Positioning mechanism for range hood air way welding

A positioning mechanism and range hood technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of relatively high requirements for welding heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

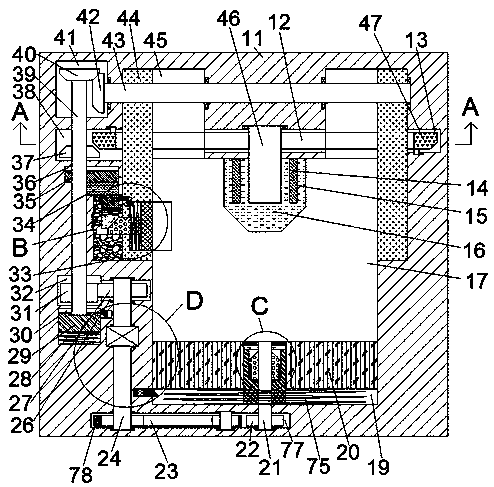

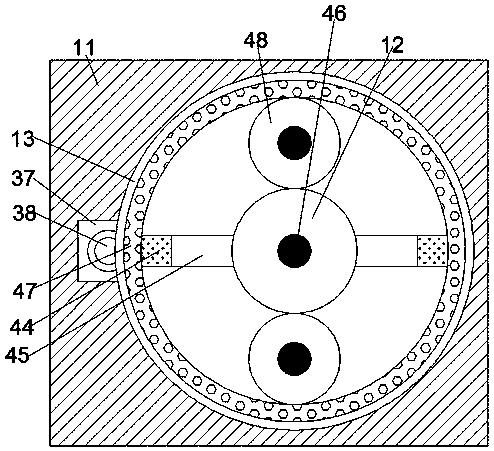

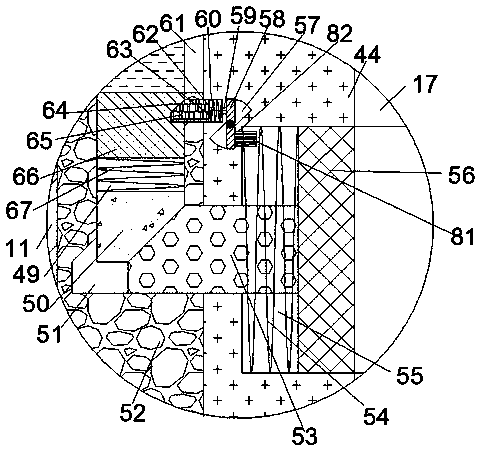

[0015] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] refer to Figure 1-6 , according to an embodiment of the present invention, a positioning mechanism for welding the air duct of a range hood, including a device main body 11, a transmission device arranged in the device main body 11, and a fixing device arranged in the device main body 11 And the positioning device arranged in the device main body 11, the transmission device includes a motor 25 fixedly arranged in the device main body 11, a first cavity 26 is arranged in the upper inner wall of the motor 25, the A first gear 27 is rotatably arranged in the first cavity 26, and the lower end of the first gear 27 is fixedly connected with a rotating shaft connected to the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com