Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Stable welding work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

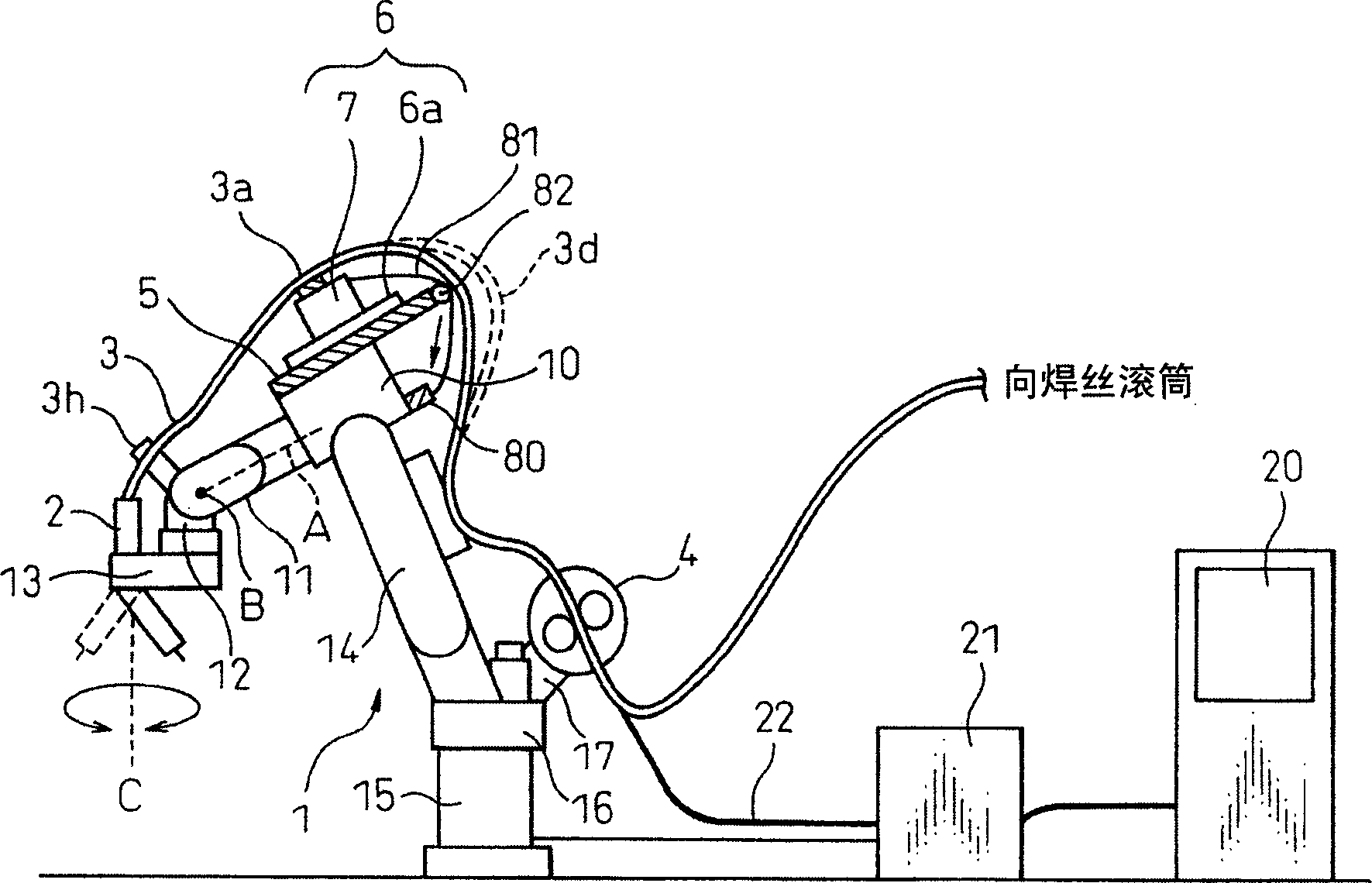

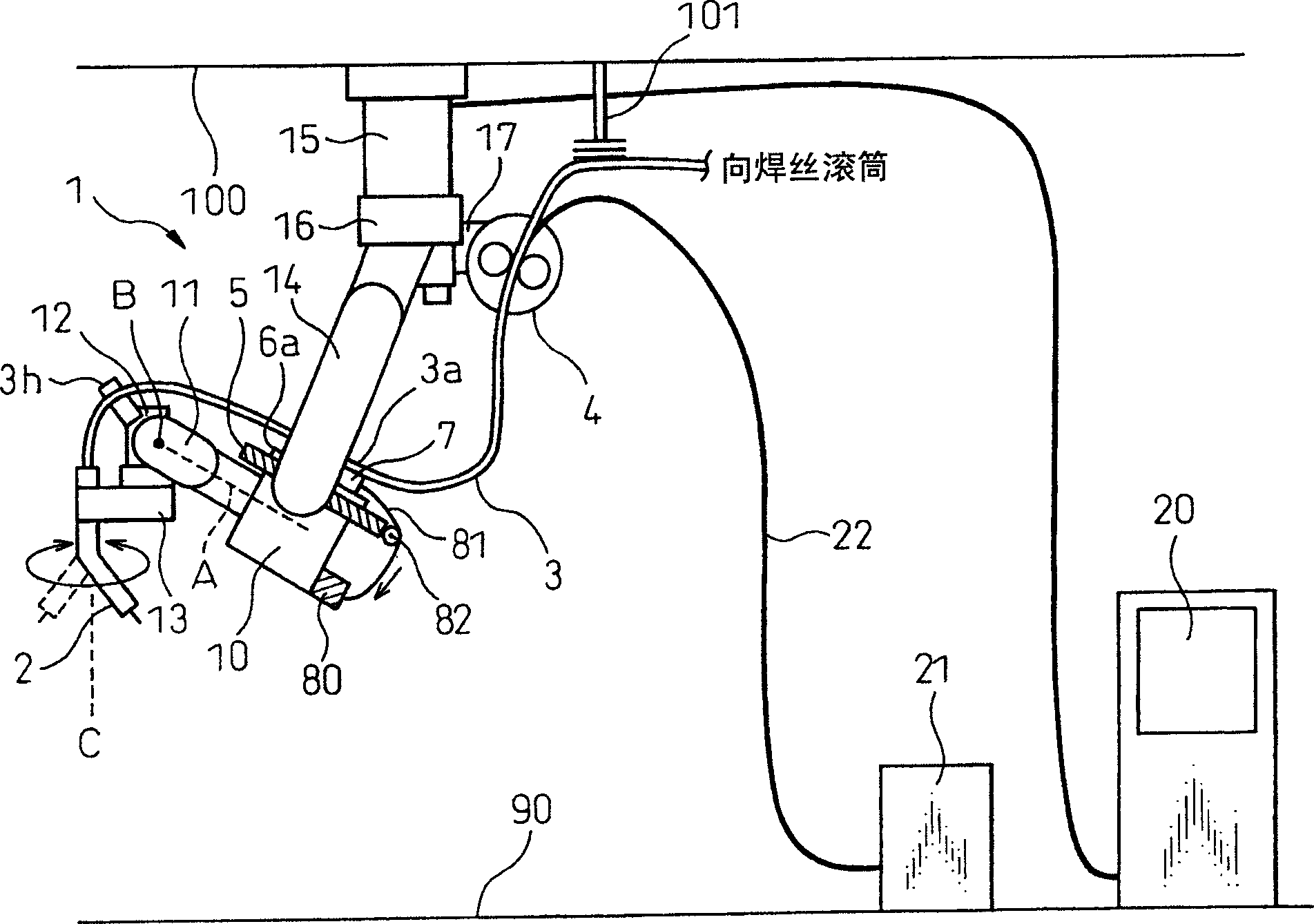

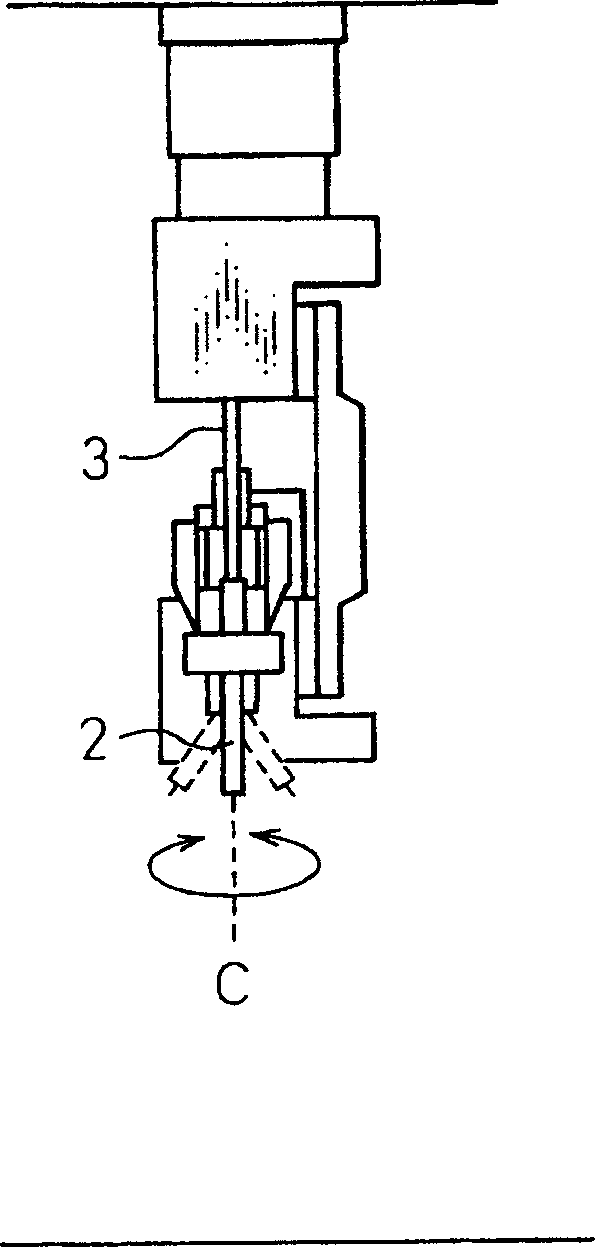

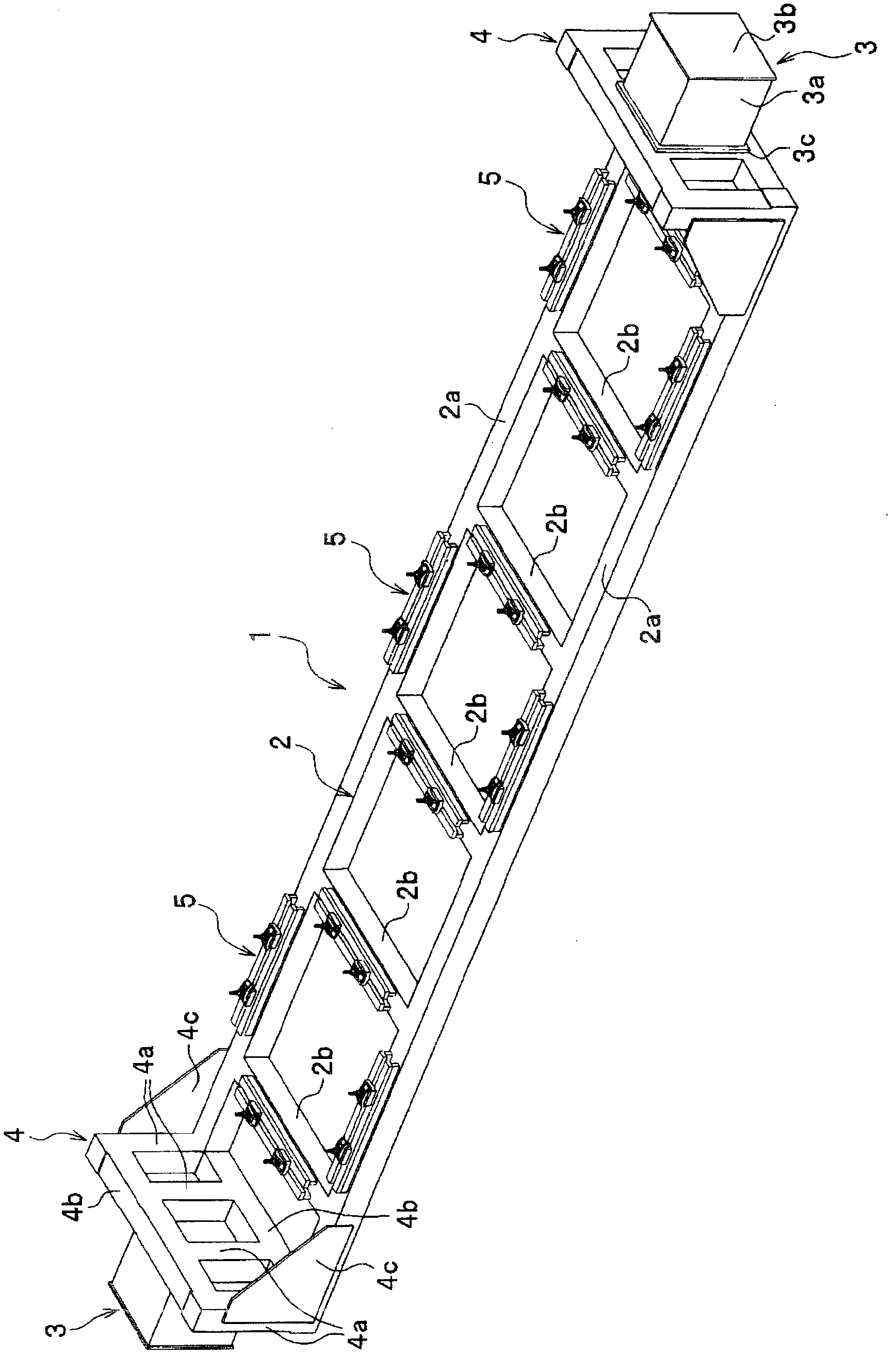

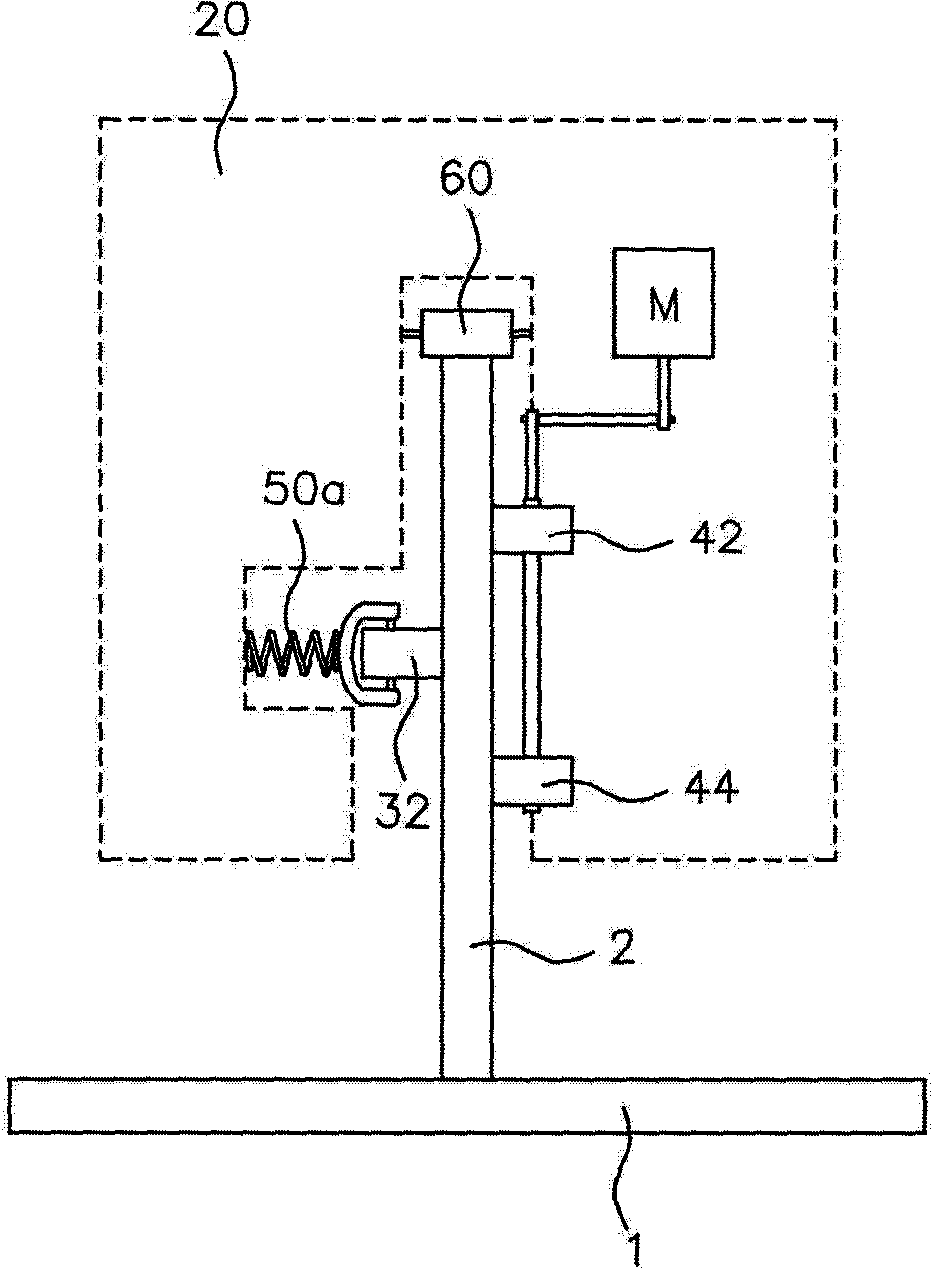

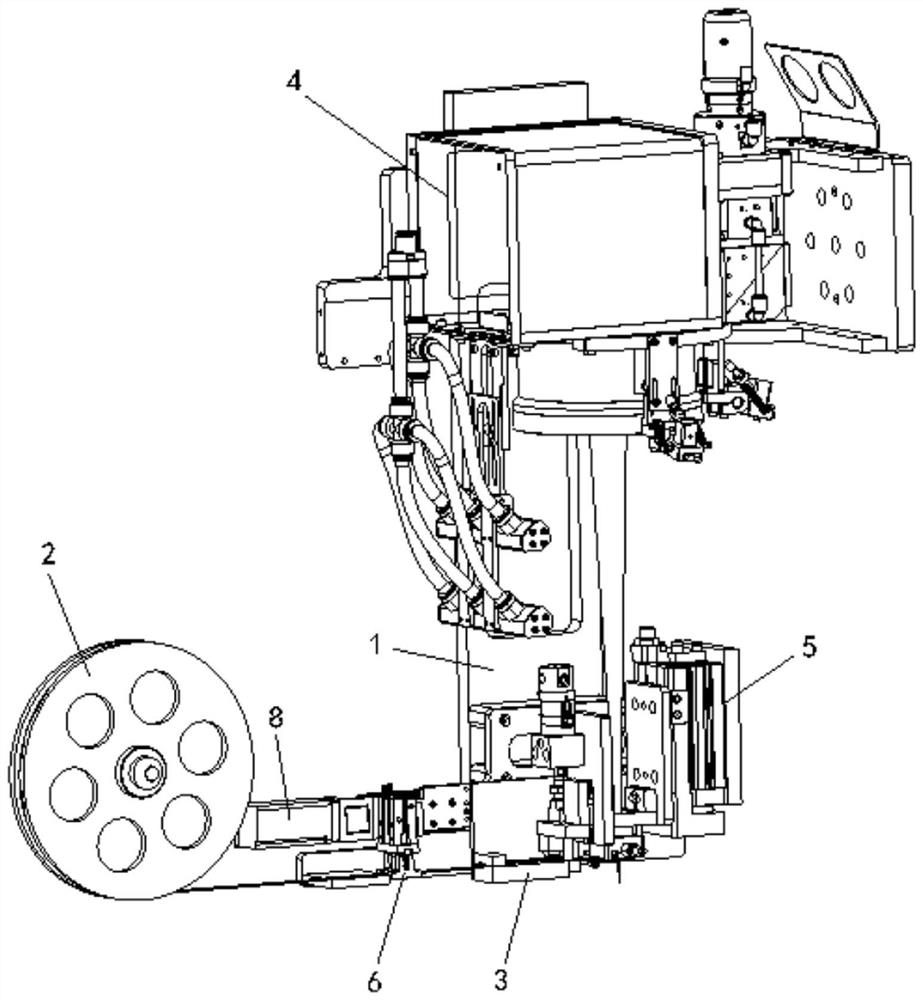

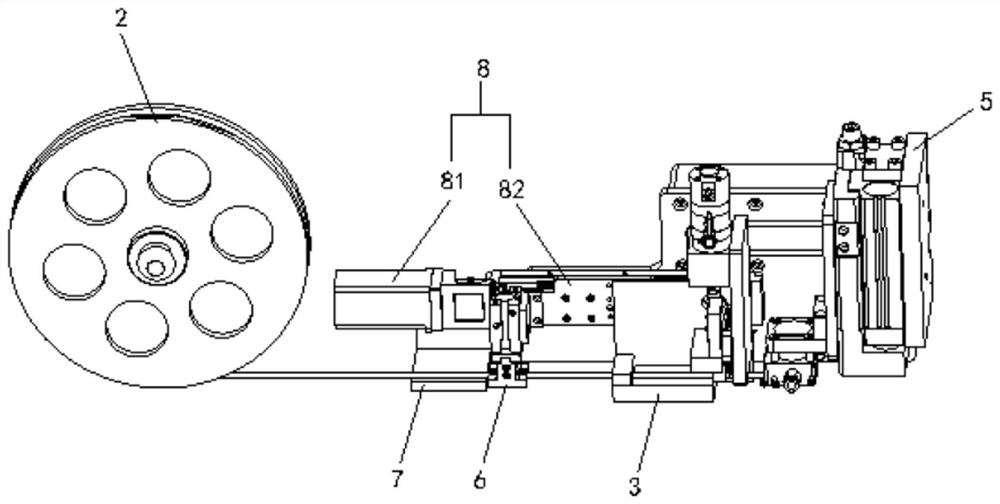

Structure for treating torch cable for arc welding robot

InactiveCN1745953AStable deliveryStable welding workProgramme-controlled manipulatorWelding/cutting auxillary devicesStable stateMechanical engineering

The invention relates to a welding torch treatment structure for a robot in the electric arc welding industry, wherein, a robot base is arranged on a ceiling part, and a first wrist unit which can rotate around a first shaft line is arranged on a front arm base; a second wrist unit which can rotate around a second shaft line is arranged on a first wrist unit; depending on the transmission mechanism, the welding torch which can rotate around an offset shaft is supported; the welding torch is arranged as the front end directing downward in the illustrated posture of the robot; the invention is provided with a linear guide and a slider via a support base, and a middle part of a torch cable or a welding wire delivery device is fixed and drawn by a tensioning device; the structure is also applicable to a wall-mounted type robot. Thereby, a welding torch cable structure is realized in an arc welding robot of a ceiling-suspension type or a wall-mounted type, capable of maintaining the behavior of the welding torch cable in a stable state as well as minimizing the interference of the welding torch cable with other objects.

Owner:FANUC LTD

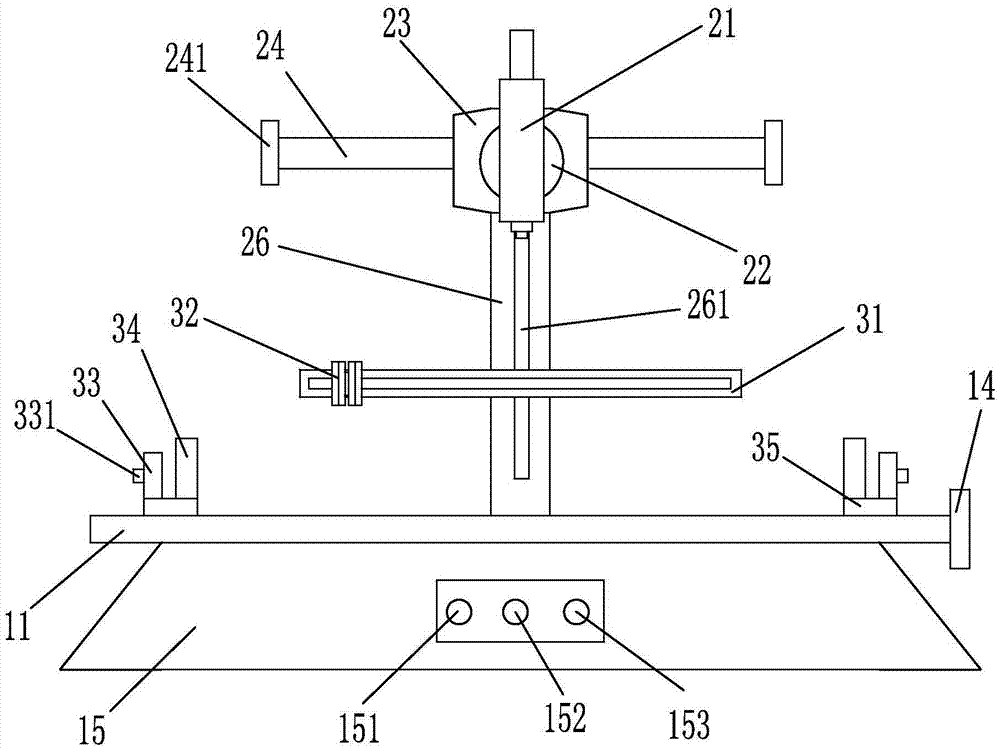

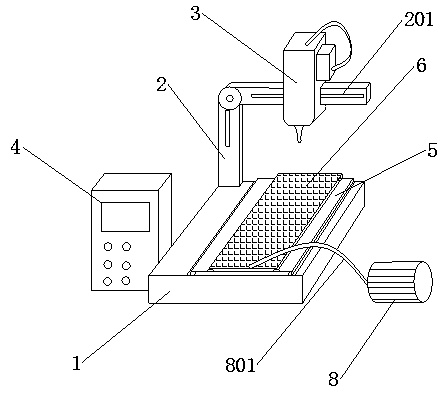

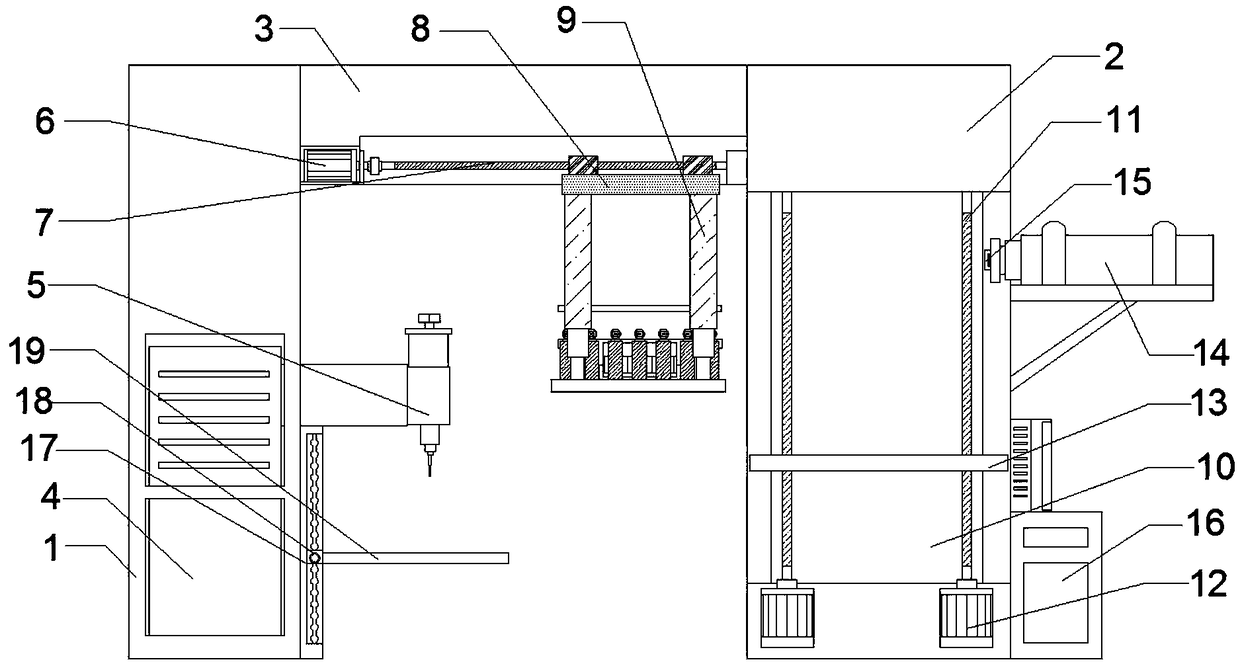

Welding machine applicable to production and processing of aluminium profiles

InactiveCN105436767AEasy to adjustEasy to clean centrallyWelding/cutting auxillary devicesAuxillary welding devicesAluminiumEngineering

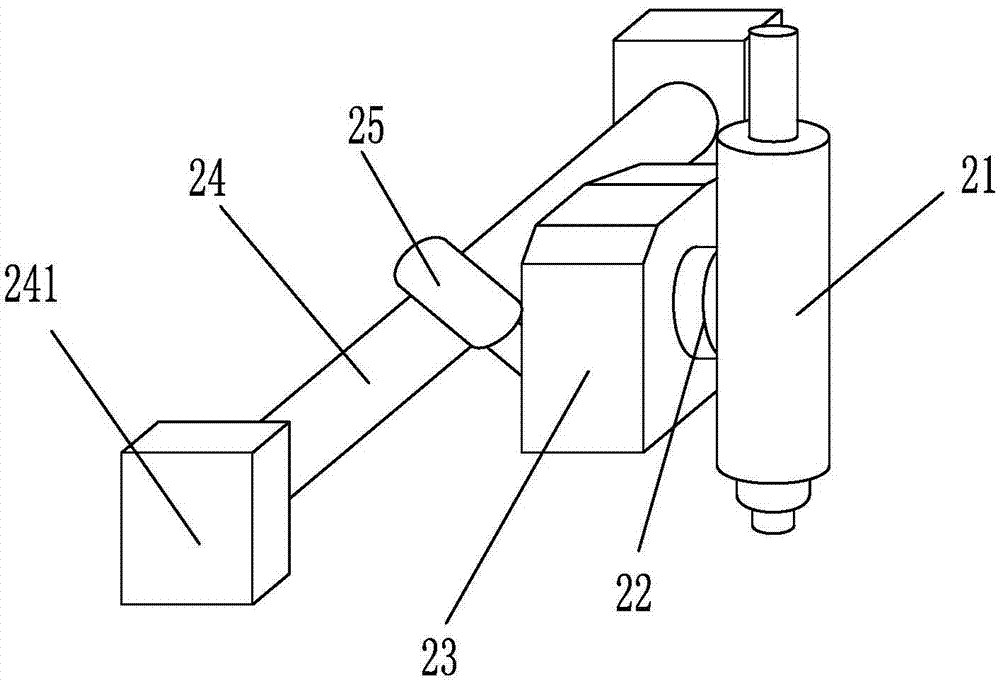

The invention discloses a welding machine applicable to production and processing of aluminium profiles. The welding machine comprises a working platform, a welding mechanism and a fixing mechanism, wherein the welding mechanism and the fixing mechanism are arranged on the working platform; a cutting plate is arranged on the working platform; cleaning through holes are formed in the cutting plate; the welding mechanism comprises a welding machine head, a rotary device and a moving device; the welding machine head is fixed on the rotary device; the rotary device comprises a rotary table and a moving machine base; the moving device comprises a moving rod, an elastic rod and a fixed support rod; the upper end of the fixed support rod is connected with the moving rod; the moving rod is connected with the elastic rod; the elastic rod slides left and right along the moving rod; the elastic rod is fixedly connected with the moving machine base; and the fixing mechanism comprises an upper material clamping device and lower material clamping devices. According to the welding machine disclosed by the invention, the applicability is good; the working stability of the welding machine is improved, and the welding effect of the welding machine is ensured; the whole process is convenient for operation and obvious in effect; and the welding efficiency is improved.

Owner:嵊州市银河铝业有限公司

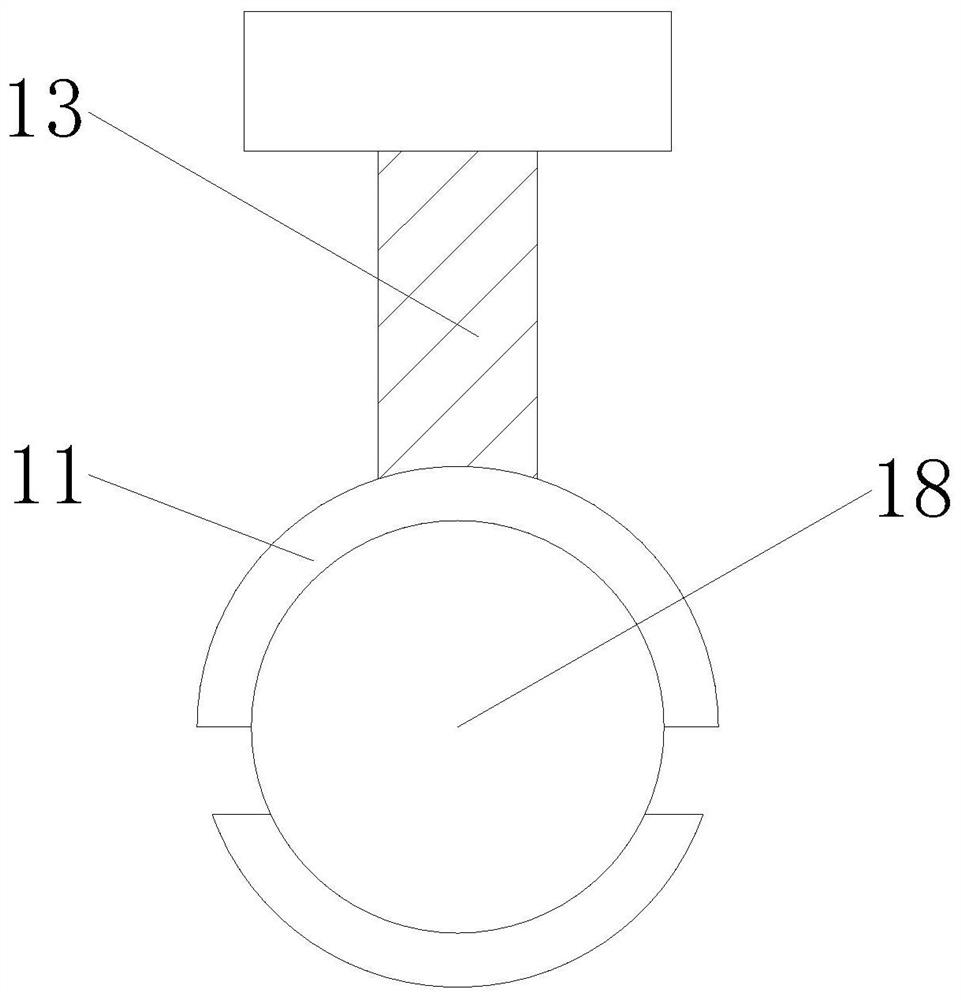

Industrial mechanical steel pipe positioning and welding device

InactiveCN112247469AConvenient welding workEasy to useEdge grinding machinesGrinding drivesWorking environmentMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to an industrial mechanical steel pipe positioning and welding device. The device comprises a workbench, trundles are fixedly connected to the lower ends of four supporting legs correspondingly, a top plate is fixedly connected to the upper ends of four supporting columns, a first screw rod is rotatably connected to the interior of a first empty groove through a bearing, a threaded block is in threaded connection with the outer side of the first screw rod, a connecting plate is fixedly connected to the upper end of the threaded block, a first through groove is formed in the middle of the connecting plate, a positioning device is rotatably connected to the interior of the first through groove through a bearing, a welding gun is fixedly connected to the lower end of the first hydraulic rod, and a protective shell is fixedly connected to the middle of the upper end of the workbench. The industrial mechanical steel pipe positioning and welding device is reasonable in structural design, convenient to use, high in practicability and functionality, high in applicability, wide in application range, capableof guaranteeing the better welding effect, capable of protecting the working environment, more convenient to use and worthy of popularization.

Owner:李高师

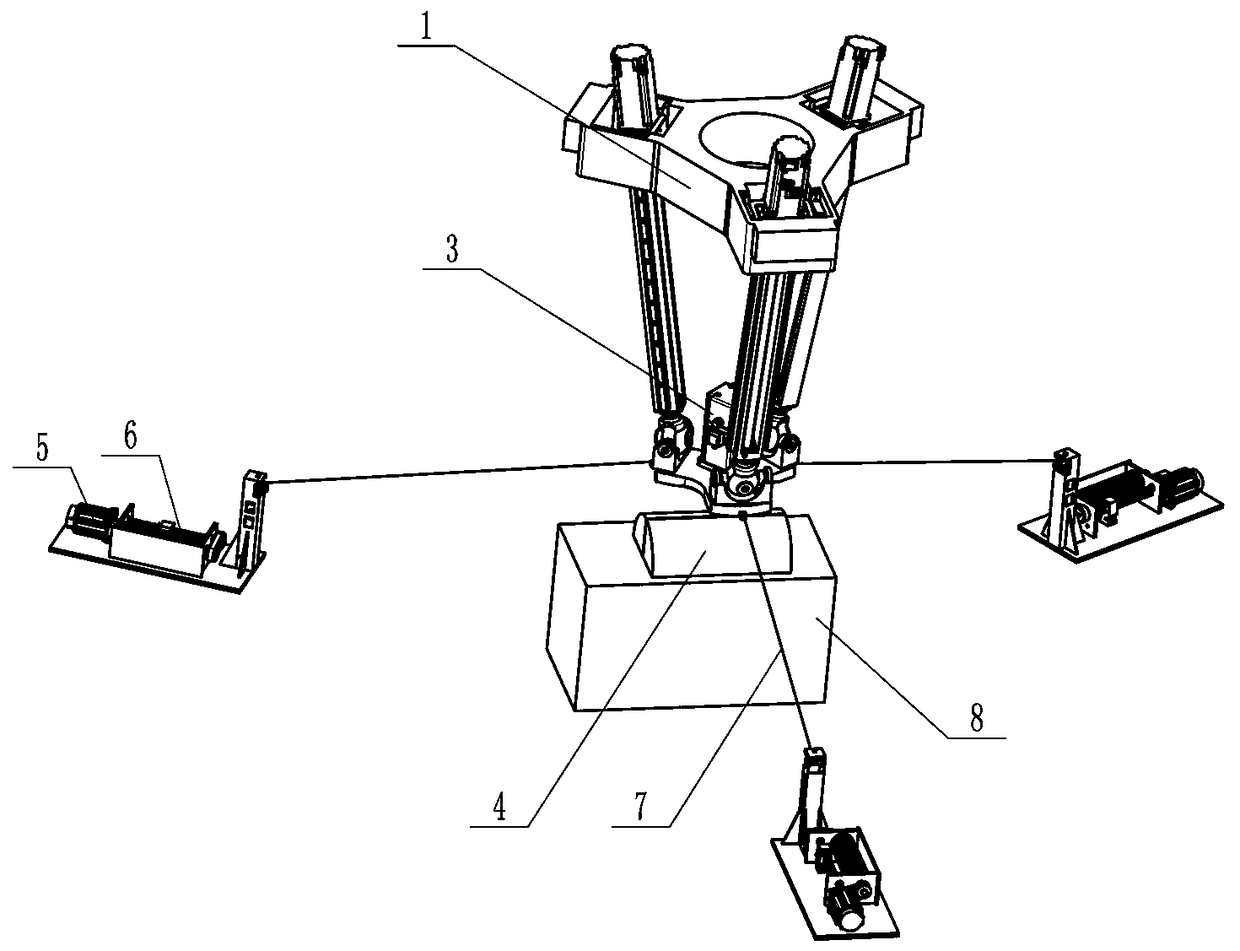

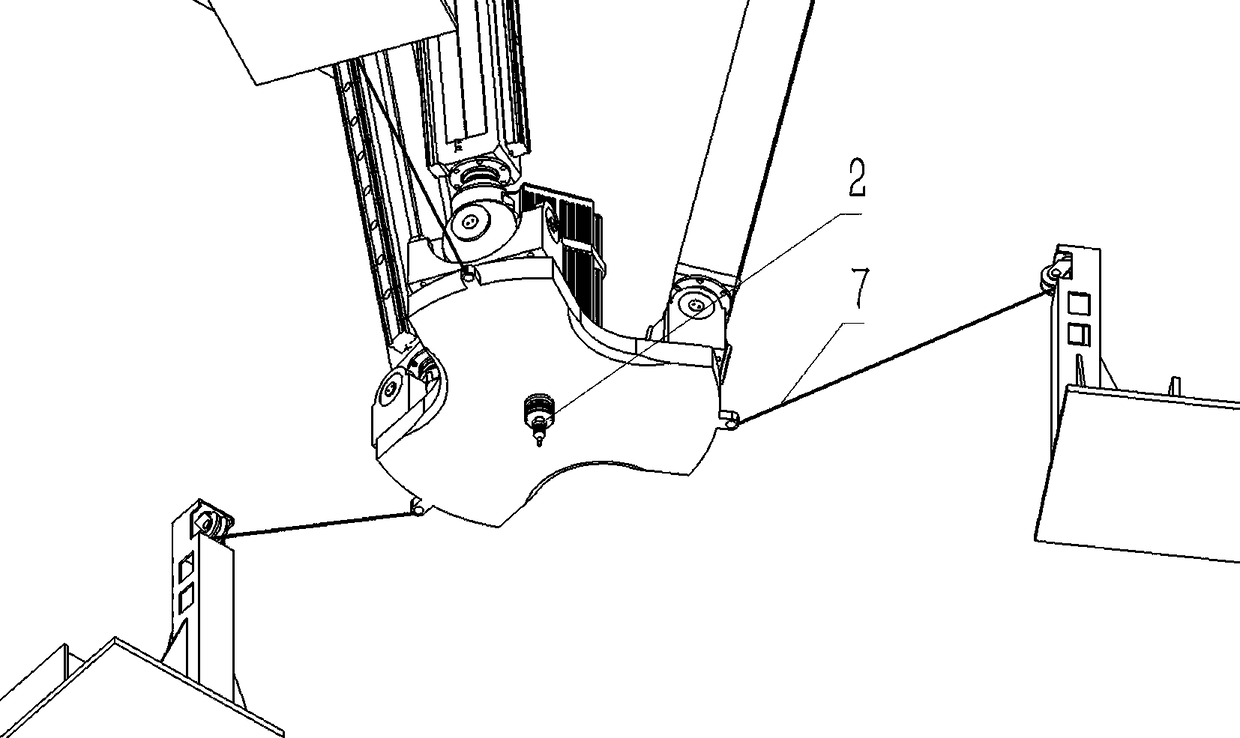

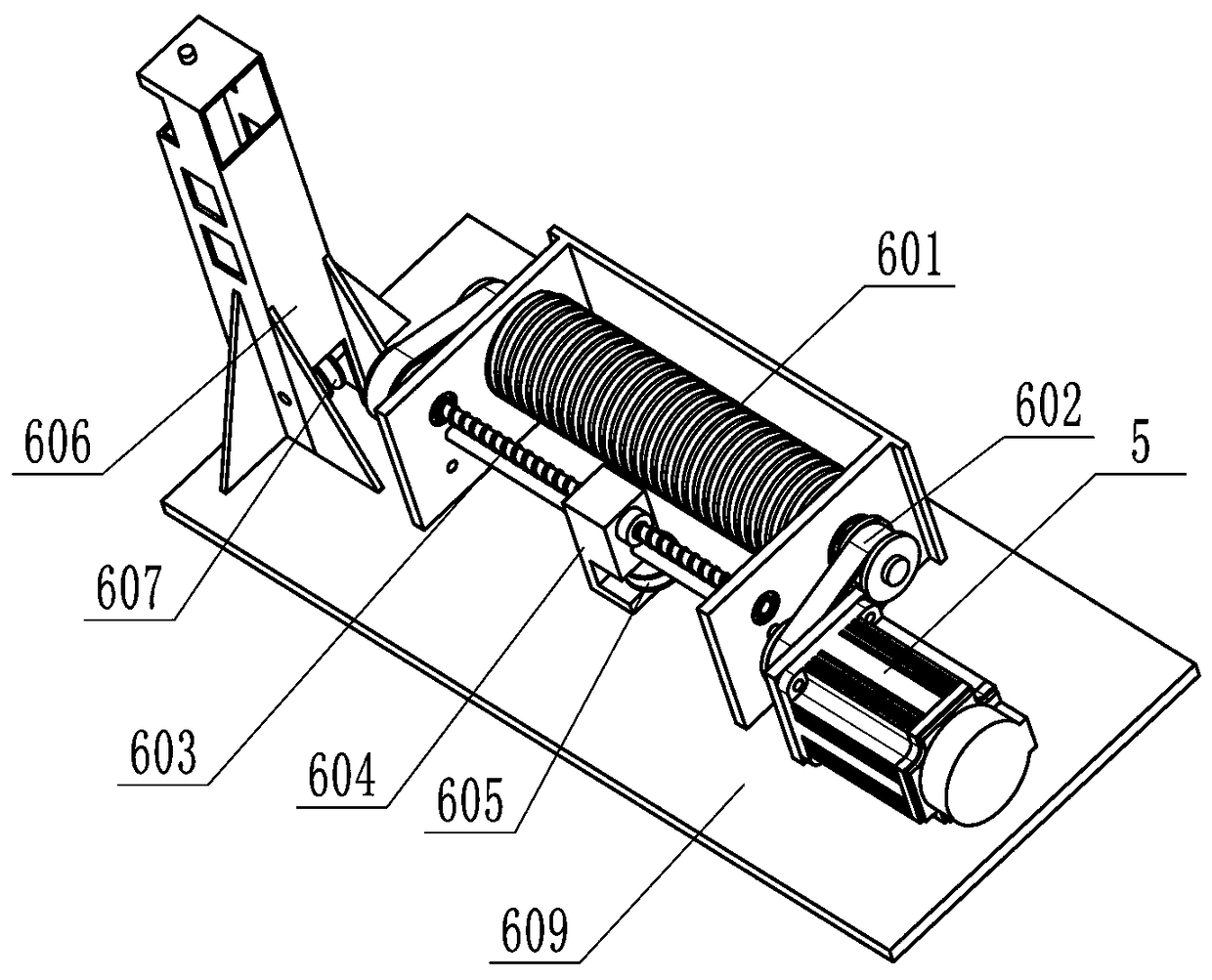

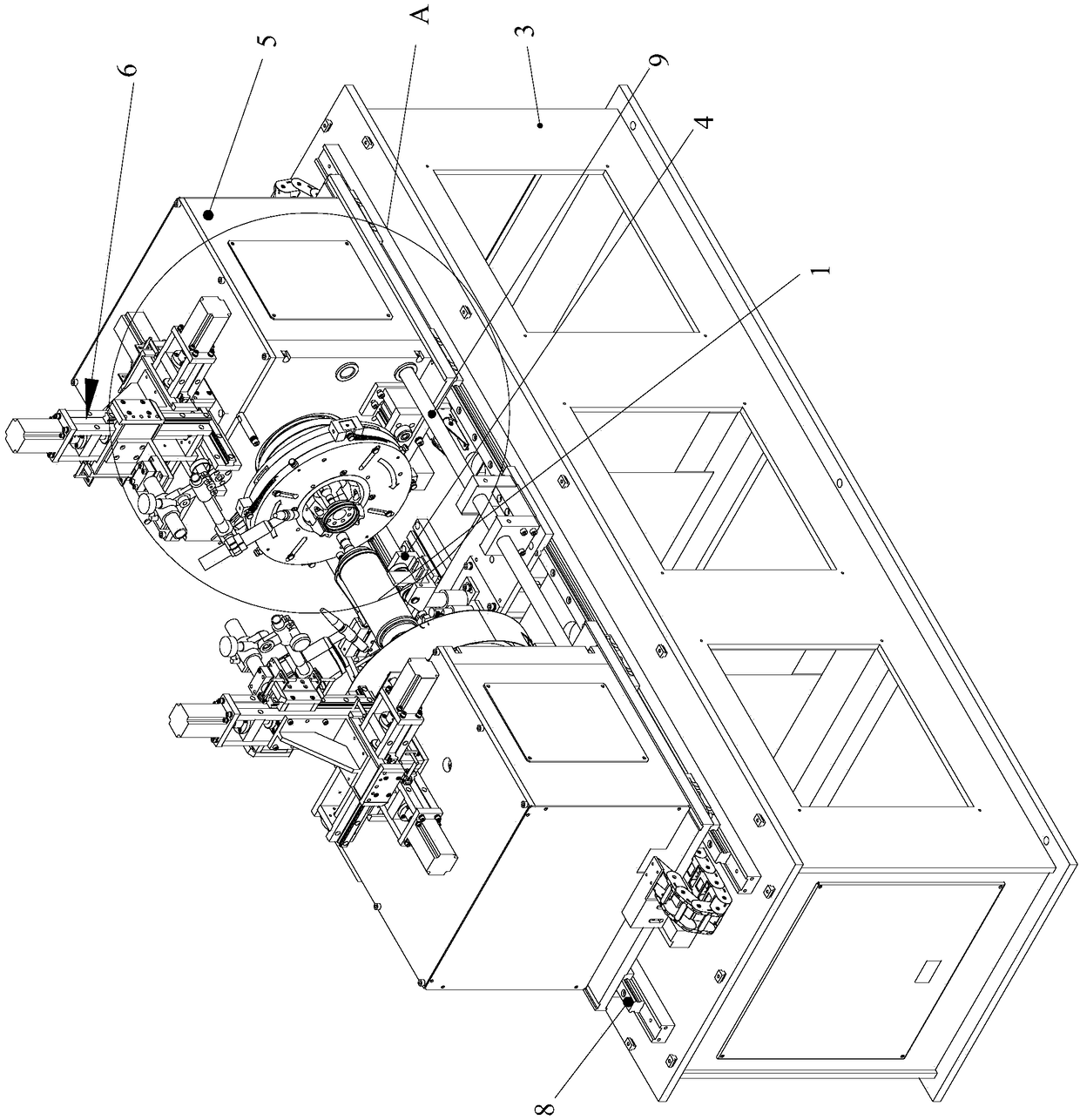

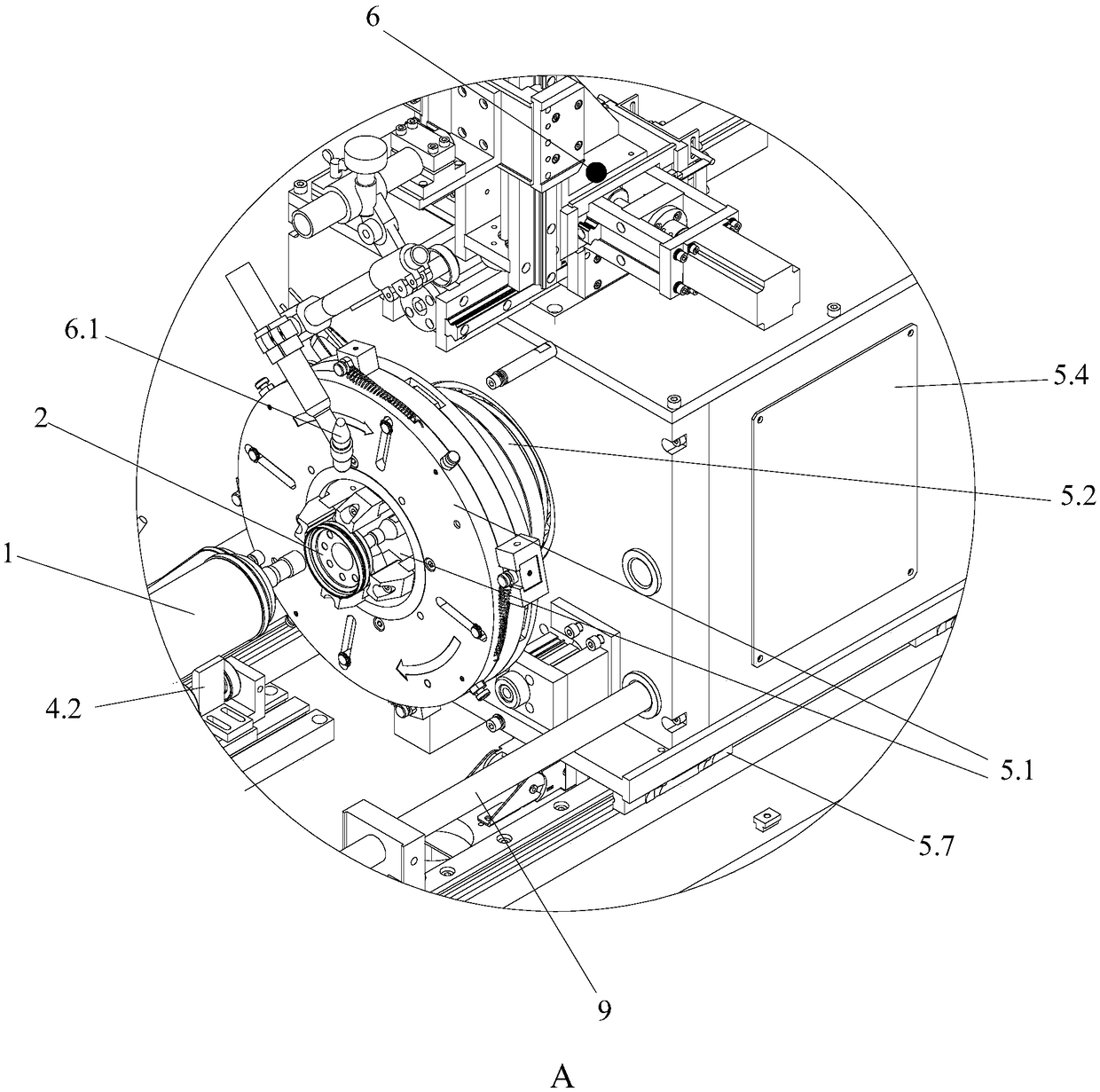

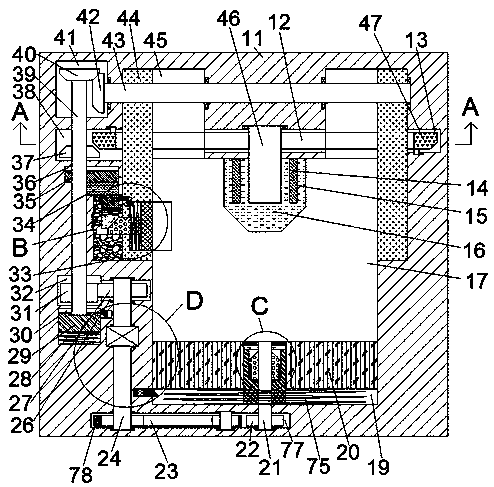

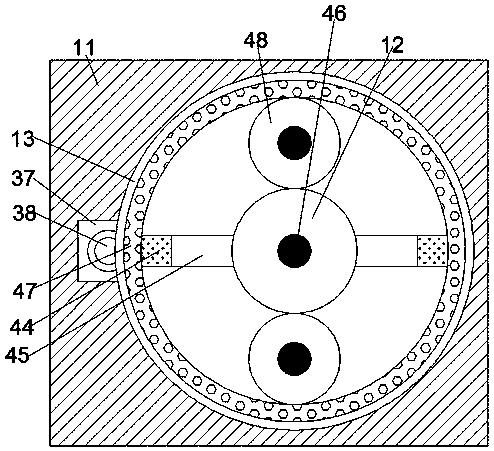

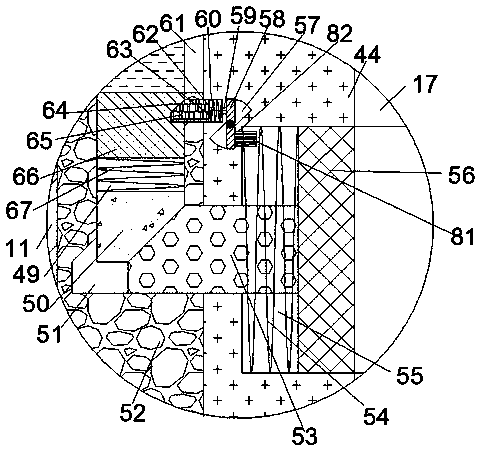

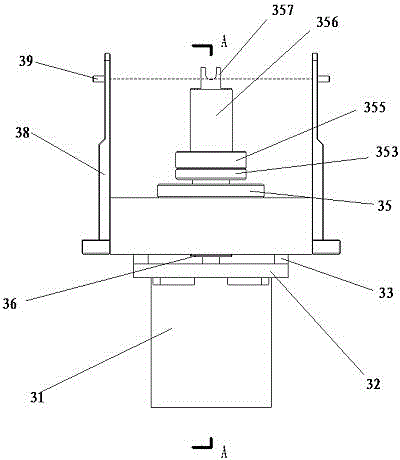

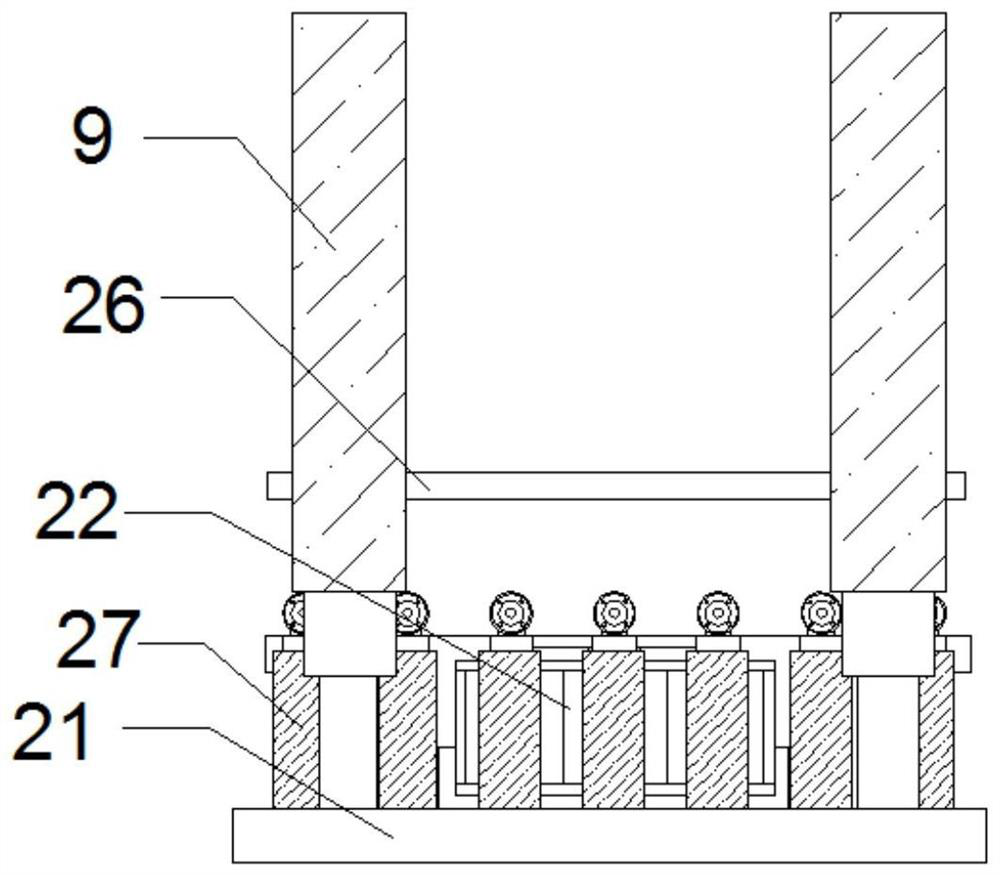

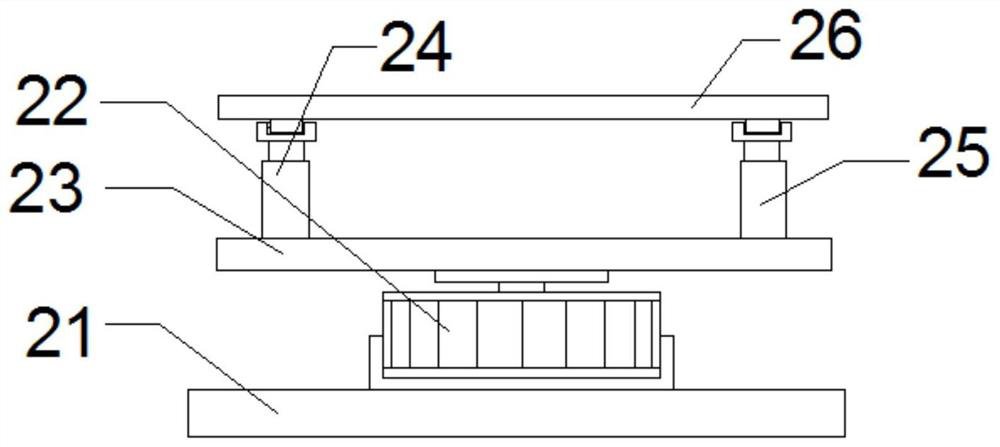

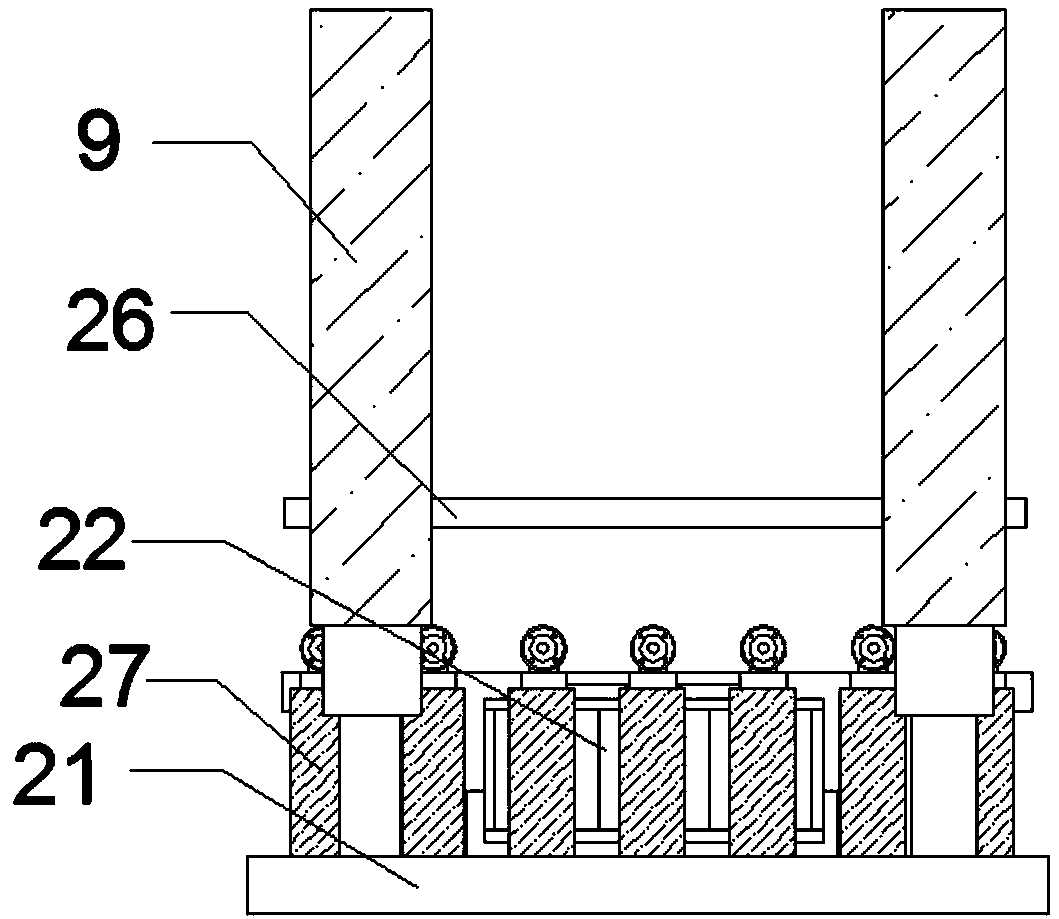

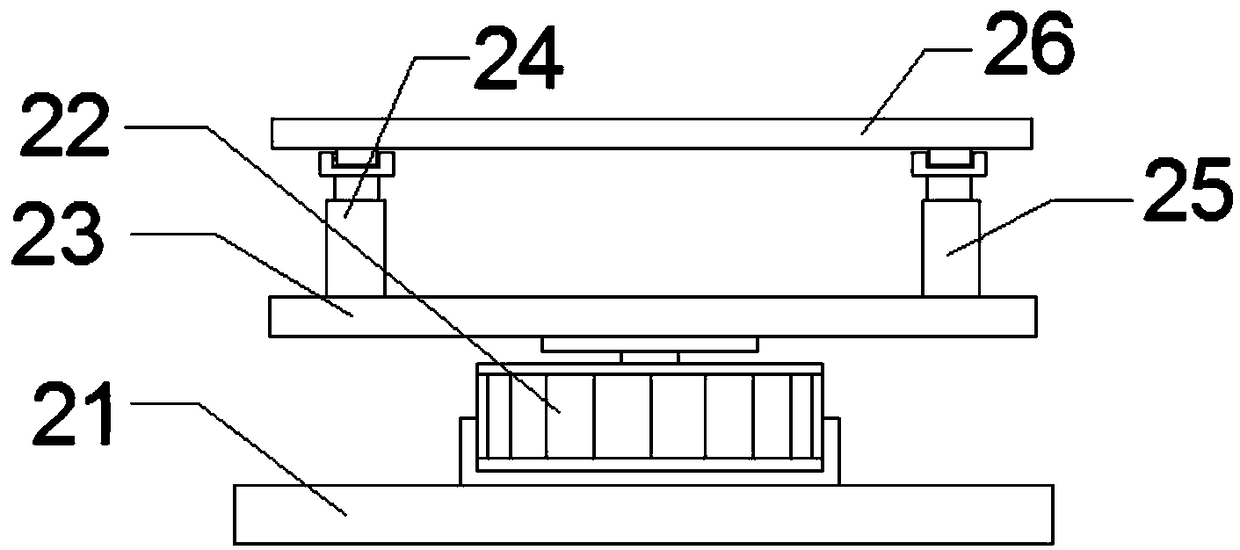

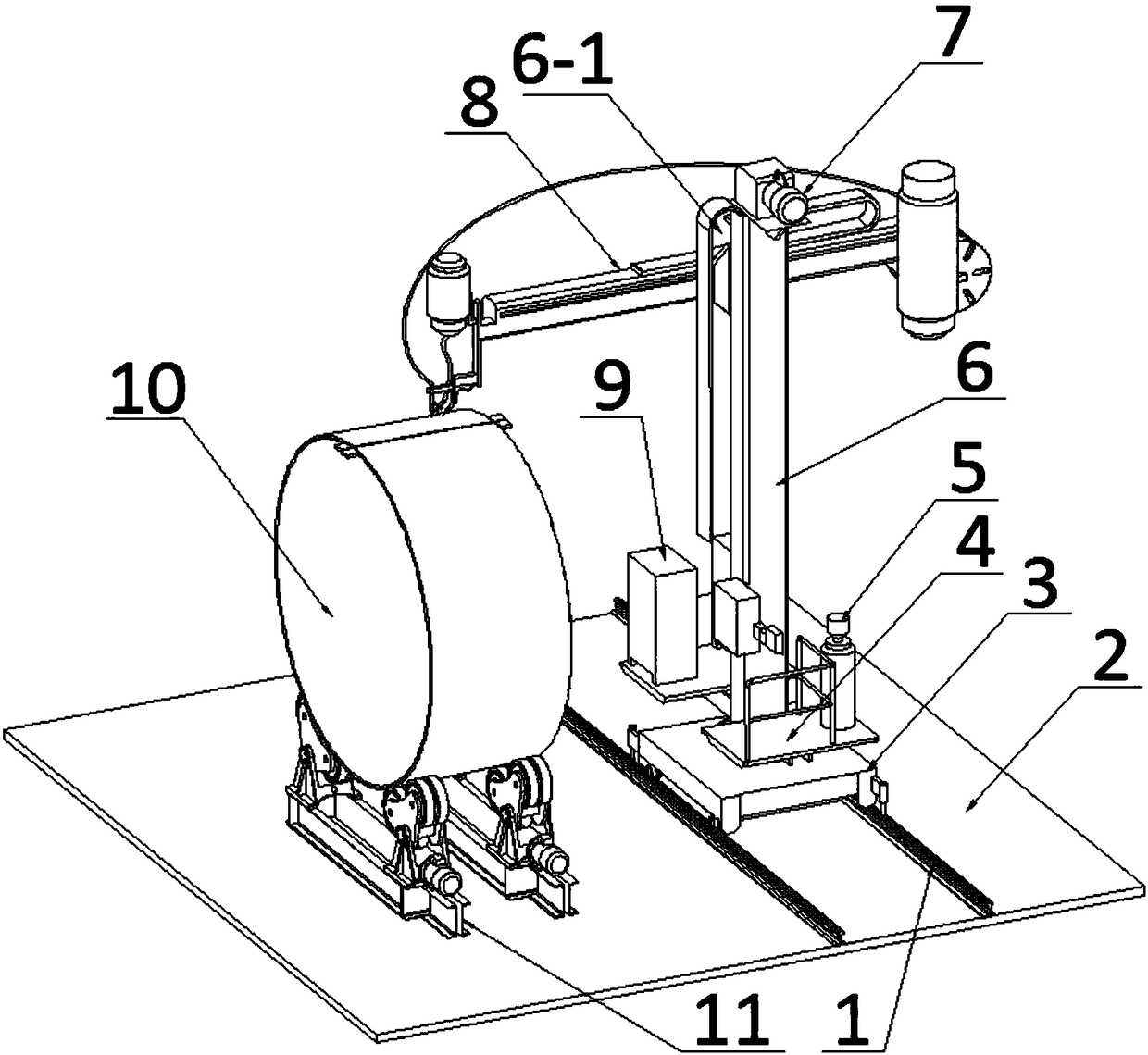

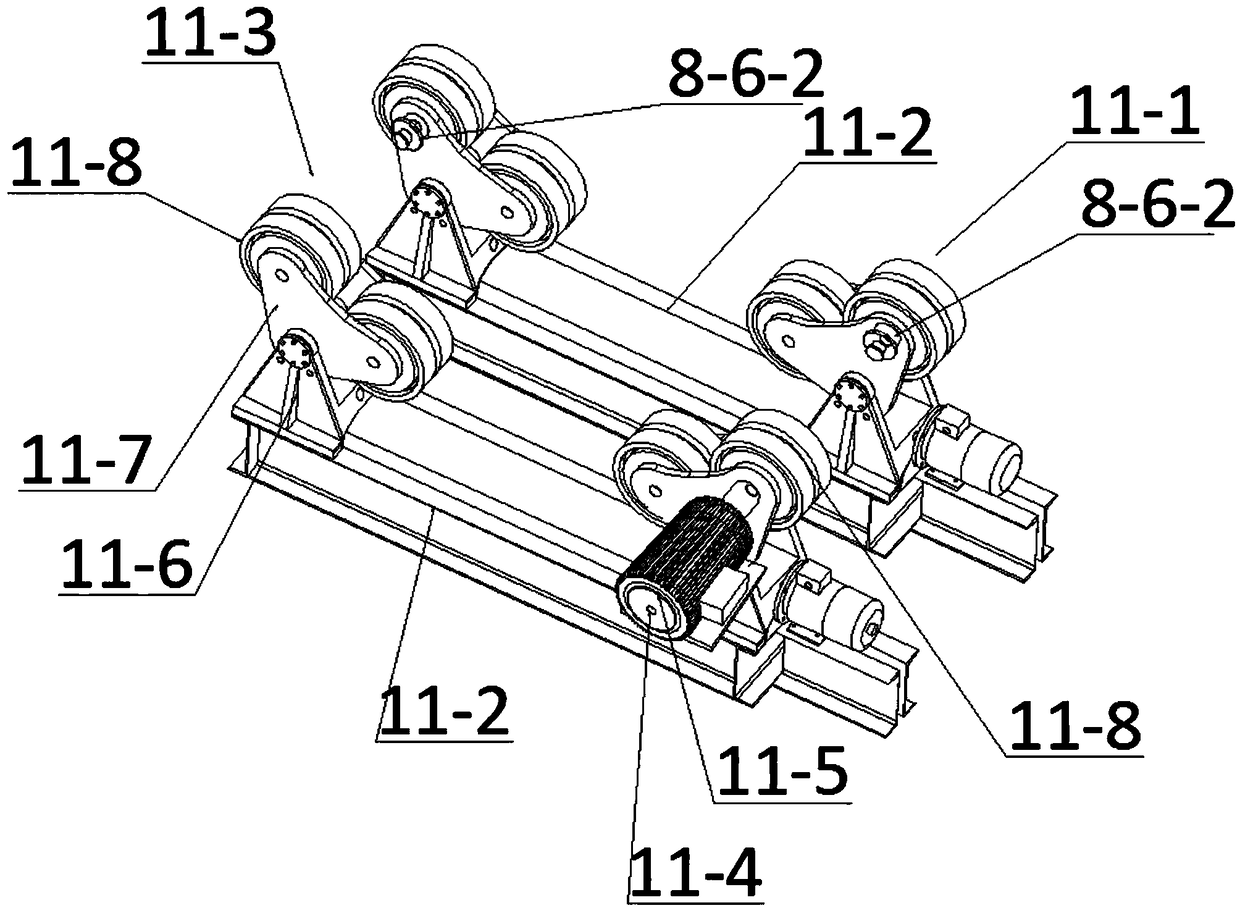

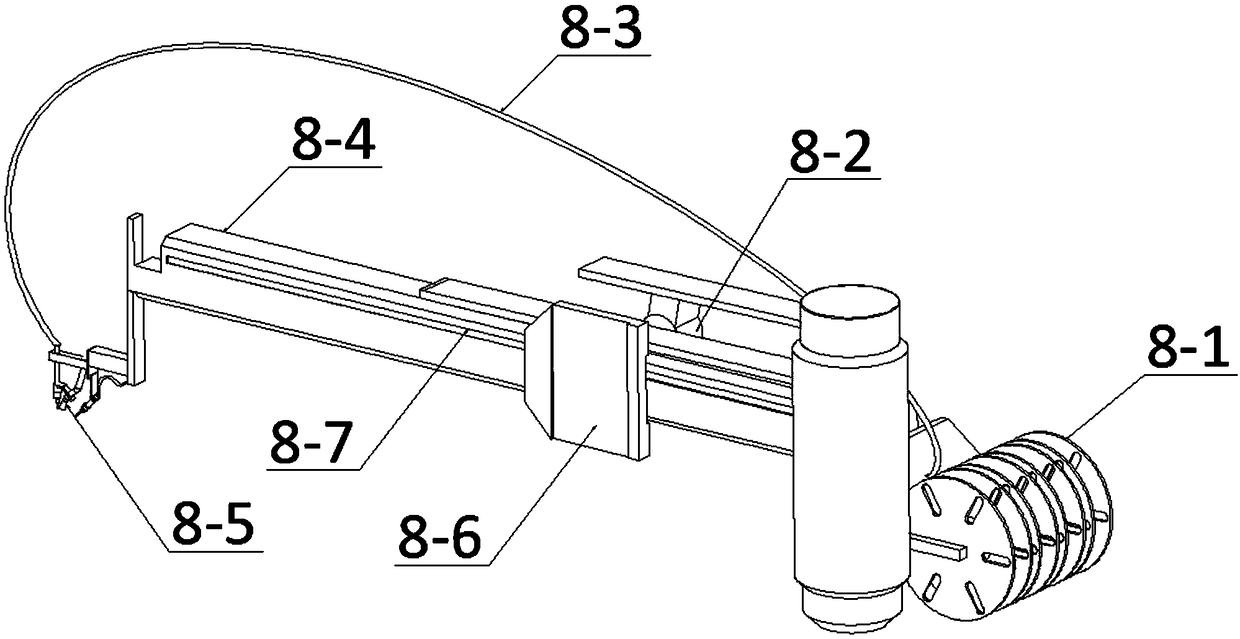

Rigid-soft cooperative stirring friction welding device

PendingCN108655558AHigh rigidity and machining accuracyImprove reliabilityProgramme-controlled manipulatorNon-electric welding apparatusProcessing accuracyEngineering

The invention relates to a rigid-soft cooperative stirring friction welding device. The rigid-soft cooperative stirring friction welding device comprises a welding robot, a stirring head arranged at the bottom of the welding robot, a working platform arranged below the welding robot and three flexible cable mechanisms uniformly arranged on the periphery of the working platform in 120 degrees and connected with the welding robot. Each flexible cable mechanism comprises a flexible cable, a tensioning device and a torque motor, wherein one end of the flexible cable is connected with the welding robot, and the other end of the flexible cable is arranged on the tensioning device. The rigid-soft cooperative stirring friction welding device is provided with the three flexible cable mechanisms connected with the welding robot. The position of the welding robot can be adjusted by adjusting the flexible cable mechanisms. The rigid-soft cooperative stirring friction welding device has high rigidity and machining precision and also has the advantage that mutual cooperation conditions between the welding robot and the flexible cables are changed according to the factors such as the welding environment and the thickness and size of welding parts so as to complete welding operation better.

Owner:HEBEI UNIV OF ENG

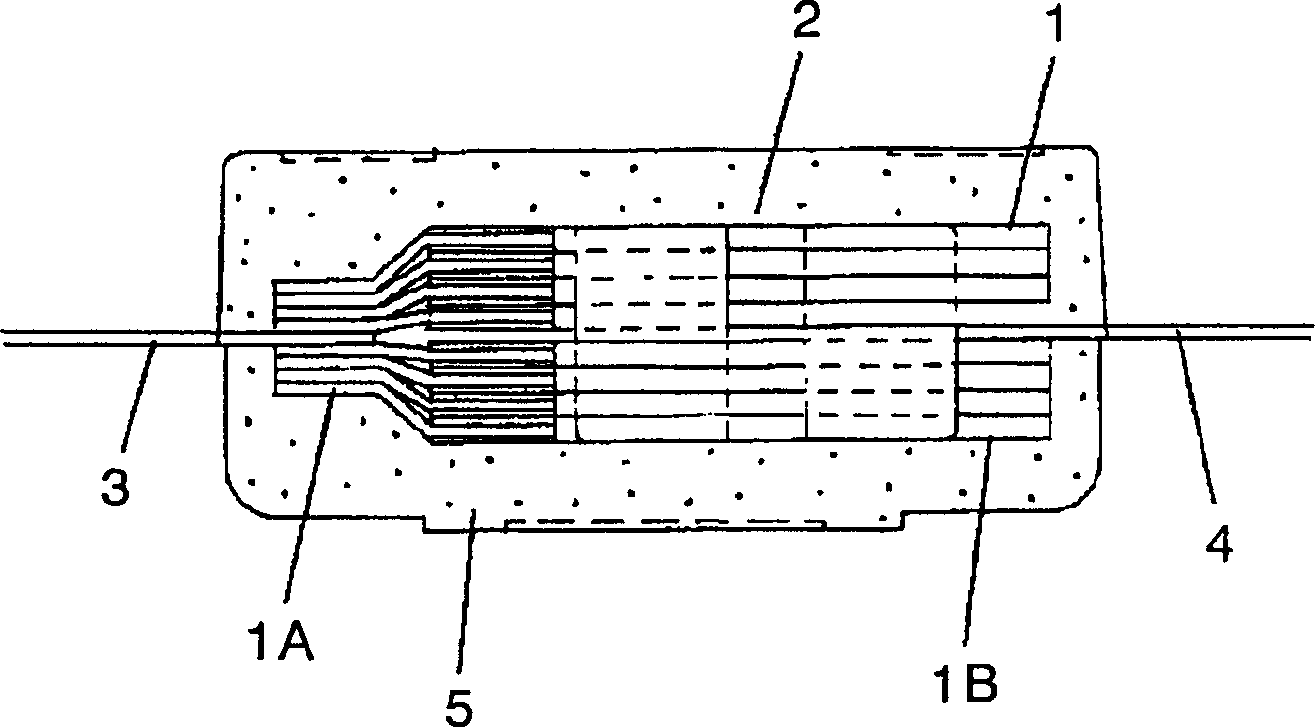

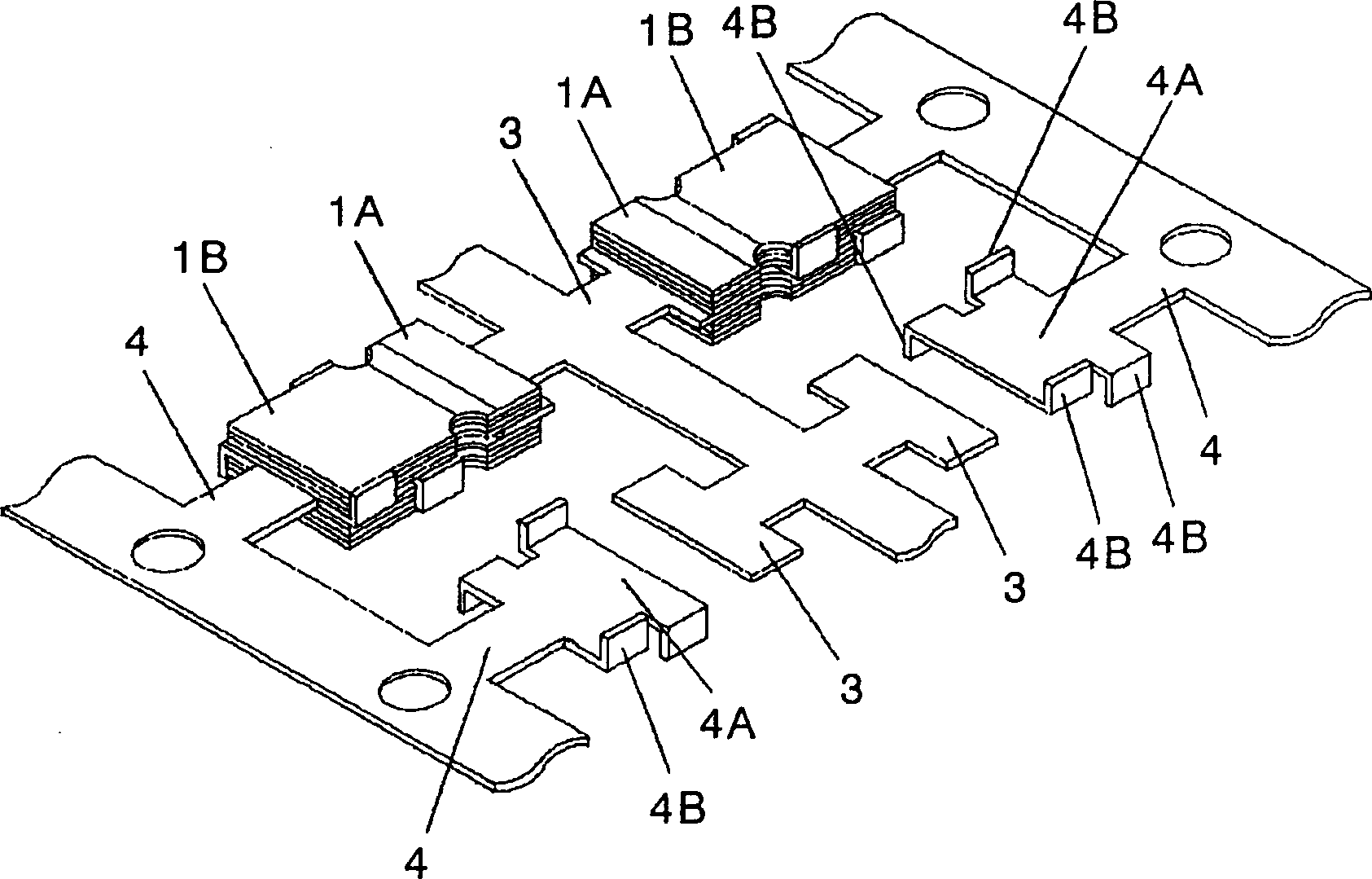

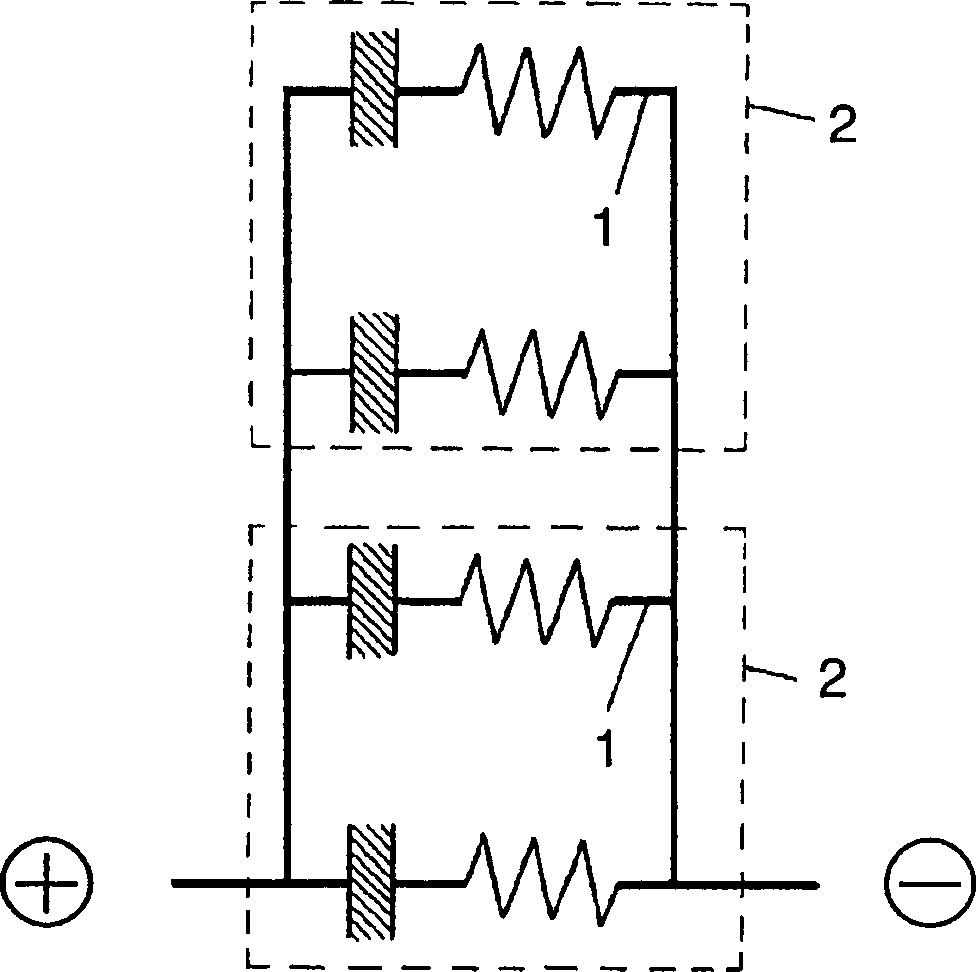

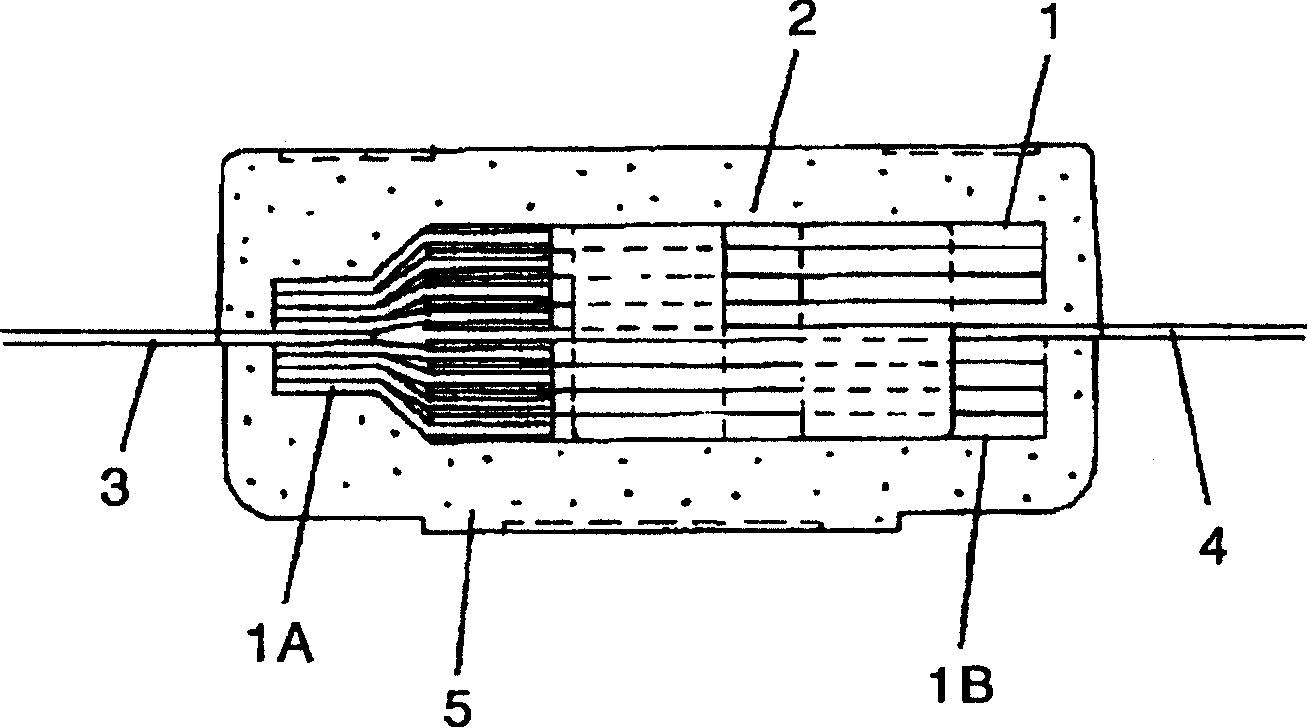

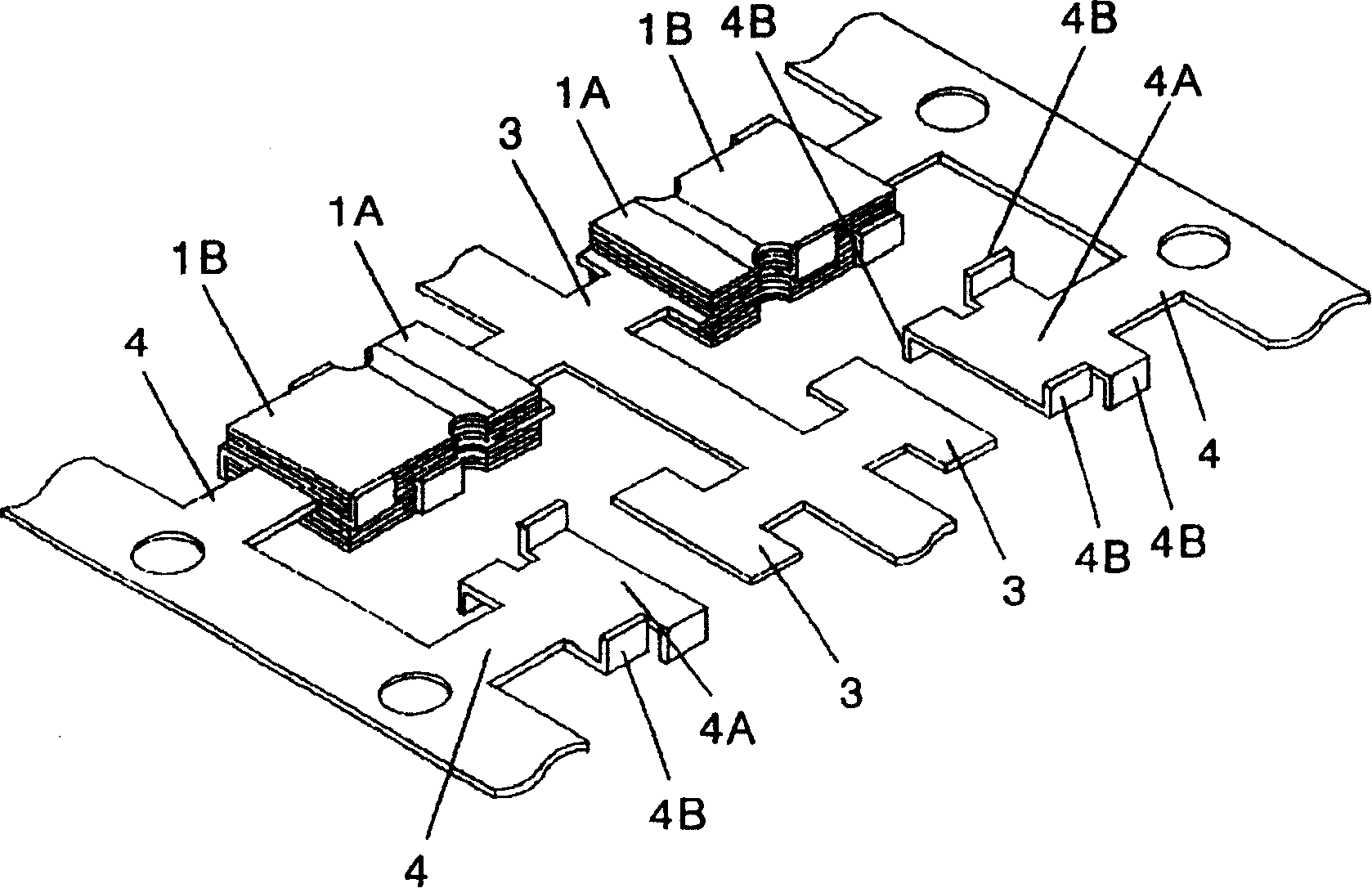

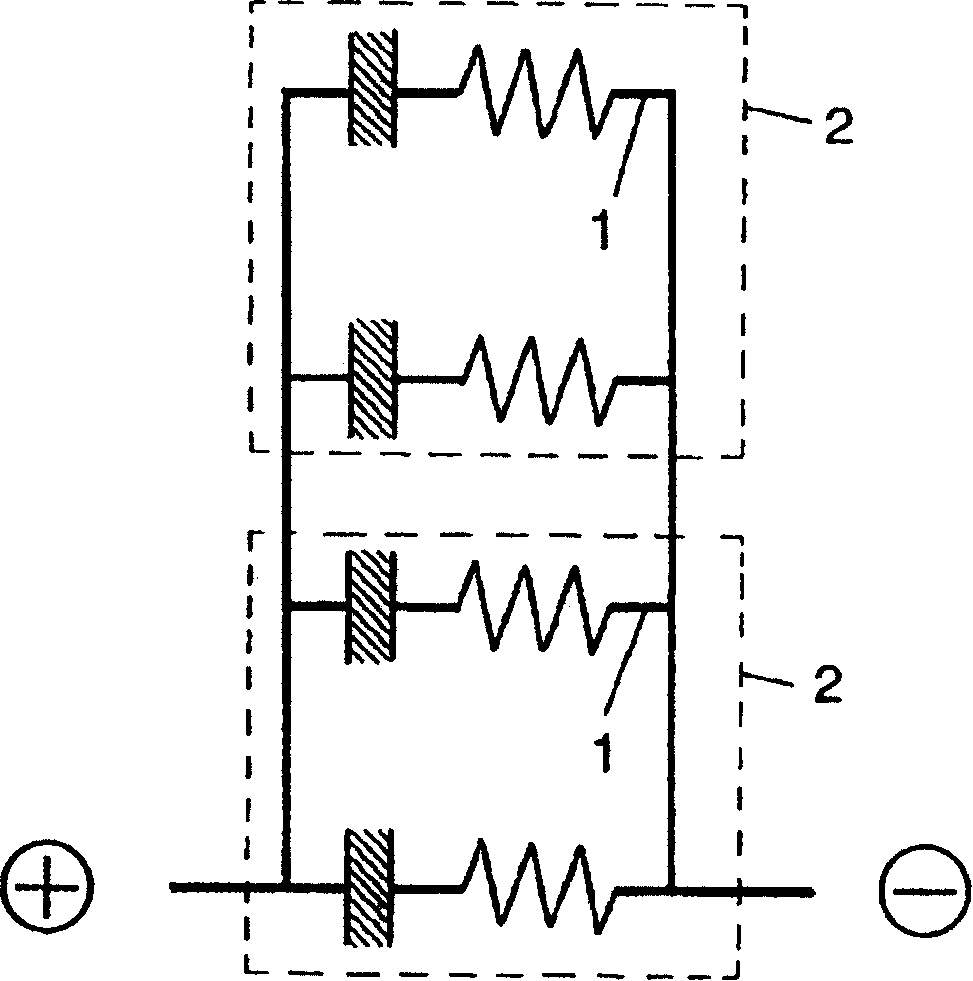

Solid electrolytic capacitor and its manufacture

InactiveCN1400615AImproved equivalent series resistance characteristicsStable welding workSolid electrolytic capacitorsCapacitanceEngineering

Provided is a solid electrolytic capacitor and manufacturing method thereof which facilitates an assembly work with simple construction to lead to a reduction of cost, realizes excellent equivalent series resistance characteristics and makes a thin configuration possible. With the solid electrolytic capacitor of the present invention, a cathode lead frame has a connecting member to connect integrally with a cathode member of a capacitor element stack body on the side surface of a capacitor element extending in the thickness direction thereof. Capacitor elements, each provided with a through hole on an anode member, are stacked on top of each other in layers and connections between capacitor elements are achieved by disposing an anode lead frame between layers. Accordingly, when a plurality of anode members are joined to the anode lead frame via a through hole provided on respective anode members of capacitor elements, stabilized welding work is allowed to be performed without any of molten aluminum foil to be released outside.

Owner:PANASONIC CORP

Automatic argon arc welding equipment for liquid storage tank

PendingCN109108433AImprove welding qualityGuarantee welding qualityWelding/cutting auxillary devicesArc welding apparatusHorizontal axisLiquid storage tank

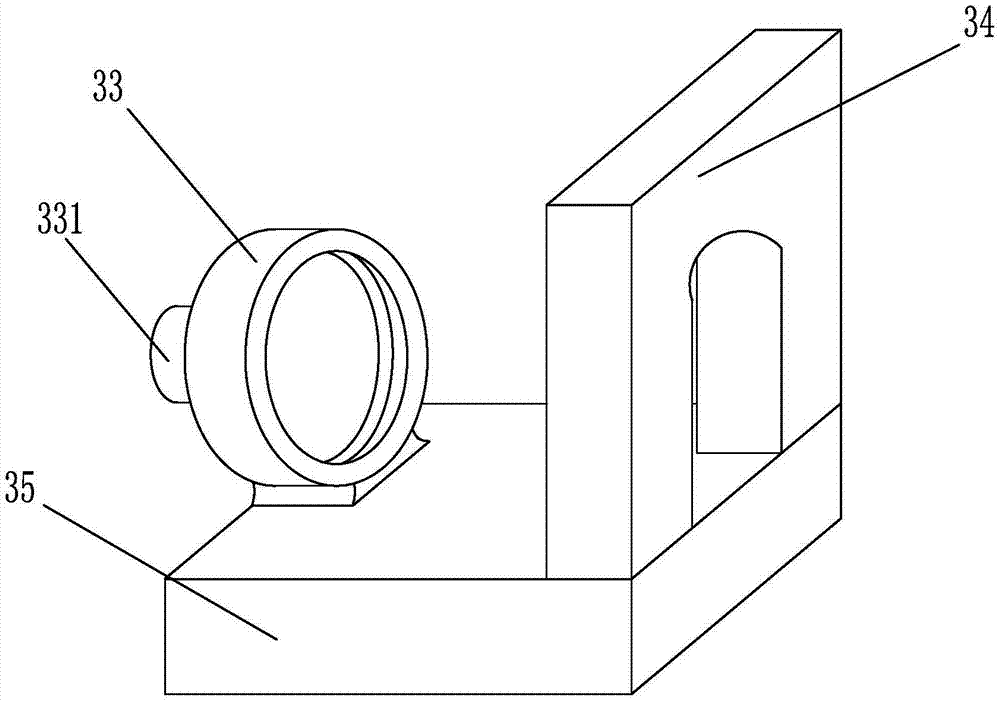

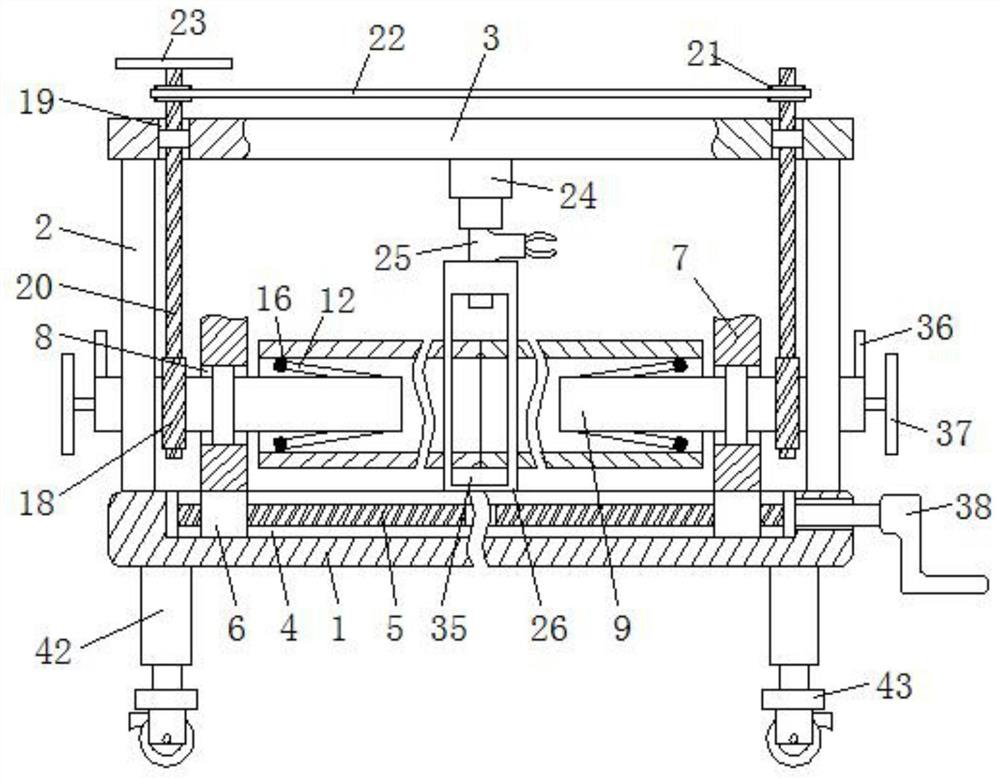

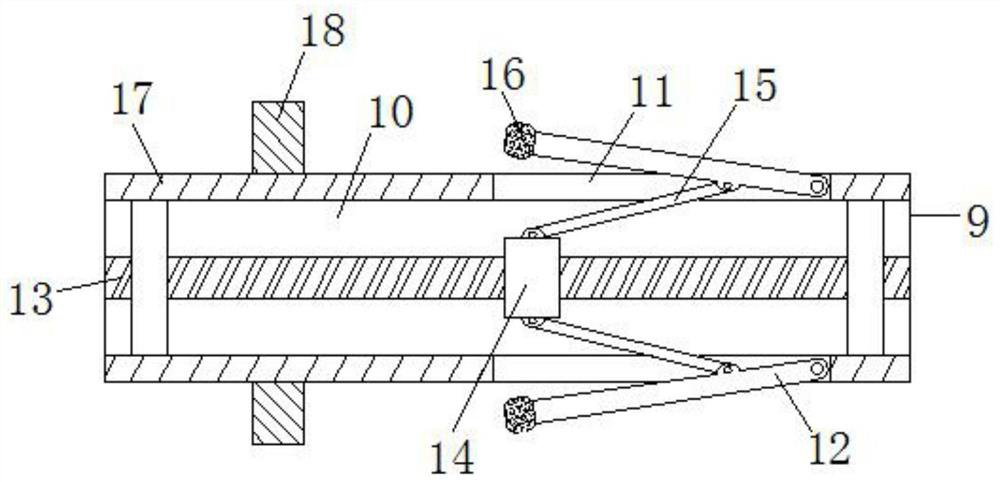

The invention provides automatic argon arc welding equipment for a liquid storage tank. The automatic argon arc welding equipment for the liquid storage tank comprises a machine frame, a supporting device, a double-spindle clamping device, a straight line walking device, welding devices and a gas protecting device. The straight line walking device is arranged on the machine frame, the double-spindle clamping device is two spindle seats with clamps, wherein the two spindle seats are arranged opposite to each other on the same horizontal axis, and the two welding devices are separately connectedwith the two spindle seats and arranged above the two spindle seats. The supporting device is arranged in the middle of the two spindle seats. The two spindle seats walk and move towards each other through the straight line walking device, end covers clamped on both sides move along the same horizontal axis to both ends of a liquid storage tank body of the supporting device, and the liquid storage tank body and the end covers are positioned and rotated on a welding station. The gas protecting device is arranged in one of the spindle seats, the gas outlet end of the gas protecting device communicates with the inner portions of the clamped end covers, and ventilation cooling and oxidation prevention during welding are realized. According to the automatic argon arc welding equipment for theliquid storage tank body, fast and reliable automatic welding between the liquid storage tank body and the end covers can be realized.

Owner:FOSHAN GOOGOL AUTOMATION TECH

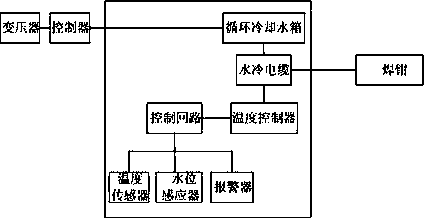

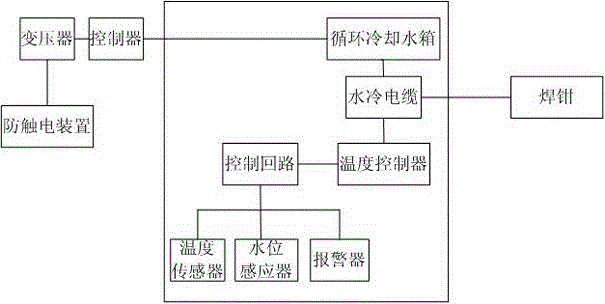

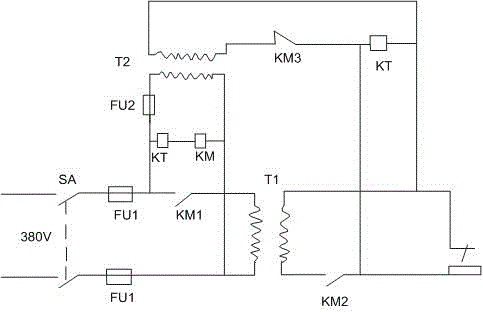

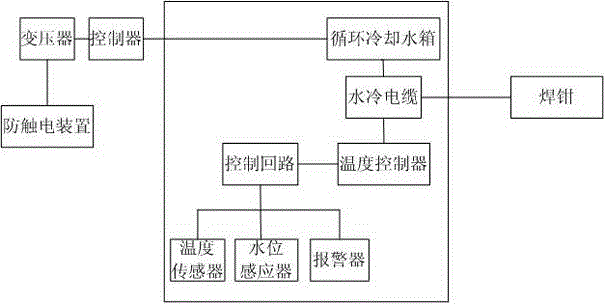

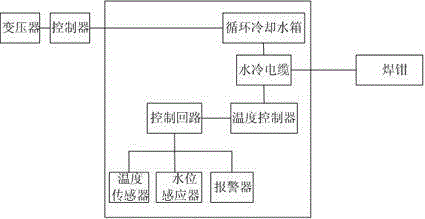

Electric welding device

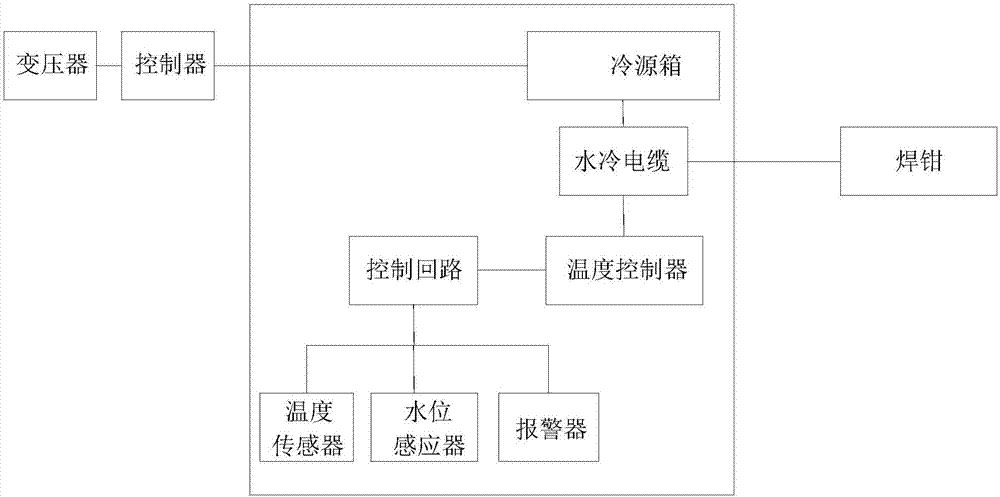

InactiveCN103801864AStable jobAvoid safety accidentsWelding/cutting auxillary devicesAuxillary welding devicesTransformerWater flow

The invention discloses an electric welding device. The electric welding device comprises a transformer, a controller, a circulating cooling water tank, a water cooling cable and welding tongs, wherein the transformer is respectively connected with the circulating cooling water tank and the controller, the water cooling cable penetrates through the circulating cooling water tank, and the welding tongs are connected with the transformer through the water cooling cable; the electric welding device further comprises a water flow flood prevention device which is arranged in the circulating cooling water tank and connected with the controller, and a cooling fan is further arranged at the top of the transformer. When a welding machine works, the transformer can generate a large amount of heat as well, and the transformer will be damaged if the heat is not treated timely, and the arranged cooling fan can take the large amount of heat generated by the transformer away to ensure stable work of the transformer.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

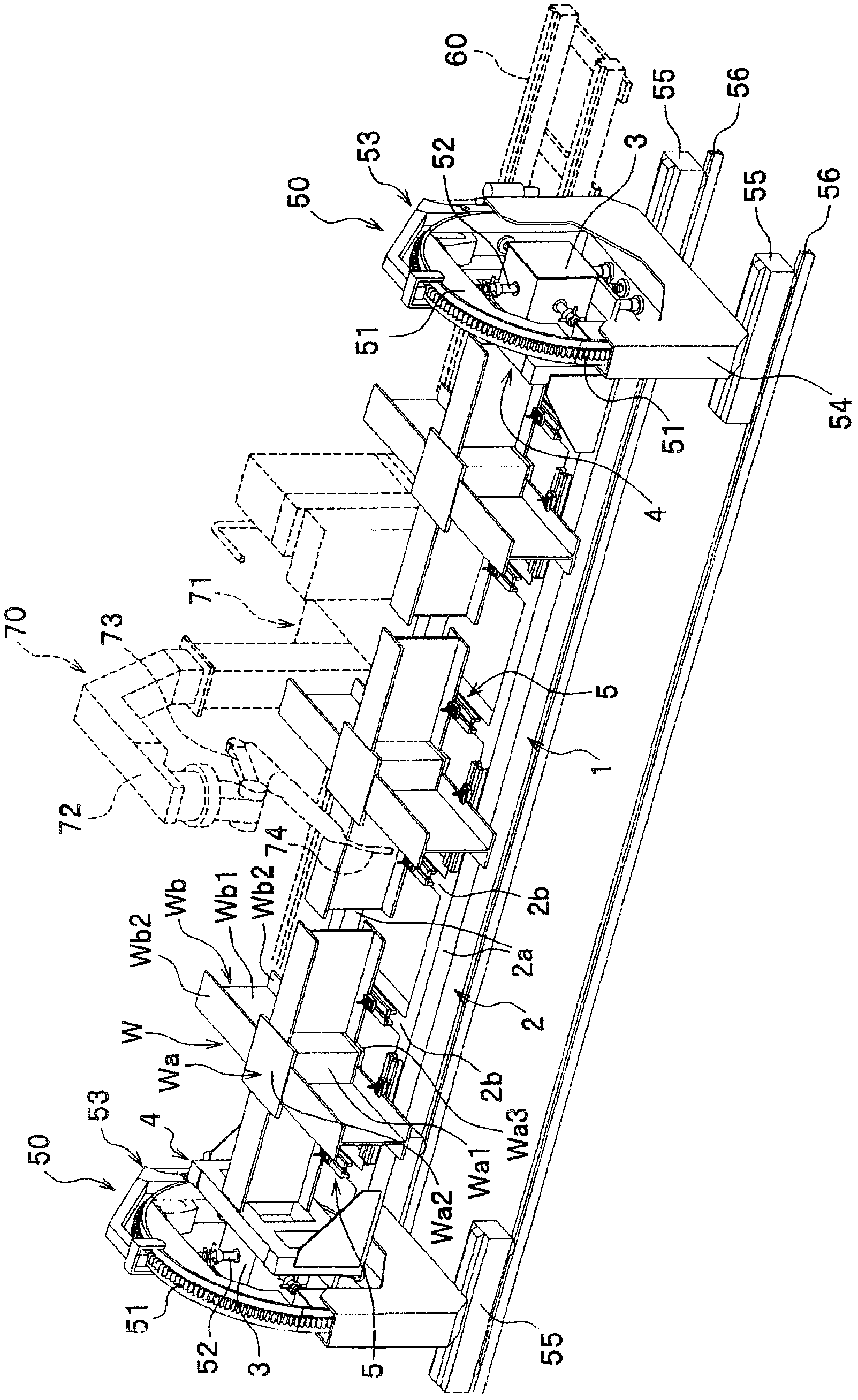

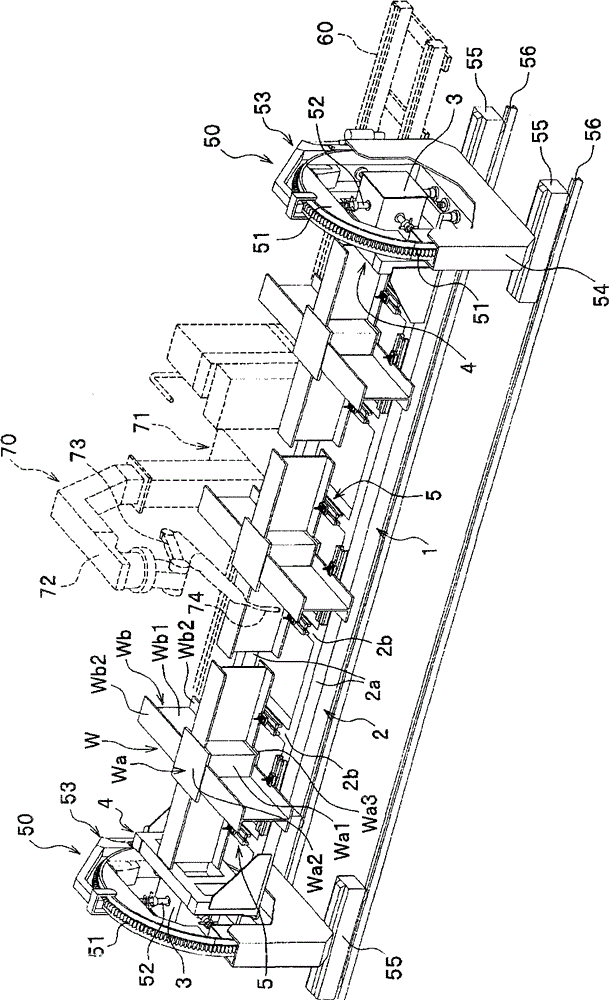

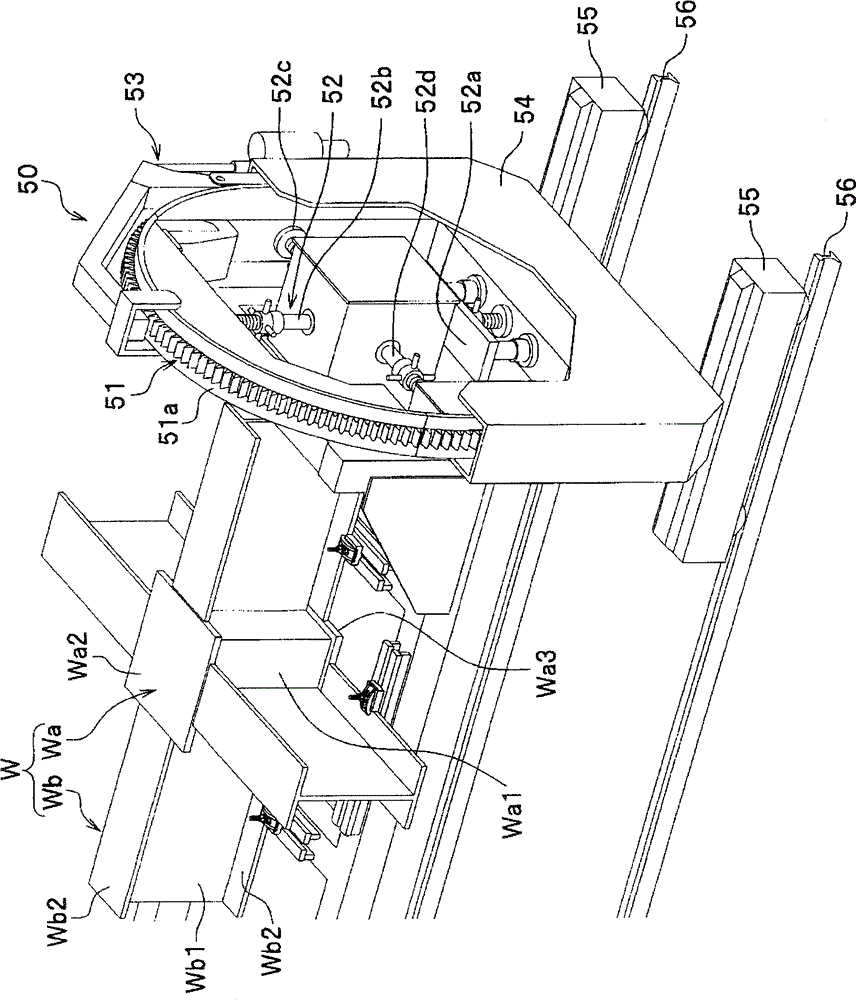

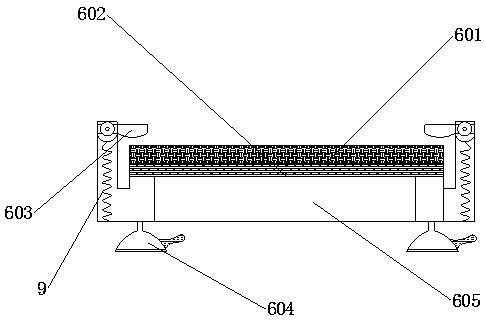

Welding supporting table for joints

ActiveCN102161144AGood effectAchieve efficiencyWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingEngineering

The invention relates to a welding supporting table for joints, the welding supporting table freely detachably supports joints formed by connection of a beam installation part and a wall surface of a joint core plate in spot welding, thereby keeping the joint at a pair of rotary transposers, the welding supporting table comprises: a mounting part disposed at a position between the pair of rotary transposers in a mode that a plurality of joints are mounted on a same plane; a supporting mechanism disposed on the mounting part and performing support of the beam installation part of the joints; a column-shaped part respectively disposed at two ends of the mounting part, and kept in a free detachable way via fixed clamping tools disposed at the inner sides of annular parts of the rotary transposers. According to the composition, joint positioning of current rotary transposers can be easily performed, a plurality of joints can welded, and original welding operation zones of the rotary transposers can be effectively used.

Owner:KOBE STEEL LTD

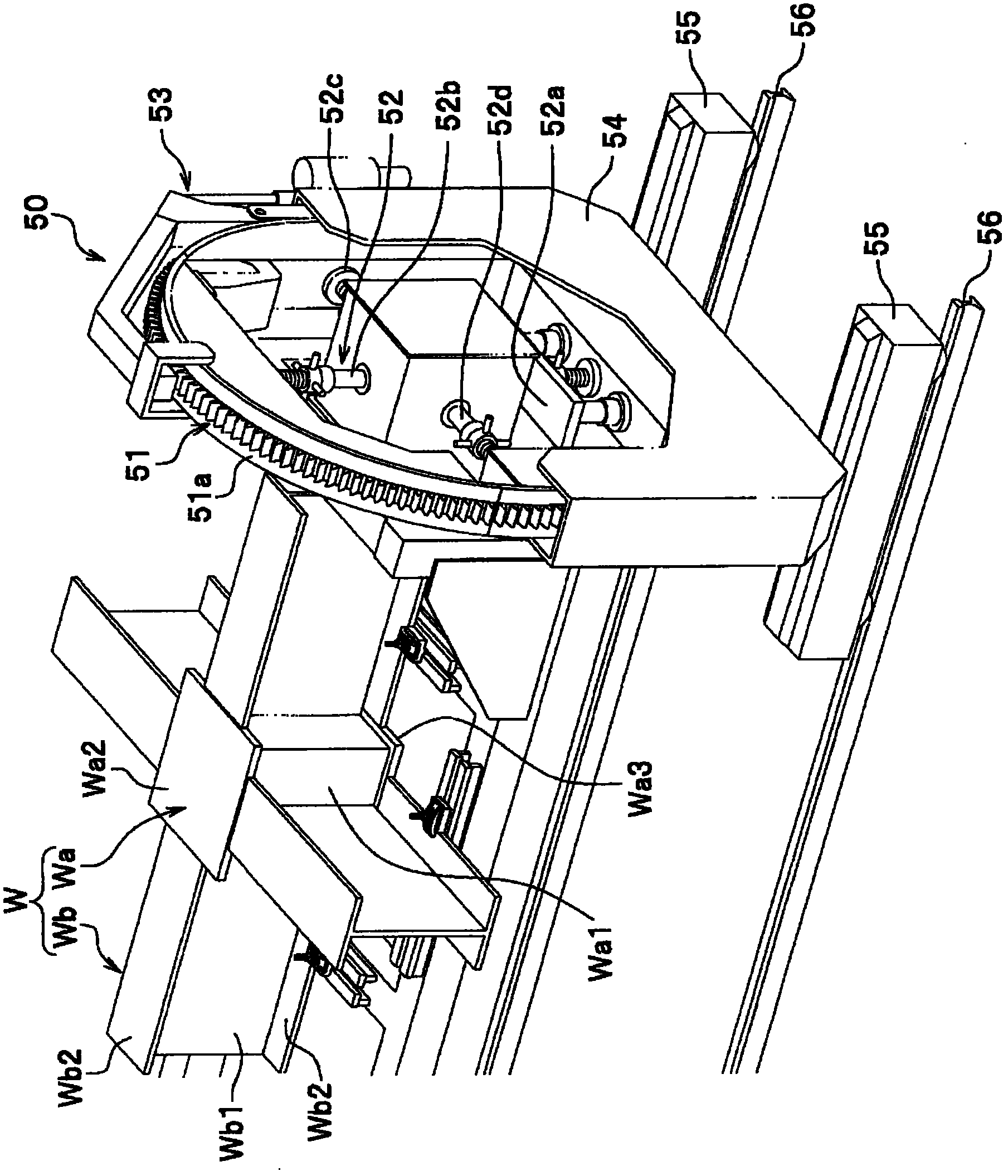

Welding carriage

InactiveCN101844288APrevent disengagementAvoid safety accidentsWelding/cutting auxillary devicesArc welding apparatusDrive wheelDrive motor

The invention relates to a welding carriage, comprising a main body which includes a horizontal member and a vertical member; a pincer clamp portion arranged on two sides of the main body for setting a pair of welding torches; a drive portion arranged on the lower side of the main body for moving the main body; wherein the drive portion includes a drive motor; a drive wheel member connected to the drive motor and moving along a lateral surface of the vertical member; a guide wheel member includes guide wheels on the other lateral surface of the vertical member; the drive wheel member moves in a way of abutting against the upper surface of the vertical member when the main body moves and it includes a pair of upper wheels which are arranged along the vertical direction and a pair of lower wheels which are disposed at a position having a certain distance from the upper wheels and the diameter of the lower wheels is smaller than that of the upper wheels. The drive wheel is characterized in that when the main body moves, the drive wheel is able to abut against the vertical member to move, so that the upper wheel diameter of the drive wheel moving along the upper surface of the vertical member is greater than that of the lower wheel, thus guaranteeing the main body to move along the upper surface of the vertical member and automatically welding the shape connection part of the horizontal member and the vertical member.

Owner:CHUNGSONG IND

Electric welding machine capable of being automatically started and stopped

InactiveCN104416264AReduce air freight timeReduce consumptionWelding/cutting auxillary devicesAuxillary welding devicesElectricityTransformer

The invention discloses an electric welding machine capable of being automatically started and stopped. The electric welding machine comprises a transformer, a controller, a circulation cooling water tank, a water-cooling cable and a pair of welding tongs, wherein the transformer is respectively connected with the circulation cooling water tank and the controller; the water-cooling cable penetrates through the circulation cooling water tank; the pair of welding tongs is connected with the transformer by virtue of the water-cooling cable; the circulation cooling water tank is internally provided with a waterflow flood prevention device which is connected with the controller; the top of the transformer is also provided with a radiator fan; the electric welding machine also comprises an automatic on-off circuit. When the electric welding machine is in operation, the transformer also generates a lot of heat, and the arranged radiator fan can take away the heat generated by the transformer so as to ensure that operation of the transformer is stably performed; due to the arranged automatic on-off circuit, idle operation time of the electric welding machine can be reduced, and the electricity consumption can be reduced; when the electric welding machine has no load, the automatic on-off circuit can control the automatic power-off of the electric welding machine; during in welding, a welding rod is contacted with a weldment, a switch in the automatic on-off circuit is turned on to supply current to the electric welding machine so as to achieve the purpose of saving energy.

Owner:张丹

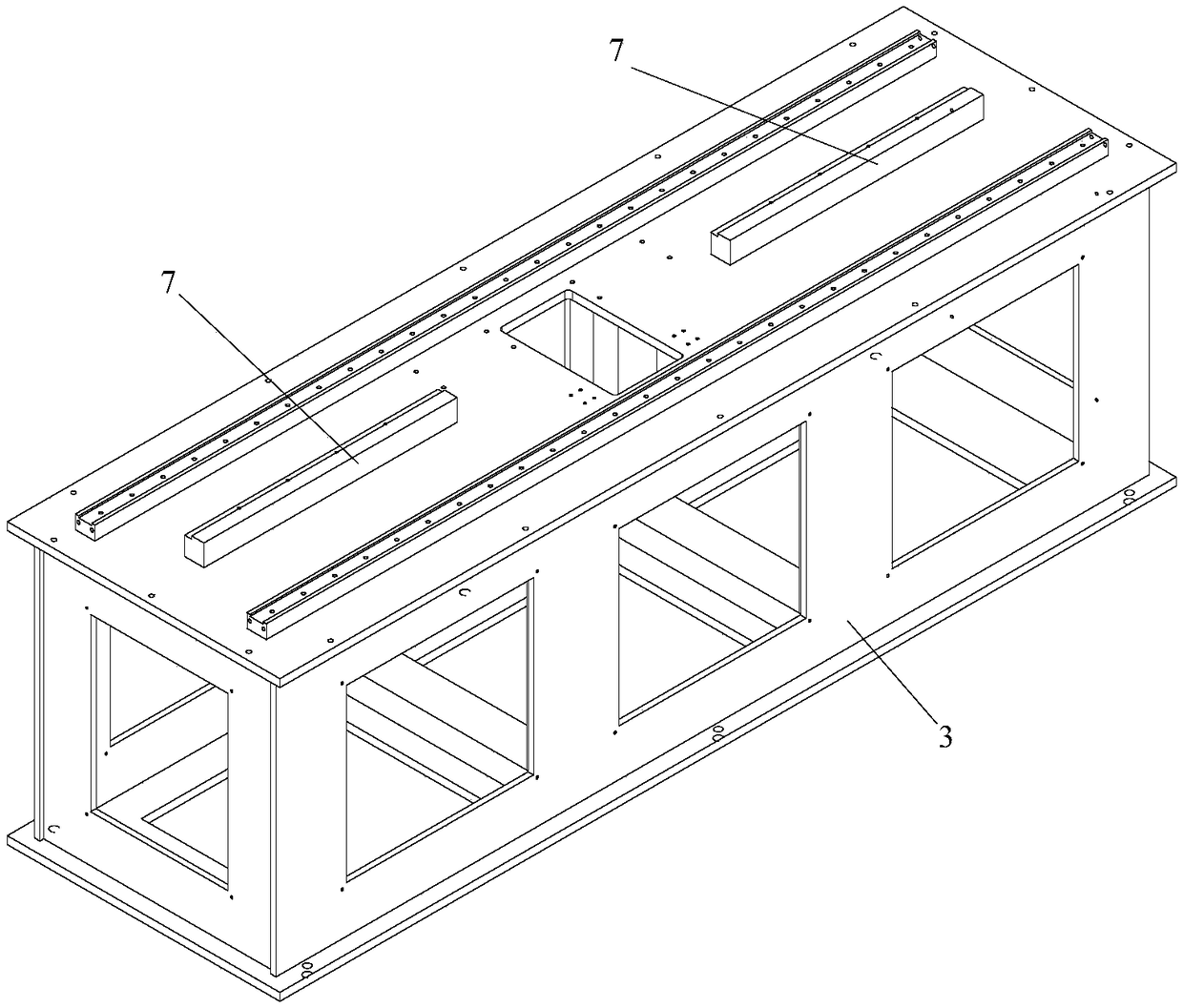

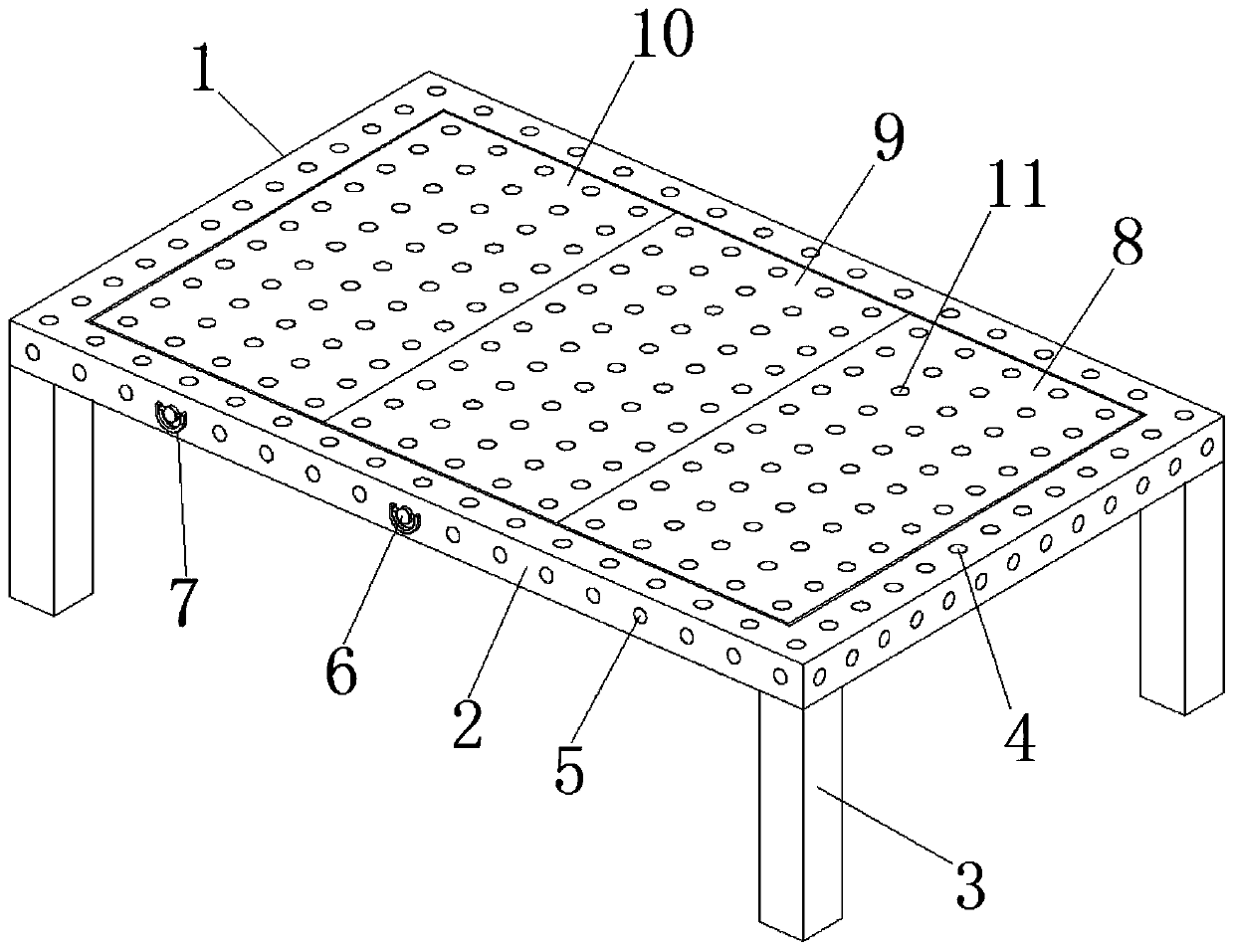

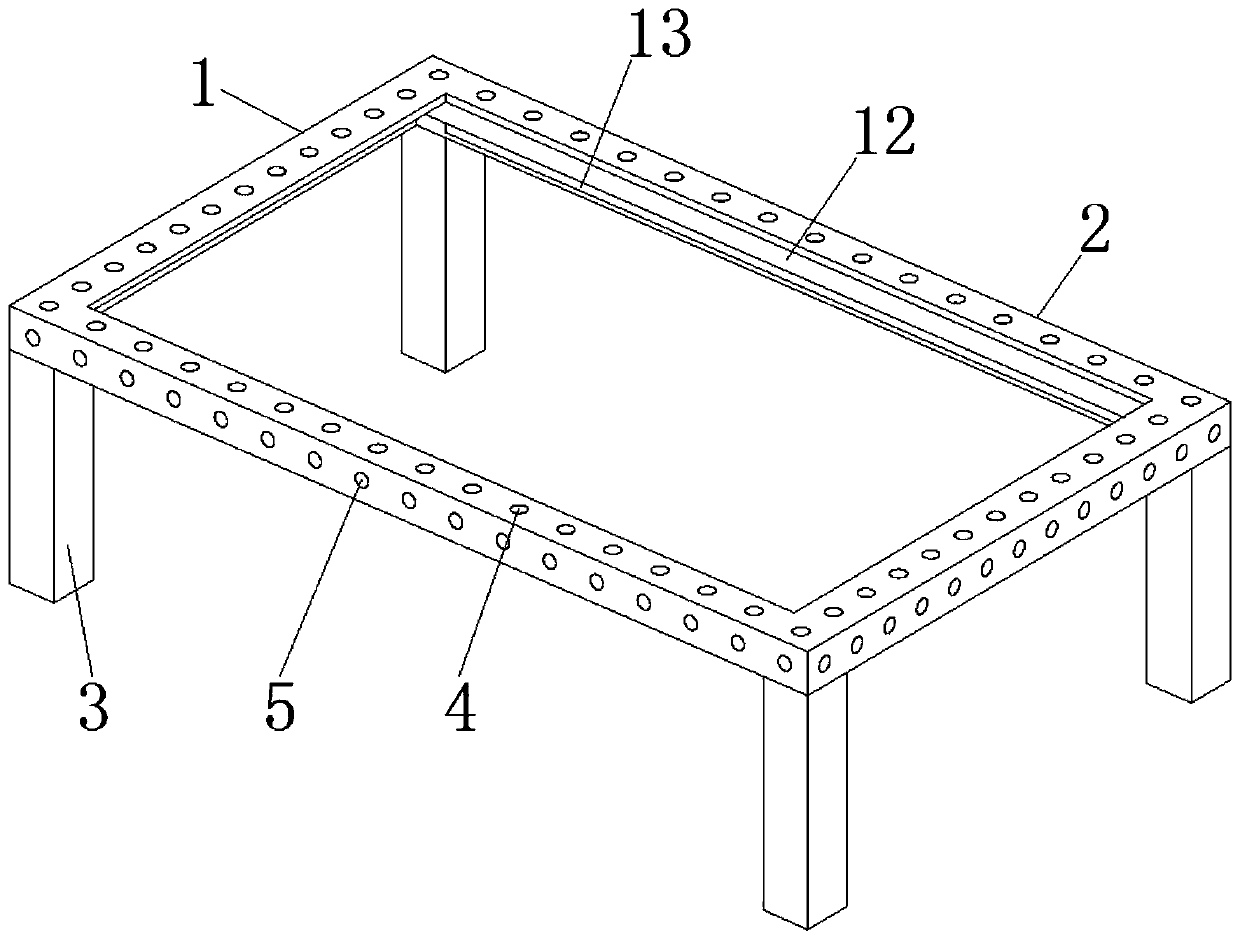

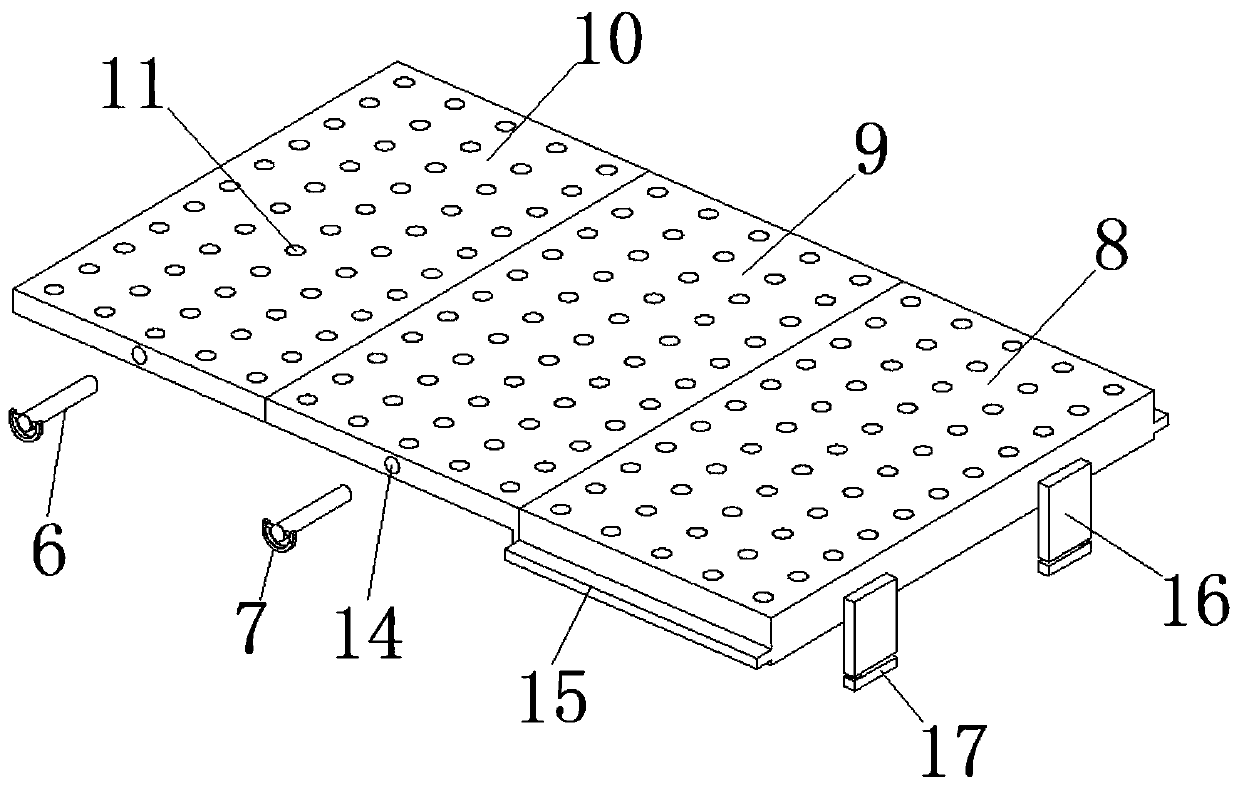

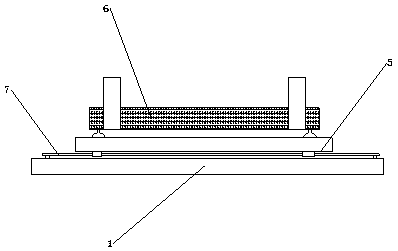

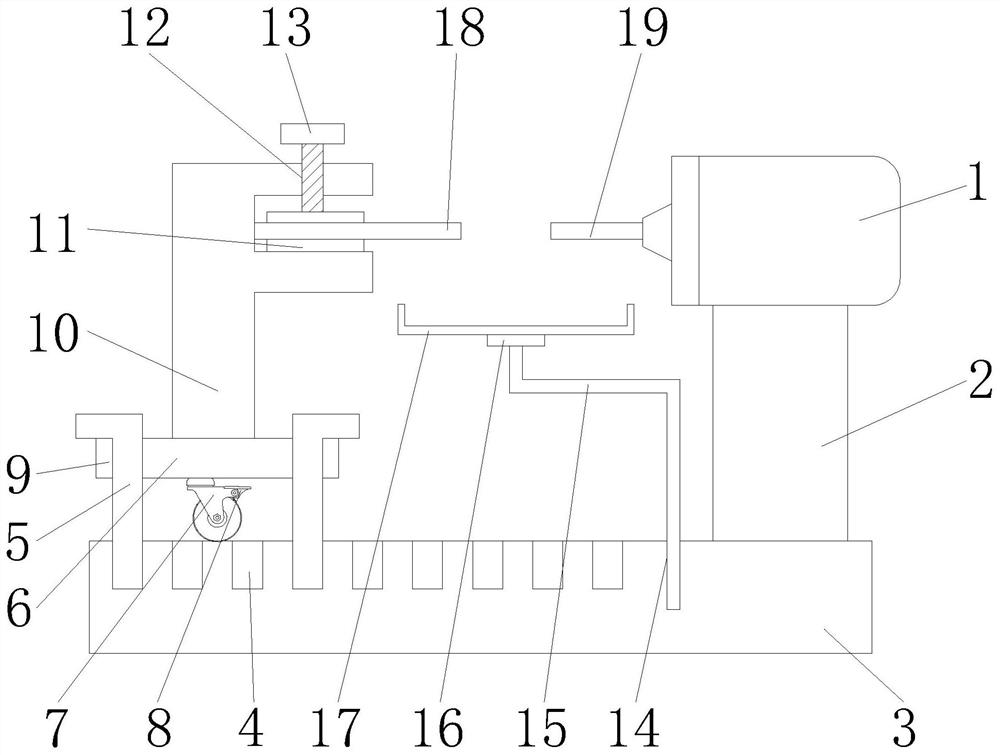

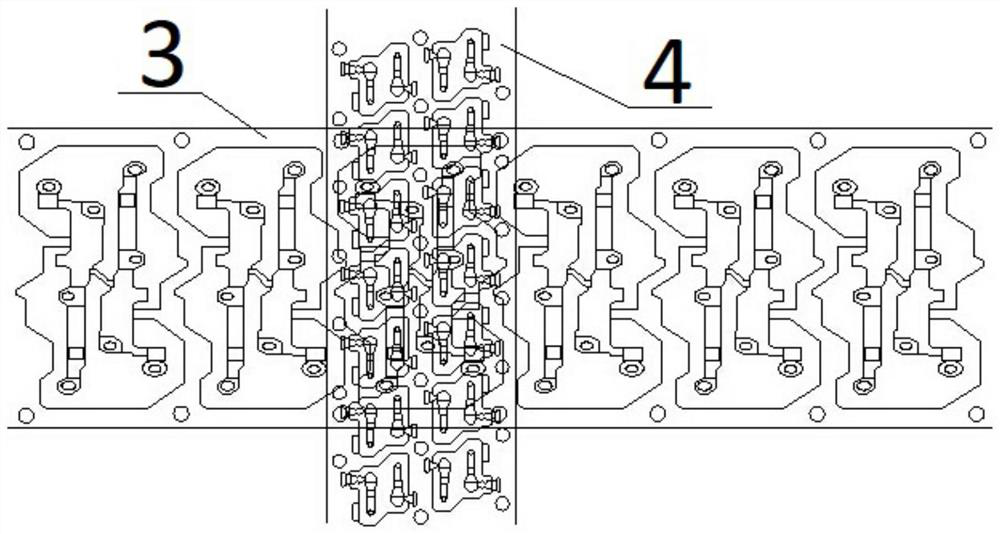

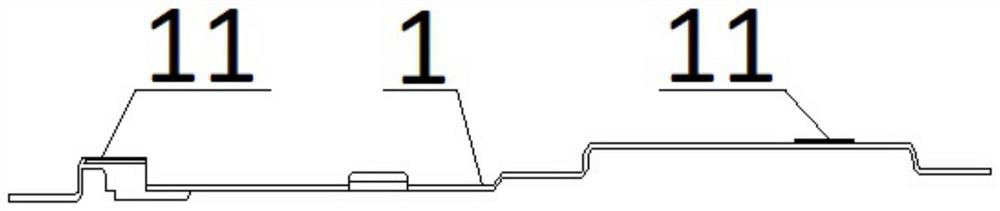

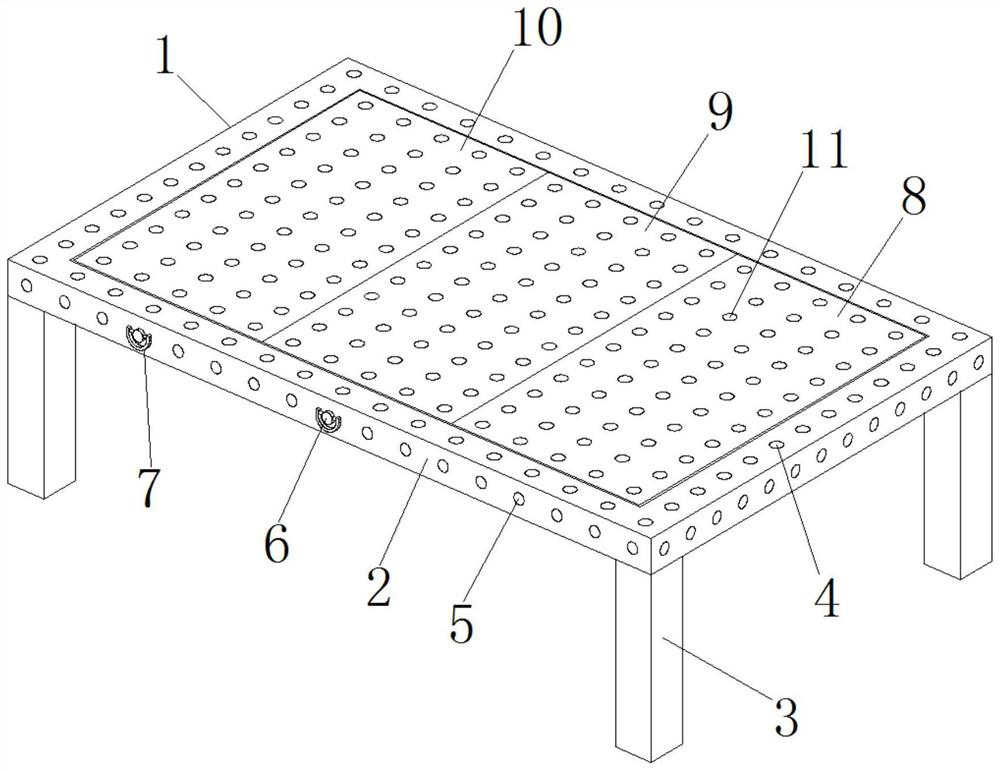

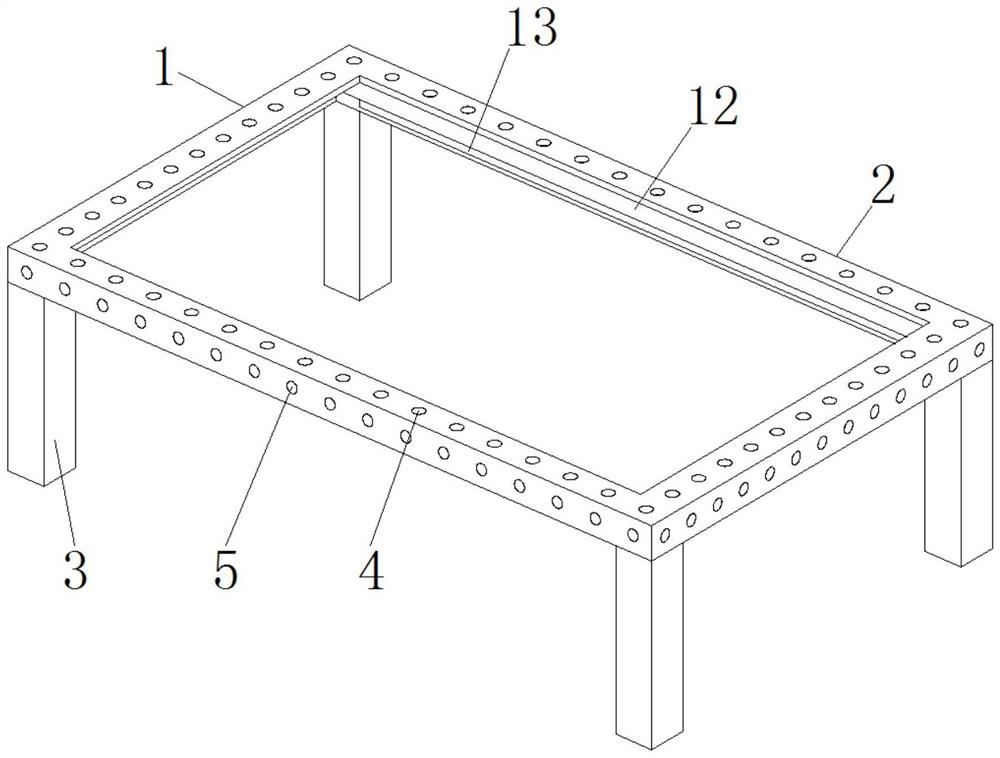

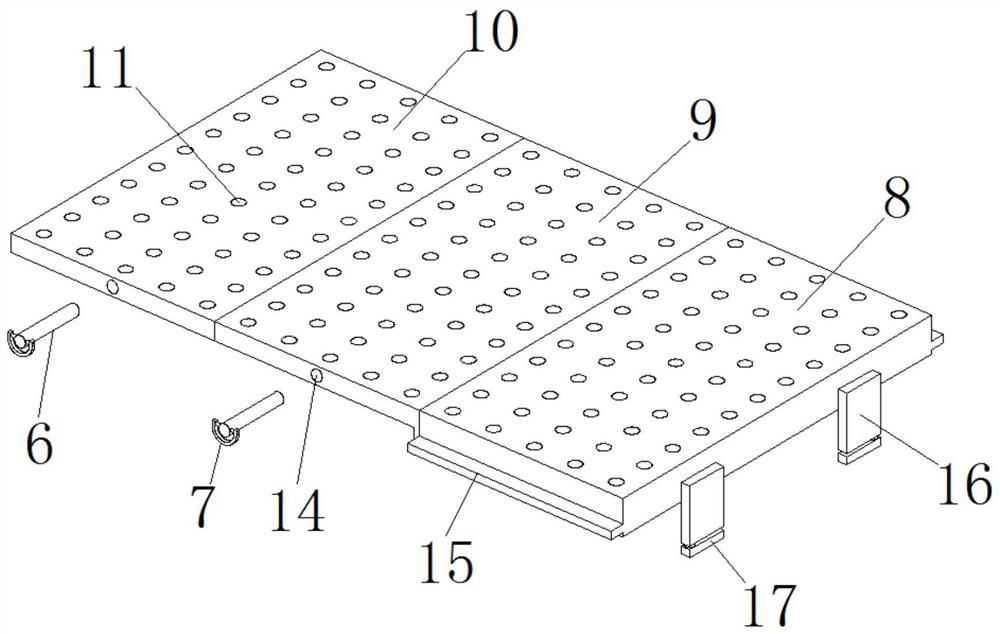

Prefabricated steel frame structure machining platform assisting in workpiece welding

ActiveCN111015063AImprove work performanceStable welding workWelding/cutting auxillary devicesAuxillary welding devicesSteel frameMachining

The invention discloses a prefabricated steel frame structure machining platform assisting in workpiece welding. The prefabricated steel frame structure machining platform comprises a first main bodyedge, second main body edges and supporting legs. The two ends of the first main body edge are fixedly connected with the second main body edges; the supporting legs are fixedly welded at the joints of the second main body edges and the first main body edge; a positioning connecting rod is mounted on the outer side of each second main body edge; a movable pull ring is mounted at the outer end of each positioning connecting rod; an upper open groove and a lower sliding groove are formed in the inner side of each second main body edge, and the lower sliding groove is located under the upper opengroove; fixed connecting holes are formed in the side edges of a first movable plate and a second movable plate; the positioning connecting rods are connected into the fixed connecting holes; and sliding protruding blocks are fixedly arranged at the two sides of a sliding supporting plate. According to the prefabricated steel frame structure machining platform assisting in workpiece welding, a fixed steel frame structure can be in an overhead state, then welding work of the steel frame structure is conveniently completed, and the welding work efficiency of the steel frame structure is improved.

Owner:山东欣怡翔精密机械制造有限公司

Electric welding machine

InactiveCN104416260AStable jobAvoid safety accidentsWelding/cutting auxillary devicesAuxillary welding devicesTransformerEngineering

The invention discloses an electric welding machine comprising a transformer, a controller, a circulating cooling water tank, a water-cooled cable and an electrode holder. The transformer is connected with both the circulating cooling water tank and the controller. The water-cooled cable penetrates the circulating cooling water tank. The electrode holder is connected with the transformer through the water-cooled cable. The electric welding machine further comprises a flood preventer disposed inside the circulating cooling water tank. The flood preventer is connected with the controller. A cooling fan is disposed on the top of the transformer. During running of the electric welding machine, the transformer also produces heat, and untimely treatment may lead to damage of the transformer; the cooling fan can bring away a great deal of generated heat, and running stability of the transformer is guaranteed.

Owner:张丹

Positioning mechanism for range hood air way welding

InactiveCN109048175ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a positioning mechanism for range hood air way welding. The positioning mechanism comprises a device body, a transmission device arranged in the device body, a fixing device arranged in the device body, and a positioning device arranged in the device body; the transmission device comprises a motor fixedly arranged in the device body; a first cavity is formed in the inner wall of the upper side of the motor; a first gear is rotationally arranged in the first cavity; the lower end of the first gear is fixedly connected with a rotating shaft in power fit connection with the upper end of the motor; a second cavity communicates into the inner wall of the left side of the first cavity; and a second gear engaged with the first gear is arranged in the second cavity. The positioning mechanism can automatically position and fix air ways, and automatically performs fixation after positioning to simplify the operation process, so that the air ways can be welded more stably.

Owner:王凯琪

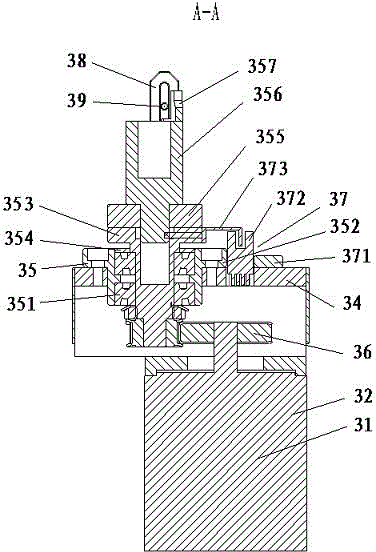

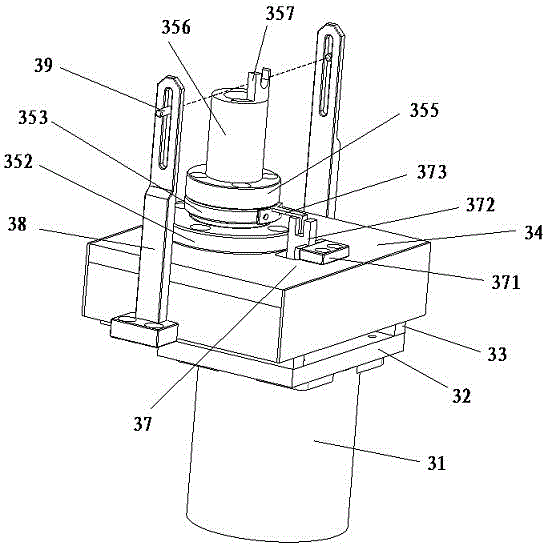

Work-piece rotation mechanism for chuck double-station welding machine

InactiveCN104889658ASubsequent process is stableAvoid deviationWelding/cutting auxillary devicesAuxillary welding devicesFixed frameSlewing bearing

The invention discloses a work-piece rotation mechanism for a chuck double-station welding machine. The mechanism comprises a rotation motor, a fixing plate is arranged on the rotation motor, vertical plates are arranged on the fixing plate symmetrically, an upper fixing plate is fixed on the vertical plates, and a rotation bearing group is arranged on the upper fixing plate and is connected with the rotation motor. A fixture location plate is arranged at the upper end of the rotation bearing group. The rotation bearing group comprises rotation bearings and snapping shafts. Bearing fixing seats are arranged on the rotation bearings. The snapping shafts penetrate the bearing fixing seats and the rotation bearings to be fixedly connected with a gear group, and fixture location plates are fixed at the upper ends of the snapping shafts. By means of the mechanism, the fixture welding of a coil fixing frame can be completed in a rapid, stable and high-quality mode, the efficiency is high, labor costs are reduced greatly, the coil subsequent product process is stable, deviations are prevented, and finally completed coil products are stable in quality and high in performance.

Owner:吴中区横泾博尔机械厂

Welding supporting table for joints

ActiveCN102161144BGood effectAchieve efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a welding supporting table for joints, the welding supporting table freely detachably supports joints formed by connection of a beam installation part and a wall surface of a joint core plate in spot welding, thereby keeping the joint at a pair of rotary transposers, the welding supporting table comprises: a mounting part disposed at a position between the pair of rotary transposers in a mode that a plurality of joints are mounted on a same plane; a supporting mechanism disposed on the mounting part and performing support of the beam installation part of the joints; a column-shaped part respectively disposed at two ends of the mounting part, and kept in a free detachable way via fixed clamping tools disposed at the inner sides of annular parts of the rotary transposers. According to the composition, joint positioning of current rotary transposers can be easily performed, a plurality of joints can welded, and original welding operation zones of the rotary transposers can be effectively used.

Owner:KOBE STEEL LTD

Stable operation pad for electronic circuit board soldering

InactiveCN109996396AExtended service lifeSolve the burrsPrinted circuit assemblingMetal working apparatusSolderingElectronic circuit

The invention discloses a stable operation pad for electronic circuit board soldering. The stable operation pad comprises a device body and a mechanical arm, wherein the mechanical arm is arranged above the device body, one end of the mechanical arm is connected with the device body in a transmission manner, a welding head track is arranged above the mechanical arm, the welding head track is embedded in the mechanical arm, a slide track is arranged above the device body, the slide track is fixedly connected on the device body, a blower is arranged at the right of the device body, and the blower is fixedly connected on the device body. The stable operation pad for electronic circuit board soldering is provided with a thermal insulating layer that is tightly attached to the operation pad, ametal net is arranged below the thermal insulating layer, the meal net is tightly attached to the thermal insulating layer that is made of a high temperature resisting material, so that high temperature due to welding is prevented from melting the workbench, and the workbench is further protected.

Owner:GUILIN SHIHUAN WASTE GAS TREATMENT EQUIP

Solid electrolytic capacitor and its manufacture method

InactiveCN100382211CNo scatteringStable welding workSolid electrolytic capacitorsCapacitanceElectrolytic capacitor

Owner:PANASONIC CORP

Application method of workshop electric welding machine

InactiveCN105057929AStable jobAvoid enteringWelding/cutting auxillary devicesAuxillary welding devicesWater flowEngineering

The invention discloses an application method of a workshop electric welding machine. Firstly, the electric welding machine is communicated with a power supply; a water inlet switch on a circular cooling water tank is opened; after cooling circulating water passes through a water flow pinger, a communication controller enables equipment to enter a working state; when a cooling water switch is closed, no cooling water passes through the water flow pinger, the controller cuts off the power supply, and a welding clamp cannot normally work due to power failure; and if the circular cooling water tank suddenly breaks water in working, a water flow flood preventer can immediately transmit a signal to the controller, an alarm is given to workers, the controller automatically cuts off the power supply until the cooling water recovers normally, and the whole equipment recovers normally to enter the working state again.

Owner:SICHUAN JINFENG CONSTR

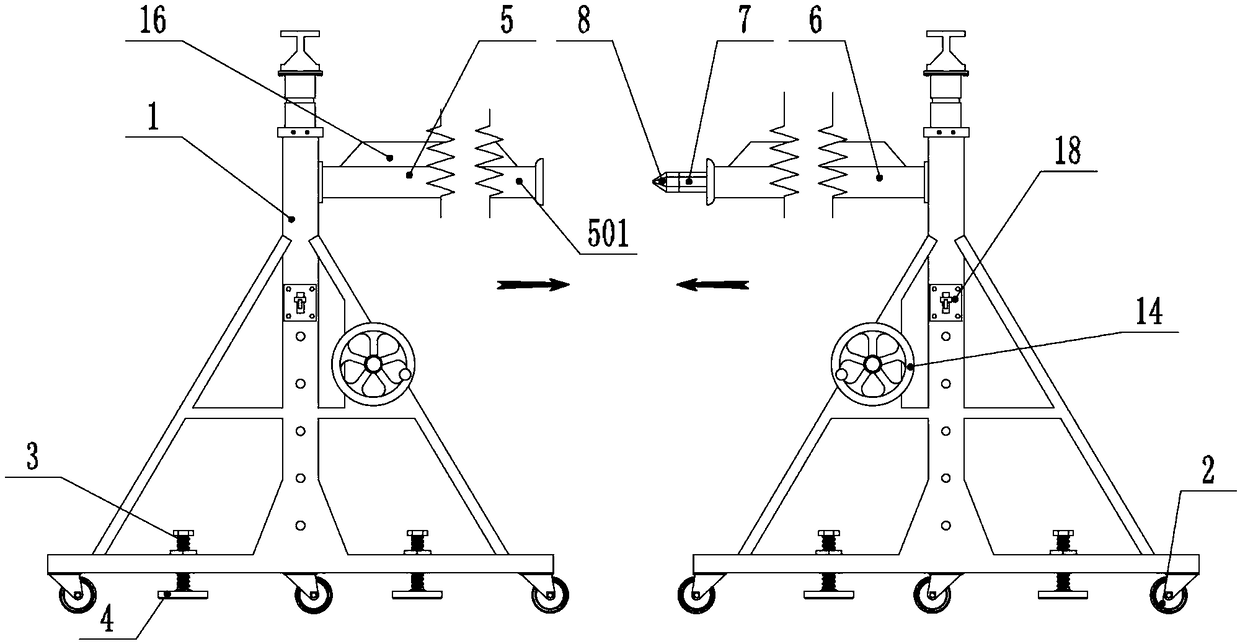

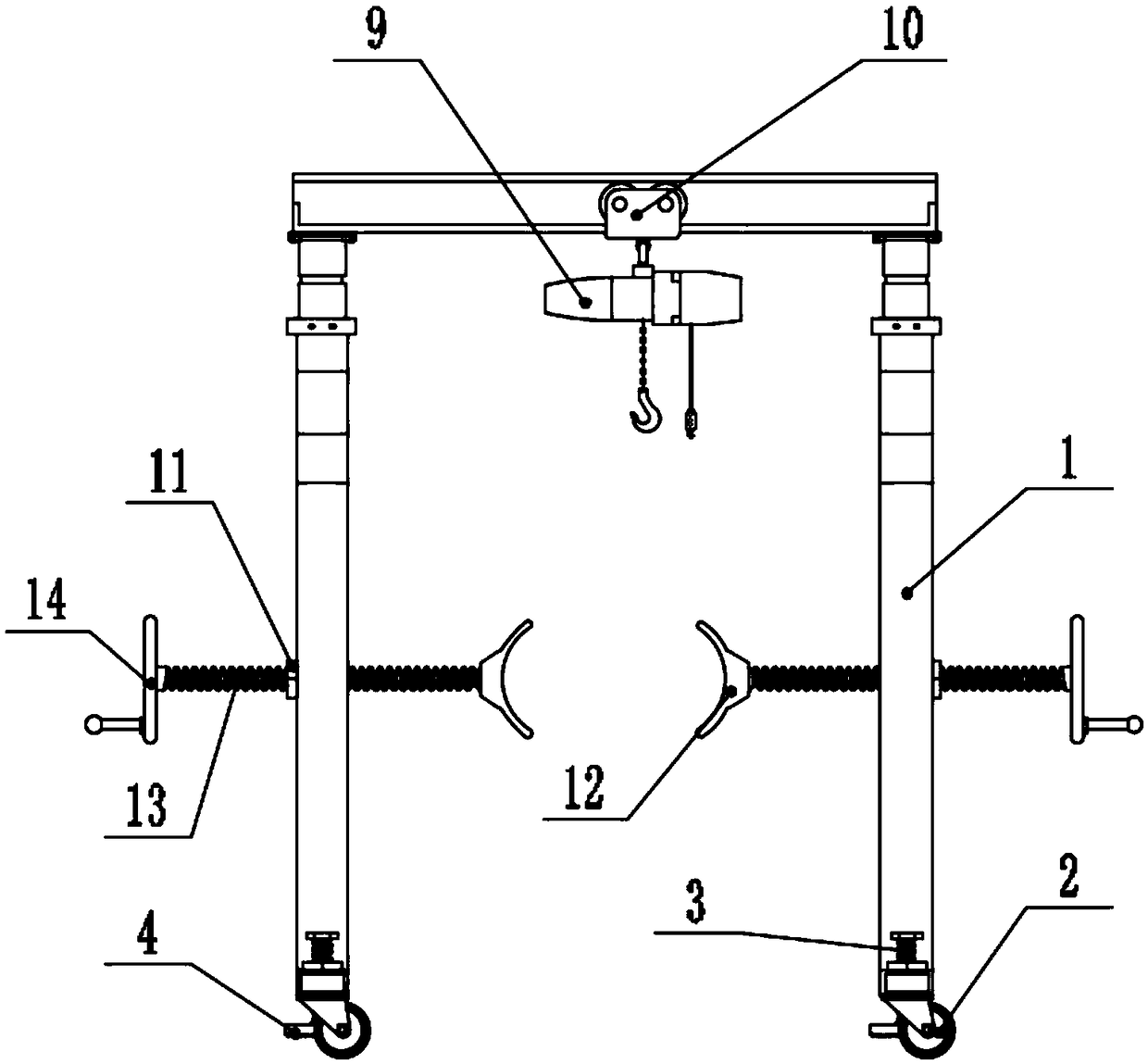

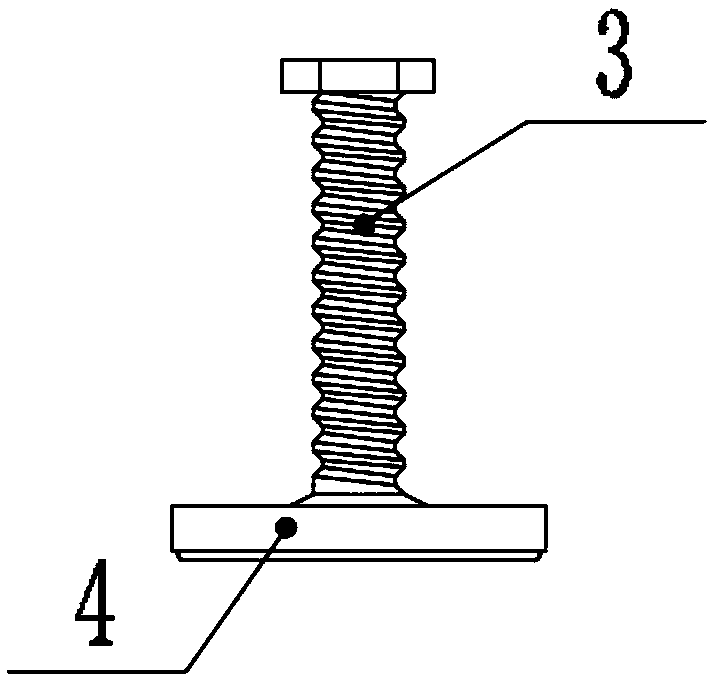

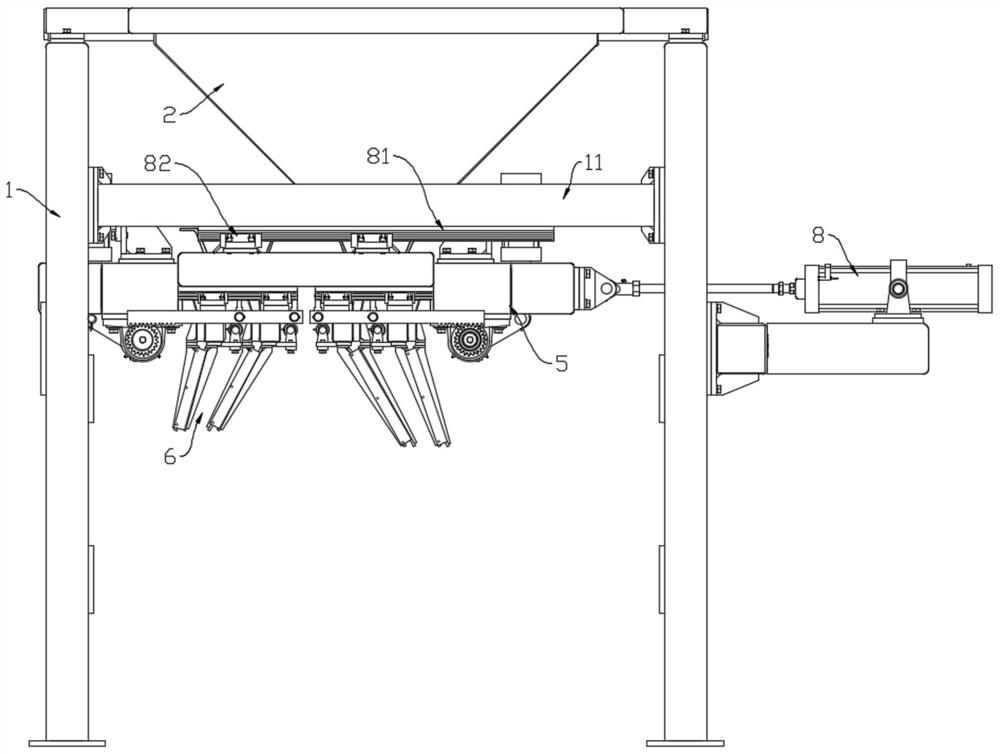

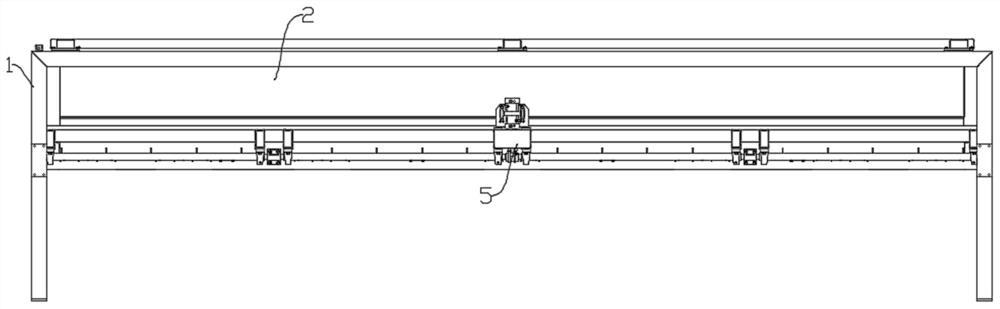

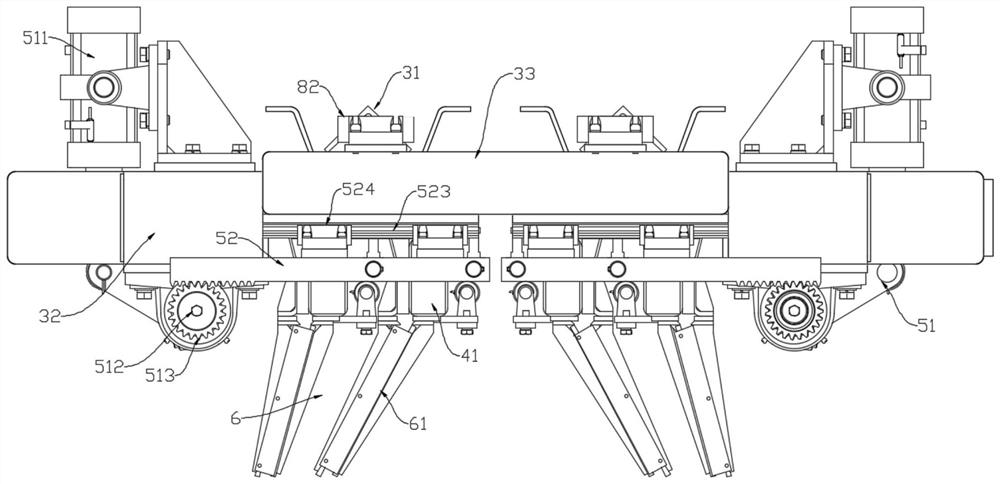

Portal frame device for welding steel pipe piles

InactiveCN108705226AEasy to fixAffect the welding effectWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringPortal frame

The invention provides a portal frame device for welding steel pipe piles. The portal frame device comprises flexible smoke discharging pipes and smoke discharging switches, wherein the tops of portalframe main bodies are I-shaped sliding rail structures; six universal wheels are mounted on the bottom end surfaces, the front end surfaces and the rear end surfaces of the portal frame main bodies;a total of eight fixed thread shafts are respectively mounted on the bottoms of two portal frame main bodies; the tops of the fixed thread shafts are hexagonal blocky structures; a total of eight fixed support plates are arranged; two ends of steel pipe piles in the hung state are fixed; the staff can conveniently and stably carry out the operation of welding the steel pipe piles in the later period; the influence on the welding accuracy of the steel pipe piles caused when the steel pipe piles shake back and forth in the portal frame main bodies can be avoided; with cooperation of the clampingthread shafts and hand wheels, the clamping diameters of two clamping blocks can be adjusted, so that the two clamping blocks are more capable of fixing the steel pipe piles with different diameter specifications; the fixing effect in the device can be improved.

Owner:梁玉燕

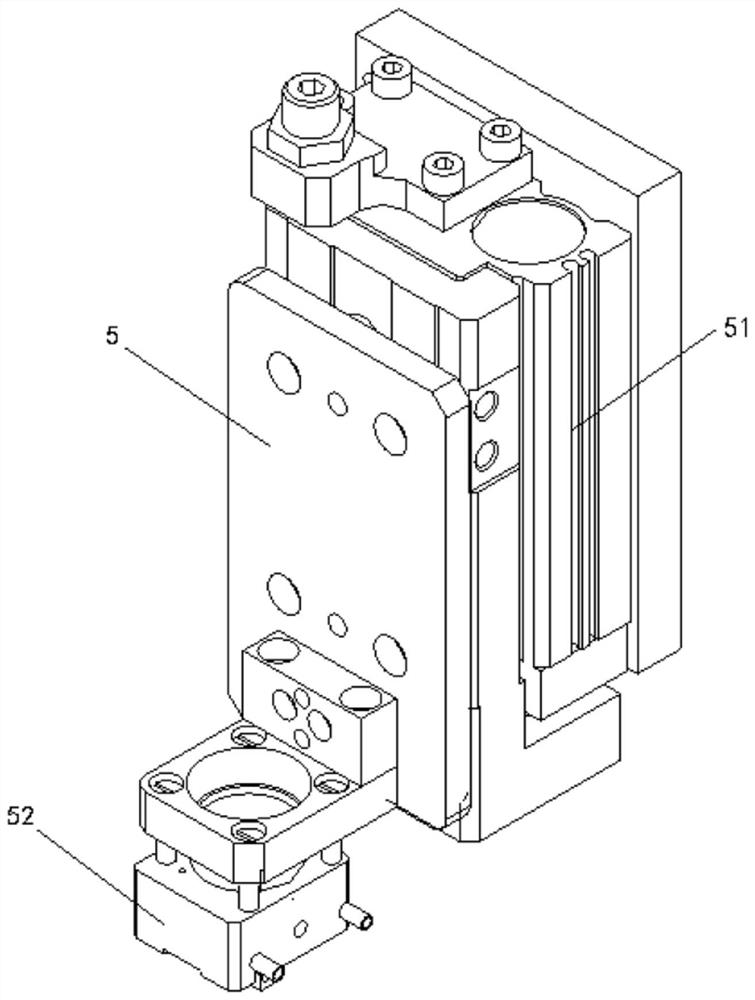

Lithium battery connecting sheet welding device

ActiveCN111360541BRealize automatic feedingStable welding workOther manufacturing equipments/toolsPhysicsLithium battery

Owner:深圳市大族锂电智能装备有限公司

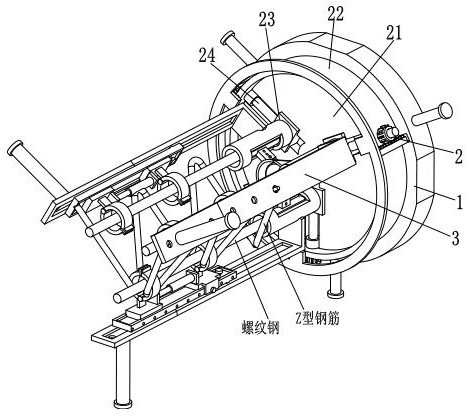

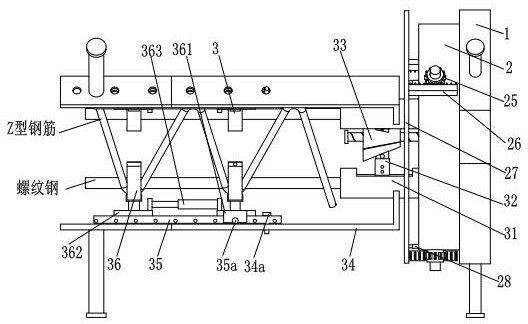

Steel bar blanking equipment and steel bar blanking process of mesh cage networking system

The invention discloses steel bar blanking equipment and a steel bar blanking process of a mesh cage networking system, and belongs to the field of steel bar welding. The equipment comprises a rack, a stock bin and a material receiving device, wherein a discharging port of the stock bin is located at the lower end of the stock bin; the material receiving device comprises a material receiving channel, a blanking channel, a material pushing mechanism, a discharging channel and a horizontal channel; an inlet of the material receiving channel is located under the discharging port of the stock bin; an inlet of the blanking channel is positioned below an outlet of the receiving channel; two ends of the horizontal channel are respectively connected with the inlet of the blanking channel and the outlet of the material receiving channel; an inlet of the discharging channel is located under an outlet of the blanking channel; the material pushing mechanism comprises a jacking and pushing unit and a material pushing unit; a pushing plate is arranged on the material pushing unit; a convex block is arranged at the upper end of the pushing plate; the convex block is located in the horizontal channel; and the jacking and pushing unit is used for driving the material pushing unit to move in the horizontal direction. The process adopts the equipment. According to the steel bar blanking equipment and the steel bar blanking process of the mesh cage networking system provided by the invention, steel bar blanking is accurate and rapid, only one steel bar falls off each time through a single blanking channel, and the working stability is high.

Owner:ANHUI KEDA IND CO LTD

Use method of welding machine for building construction

InactiveCN107442910AStable jobAvoid enteringWelding coupling meansWater sourceAgricultural engineering

The invention discloses a method of using a welding machine for building construction. First, the welding machine is connected to the power supply, and the water inlet switch on the cold source box is turned on. After the cold source passes through the water flow transmitter, the controller is connected to let the equipment Enter the working state; when the cold source switch is turned off, no cooling water passes through the water flow transmitter, the controller cuts off the power, and the welding tongs cannot work normally; if the cold source box suddenly cuts off water during work, the water flow preventer will immediately The signal is transmitted to the controller, and a warning is issued to inform the staff. At the same time, the controller automatically cuts off the power supply until the cooling water returns to normal, and the entire equipment also returns to normal and enters the working state again.

Owner:张贵友

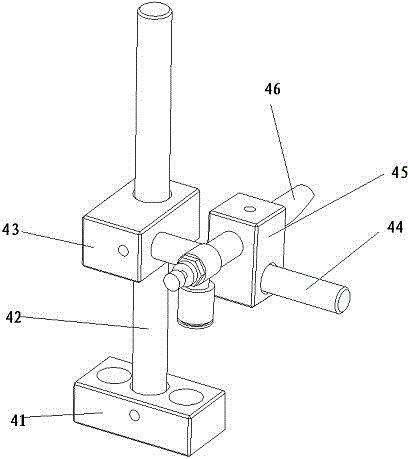

Nitrogen adjustment mechanism for chuck double-station welding machine

InactiveCN104889616ASubsequent process is stableImprove product qualityWelding/cutting auxillary devicesAuxillary welding devicesAgricultural engineeringNitrogen

The invention discloses a nitrogen adjustment mechanism for a chuck double-station welding machine. The mechanism comprises a vertical guide rod fixing block fixed with an upper rack bottom plate. A vertical guide rod is arranged on the vertical guide rod fixing block, a cross guide rod fixing block is arranged on the vertical guide rod, a cross guide rod is arranged on the cross guide rod fixing block, a nitrogen tube fixing block is arranged on the cross guide rod, and a nitrogen spray tube is arranged on the nitrogen tube fixing block. By mean of the mechanism, nitrogen can be adjusted according to the welding unit position, the coil subsequent product process is stable, deviations are prevented, and finally completed coil products are stable in quality and high in performance.

Owner:吴中区横泾博尔机械厂

Welding lathe for welding workshop

InactiveCN114603276ASolve the inconvenience of adjustmentImprove applicabilityWelding/cutting auxillary devicesAuxillary welding devicesBrake padPulley

The invention relates to the technical field of welding lathes, and discloses a welding lathe for a welding workshop, which comprises a welding machine body, the bottom of the welding machine body is fixedly connected with a fixing frame, the bottom of the fixing frame is fixedly connected with a base, the top of the base is provided with a limiting groove, and the inner wall of the limiting groove is movably connected with a limiting block. And a pulley is movably connected to one side of the limiting block, a pulley is fixedly connected to the bottom of the pulley, a brake pad is fixedly connected to one side of the pulley, and a baffle is fixedly connected to one side of the pulley. According to the welding lathe for the welding workshop, the purpose of being convenient to adjust is achieved, the problem that a common welding lathe for the welding workshop is inconvenient to adjust is solved, the welding lathe can adapt to welding materials of different lengths, and therefore the applicability of the welding lathe is enhanced, daily welding work is facilitated, and the welding work efficiency is improved; and great convenience is brought to daily work of people.

Owner:湖南省金峰机械科技有限公司

A fixed electric welding machine support for automatic control

ActiveCN109079386BIncrease flexibilityLower working heightWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlElectric machinery

The invention discloses a fixed electric welding machine support for automatic control. The fixed electric welding machine support comprises a frame A, a frame B, a cross frame, electric lifting columns, a computer and an electric push rod, wherein the frame A is arranged at one end of the cross frame through a supporting frame; in addition, the frame B is arranged at the other end of the cross frame through the supporting frame; a fixed electric welding machine is arranged at the bottom in the frame A through a protective frame; a welding head is arranged on one side of the top of the fixed electric welding machine and is positioned on one side of the frame A; a sliding chute is formed in the bottom of the welding head through bolts and is also formed in the frame A; a first positive andnegative rotation motor is arranged on one side of the bottom of the cross frame through the protective frame; besides, a first screw is arranged on the other side of the bottom of the cross frame through a fixed shaft sleeve. When a welding part on a feeding plate reaches a detection position of an infrared switch, the detection end of the infrared end is triggered to close the rotation of secondpositive and negative rotation driving motors, so that the ascending work of the feeding plate by second positive and negative rotation driving motors is stopped and further horizontal height of thewelding part on the feeding plate corresponds to an electric push rod.

Owner:XIANGYANG ZHONGXINGHE AUTO PARTS CO LTD

Fixed electric welding machine support for automatic control

ActiveCN109079386AIncrease flexibilityLower working heightWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlEngineering

The invention discloses a fixed electric welding machine support for automatic control. The fixed electric welding machine support comprises a frame A, a frame B, a cross frame, electric lifting columns, a computer and an electric push rod, wherein the frame A is arranged at one end of the cross frame through a supporting frame; in addition, the frame B is arranged at the other end of the cross frame through the supporting frame; a fixed electric welding machine is arranged at the bottom in the frame A through a protective frame; a welding head is arranged on one side of the top of the fixed electric welding machine and is positioned on one side of the frame A; a sliding chute is formed in the bottom of the welding head through bolts and is also formed in the frame A; a first positive andnegative rotation motor is arranged on one side of the bottom of the cross frame through the protective frame; besides, a first screw is arranged on the other side of the bottom of the cross frame through a fixed shaft sleeve. When a welding part on a feeding plate reaches a detection position of an infrared switch, the detection end of the infrared end is triggered to close the rotation of secondpositive and negative rotation driving motors, so that the ascending work of the feeding plate by second positive and negative rotation driving motors is stopped and further horizontal height of thewelding part on the feeding plate corresponds to an electric push rod.

Owner:XIANGYANG ZHONGXINGHE AUTO PARTS CO LTD

A different plane welding technology and welding equipment using the same

ActiveCN110052760BAccurate focusLow costWelding/cutting auxillary devicesAuxillary welding devicesMaterial resourcesIndustrial engineering

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

A prefabricated steel frame structure processing platform for assisting workpiece welding

ActiveCN111015063BImprove work performanceStable welding workWelding/cutting auxillary devicesAuxillary welding devicesSteel frameInternal connection

The invention discloses a prefabricated steel frame structure processing platform for assisting workpiece welding, which comprises a first main body side, a second main body side and supporting legs. The connection between the two main body sides and the first main body side is fixedly welded with supporting legs, the outside of the second main body side is equipped with a positioning connecting rod, and the outer end of the positioning connecting rod is equipped with a movable pull ring, and the second main body side There are upper slots and lower slots on the inner side of the upper slot, and the lower slots are located below the upper slots. The sides of the first movable plate and the second movable plate are provided with fixed connection holes, and the interior of the fixed connection holes is connected with a positioning connection. rod, and sliding lugs are fixedly arranged on both sides of the sliding support plate. The prefabricated steel frame structure processing platform for auxiliary workpiece welding can make the fixed steel frame structure in an overhead state, thereby facilitating the completion of the welding work of the steel frame structure, and improving the welding work efficiency of the steel frame structure.

Owner:山东欣怡翔精密机械制造有限公司

A steel structure truss welding process

ActiveCN110961813BAvoid accumulationReduce stepsWelding/cutting auxillary devicesAuxillary welding devicesCircular discGear drive

Owner:山东东恒新材料科技有限公司

Welding device used for underground engineering waste water pipeline and working method of welding device

InactiveCN108480890AAchieve regulationStable welding workWelding/cutting auxillary devicesAuxillary welding devicesControl engineering

The invention discloses a welding device used for underground engineering waste water pipelines and a working method of the welding device. The left side of the upper part of a fixed plate is fixedlyconnected with a workpiece holder; a rotating platform is rotatably connected with the upper part of a moving trolley through a rotating shaft fixedly connected with the lower part of the rotating platform; a support pillar is fixedly arranged at the front side of the upper part of the rotating platform; the front side of the support pillar is provided with a vertical slideway; the top part of thesupport pillar is fixedly provided with a vertical driving motor; a welding arm consists of a fixed arm and a sliding arm; the lower part of the left end of the sliding arm is fixedly connected withwelding tongs; the right end of the fixed arm is fixedly connected with reels; one side, near the slideway, of a slider is provided with two sliding chutes II which extend vertically and of which thecross sections are in a shape of T; a sliding rail of which the cross section is in the shape of T is glidingly assembled in each of the two sliding chutes II; upper ends and lower ends of the two sliding rails are respectively and fixedly connected with the upper end and the lower end of the slideway; and two lubricating oil filling devices are fixedly arranged at the front side of the slider ina manner of being respectively corresponding to the sliding chutes II. The welding device is convenient and fast in operating process and high in operation efficiency, and is suitable for welding operation of round workpieces.

Owner:XUZHOU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com