Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Shorten inventory time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

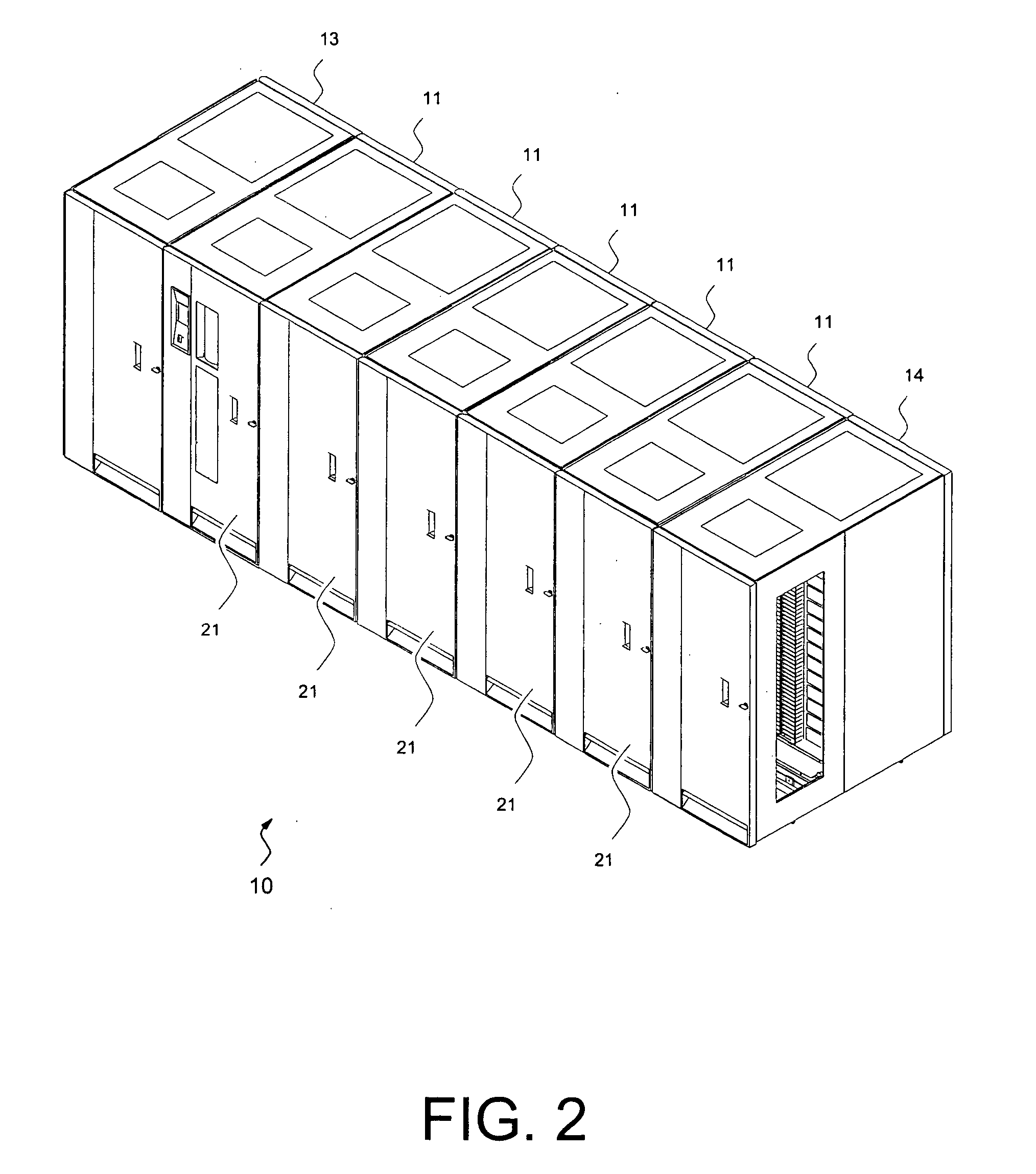

Reducing inventory after media access in an automated data storage library

InactiveUS7200722B2Shorten inventory timeDigital data processing detailsRecord information storageLibrary scienceData store

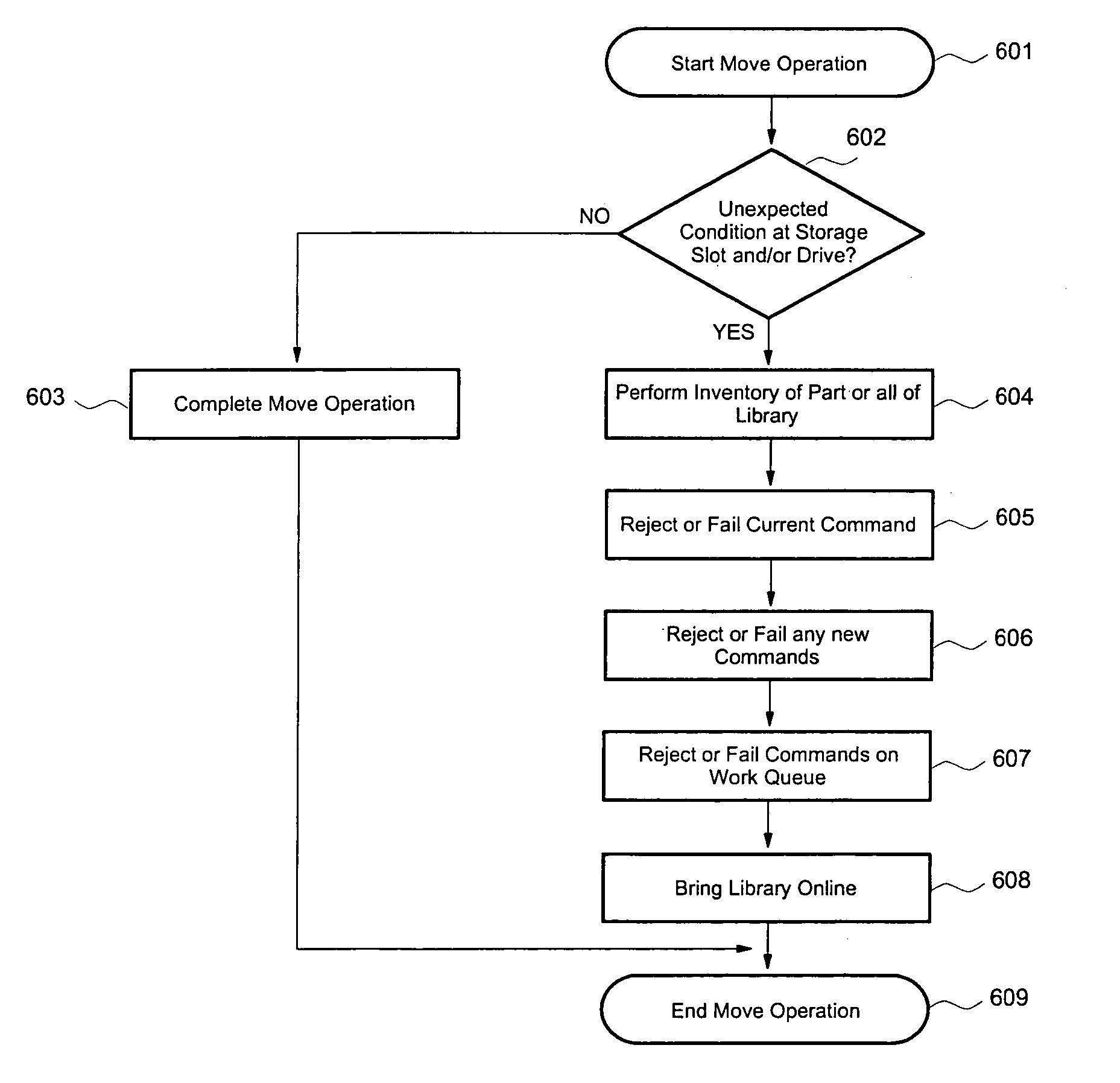

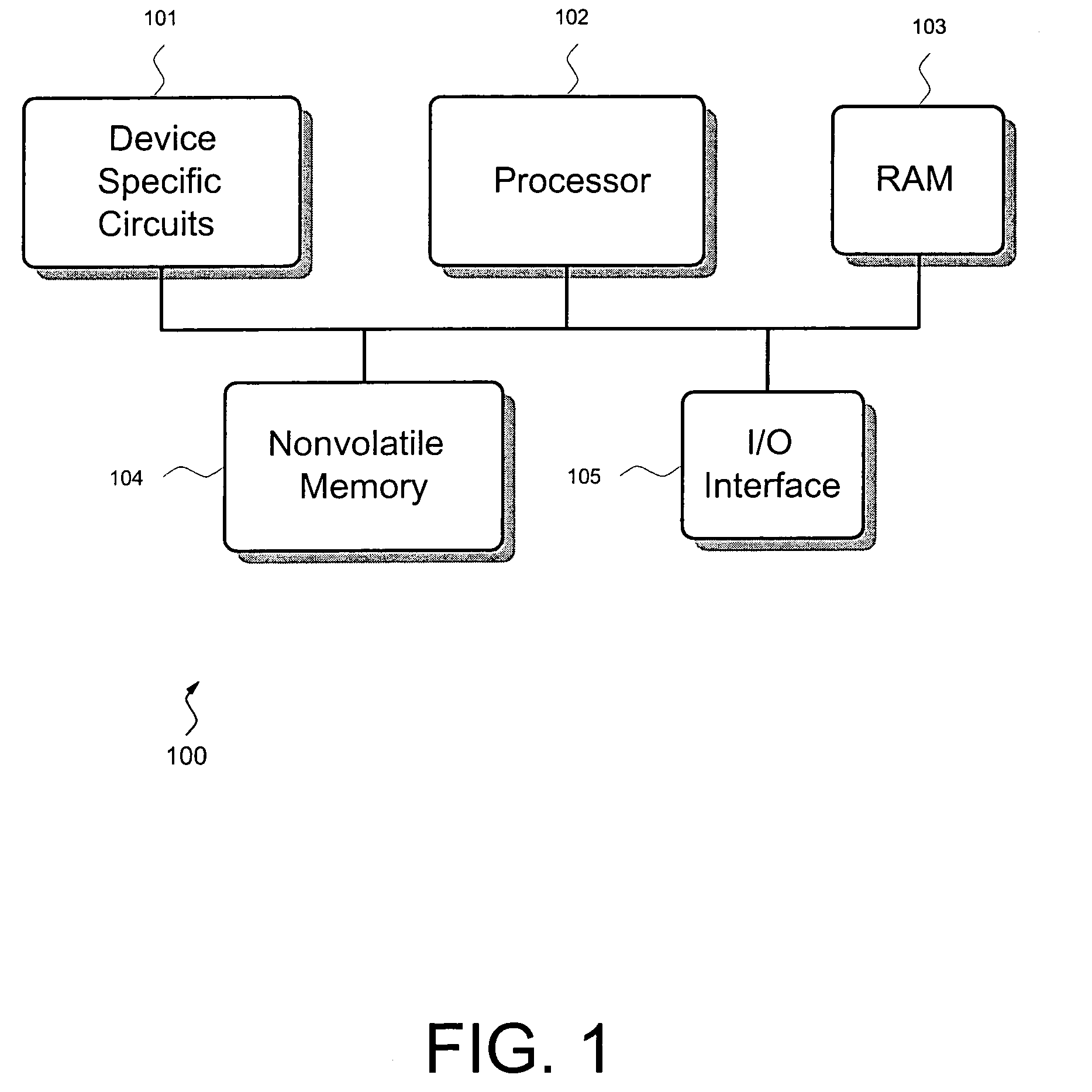

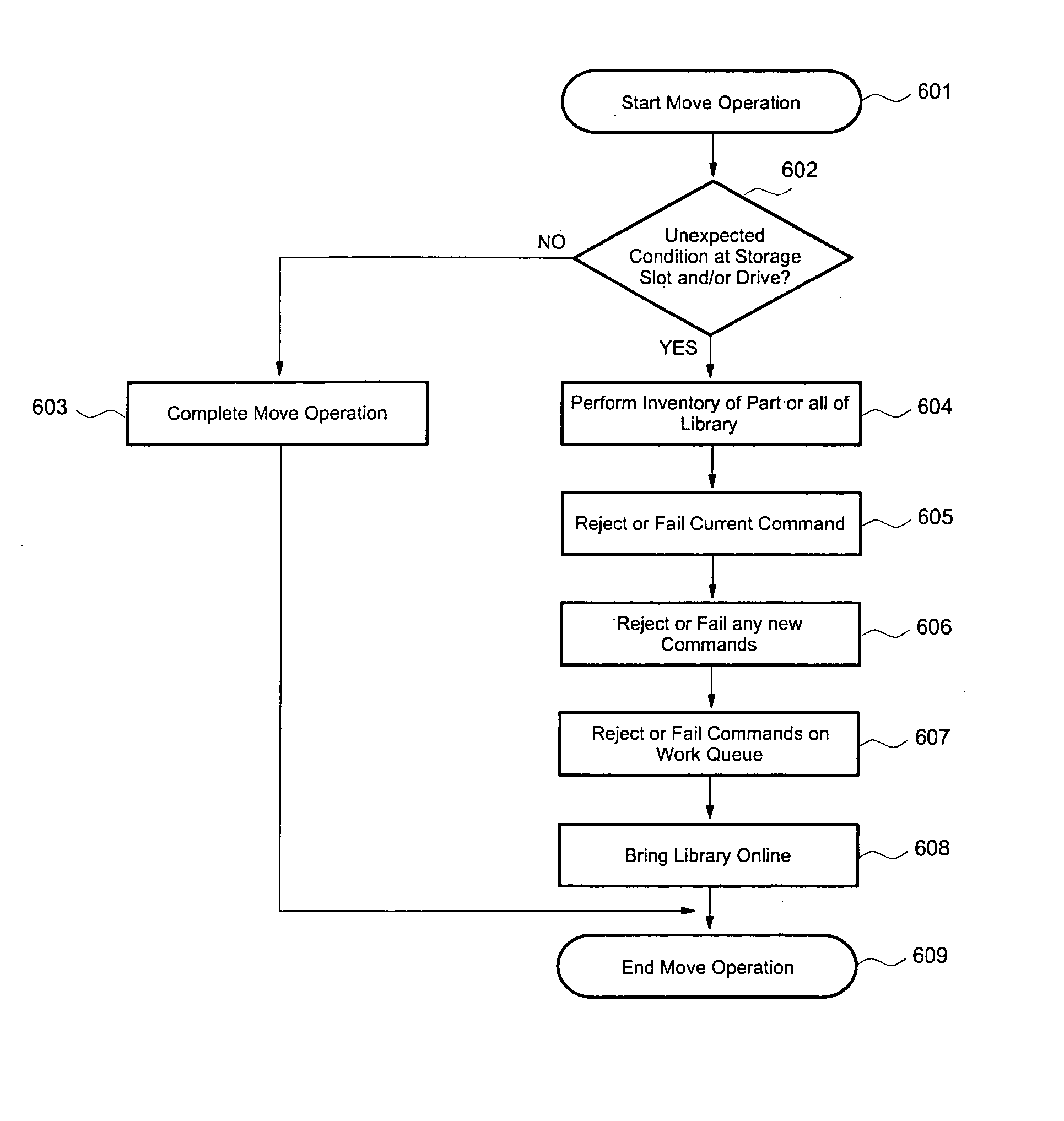

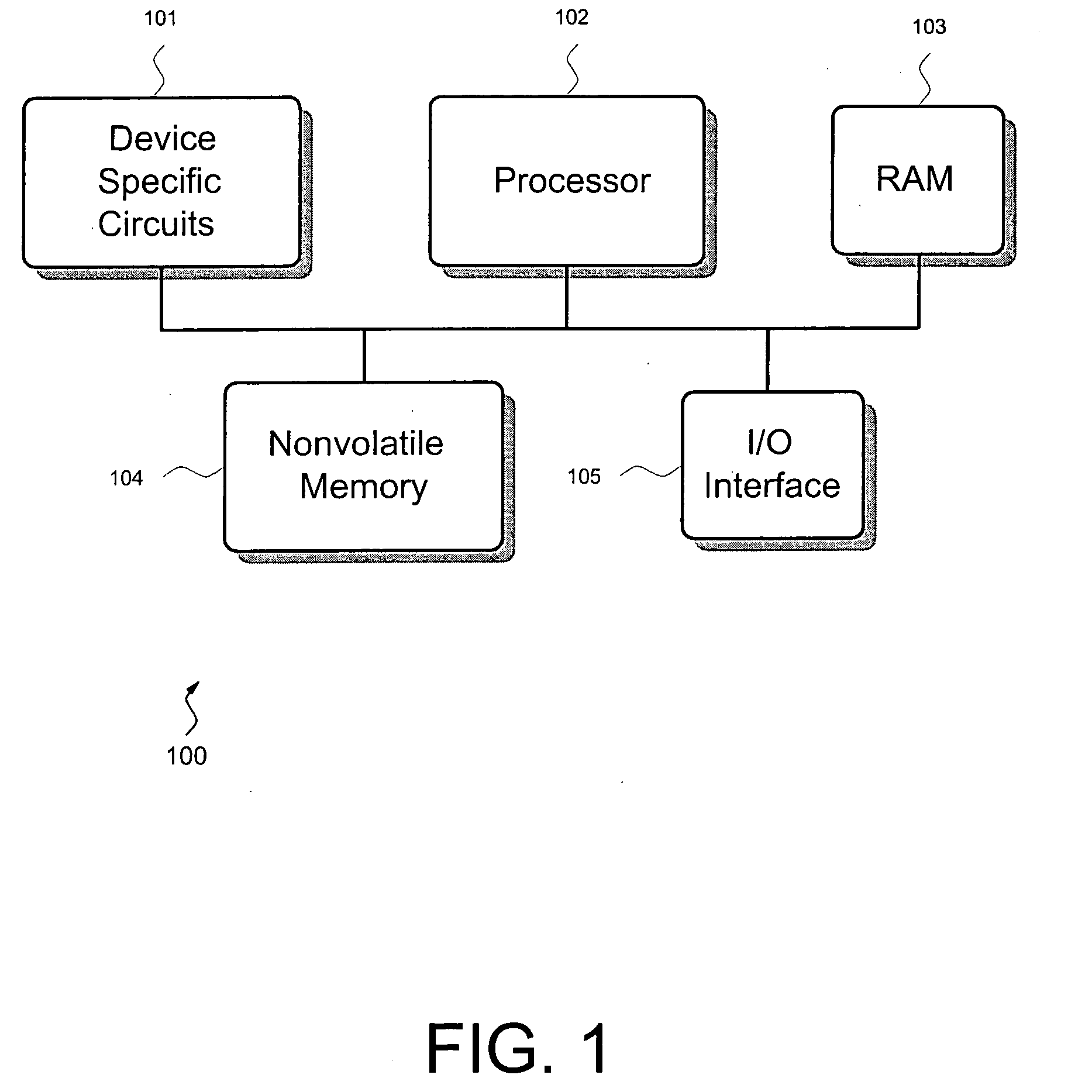

An automated data storage library provides for reducing inventory after media access. Media is moved, inserted, or removed without opening the access door normally associated with accessed media. A media status of a data storage drive within the automated data storage library is checked. An unexpected condition is detected at the data storage drive. An inventory of at least part of the library is performed for the unexpected condition. Alternately, a move operation is initiated for a data storage media wherein an unexpected condition is detected at the source and / or target location of the move operation. An inventory of at least part of the library is performed for the unexpected condition. In either embodiment, the unexpected condition includes a state of the automated data storage library which is inconsistent with a library database, such as a presence or absence of a data storage media in the location, or a data storage media in the location having an identifier which is inconsistent with the library database. The automated data storage library is brought back on-line after performing the inventory.

Owner:IBM CORP

Reducing inventory after media access in an automated data storage library

InactiveUS20050261800A1Shorten inventory timeDigital data processing detailsRecord information storageLibrary scienceData store

An automated data storage library provides for reducing inventory after media access. Media is moved, inserted, or removed without opening the access door normally associated with accessed media. A media status of a data storage drive within the automated data storage library is checked. An unexpected condition is detected at the data storage drive. An inventory of at least part of the library is performed for the unexpected condition. Alternately, a move operation is initiated for a data storage media wherein an unexpected condition is detected at the source and / or target location of the move operation. An inventory of at least part of the library is performed for the unexpected condition. In either embodiment, the unexpected condition includes a state of the automated data storage library which is inconsistent with a library database, such as a presence or absence of a data storage media in the location, or a data storage media in the location having an identifier which is inconsistent with the library database. The automated data storage library is brought back on-line after performing the inventory.

Owner:IBM CORP

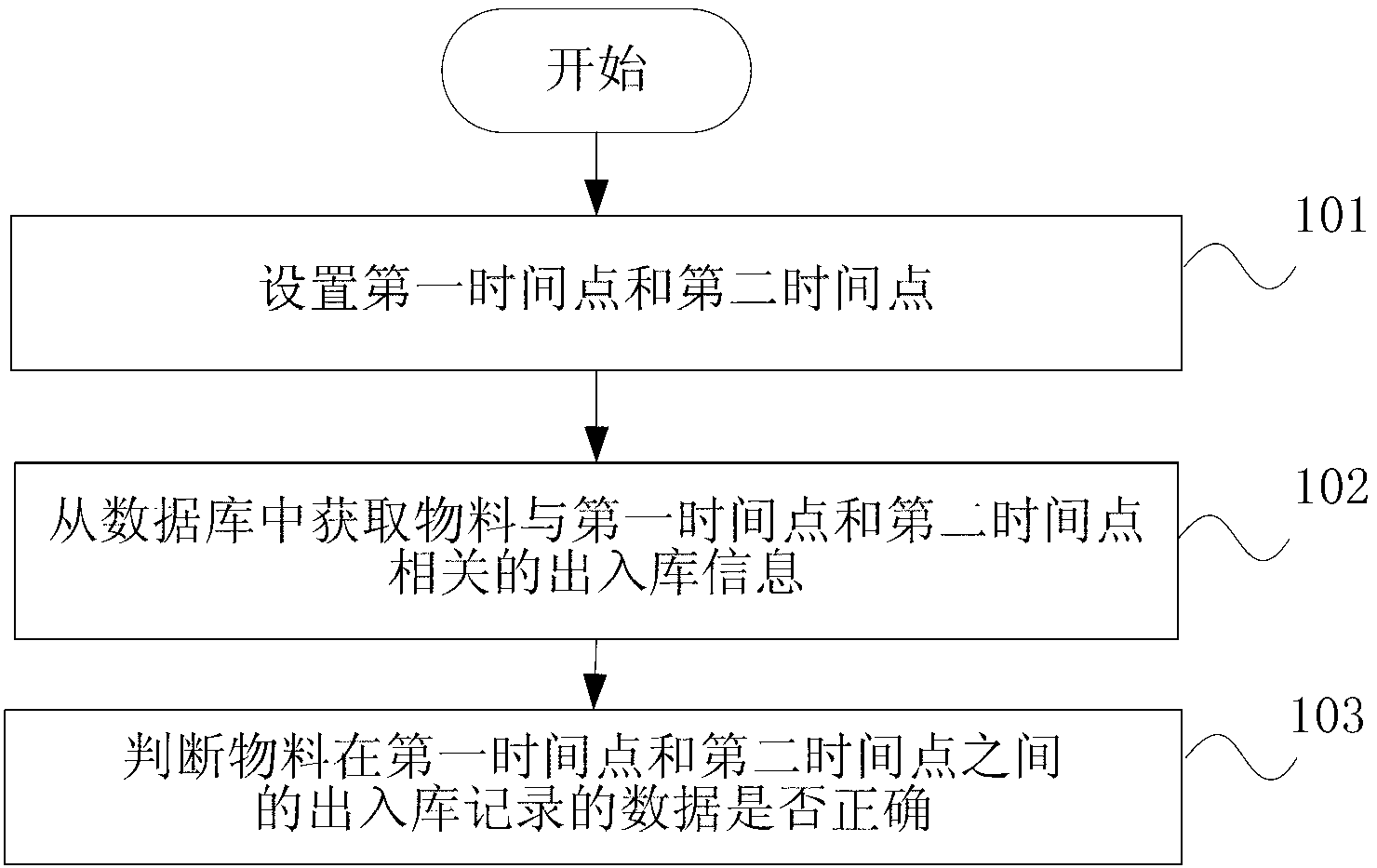

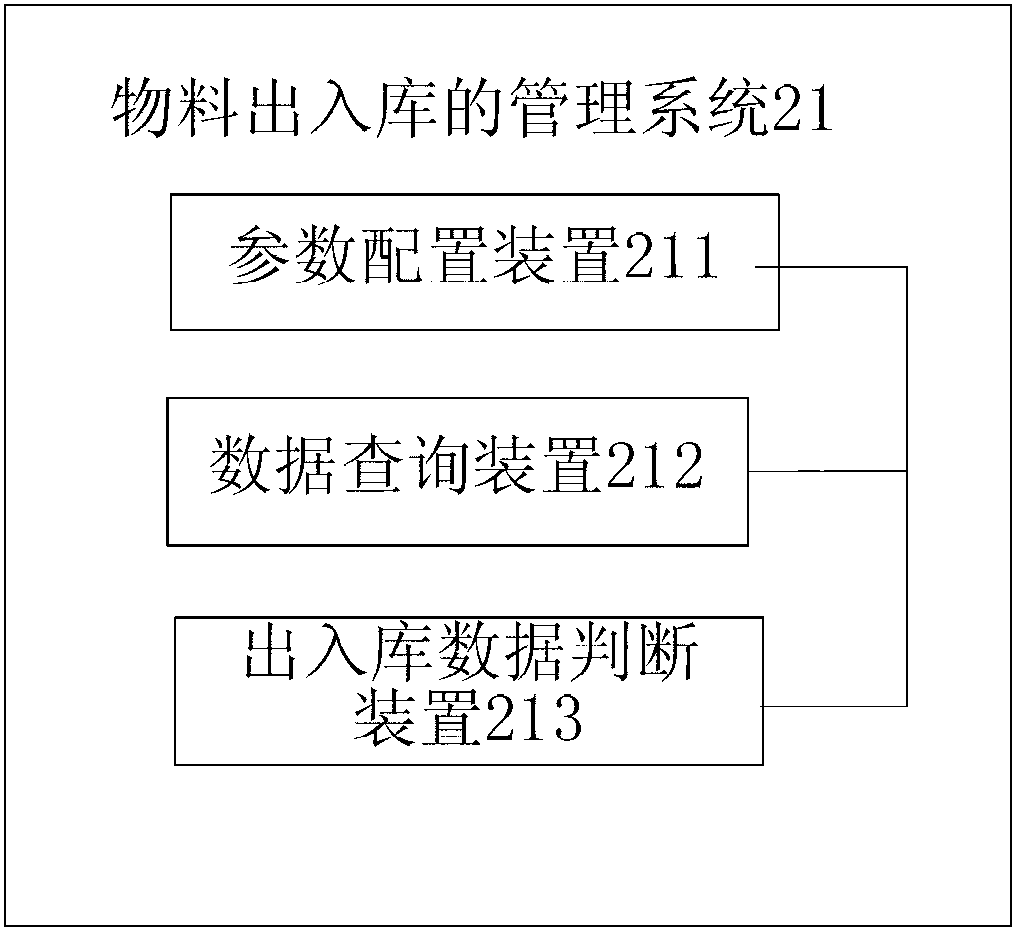

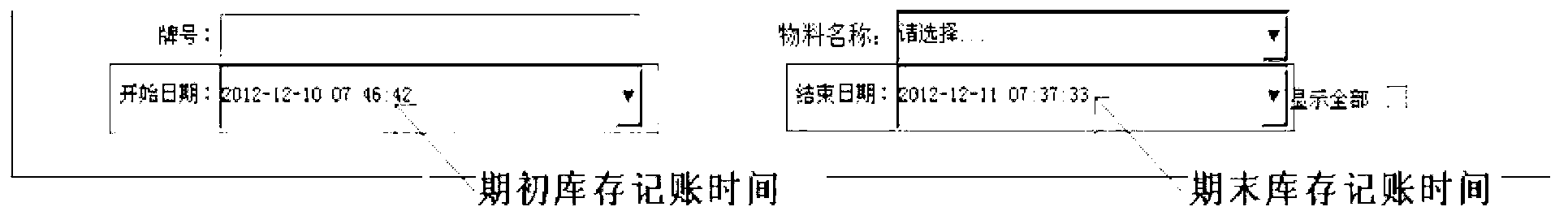

Warehouse management method and system

InactiveCN103295118APrecise positioningAvoid wide-ranging inventoryLogisticsData warehouseComputer science

The invention discloses a warehouse management method and system. The warehouse management method includes that first timing point and second timing point are set up, and data of warehouse records of materials between the first timing point and the second timing point are correct when a warehouse record difference is judged to be zero; the warehouse record difference = material warehoused in the first timing point + total number of the materials warehoused between the first timing point and the second timing point - total number of the material ex-warehoused between the first timing point and the second timing point + total number of the material warehoused from the second timing point to current timing point - total number of the material ex-warehoused from the second timing point to the current timing point - current warehouse of the materials. By the aid of the warehouse management method and system, warehouse information at any timing points can be recorded, all warehouse situations from any two optional timing points to the current timing point and the warehouse information of the two timing points can be inquired at the same time, errors leading to warehouse mistakes can be accurately allocated, so that a wide range of blind checking can be avoided, and checking efficiency can be improved.

Owner:LONGYAN CIGARETTE FACTORY

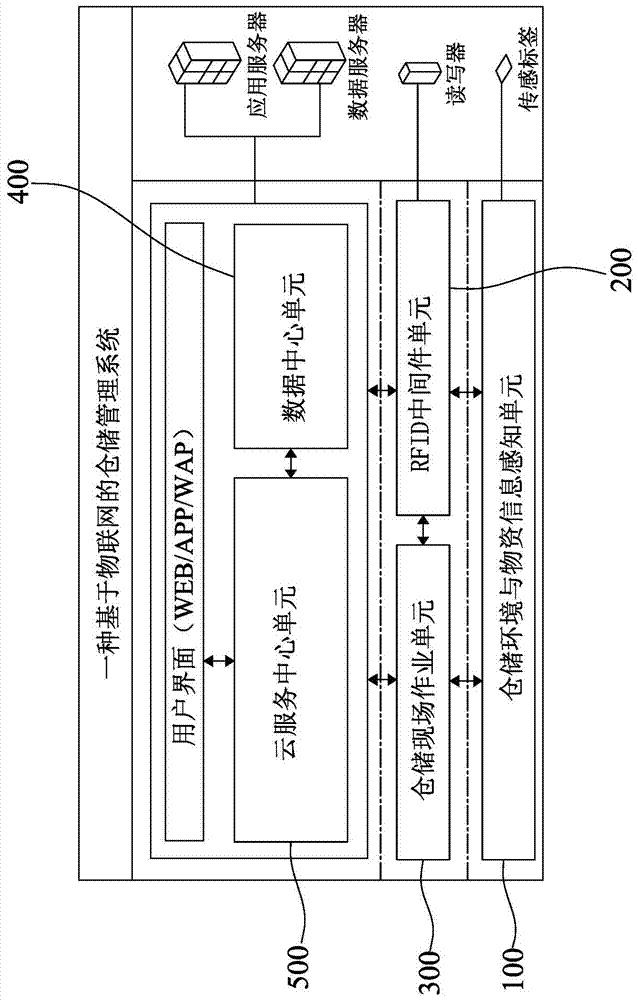

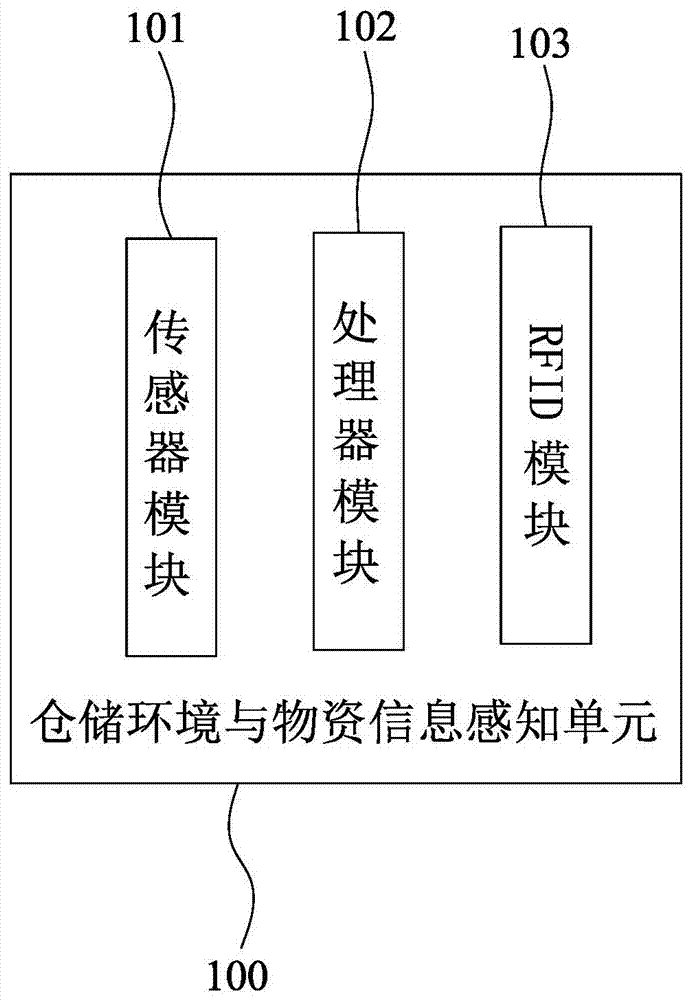

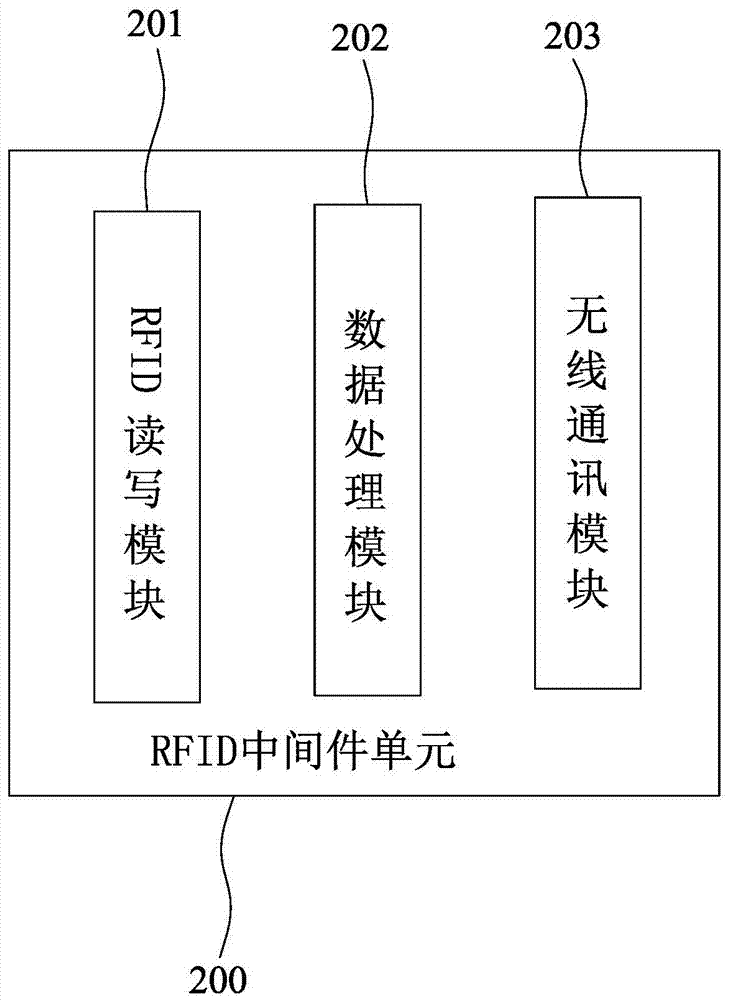

Warehouse management system based on Internet of Things, and warehousing quality risk estimation method based on warehouse management system

InactiveCN107358388AShorten inventory timeImprove inventory accuracyCo-operative working arrangementsLogisticsCold chainApplication server

The invention discloses a warehouse management system based on the Internet of Things, and a warehousing quality risk estimation method based on the warehouse management system, and relates to the field of cold chain logistics and intelligent warehousing. The system comprises a warehousing environment and material information sensing unit, an RFID middleware unit, warehousing onsite operation units, a data center unit, and a cloud service center unit. The warehousing environment and material information sensing unit is integrated on a sensing label. The RFID middleware unit is integrated on an RRID reader-writer. The warehousing onsite operation units are integrated on the reader-writer and a warehouse working terminal. The data center unit is deployed on the data server. The cloud service center unit is deployed on an application server. According to the invention, a BP neural network algorithm is creatively used for the risk early warning of the system, thereby achieving the real-time state analysis and warning of cold chain warehoused materials, and effectively solving a problem of warehousing quality risk estimation and alarm of fresh agricultural products in a cold chain warehouse. The system is good in application prospect.

Owner:厦门嵘拓物联科技有限公司

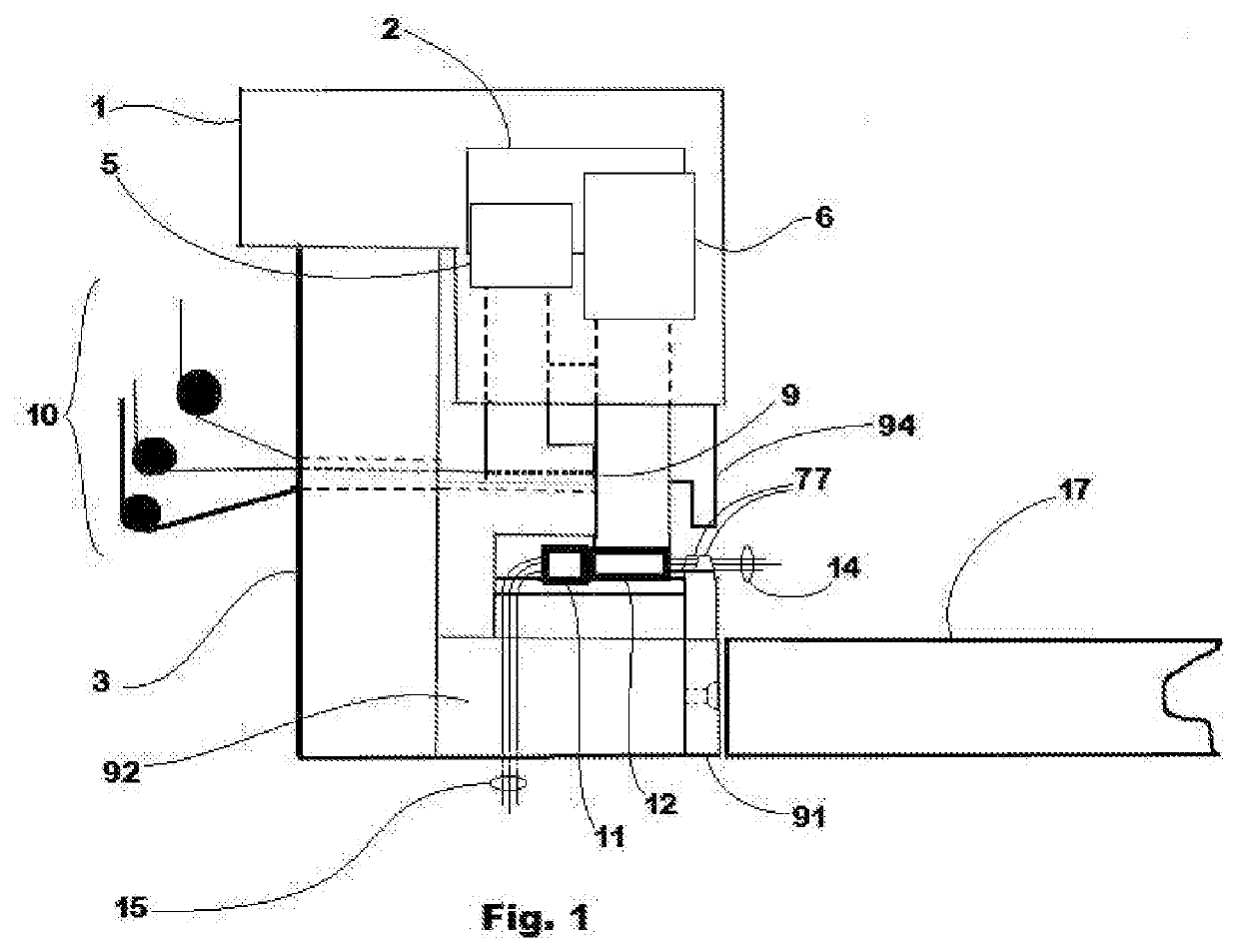

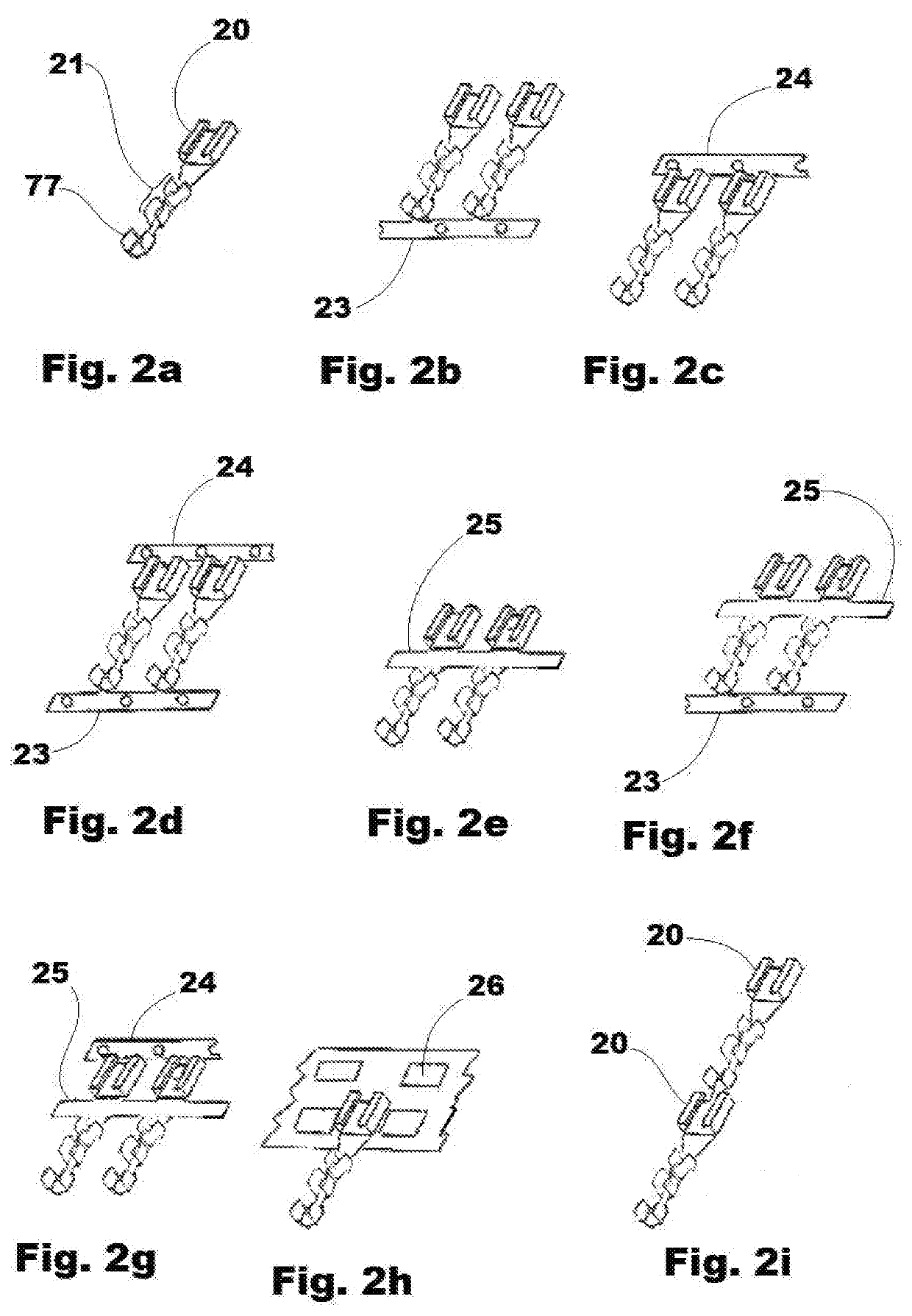

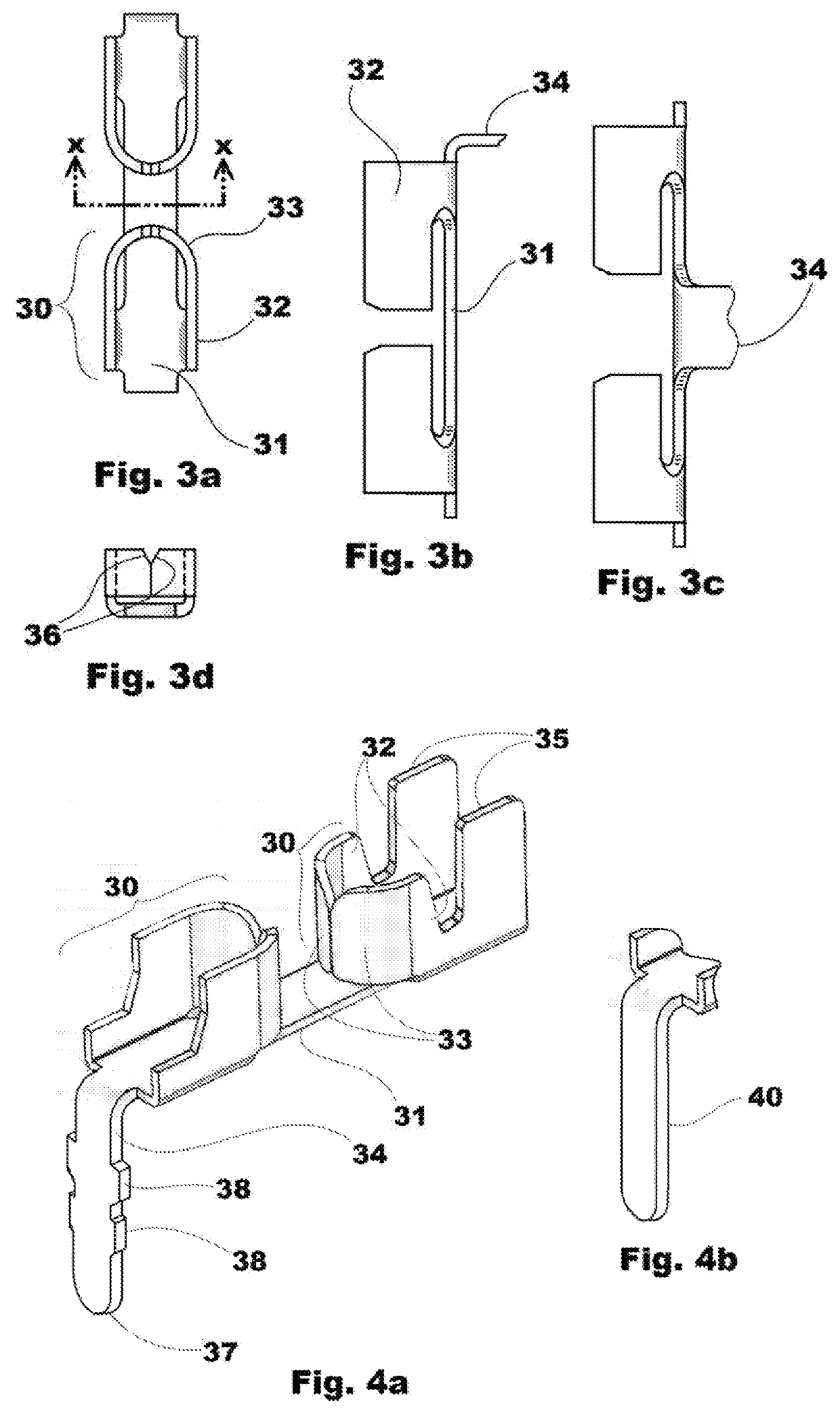

Insulation displacement termination (IDT) for applying multiple electrical wire gauge sizes simultaneously or individually to electrical connectors, stamped and formed strip terminal products, and assembly fixtures thereof

ActiveUS20200006868A1Simplification and savingCheapElectrically conductive connectionsCoupling device detailsElectrical connectionStructural engineering

An insulation displacement connector (IDC) includes clamping terminals or contacts which make two redundant contacts into the wires instated into them. The inventive contact comprises a flat strip section, four J-shaped cantilevers each having a straight section and an arcuate section, with a portion of each of said straight section attached to the flat strip section, and the cantilevers arranged into two pairs each having two arcuate sections curving towards each other to form a pincer section. The two pincer pairs face toward each other on the strip. A wire received into both pincer pairs is held securely because any tension applied to the wire forced at least one pincer set to clamp together harder on the wire. The inventive contacts reside in an insulator housing of an insulation displacement terminal (IDT) connector assembly which can accept wires of mixed sizes.

Owner:TILLOTSON JR JOHN D

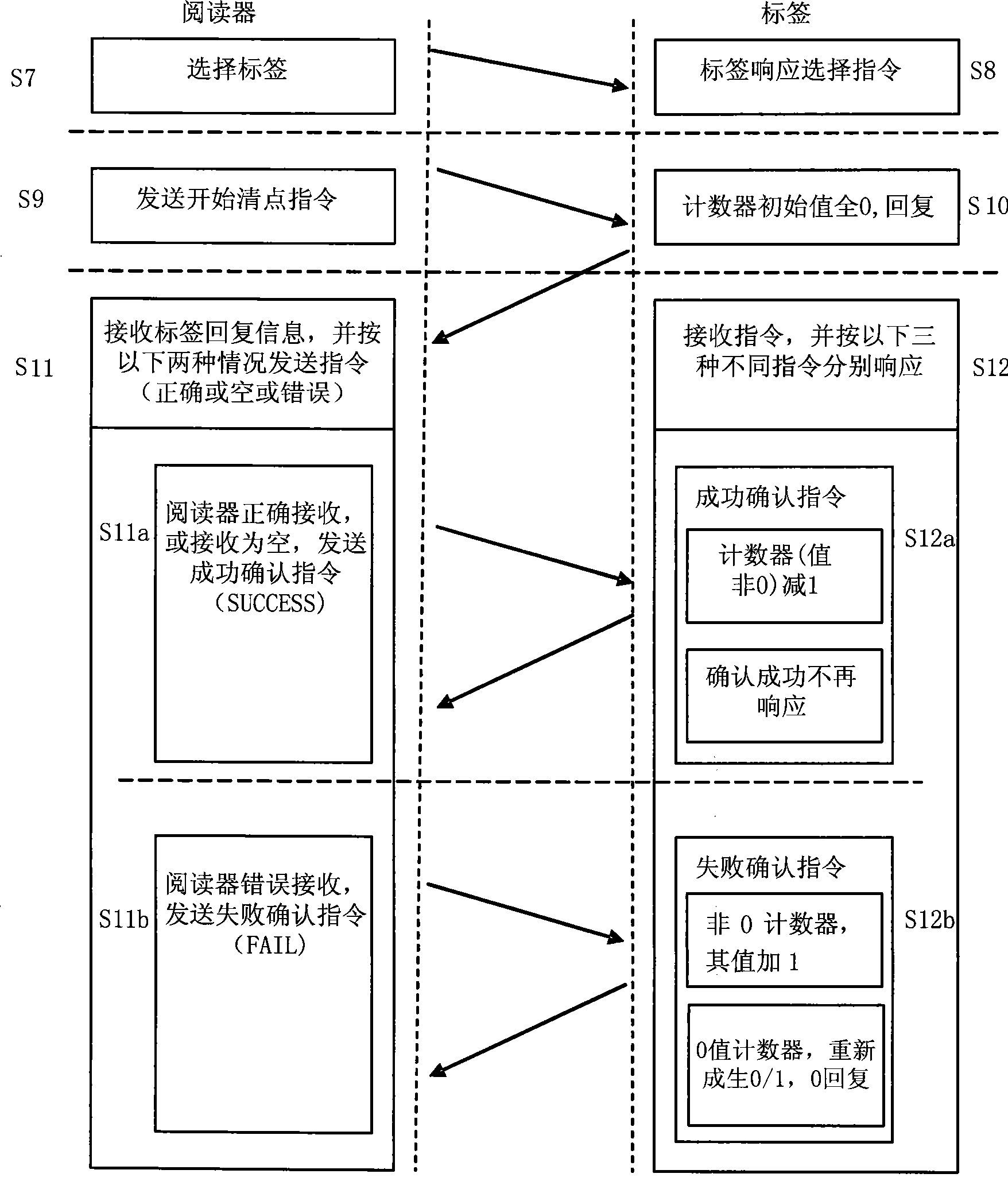

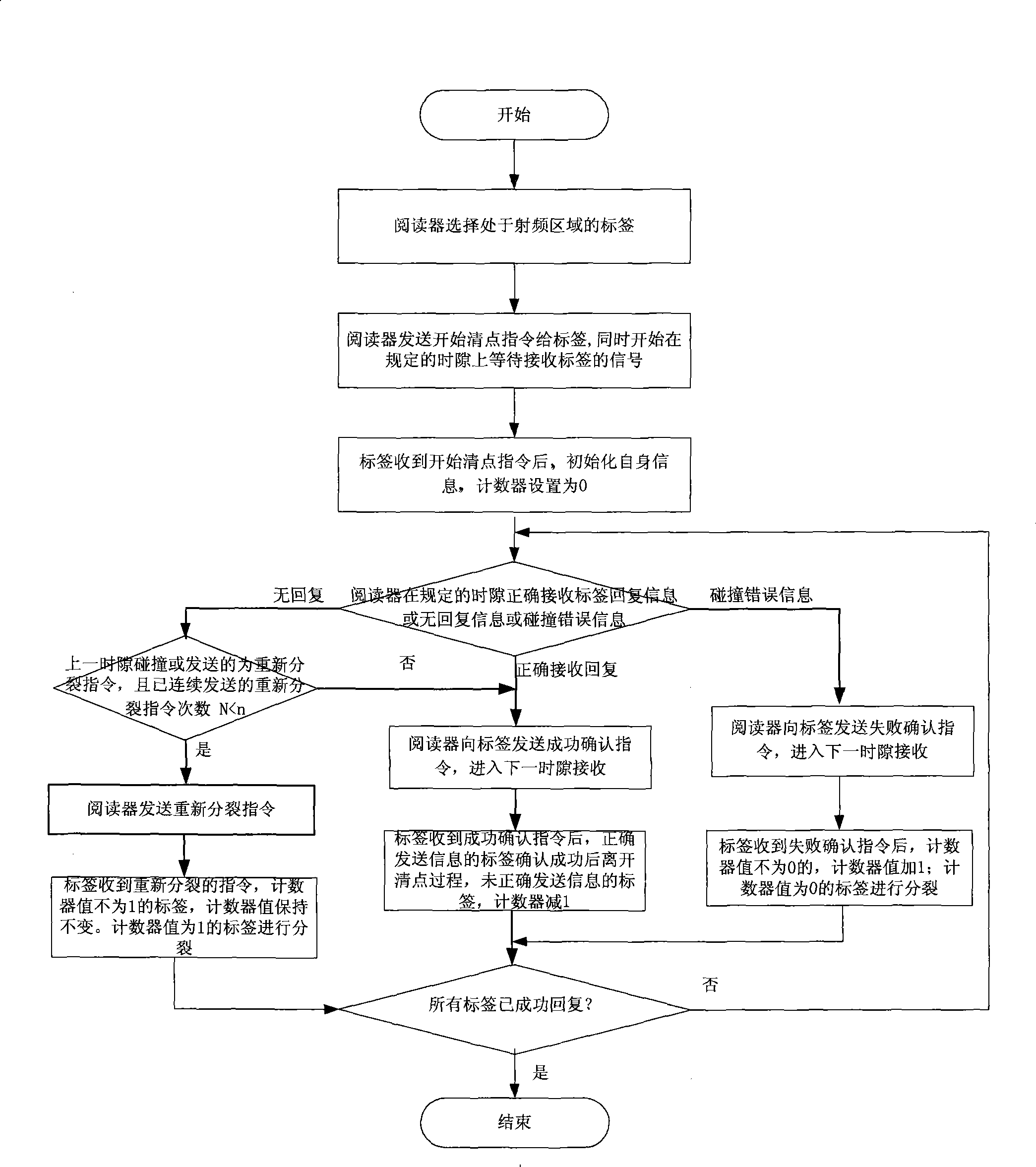

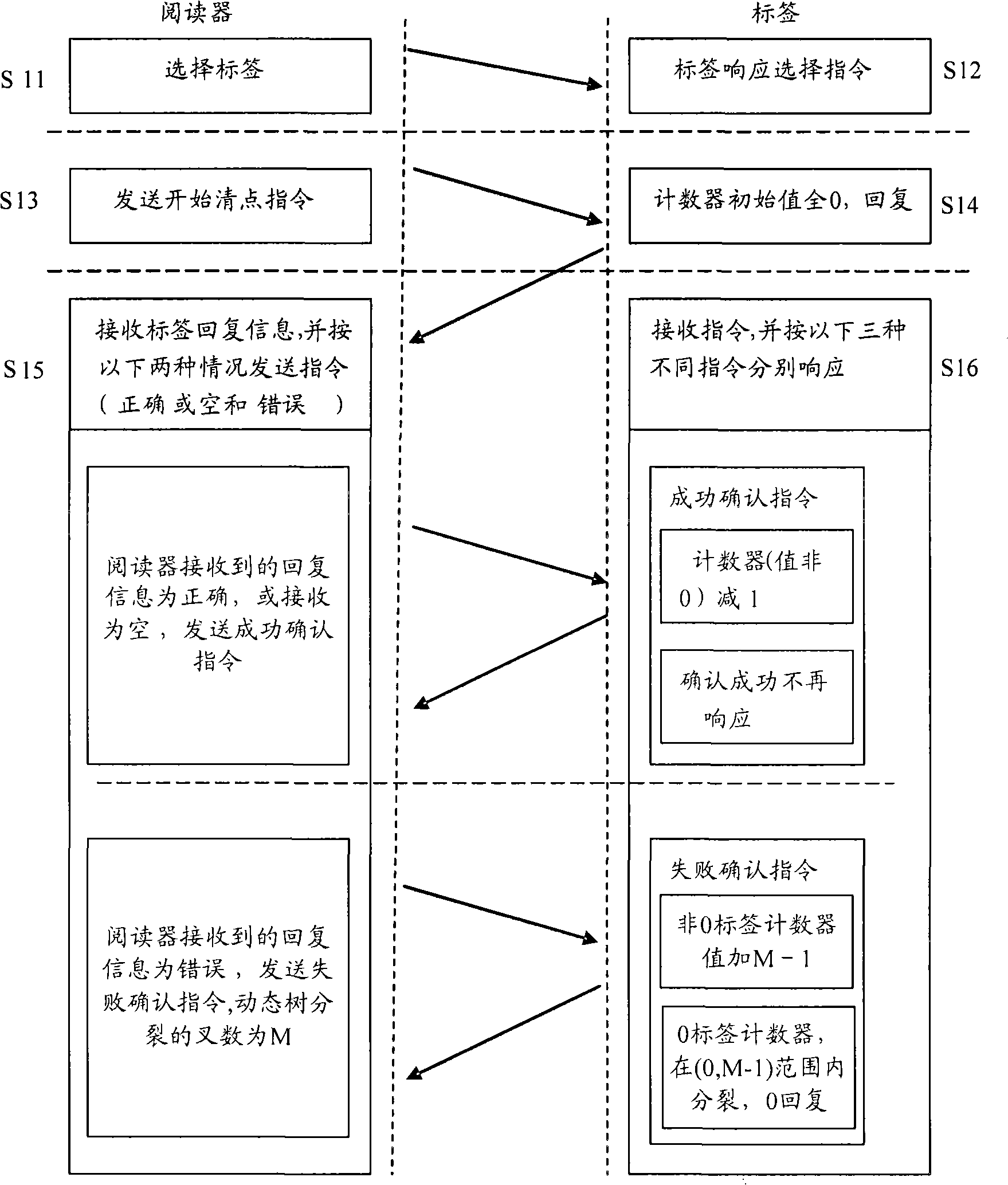

Multiple-label anti-collision method for radio frequency recognition

ActiveCN101441699AOptimize inventory processImprove inventory efficiencyMemory record carrier reading problemsComputer hardwareRadio frequency

The invention discloses a method for anti-collision of multi-tags of radio frequency identification, which comprises the following steps: (a) a reader counts tags; (b) after receiving a command for beginning to count, the counter is set to be 0 and the tag replies to the reader; and (c) if correctly receiving the reply information of the tags, the reader sends a success confirmation instruction, the tags which correctly reply information exit from the counting process, and the counter value of the tags which do not correctly reply information subtracts 1; if the reader incorrectly receives the reply information of the tags, the reader sends a failure confirmation instruction, and the counter value of the tags, which is not 0, adds 1, and the tags with the counter value of 0 are divided; if the reader does not receive the reply information of the tags and incorrectly receives the return information of the tags at the last time slot, the reader sends a re-dividing instruction to the tags, the counter value of the tags, which is not 1, is remained, and the tags with the counter value of 1 are divided; and (d) the tags with the counter value of 0 reply to the reader, and the step (c) is carried out. The method improves counting efficiency of the multi-tags.

Owner:ZTE INTELLIGENT IOT TECH

RFID rapid inventory method

InactiveCN107992919AShorten inventory timeImprove real-time operationCoin-freed apparatus detailsCo-operative working arrangementsData informationLabeled data

The invention relates to an intelligent vending machine technology and provides an RFID rapid inventory method to solve the problems that when there are many goods in a vending system at present, a main controller needs to perform duplication eliminating processing in a large amount of label data, which increases the amount of data transmitted and processed by the system, prolongs the inventory time of the vending system and reduces operation real-time performance of the vending system. The main points of the technical scheme are that the main controller detects door opening / closing signals atevery moment; if a door opening signal and a door closing signal are detected once within the specified time, name call information is sequentially sent to a sending point of each electronic tag oneby one according to an electronic tag list stored in a local database; if response information of all the electronic tags is received, no processing is performed, otherwise it is recorded that goods corresponding to the electronic tags which do not respond to the information have been sold out, and then it is judged whether the data information of the electronic tag responding to the information is consistent with the data information of the electronic tag corresponding to broadcast. If the data information of the electronic tag responding to the information is consistent with the data information of the electronic tag corresponding to broadcast, the electronic tag list stored in the local database is updated.

Owner:四川长虹技佳精工有限公司

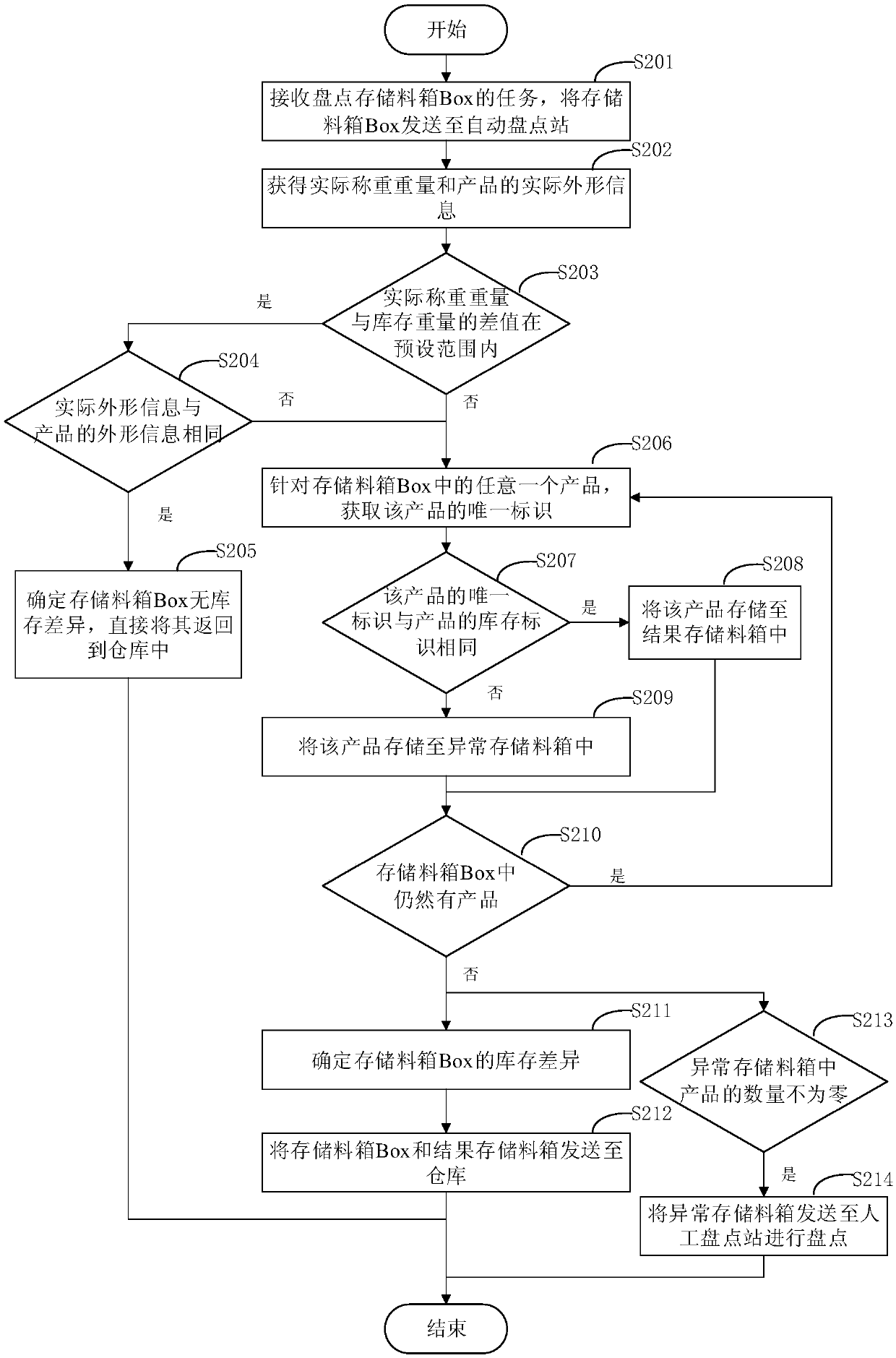

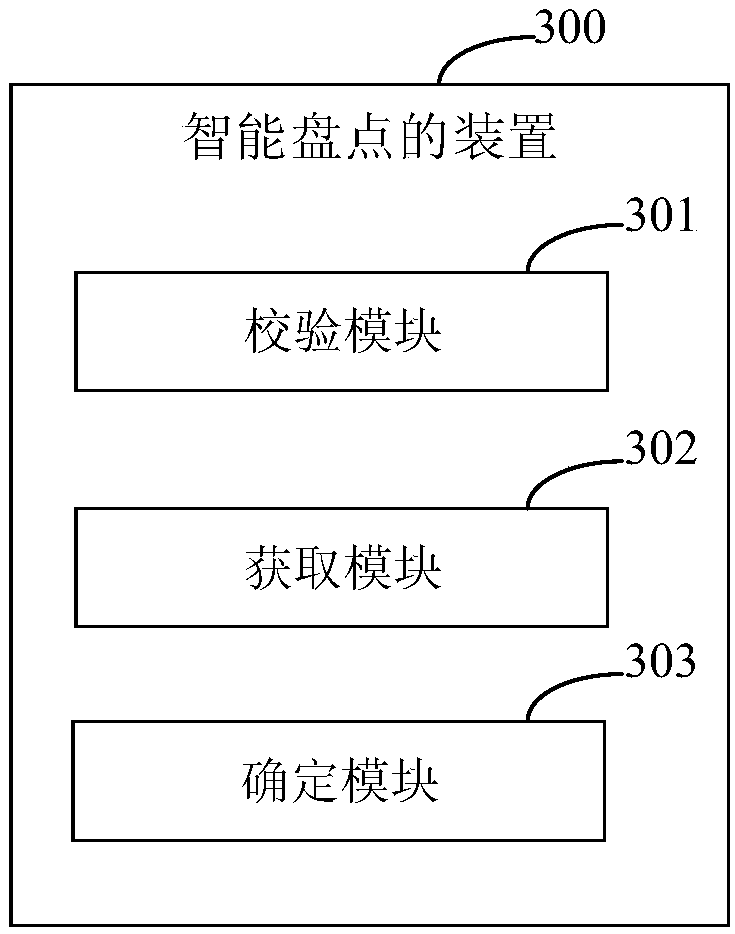

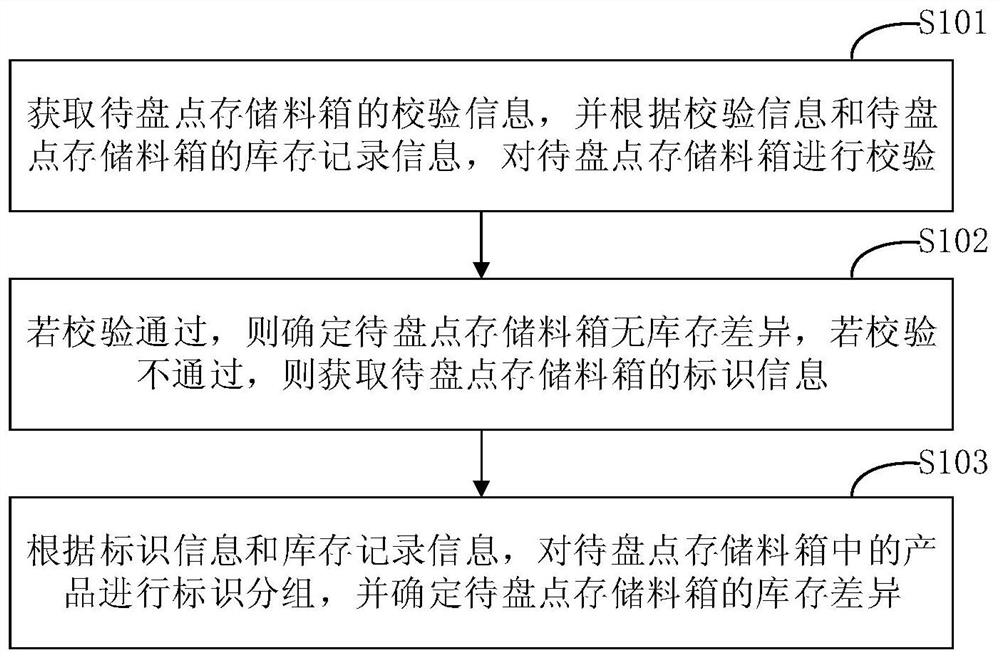

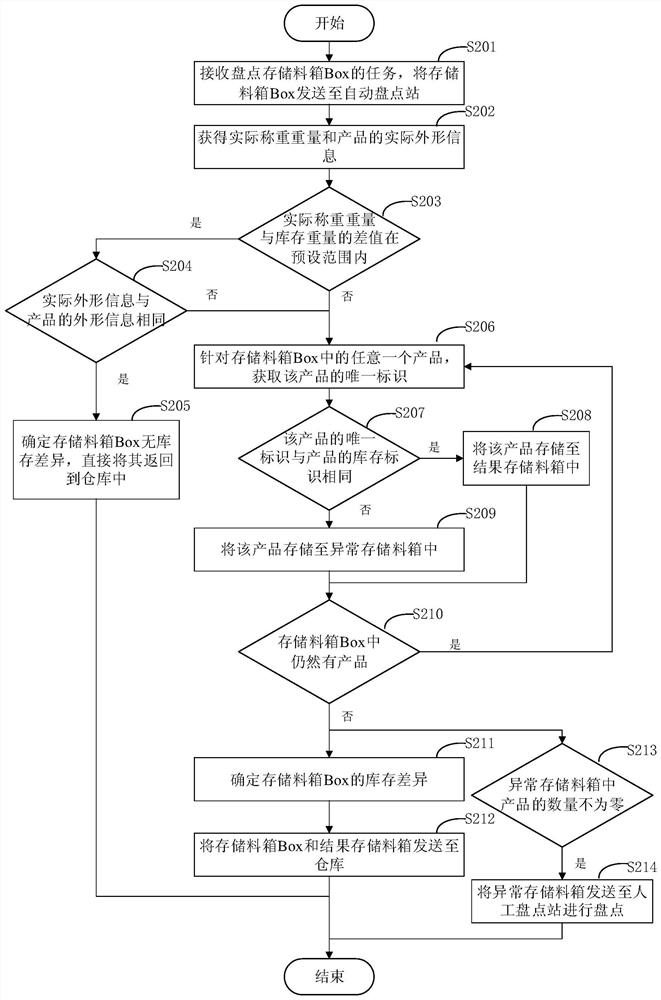

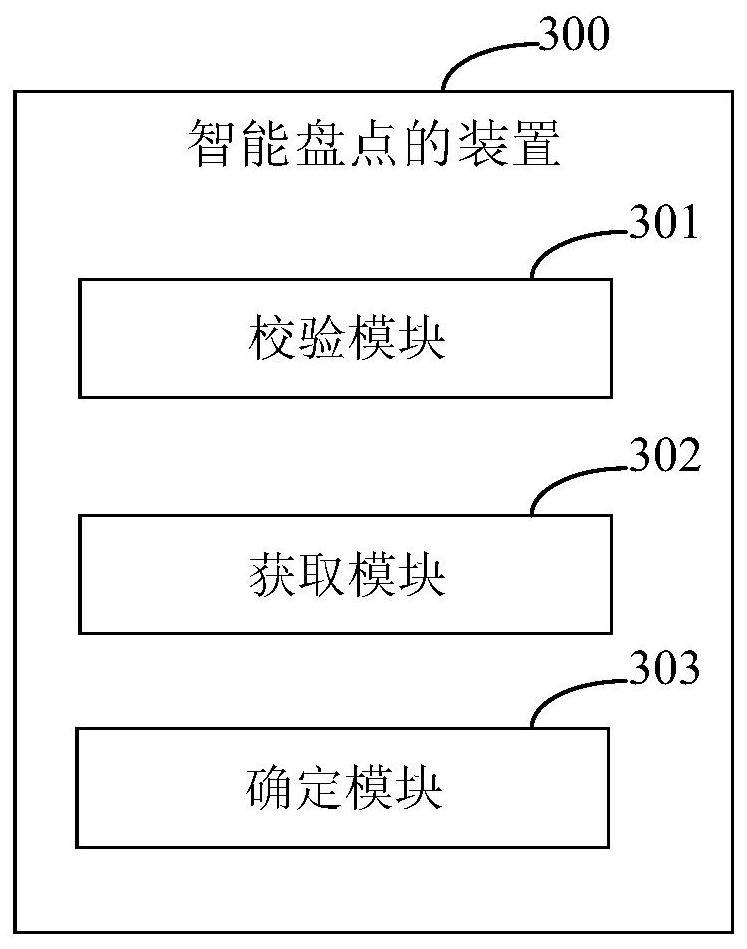

Method and device of automatic check

ActiveCN110371560ARealize automated inventoryAvoid time costStorage devicesNO storageSoftware engineering

The invention discloses a method and device of automatic check, and relates to the technical field of computers. One specific embodiment of the method comprises the steps of acquiring the check information of a storage material box to be checked, and checking the storage material box to be checked according to the check information and the storage record information of the storage material box tobe checked; determining that the storage material box to be checked has no storage difference if the storage material box to be checked passes the check, and acquiring the identification information of the storage material box to be checked if the storage material box to be checked does not pass the check; and carrying out identification grouping on the products in the storage material box to be checked, and determining the storage difference of the storage material box to be checked according to the identification information and the storage record information. With the embodiment of the method of automatic check, the storage material box to be checked can be checked and subjected to identification grouping according to the acquired check information, identification information and storage record information, then the storage difference can be determined, the storage material box to be checked can be automatically checked, and the time cost and labor cost are reduced.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

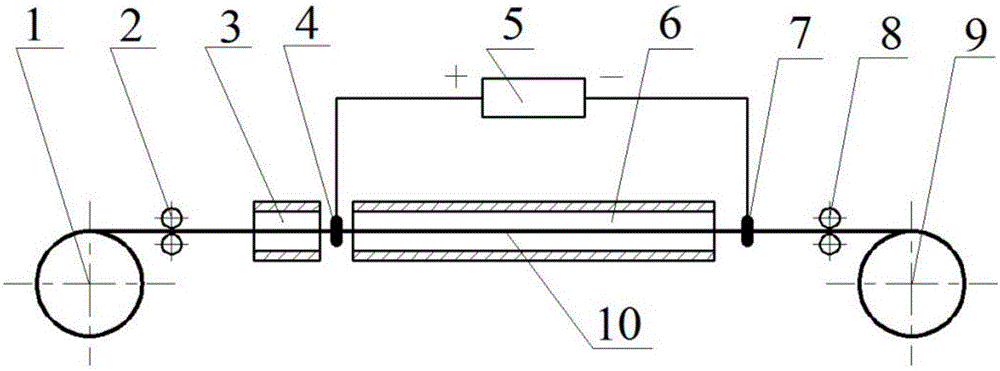

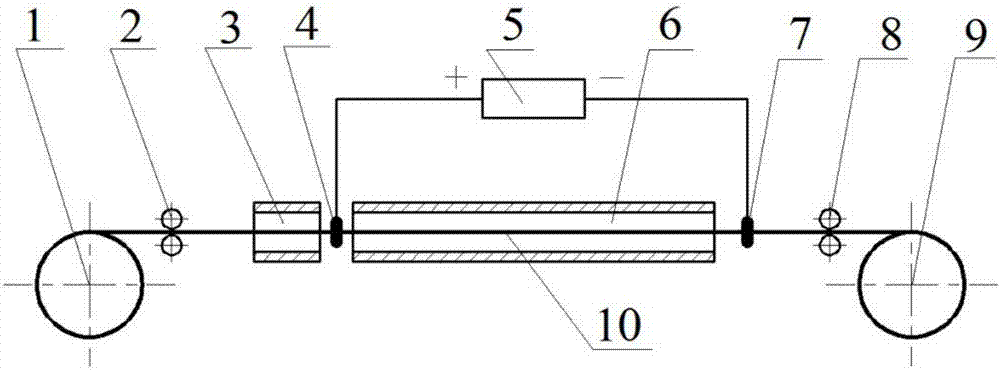

Device for realizing aging of hard wire coiled rod by applying pulse current and treatment method

InactiveCN105779753AQuickly achieve timelinessShorten inventory timeFurnace typesHeat treatment furnacesPulse power supplyMechanical property

A device for realizing aging of a hard wire coiled rod by applying pulse current and a treatment method belong to the technical field of wire material production and wire product preparation. The device mainly consists of a pulse power supply, a tubular preheating furnace, a tubular soaking pit, an uncoiling device, a pinch roller, a guide roller, a coiling device and an electrode. Atom diffusion and dislocation movement is promoted by an external field technology, that is pulse current. Structural defects of materials, produced in rolling and cooling processes, are improved through controlling the density (50-300A / mm<2>) and the frequency (20-80Hz) of pulse current in the coiled rod and combining the soaking effect of the tubular soaking pit, and mechanical properties are improved, so that the aging of the hard wire coiled rod is realized. The device and the treatment method have the advantages that aging treatment time is short, the effect is remarkable, warehousing time required by natural aging can be shortened, and enterprise circulating fund pressure is relieved.

Owner:UNIV OF SCI & TECH BEIJING

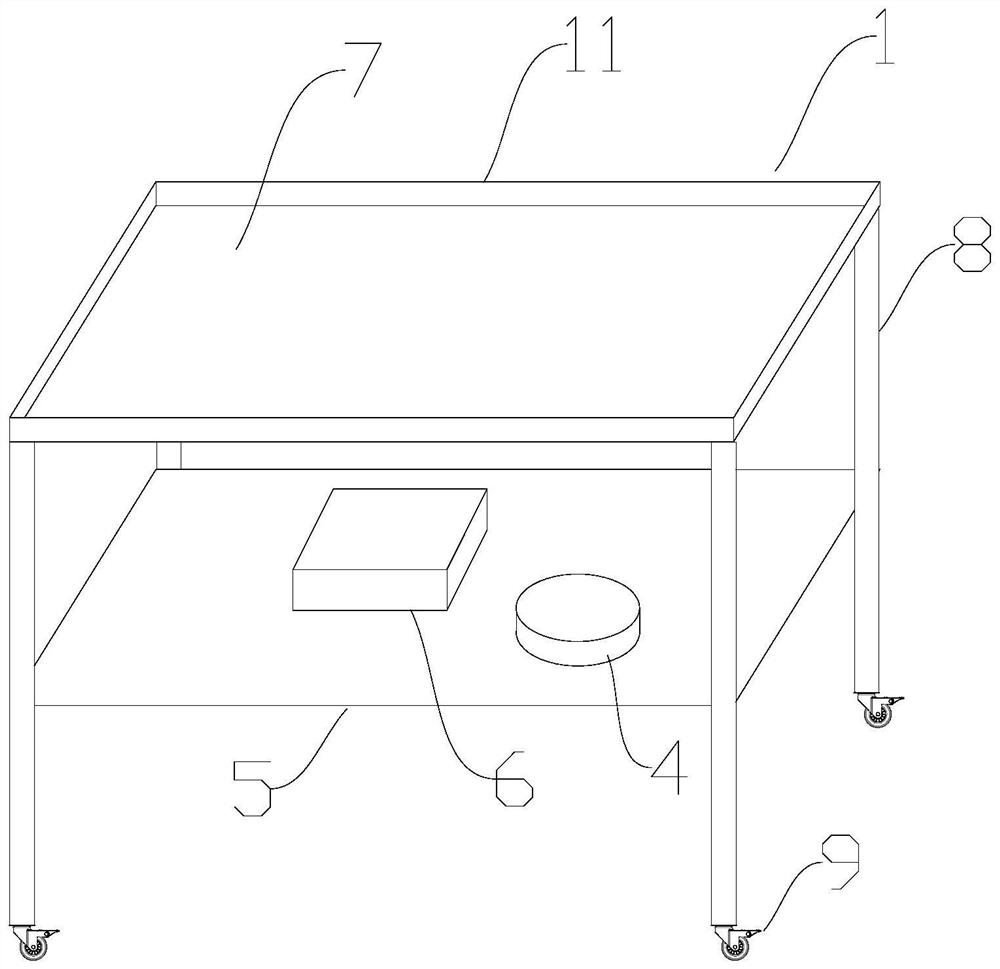

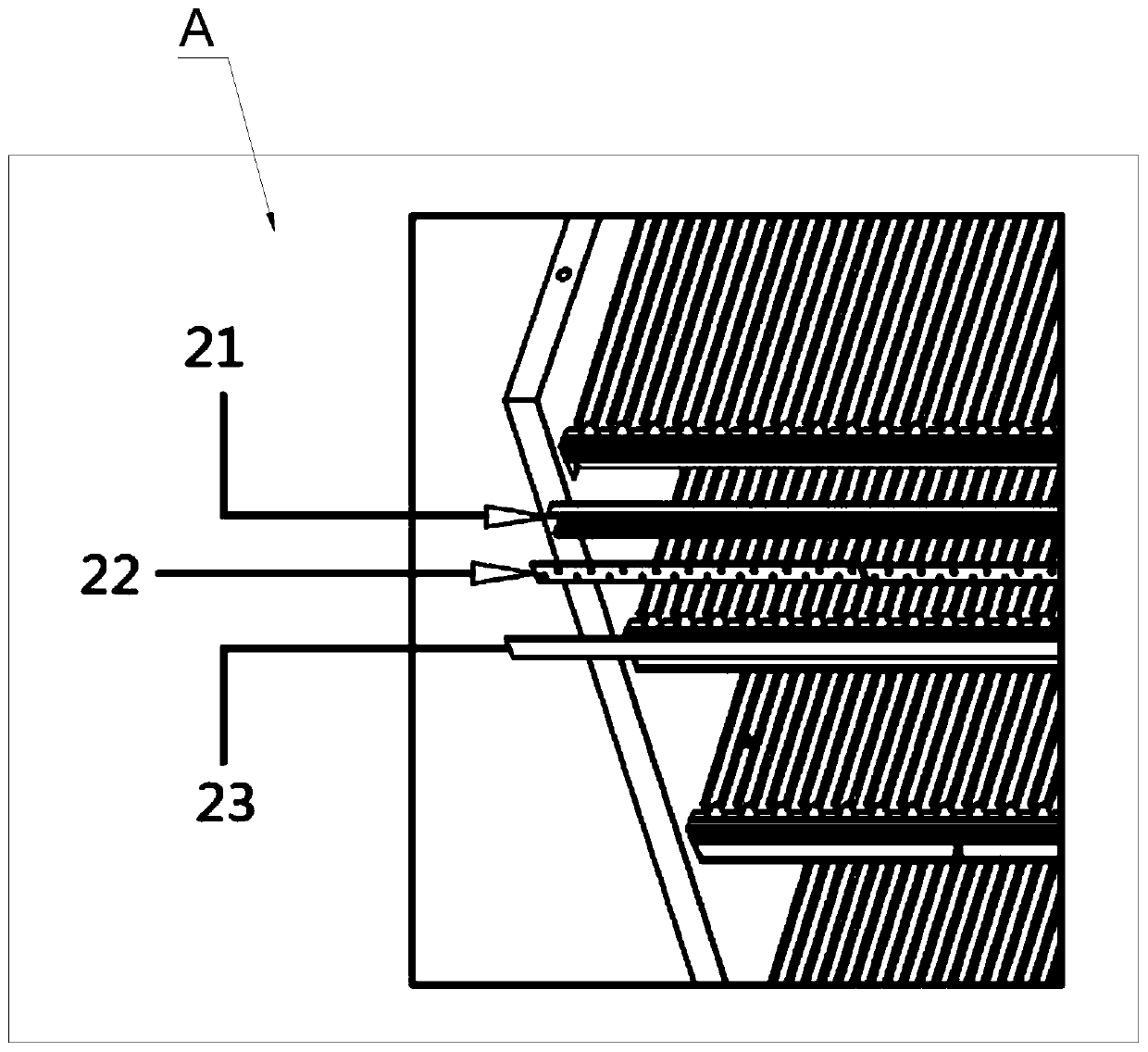

Electronic surgical instrument counting table and counting system

InactiveCN111603248AImprove inventory efficiencyQuick inventorySurgical furnitureDiagnosticsInformation processingEngineering

The invention provides an electronic surgical instrument counting table and relates to the technical field of medical assistance. The electronic surgical instrument counting table comprises a countingtable body, and RFID readers, a communication module and a power supply module which are arranged on the counting table body, wherein the power supply module is electrically connected with the RFID reader and the communication module; the communication module is in communication connection with the RFID reader; the counting table body comprises at least one instrument storage plate; and a plurality of RFID readers are arranged on the instrument storage plate. The invention further provides an electronic surgical instrument counting system, which comprises an electronic surgical instrument counting table, a surgical instrument and an information processing terminal. The information processing terminal is in communication connection with the communication module. The system has the following beneficial effects that: the accuracy of instrument counting is obviously improved, the instrument counting time is obviously shortened, the accuracy of instrument integrity inspection is much higher than that of existing manual naked eye inspection, the safety protection performance of surgical instruments is greatly improved, and the safety of a surgical patient in the perioperative period iseffectively guaranteed.

Owner:LONGHUA HOSPITAL SHANGHAI UNIV OF TRADITIONAL CHINESE MEDICINE

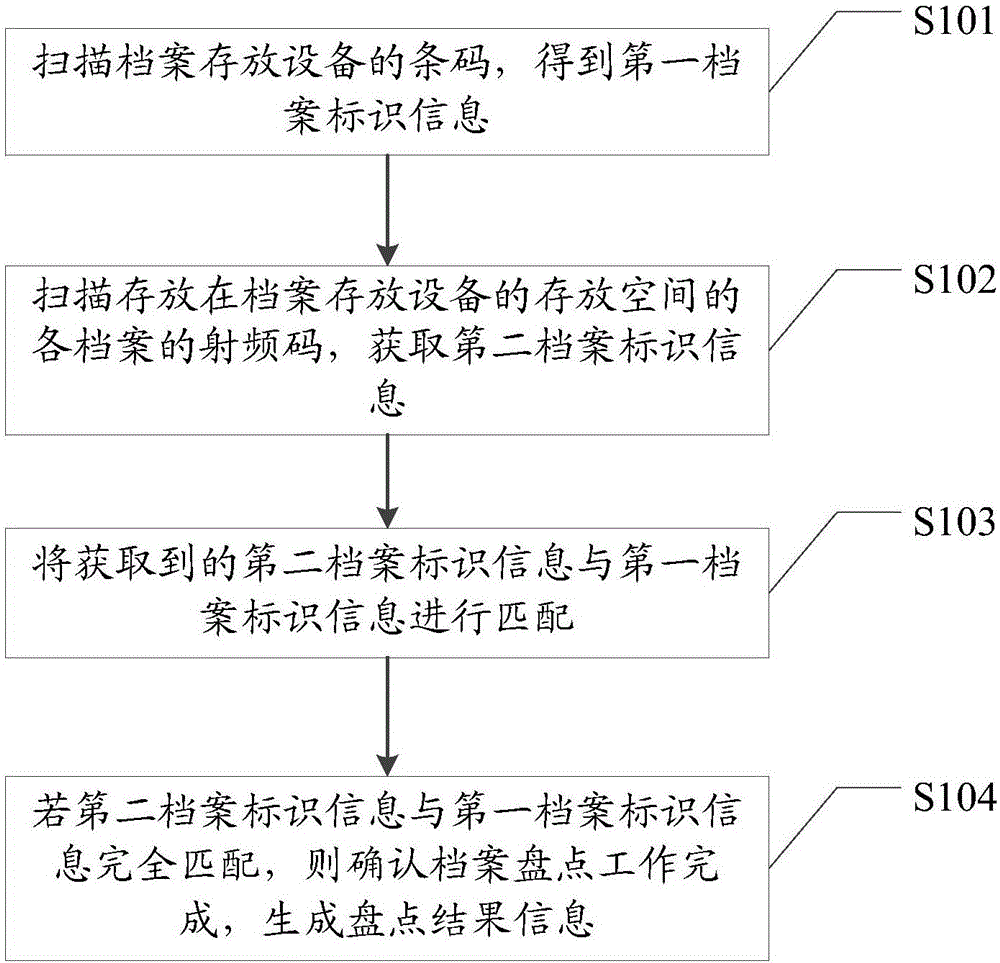

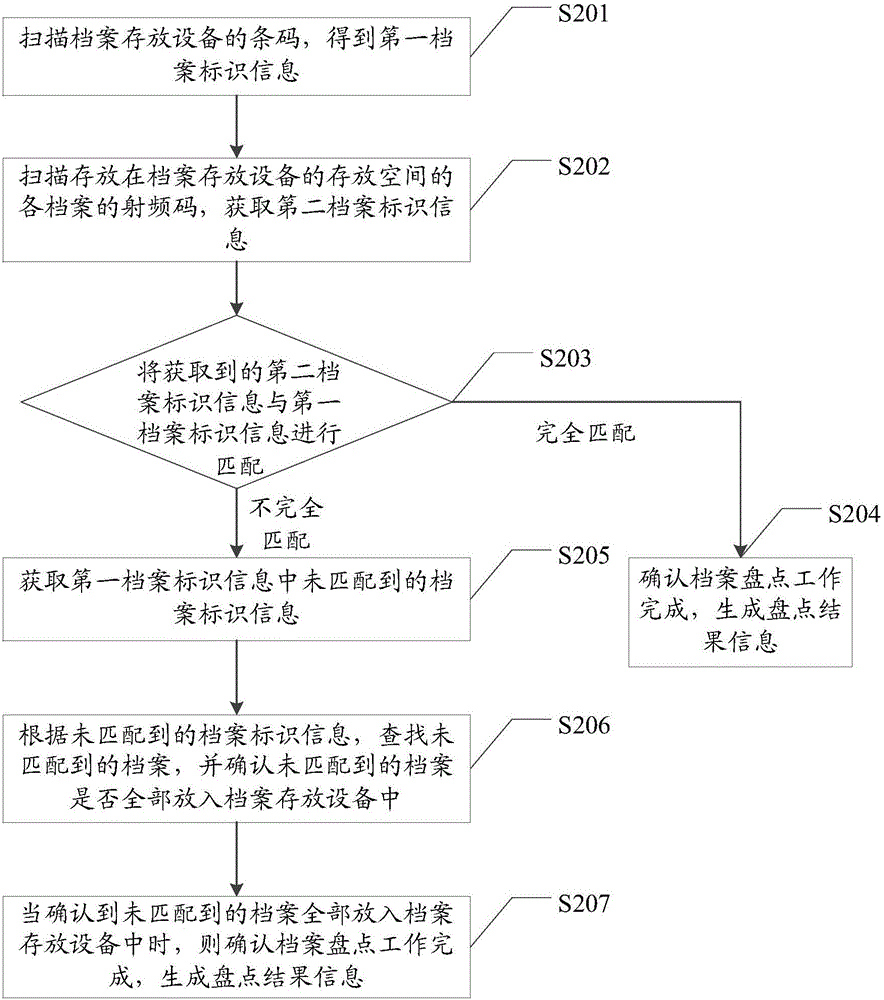

File checking method, apparatus, and system

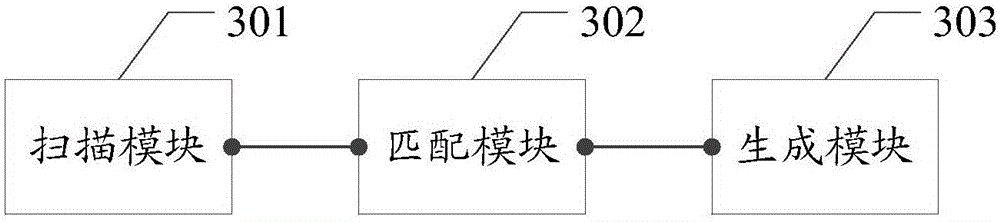

PendingCN106372695AShorten inventory timeImprove inventory efficiencyCo-operative working arrangementsRadio frequencyDatabase

The embodiment of the invention, which is suitable of the technical field of communication, provides a file checking method, apparatus, and system. The method comprises: a bar code of a file storing device is scanned to obtain first file identifier information; radio-frequency codes of all files stored in storage space of the file storing device are scanned to obtain second file identifier information; matching of the obtained second file identifier information and the first file identifier information is carried out; and if complete matching is determined, file checking work is completed and checking result information is generated. Compared with the prior art, the method has the following advantages: files can be checked automatically by scanning the file storing device and the file bar codes and carrying out automatic matching, so that the file checking time is saved and the file checking efficiency is increased.

Owner:SHENZHEN SEA SKY LAND TECH

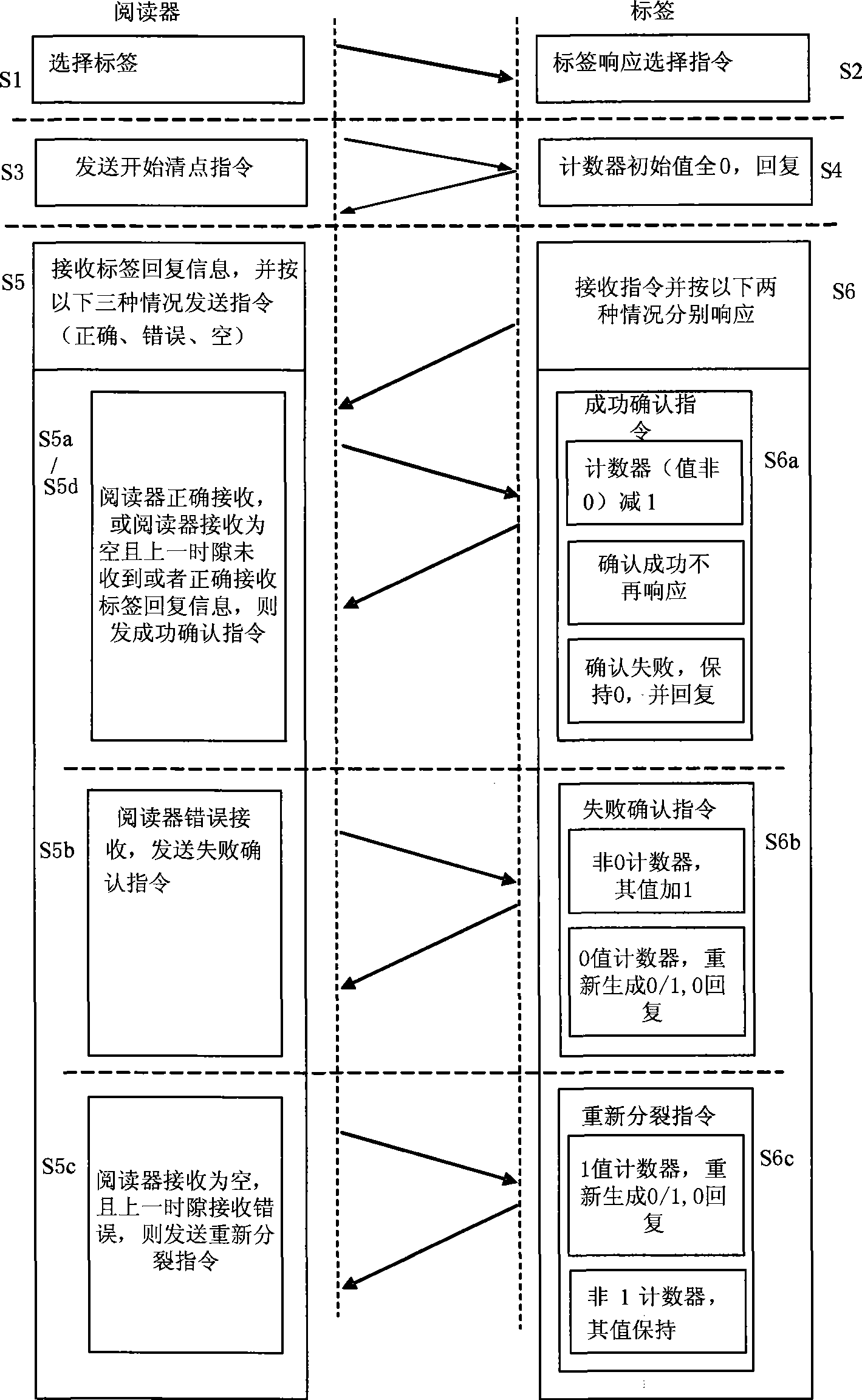

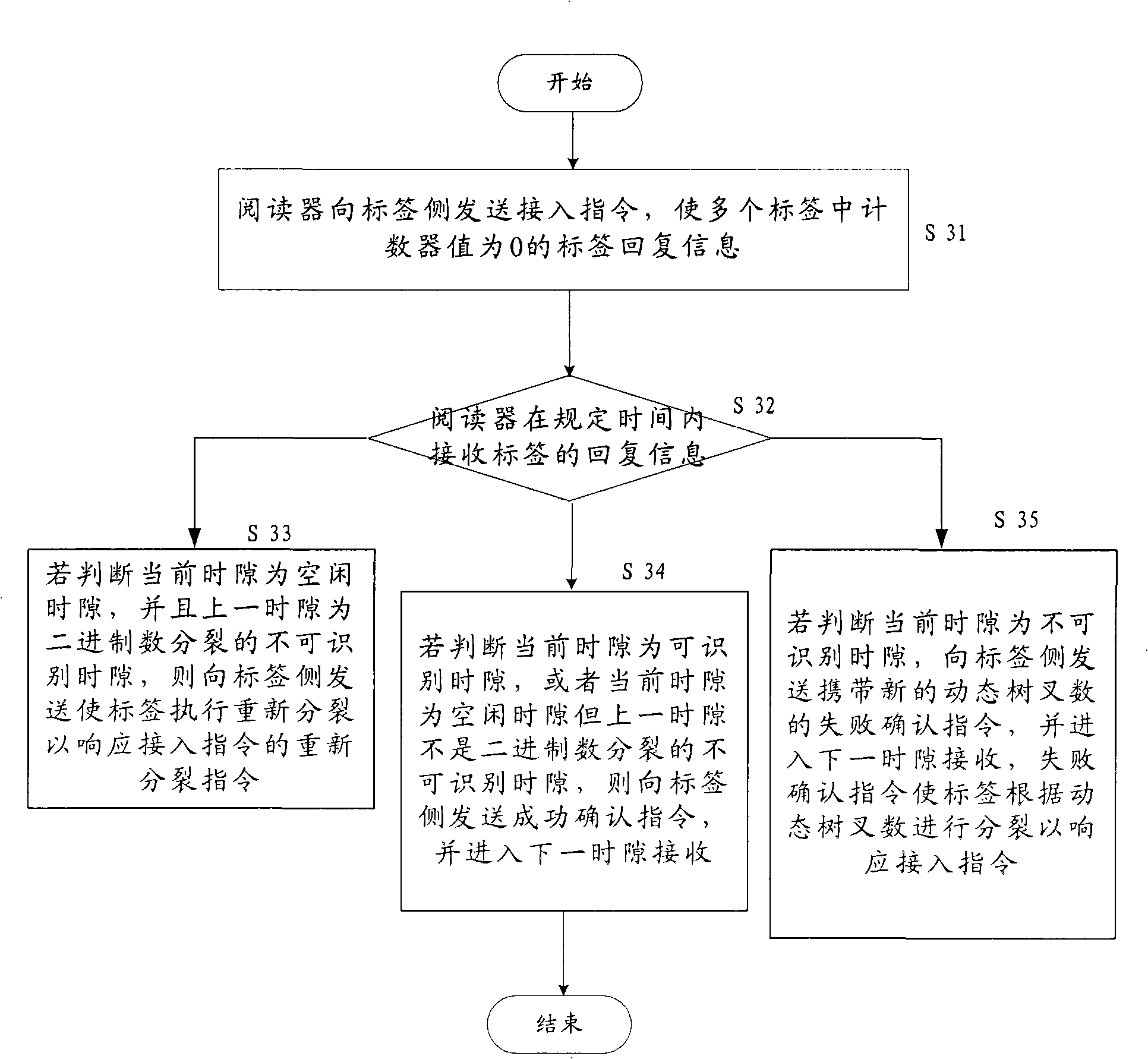

Radio frequency recognition system and its anticollision counting method

ActiveCN101286193ASolve wasteImprove inventory efficiencySensing record carriersRadio frequencyComputer science

The invention provides an anti-collision inventorying method used for radio frequency identification, comprising the following steps that: a reader sends an access command to the label side, thus allowing a plurality of labels with the counter value of 0 to reply information; the reader receives the replied information of the labels within the specified time, wherein, the anti-collision inventorying is carried out according to the received situation. The invention further provides a radio frequency identification system. The anti-collision inventorying method can effectively improve the inventorying efficiency of the labels.

Owner:ZTE INTELLIGENT IOT TECH

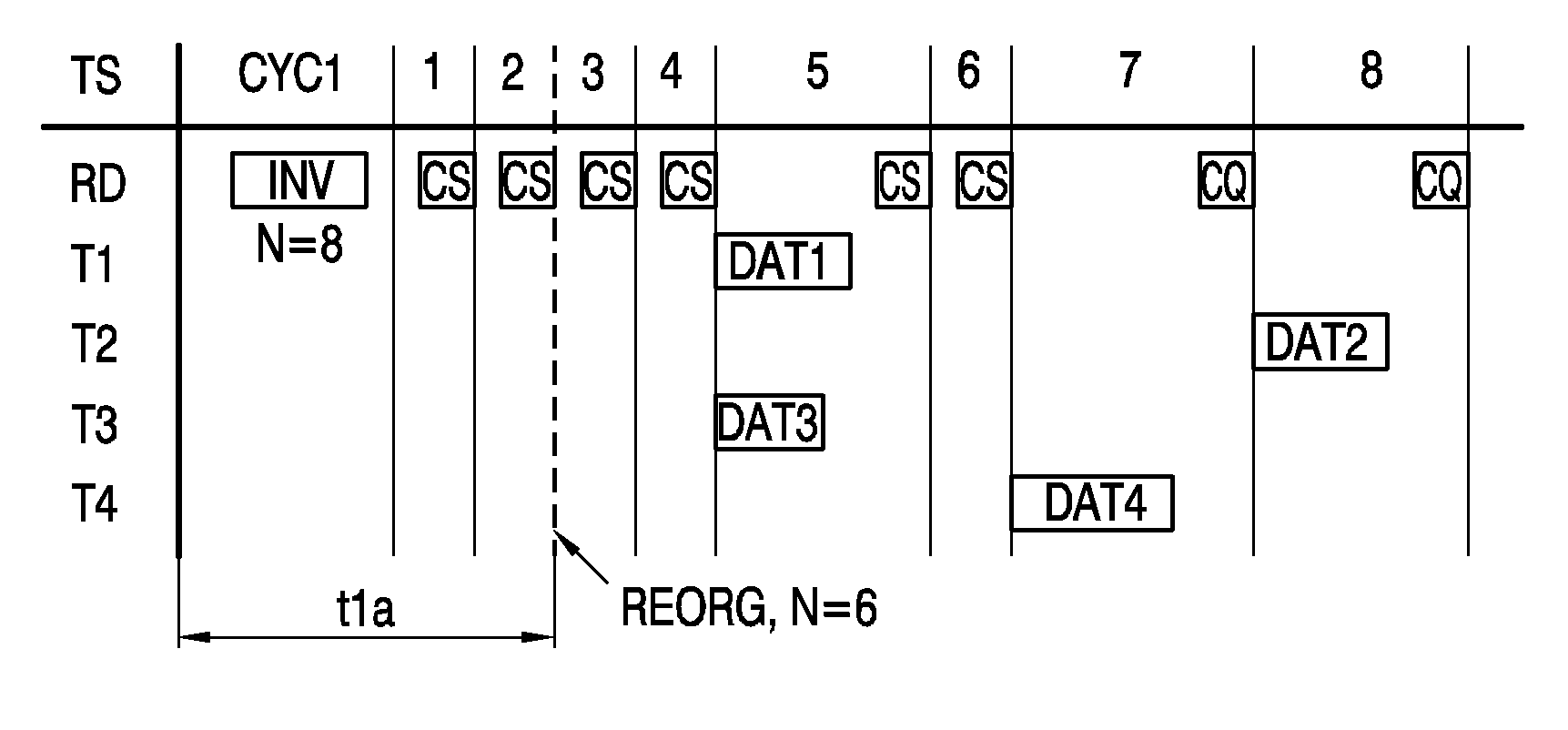

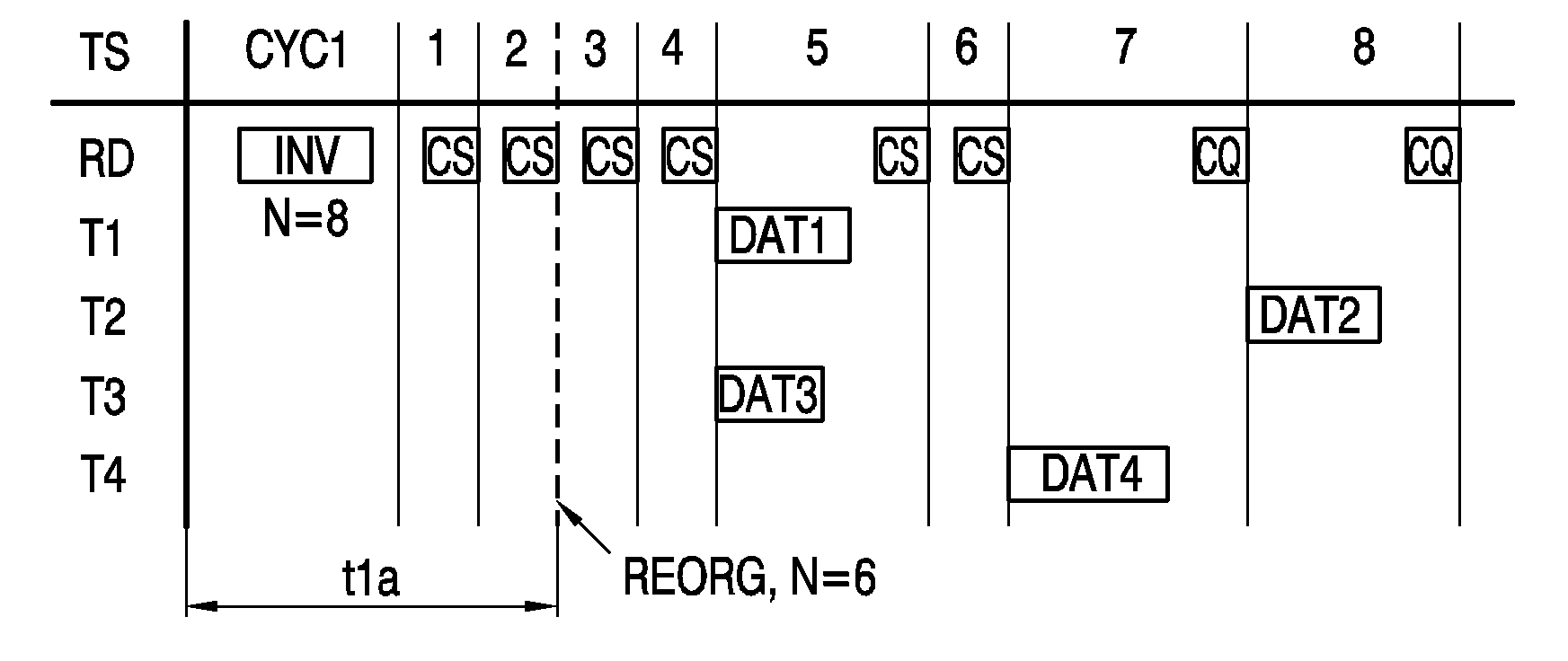

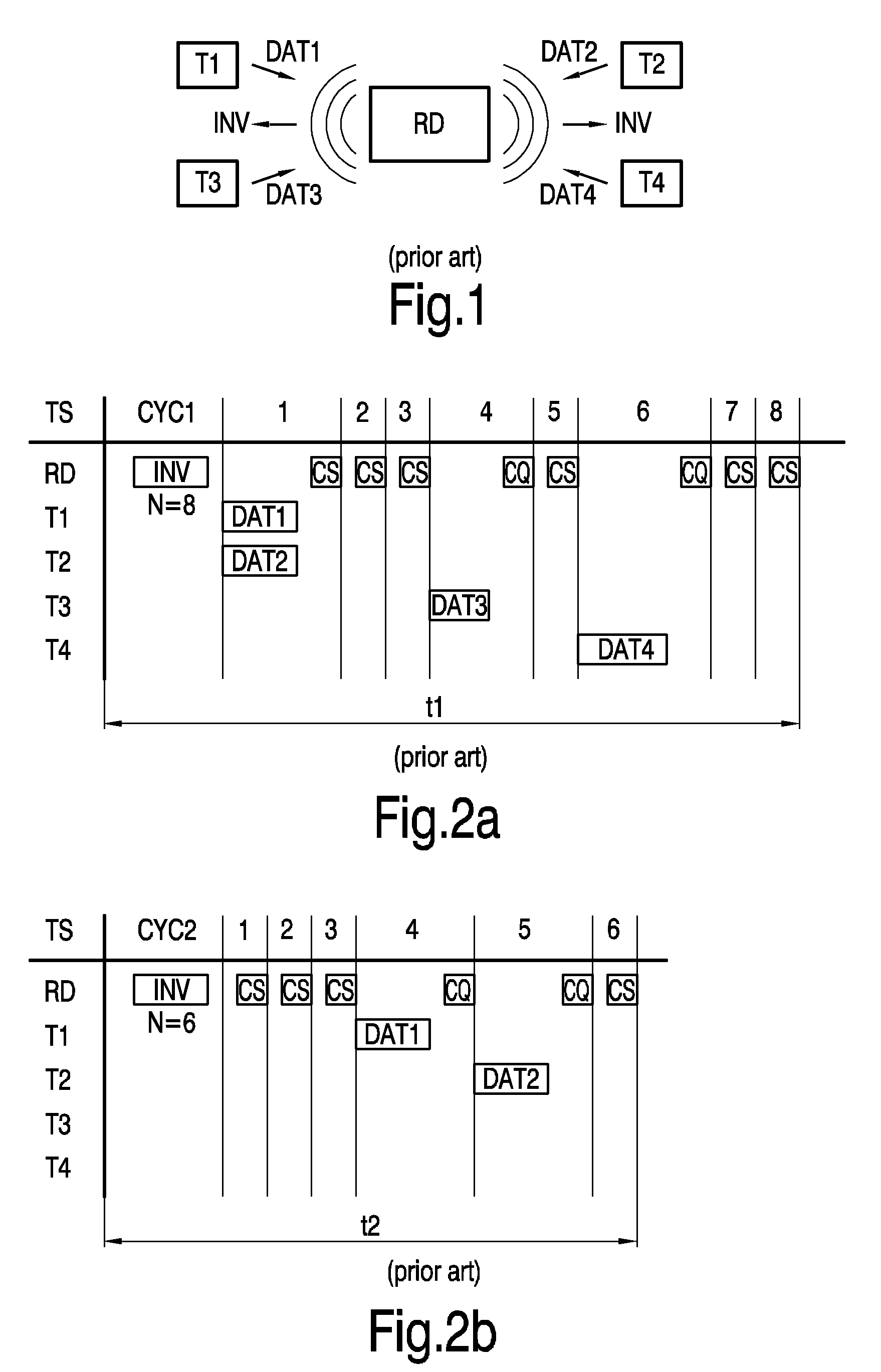

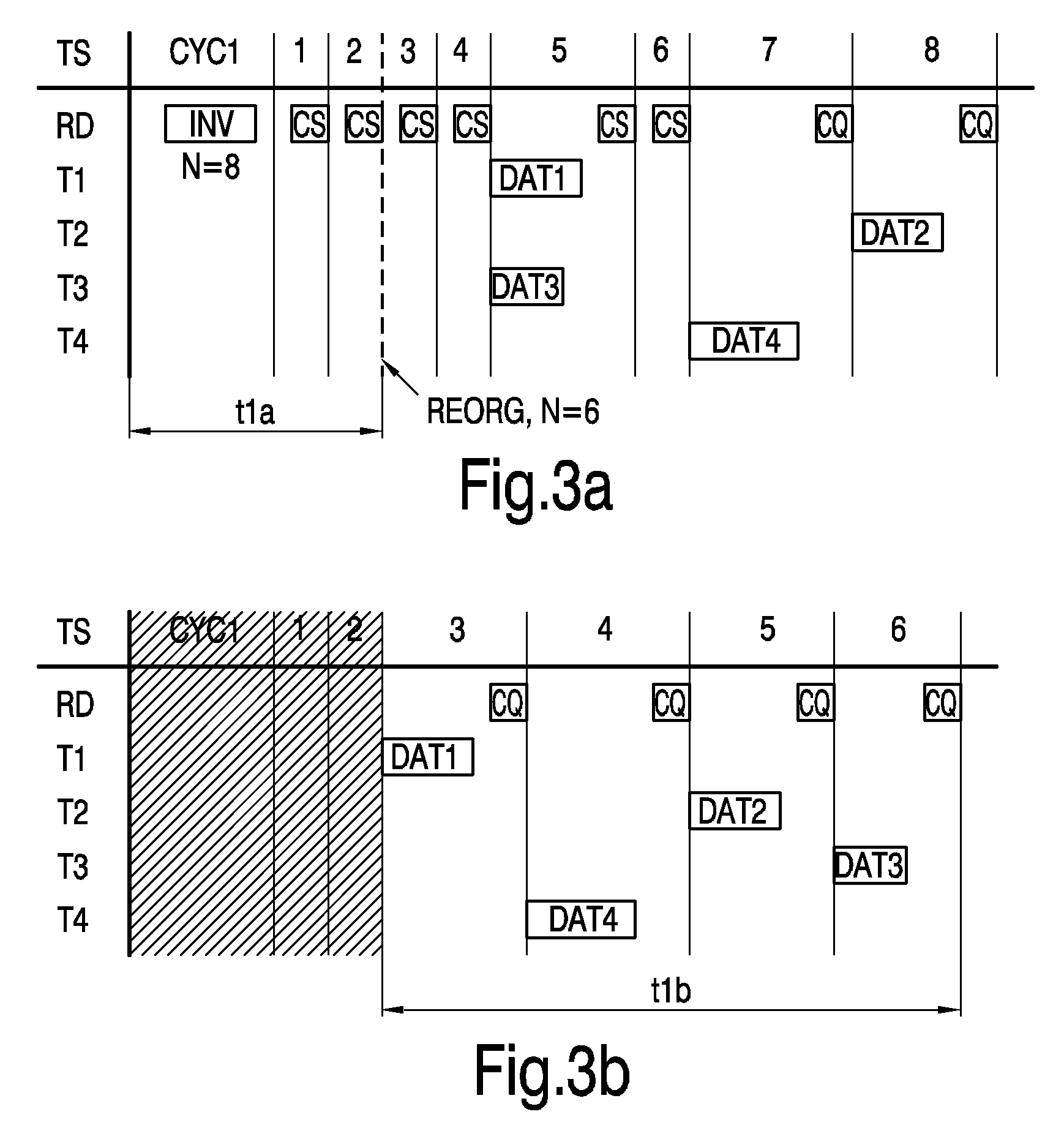

Method of Reading Data From Transponders Through a Reader, a Transponder, and a Reader

ActiveUS20080272891A1Reduce riskReduce probabilityMemory record carrier reading problemsTime-division multiplexHuman–computer interactionTransponder

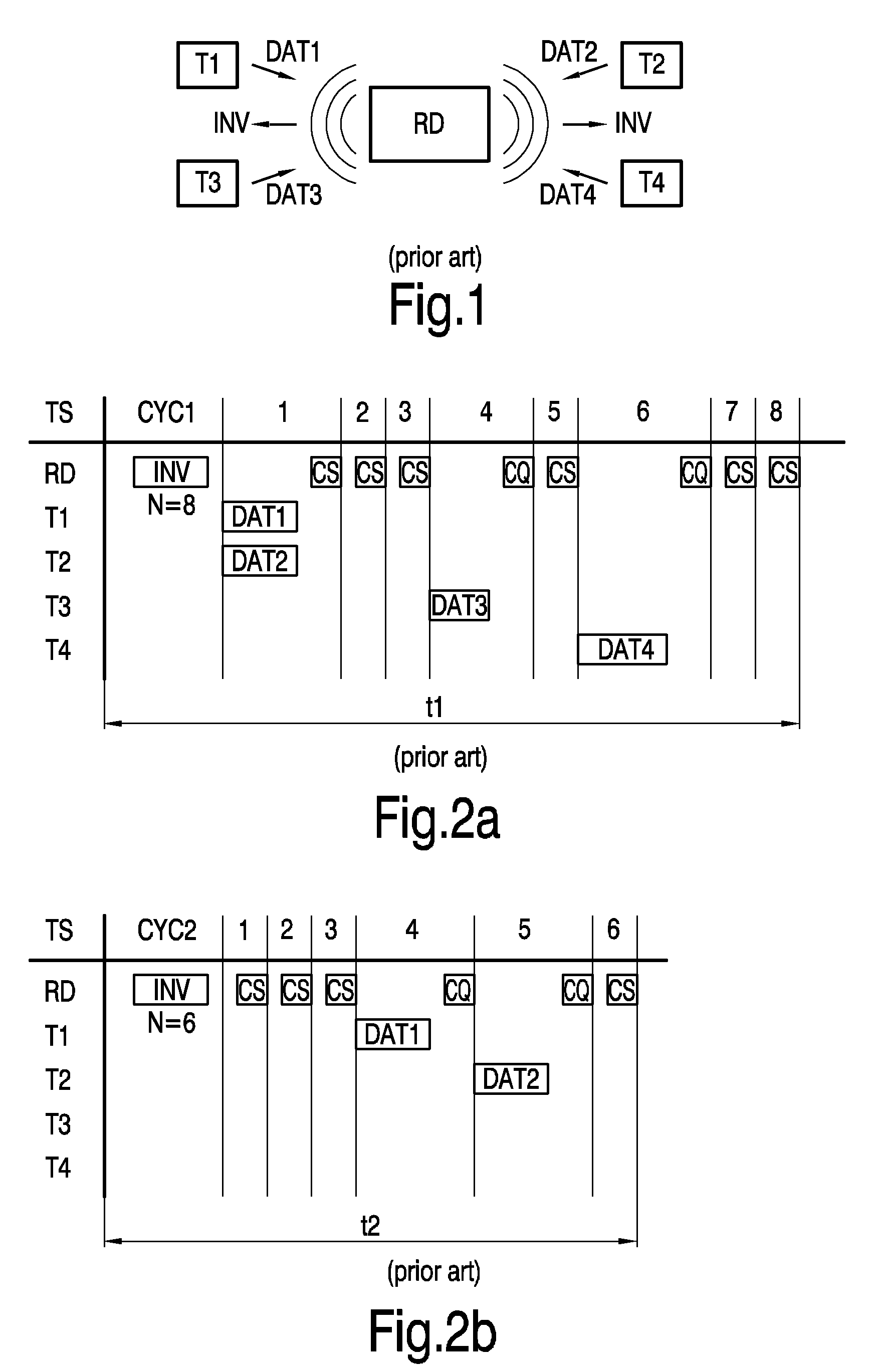

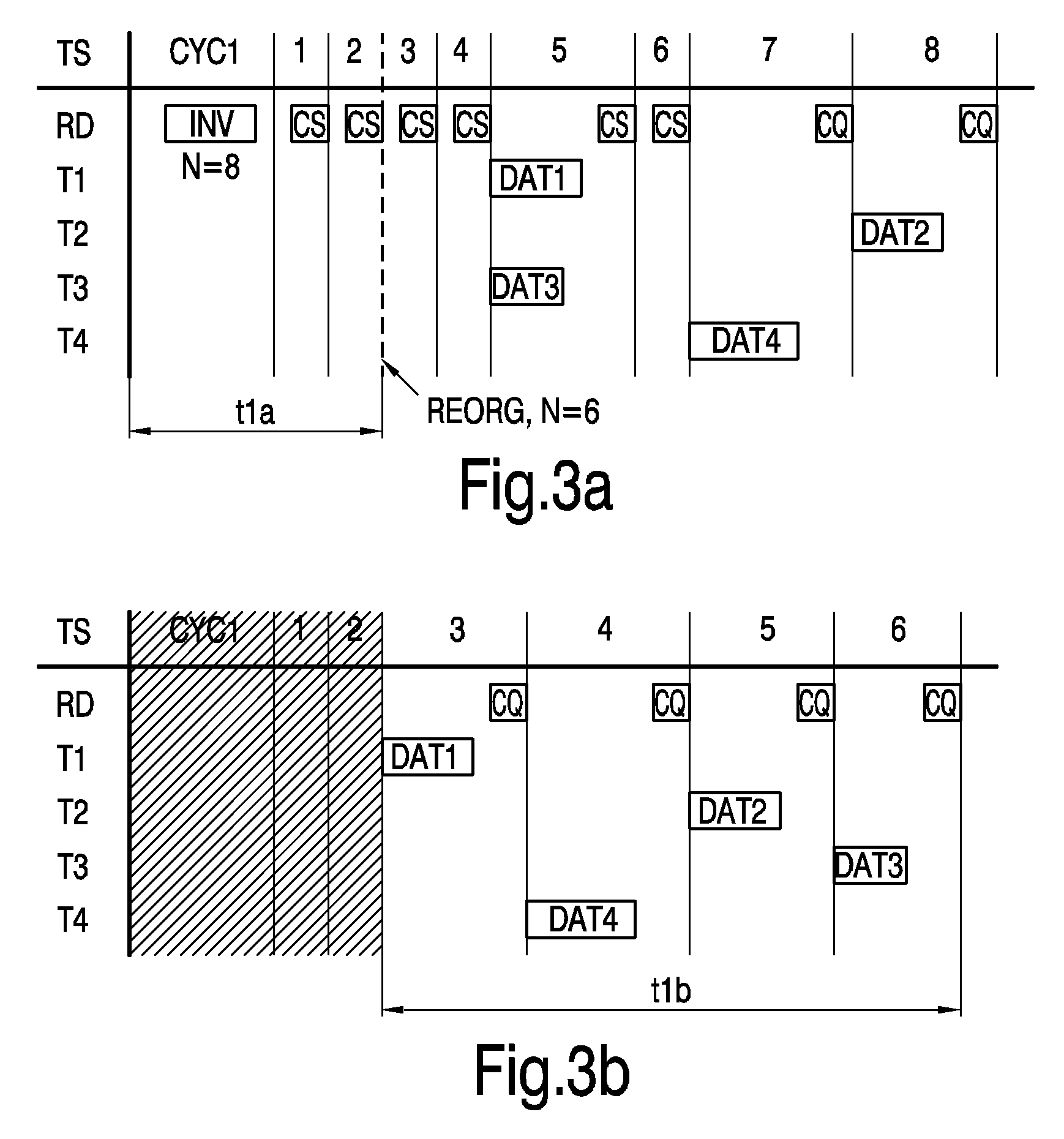

A method of reading data (DAT1 . . . DAT4) from transponders (T1 . . . T4) by means of a reader device (RD) during a number (N) of time slots (TS) is disclosed, wherein the seizure of said time slots (TS) by the transponders (T1 . . . T4) is observed in both the reader device (RD) and the transponders (T1 . . . T4). A reorganization (REORG) is performed in dependence on said seizure, wherein both the reader device (RD) and the transponders (T1 . . . T4) choose a new number (N) of time slots (TS). In addition, the transponders (T1 . . . T4) select one of the new time slots (TS) in which to send data (DAT1 . . . DAT4) back to the reader device (RD) so as to adapt the system's capacity to the real demands. Preferably, said reorganization (REORG) takes place without communication between the reader device (RD) and the transponders (T1 . . . T4). The invention further relates to a transponder (T1 . . . T4) and to a reader device (RD) for implementing the inventive method.

Owner:NXP BV

Signature card inventory device suitable for batch loading and throwing and inventory method thereof

PendingCN111652562AReal-time monitoring of flow conditionsInventory does not affectFinanceCo-operative working arrangementsEmbedded systemRadio frequency

The invention provides a signature card inventory device suitable for batch loading and throwing and an inventory method of the signature card inventory device. The signature card inventory device comprises an signature card inventory device and a signature card counting device, wherein the automatic door that can be opened or closed, ; the invention discloses a drawer box capable of pushing outand pulling in an automatic door. Wherein a A seal card pasted with an RFID electronic tag can be placed in the drawer box, an RFID radio frequency antenna is installed on the automatic door, the RFID radio frequency antenna is in wireless communication with the RFID electronic tag in the drawer box, and the RFID reader-writer is in communication connection with the RFID radio frequency antenna.The drawer box with the signature card is pulled back to the automatic door, and the RFID radio frequency antenna is started to scan the RFID electronic tag in the drawer box at the same time; according to the invention, the check of the signature cards is completed immediately, the after-event check mode that all the to-be-signed cards are loaded into the signature card cabinet and then checked according to the set time period in the prior art is changed, batch loading and batch check of the signature cards can be realized at the same time, the check efficiency is improved, and the check timeis shortened.

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

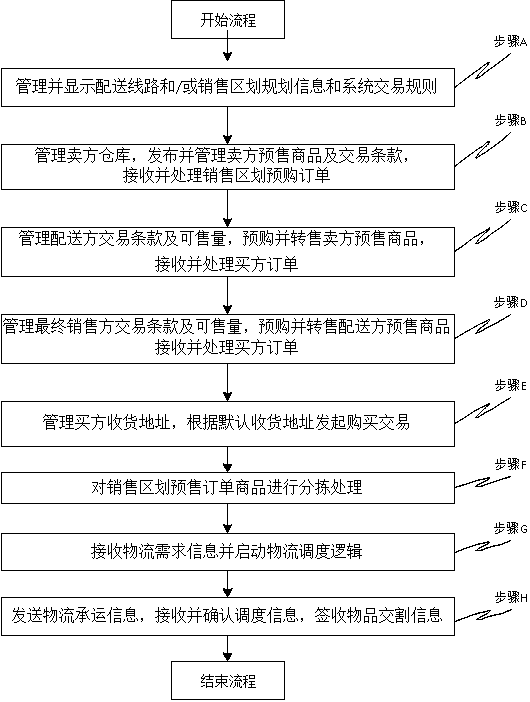

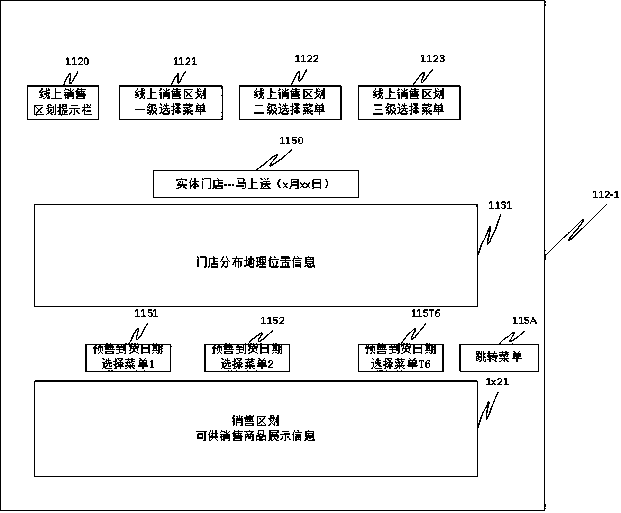

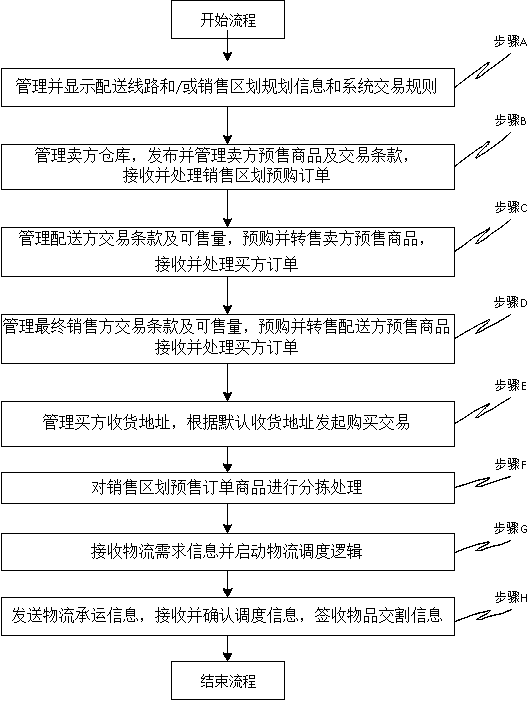

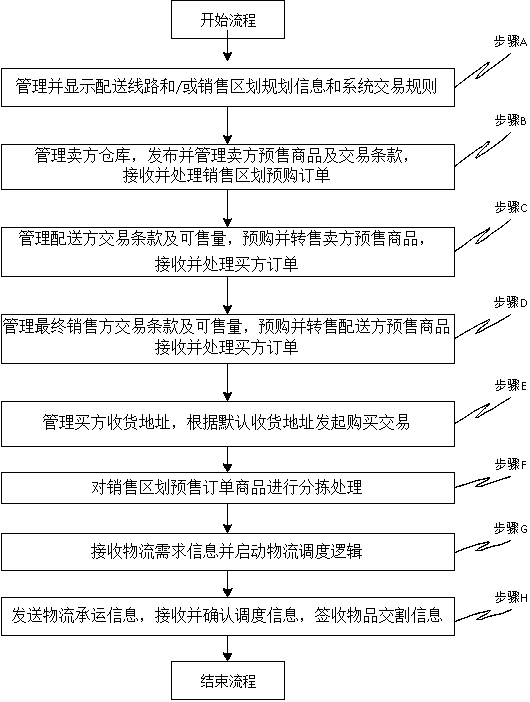

Timing supply chain e-commerce final sales system and method

PendingCN110866798AImplement sales scope managementRealize managementBuying/selling/leasing transactionsLogisticsE-commerceFinancial transaction

The invention discloses a timing supply chain e-commerce final sales system and method. A final interface device is used for receiving and / or initiating the service request and sending and / or receiving the response information. A final reselling manager is used for pre-purchasing the goods of a distributor and reselling according to the transaction terms. A final order manager is used for receiving and processing final pre-sale orders through the final order manager, and generating sold inventory and to-be-sold inventory; signing for the pre-purchased commodities through the final distributor, carrying out distribution processing on the sold inventory commodities, and generating a final distribution plan. A spot-selling manager is used for publishing the currently expected stock commodities through the on-sale manager, and receiving and processing a final seller sales order. Therefore, pre-selling and on-site selling of commodities at a final point of sale are realized, pre-sold tailings are transferred to on-site selling, loss of the final link is reduced, and balance between pre-selling and on-site selling is achieved.

Owner:珠海市卓优信息技术有限公司

Method for rapidly measuring particle size of titanium nitride in high-speed wire steel

ActiveCN103926177AImproved granularity recognitionEasy to manufactureParticle size analysisTitanium nitrideSpectrometer

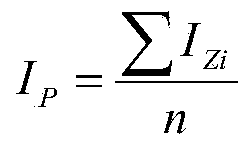

The invention discloses a method for rapidly measuring the particle size of titanium nitride in high-speed wire steel. The method comprises the following steps of analyzing a sample on a spark spectrometer, opening a time-resolved window at 60 to 350 microseconds, performing spark discharge on the sample 1,000 to 2,000 times, and recording the measured light intensity of a titanium channel during the discharge each time; calculating an average value Ip and the standard deviation S of regular pulses I(Zi), calculating a threshold value Y of the pulse light intensity, converting the titanium irregular pulse intensity I(Yi) and the titanium regular pulse intensity I(Zi) into corresponding titanium content by using a standard curve respectively, calculating the content of titanium in the titanium nitride by using a difference value of the converted titanium content, calculating the content of the titanium nitride, and converting the content of the titanium nitride into the mass of the titanium nitride so as to finally obtain the particle size of the titanium nitride. According to the method, requirements on the preparation of the sample are un-harsh, the high measurement speed is ensured, the omission is avoided, a lower limit value of detection on the particle size of the titanium nitride can be lowered to be less than 1 micrometer, and a new solution is provided for the rapid measurement on the particle size of the titanium nitride.

Owner:武汉钢铁有限公司

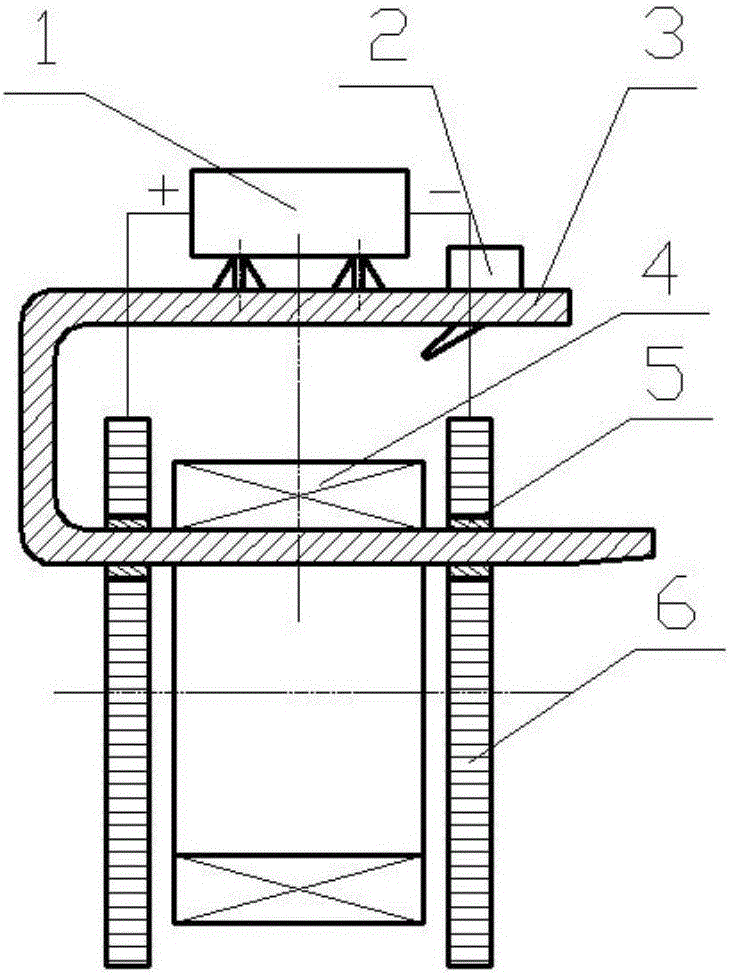

Device for realizing online ageing of hard wire rods by applying pulsed magnetic field and processing method

InactiveCN105755272ARealize online agingShorten inventory timeFurnace typesHeat treatment furnacesWire rodTemperature control

The invention discloses a device for realizing online ageing of hard wire rods by applying a pulsed magnetic field and a processing method, and belongs to the technical field of wire rod production and product preparation. The device is characterized in that a magnetic field generation device for online ageing is imported onto conveying equipment after the collection and coiling of wire rod production lines. The device mainly consists of a pulsed power supply, an induction coil, a C-shaped hook, a bearing sleeve and a temperature control device. According to the method, the structure defects, generated in the rolling and cooling processes, of the materials are improved through controlling the magnetic field intensity (10000-30000A / m), the magnetic field frequency (20-100Hz) and the magnetic field action time (300-600s) by utilizing a magnetic field technology and combining the afterheat after the collection coiling, so that the mechanical property is improved and the online ageing of the hard wire rods is realized in the conveying process. According to the device and the method, the inventory time required by the natural ageing can be shortened.

Owner:UNIV OF SCI & TECH BEIJING

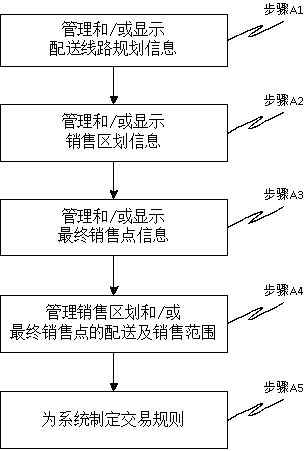

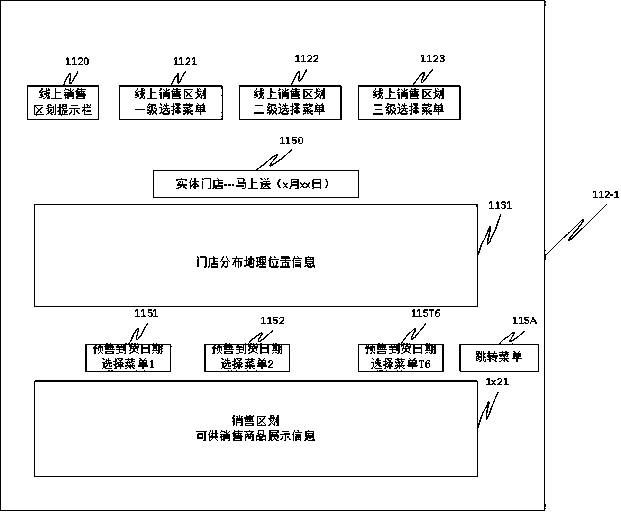

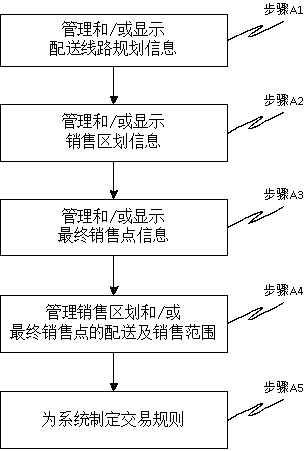

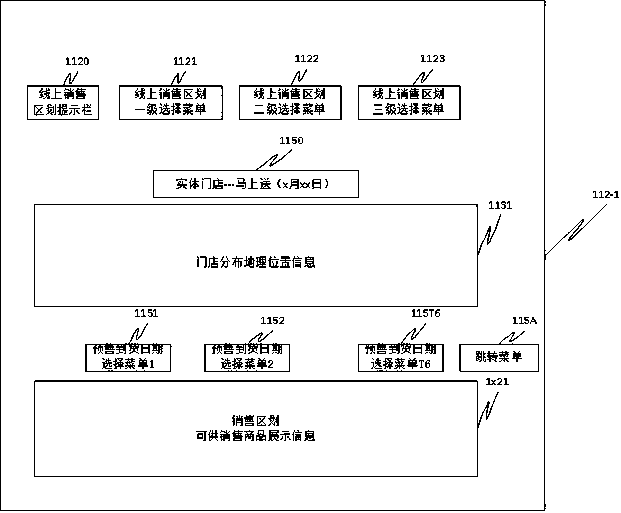

Distribution line and sales regionalization planning system and method thereof

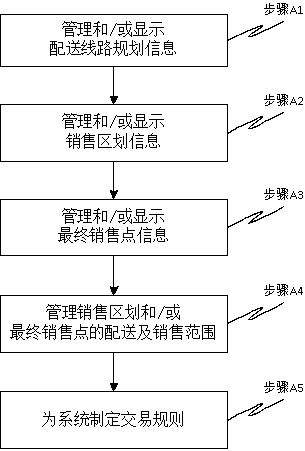

PendingCN110866710AImplement sales scope managementRealize managementBuying/selling/leasing transactionsLogisticsLogistics managementOperations research

Disclosed is a distribution line and sales regionalization planning system and method thereof. A distribution line planner is used for managing and displaying distribution line information. A final point-of-sale planner is used for managing and displaying final point-of-sale distribution information. A coverage range manager used for managing and displaying the sales and distribution coverage range of the sales area. Therefore, planning and management of a sales area are realized, carpooling and shipping are performed on each line, the logistics efficiency is improved, and the logistics costis reduced.

Owner:珠海市卓优信息技术有限公司

Production method for one-steel multi-grade pipeline steel blank

The invention discloses a production method for a one-steel multi-grade pipeline steel blank, and relates to the technical field of steel smelting. Pipeline steel is mainly used for petroleum pipelineconveying and natural gas pipeline conveying, a pipeline product is designed through a low-carbon component system with a C content of less than 0.080% according to the use need stability and safetyof the product, and a component design with components which are applicable to many pipeline grades is carried out on the product according to the product yield requirement and the product performancerequirement, so that the smelting brands of the pipeline product are effectively reduced, production scheduling is benefited, and a blank stock is reduced; and through the design thought, the numberof pipeline steel types is effectively reduced, the steel types for pipelines are reduced to be more than 30 from the previous number of more than 50, and moreover, the replacement usability of the steel types is greatly improved, stocked blanks are effectively controlled, and the production operation rate of a steel plant is increased.

Owner:NANJING IRON & STEEL CO LTD

Timing supply chain pre-selling system and method thereof

PendingCN110866797AImplement sales scope managementRealize managementMarket predictionsReservationsIndustrial engineeringPurchase order

Disclosed is a timing supply chain pre-selling system and method. Through a pre-selling information publisher, a pre-selling party publishes pre-selling commodity information based on upstream sellingcardinal number pre-purchasing commodities and / or according to the selling cardinal number of the pre-selling party, and manages customers participating in pre-selling based on receiving and delivering addresses through the pre-selling customer manager. Through the pre-purchase order manager, a client order is received according to the pre-sale period, and the pre-purchase order is generated, sothat multi-stage pre-sale management is realized, and various risks caused by spot sales are avoided.

Owner:珠海市卓优信息技术有限公司

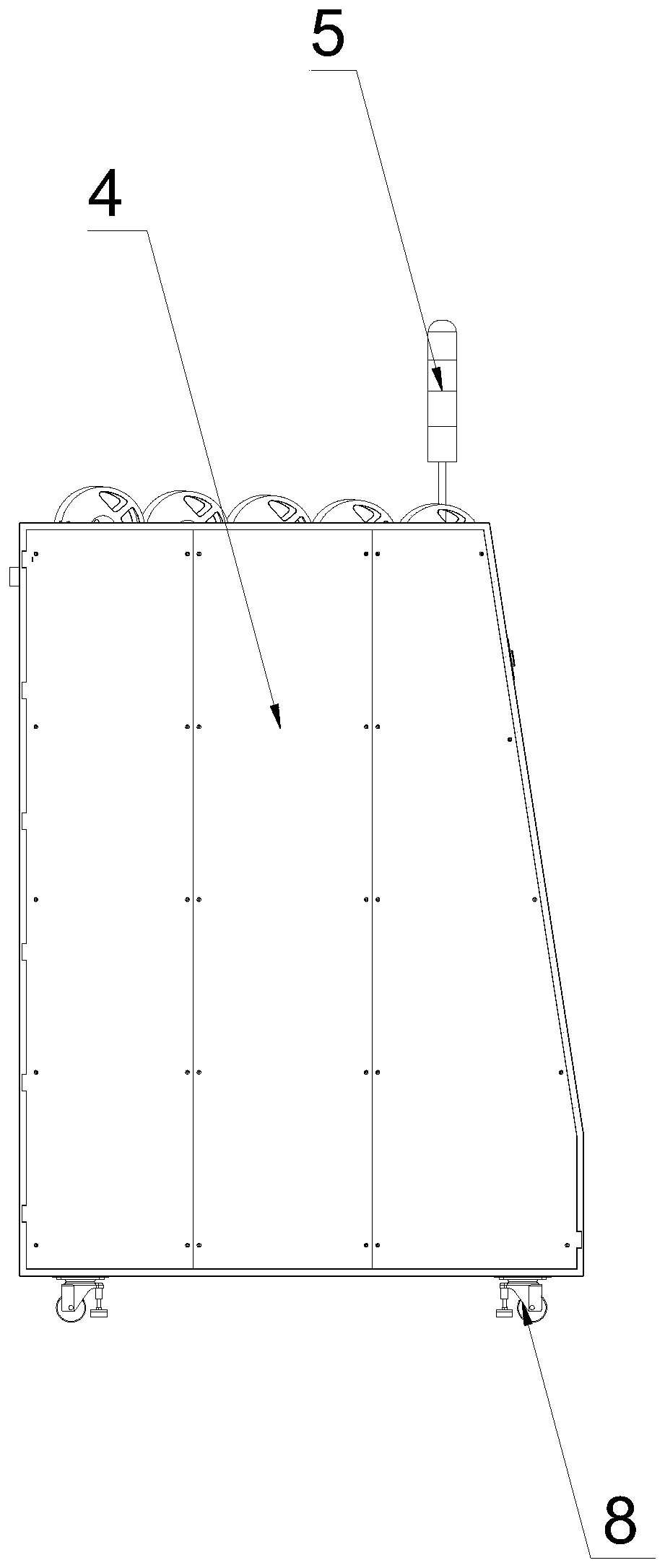

SMT patch material intelligent management equipment

The invention discloses SMT patch material intelligent management equipment, which comprises a main body, a single lamp label and a controller, wherein the main body comprises two groups of fixed plates and multiple groups of partition plates; the multiple groups of partition plates are arranged at equal intervals from top to bottom; the two groups of fixed plates are arranged at two ends of the groups of partition plates; the controller is arranged on the fixed plate; an ERP / MES system is arranged in the controller; a roadway lamp and the single lamp label are arranged on the fixed plate; thepartition plate is obliquely arranged and provided with a strip-shaped channel; aluminum profile plates are arranged at the front end part and the rear end part of the partition plate; a PCB lamp panel is arranged on the outer side of the aluminum profile plate; a plurality of LED indicating lamps are arranged on the PCB lamp panel in an embedded mode, and a tempered glass layer is arranged on the surface of the PCB lamp panel; the LED indicating lamp is a three-color indicating lamp; and the PCB lamp panel is in signal control connection with the ERP / MES system. Thus, the operation of quickly receiving and sending materials according to light indication is automatically realized, the plot ratio is improved, the warehouse size area is reduced, the inventory time is shortened, and errors in the material sending and feeding processes are avoided.

Owner:SHENZHEN RUIYIBO TECH

Method of reading data from transponders through a reader, a transponder, and a reader

ActiveUS8253540B2Shorten inventory timeReduce processing timeMemory record carrier reading problemsTime-division multiplexHuman–computer interactionTransponder

Owner:NXP BV

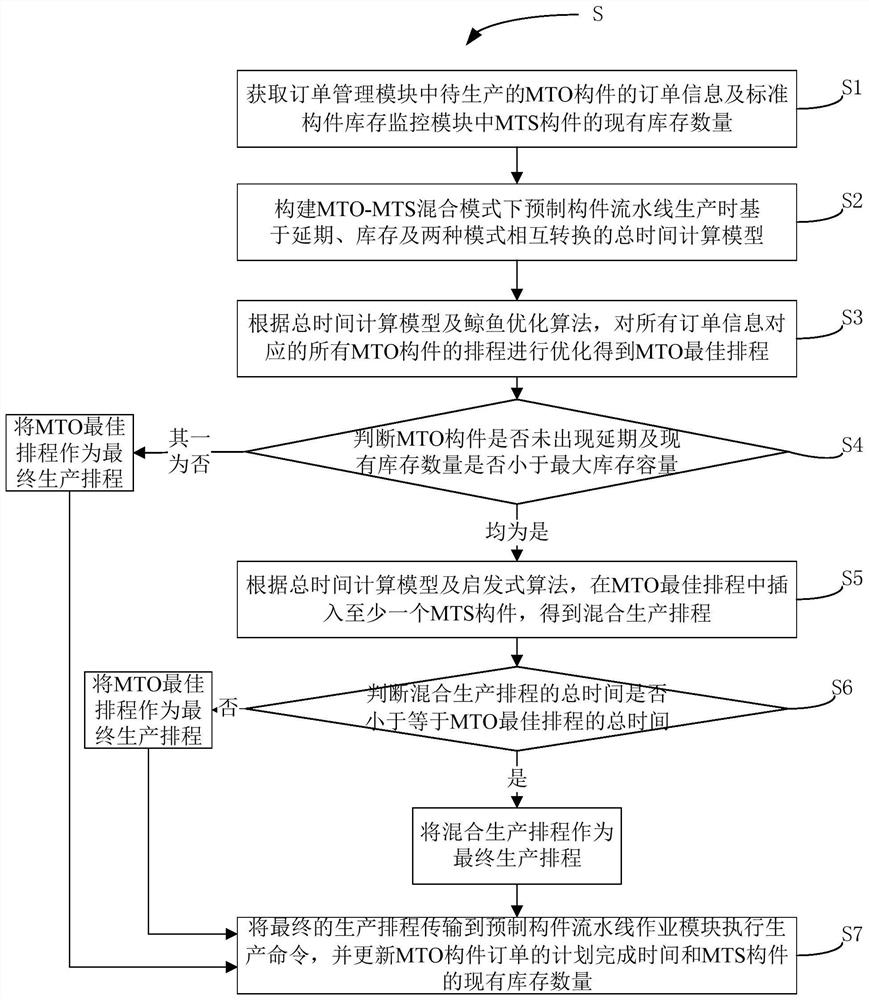

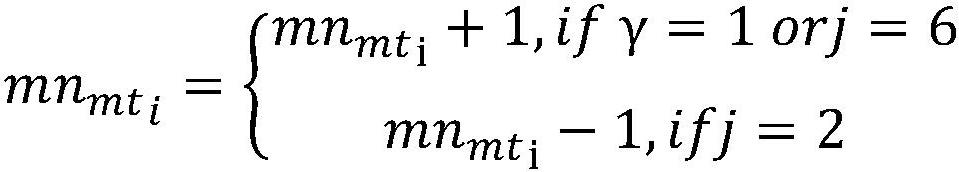

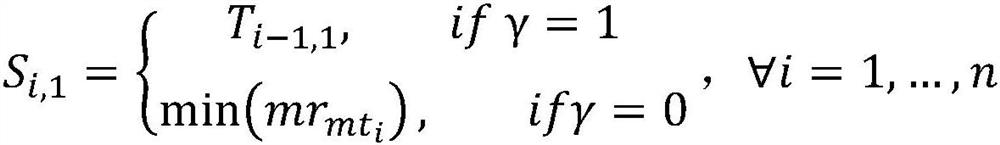

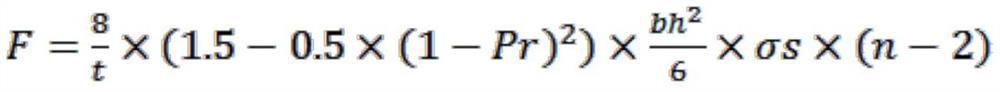

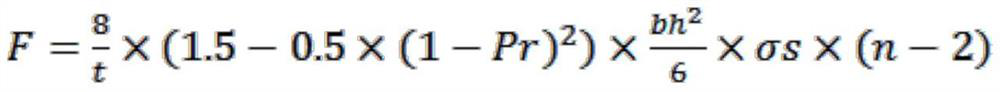

Production scheduling method for MTO-MTS mixed assembly type building prefabricated parts

ActiveCN111626513AOptimizing Mixed Production SchedulingMixed production optimizationForecastingArtificial lifeProduction scheduleCompletion time

The invention discloses a production scheduling method for an MTO-MTS hybrid fabricated building prefabricated parts. The method comprises the steps: constructing a total time calculation model; obtaining an MTO optimal schedule according to the total time calculation model and a whale optimization algorithm; entering the next step when the MTO component is not delayed and the existing inventory quantity is less than the maximum inventory capacity, otherwise, taking the optimal MTO schedule as the final production schedule, and entering the last step; according to the total time calculation model and a heuristic algorithm, inserting an MTS component into the MTO optimal schedule to obtain a hybrid production schedule; if the total time of the mixed production schedule is less than or equalto the total time of the MTO optimal schedule, taking the mixed production schedule as a final production schedule, otherwise, taking the MTO optimal schedule as the final production schedule, and then entering the next step; and transmitting the final production schedule to a prefabricated part assembly line work module to execute a production command, and updating the planned completion time ofthe MTO component order and the existing inventory quantity of the MTS components.

Owner:SICHUAN AGRI UNIV

Gauze counting device and counting system

ActiveCN111358572AShorten inventory timeImprove work efficiencySurgical furnitureOperating theatresControl cell

The invention relates to the technical field of medical instruments, in particular to a gauze counting device and counting system. The gauze counting device comprises a base, wherein a control unit iscentrally arranged at the front part of the base, and a plurality of groups of placing units are uniformly arranged at the front part of the base. The disclosed gauze counting system comprises a control module, a weighing module, a state display module, a door opening module and a voice prompt module. The device can solve the important problem that management and counting of the gauze in the operation are always plagued to the medical staff of an operating room, thereby avoiding gauze missing, the personal safety of a patient, influence to the rehabilitation of the patient, the adverse effectof irreparable medical accidents to the career of doctors caused by the medical staff by eliminating conflicts between doctors and patients; and by singly placing the gauze used for each patient in an operation, the counting time is effectively shortened, the workload of counting is reduced and the working efficiency is improved.

Owner:BEIJING YOUAN HOSPITAL CAPITAL MEDICAL UNIV

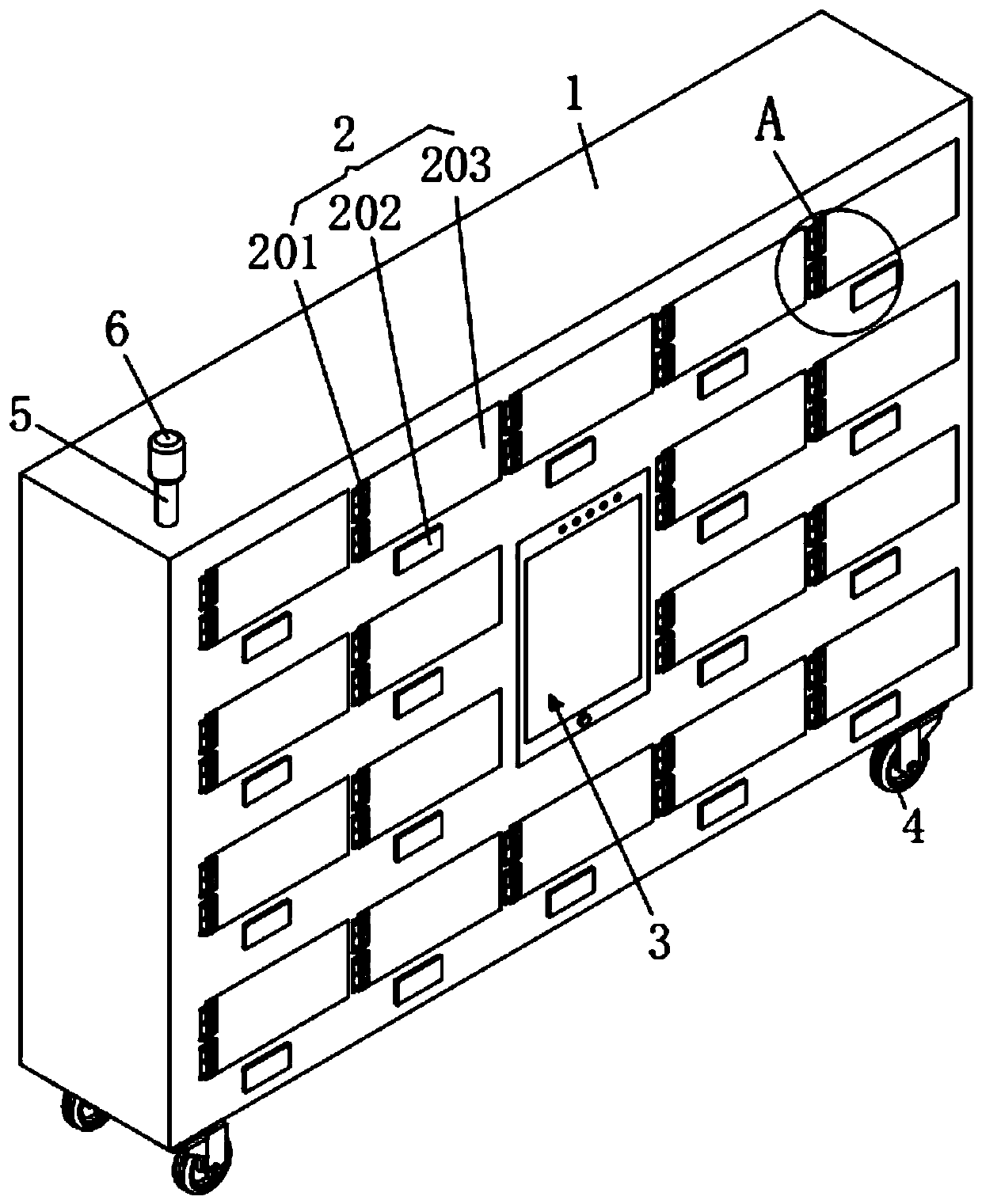

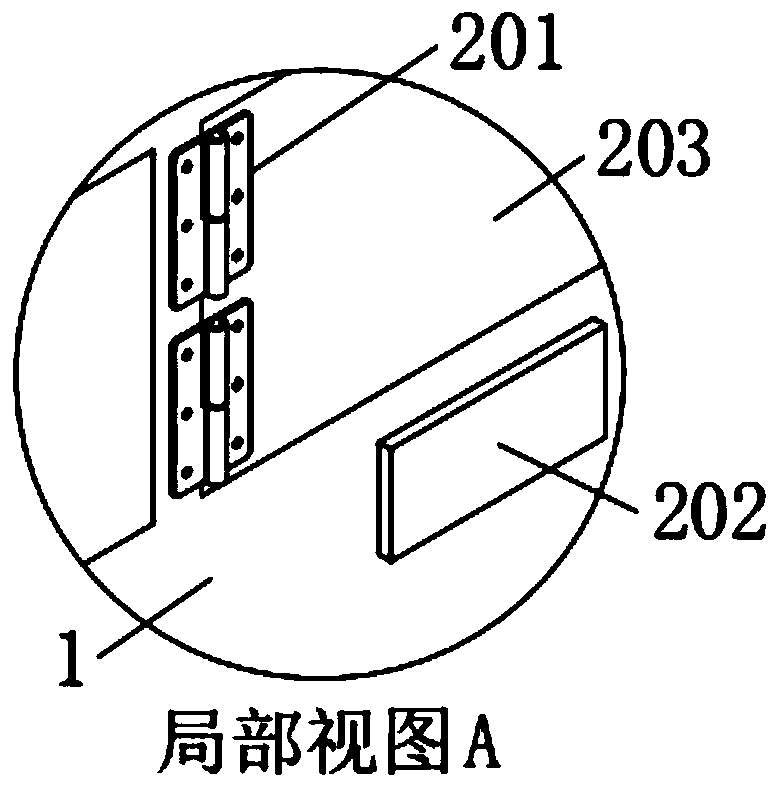

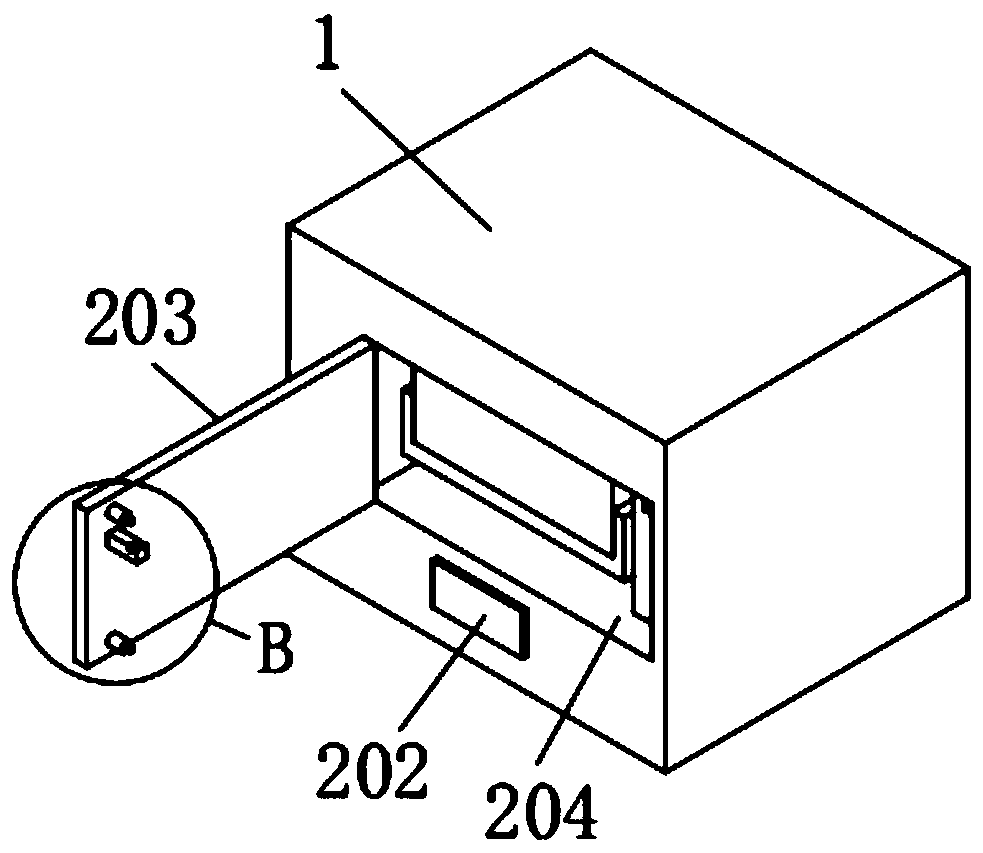

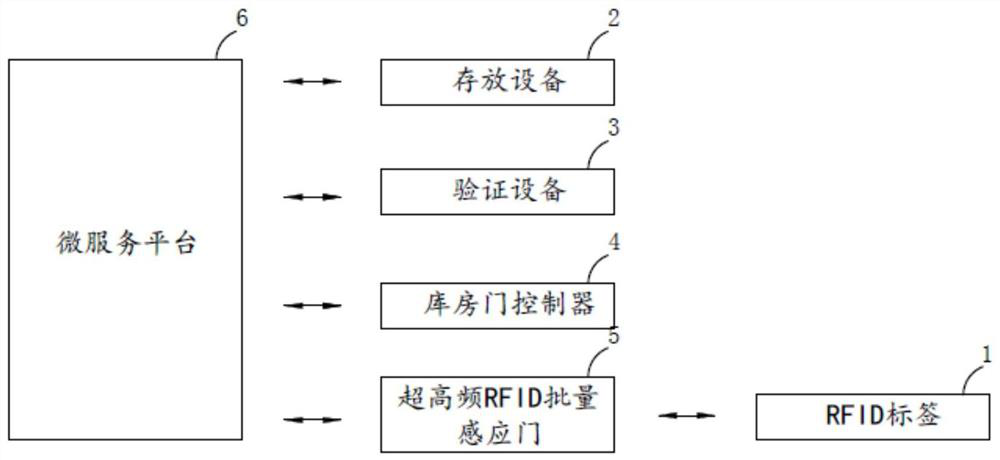

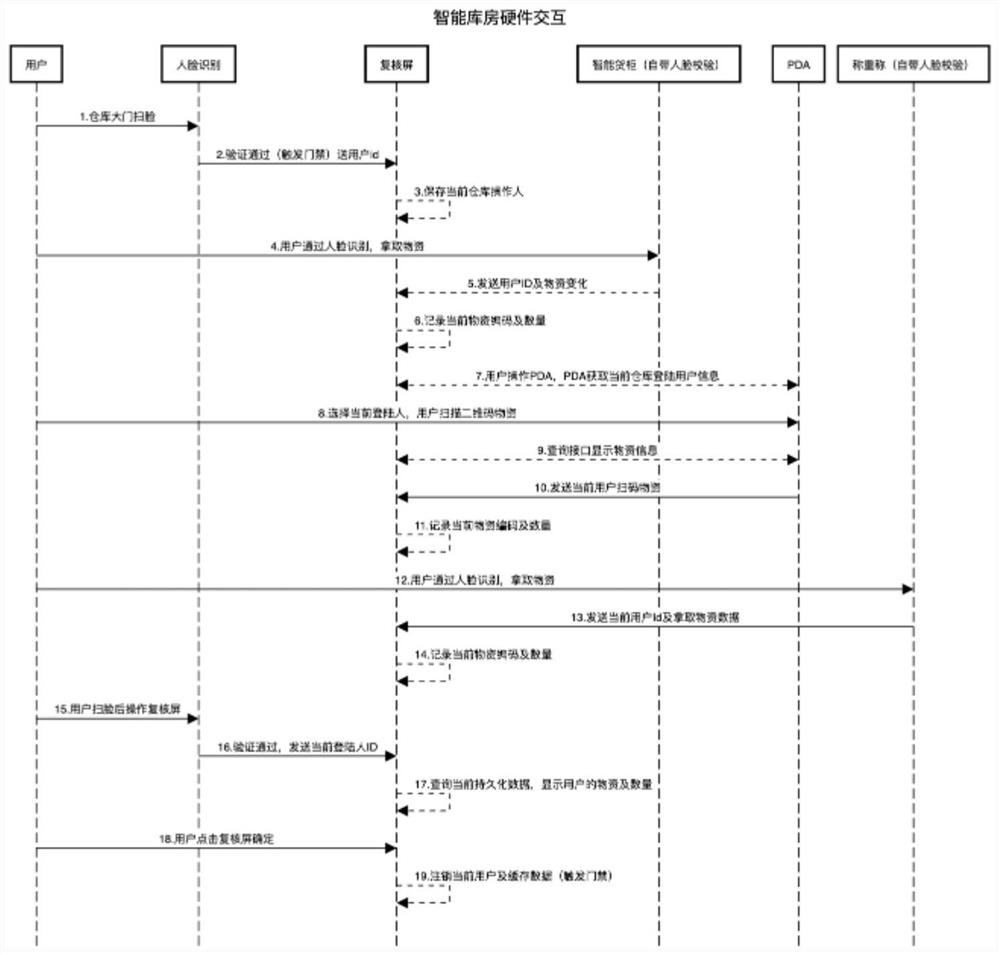

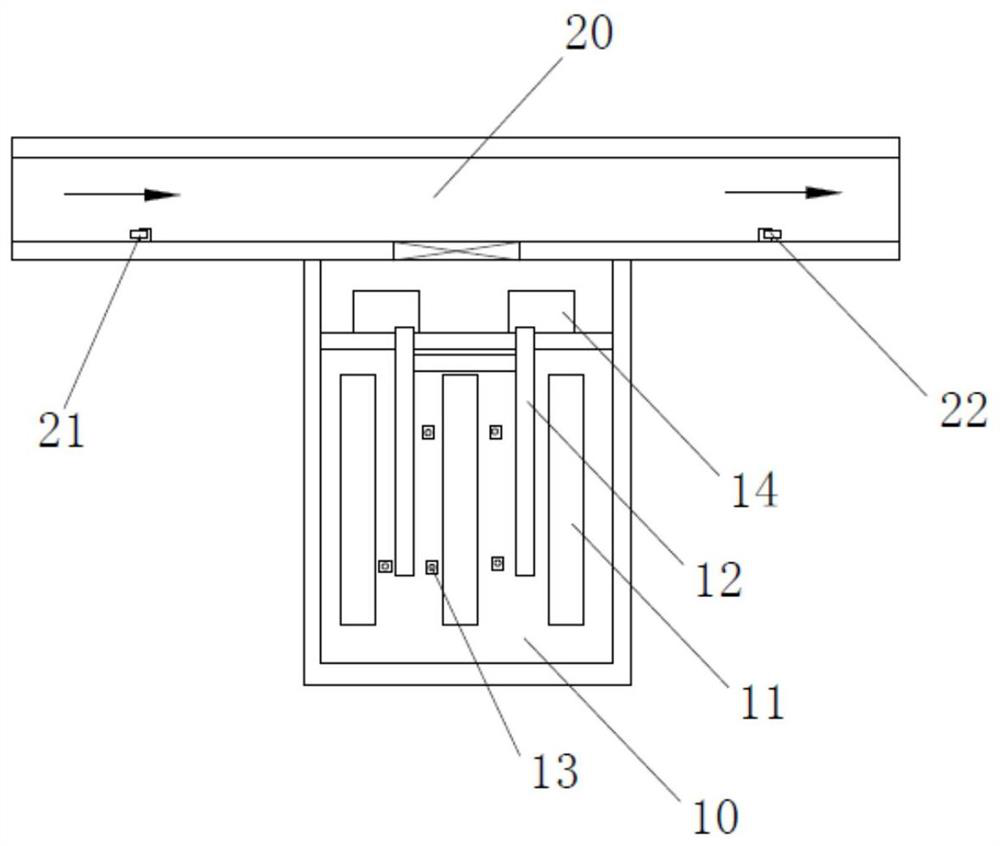

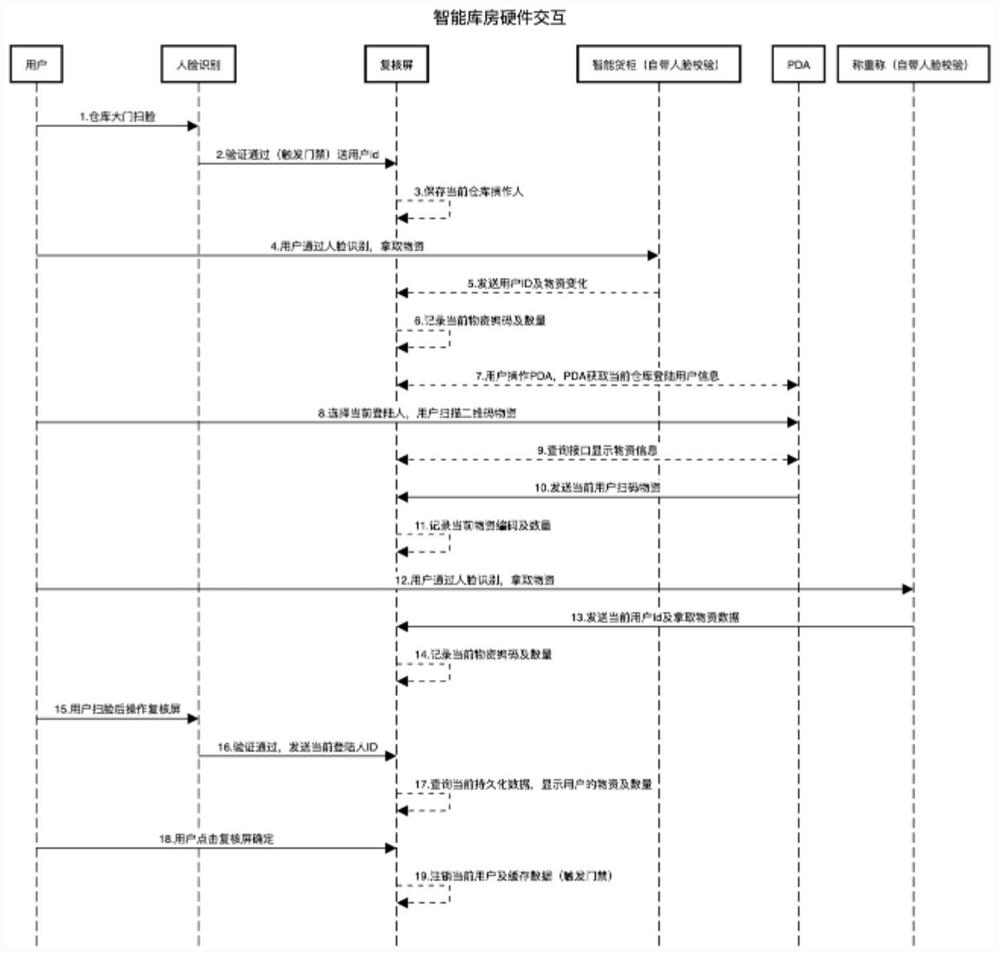

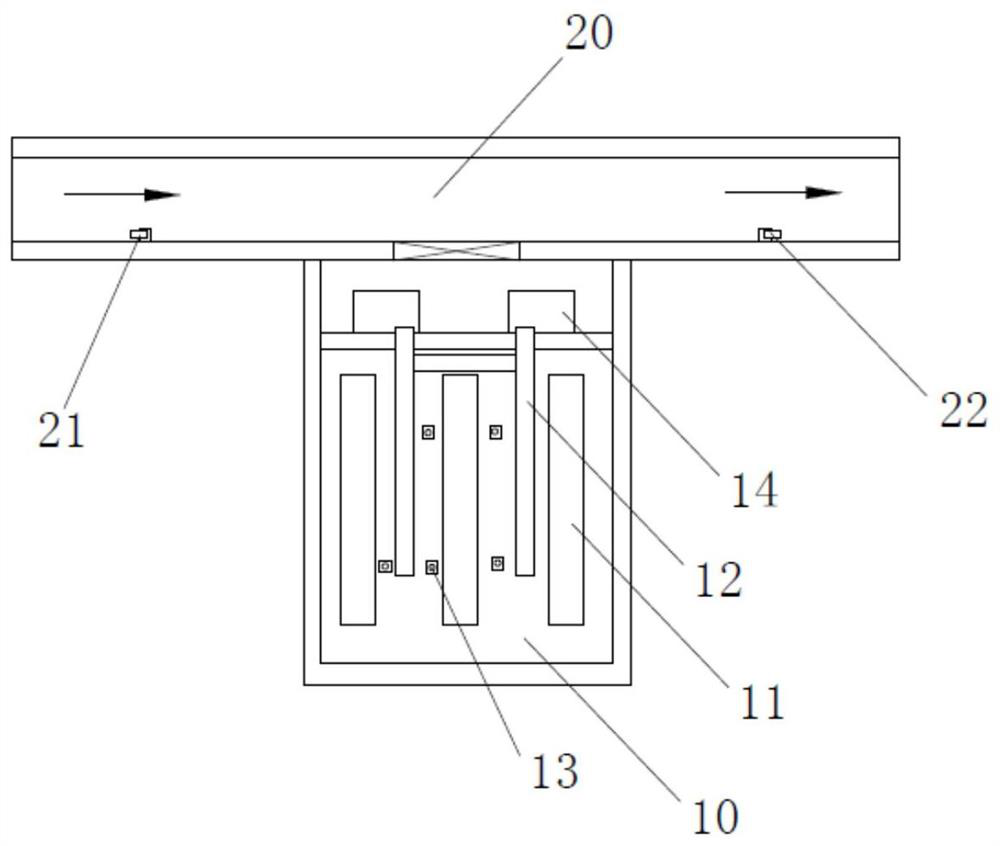

Unmanned warehouse management system based on microservice architecture equipped with RFID UHF technology

ActiveCN113627843BTimely warningAvoid churnCo-operative working arrangementsLogisticsMaterials managementEmbedded system

The present invention provides an unmanned warehouse management system equipped with RFID ultra-high frequency technology based on a micro-service architecture, including: a plurality of RFID tags, respectively bound to each material; storage equipment, set in an unmanned warehouse for storage Materials; verification equipment, installed at the warehouse door or in the aisle in front of the unmanned warehouse, used to verify the identity of personnel; warehouse door controller, used to control the opening or closing of the door of the unmanned warehouse; UHF The RFID batch sensing door is set at the door of the unmanned warehouse, and is used to read the information in the RFID tag on the materials taken out of the unmanned warehouse; the micro-service platform is connected with the storage equipment and the warehouse door controller respectively. , Verification equipment and UHF RFID batch sensor door communication connection. The unmanned warehouse management system equipped with RFID ultra-high frequency technology based on the micro-service architecture of the present invention realizes the intelligentization of warehouse management and improves the efficiency of material management.

Owner:THREE GORGES HI TECH INFORMATION TECH CO LTD +1

Unmanned storehouse management system based on micro-service architecture and carrying RFID ultrahigh frequency technology

ActiveCN113627843AAvoid churnEffective online early warning measuresCo-operative working arrangementsLogisticsMicroservicesMaterials management

The invention provides an unmanned warehouse management system based on a micro-service architecture and carrying an RFID ultrahigh frequency technology; the system comprises a plurality of RFID tags which are respectively bound with each material; storage equipment which is arranged in the unmanned storehouse and is used for storing materials; verification equipment which is arranged at a storeroom door or in a passageway in front of the door of the unmanned storeroom and is used for verifying the identity of the personnel; a warehouse door controller which is used for controlling opening or closing of a door of the unmanned warehouse; an ultrahigh frequency RFID batch induction door which is arranged at the position of a door of the unmanned warehouse and used for reading information in the RFID tags on the materials taken out from the unmanned warehouse; a micro-service platform, which is respectively in communication connection with the storage equipment, the storehouse door controller, the verification equipment and the ultrahigh frequency RFID batch induction door. According to the unmanned storehouse management system based on the micro-service architecture and carrying the RFID ultrahigh frequency technology, intelligentization of storehouse management is realized, and the efficiency of material management is improved.

Owner:THREE GORGES HI TECH INFORMATION TECH CO LTD +1

Method and device for automatic stocktaking

The invention discloses a method and a device for automatic inventory, and relates to the technical field of computers. A specific implementation of the method includes: obtaining the verification information of the storage bin to be inventoried, and verifying the storage bin to be inventoried according to the verification information and the inventory record information of the storage bin to be inventoried; if the verification is passed, Then it is determined that there is no inventory difference in the storage bins to be counted. If the verification fails, the identification information of the storage bins to be counted is obtained; according to the identification information and inventory record information, the products in the storage bins to be counted are identified and grouped, and determined. Inventory variances for storage bins to be counted. According to the obtained verification information, identification information and inventory record information, the storage bins to be counted can be checked and identified and grouped, and the inventory difference can be determined, so as to realize the automatic count of the storage bins to be counted and reduce the time. cost and labor costs.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

System and method for arranging freight transport work in advance based on packaging flow

The invention provides a system and method for arranging freight transport work in advance based on a packaging flow. The system is composed of a freight transport service call device, a truck information receiving and storage device, a storage area location information storage device, a packaging and freight transport work combination device, a cargo taking device, and post-packaging cargo transport device. The packaging and freight transport work combination device distributes storage positions of non-packaged cargo based on a specific distribution rule according to a packaging and freight transport work flow, generates distribution information, and sends the information to the cargo taking device; storage locations of cargo that is going to be packaged completely are obtained; a propertruck is selected by combining truck information stored by the truck information receiving and storage device and corresponding truck information is sent to the freight transport service call device for calling.

Owner:耀灵人工智能(浙江)有限公司

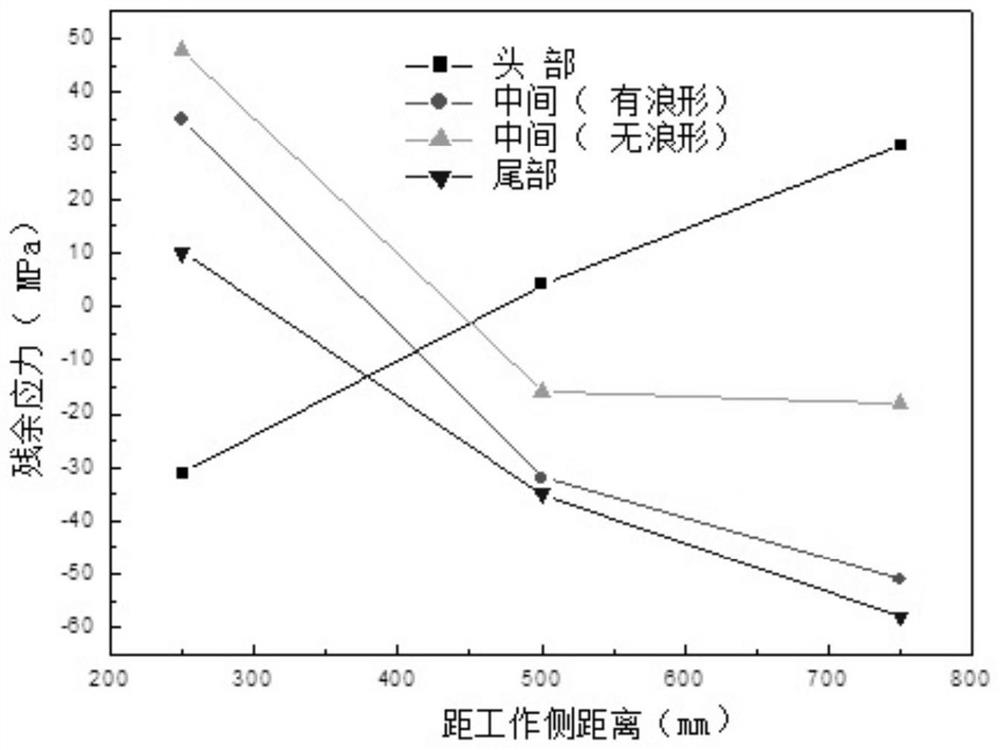

Method for eliminating residual stress of hot-rolled strip steel in high-temperature state

ActiveCN113617843AShorten inventory timeShorten process timeMetal rolling arrangementsProcess efficiency improvementManufacturing lineManufacturing engineering

The invention relates to a method for eliminating residual stress of hot-rolled strip steel in a high-temperature state, a straightening unit is additionally arranged between a continuous rolling finishing mill and a coiling machine of a hot continuous rolling production line, and the hot-rolled strip steel after finish rolling directly enters the straightening unit, is straightened in the high-temperature state and then enters the coiling machine to be coiled. The strip steel is straightened through rolling waste heat, so that the capacity requirement of straightening equipment is greatly reduced, secondary heating is not needed, and energy consumption is reduced; and a conventional off-line stress control mode of the hot-rolled strip steel is improved into an on-line stress control mode, the economical and efficient targets are achieved, and a precedent of on-line control of the residual stress index of the hot-rolled strip steel is created.

Owner:ANGANG STEEL CO LTD

A hard-wire wire rod aging device and processing method using pulse current

InactiveCN105779753BQuickly achieve timelinessShorten inventory timeFurnace typesHeat treatment furnacesEngineeringPulse power supply

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com