Fixed electric welding machine support for automatic control

A fixed, electric welding machine technology, applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of cumbersome welding parts, no feeding mechanism, single function, etc., and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

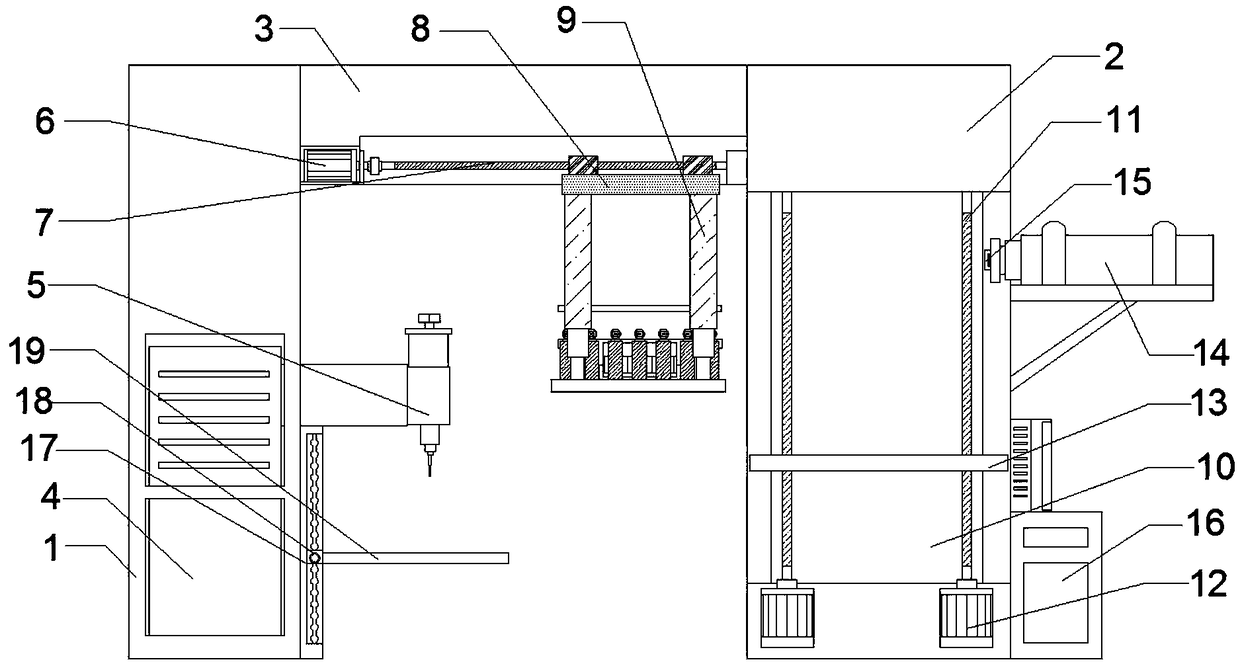

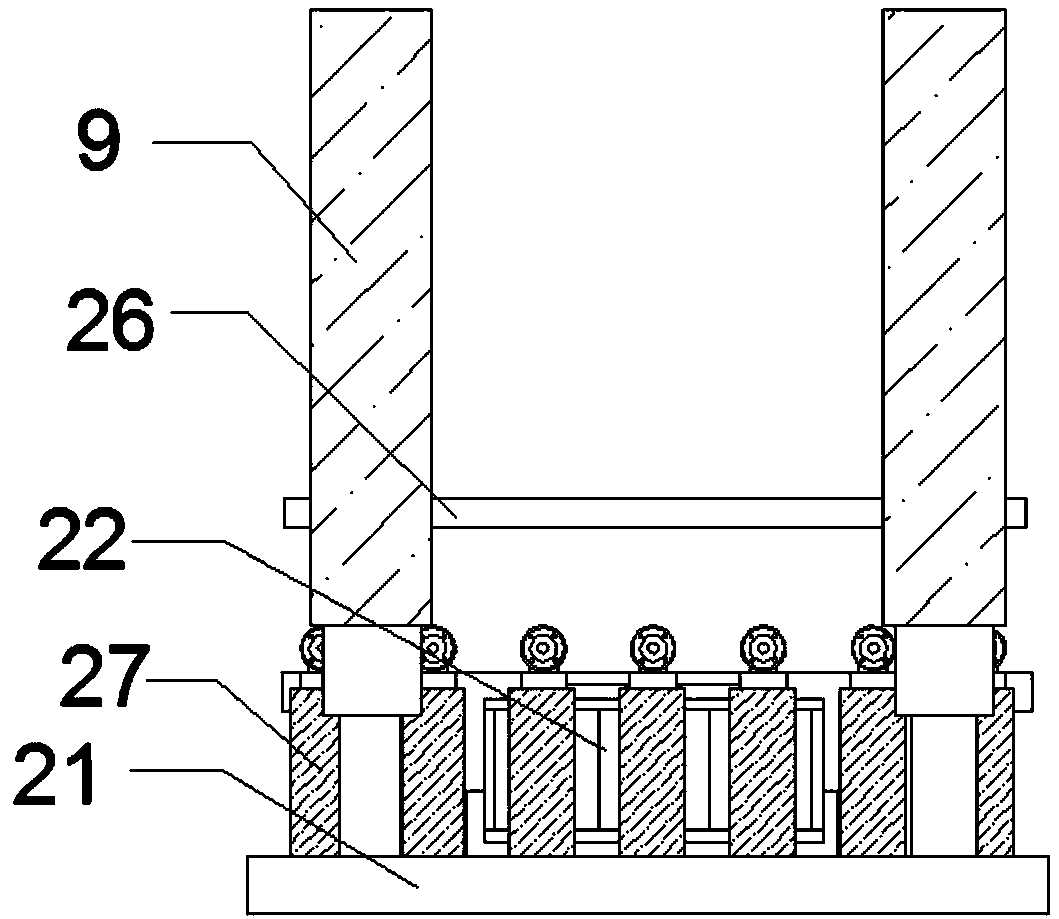

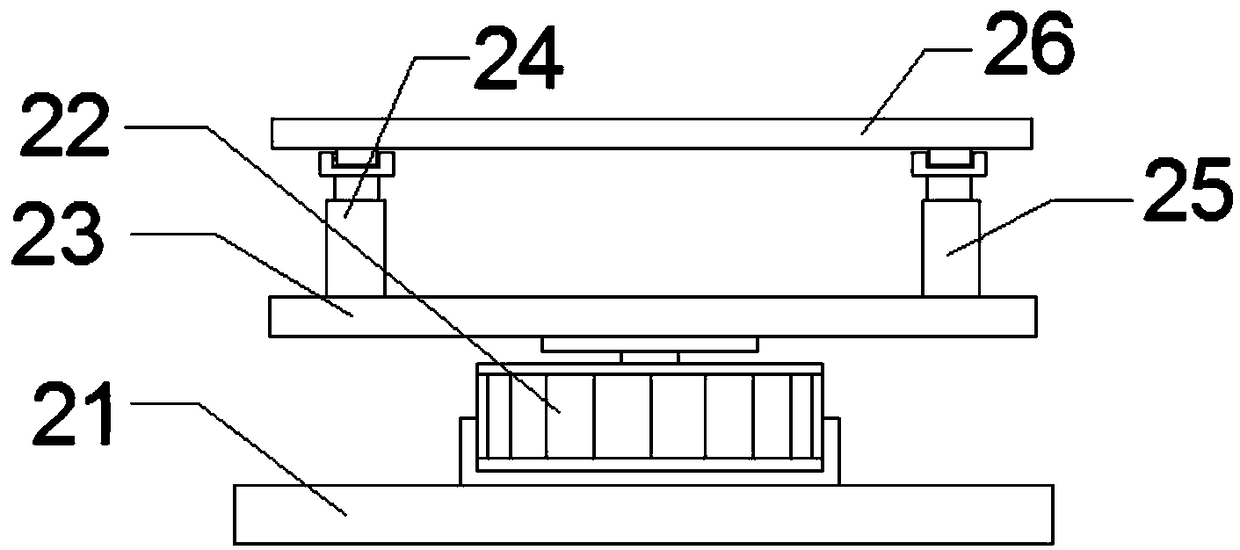

Embodiment 1

[0022] Such as Figure 1-4 As shown, a fixed fixed electric welding machine support for automatic control includes A frame 1, B frame 2, horizontal frame 3, electric lifting column 9, computer 16 and electric push rod 14, and one end of the horizontal frame 3 The A frame 1 is installed through the support frame, and the B frame 2 is installed on the other end of the cross frame 3 through the support frame. Head 5, the welding head 5 is located on the side of the A frame 1, the bottom of the welding head 5 is installed with a chute 17 through a bolt, and the chute 17 is installed on the A frame 1, and the bottom side of the horizontal frame 3 passes through the protective frame The first forward and reverse drive motor 6 is installed, and the other side of the bottom of the cross frame 3 is installed with the first screw mandrel 7 through the fixed bushing. end connection, the bottom of the first screw rod 7 is installed with a load-bearing plate 8 through a slider, and the bo...

Embodiment 2

[0029] Such as Figure 1-4 As shown, a fixed fixed electric welding machine support for automatic control includes A frame 1, B frame 2, horizontal frame 3, electric lifting column 9, computer 16 and electric push rod 14, and one end of the horizontal frame 3 The A frame 1 is installed through the support frame, and the B frame 2 is installed on the other end of the cross frame 3 through the support frame. Head 5, the welding head 5 is located on the side of the A frame 1, the bottom of the welding head 5 is installed with a chute 17 through a bolt, and the chute 17 is installed on the A frame 1, and the bottom side of the horizontal frame 3 passes through the protective frame The first forward and reverse drive motor 6 is installed, and the other side of the bottom of the cross frame 3 is installed with the first screw mandrel 7 through the fixed bushing. end connection, the bottom of the first screw rod 7 is installed with a load-bearing plate 8 through a slider, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com