Prefabricated wall body of fabricated building

A prefabricated wall, prefabricated technology, applied in construction, building components, building materials, etc., can solve problems such as poor connection strength, and achieve the effects of improving movement stability, work stability, and connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

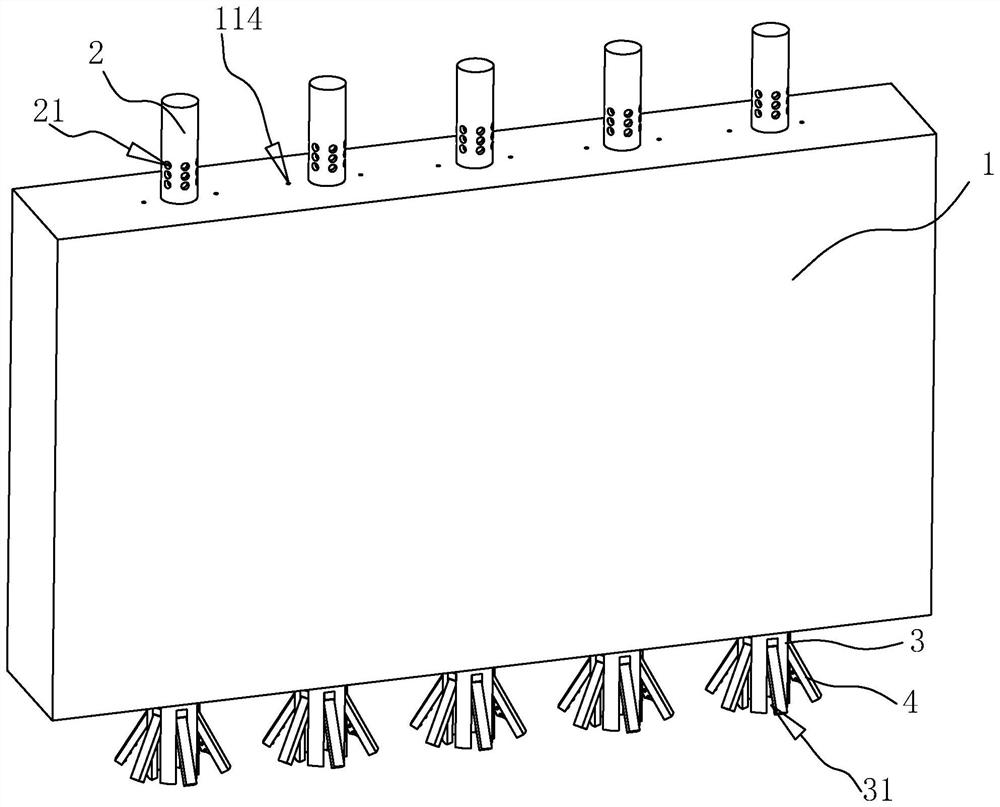

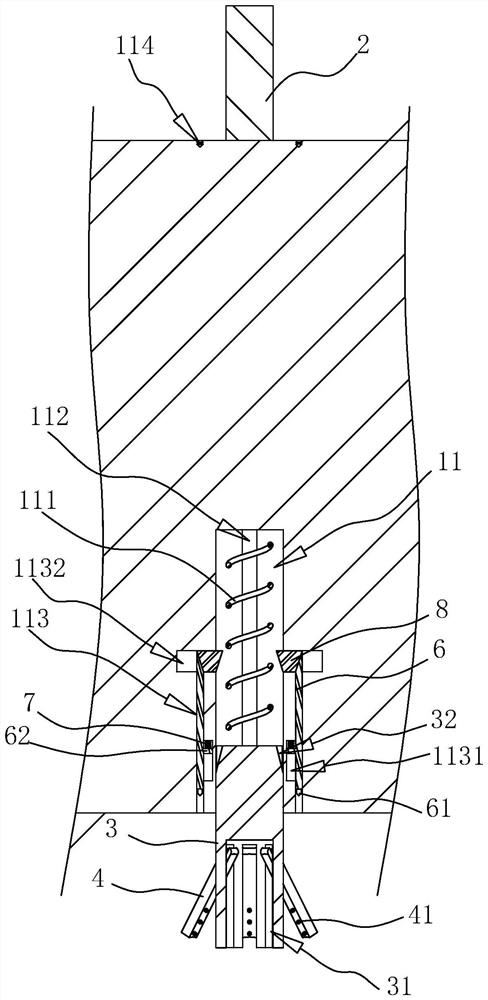

[0033] Attached to the following Figure 1-Figure 2 This application will be described in further detail.

[0034] The embodiment of the present application discloses a prefabricated wall of a prefabricated building. refer to figure 1 and figure 2, the prefabricated wall body of the prefabricated building includes a wall body 1, the wall body 1 is arranged in a cuboid shape, the top of the wall body 1 is vertically fixed with a plurality of steel bars 2, and the plurality of steel bars 2 are arranged at intervals along the length direction of the wall body 1, corresponding to The bottom of the wall body 1 is provided with a plurality of accommodating grooves 11 arranged in the vertical direction along its own length direction. A connecting sleeve 3 is arranged inside the accommodating groove 11 along its own length direction, the bottom of the connecting sleeve 3 is open, and the connecting sleeve 3 is connected with the steel bar 2 on the adjacent wall 1 to The fixation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com