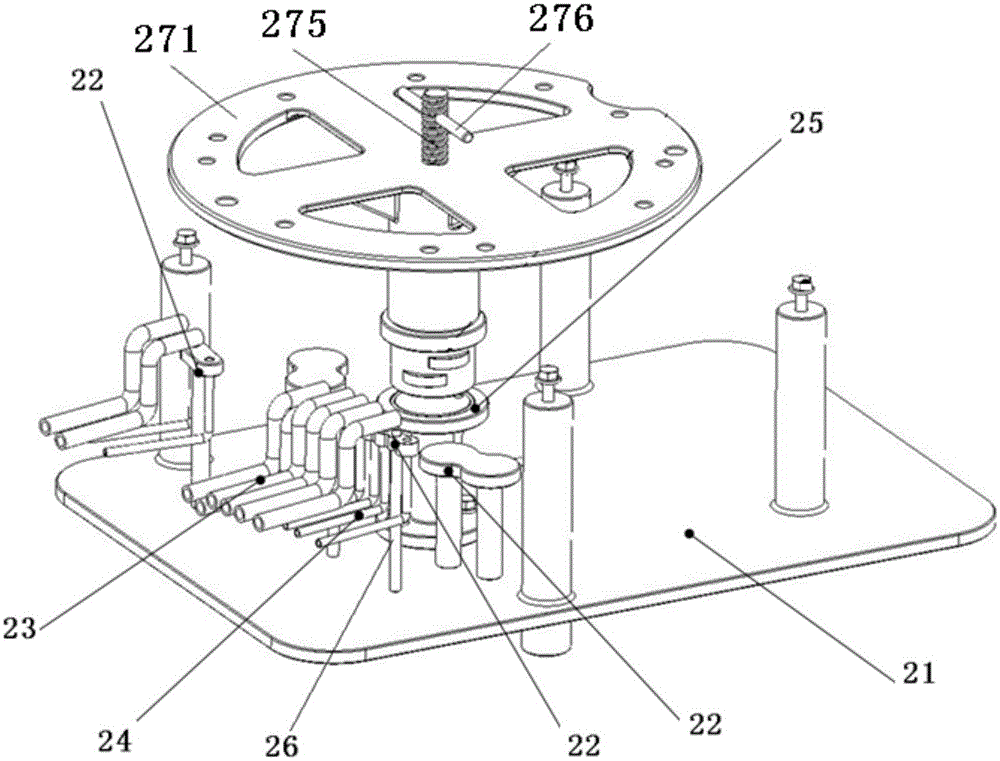

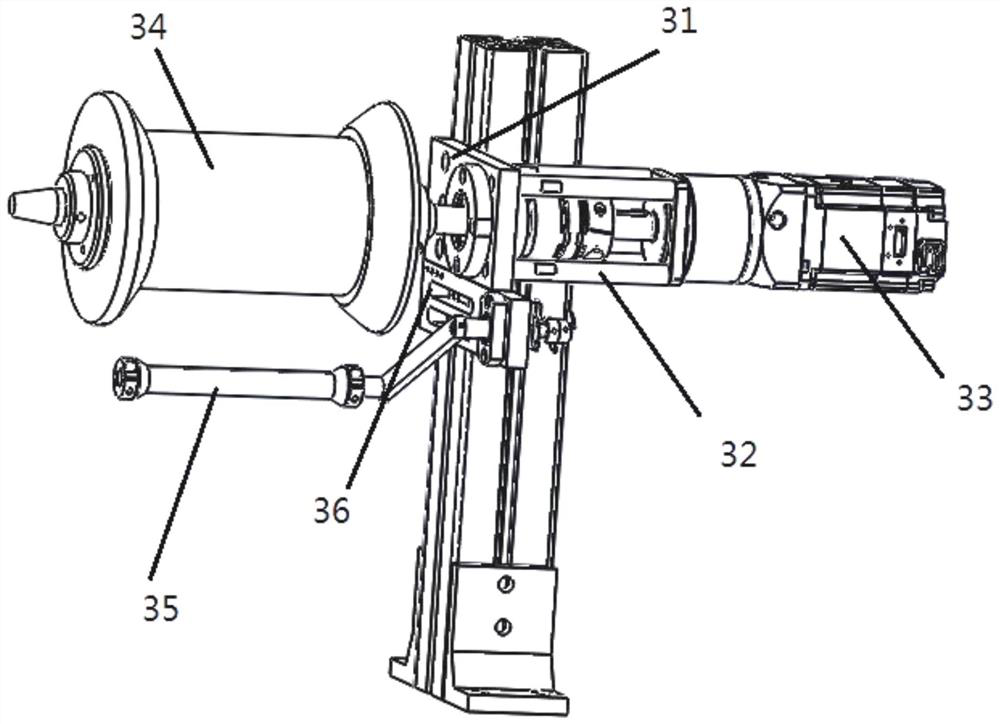

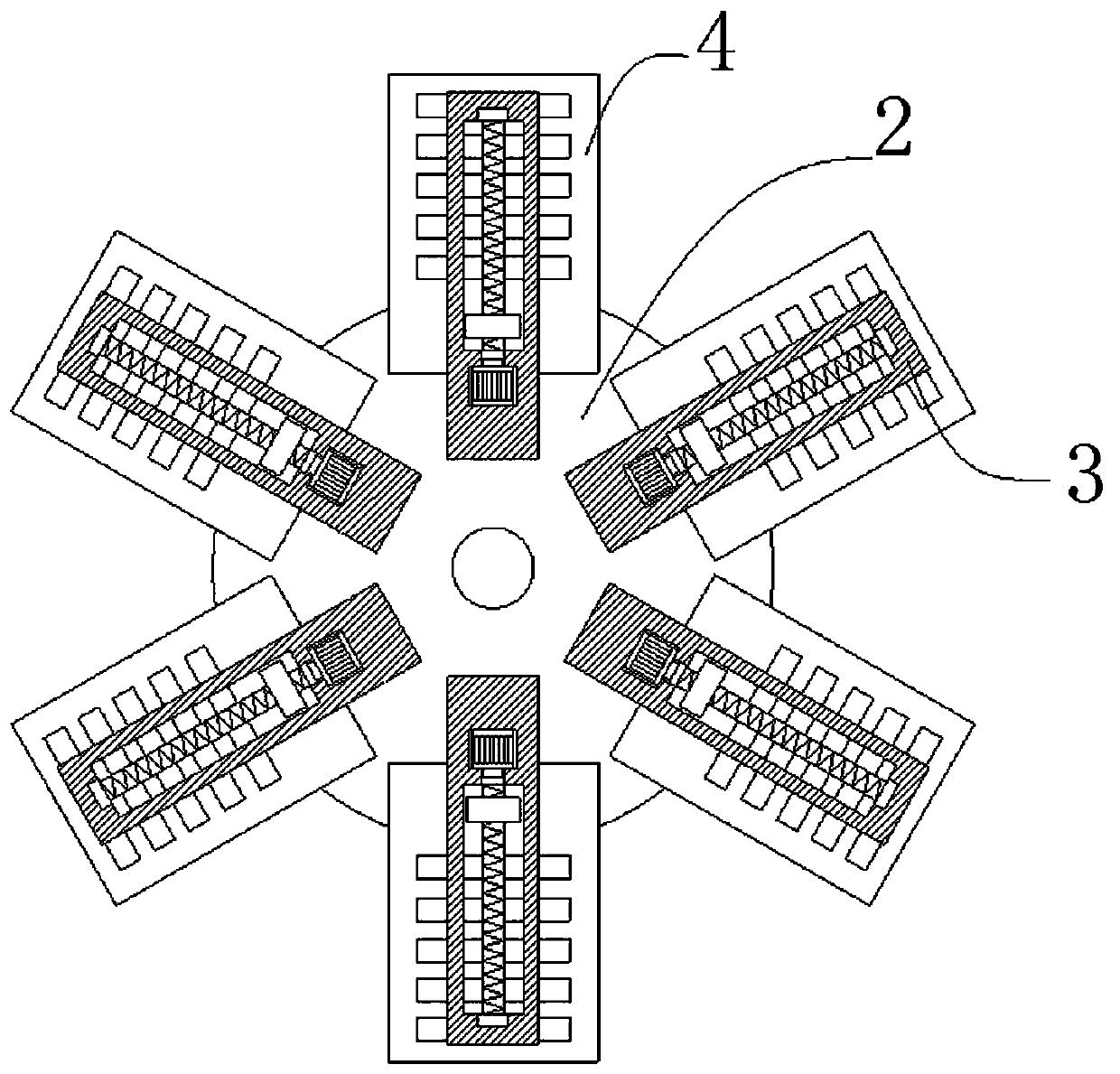

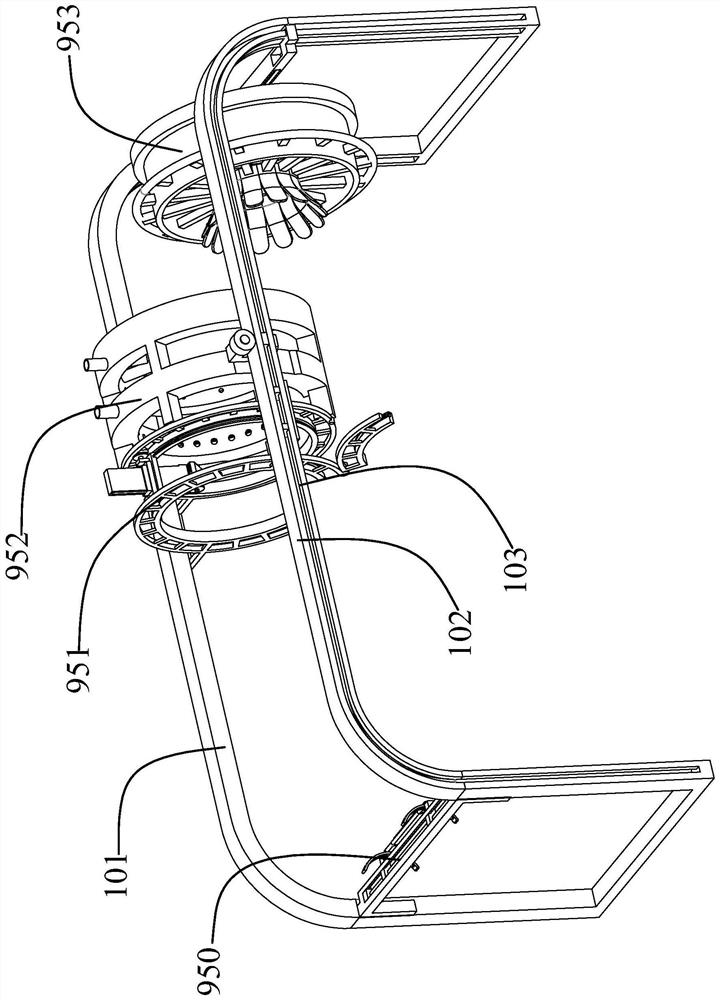

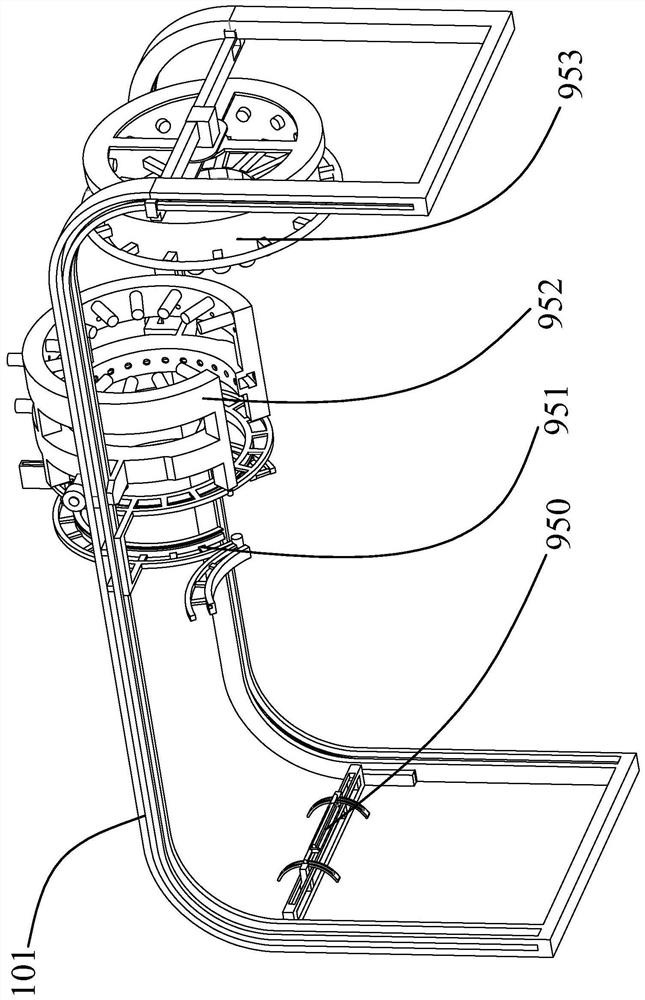

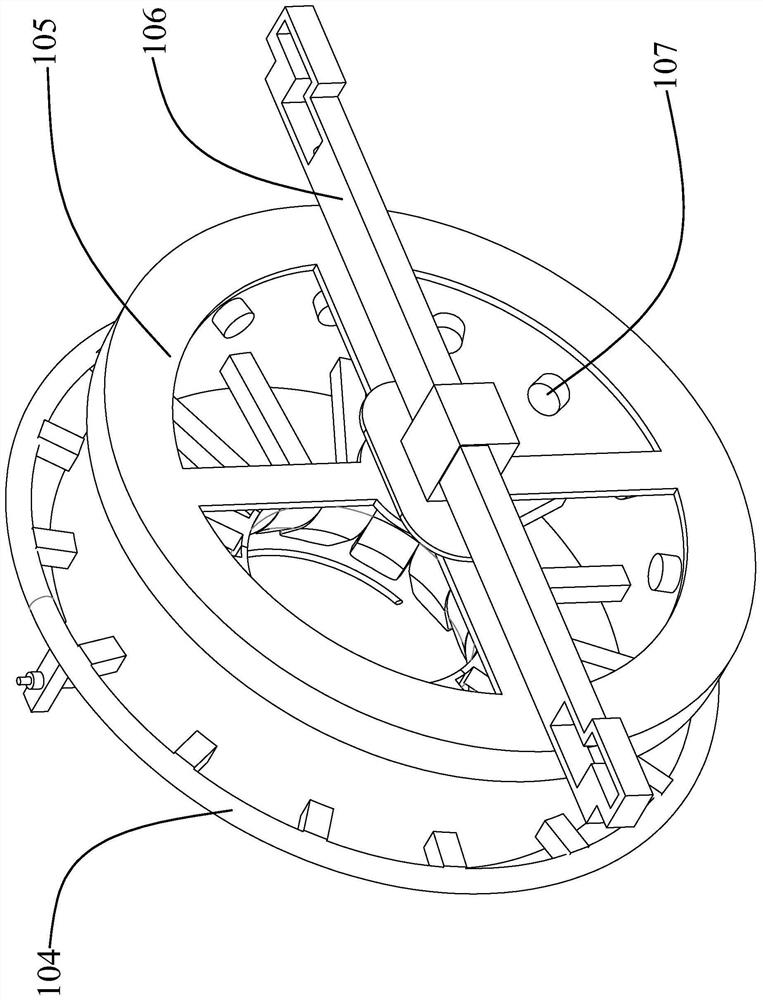

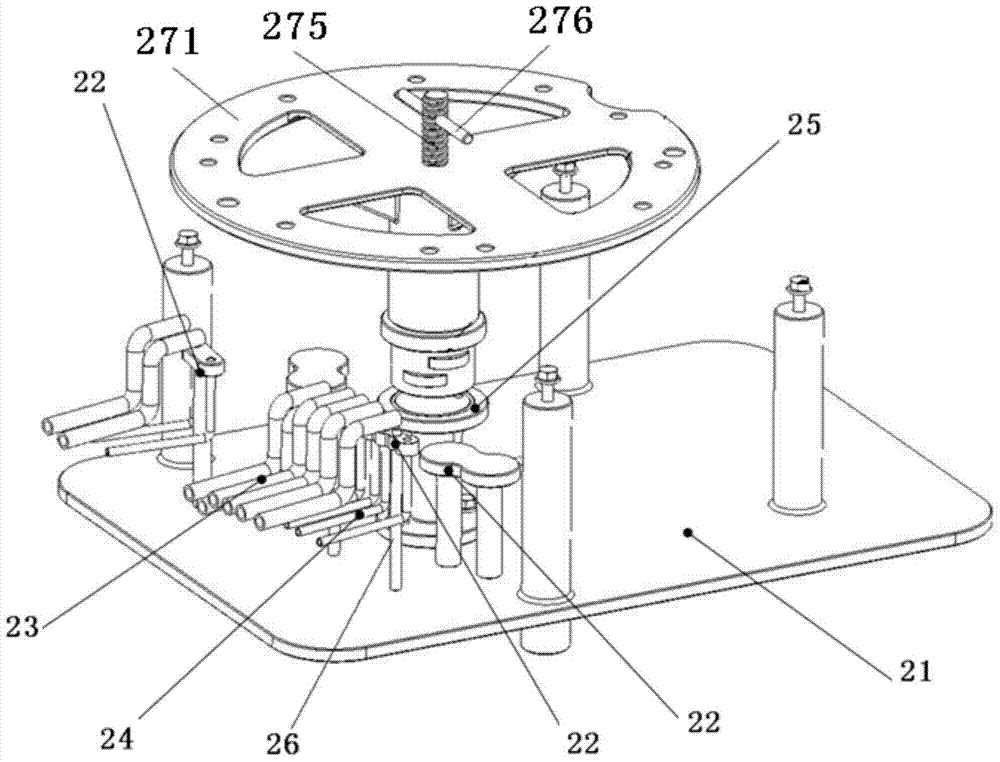

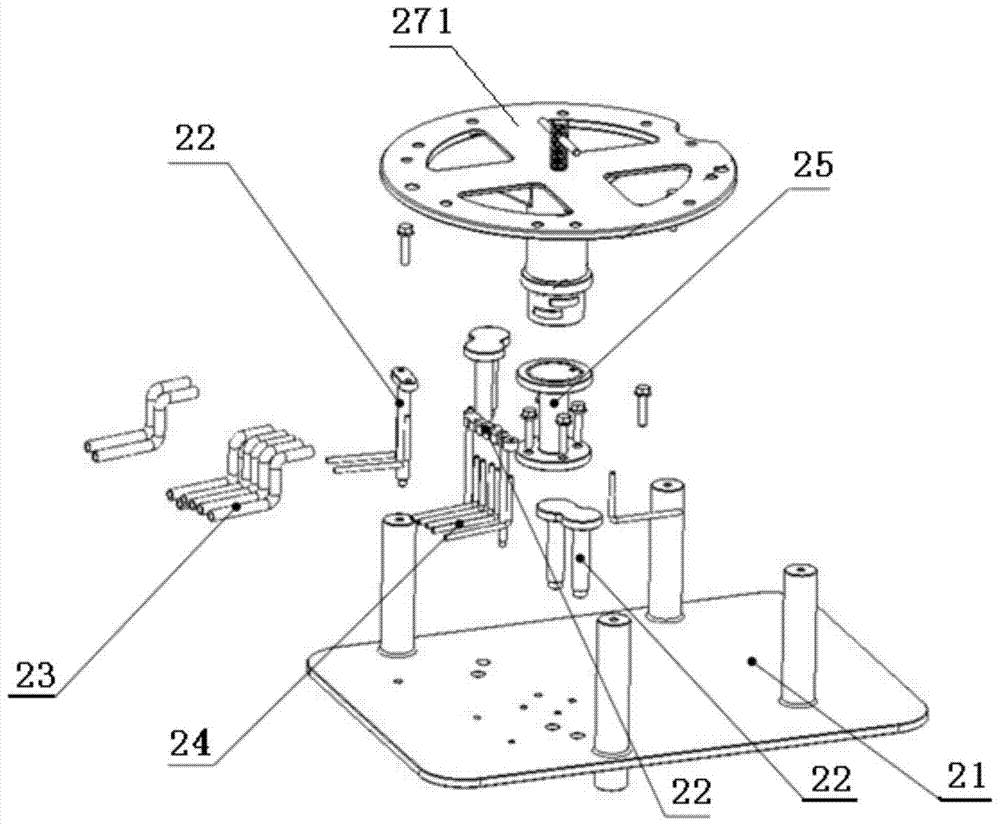

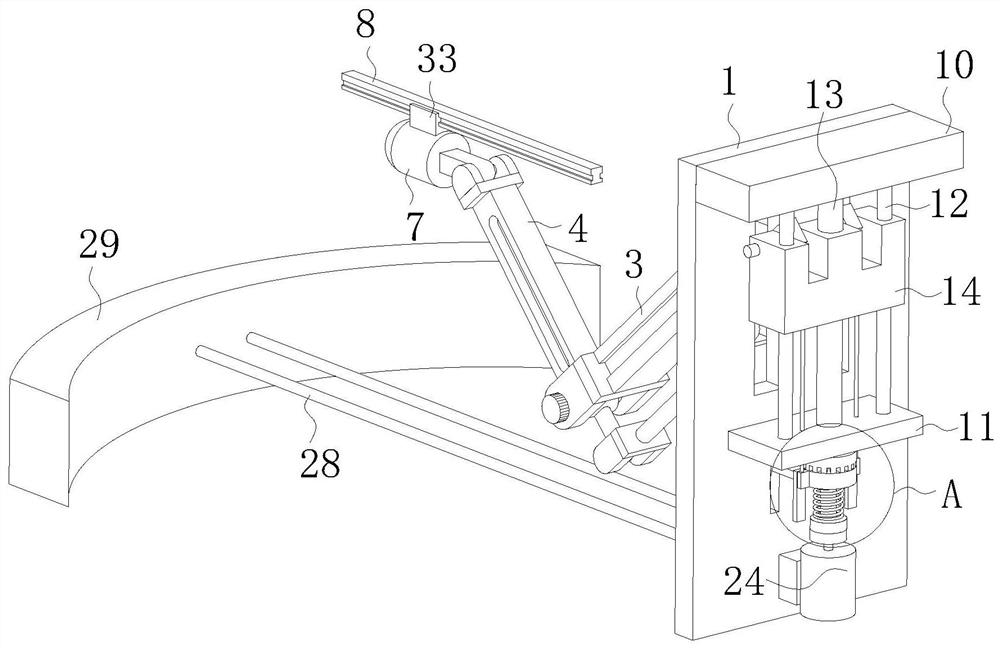

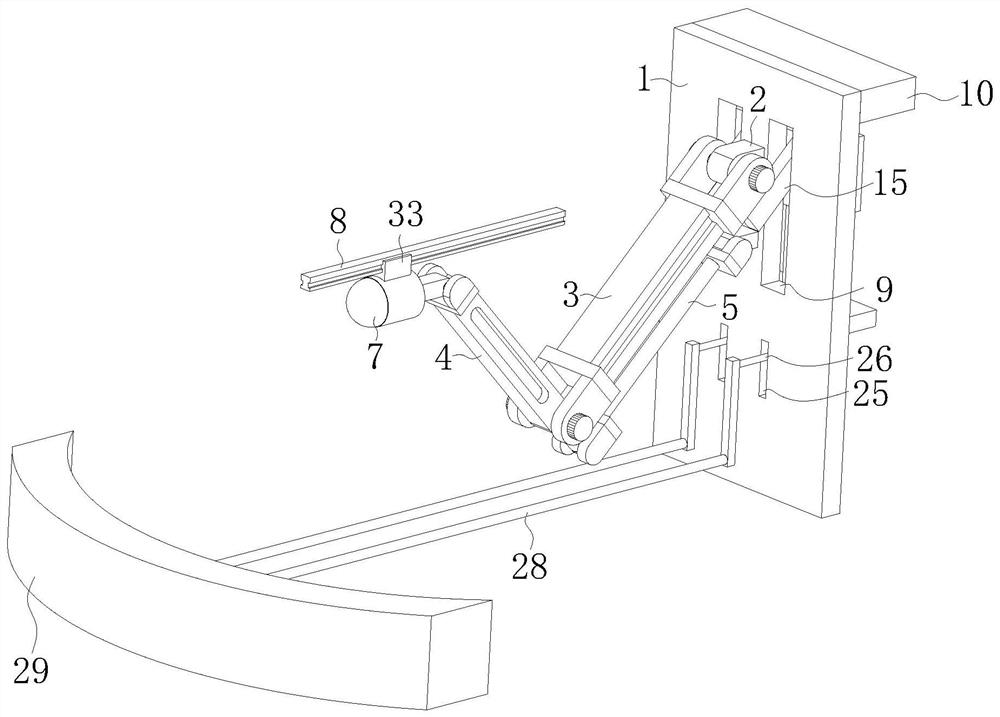

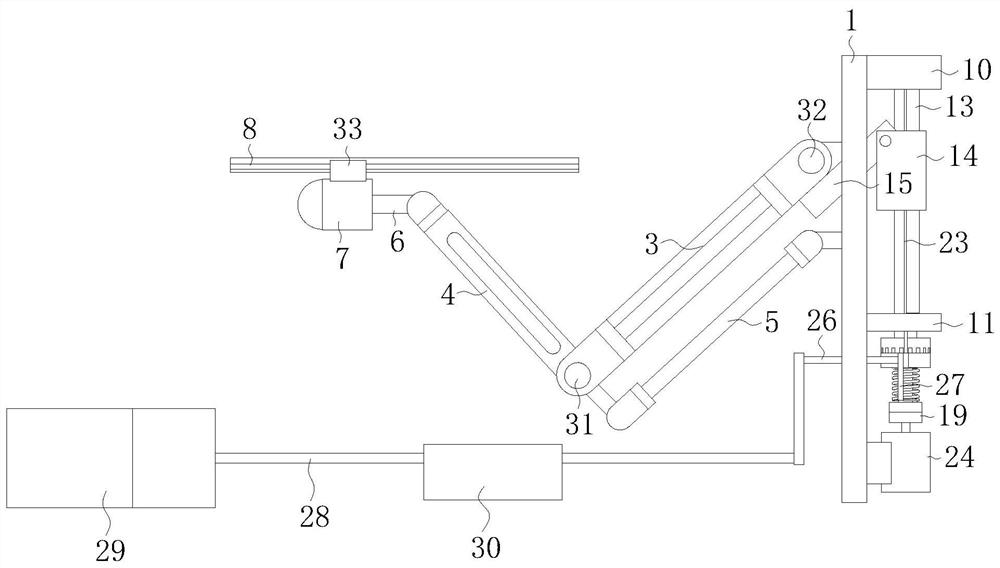

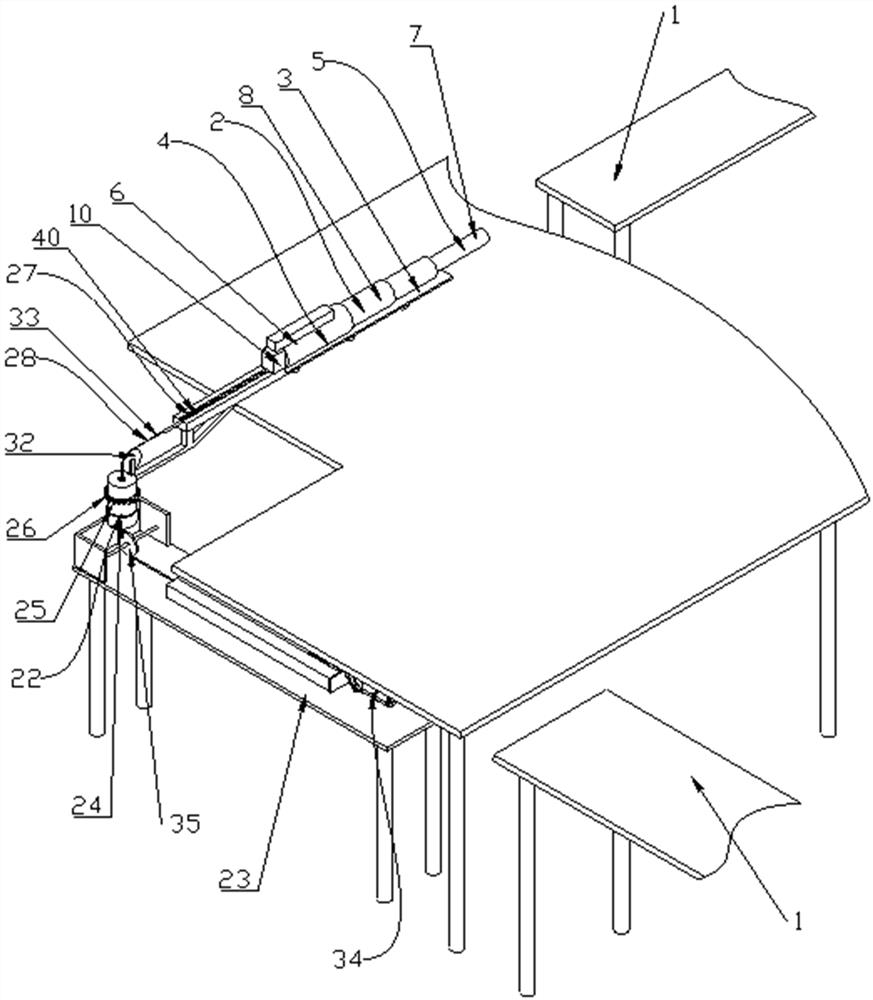

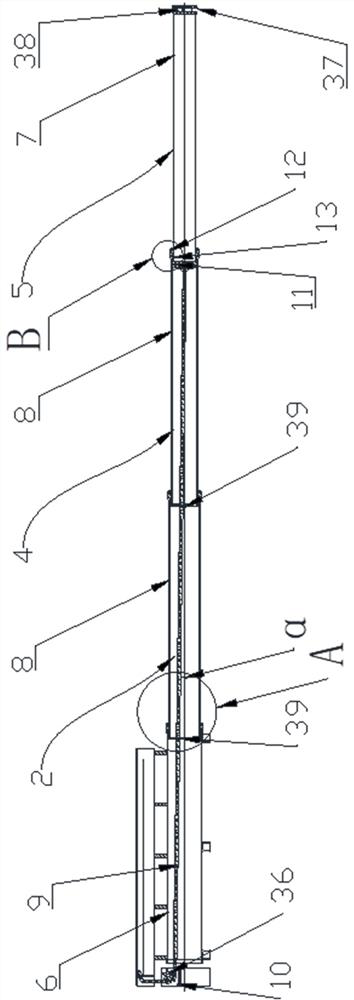

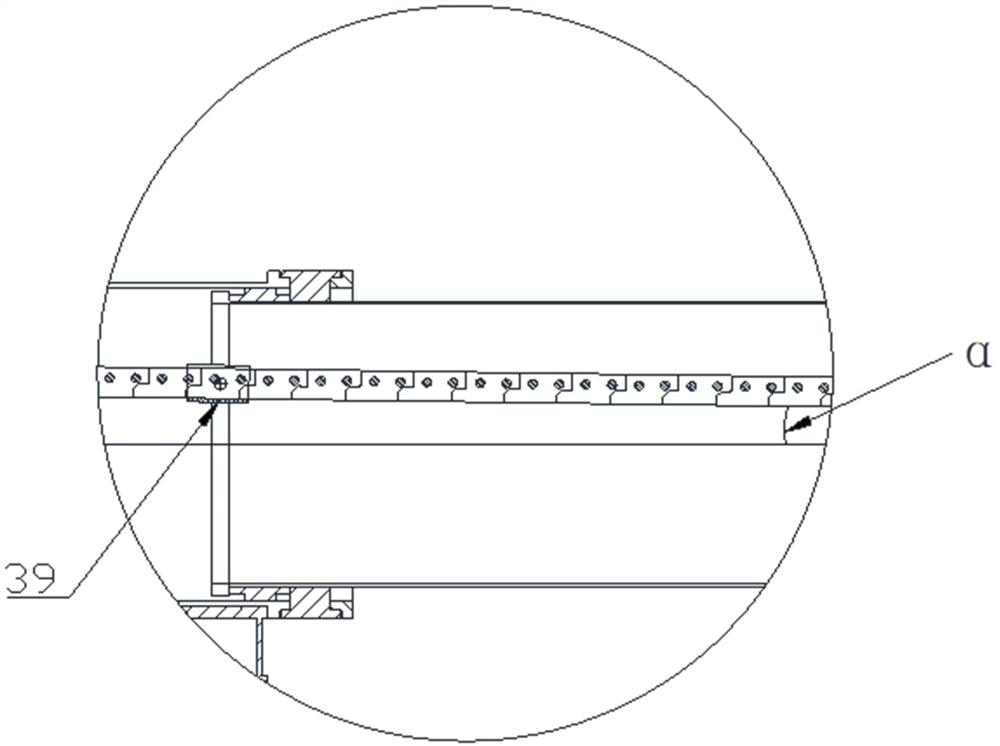

Intelligent racking-platform discharging pipe system

ActiveCN105822239ASmall footprintStretch out smoothlyDrilling rodsDrilling casingsMeasurement deviceManipulator

The invention relates to the technical field of petroleum equipment, in particular to an intelligent racking-platform discharging pipe system. The intelligent racking-platform discharging pipe system comprises a supporting seat, a rotary table, a rotary driving mechanism, a clamping claw, a linear movement mechanism, a mechanical arm and a controller, wherein the mechanical arm mainly consists of a fixing seat, a front arm, a rear arm, a front arm connecting rod, a rear arm connecting rod, a front arm oil cylinder, a rear arm oil cylinder and a connecting plate. Horizontal movements of the intelligent racking-platform discharging pipe system can be achieved through the linear movement mechanism. The rotary driving mechanism adopts a rotary speed reducer with an encoder, is reliable and compact in structure and can accurately control a rotary angle. A clamping claw can be always kept in a horizontal state, the travel relation between the front arm oil cylinder and the rear arm oil cylinder can be controlled through a first angle measurement device, a second angle measurement device and the controller to achieve horizontal-linear movements of the clamping claw so that extending and retraction of the mechanical arm can be more stable. The clamping claw is compact in structure and small in occupied space, and fingerboard locks and fingerboard pneumatic stop rods can play a safe protection role and prevent a tubular column from dropping out.

Owner:QINGDAO JIERUI IND CONTROL TECH CO LTD

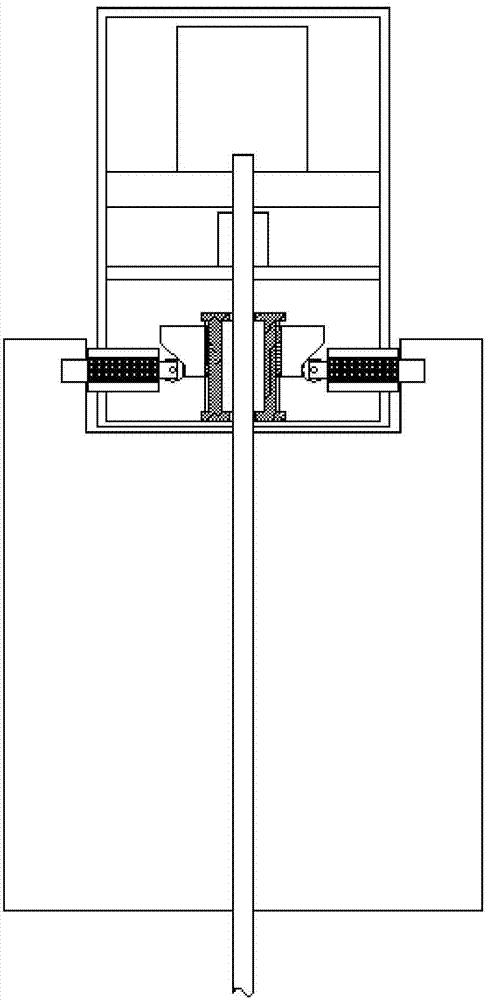

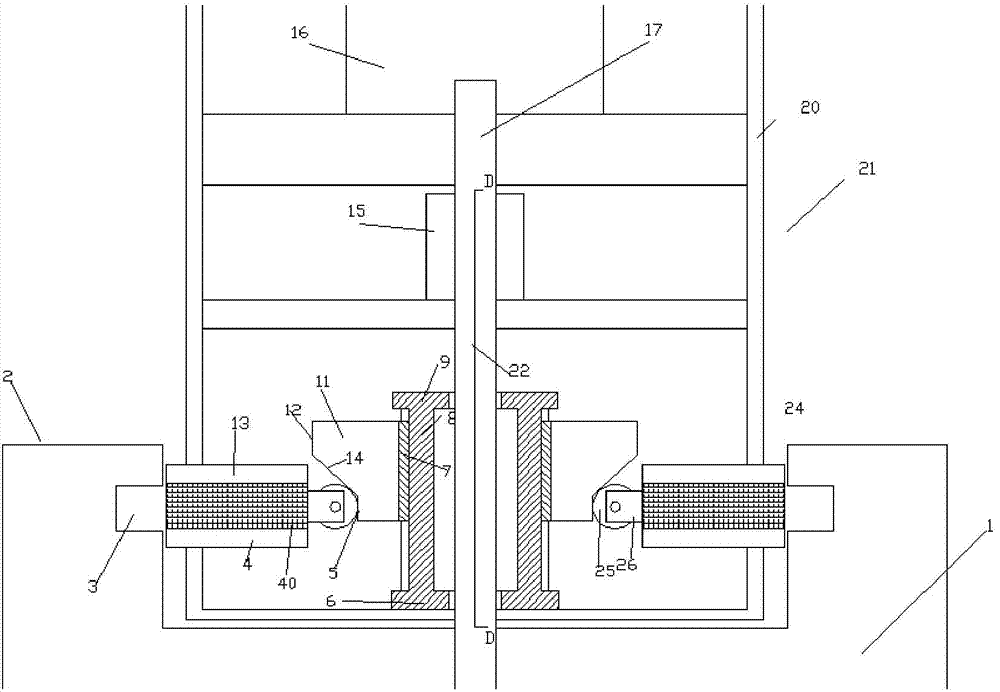

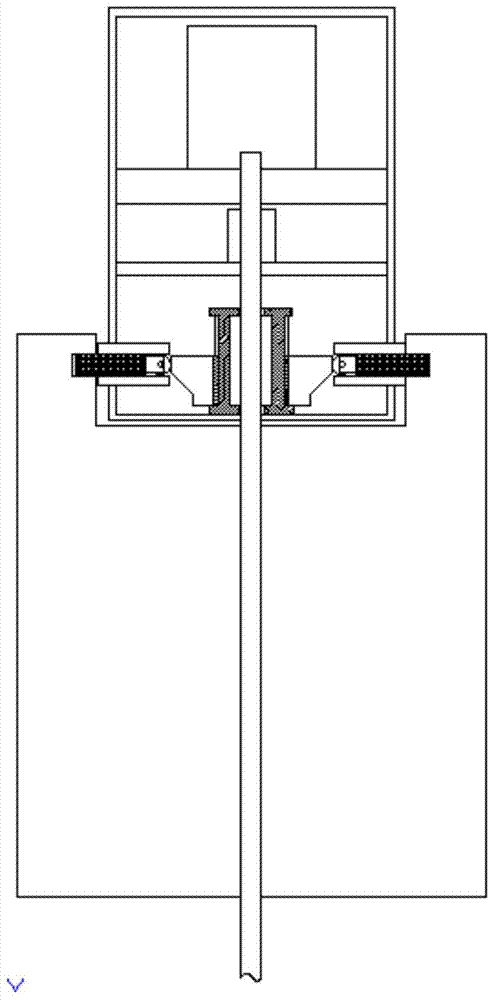

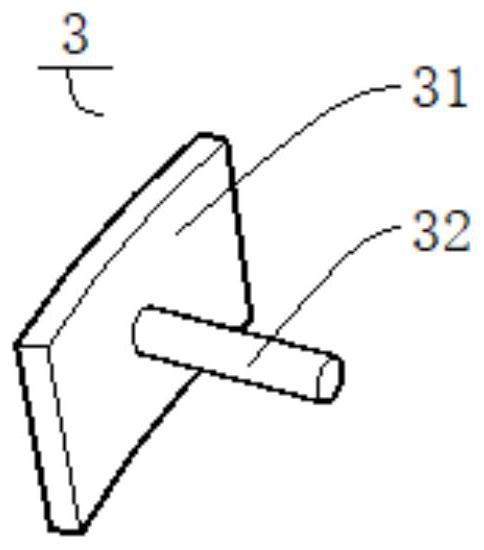

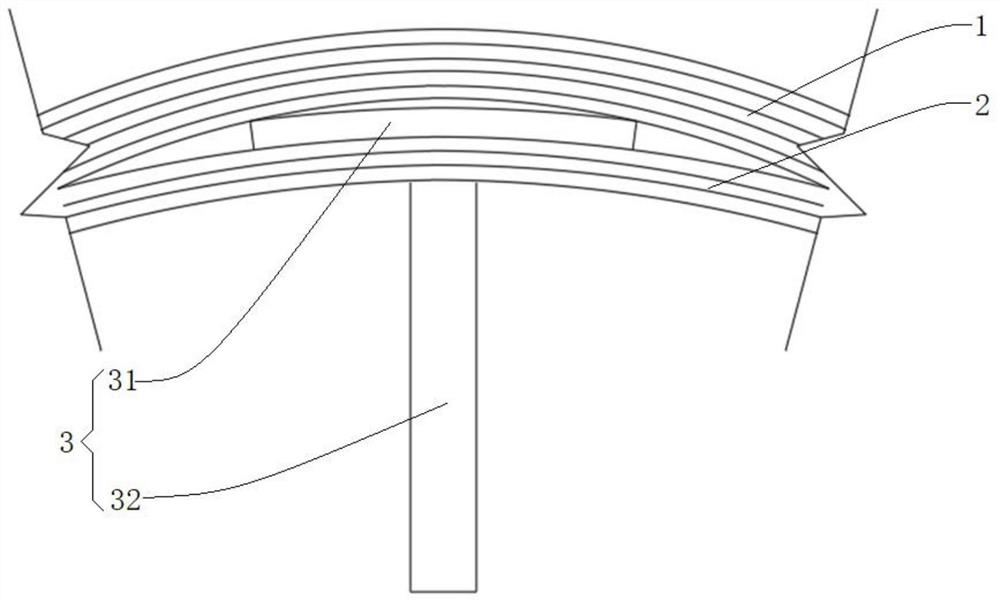

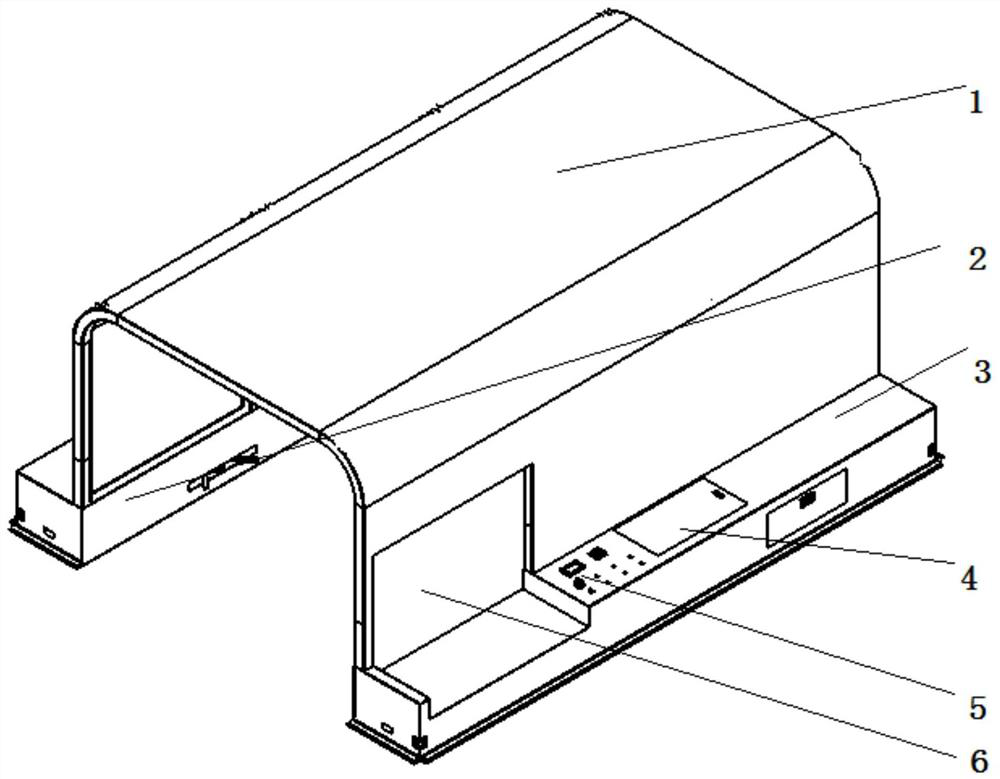

Lifting door plank device capable of being self-locked by use of single screw

ActiveCN104499868AReduce usageReduce distractionsBarrages/weirsPower-operated mechanismDrive motorScrew thread

The invention provides a lifting door plank device capable of being self-locked by use of a single screw. The lifting door plank device comprises a door plank (1) and a door plank lifting driving device (21); the door plank lifting driving device (21) comprises a housing (20) which is fixed on a supporting base; a door plank lifting driving motor (16) is fixed in the housing (20); the door plank lifting driving motor (16) is in power connection with the upper end of a door plank lifting driving lead screw (17); the door plank lifting driving lead screw (17) is in screw-thread fit with a threaded hole formed in the door plank (1); convex shoulders (2) are arranged on the two sides of the upper edge of the door plank (1); locking holes (3) open towards the middle of the door plank (1) and perpendicular to the door plank lifting driving lead screw (17) are formed in the inner side surface of the two convex shoulders (2).

Owner:JIANGSU LONGCHANG CHEM

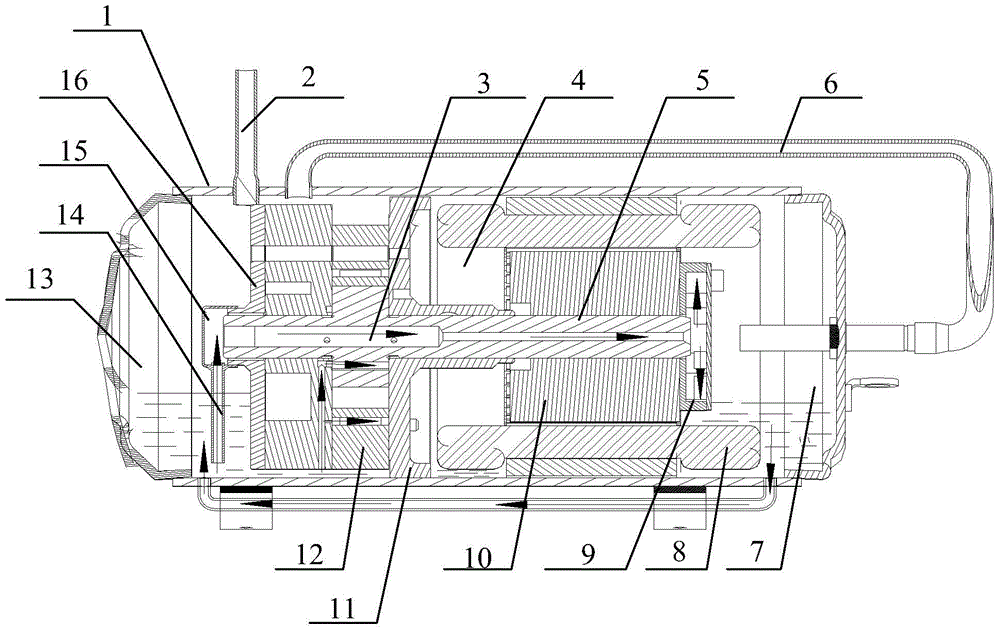

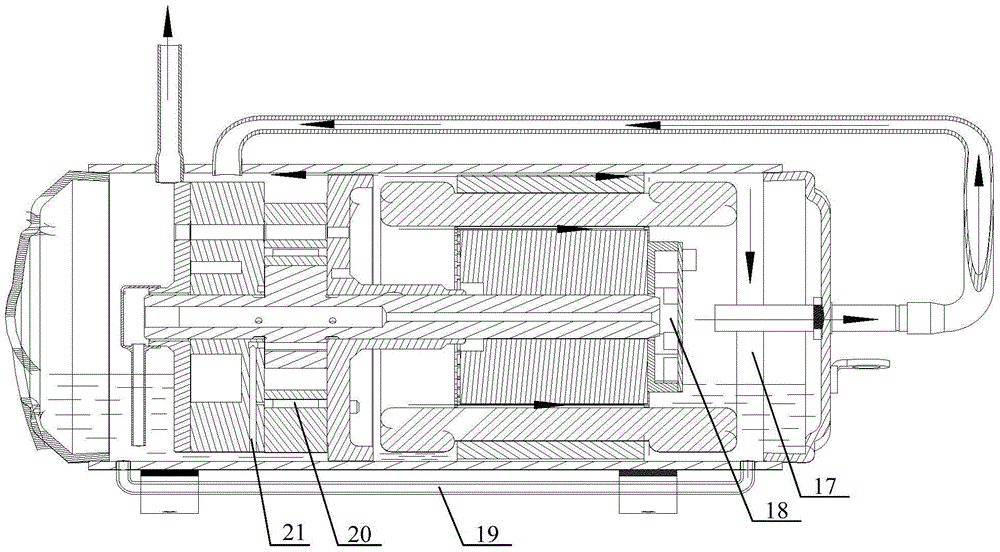

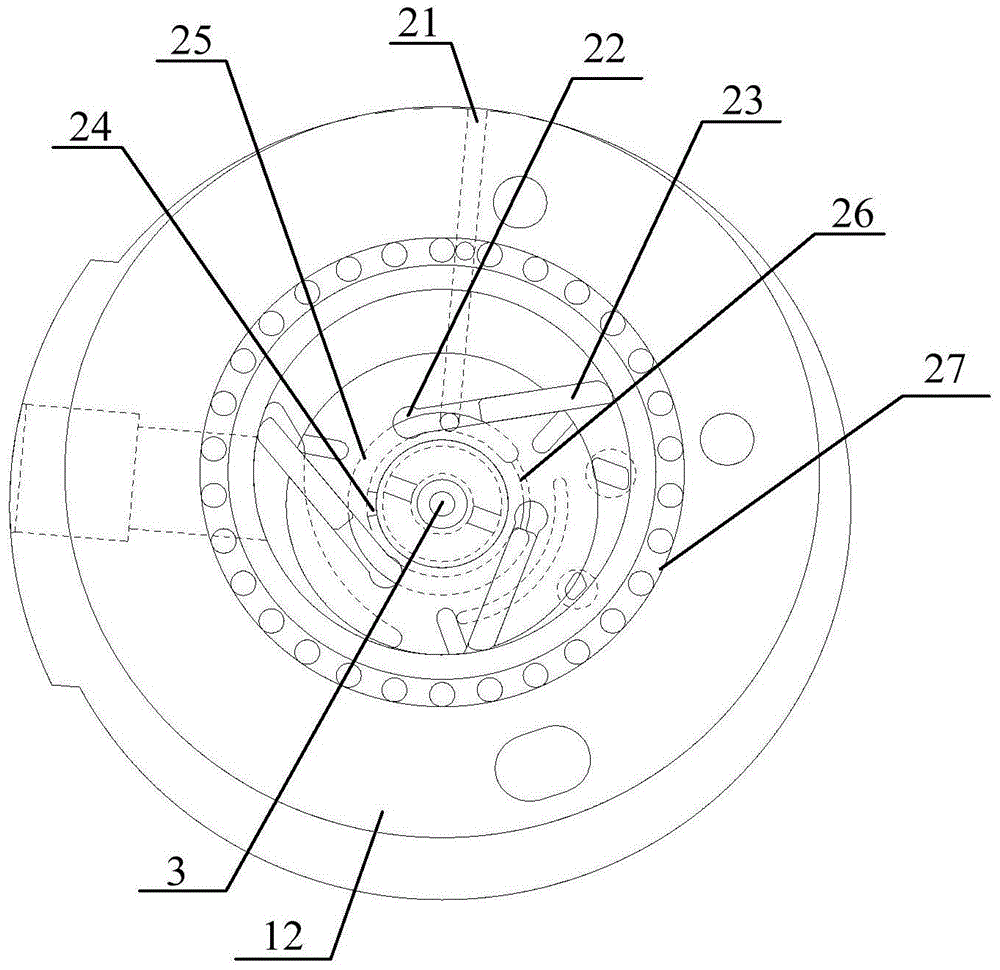

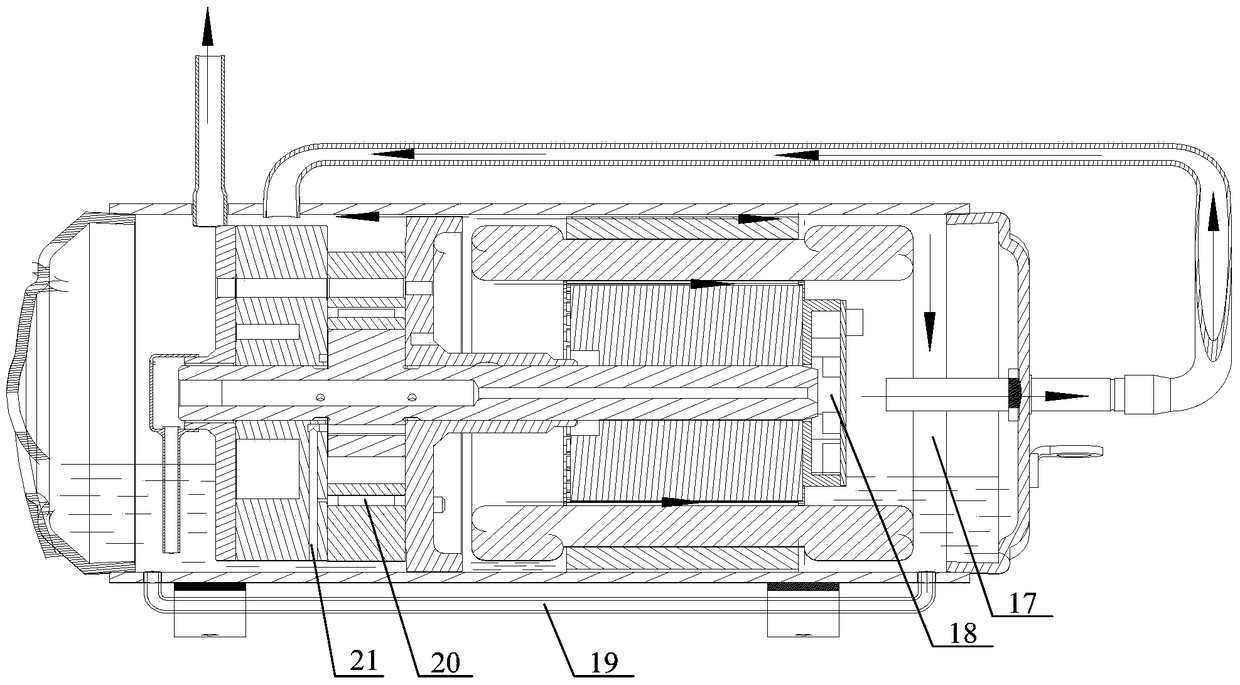

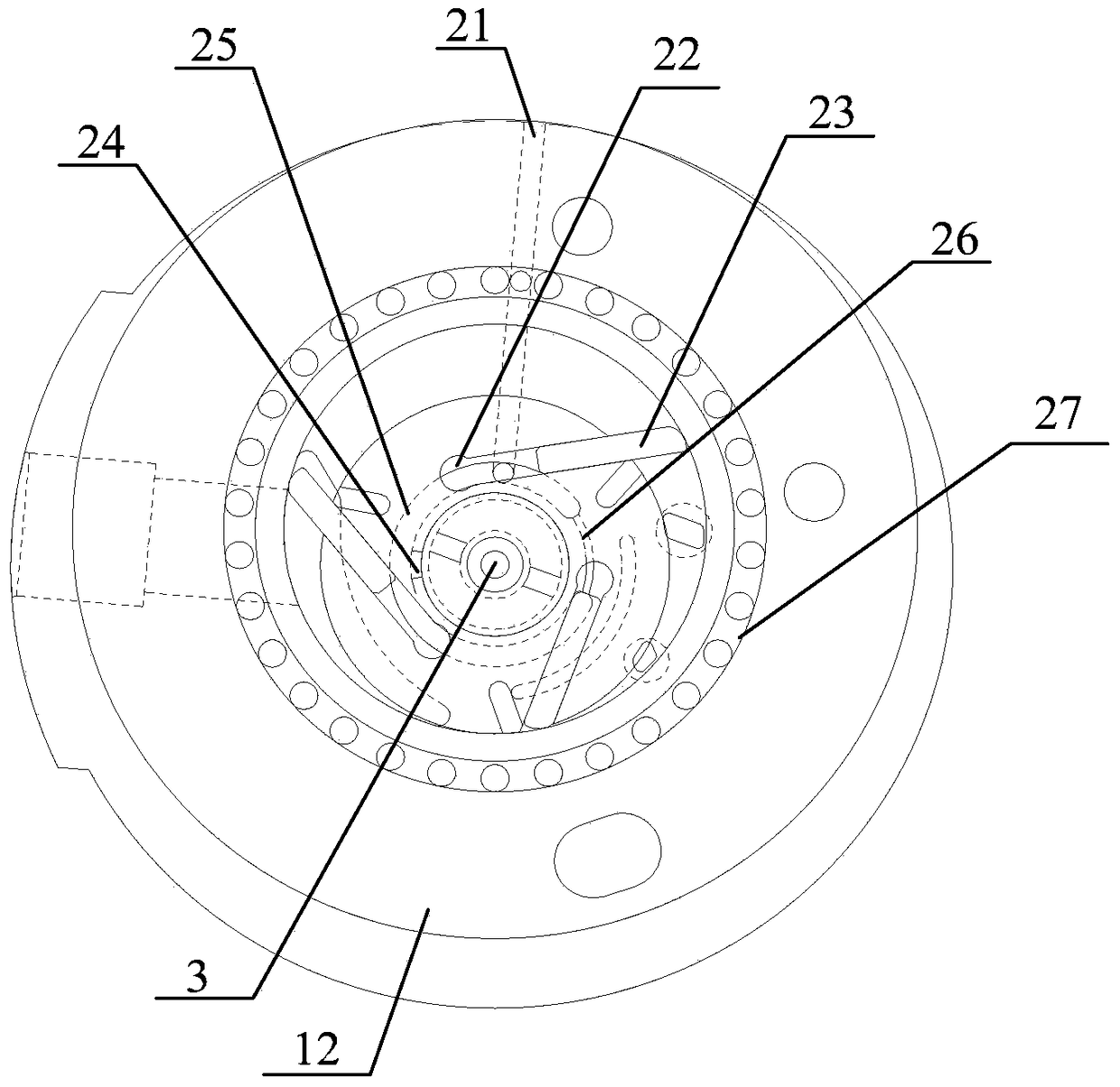

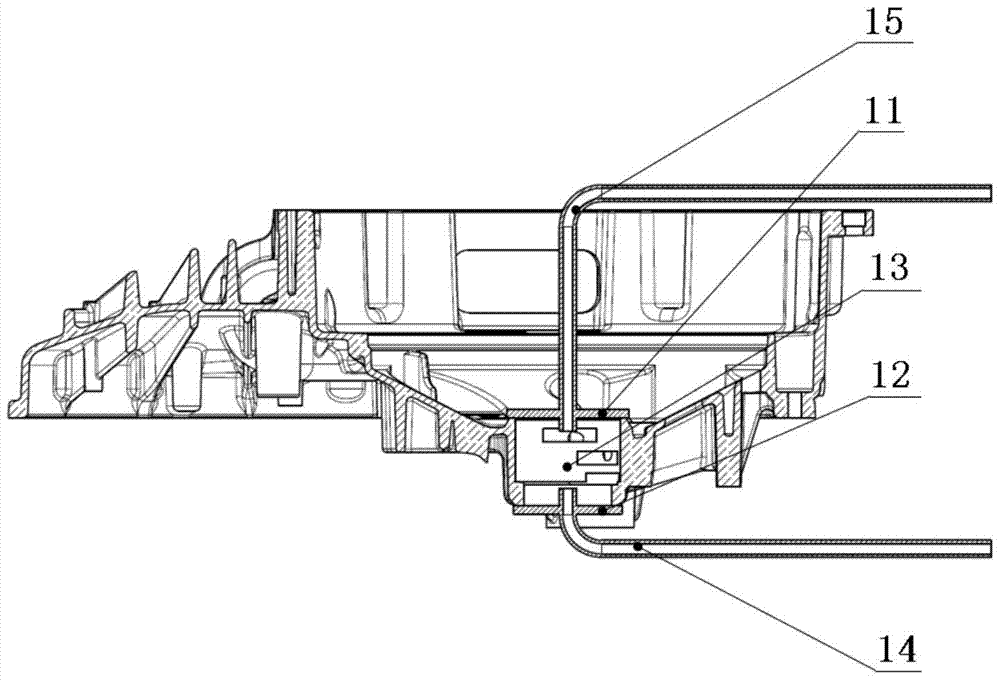

Horizontal compressor and temperature adjusting device

ActiveCN106481555AStretch out smoothlyEnough supportRotary piston pumpsRotary piston liquid enginesBack pressureOil storage

The invention relates to a horizontal compressor which comprises a shell, a lower flange, an air cylinder, an upper flange and a motor. The lower flange, the air cylinder, the upper flange and the motor are sequentially arranged in the shell. An oil storage cavity is formed by the lower flange and the shell. A rotor is rotationally arranged in the air cylinder through a main shaft. The horizontal compressor further comprises a center oil hole penetrating the main shaft, a radial hole formed in the main shaft and communicating with the center oil hole, an oiling pipe fixedly connected to the end, located in the oil storage cavity, of the main shaft and communicating with the center oil hole, a lower flange back pressure groove formed in the lower flange and communicating with a sliding piece installation groove of the rotor, a groove for communicating the lower flange back pressure groove and the radial hole of the main shaft, an exhaust cavity communicating with an exhaust hole of the air cylinder and the center oil hole of the main shaft, and a fan installed at the other end of the fan, wherein the bottom end of the oiling pipe is close to the bottom of the oil storage cavity. According to the horizontal compressor, smooth stretching-out of a sliding piece during starting of the compressor and attachment between the sliding piece and the air cylinder during normal running of the compressor are effectively ensured. The invention further discloses a temperature adjusting device comprising the horizontal compressor.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

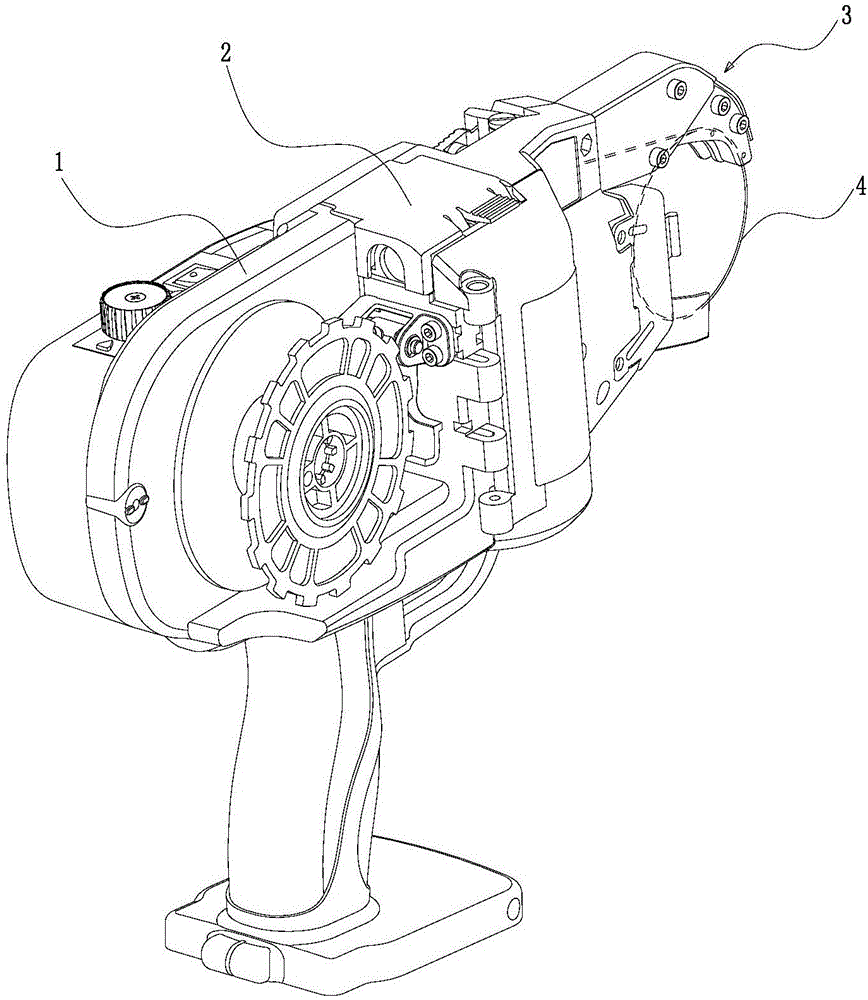

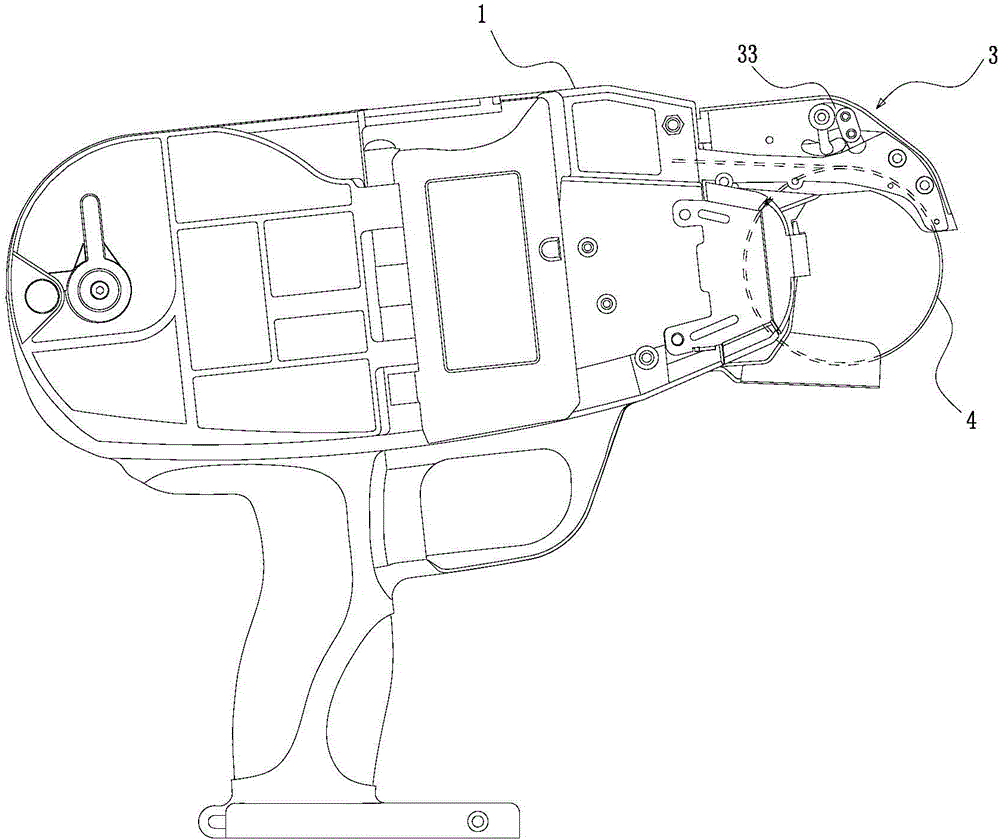

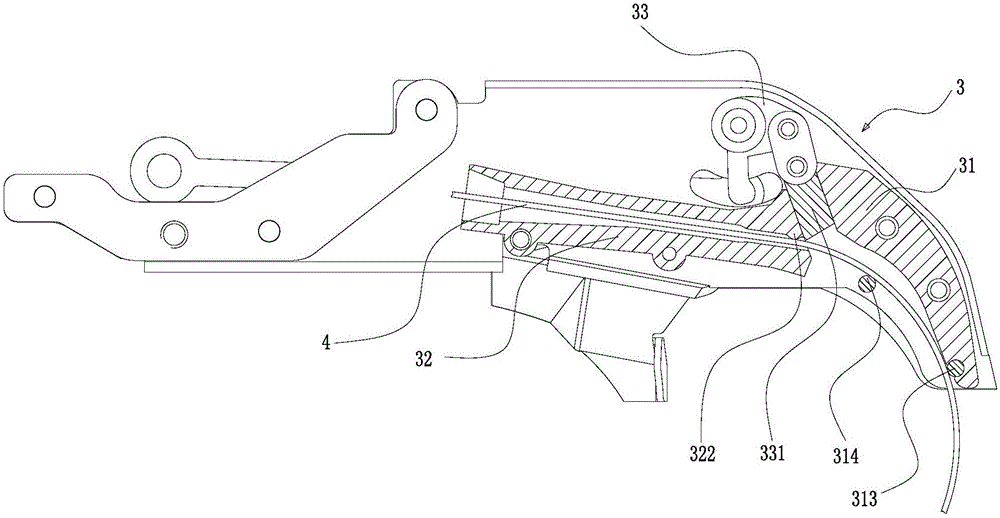

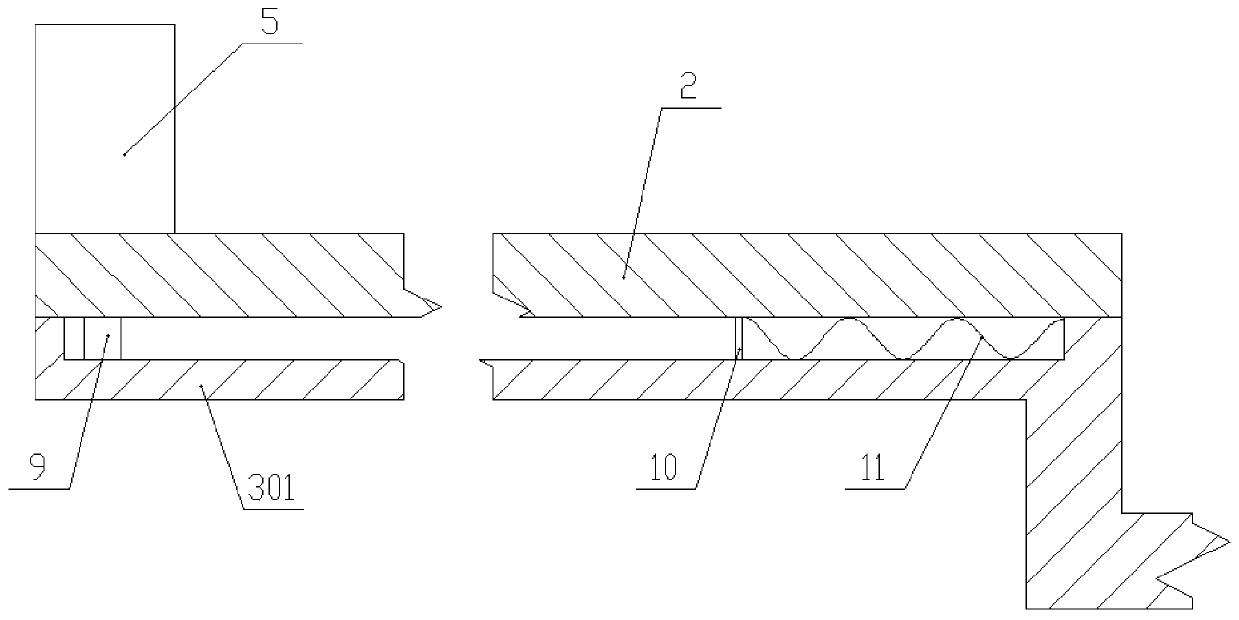

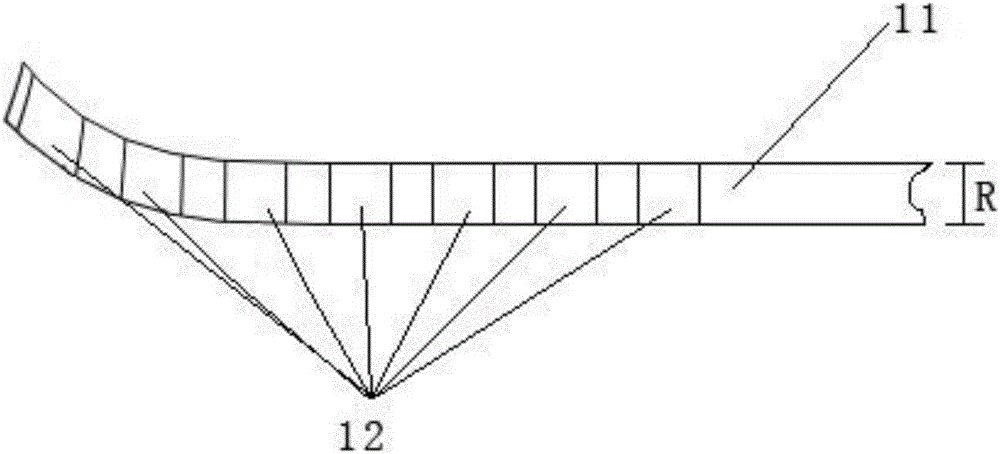

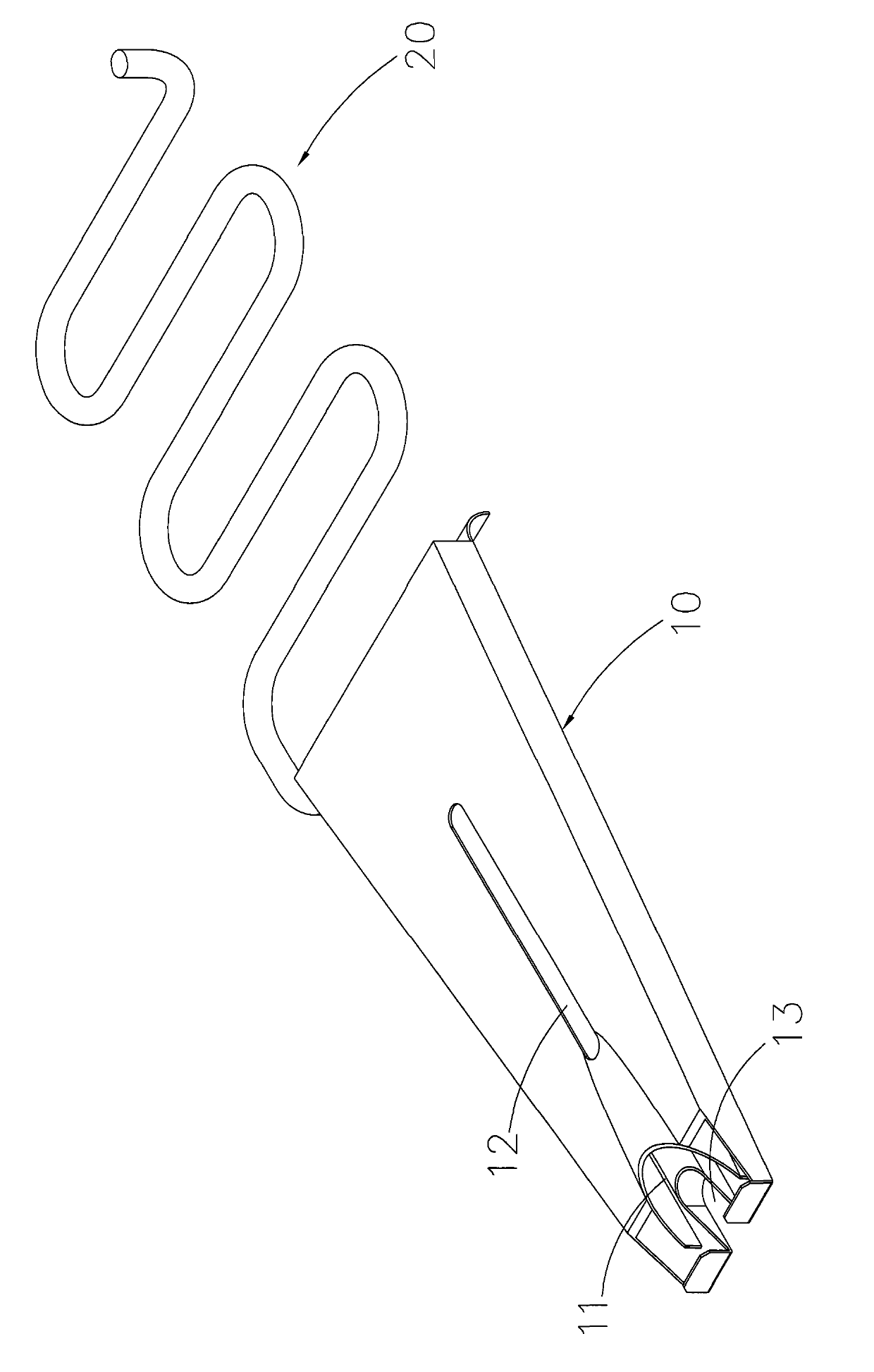

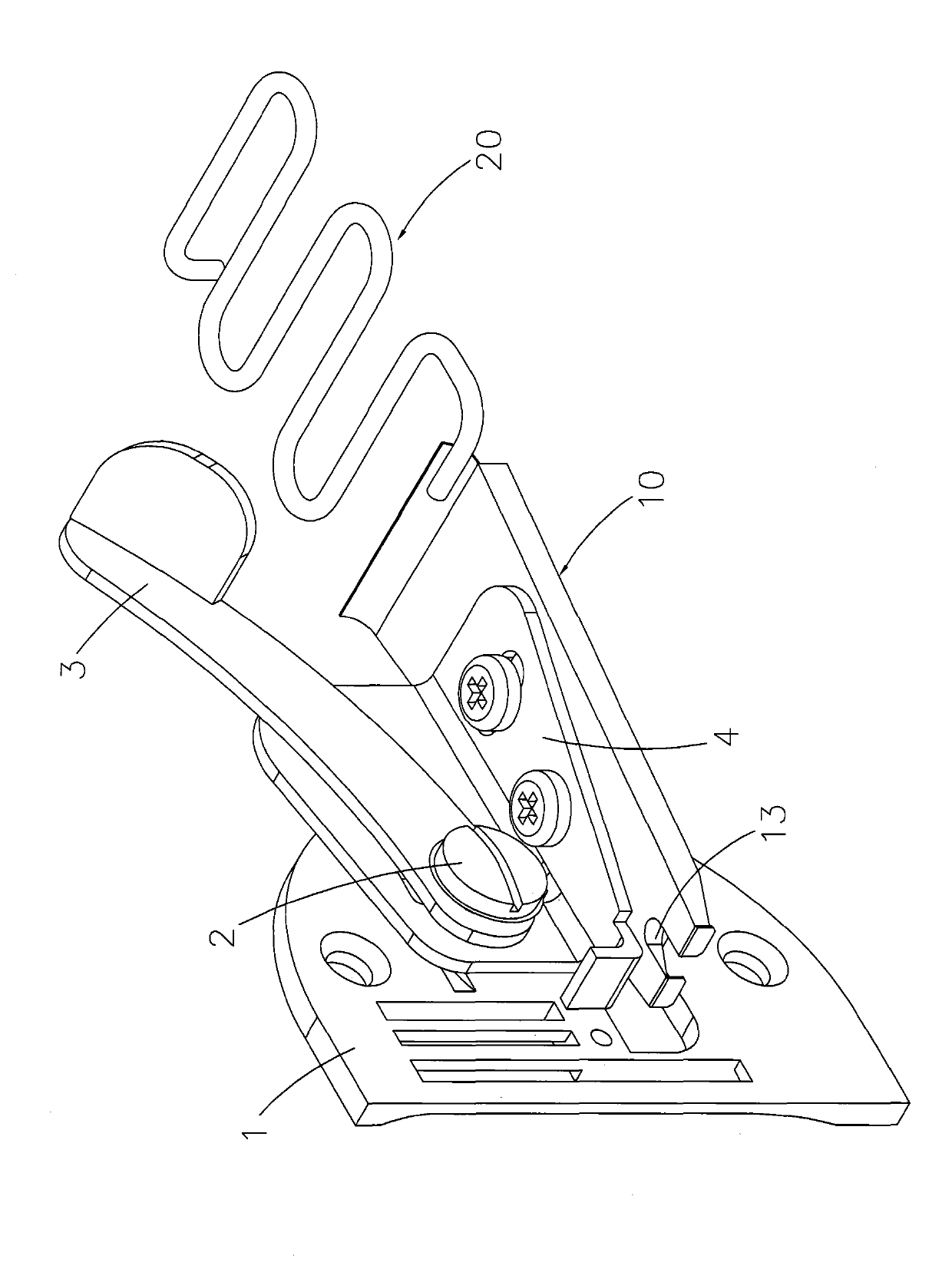

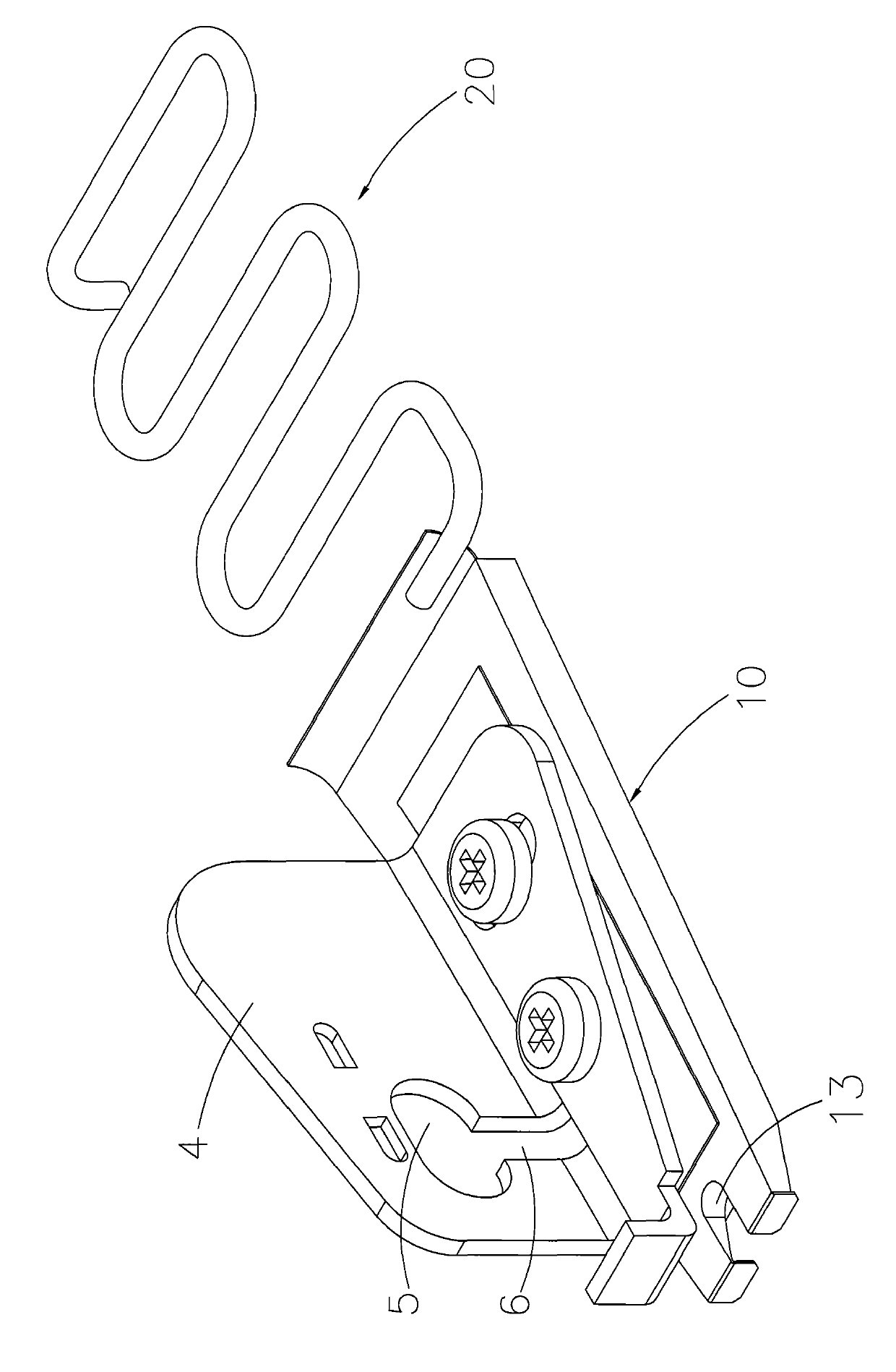

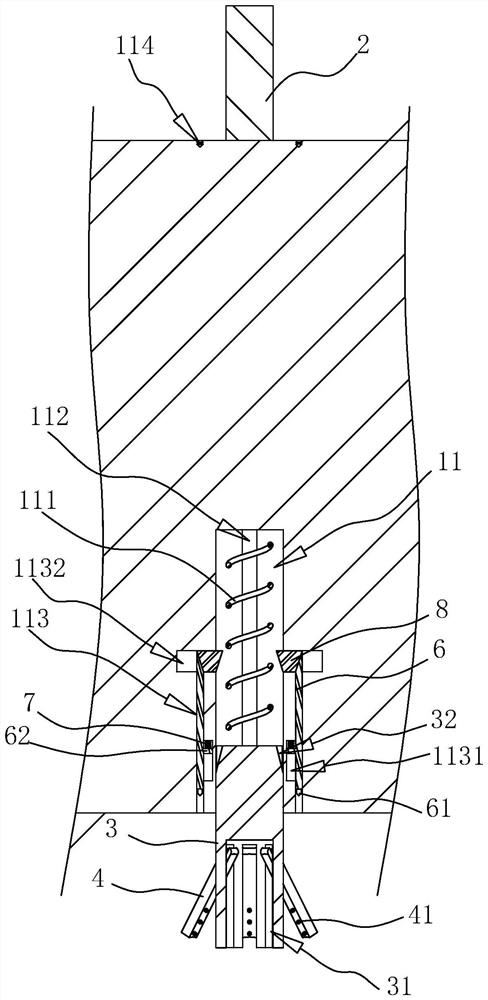

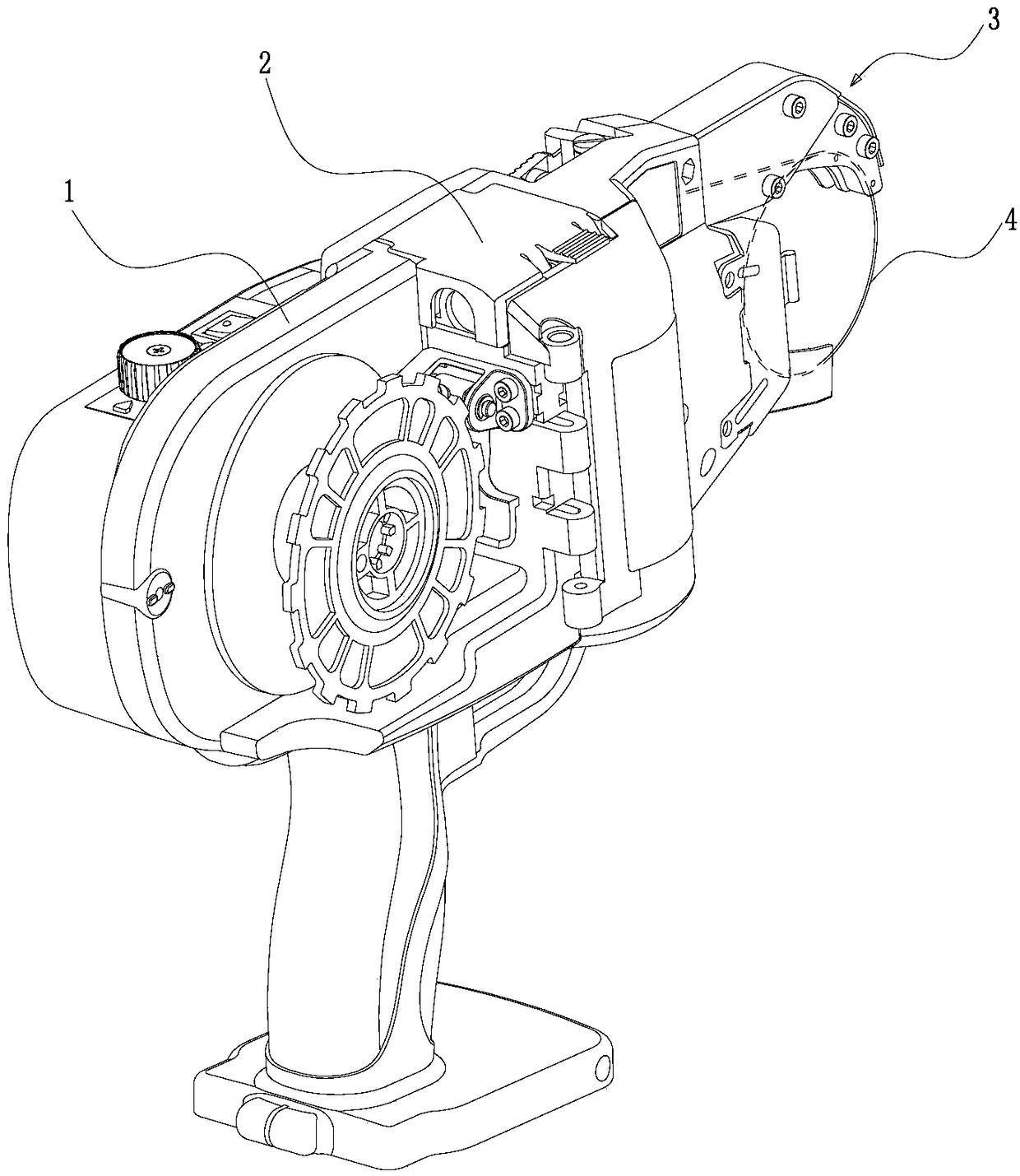

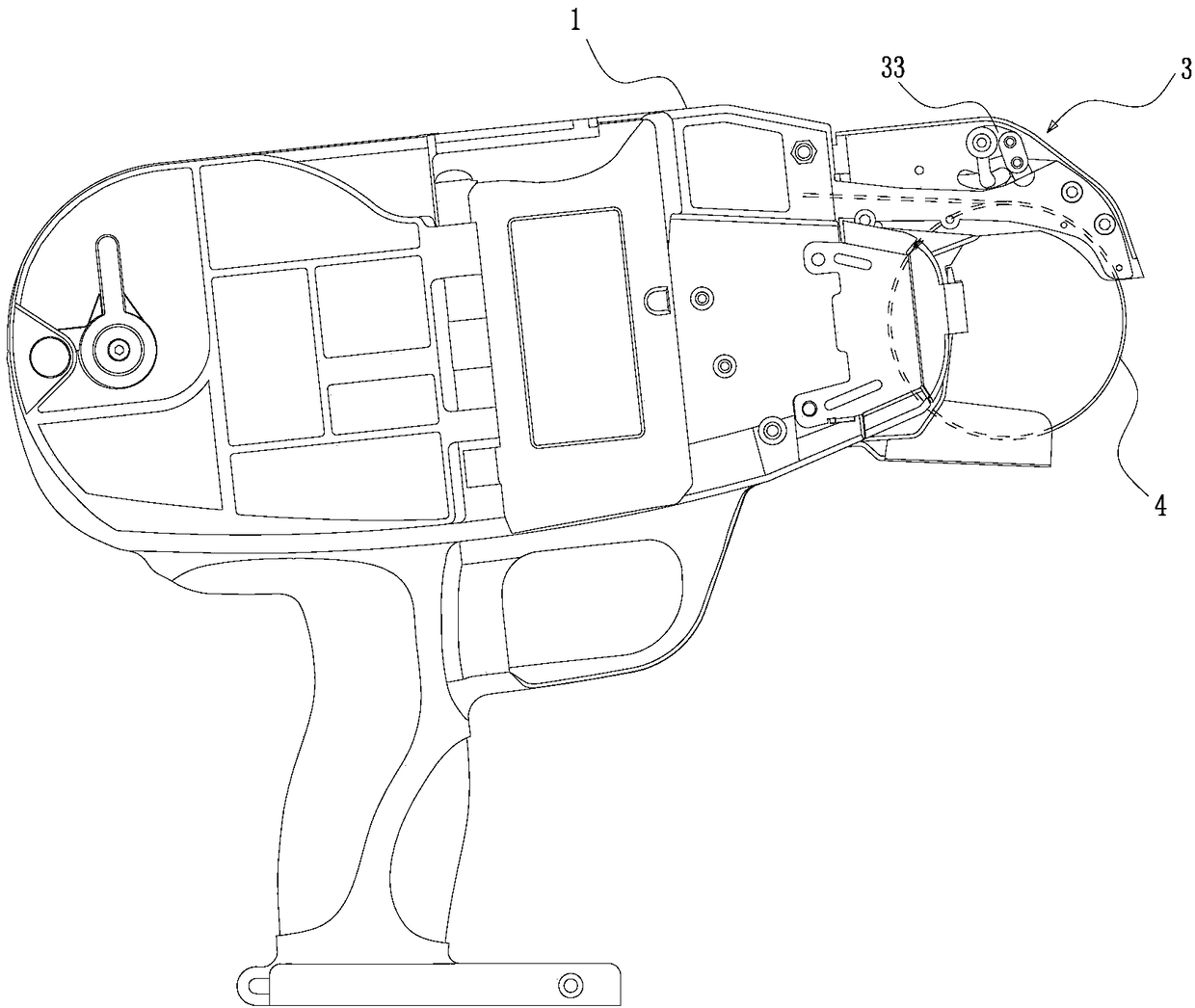

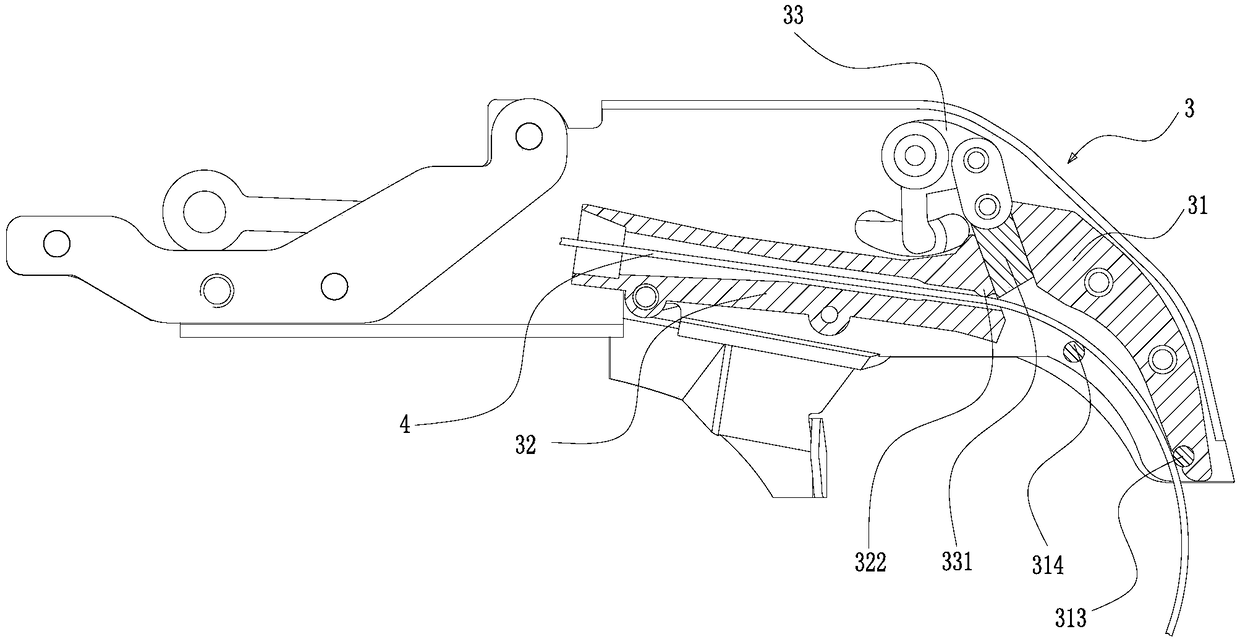

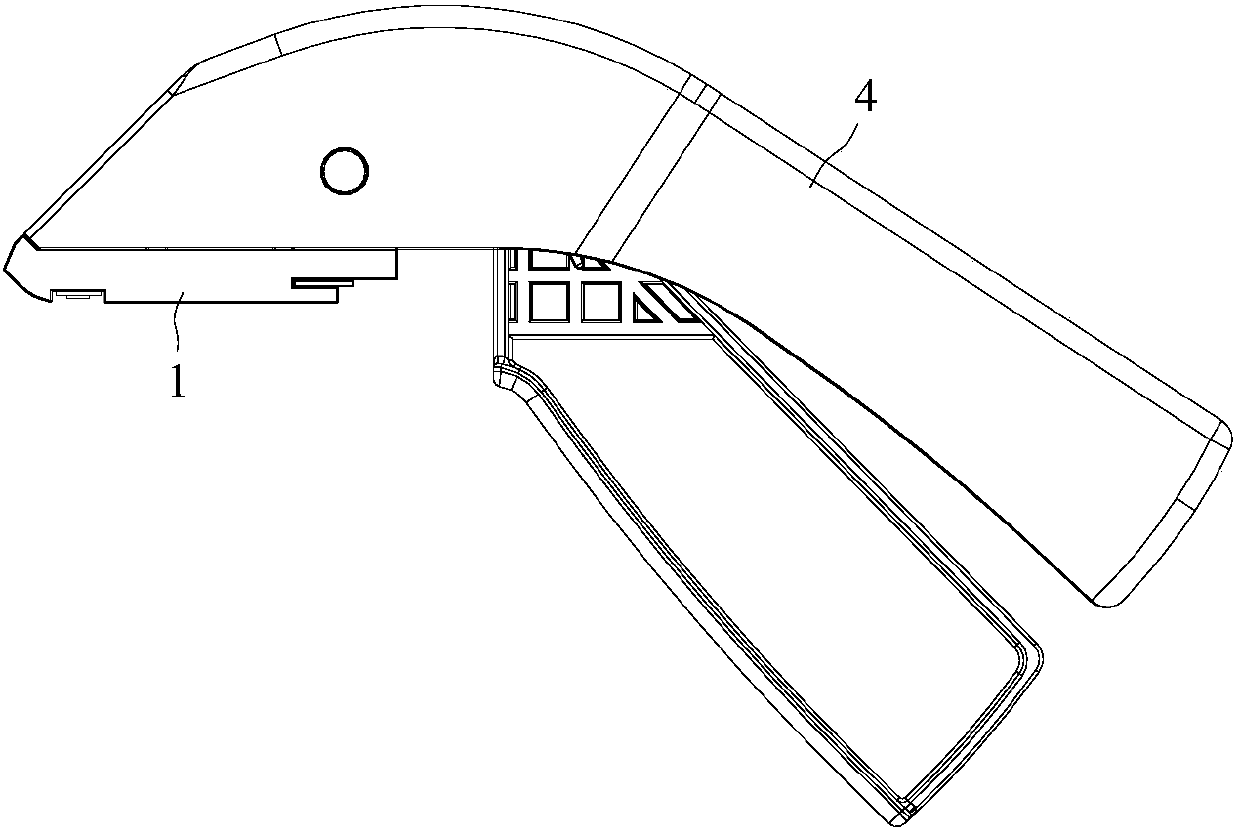

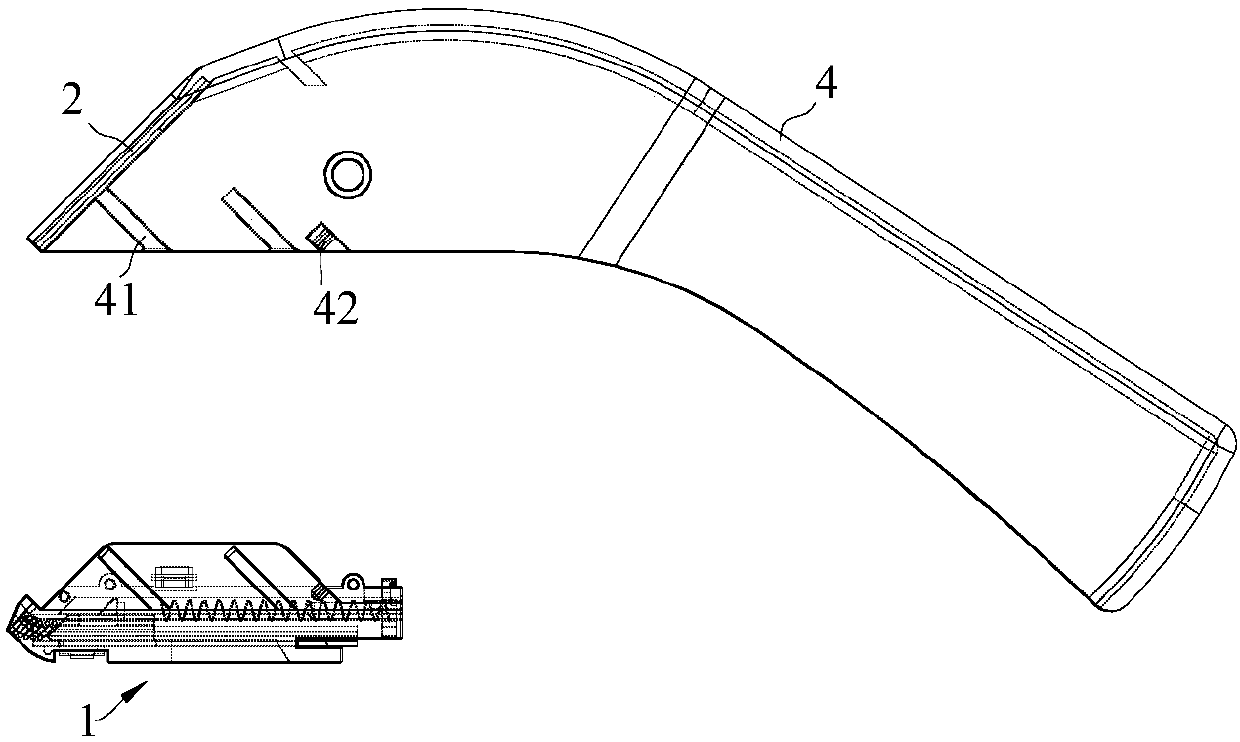

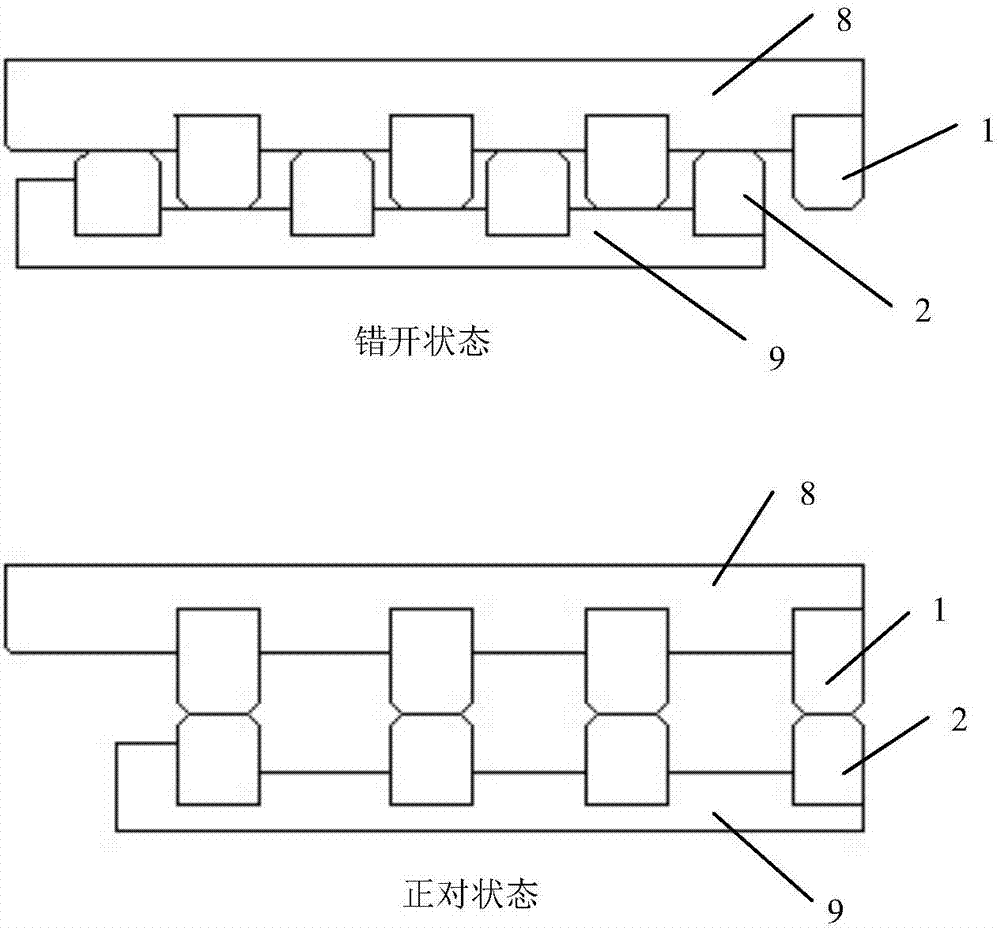

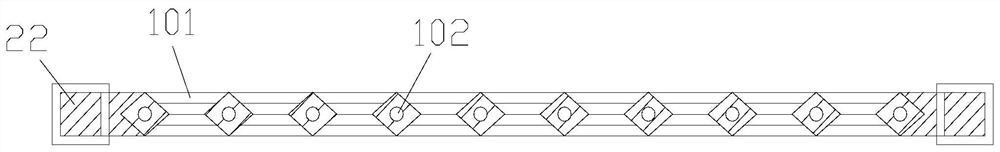

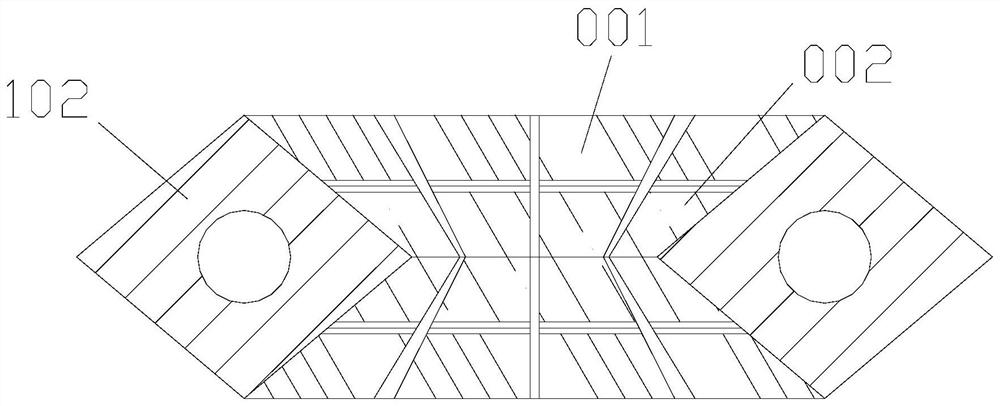

Integrated wire discharge and guide mechanism and rebar tying machine

The invention discloses an integrated wire discharge and guide mechanism and a rebar tying machine and belongs to the field of rebar tying devices. According to the technical scheme, in order to solve the problems that in the prior art, the number of component parts of a guide structure of a rebar tying machine is large, machining is complex, dimension error accumulation and installation position deviation are liable to occur, and the steel wire circle formation dimension is not stable or steel wires cannot extend out, the integrated wire discharge and guide mechanism comprises a curved wire discharge part and a wire guide part, wherein the curved wire discharge part and the wire guide part are transversely formed on a sheet substrate in a front-and-back mode, a longitudinal groove is formed between the curved wire discharge part and the wire guide part, the curved wire discharge part is provided with a boss, the arc wall of the boss and the surface area of the curved wire discharge part form a guide part which is used for guiding the steel wires to move, and at least one guide piece is arranged in the guide part. The wire discharge part and the wire guide part are integrally formed, the number of the parts is small, machining and formation are convenient, dimension error accumulation and installation position deviation are reduced, the steel wire circle formation dimension is stable, and the steel wires can extend out smoothly.

Owner:TAIZHOU XINDALU ELECTRONICS TECH

Circulating type environmental sewage treatment device

InactiveCN110902893AConvenient for centralized slag removalThe movement process is ingeniousTreatment involving filtrationMultistage water/sewage treatmentTreatment pondStructural engineering

The invention discloses a circulating type environmental sewage treatment device. The device comprises a treatment tank and a filter plate, the filter plate comprises an upper filter plate, a lower filter plate and a partition plate; the partition plate is in a stable L shape in a non-deslagging state; one end of a horizontal plate section of the partition plate is hinged to the right side of thetreatment tank; a roller of the upper filter plate can roll in a guide groove in the upper surface of an upper-layer plate, so that the upper filter plate horizontally extends out of the upper-layer plate rightwards; a limiting strip extending into a sliding groove in the upper surface of the upper-layer plate is fixedly connected to the surface of the side, opposite to a balancing weight, of theupper filter plate, a contact strip is connected with the end of a vibration spring installed in the sliding groove, and when the upper filter plate slides out of the upper-layer plate, the contact strip makes contact with the limiting strip and collides with the limiting strip, so that the vibration spring is compressed and reciprocates in the sliding groove; the concave part of the lower filterplate is matched with the arc surface of the corner outer wall of the partition plate. The device is used for circularly purifying sewage, and is simple, efficient and easy for deslagging.

Owner:重庆尚泽源环保科技有限公司

Encephalic electrode

ActiveCN106108895AEasy to insertStretch out smoothlyCatheterDiagnostic recording/measuringElectrocoagulationRadiofrequency ablation

The invention provides an encephalic electrode. A rigid outer tube is sleeved with an electrode body. In the use process, the electrode body is firstly taken out, the outer tube is inserted into the cranium, and due to the fact that the outer tube is rigid, the outer tube can be conveniently inserted into the cranium under stress. After the outer tube is used for precise locating, the electrode body is inserted into the outer tube, and due to the fact that the electrode body is flexible, in the process of inserting the electrode body into the outer tube from one end, the electrode body stretches into the outer tube under the condition of elastic deformation and stretches out from an opening; after the arc-shaped stretches out, after the electrode body is restored to the original shape and reaches the position, the outer tube can be drawn out, the electrode body is in contact with surrounding brain tissue, and the condition of the brain is detected. According to the encephalic electrode, the arc-shaped end is arranged at the front end of the electrode body, after the arc-shaped end is arranged, the electrode body can be rotated to adjust the position of the arc-shaped end at the front end in the cranium, and therefore the range of implementing the electrocoagulation damage operation or radiofrequency ablation is greatly widened; through testing, in the same state of other conditions, compared with a vertical electrode, the range is widened by about 8 times.

Owner:CHANGZHOU RUISHENAN MEDICAL DEVICES

Binding device on sewing machine

A binding device on sewing machine comprises a binding forming element and a flattening element with the front end fixed on the back end of the binding forming element, wherein the binding forming element is provided with a U-shaped forming slot for a binding cloth piece passing through; the outer surface of the binding forming element is provided with a guide slot extending along the length direction of the binding forming element; and the guide slot is communicated with the forming slot. When the binding cloth piece enters from the back part of the forming slot, a user can push the binding cloth piece forwards through the guide slot by using foreign object, such as a needle, so as to smoothly extend outside from the front part of the forming slot.

Owner:SIAOTE FASHION SUZHOU

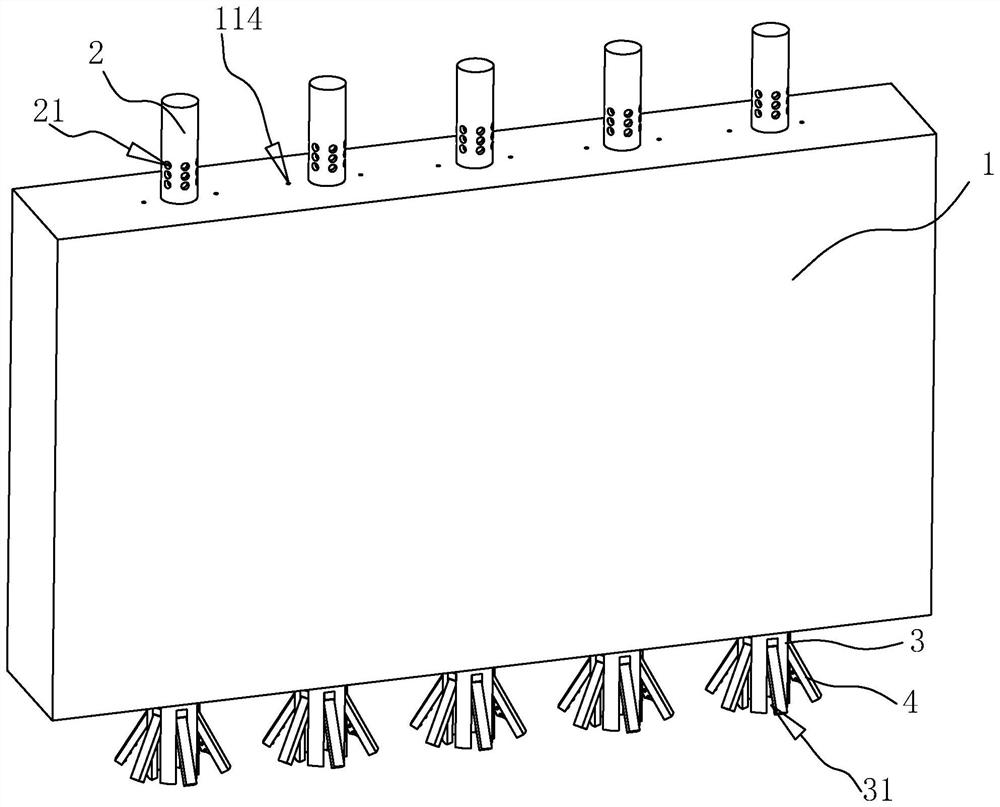

Prefabricated wall body of fabricated building

ActiveCN114775891AImprove connection strengthImprove motion stabilityConstruction materialWallsClassical mechanicsRebar

The invention relates to the technical field of fabricated buildings, in particular to a prefabricated wall of a fabricated building, which comprises a wall body, reinforcing steel bars are arranged at the top of the wall body, a containing groove in the vertical direction is formed in the bottom of the wall body, and a connecting sleeve is slidably arranged in the containing groove in the length direction of the containing groove; a control piece used for controlling the sliding degree of the connecting sleeve is arranged in the containing groove, a mounting groove is formed in the outer wall of the connecting sleeve and communicates with the interior of the connecting sleeve, a clamping rod is hinged to the interior of the mounting groove, one end of the clamping rod is located in the connecting sleeve, and the other end of the clamping rod is located on the outer side of the connecting sleeve. First elastic pieces used for achieving relative fixing of the clamping rods are arranged in the mounting grooves, clamping blocks are arranged in the clamping rods, and clamping grooves matched with the clamping blocks are formed in the outer walls of the steel bars. The connecting structure has the advantage that the connecting strength of the fabricated wall body is improved.

Owner:广东国嘉建设工程有限公司

An integrated wire outlet and guide wire mechanism and a steel bar binding machine

The invention discloses an integrated wire discharge and guide mechanism and a rebar tying machine and belongs to the field of rebar tying devices. According to the technical scheme, in order to solve the problems that in the prior art, the number of component parts of a guide structure of a rebar tying machine is large, machining is complex, dimension error accumulation and installation position deviation are liable to occur, and the steel wire circle formation dimension is not stable or steel wires cannot extend out, the integrated wire discharge and guide mechanism comprises a curved wire discharge part and a wire guide part, wherein the curved wire discharge part and the wire guide part are transversely formed on a sheet substrate in a front-and-back mode, a longitudinal groove is formed between the curved wire discharge part and the wire guide part, the curved wire discharge part is provided with a boss, the arc wall of the boss and the surface area of the curved wire discharge part form a guide part which is used for guiding the steel wires to move, and at least one guide piece is arranged in the guide part. The wire discharge part and the wire guide part are integrally formed, the number of the parts is small, machining and formation are convenient, dimension error accumulation and installation position deviation are reduced, the steel wire circle formation dimension is stable, and the steel wires can extend out smoothly.

Owner:TAIZHOU XINDALU ELECTRONICS TECH

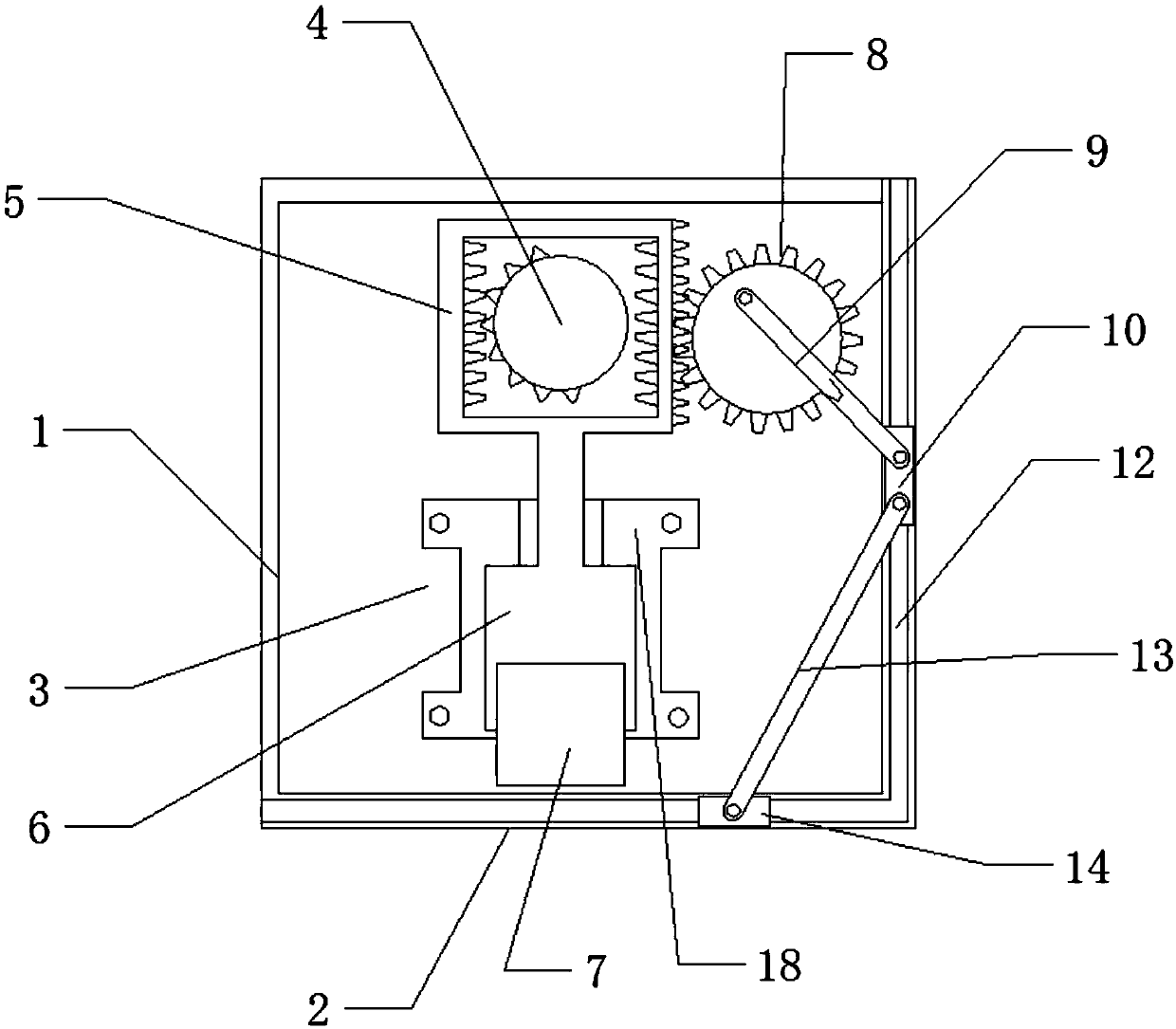

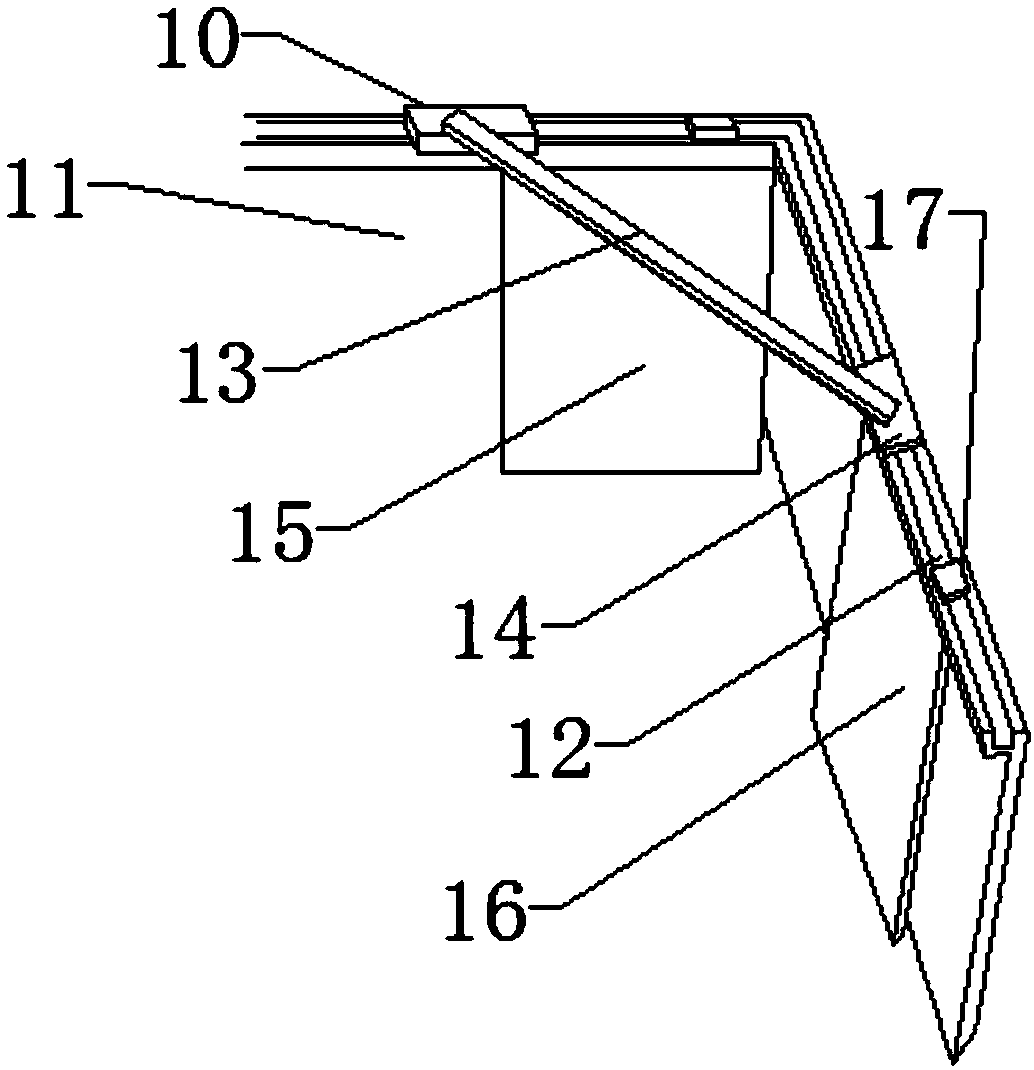

Smart street traffic dustproof camera

InactiveCN107819996AImprove stabilityStretch out smoothlyTelevision system detailsFouling preventionComputer scienceDust pollution

The invention discloses a smart street traffic dustproof camera, which belongs to a smart camera with a dustproof function in the field of cameras and aims to provide the smart street traffic dustproof camera. The technical scheme is that the camera comprises a camera box body, wherein a sliding mechanism is arranged in the box body, a gear is arranged at one end of the sliding mechanism, straightteeth are arranged on half of the circumference of the gear, a sliding frame is arranged on the outer ring of the gear, the straight teeth that can be meshed with the gear are arranged on both sidesof the sliding frame, one end of the sliding frame close to a sliding door is connected with a camera base, a camera is arranged at the upper end of the camera base, one side of the sliding frame is meshed with a gear B, the gear B is connected with a movable sliding rod A, and the sliding rod A is connected with a movable door that can save the accommodating space. The invention provides the camera with the dustproof function, which aims to reduce the dust pollution of street cameras and ensure the work effect of the street cameras.

Owner:SICHUAN ZHONGYONG PHARMA CO LTD

Skin stapler nail cartridge connecting structure

InactiveCN107802307AReduce cost inputReduce in quantitySurgical staplesSingle useSurgical instrument

The invention discloses a nail cartridge connection structure for a skin suturing device, which is used in the technical field of surgical instruments and includes a mother body and a nail cartridge. The nail cartridge is installed on the mother body through a quick-release structure. The structure includes guide protrusions and card protrusions on the positioning connection part of the mother body and guide grooves and card slots on the mother body. There is a nail storage bin inside the nail bin, and the nail outlet is provided at the front end of the nail storage bin. , the nail magazine is provided with a nail presser plate passing groove above the nail outlet, and the front end of the positioning connection part of the mother body is provided with a nail presser plate guide surface that can guide the nail presser plate into the nail presser plate passage groove. The mother body and the staple cartridge adopt a detachable split structure design. The staple cartridge can be designed for one-time use, and the mother body is designed to be reusable. The mother body can be used repeatedly after cleaning and sterilization, which not only reduces the cost input of the skin stapler , but also reduce the amount of medical waste. At the same time, it can ensure that the nail plate can be smoothly guided to protrude after the connection, so as to realize the nail pushing.

Owner:GUANGZHOU KEHUIZE BIOTECH CO LTD

A horizontal compressor and temperature adjustment equipment

ActiveCN106481555BStretch out smoothlyEnough supportRotary piston pumpsRotary piston liquid enginesFlangeBack pressure

Owner:GREE ELECTRIC APPLIANCES INC +1

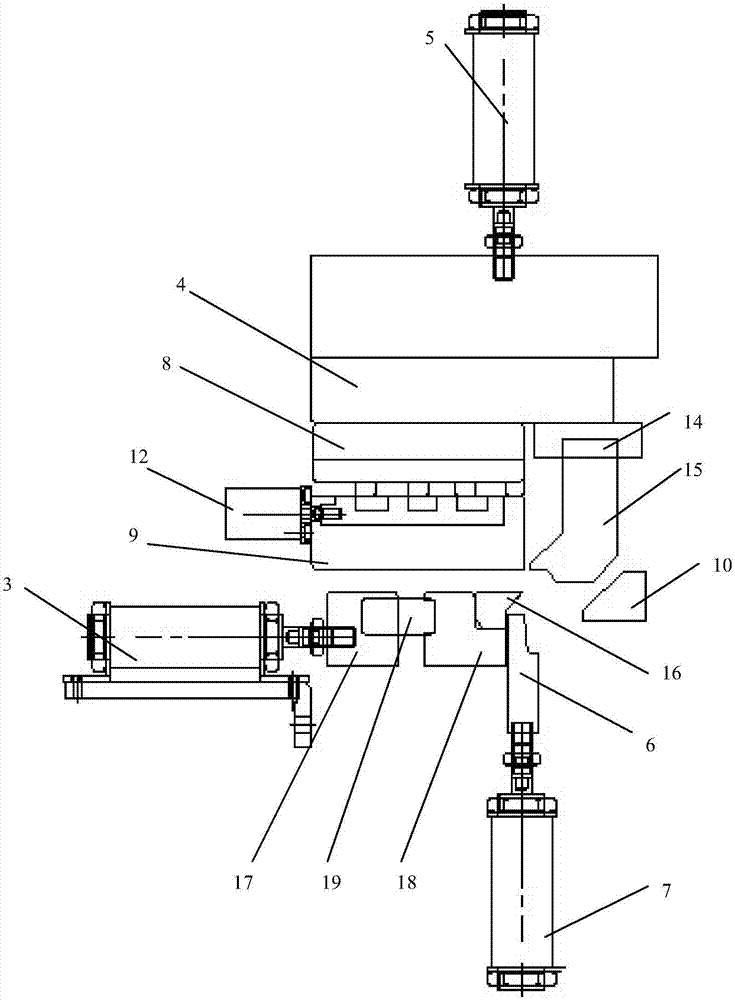

Automatic gearbox shell oil duct air tightness detection tool

ActiveCN105043691AStretch out smoothlyAvoid stickingMeasurement of fluid loss/gain rateEngineeringAir tightness

The invention discloses an automatic gearbox shell oil duct air tightness detection tool comprising bottom plugging blocks mounted on a bottom plate. A top plugging assembly comprises a top cover which fits a shell, a top ring which sleeves a bearing hole, and a guide column which is mounted on the top cover in a sliding manner through a sliding guide member, wherein the sliding direction of the guide column relative to the top cover is the direction near or away from the bearing hole, the periphery of the top ring is provided with a via hole, a plugging block is arranged on the circumference of the guide column, an elastic member is arranged between the plugging block and the top ring, and the plugging block passes through the via hole and is inserted into an oil duct communicated with the bearing hole when the elastic member is compressed under pressing of the guide column. Therefore, based on plugging of oil ducts communicated with the bearing hole realized through a plugging function, an oil duct hole can be separately plugged when multiple oil ducts are communicated with the same bearing hole, false detection occurring when oil ducts are communicated is avoided, the reliability of detection results is improved, and the quality risk is avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

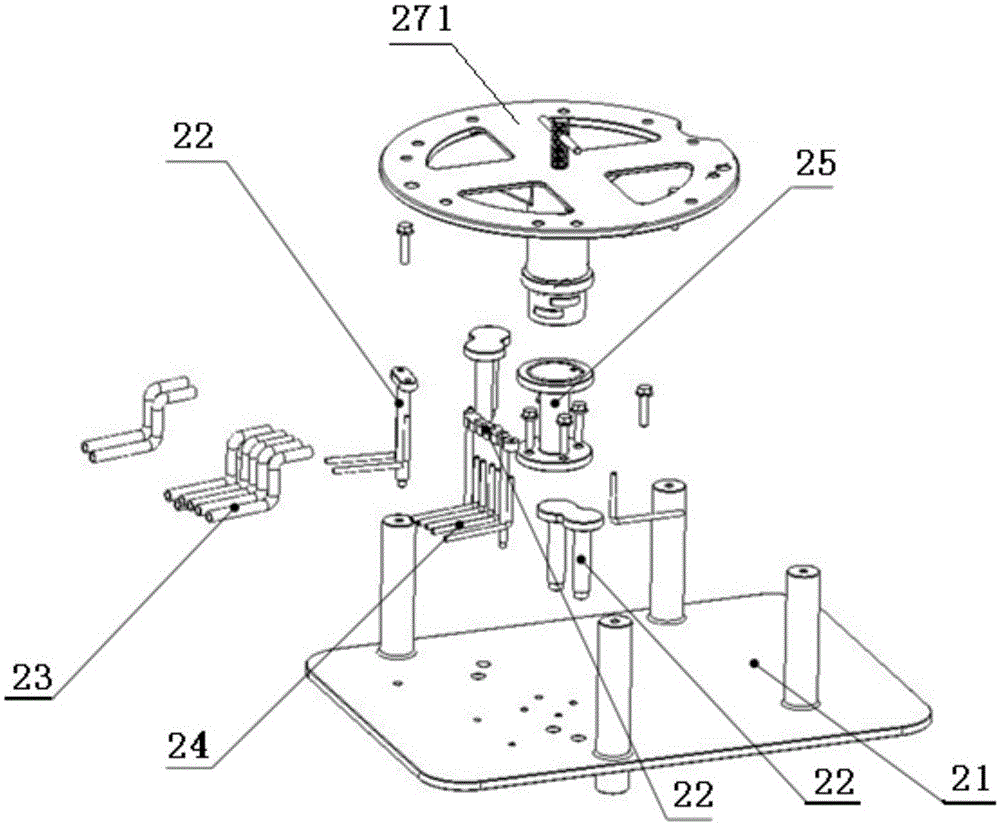

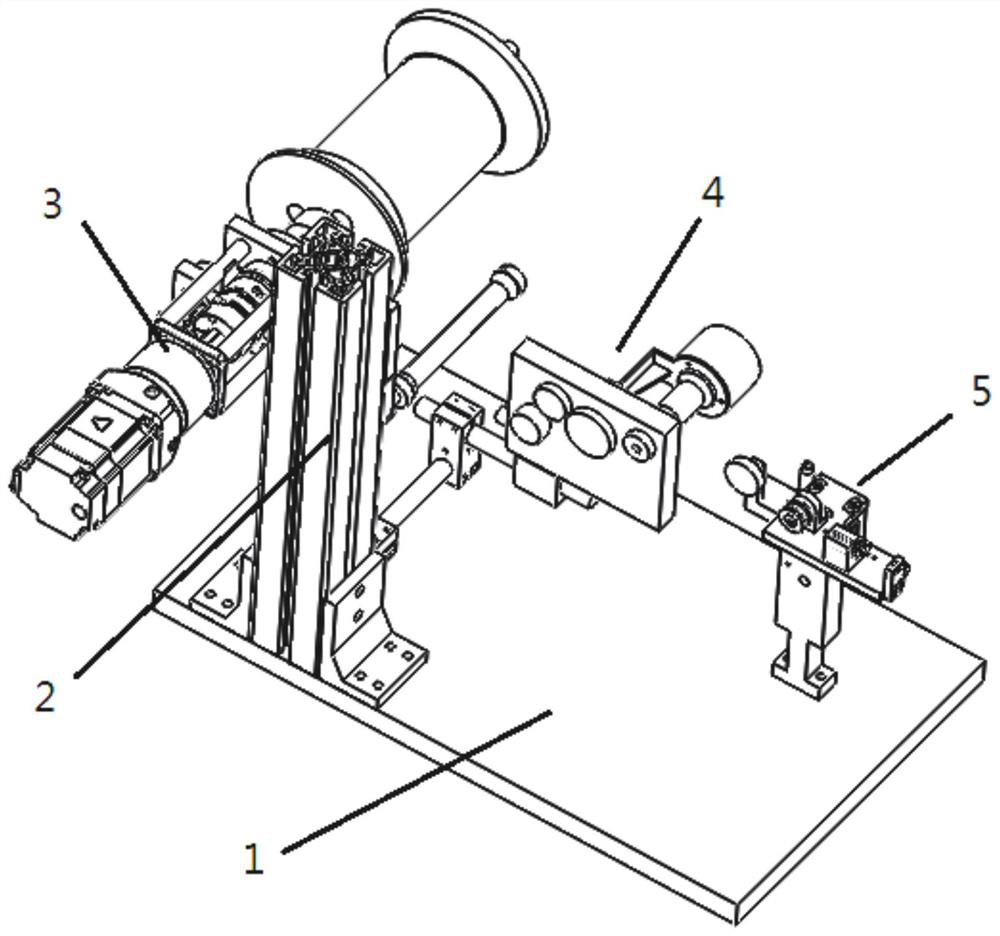

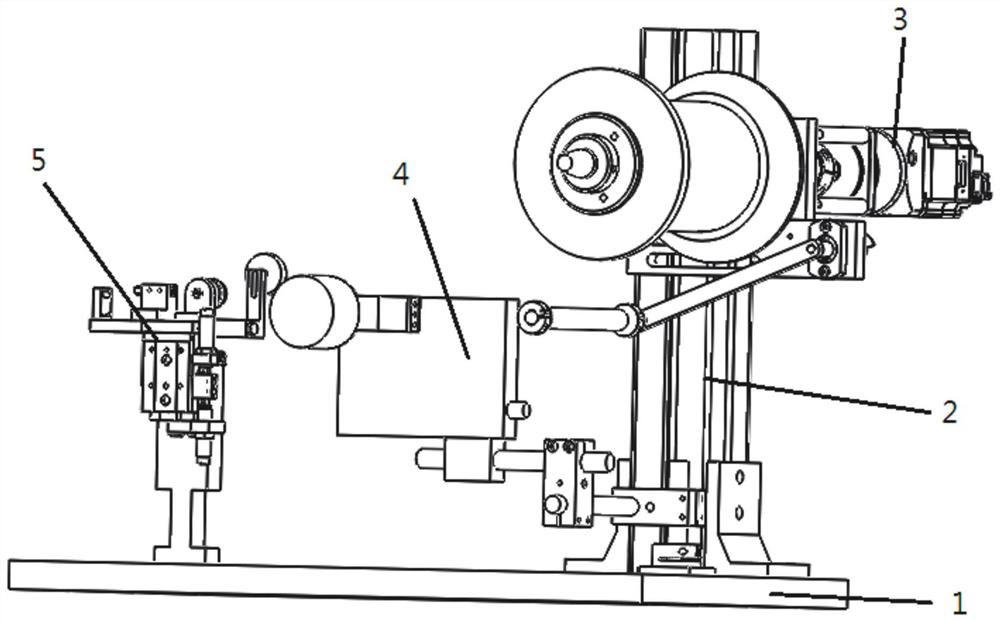

Ultrathin inductor winding and feeding device

PendingCN111668018AImprove the winding effectControl lengthCoils manufacturePrime moverInductor windings

The invention discloses an ultrathin inductor winding and feeding device which comprises a pay-off device, a tension mechanism, a wire outlet mechanism and a winding shaft which are sequentially arranged. The pay-off device comprises a pay-off wheel and a prime mover, the pay-off wheel is connected to the output end of the prime mover, the tension mechanism comprises a plurality of tensioning wheels and an encoder, the encoder is connected with one of the tensioning wheels, and the wire outlet mechanism comprises a wire outlet nozzle. The encoder is in communication connection with the prime mover, and the encoder is used for controlling the prime mover to work; a rope extends out of the pay-off wheel, passes through the multiple tensioning wheels and then enters the wire outlet nozzle, and the rope extends out of the wire outlet nozzle and then is wound on the winding shaft. Through the combined action of the pay-off device, the tension mechanism and the wire outlet mechanism, it is guaranteed that a good winding effect is achieved during inductor production.

Owner:华萃微感电子(江苏)有限公司

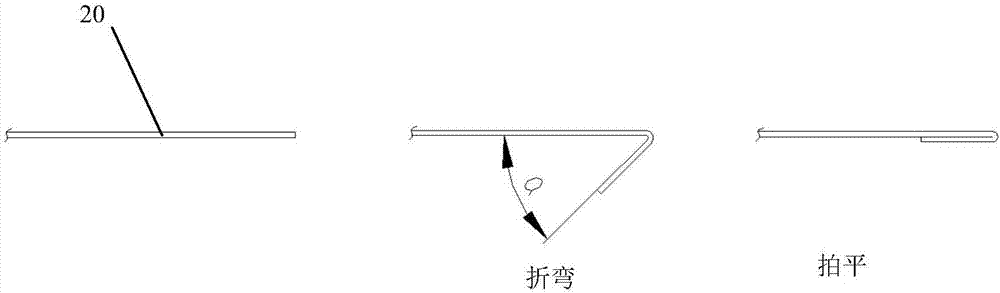

Bending and flattening mold and bending and flattening mold assembly

The invention provides a bending and flattening mold and relates to the technical field of forging and pressing molds. The bending and flattening mold comprises an upper mold body and a lower mold body. The upper mold body comprises a bending upper mold body, a pressing mold body and an upper mold drive component. The lower mold body comprises a bending lower mold body, a flattening mold body, a lower mold drive component and a lower mold switching component. The pressing mold is used for pressing a plate located between the upper mold body and the lower mold body. The bending upper mold body is in cooperation with the bending lower mold body to complete the bending process of the plate. The upper mold drive component is used for driving the bending upper mold body to move up and down. The flattening mold body is used for completing the flattening process of the plate. The lower mold drive assembly is used for driving the flattening mold body to complete the flattening process. The lower mold switching assembly is used for enabling the bending lower mold body to keep away from the flattening mold body when the flattening mold body completes the flattening process. The bending and flattening mold solves the problems that by means of the prior art, when the plate is bent and flattened, the number of the production processes is large, and the production tact is large.

Owner:青岛海德马克智能装备有限公司

Composite material winding pipe, inflation core mold and composite material winding pipe machining method

PendingCN113276439AImprove structural strengthIncrease contact areaTubular articlesEngineeringStructural engineering

The invention discloses a composite material winding pipe, an inflation core mold and a composite material winding pipe machining method. The composite material winding pipe comprises a first structural layer, a second structural layer and shear keys, the second structural layer is connected to the outside of the first structural layer, each shear key comprises a matching part and a fixing part, the matching parts are connected between the first structural layer and the second structural layer, one ends of the fixing parts are connected with the matching parts, and the other ends extends out of the first structural layer in the direction away from the second structural layer. The composite material winding pipe is used for internally pouring concrete to form a composite material winding pipe-concrete combined member, the shear keys arranged in the interior of the composite material winding pipe-concrete combined member improve the integrity and the mechanical property of the composite material winding pipe-concrete combined member, parts of structures of the shear keys extend out of the first structural layer and is solidified together with the first structural layer, the shear keys cannot damage the composite material winding pipe in the assembling process, the shear keys are tightly combined with the composite material winding pipe, and the structural strength of the winding pipe is improved.

Owner:TSINGHUA UNIV

Agent bottle taking device used for chemical experiments

ActiveCN109969569AEasy accessImprove work efficiencyShock-sensitive articlesDischarging meansBottleChemical engineering

The invention provides an agent bottle taking device used for chemical experiments, and relates to the field of chemical experiments. Classification can be conducted on types of agent bottles; and a rotation regulation device and telescopic devices are added, and therefore the effect that taking is facilitated is improved. The agent bottle taking device used for the chemical experiments comprisesa supporting fixed device, the rotation regulation device, the telescopic taking devices and agent bottle placement devices. The rotation regulation device is movably installed in the supporting fixeddevice. The telescopic taking devices are fixedly installed at the bottom end of the rotation regulation device. According to the agent bottle taking device used for the chemical experiments, each set of first connection supporting blocks are evenly distributed on the bottom face of a supporting rotary plate, each set of first connection supporting blocks are fixedly installed on the supporting rotary plate, the agent bottles can be placed in a classified manner, the agent bottles of the same type are placed in multiple sets of positioning groove holes in a set of agent bottle containing plates, and therefore the work efficiency of convenient agent bottle taking is improved.

Owner:闫童舒

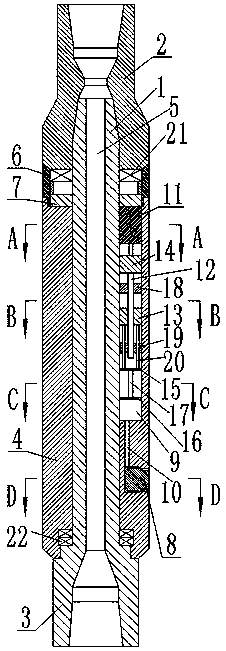

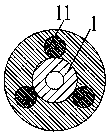

Guiding pipe

The invention discloses a guiding pipe, which comprises a pipe body, a mandrel, an upper joint and a lower joint. The pipe body is located between the upper joint and the lower joint, and a measurement and control pipe nipple sleeving the mandrel is arranged between the upper end of the pipe body and the upper joint; a measurement and control instrument is arranged between the measurement and control pipe nipple and the mandrel, and three or more guiding blocks are arranged on the lower part of the pipe body and pushed by a hydraulic system to stretch out in the radial direction of the pipe body; the hydraulic system comprises a power assembly, a piston assembly and a hydraulic oil cavity; the power assembly comprises three or more sets of power components, and the piston assembly comprises three or more sets of piston components; the piston components are located in piston cavities which are mutually independent, and the hydraulic oil cavity comprises three or more mutually independent sub hydraulic oil cavities; and the piston components are driven by the power components, and the lower ends of the sub hydraulic oil cavities communicate with cavities through hydraulic oil channels correspondingly, wherein the lower parts of the guiding blocks are located in the cavities. The guiding pipe is relatively simple in structure and relatively low in manufacturing cost and maintenance cost.

Owner:ZOUCHENG YANKUANG TAIDE IND & TRADE CO LTD

Minimally invasive surgery distraction device and minimally invasive surgery distraction system

PendingCN111419303AConvenient to judge the locationEasy to operateSurgical field illuminationMuscle tissueSpinal column

The invention relates to a minimally invasive surgery distraction device and a minimally invasive surgery distraction system, and solves the technical problems that prior spinal minimally invasive surgery distraction devices are difficult to operate, the distraction angle is fixed and cannot be freely adjusted, and the distraction action is not stable enough and is easy to damage muscle tissues. The device comprises a distraction cylinder assembly, a support frame, a base, a threaded driving rod outer sleeve, a light source interface component and a threaded driving rod, the distraction cylinder assembly comprises a left distraction half cylinder and a right distraction half cylinder, the top of the left distraction half cylinder is rotationally connected to the base through a first rotating shaft, the top of the right distraction half cylinder is rotationally connected to the base through a second rotating shaft, the threaded driving rod outer sleeve is connected to the base, the threaded driving rod is matched with the threaded driving rod outer sleeve, and a screw is connected to the top of the threaded driving rod; and the bottom of the threaded driving rod is connected to theleft distraction half cylinder through a first transmission connecting rod, and the bottom of the threaded driving rod is connected to the right distraction half cylinder through a second transmissionconnecting rod. The device is widely applied to the technical field of medical instruments.

Owner:SHANDONG WEIGAO ORTHOPEDIC DEVICE COMPANY

Automatic lamb wool shaving equipment

ActiveCN112997909AAvoid getting stuckImprove usabilityClimate change adaptationOther apparatusWoolSupport plane

The invention discloses automatic lamb wool shaving equipment. The equipment structurally comprises supporting frames which are symmetrically arranged; a lamb head fixing device which fixes the head of a lamb through an elastic rope and is easy to release is arranged on one sides of the supporting frames; a main guide rail is arranged in each supporting frame; a main rack is fixedly arranged on one side of each main guide rail; a lamb body cleaning device for cleaning and blow-drying wool is arranged on the main guide rails in a sliding mode; a lamb body trimming device for trimming the wool and preventing jamming is arranged on one side of the lamb body cleaning device; and a tail trimming device for removing the lamb tail wool is arranged on the other sides of the supporting frames. Through the design of a lamb head guide block, the lamb head can easily enter a fixing shell to be fixed, so that the usability of the equipment is improved; and the design of the lamb body cleaning device is adopted, and through the design of brushing nozzles and air blowing holes, the equipment can clean the wool, so that a cutter is prevented from being jammed in the trimming process.

Owner:上海汇圣林业有限公司

An external hug type vehicle handling device

The invention provides an externally embraced vehicle handling device, which includes a base, the base is divided into a first base and a second base, the first base and the second base are connected by an arc-shaped protective shed, A hollow arc-shaped channel is formed between the two, and the inside of the first base and the second base are equipped with a lifting mechanism and a clamping mechanism, and the clamping mechanism is placed on the lifting mechanism, through the The lifting mechanism drives the clamping mechanism to move up and down in the base. The outer hug type vehicle handling device described in the present invention can clamp and transport the vehicle after placing the vehicle in its arc-shaped protective shed, without being limited by the height of the chassis of the vehicle, it can realize automatic parking and save energy during transportation. It saves manpower, saves time, and at the same time protects itself during the process of transshipment.

Owner:TIANJIN LONYU SCI & TECH PROGRESS

A tool for testing the air tightness of the oil channel of the automatic transmission case

ActiveCN105043691BStretch out smoothlyAvoid stickingMeasurement of fluid loss/gain rateAutomatic transmissionEngineering

The invention discloses a tool for detecting the air tightness of the oil channel of an automatic transmission case, which includes a bottom block installed on the bottom plate, a top block assembly including a top cover fitted with the casing, and a top cover fitted in a bearing hole. The ring and the guide post are slidably installed on the top cover through the guide slider. The sliding direction of the guide post relative to the top cover is the direction close to or away from the bearing hole; Blocking block, there is an elastic piece between the blocking block and the top ring, and when the elastic piece is in a compressed state under the pressure of the guide post, the blocking block passes through the through hole and is inserted into the oil passage communicating with the bearing hole. In this way, the sealing of the oil passage connected to the bearing hole through the sealing effect enables the individual sealing of the oil passage hole at that place when multiple oil passages communicate with the same bearing hole, thereby avoiding the False detection occurs when the oil passage is penetrated, which improves the reliability of the detection results and avoids quality risks.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A damage-resistant ranging sensor for driverless cars

InactiveCN110371041BSolve the problem of difficult protection distance sensorIncrease frictionVehicle componentsElectric machineryStructural engineering

Owner:XIAN AERONAUTICAL UNIV

Multi-country universal electric adaptor

InactiveCN100433470CStretch out smoothlyEasy to operateCoupling device connectionsRotary switchMulti country

An electric plug adaptor of international- universal type consists of top cover, base two sliding slots on external wall, standard plug corresponding to each sliding slot position, rotary switch including a bar sliding block and a braking button. It is featured as setting a ledge and a groove closing to ledge bottom on top of plug to let bar sliding block slide along each ledge through bar sliding slot in order to have only one plug of plug adaptor connected on independently and selectively.

Owner:张锡帆

Horizontal conveying device

ActiveCN114148736ASolve control problemsIt is more difficult to solve the maintenanceControl devices for conveyorsPull forceEngineering

The invention relates to the technical field of material conveying, and provides a horizontal material conveying device which comprises a material conveying table and a pushing device arranged on one side of the material conveying table, the pushing device is used for pushing materials on the material conveying table and comprises a telescopic part arranged on a support, and the telescopic part comprises a plurality of telescopic arms with different diameters; the telescopic arm with the largest diameter is a connecting arm, the telescopic arm with the smallest diameter is a pushing arm, the other telescopic arms are transmission arms, after the first driving mechanism drives the rigid chain to move through the chain wheel, the encoder collects rotation information of the chain wheel, the rigid chain drives the pushing arm and the transmission arms to move in sequence, and the rigid chain stretches out in the horizontal downward direction; the bracket is rotationally arranged at the tail end of each stage of telescopic arm in the telescopic direction, the rigid chain is lapped on the bracket, and the pushing disc is arranged at the end of the pushing arm through the push-pull force sensor. According to the technical scheme, the problem that the material position accuracy is not high when a conveying device conveys materials in the related technology is solved.

Owner:秦皇岛优益创联特种车辆制造有限公司

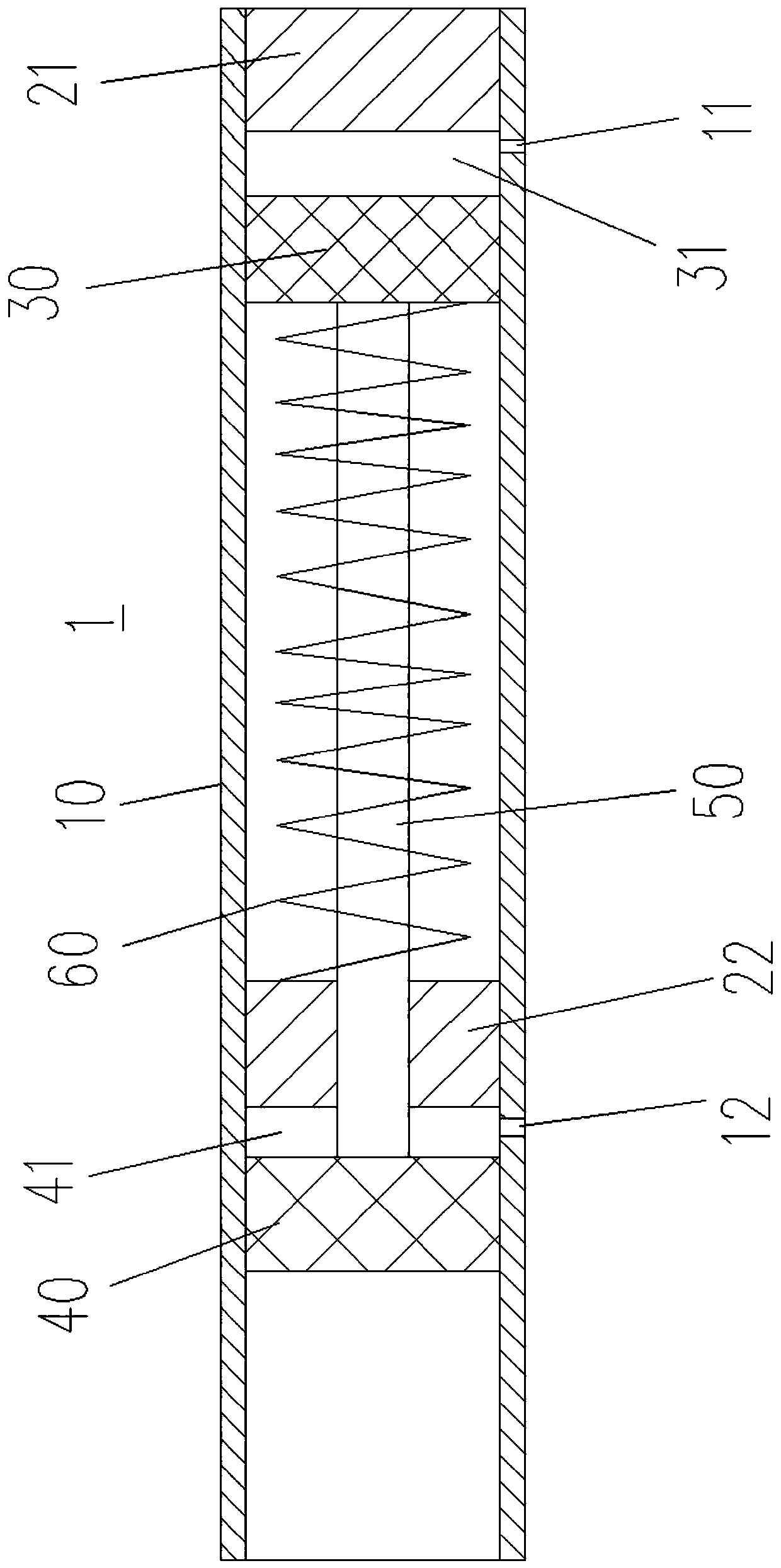

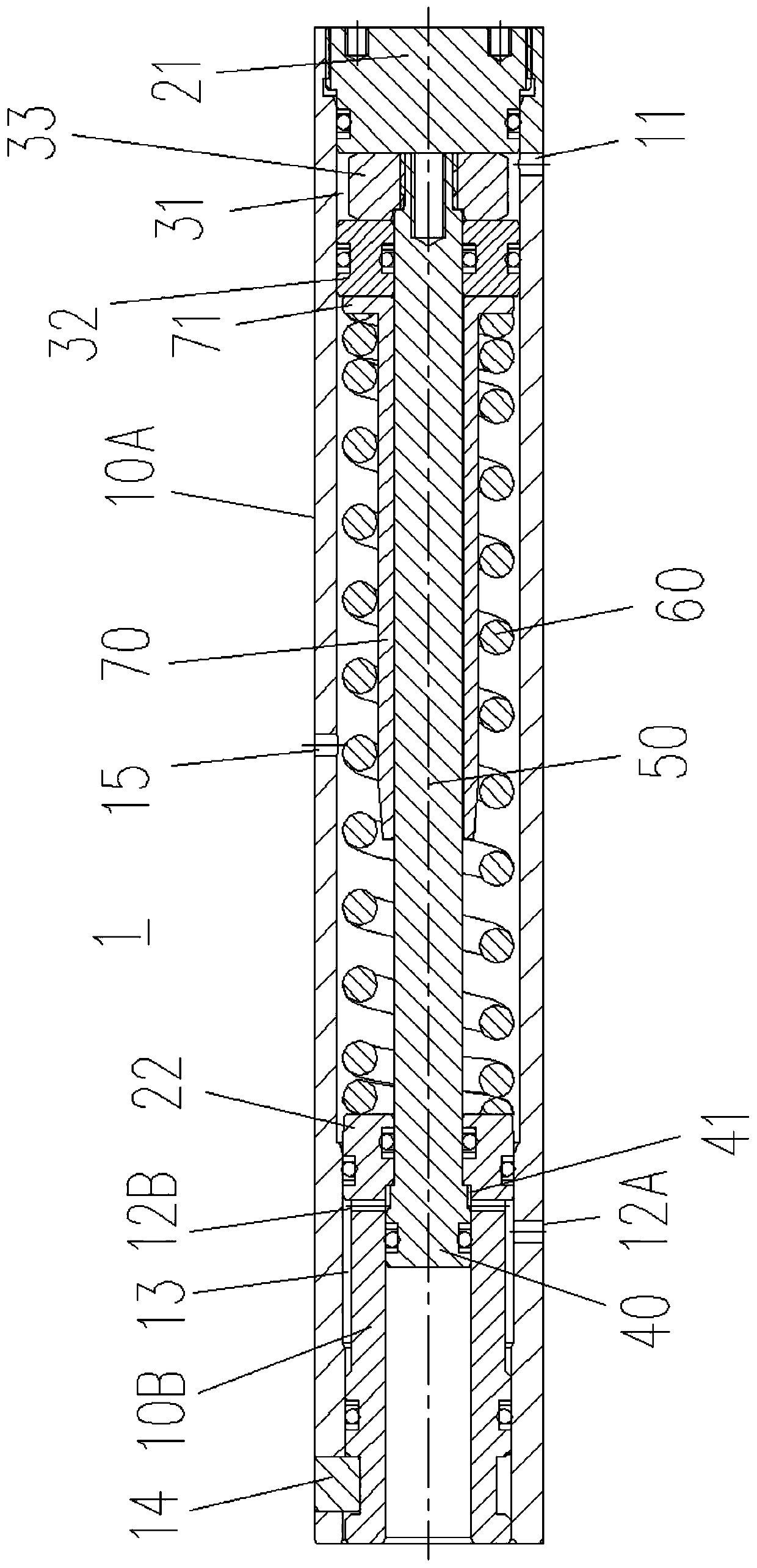

Accumulator and downhole measuring device including same

The invention relates to an energy accumulator and a downhole measuring device equipped with the same. The energy accumulator comprises a cylinder body, a first sealing plate, a second sealing plate,a first piston part, a second piston part and an elastic component, wherein the first sealing plate and the second sealing plate are fixedly accommodated in the cylinder body and spaced from each other in the longitudinal direction; the first piston part is arranged in the cylinder body, and positioned between the first sealing plate and the second sealing plate; a first piston cavity is formed between the first piston part and the first sealing plate; the second piston part is positioned on the side, away from the first sealing plate, of the second sealing plate; a second piston cavity is formed between the second piston part and the second sealing plate; and the elastic component is positioned between the first piston part and the second sealing plate, and can be compressed correspondingto the movement of the first piston part away from the first sealing plate and / or the movement of the second piston part away from the second sealing plate. The energy accumulator is convenient to use.

Owner:CHINA PETROLEUM & CHEM CORP +1

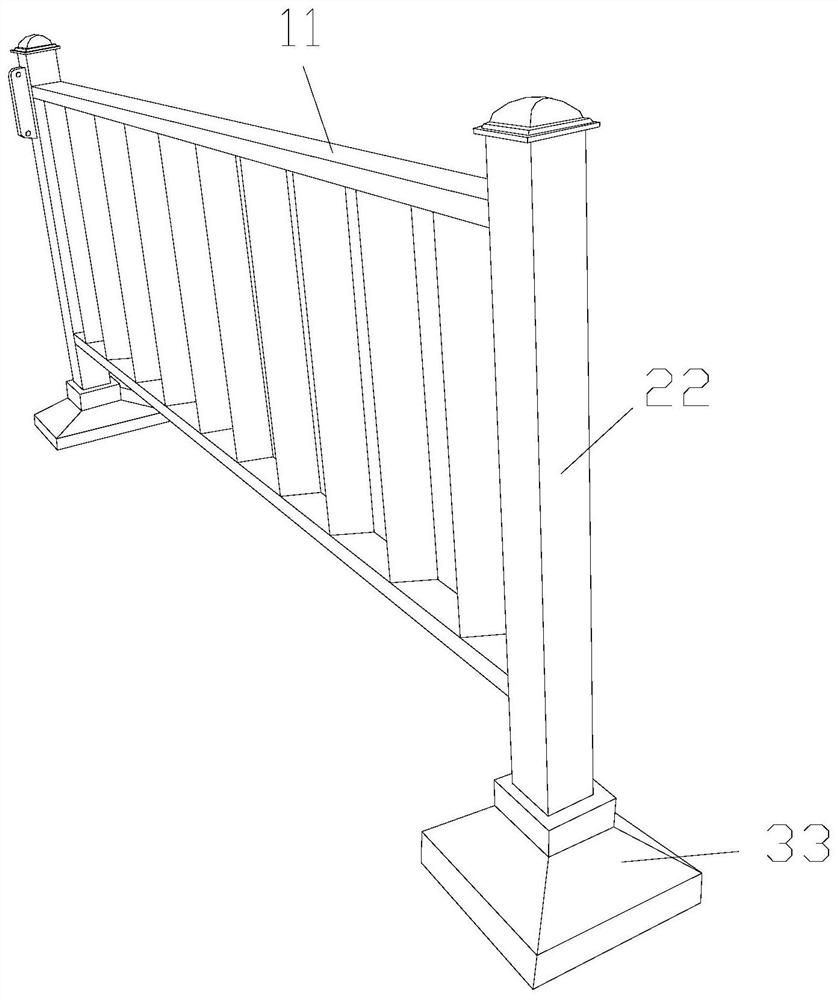

Multipurpose municipal road isolation belt

InactiveCN112342965APlay a limiting roleStretch out smoothlyRoadway safety arrangementsAdhesiveArchitectural engineering

The invention discloses a multipurpose municipal road isolation belt which structurally comprises a rod frame, supporting rods and a bottom fixing base, the supporting rods are vertically fixed to theleft end and the right end of the rod frame, the bottom ends of the supporting rods are embedded into the bottom fixing base and fixed to each other, joint swing rods and joint supporting rods of thesupporting rods can be bent and stressed, and the whole bearing force is evenly separated through the joint supporting rods. When the joint supporting rods are bent, when the hard head abuts againstthe surface of the clamping block, an abutting object is moved in an abutting mode according to the swinging distance of external force, the limiting effect is achieved, the moving space of the hard head is properly adjusted, and when the object is placed in a bent channel, the object can be bent, swung and clamped to conform to a curve, the inner fixing blocks connected inside are separated through the middle adhesive tape, the soft body inside the inner fixing blocks can be pulled open and move along with the connection portion, and when the adhesive layer is stressed, the balloon can be smoothly expanded to support the expansion range of the outer layer, and when the object is bent, the balloon can keep the counter-force effect all the time to assist in return.

Owner:刘传兵

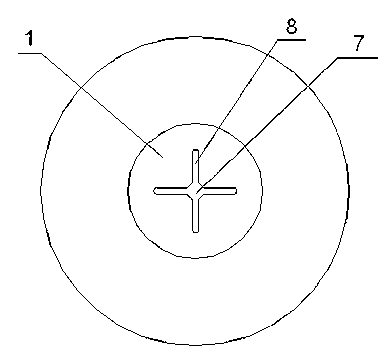

Rectal injury discriminator

InactiveCN102429641BEasy to observeClear identificationDiagnostic recording/measuringSensorsDiscriminatorIntestinal walls

The invention discloses a rectal injury discriminator, which comprises an outer bushing and an inner bushing arranged in the outer bushing, wherein one end of the outer bushing is provided with a mushroom head; the mushroom head is provided with a hole; an elastic isolation film is covered on the hole, and is provided with a punctate through hole and a cross-shaped groove which is connected with the punctate through hole; one end of the inner bushing is provided with a pipe cavity opening which is close to the mushroom heat; the other end of the inner bushing is provided with an inner bushingjoint; and the inner bushing is provided with a switch which is positioned between the pipe cavity opening and the inner bushing joint. By adopting the rectal injury discriminator, a rectal mucosa can be spread appropriately, and damage on an intestinal wall can be observed conveniently from the periphery of a recta in the surgical area; and after the inner bushing is inserted, water is introduced into the recta through the inner bushing and the pipe cavity opening on the inner bushing, a recta cavity is full, and recta damage can be judged by observing whether water leaks on the outer surface of the intestinal wall in the surgical area.

Owner:JIANGSU PROVINCE HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com