Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Reduce construction joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

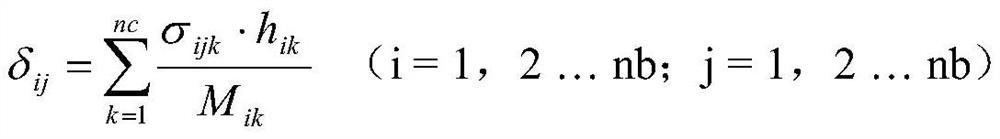

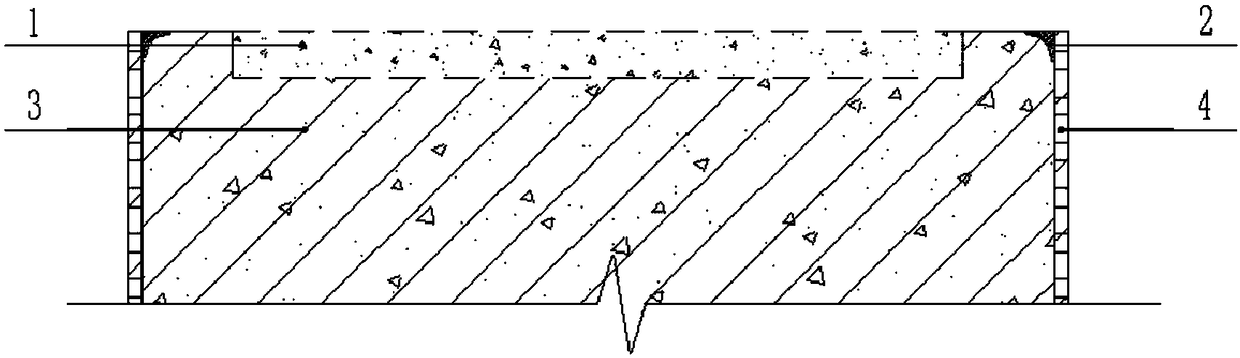

Construction method for large-area concrete weighbridge

ActiveCN102691401AOvercome the technical problem that the flatness is difficult to controlOvercome the problem of too much usageFlooringWater flowEngineering

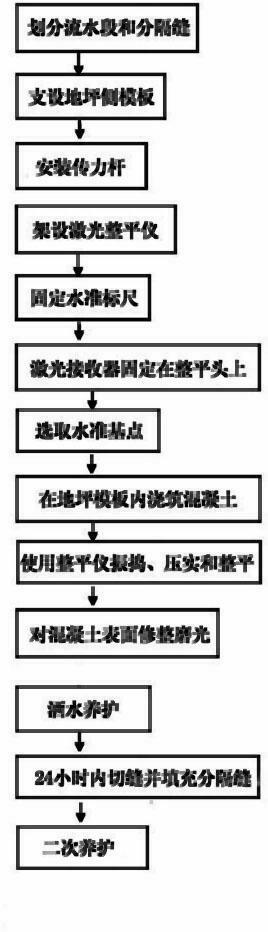

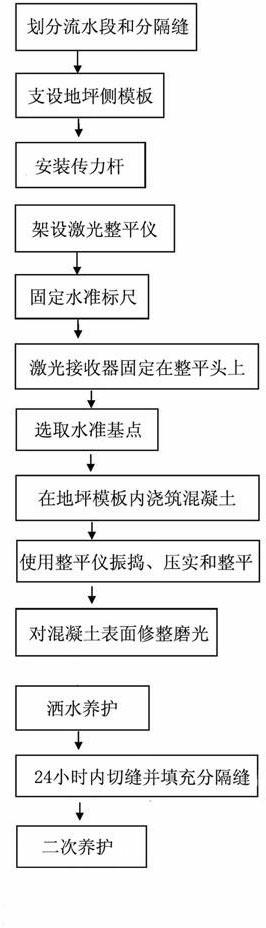

The invention discloses a construction method for a large-area concrete weighbridge. The construction method comprises the steps of: dividing the locations of a construction water flowing section and a construction separation joint, erecting a weighbridge side template, installing a force transmission rod at a junction of the water flowing section, erecting a laser leveller, fixing a levelling staff, selecting a levelling base point, pouring concrete in a space surrounded by weighbridge templates, vibrating, compacting and levelling the weighbridge by the leveller, finishing surface conditioning and polishing of the concrete weighbridge before the final solidification of the concrete, maintaining the concrete weighbridge, cutting the construction separation joint within 24h, stuffing the construction separation joint and carrying out secondary maintenance. By the construction method, the technical problem that the whole levelling degree of the large-area weighbridge is very difficult to control is solved; the problems that the cost of later maintenance of the ground and the use quantity of the templates are very high since the construction joint of the large-area concrete weighbridge is very prone to breakage is solved; and the problems such as breakage along a warehouse dividing joint on the large-area concrete weighbridge, easy hollowing in the layered pouring of the weighbridge, easy cracking and the like are solved.

Owner:北京城建建设工程有限公司

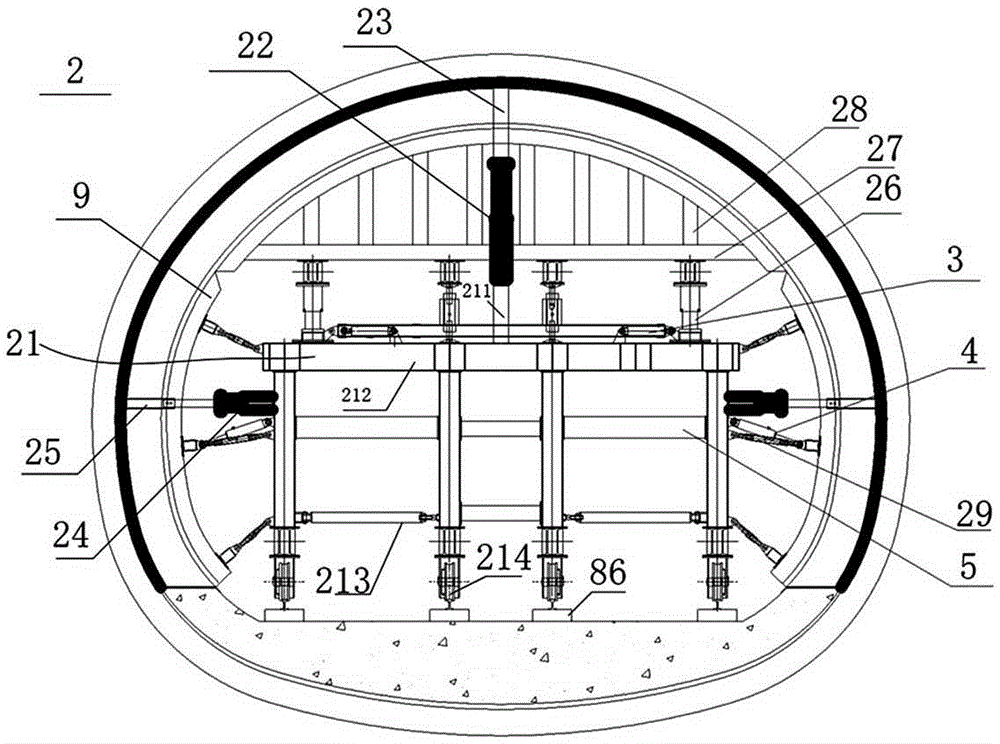

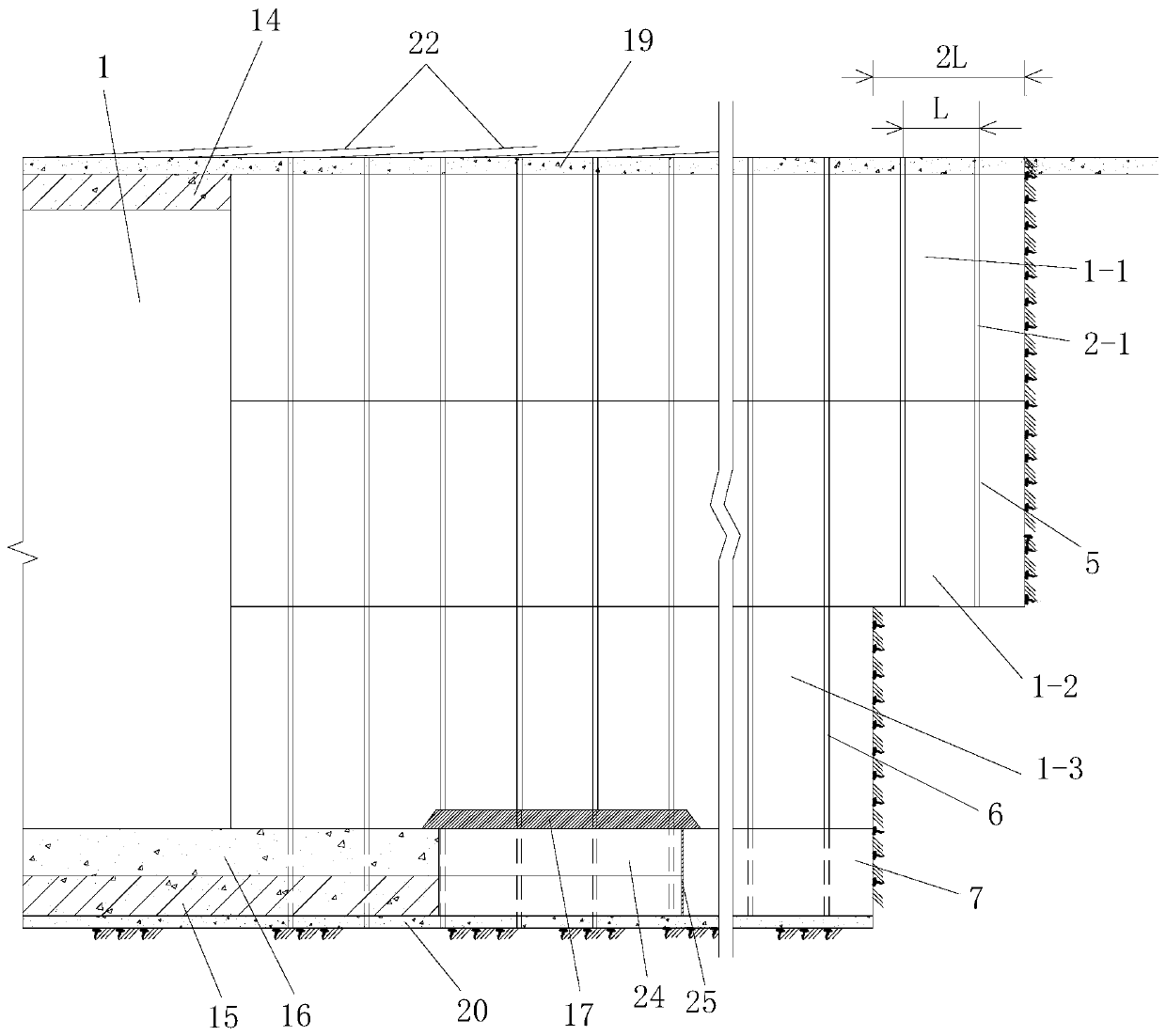

Tunnel underground excavation and lining construction trolley and tunnel underground excavation and lining construction method

ActiveCN105386778ASimple construction methodShorten the construction periodUnderground chambersTunnel liningSupporting systemEngineering

Owner:北京住总集团有限责任公司

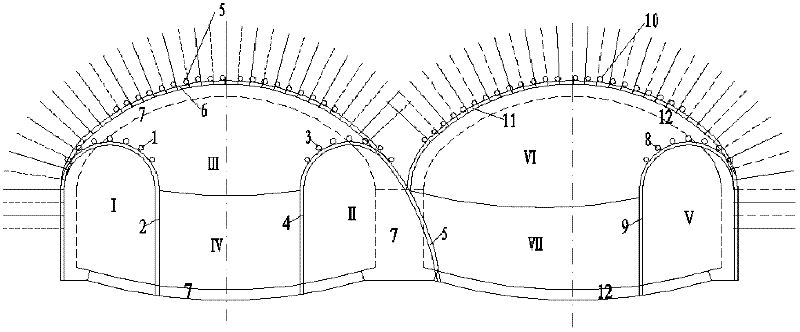

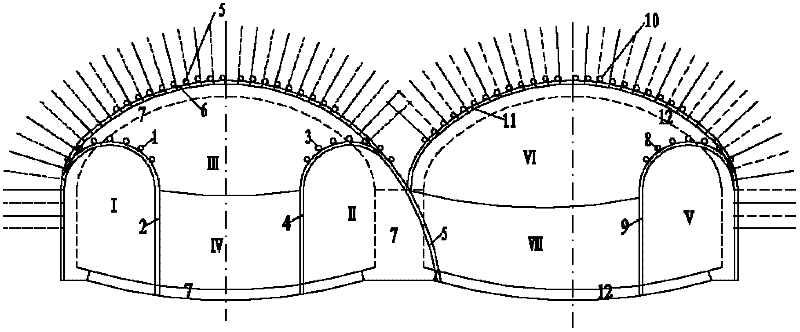

Rapid construction method of weak surrounding rock large-section multi-arc tunnel

InactiveCN102373930AImprove construction progressShorten the construction periodUnderground chambersTunnel liningStructure of the EarthRapid construction

The invention discloses a rapid construction method of a weak surrounding rock large-section multi-arc tunnel. According to the invention, in tunnel construction, the main tunnel on one side of the multi-arc tunnel and the place of a partition wall are synchronously excavated; the tunnel excavation is implemented by using a double side-wall heading method; then, a primary support and the partition wall are constructed before the secondary lining of the tunnel; and finally, the main tunnel on the other side of the multi-arc tunnel is excavated by using a single side-wall heading method, and a corresponding support structure is built. Compared with the traditional multi-arc tunnel construction method, the construction method disclosed by the invention does not need to cut through a middle guide tunnel and build the partition wall before excavating the main tunnels on the two sides, thereby greatly accelerating the construction of the multi-arc tunnel, shortening the construction period and properly lowering the construction cost.

Owner:CENT SOUTH UNIV

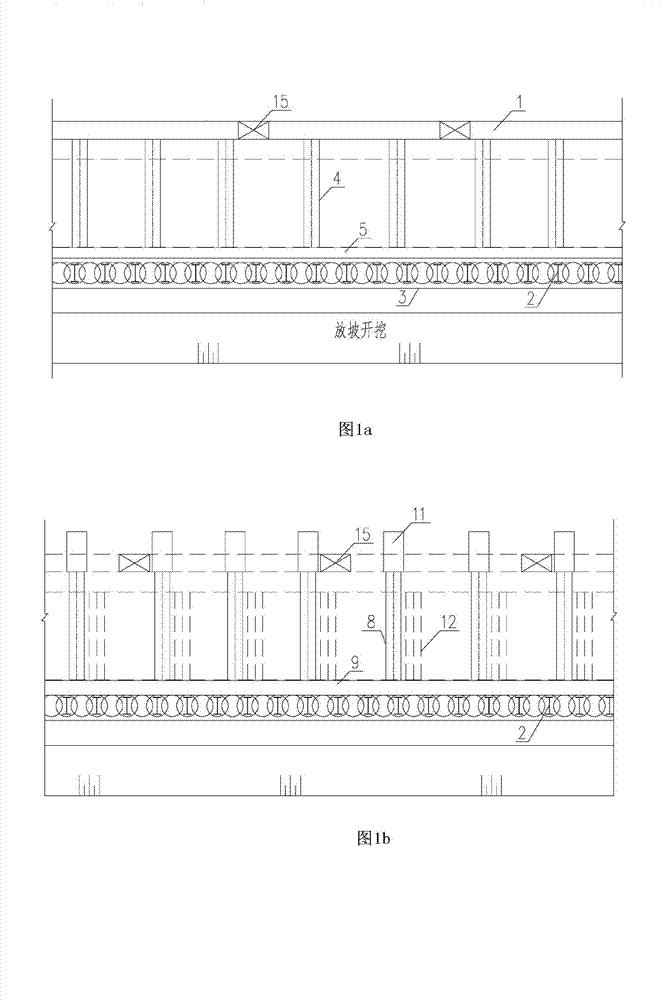

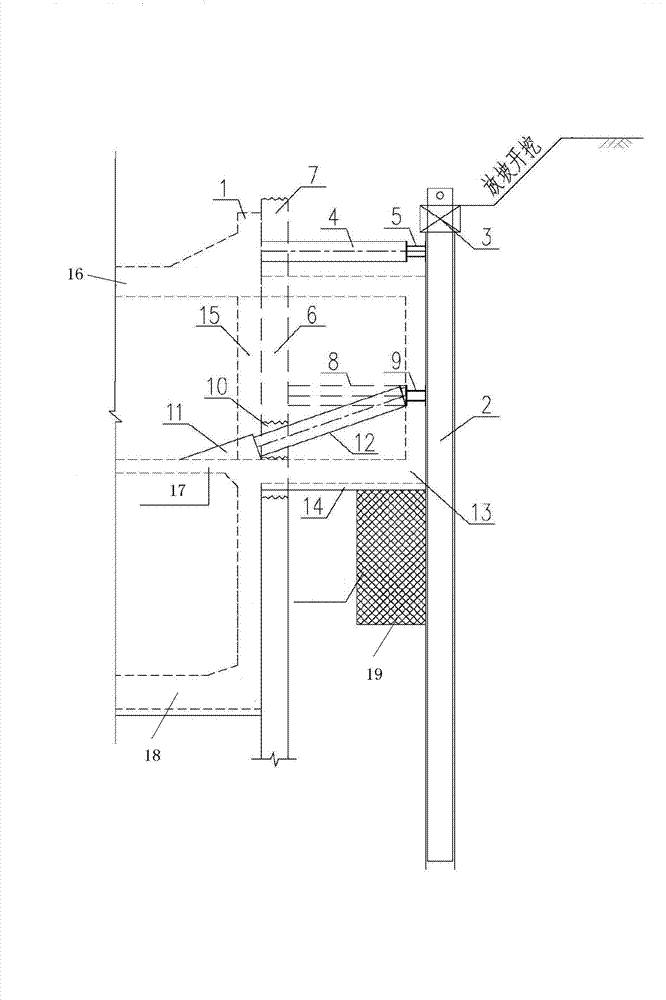

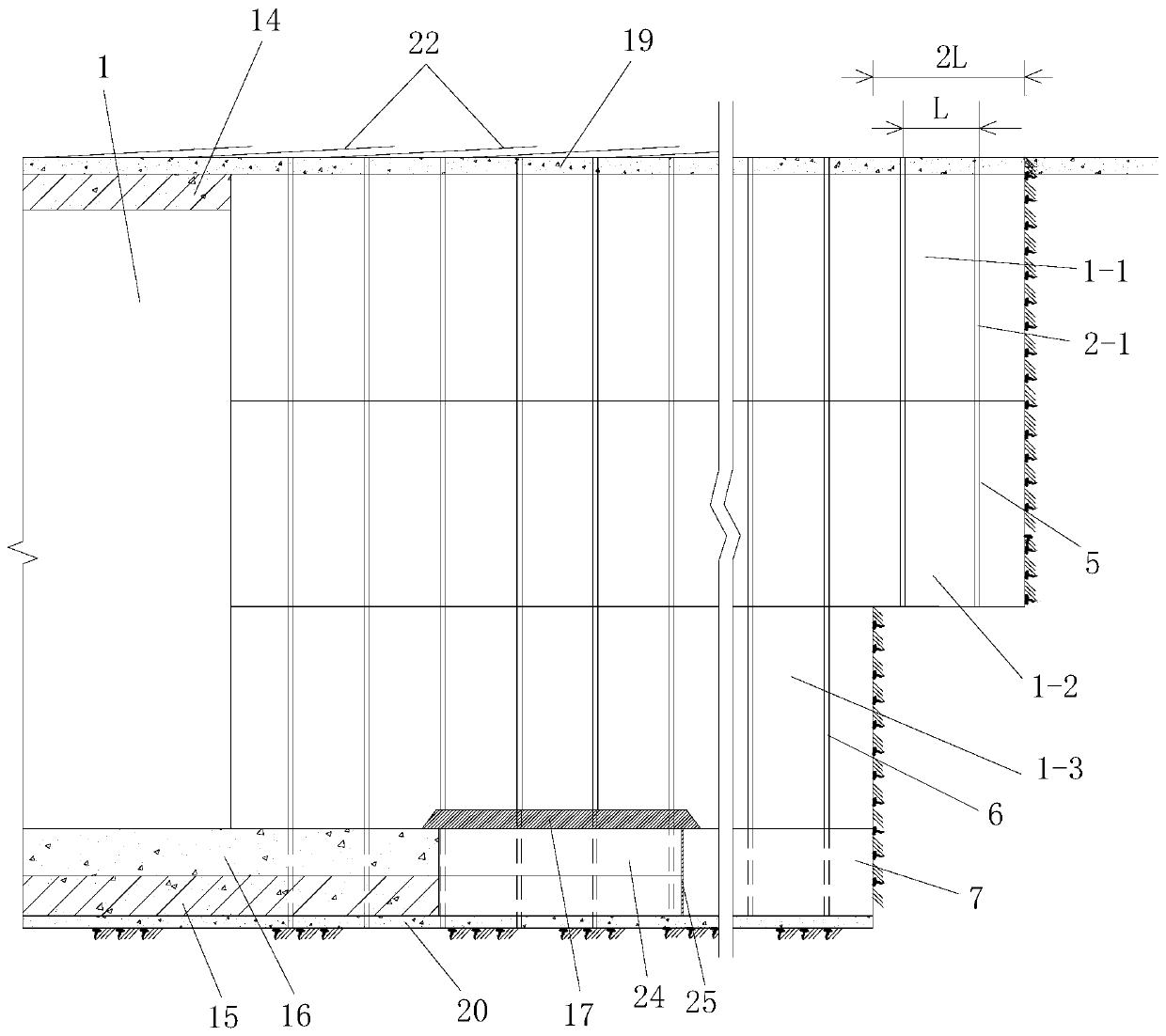

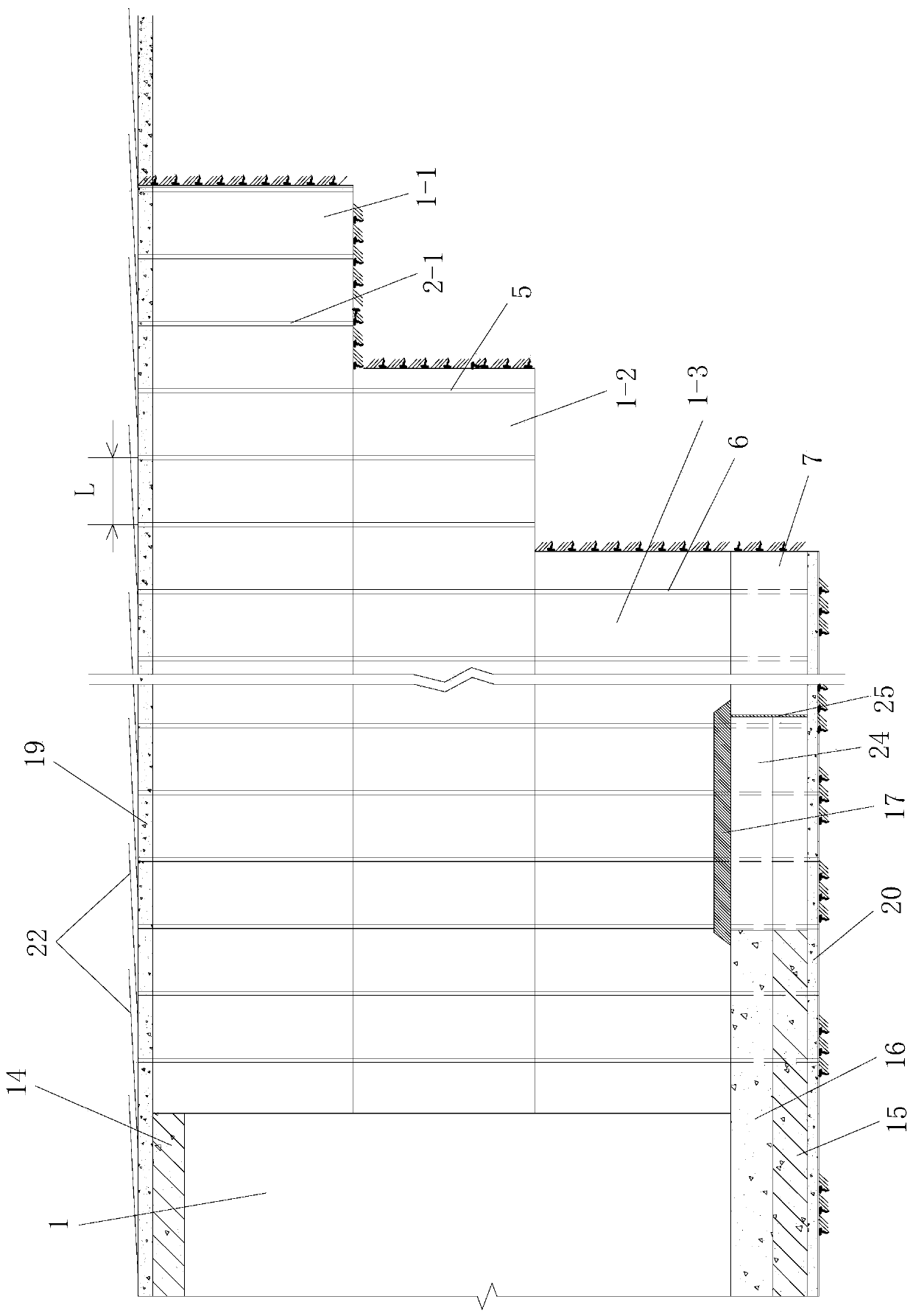

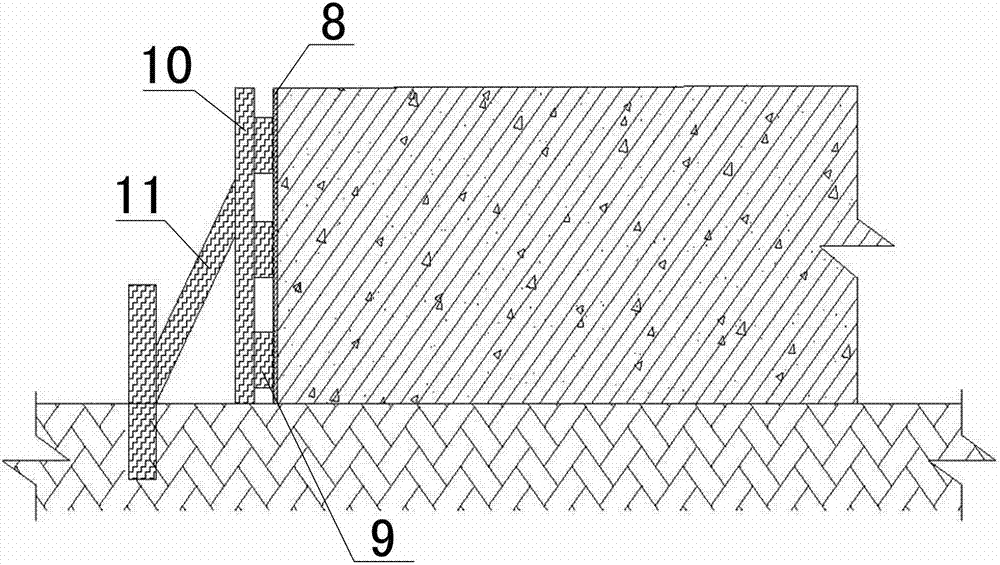

Method for supporting foundation pit next to established underground structure

ActiveCN103590404AEasy and fast conversionReduce construction riskArtificial islandsProtective foundationReinforced concreteAxial force

The invention discloses a method for supporting a foundation pit next to an established underground structure. The method is characterized in that one end of a supporting member of the foundation pit built after underground structure establishment is supported on a vertical or horizontal member of an established body structure, supporting axial force is directly transferred to the member of the established body structure, one end of the supporting member can be supported on the established body structure by changing supporting after the foundation pit built after underground structure establishment is excavated to the pit bottom, and then base plate water-proof layer and reinforced concrete base plate construction, side wall water-proof layer and reinforced concrete side wall construction and top plate reinforced concrete and water-proof layer construction are sequentially performed. The method has the advantages that on the premise that engineering construction, operation safety and engineering quality are ensured, the engineering construction is simple, quick and convenient, construction risk is reduced, construction joints and construction processes are decreased, a construction period is shortened, and the construction cost is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

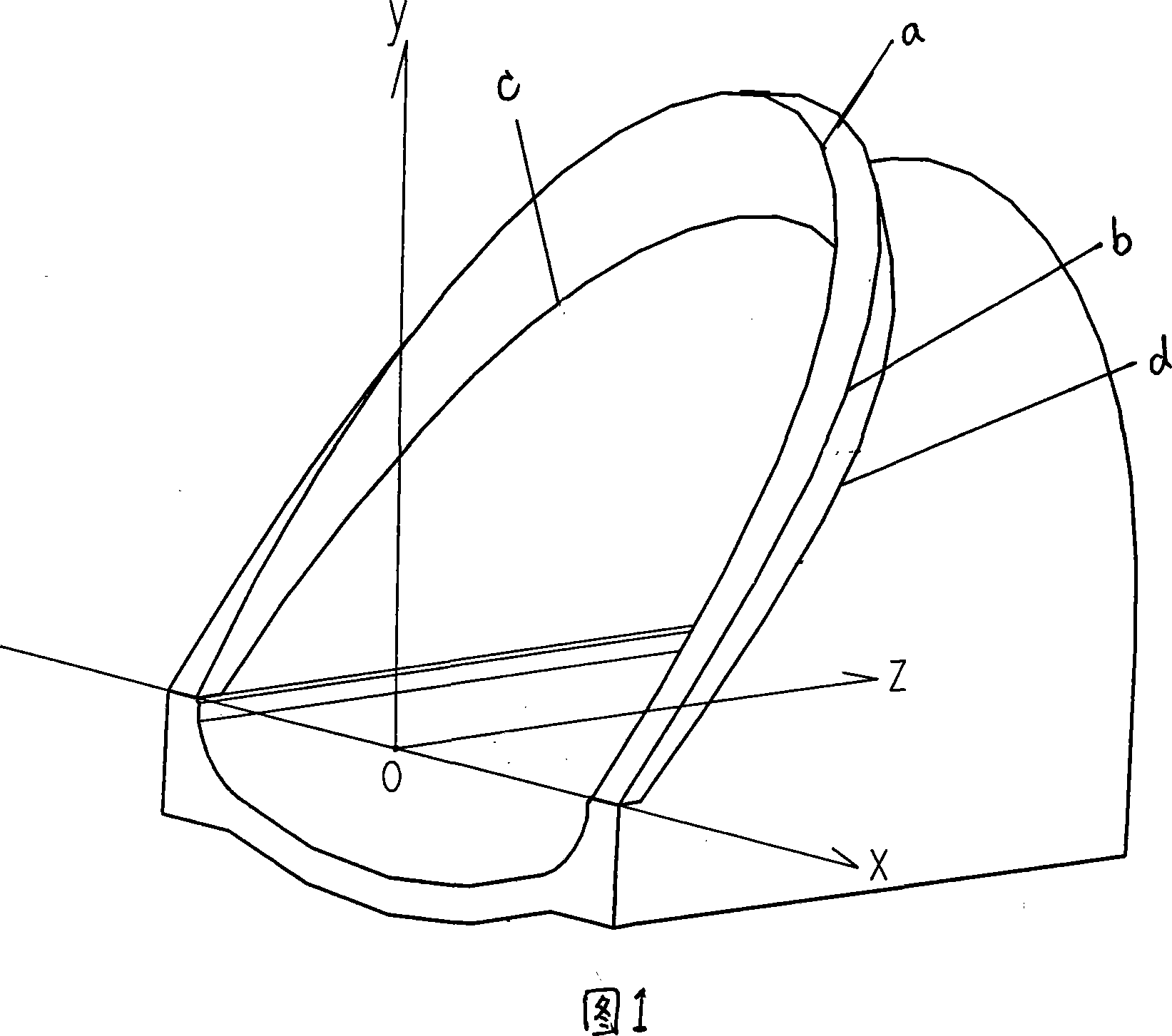

Railway large-bore tunnel oval-shaped table-board cap brim bias-cutting type hole-door construction method

InactiveCN101182773AEasy to installFacilitate mechanized constructionTunnelsInternal modeRailway tunnel

The present invention relates to the art of railway tunnel construction technology, in particular to a brim-type clip portal construction method of an oval platform of a railway large cross-section tunnel, which solves the problems of the simple separated template technology, such as complicated template installation, the large deviation of structural size and many construction joints. (1) an internal mode, an external mold and an end mold of the brim are manufactured; (2) the hookup lines of the upper mouth and the lower mouth of the internal mold and the external mold are confirmed; (3) the internal mold is arranged according to the hookup lines of the upper mouth and the lower mouth; (4) a brim reinforcing steel bar is colligated; (5) the external mold of the brim is arranged according to the hookup lines of the upper mouth and the lower mouth; (6) the hookup control line of the end mold of the brim is confirmed and then an alternative installation method is adopted; (7) a brim concrete is symmetrically poured. The present invention has the advantages of convenient mechanical construction, small labor investment, multi-faceted parallel operation, simple template installation, high work efficiency and less deviation of structural size, thus ensuring the smooth and pleasing appearance and size; one-time pouring and less construction joints, thus strengthening the waterproof performance of the bright door and the portal.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

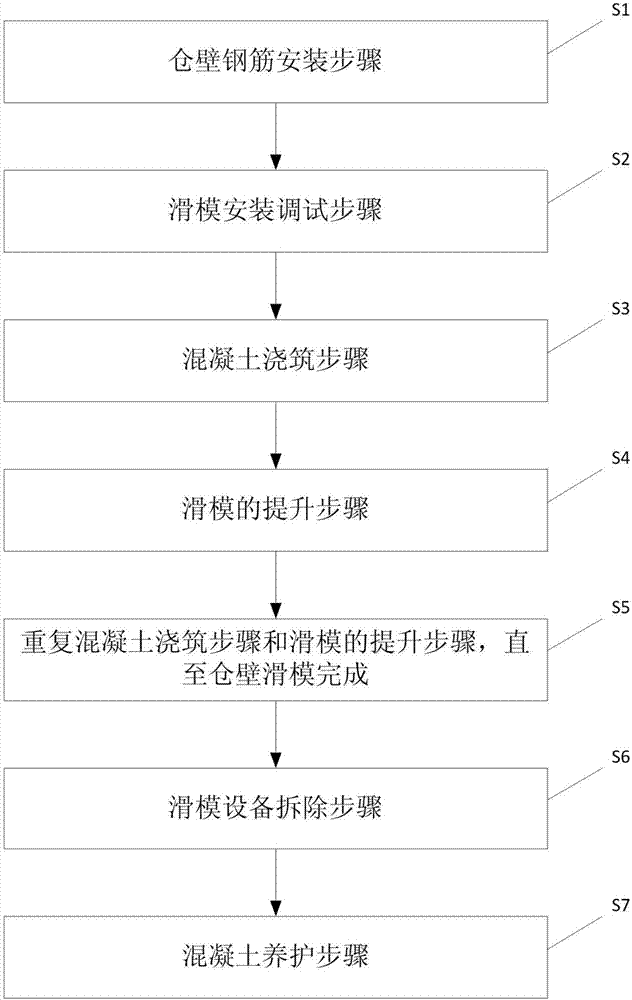

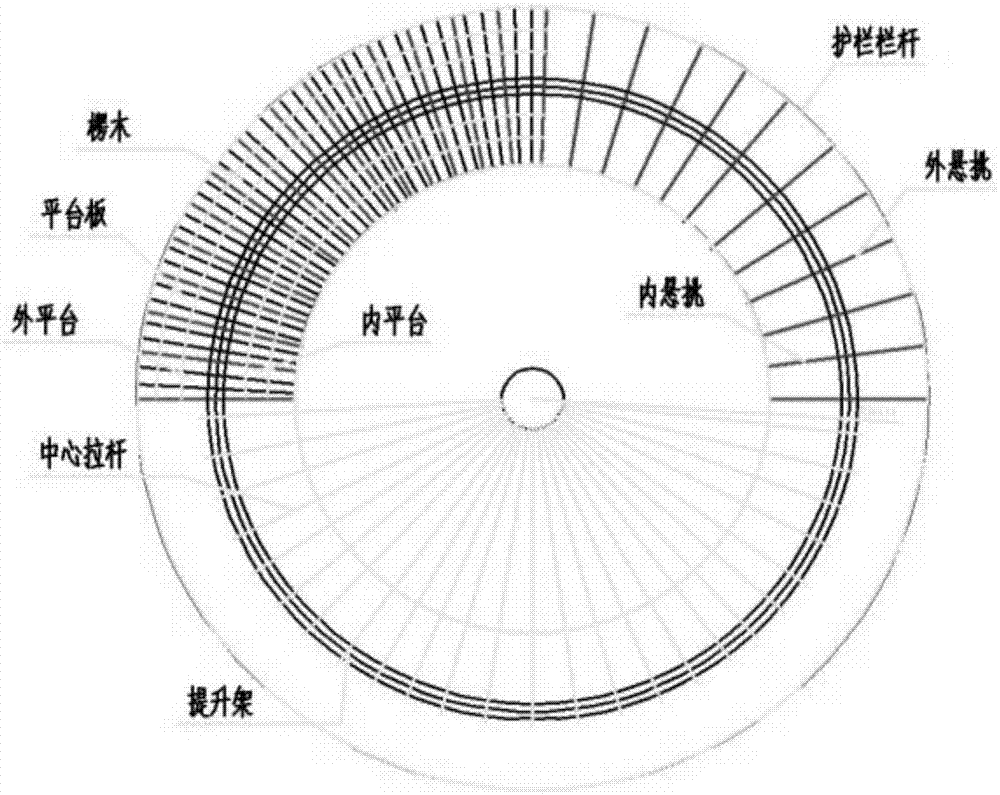

Construction method of sliding formwork for large-diameter silo

InactiveCN107882321ASave materialLabor savingForms/shuttering/falseworksBuilding material handlingFalseworkThree stage

The invention discloses a construction method of a sliding formwork for a large-diameter silo. The construction method comprises the steps that 1, silo wall steel bar mounting is conducted; 2, slidingformwork mounting and debugging are conducted; 3, concrete pouring is conducted; 4, sliding formwork lifting is conducted, wherein tank wall sliding formwork lifting is divided into three stages, namely primary sliding, normal sliding rising and tank wall top formwork sliding rising; 5, concrete pouring and sliding formwork lifting are repeated till the silo wall sliding formwork is completed; 6,sliding formwork device dismantling is conducted; and 7, concrete curing is conducted. According to the construction method, only one set of formworks is used, the formworks and an operating platformare lifted through a hydraulic jack, formwork supporting and scaffold setting up are not needed any longer, and thus the formworks, scaffold materials and manual work can be greatly saved; continuousoperation is kept during construction, various working procedures are simplified, the sections of the formworks do not need to be mounted and dismounted completely, and thus the construction speed ishigh; and concrete adopts continuous pouring, construction joints can be reduced, and integrality of a building can be ensured.

Owner:中铁建设集团南方工程有限公司

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

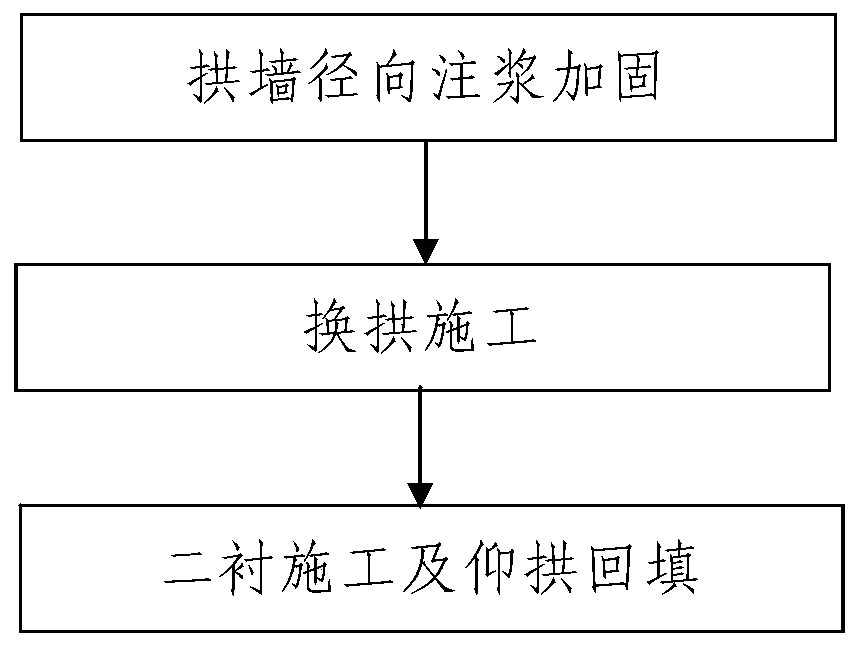

Method for beyond-limit arch replacing construction during preliminary bracing of large-section loess tunnel

ActiveCN110656959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a method for beyond-limit arch replacing construction during preliminary bracing of a large-section loess tunnel. The method includes the steps of firstly, conducting radial grouting reinforcement on an arch wall, wherein radial grouting reinforcement is conducted on an arch replacing required section where arch replacing is required in the constructed loess tunnel from back to front; and secondly, conducting arch replacing construction, wherein a reinforced preliminary bracing structure in the arch replacing required section is detached, and preliminary bracing construction is conducted on the arch replacing required section synchronously in the detaching process. The method is simple in step, reasonable in design, simple in construction and good in use effect; theradial grouting reinforcement is conducted on the arch wall to reinforce the arch wall of a tunnel hole first, so the structural stability of the tunnel in the arch replacing process is ensured; segmented reinforcing is conducted on the preliminary bracing structure of the tunnel through a plurality of sleeve arch units for a reinforced sleeve arch in the arch replacing required section, so detaching is convenient; and moreover, the sleeve arch units are complementary and together improve the supporting force, so the adverse effects on the structural stability of the tunnel in the detaching process of each sleeve arch unit can be effectively reduced, and the safety and reliability of the arch replacing construction process are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

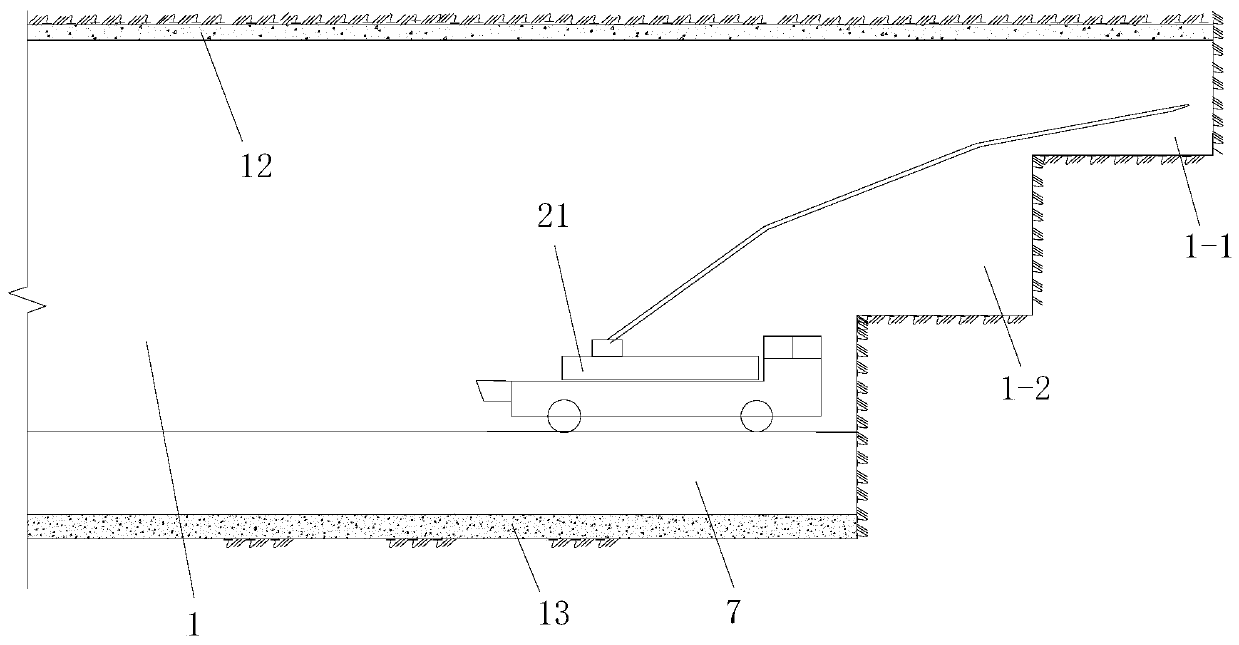

Loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles

PendingCN110671131AReasonable designReduce construction costsUnderground chambersTunnel liningStructural engineeringGeotechnical engineering

The invention discloses a loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles. The structure comprises the multiple rows of high pressure jet grouting piles for reinforcing soil on the lower portion of a tunnel, and each high pressure jet grouting pile passes through a tunnel invert structure and a collapsible loess stratum from top to bottom andthen extends into a non collapsible loess stratum. The method comprises the following steps of firstly, tunnel excavating and preliminary bracing; secondly, second lining construction; and thirdly, foundation base reinforcing. The structure is reasonable in design, easy and convenient to construct and good in use effect. The multiple rows of high pressure jet grouting piles are adopted for carrying out foundation base reinforcing on a loess tunnel, a loess tunnel foundation base can be simply and rapidly effectively reinforced, the tunnel foundation base settling volume can be effectively controlled, meanwhile, the upper surface of a secondary lining inverted arch is adjusted to the horizontal plane, a construction platform is provided for the high pressure jet grouting piles, the loess tunnel foundation base reinforcing process can be further quickened, the high pressure jet grouting piles and the tunnel invert structure are fastened and connected into a whole, and the loess tunnel foundation base reinforcing effect can be further improved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

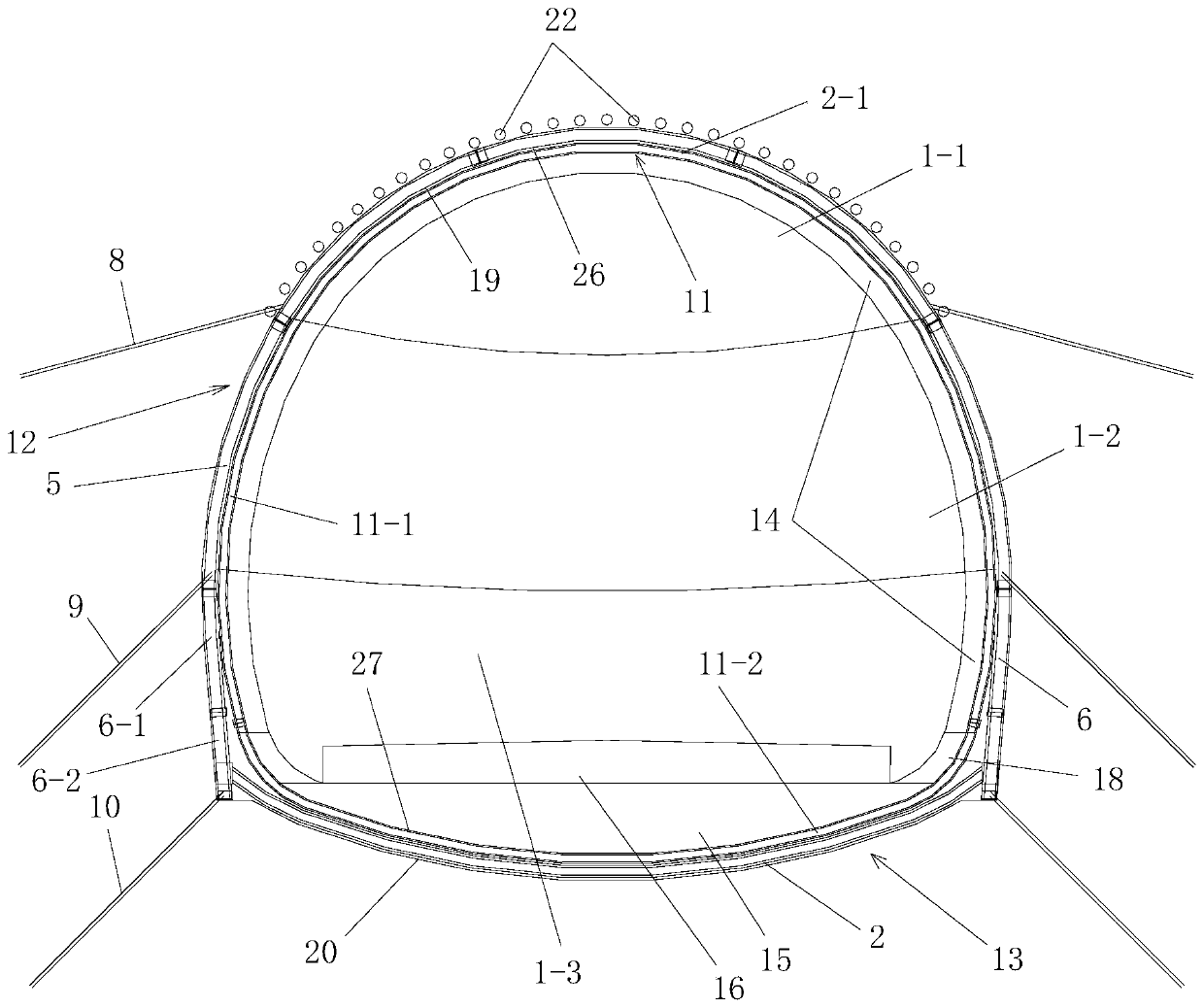

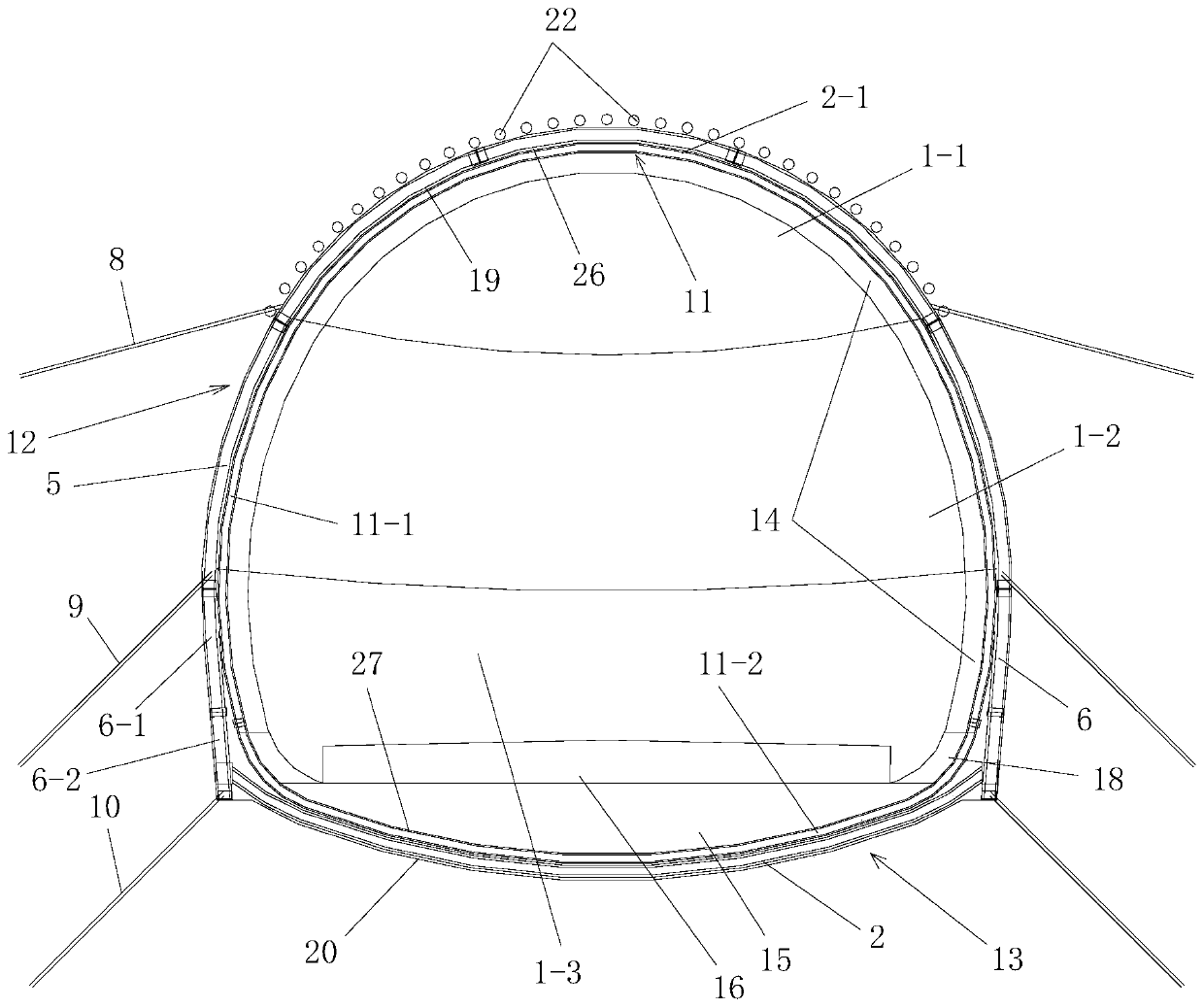

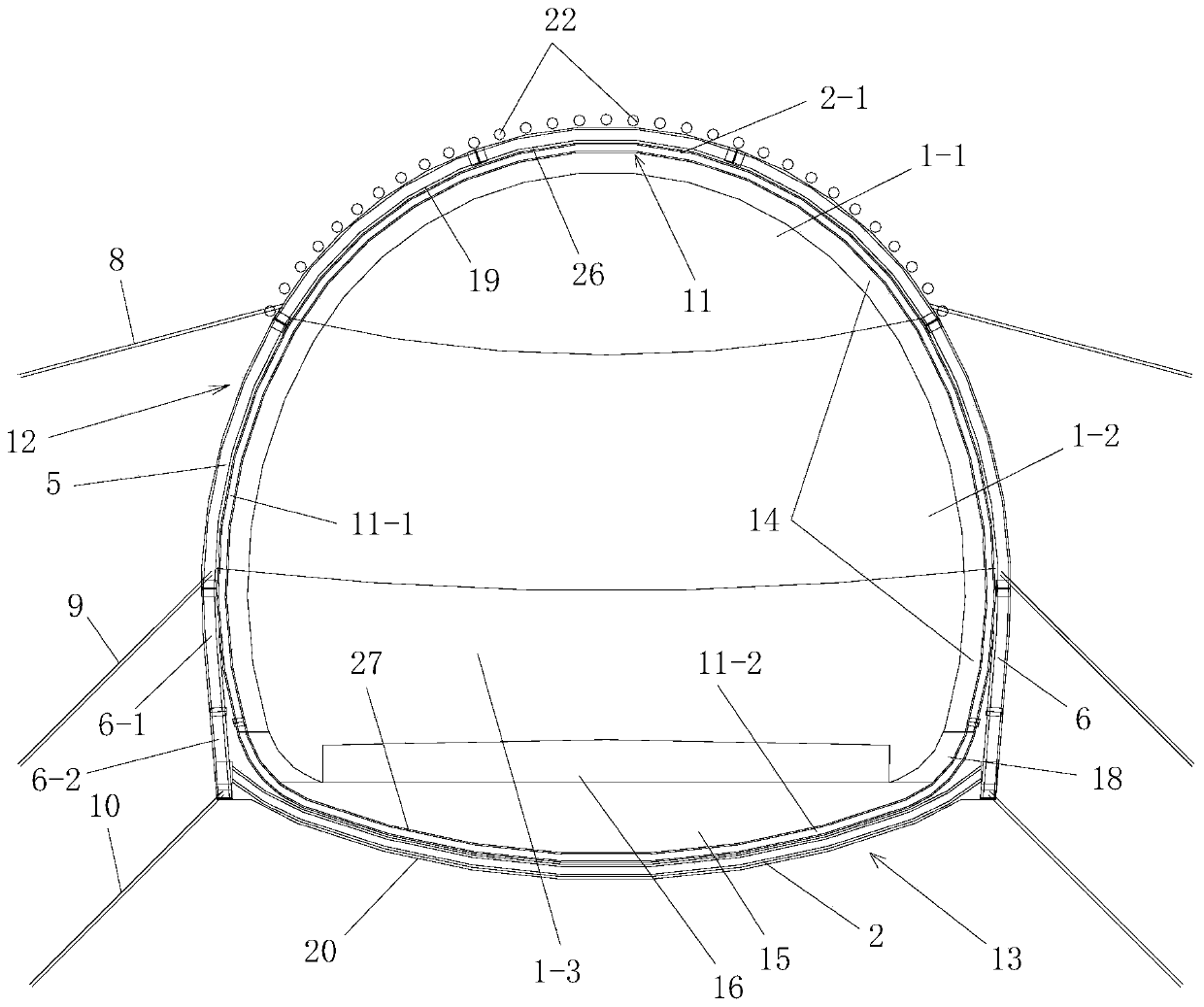

Large-section loess tunnel supporting system and supporting construction method

PendingCN110761808AReasonable structural designEasy constructionUnderground chambersTunnel liningGeotechnical engineeringStructure support

The invention discloses a large-section loess tunnel supporting system and a supporting construction method. The large-section loess tunnel supporting system comprises a tunnel forepoling structure, atunnel initial supporting structure and a tunnel secondary lining. The upper surface of an inverted arch secondary lining in the tunnel secondary lining is a horizontal plane, and an inverted arch backfill layer is arranged on the horizontal plane. The supporting construction method comprises the following steps of firstly digging a tunnel and conducting initial supporting; and secondly constructing the secondary lining and backfilling the inverted arch. The large-section loess tunnel supporting system is reasonable in design, easy and convenient to construct, high in construction efficiencyand good in use effect, the tunnel forepoling structure, the tunnel initial supporting structure and the tunnel secondary lining constitute a combined supporting system to stably and reliably supportthe large-section loess tunnel, the upper surface of the inverted arch of the secondary lining is adjusted to be a horizontal plane, the construction process of the inverted arch of the tunnel can beeffectively simplified, and the rigidity of the inverted arch of the tunnel is greatly improved; in this way, the construction efficiency of the tunnel secondary lining is improved, the ring sealingtime of the tunnel secondary lining is shortened, the integrity of the tunnel secondary lining is higher, and the overall force bearing effect is better.

Owner:CHINA RAILWAY 20 BUREAU GRP

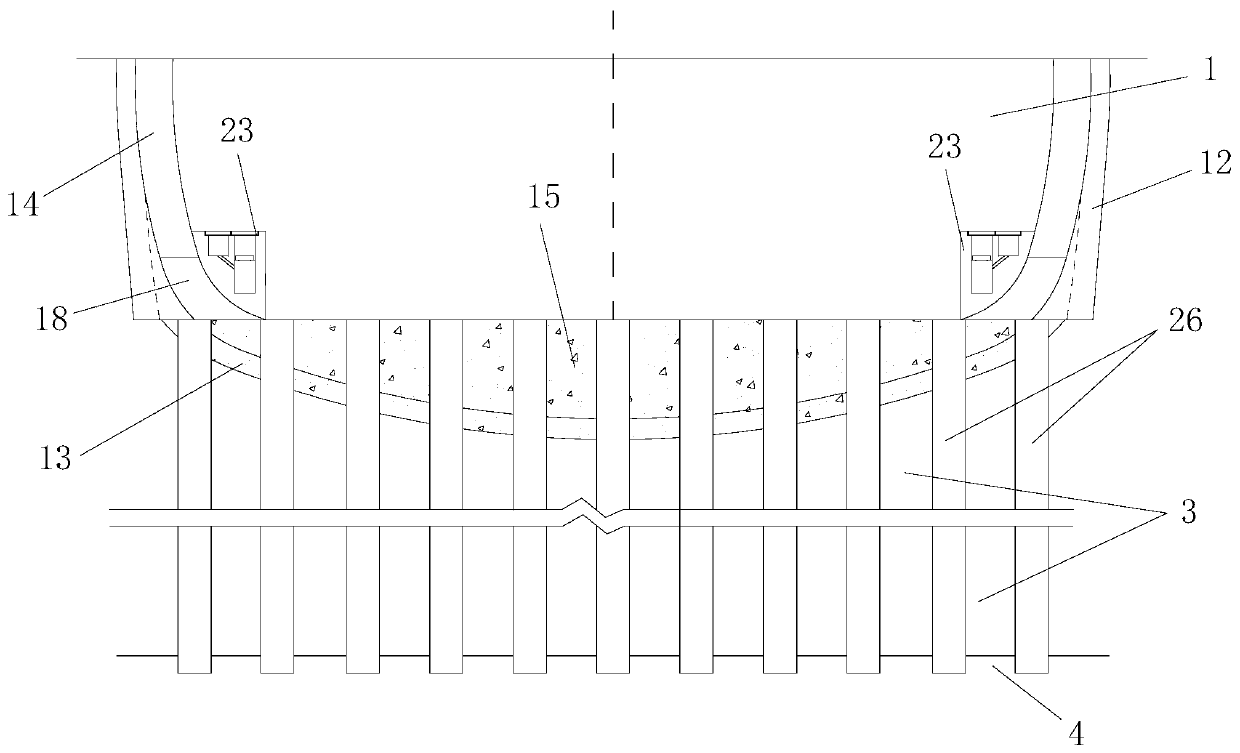

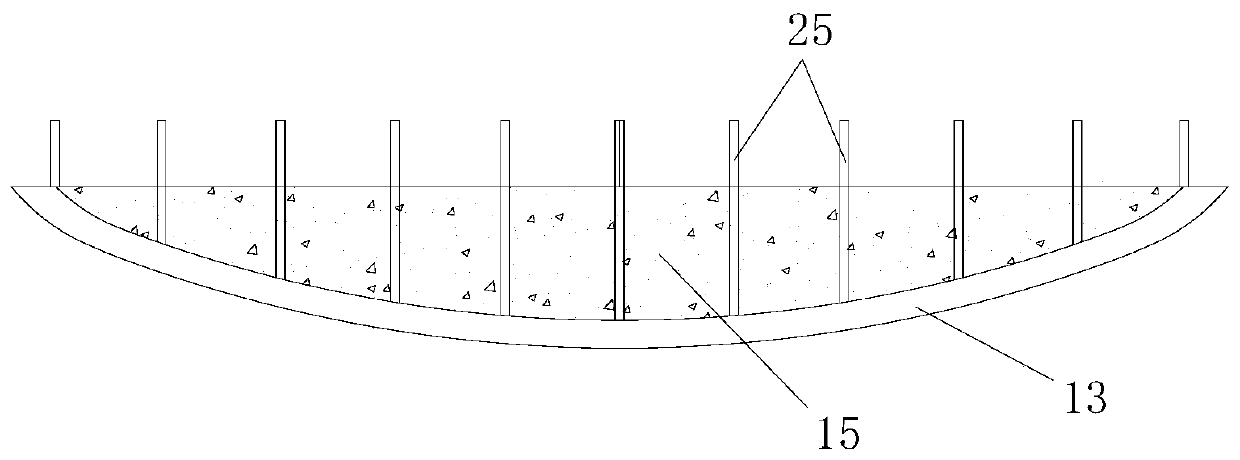

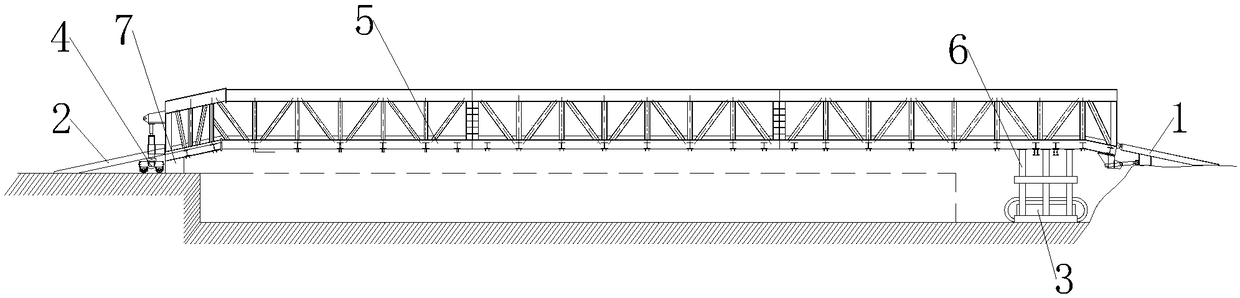

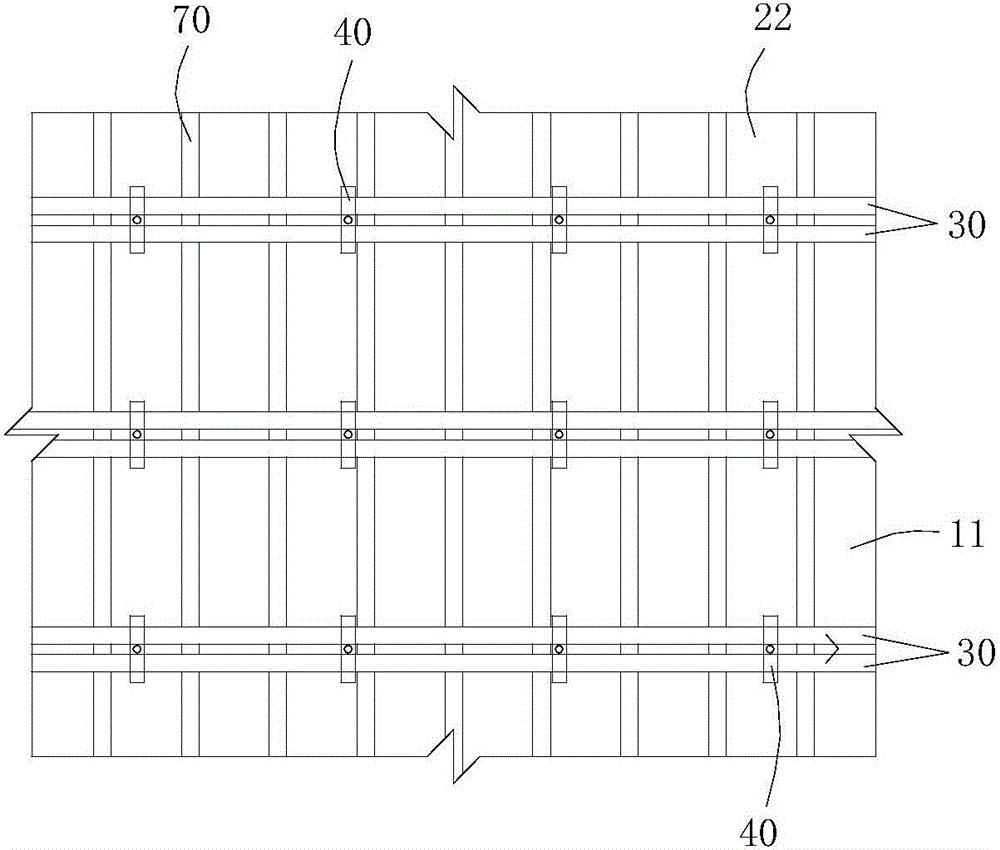

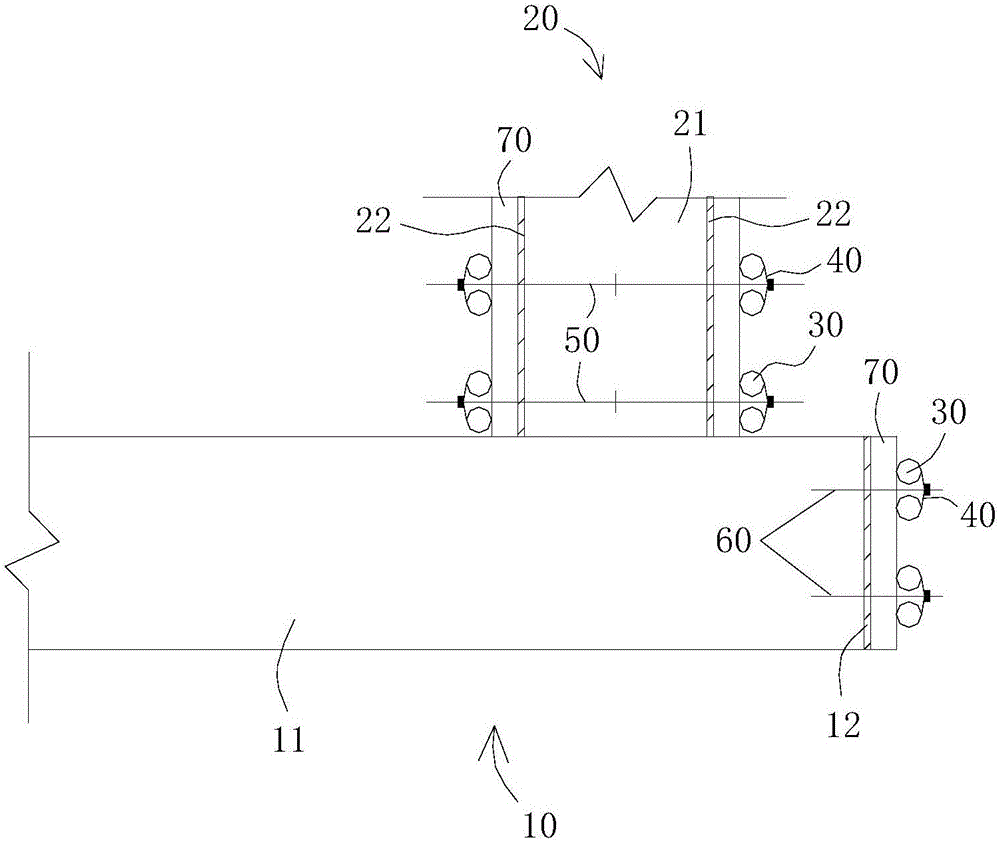

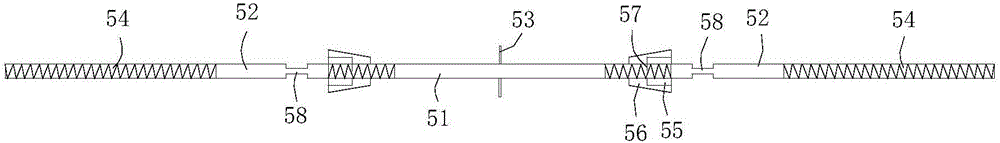

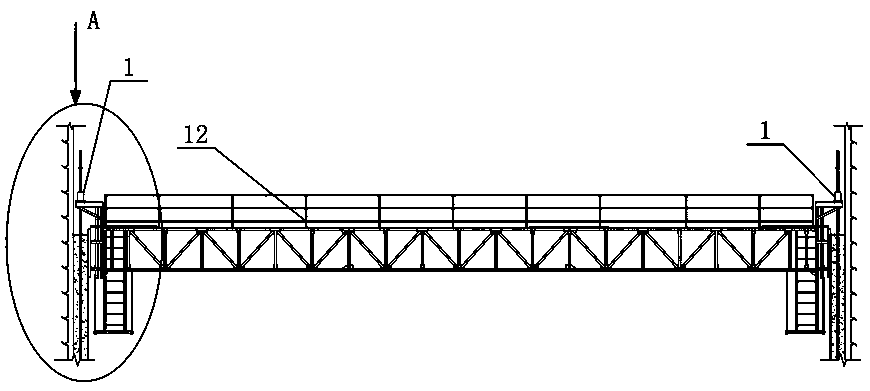

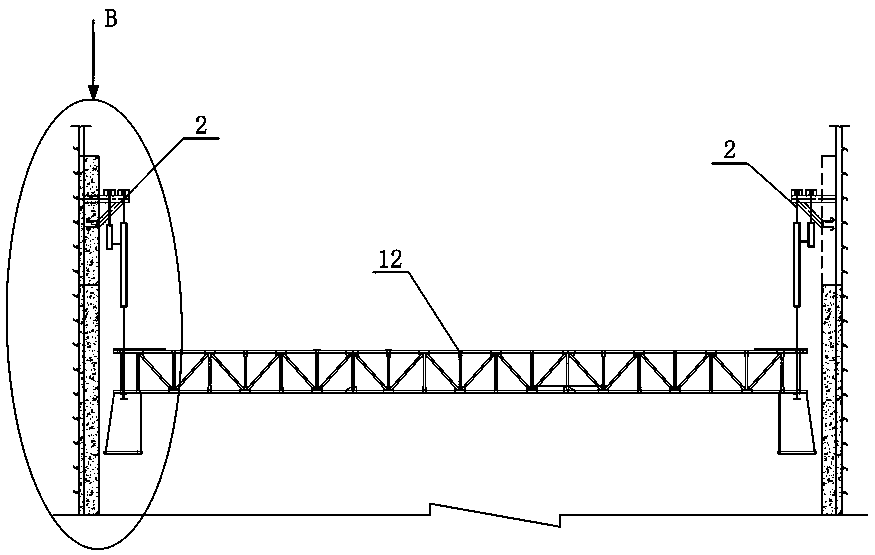

Tunnel inverted arch integral and self-propelled type long trestle structure and construction method

InactiveCN109139039ASmall construction impactReduce construction jointsUnderground chambersTravelling bridgesTunnel constructionBearing capacity

The invention provides a tunnel inverted arch integral and self-propelled type long trestle structure and a construction method. The tunnel inverted arch integral and self-propelled type long trestlestructure comprises a front end approach bridge, a rear end approach bridge, a driving walking system, a driven walking system and a main bridge. The driving walking system supports at the front end of the main bridge through a front end fixing and supporting device, and the driven walking system supports at the rear end of the main bridge through a rear end fixing and supporting device. One end of the front end approach bridge is connected with the front end of the main bridge, and one end of the rear end approach bridge is connected with the rear end of the main bridge. A modularized structure capable of being disassembled and installed rapidly is adopted, the structural design is reasonable, and the bearing capacity is large; the influence on a tunnel face construction is small; the investment of labor cost and equipment cost of the inverted arch construction is reduced, and the cost is reduced; the construction efficiency is improved, and the period of the tunnel construction is shortened; and construction joints of an inverted arch are reduced, the integrity of the inverted arch is improved, and the quality of inverted arch concrete is improved.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

Construction method of loess tunnel entrance section through landslide mass

ActiveCN110778328AThe method steps are simpleReasonable designUnderground chambersExcavationsLandslideStructural engineering

The invention discloses a construction method of a loess tunnel entrance section through a landslide mass. The method comprises the following steps that 1, an entrance soil layer is pre-reinforced; 2,a tunnel entrance is constructed; 3, excavation and initial support construction is conducted on the reinforced tunnel section; 4, a reinforced tunnel section base is reinforced; 5, the reinforced tunnel section is subjected to secondary lining construction; 6, excavation and initial support construction is conducted on a rear side tunnel section; and 7, the rear side tunnel section is subjectedto secondary lining construction. The method is reasonable in design, simple and convenient to construct and good in use effect, cement-soil mixed piles are adopted for pre-reinforcement before excavation, a construction process of the tunnel entrance section through the landslide mass is guaranteed to be safe and reliable, meanwhile, the tunnel entrance section is excavated by adopting a three-step excavation method, the reinforced tunnel section base is reinforced, an excavation process of the tunnel entrance section through the landslide mass can be guaranteed to be safe and reliable, in addition, the influence on the stability of a soil layer on the circumferential side of the tunnel entrance is small, and the stability of the excavated and formed tunnel entrance can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

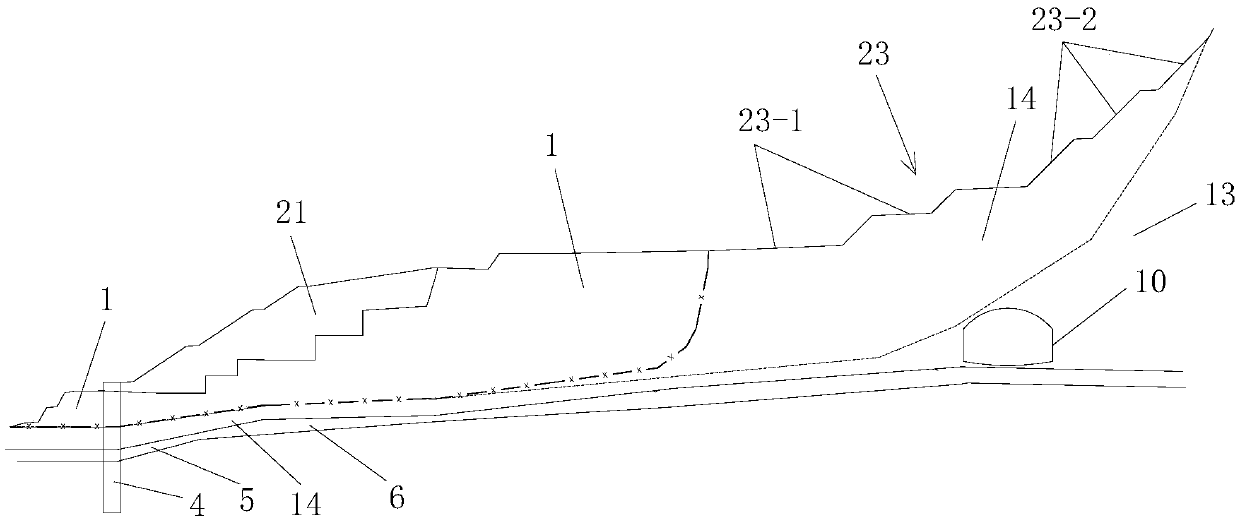

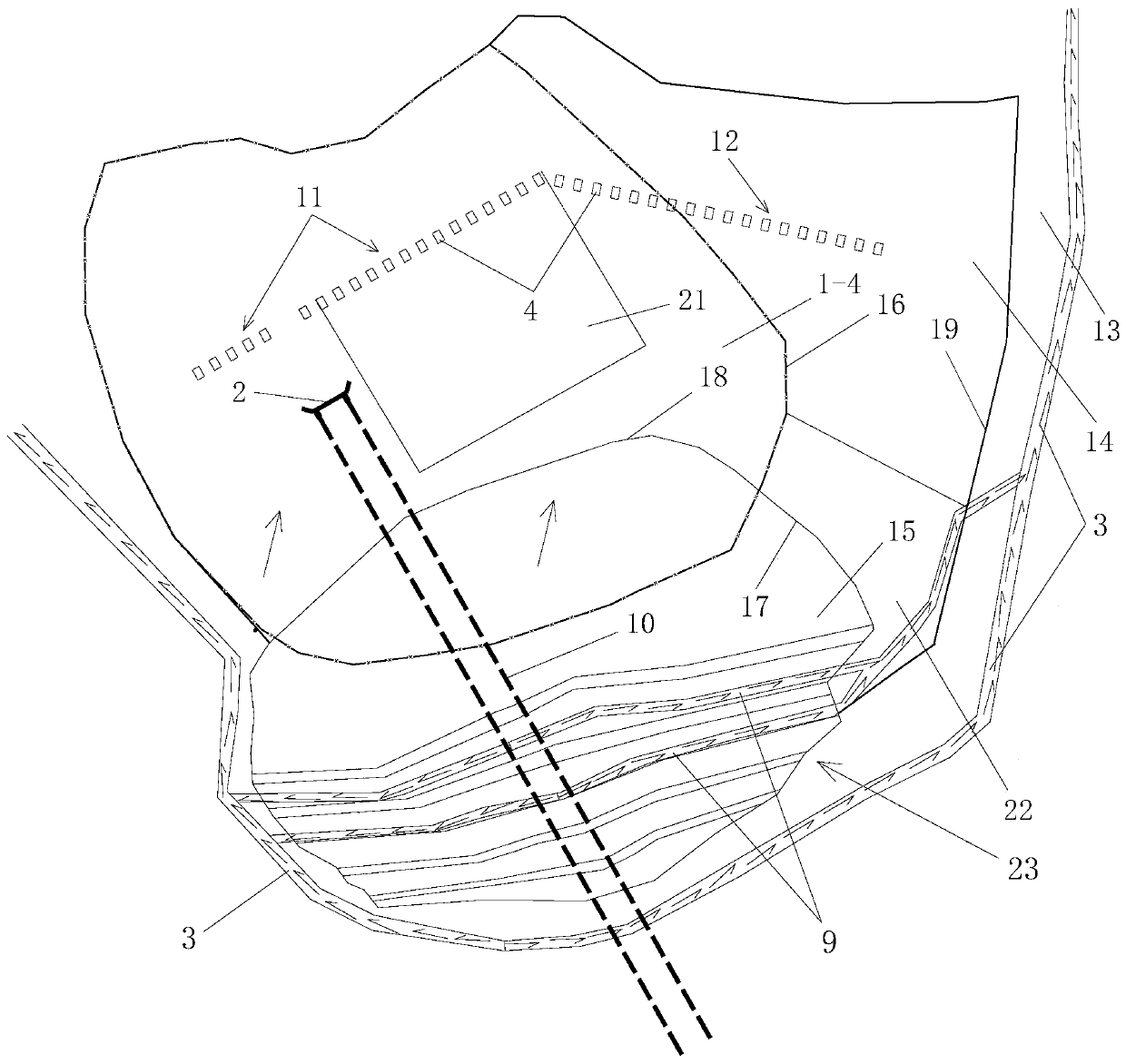

Tunnel portal section pre-reinforcement and excavation construction method based on partition blasting

ActiveCN110847929AConstruction safetyStable structureUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel portal section pre-reinforcement and excavation construction method based on partition blasting. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, earth surface pre-reinforcement, and specifically, reinforcing the surface of a backfill section in a construction tunnel portal section through adopting a cement soil stirring pile; and 3, tunnel excavation construction, and specifically, carrying out excavation construction from rear to front in a plurality of excavation sections, wherein the process comprises the following steps of surveying and setting out, performing drilling and blasting construction, excavating an upper portal body, excavating a middle portal body and excavating a lower portal body. The construction method is reasonable in design, simple and convenient in construction and good in use effect; the underground water level is reduced through precipitation pre-reinforcement, and then surroundingrock is effectively reinforced; after the backfill section is subjected to surface pre-reinforcement through using the cement soil stirring pile, a three-step synchronous excavation mode is used forcarrying out partition blasting excavation, so that it is ensured that the tunnel excavation process is safe and reliable and a tunnel structure is stable.

Owner:CHINA RAILWAY 20 BUREAU GRP

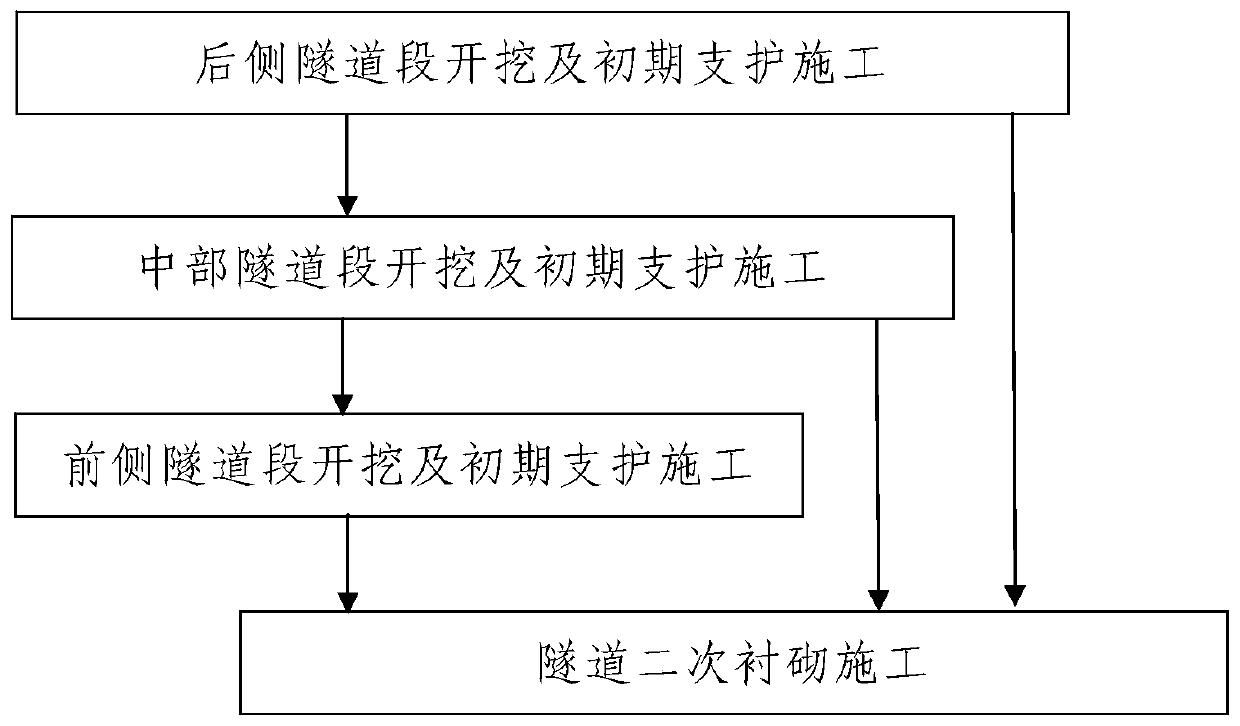

Tunnel construction method for passing through boundary strata of earth and stone

ActiveCN110985003AEffective reinforcementThe method steps are simpleUnderground chambersDrainageArchitectural engineeringDrilling and blasting

The invention discloses a tunnel construction method for passing through the boundary stratum of earth and stone. The tunnel construction method comprises the following steps: I, excavation of a reartunnel segment and initial supporting construction; II, excavation of a middle tunnel segment and initial supporting construction; III, excavation of a front tunnel segment and initial supporting construction, wherein the rear tunnel segment, the middle tunnel segment and the front tunnel segment are all three-step synchronous excavated tunnel segments; and in the process of excavation from rear to front, constructing the secondary lining of the tunnel on the inner side of the initial supporting structure of the constructed tunnel from rear to front. The tunnel construction method has the advantages of reasonable design, simple construction and good use effect. The tunnel construction method selects an appropriate drilling and blasting method according to the position relationship betweenthe earth and stone interface and a tunnel hole, adopts a three-step synchronous excavation way to carry out blasting excavation, can ensure the safe and reliable excavation process of the tunnel passing through the boundary stratum of earth and stone, and can ensure the stable structure of the tunnel. Moreover, in the excavation process, the initial supporting structure and the secondary lining of the tunnel are adopted to provide stable and reliable supporting for the large-section tunnel.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Through landslide body loess tunnel construction method

ActiveCN110905529AThe method steps are simpleReasonable designUnderground chambersTunnel liningTrackwayLandslide

The invention discloses a through landslide body loess tunnel construction method. The through landslide body loess tunnel construction method comprises the following steps of constructing a tunnel entrance section and a tunnel exit section simultaneously; and respectively constructing an inclined shaft auxiliary construction inlet section and an inclined shaft auxiliary construction outlet section through a tunnel inclined shaft when the tunnel entrance section and the tunnel exit section are constructed. The through landslide body loess tunnel construction method is reasonable in design, convenient to construct and good in using effect; the loess strata in the construction area where the tunnel entrance section is positioned is subjected to reinforcement treatment by using a cement soilmixing pile in advance before excavation, and the reinforcement length and the reinforcement depth are effectively limited; a loose soil body on a hole body of a tunnel hole is solidified in advance so as to ensure the safety and reliability of the construction process of a hole inlet section of the through landslide body loess tunnel; meanwhile, in the construction process of the tunnel by adopting a three-step excavation method, the construction process of track plates is completed synchronously, so that the construction process of the loess tunnel can be completed easily, conveniently and quickly; and the stability of an excavated and formed tunnel hole can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

Construction method of water-rich loess tunnel capable of passing through loess gulley

ActiveCN110792440AThe method steps are simpleReasonable designUnderground chambersTunnel liningTunnel constructionLoess

The invention discloses a construction method of a water-rich loess tunnel capable of passing through a loess gulley. The water-rich loess tunnel comprises a tunnel entrance entering section, a gulleyshallow-buried tunnel section and a front side tunnel section, wherein the gulley shallow-buried tunnel section is connected between the tunnel entrance entering section and the front side tunnel section; the construction method comprises the following steps: 1, constructing the tunnel entrance entering section; 2, constructing the gulley shallow-buried tunnel section; and 3, constructing the front side tunnel section. The construction method is simple in step, reasonable in design, simple and convenient in construction and excellent in using effect; the reasonable look-ahead reinforcing method and the tunnel base reinforcing method are selected to reinforce the tunnel soil mass according to different stratums of the tunnel entrance entering section, the gulley shallow-buried tunnel section and the front side tunnel section, the excavation process of the water-rich large-cross-section loess tunnel can be effectively ensured to be safe and reliable, and the stability of the dug formedtunnel can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

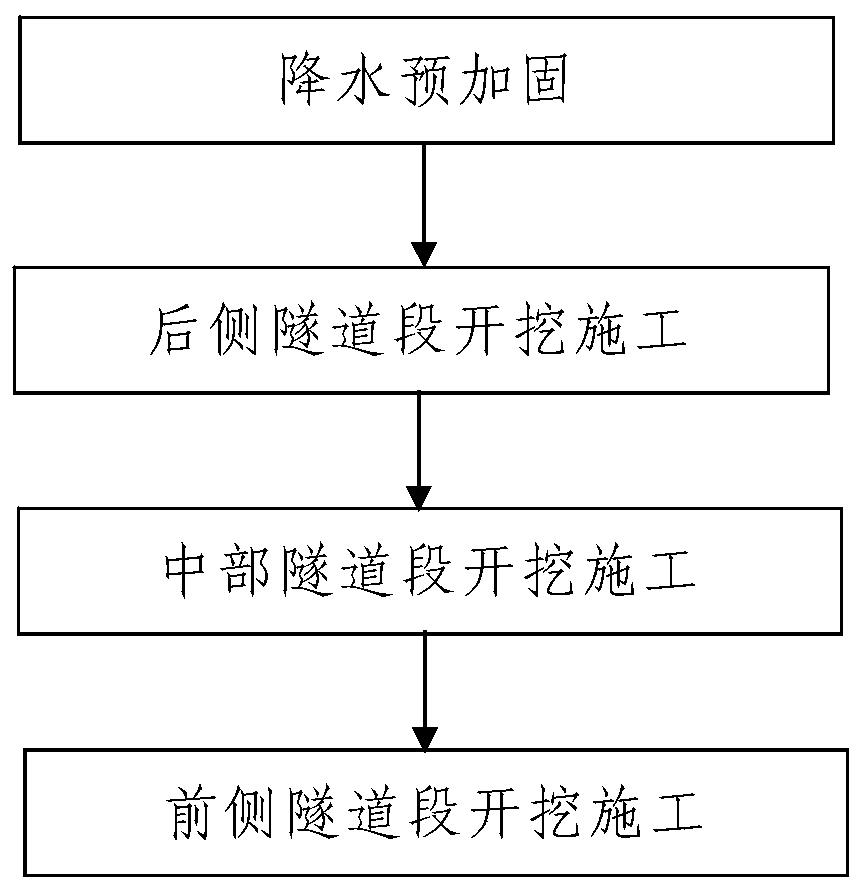

Construction method of soil-stone boundary tunnel passing through loess valleys

ActiveCN110700860AEffective reinforcementThe method steps are simpleUnderground chambersTunnel liningGround water levelStructure support

The invention discloses a construction method of a soil-stone boundary tunnel passing through loess valleys. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, excavation construction of a rear side tunnel section; 3, excavation construction of a middle tunnel section; and 4, excavation construction of a front side tunnel section, wherein the middle tunnel section and the front side tunnel section are three-step synchronous excavation tunnel sections; and in the excavation process from back to front in the step 2, the step 3 and the step 4, primarysupport is synchronously carried out on the excavated tunnel from back to front, and secondary lining of the tunnel is constructed on the inner side of the constructed and formed tunnel primary support structure from back to front. The construction method is reasonable in design, simple and convenient to construct and good in use effect, the underground water level is reduced through precipitationpre-reinforcement, surrounding rock is effectively reinforced, then blasting excavation is carried out in a three-step excavation mode, so that the excavation process of the soil-stone boundary tunnel passing through the loess valleys can be ensured to be safe and reliable, and the stability of the tunnel structure can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

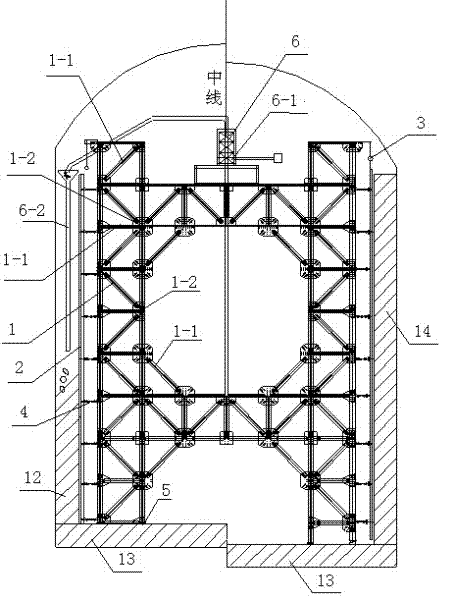

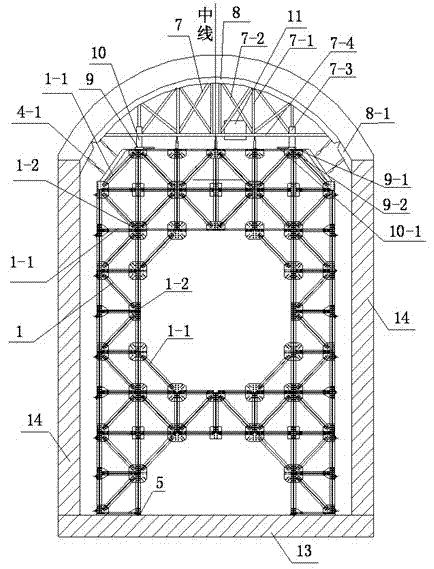

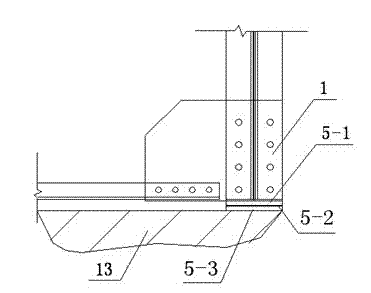

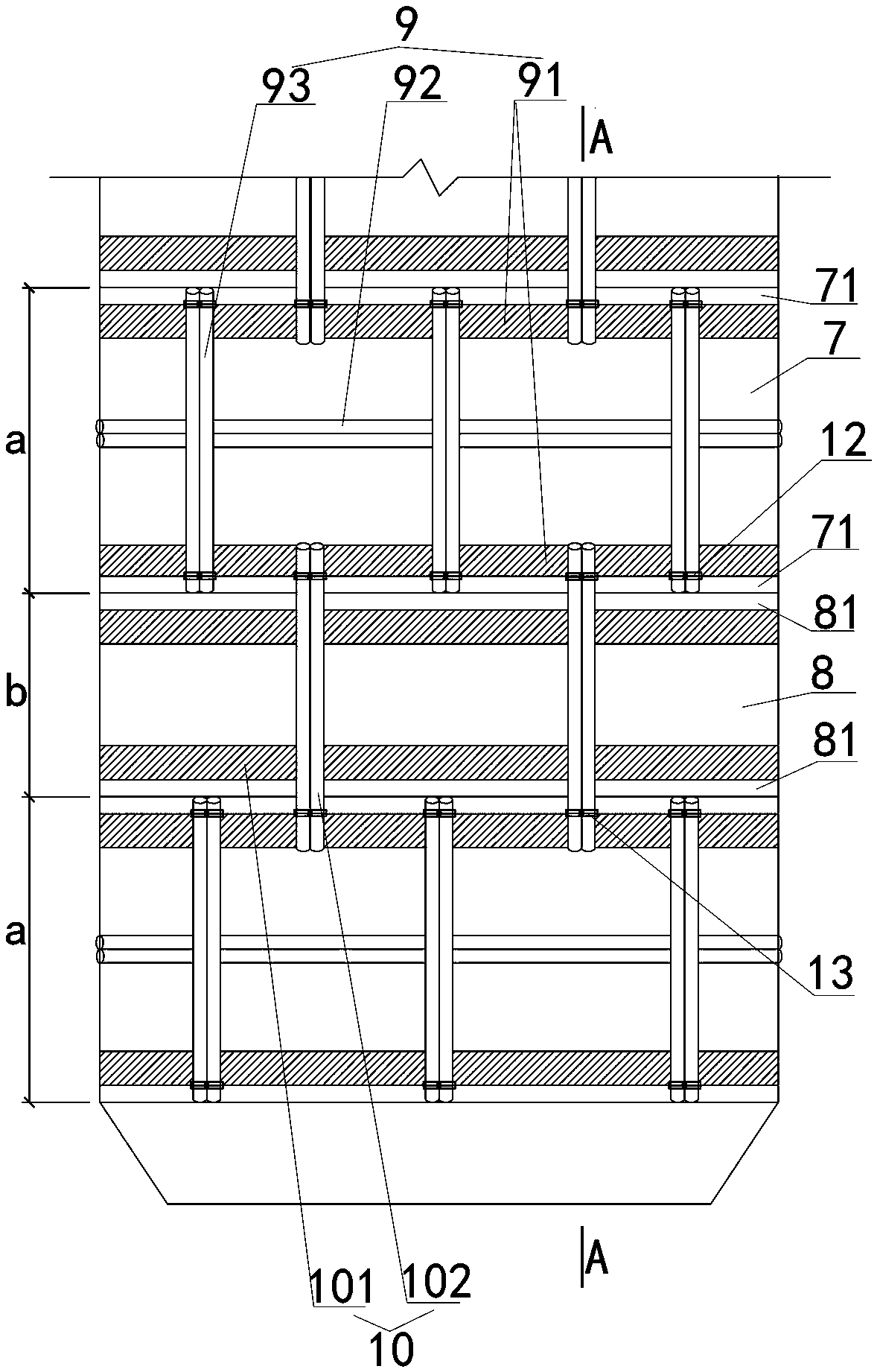

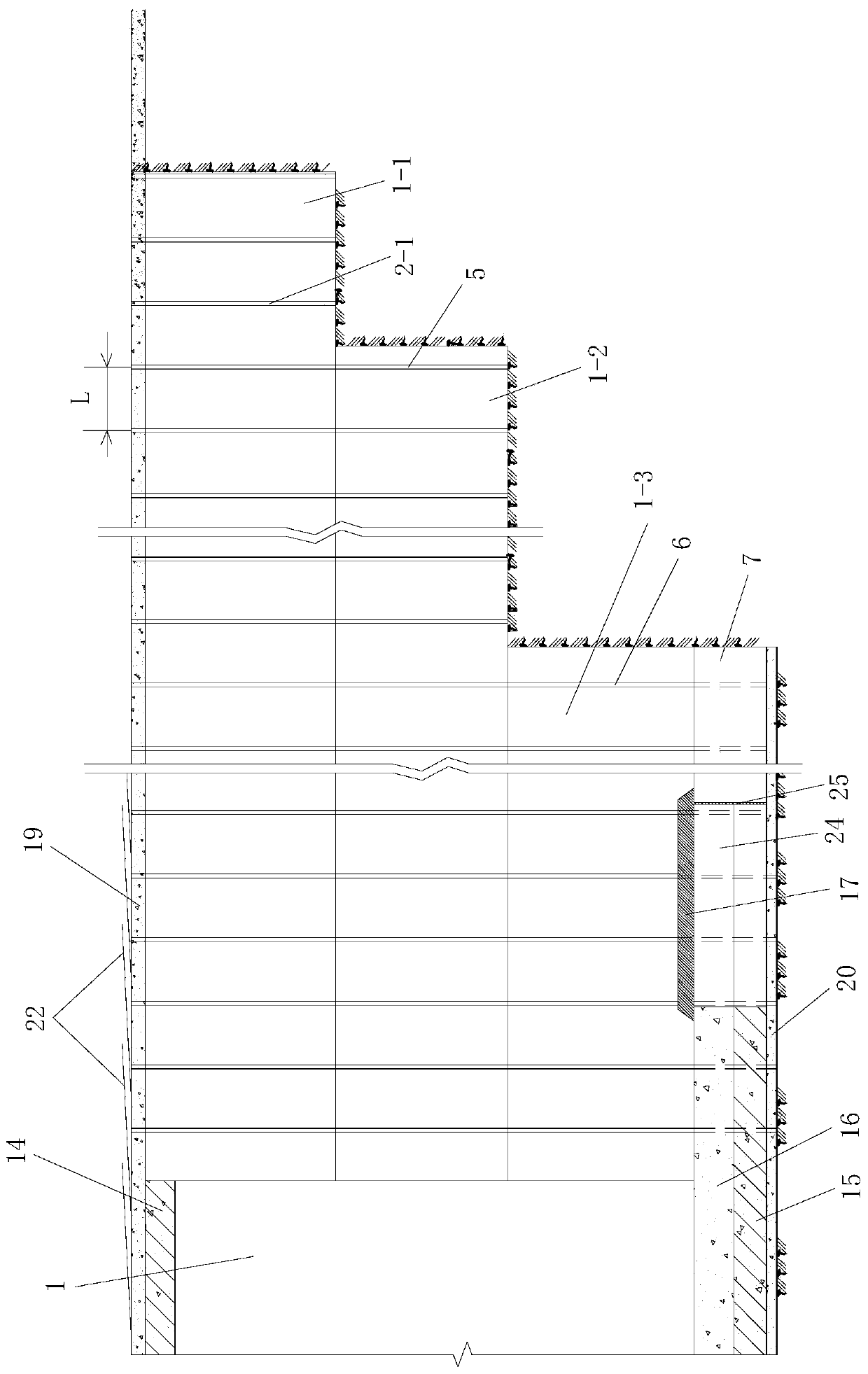

Construction desk frame for large-cross-section hole type spillway

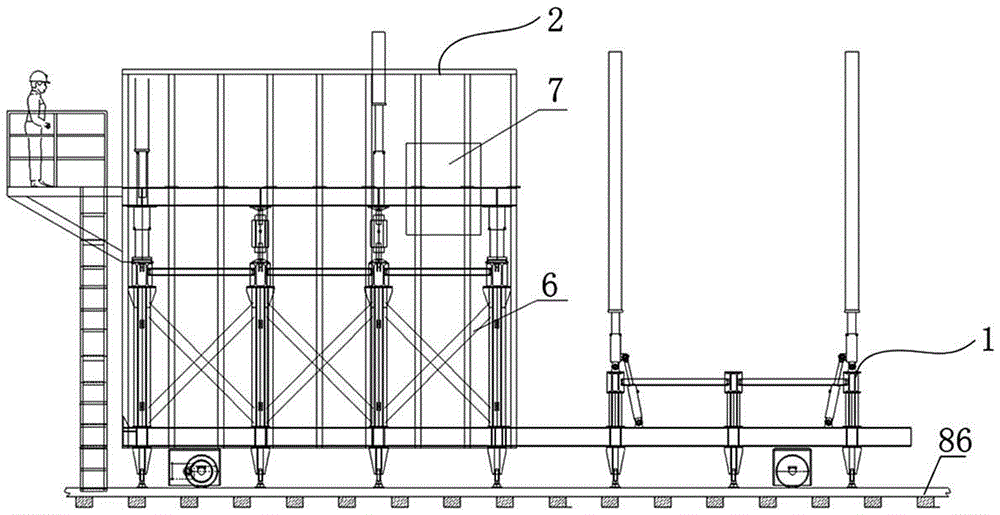

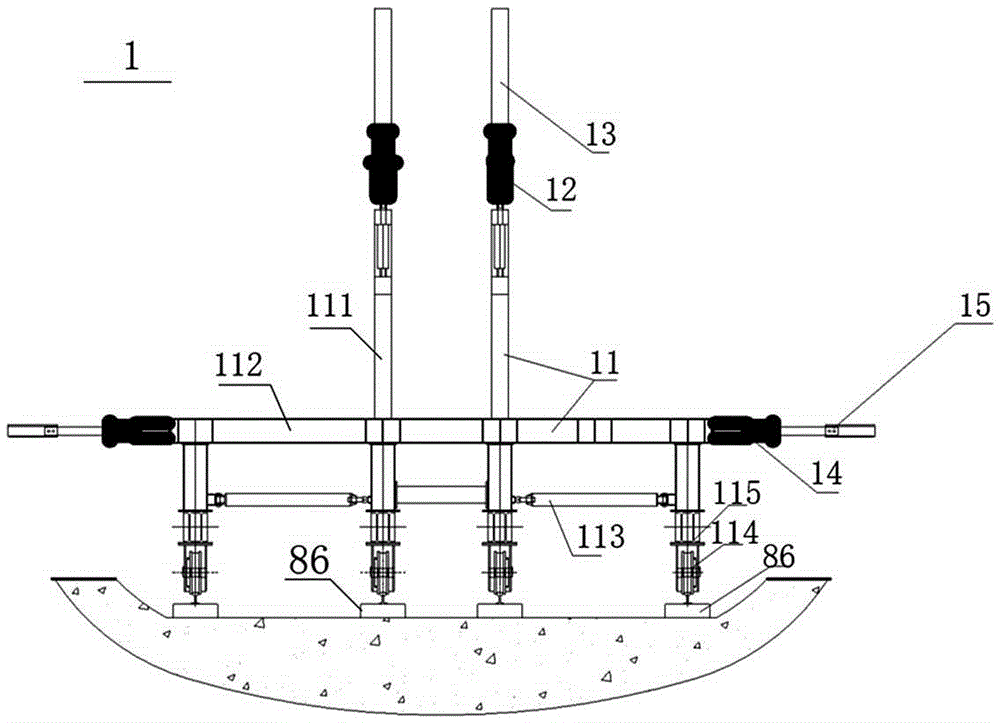

InactiveCN102477865AGuaranteed stiffnessGuaranteed flatnessUnderground chambersTunnel liningUltimate tensile strengthSpillway

The invention discloses a construction desk frame for a large-cross-section hole type spillway, and the construction desk frame comprises a desk frame main body (1). Side wall templates (2) are arranged on two sides of the desk frame main body (1) and are mutually connected through a first adjustable push rod (4); chain hoists (3) are arranged at the top of the two sides of the desk frame main body (1); a material distributing device (6) is arranged on the upper surface of the desk frame main body (1); a crown desk frame (7) is arranged at the upper part of the desk frame main body (1); a crown template (8) is arranged on the upper surface of the crown desk frame (7); a crown moving device (9) is mounted between the crown desk frame (7) and the desk frame main body (1); and a sliding waking device (5) is further arranged at the lower part of the desk frame main body (1). By using the construction desk frame for the large-cross-section hole type spillway, the construction of a super-large-cross-section hydraulic grotto is carried out; the operation is flexible; the interference to other working procedures is deceased; the in-position movement is simple and easy; and the working strength is decreased. On the aspect of lining quality, furthermore, a purpose-made large-sized steel template is adopted; the rigidity and the smoothness of the template are guaranteed; construction joints are reduced; and the guarantee of meeting a hydraulic concrete lining high standard is provided.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

Deep-buried loess tunnel deformation control construction structure based on cover arch and method

PendingCN110671132AReasonable designEasy constructionUnderground chambersTunnel liningArchitectural engineeringDeformation control

The invention discloses a deep-buried loess tunnel deformation control construction structure based on a cover arch and a method. The structure comprises a tunnel primary support structure body for primary support of a tunnel and the reinforcement cover arch arranged on the inner side of the tunnel primary support structure body, wherein the tunnel primary support structure body and the reinforcement cover arch form a reinforced primary support structure body. The method comprises the following steps of 1, carrying out tunnel excavation and primary support; and 2, carrying out reinforcement arc arch construction. The structure and the method have the advantages of being reasonable in design, simple and convenient in construction and good in use effect, the reinforcement cover arch is adopted to reinforce the tunnel primary support structure body and form the reinforced primary support structure body, an isolation layer is arranged between the reinforcement arc arch and the tunnel primary support structure body, in addition, the reinforcement cover arch adopts a plurality of cover arch units to reinforce the tunnel primary support structure body in a segmented mode, so that the construction is simple and convenient, moreover, the reinforced primary support structure body formed by construction has certain self-adaptive capacity and can effectively adapt to the deformation condition of soil mass on the peripheral side of the tunnel, and therefore the deformation resistance of the reinforced primary support structure body can be effectively enhanced.

Owner:CHINA RAILWAY 20 BUREAU GRP

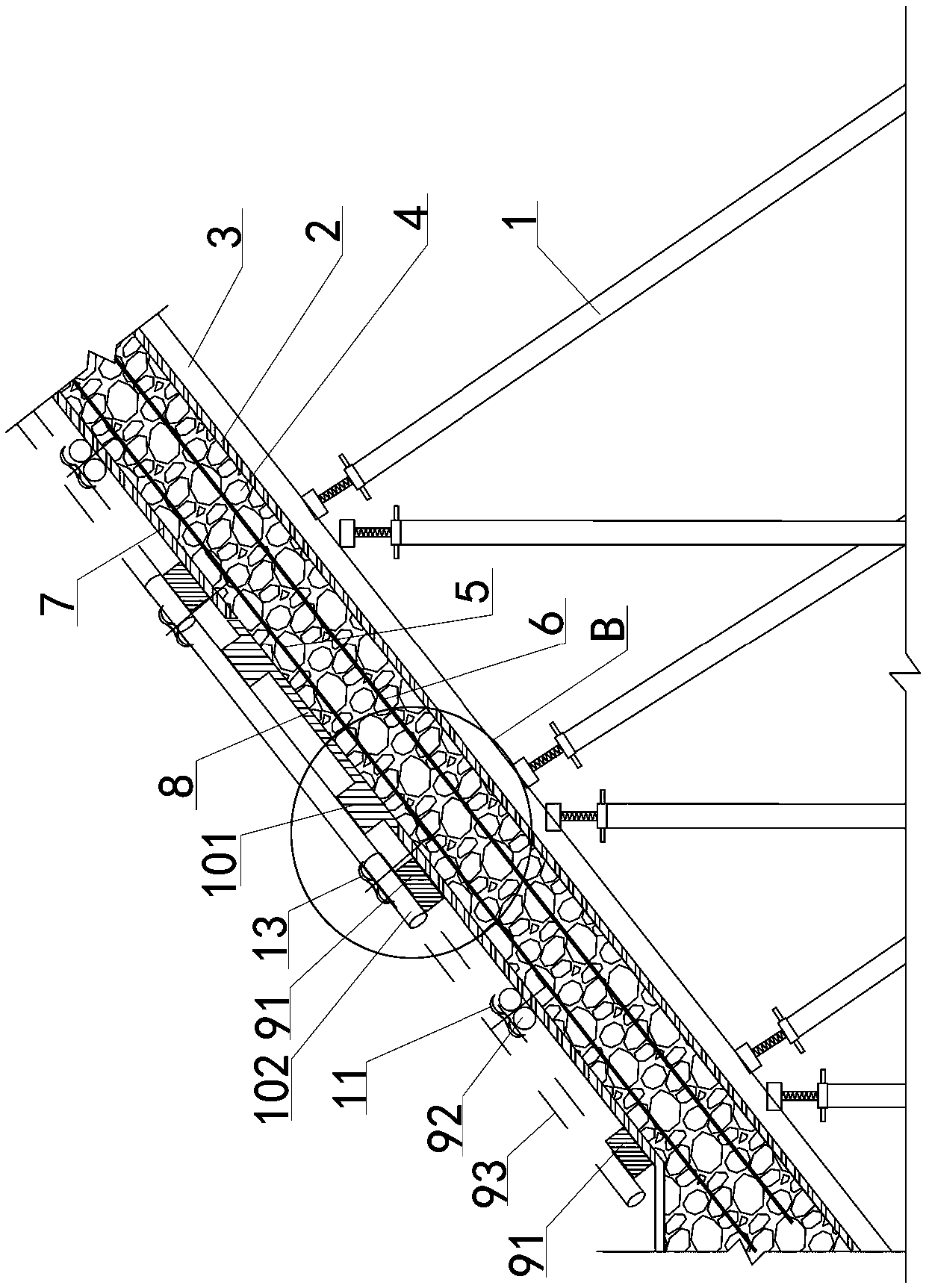

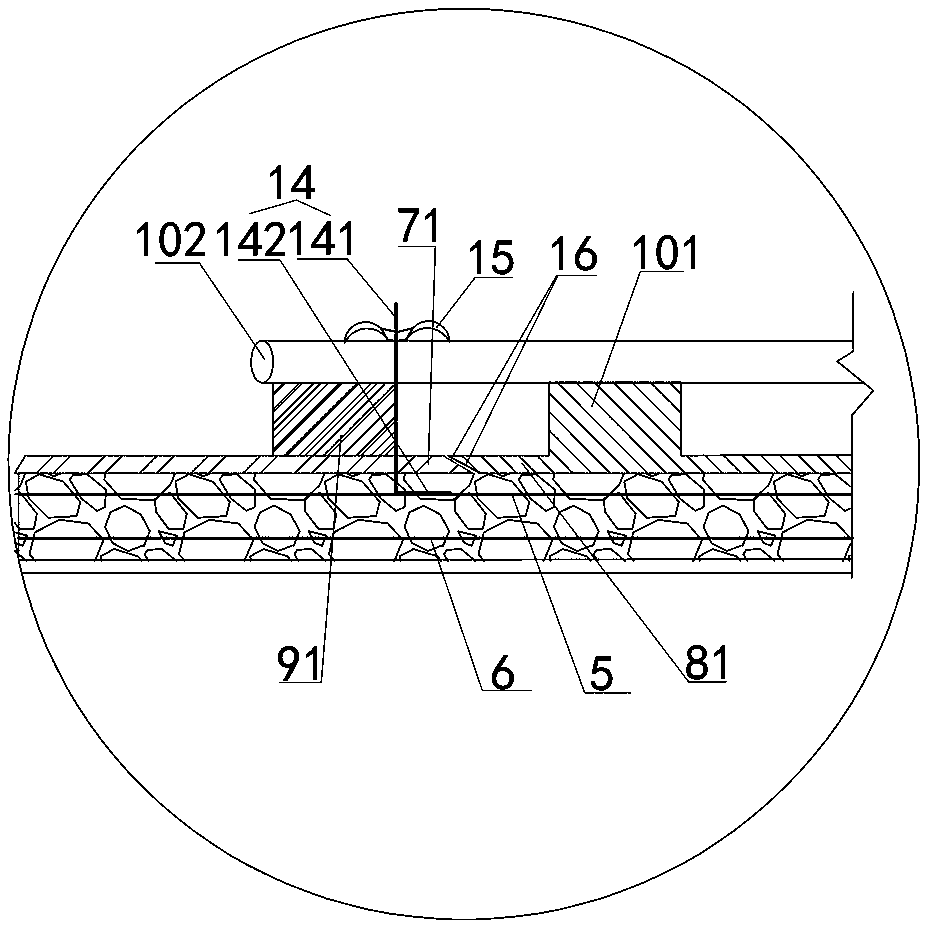

Large-span arch bridge empty case cast-in-situ arch ring template system and construction method thereof

PendingCN107700368AEasy to get materialsLess template damageBridge erection/assemblyArch-type bridgeRebarProcessing plants

The invention discloses a large-span arch bridge empty case cast-in-situ arch ring template system and a construction method thereof. The template system comprises a template structure, a supporting bracket body and an arc ring; the template structure comprises a bottom template, a bottom template keel, a cover template and a cover template keel; the cover template comprises a fixing front-positioned template unit and a moving back-positioned template unit; the cover template keel comprises a front-positioned keel unit and a back-positioned keel unit. Side walls of a front-positioned edge anda back-positioned edge are oblique faces which are adapted to each other in orientation and closed to each other. The construction method includes factory processing of the cover die, the bottom template construction, cover template construction, concrete pouring, and others. The construction method is simple and convenient to operate; the structure concrete has good quality and shaping; the cast-in-situ arch ring template system can be applied to the concrete casting of the bottom plate and the top plate of the cast-in-situ box type arch ring structure, and also applied to the template systemof other cast-in-situ large slope bevel reinforced concrete structure.

Owner:CHINA CONSTR FIRST GROUP THE FIFTH CONSTR +1

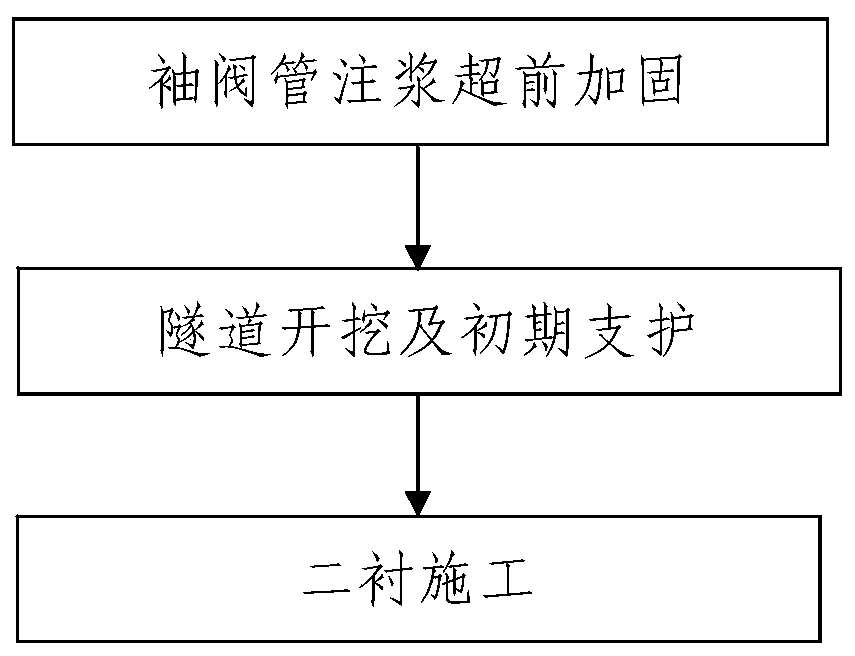

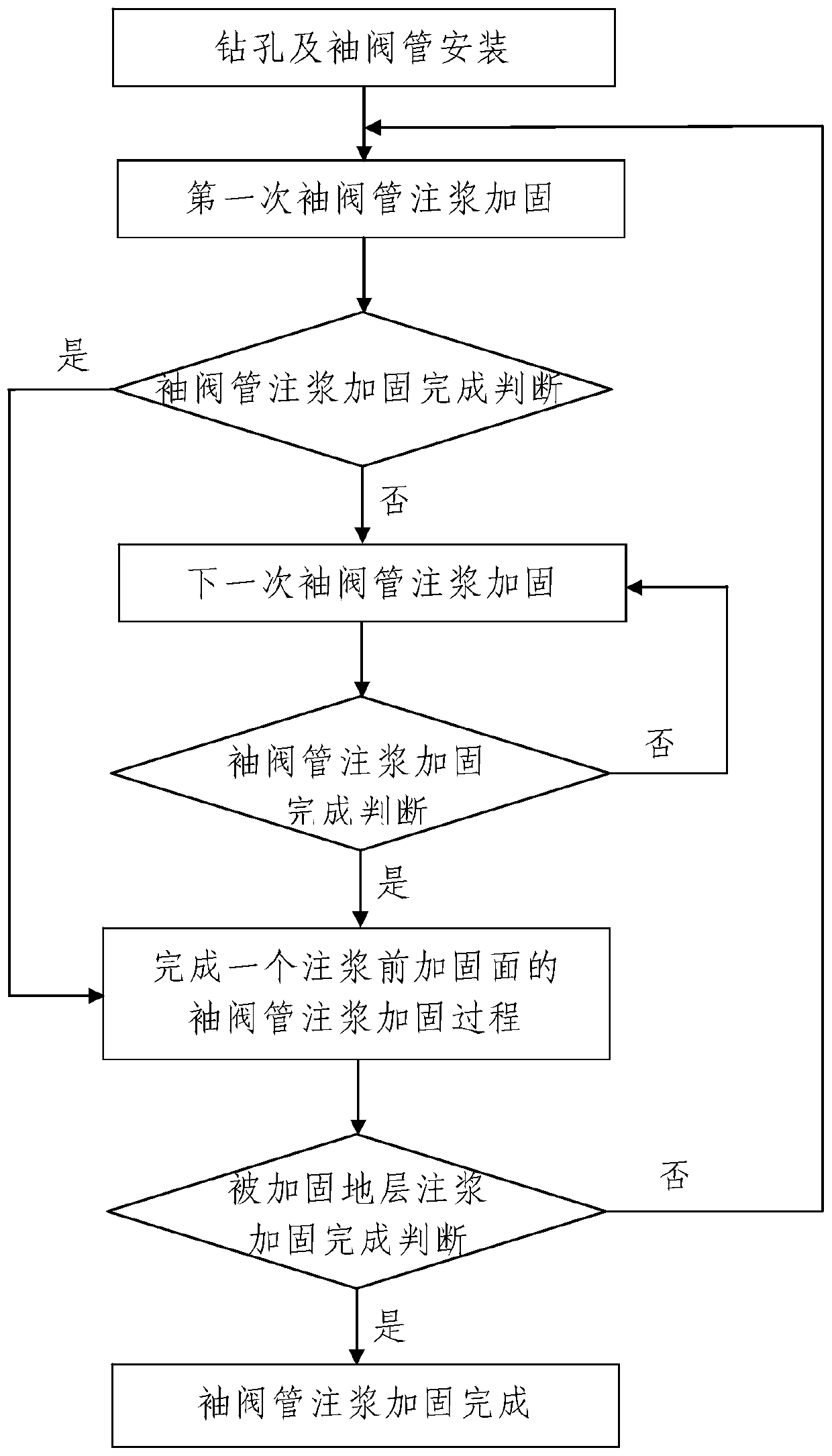

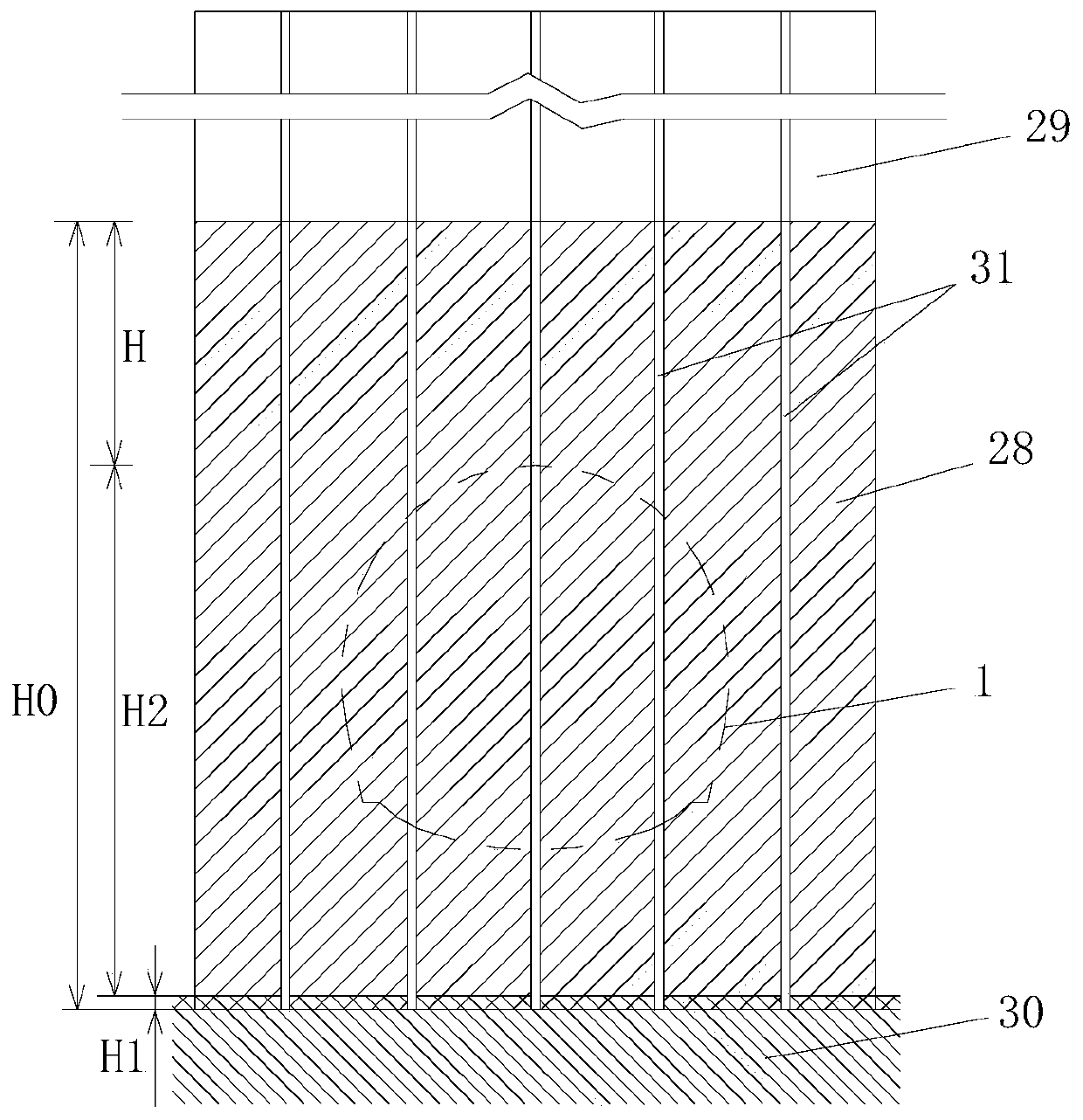

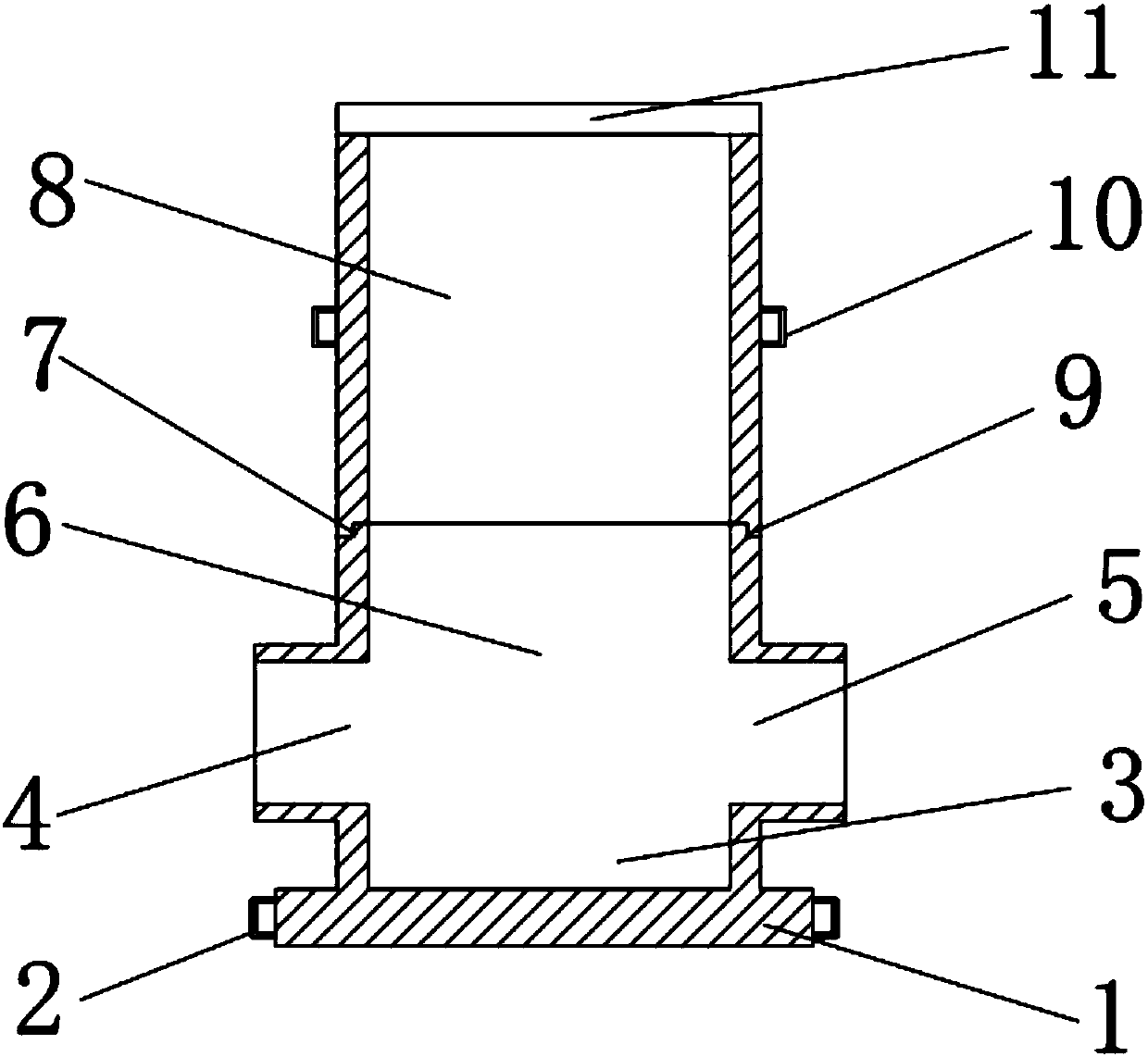

Construction method of shallow-buried tunnel in loess gully

ActiveCN110761795AThe method steps are simpleReasonable designUnderground chambersTunnel liningEarth surfacePipe

The invention discloses a construction method of a shallow-buried tunnel in a loess gully. The construction method comprises the following steps: 1, grouting a sleeve valve pipe for advancing reinforcement: carrying out sleeve valve pipe grouting for reinforcement on a stratum in the construction area of the constructed shallow-buried tunnel; 2, carrying out tunnel excavation and preliminary bracing; and 3, constructing a second lining. The construction method is simple in step, reasonable in design, simple and convenient in construction and excellent in using effect; the sleeve valve pipe isadopted and a plurality of rows of grouting holes are adopted to grout the reinforced stratum for reinforcement; the range of the reinforced stratum is specifically limited; both the tunnel hole bodyand the tunnel base can be reinforced, and the reinforcement effect is reliable; the shallow-buried tunnel construction method is particularly suitable for advancing reinforcement and excavation construction of the shallow-buried tunnel section which is positioned in a loess gully and is adjacent to an earth and stone interface, and the earth's surface of the shallow-buried tunnel is a silting-upland layer. The construction method can effectively ensure safety and reliability of the excavation process of the shallow-buried tunnel in the loess gully, can effectively improve the stability of the excavated tunnel hole and can effectively improve the bearing force of the tunnel base.

Owner:CHINA RAILWAY 20 BUREAU GRP

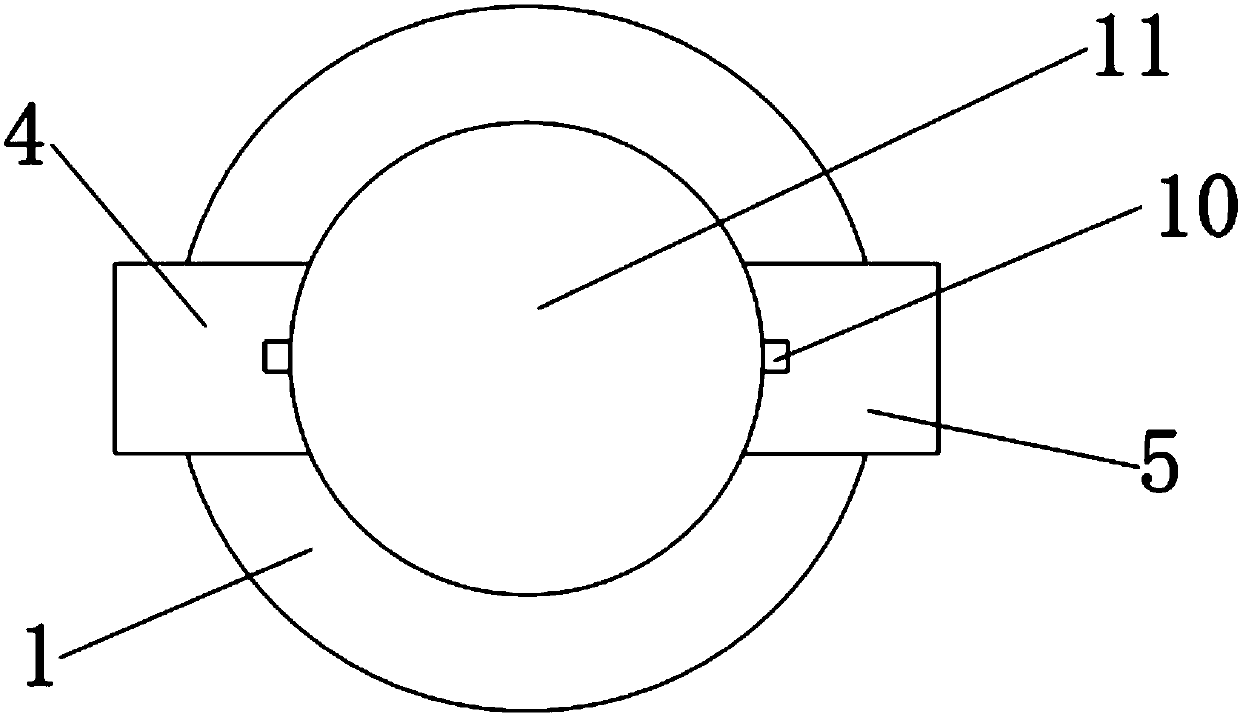

Prefabricated circular manhole with integrated base and chamber

InactiveCN107780514AReduce construction jointsImprove sealingSewerage structuresCost savingsEngineering

The invention discloses a prefabricated and assembled circular inspection well in the technical field of inspection wells, in which the base and the well chamber are integrated. Sedimentation chamber, the base of this kind of inspection well is an integral structure with the sludge sedimentation chamber and the lower well chamber, which reduces a construction joint, while the lower well chamber, water inlet pipe and outlet pipe are an integral structure, which reduces construction joints and increases inspection. The tightness of the well, the setting of the base suspension rings on both sides of the base and the upper well chamber suspension rings on both sides of the upper well chamber make the inspection well have a stress-bearing place when the crane is installed, and the installation is very convenient. The setting of the silt sedimentation chamber makes the water flow When the silt can settle down, the inspection well has simple structure, convenient maintenance, convenient hoisting operation, shortens the construction period and saves the cost.

Owner:ANHUI WANAN ENVIRONMENT ENG

Pouring formwork and construction method for once forming of bottom plate and pond wall of water treatment structure

InactiveCN106121335ARealize one-time moldingImprove impermeabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupport surfaceWater treatment

The invention provides a pouring formwork and a construction method for once forming a bottom plate and a pond wall of a water treatment structure. The pouring formwork comprises a bottom plate mould and a pond wall mould located on the bottom plate mould. In a concrete pouring process, pond wall lower opening concrete pouring is accomplished, an operator waits pond wall lower opening concrete to reach certain strength and to be able to provide a supporting surface for subsequent pond wall concrete pouring, and during the period, bottom plate concrete and pond wall concrete are alternately poured, so that the effect of reducing the pond wall concrete pouring speed is achieved, and side pressure on the pouring formwork by the pond wall concrete is reduced; the once forming of bottom plate and pond wall concrete construction is accomplished by controlling the concrete pouring order and the pond wall concrete pouring speed.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

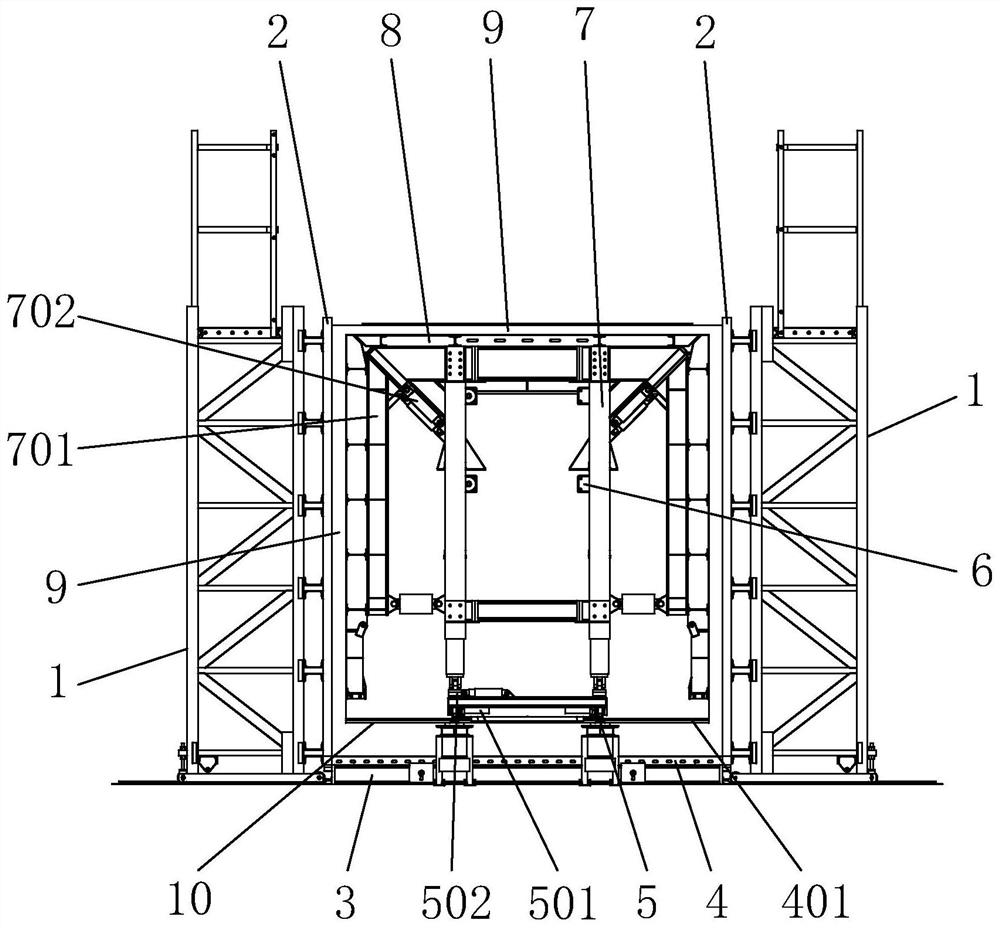

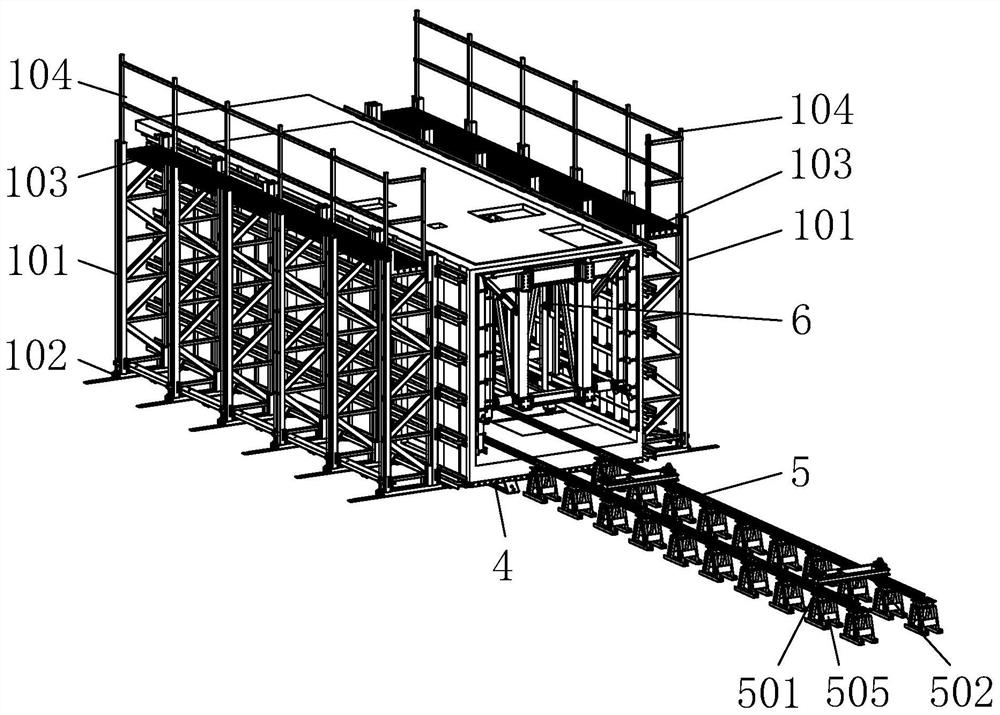

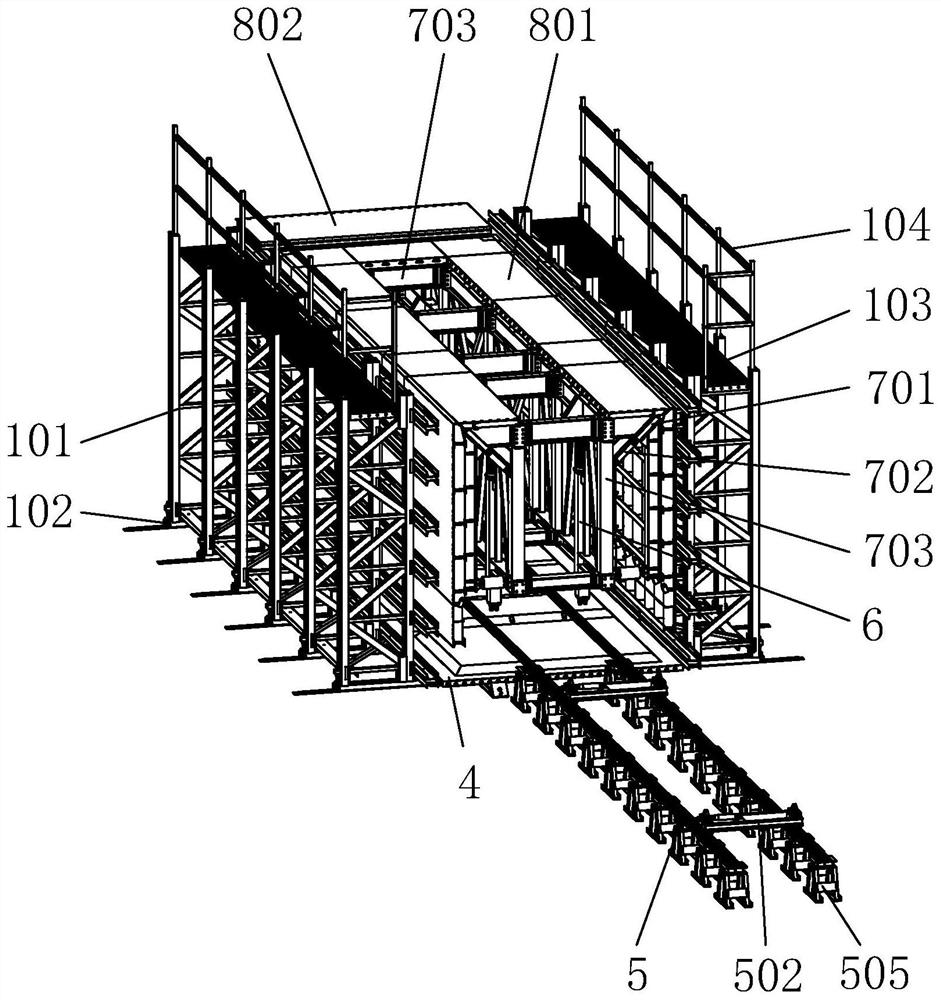

Prefabricated part formwork system and operation method thereof

PendingCN114182952AImprove appearance qualityImprove integrityForms/shuttering/falseworksBuilding material handlingArchitectural engineeringSteel frame

The invention discloses a prefabricated part formwork system which comprises an outer wall steel frame assembly and an outer wall body formwork, a bottom steel frame assembly and a bottom formwork lower formwork are arranged between the lower ends of the outer wall steel frame assembly, and the formwork system further comprises a rail located above the bottom formwork lower formwork. The track is connected with a movable seat capable of moving front and back through a walking mechanism, the movable seat is connected with an inner wall steel frame assembly through a jacking mechanism, and the two sides of the inner wall steel frame assembly are connected with inner wall side formworks through oblique guide mechanisms and driving mechanisms correspondingly. The invention further discloses an operation method of the prefabricated part formwork system, integrality is good, one-time pouring of the concrete can be achieved through all the formworks, construction joints are reduced, the construction efficiency is improved, and the construction cost is reduced. Through-wall opposite pulling is not needed, the structural appearance and the waterproof performance of the component are better, and the device has the advantages of being high in automation degree, rapid in formwork removal and the like.

Owner:JIANGXI GETO NEW MATERIALS CORP LTD

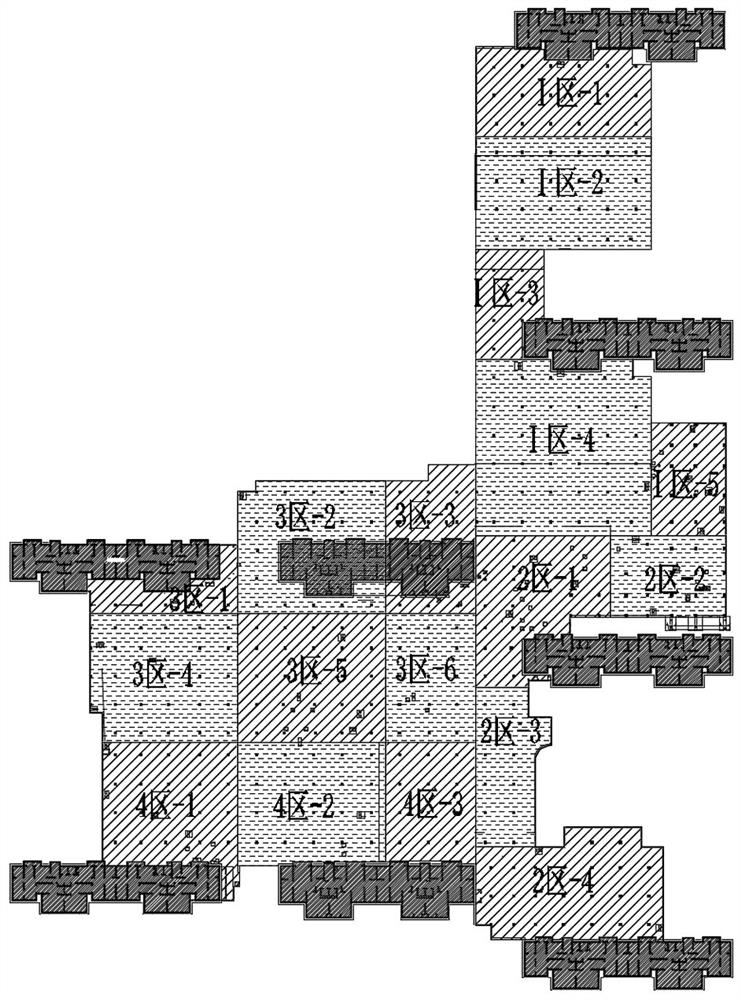

Construction method for canceling settlement post-cast strip in jump warehouse operation

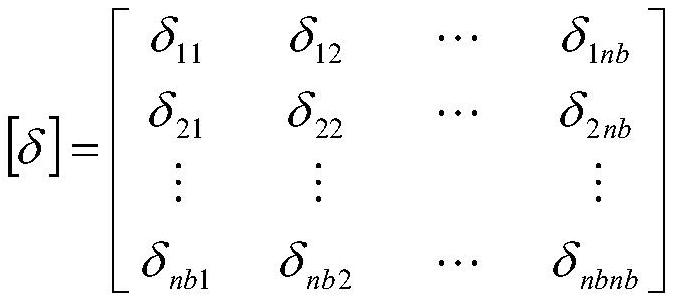

PendingCN112132706AConducive to reasonable choiceReduce plugging processGeometric CADData processing applicationsInternal forcesConstruction engineering

The invention discloses a construction method for canceling a settlement post-cast strip in jump warehouse operation. The construction method comprises the following specific implementation steps: 1,defining various conditions of a building field; 2, establishing a calculation model; 3, calculating settlement and a foundation internal force of each node; 4, performing collaborative calculation analysis step by step; 5, analyzing whether settlement meets a design requirement or not, and if not, carrying out foundation treatment; and 6, performing running water interval division on a construction section. According to the invention, the settlement of the building is calculated, and the settlement which does not meet the requirements is subjected to foundation treatment so that the sequential implementation of a subsequent jump warehouse method is ensured, and the design and construction requirements are met; a settlement post-cast strip is omitted, one-time casting forming is achieved,a later-period plugging procedure can be reduced, and a construction period can be shortened; the settlement post-cast strip is omitted, construction joints are reduced, the construction joints are convenient to clean, and an integral structure is formed as soon as possible; and in addition, a site space, the construction time and the construction cost can be greatly saved.

Owner:北京城建建设工程有限公司 +1

Method for secondary grouting in equipment foundation construction process

InactiveCN108265746AReduce installation processReduce formwork processFoundation engineeringWater storageMass concrete

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

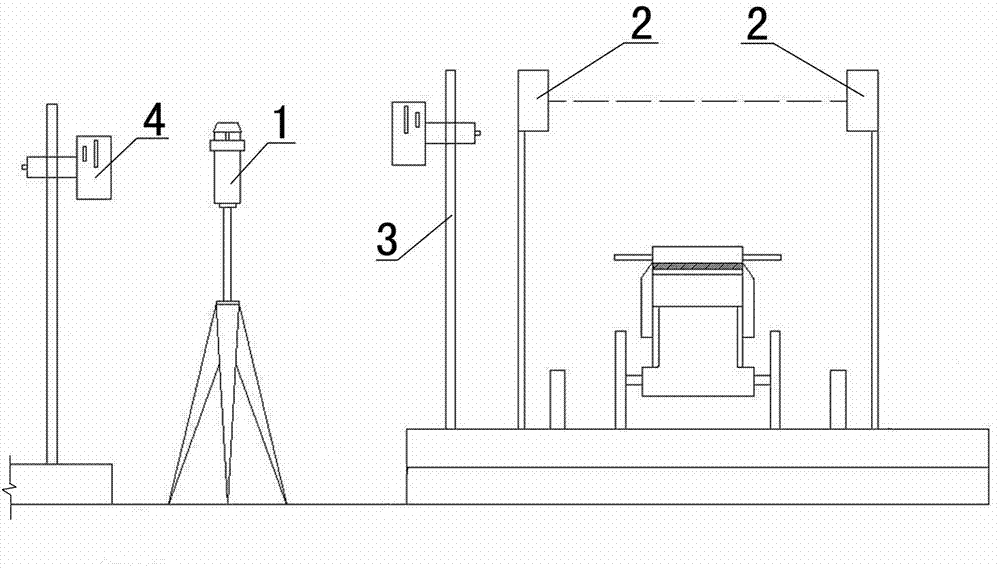

Construction method for large-area concrete weighbridge

ActiveCN102691401BOvercome the technical problem that the flatness is difficult to controlOvercome the problem of too much usageFlooringWater flowLaser

The invention discloses a construction method for a large-area concrete weighbridge. The construction method comprises the steps of: dividing the locations of a construction water flowing section and a construction separation joint, erecting a weighbridge side template, installing a force transmission rod at a junction of the water flowing section, erecting a laser leveller, fixing a levelling staff, selecting a levelling base point, pouring concrete in a space surrounded by weighbridge templates, vibrating, compacting and levelling the weighbridge by the leveller, finishing surface conditioning and polishing of the concrete weighbridge before the final solidification of the concrete, maintaining the concrete weighbridge, cutting the construction separation joint within 24h, stuffing the construction separation joint and carrying out secondary maintenance. By the construction method, the technical problem that the whole levelling degree of the large-area weighbridge is very difficult to control is solved; the problems that the cost of later maintenance of the ground and the use quantity of the templates are very high since the construction joint of the large-area concrete weighbridge is very prone to breakage is solved; and the problems such as breakage along a warehouse dividing joint on the large-area concrete weighbridge, easy hollowing in the layered pouring of the weighbridge, easy cracking and the like are solved.

Owner:北京城建建设工程有限公司

Flatness controllable high precision floor construction method

The invention discloses a flatness controllable high precision floor construction method which comprises the following steps: construction preparation and arrangement of points warehouse seams and kerfs; laying off of control points, and secondary closed measurement of all control points of a floor, wherein elevations of all the control points of the floor are in a same horizontal plane; templateand reinforcing steel bar construction and checking of templates; concrete pouring; treatment of a concrete ground; concrete curing; and floor protection. The flatness controllable high precision floor construction method has the beneficial effects that the flatness controllable high precision floor construction method is high in effect and good in quality; the points warehouse seams are reduced;the integrity of the ground is better; alternation of follow-up work is facilitated; and the follow-up maintenance cost of the floor can be reduced.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

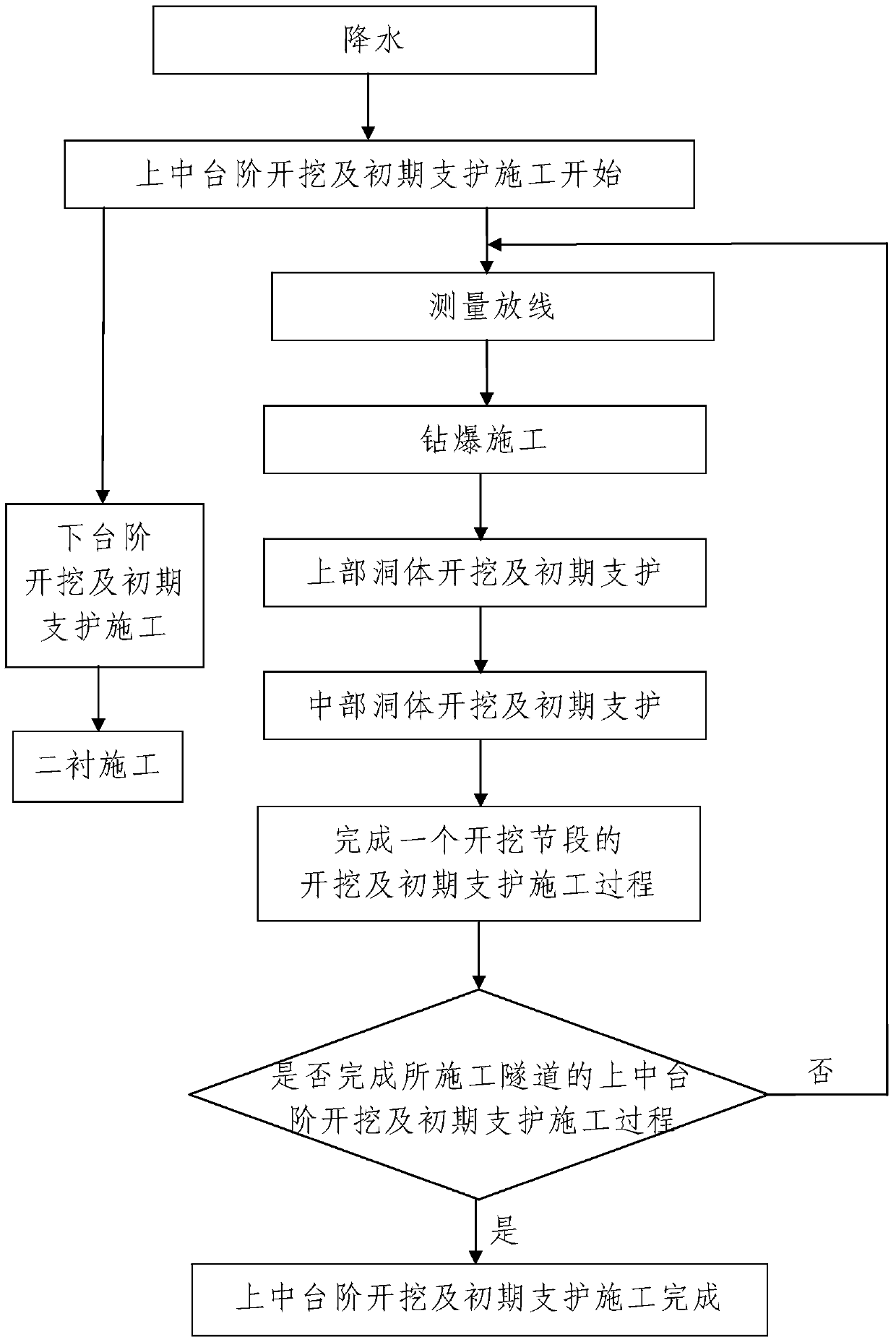

Large-section tunnel excavation and support construction method for crossing soil-rock boundary stratum

ActiveCN110821500AThe method steps are simpleReasonable designUnderground chambersBlastingStructural engineeringCave

The invention discloses a large-section tunnel excavation and support construction method for crossing a soil-rock boundary stratum. The method comprises the following steps of first, upper middle step excavation and initial support construction, specifically, carrying out upper step excavation and initial support construction on a construction tunnel by a plurality of excavation sections from rear to front, and when any excavation section is subjected to upper step excavation and initial support construction, the process comprises the following steps of measuring pay-off, drilling and blasting construction, excavation and initial support of an upper cave, and excavation and initial support of a middle cave; second, lower step excavation and initial support construction; and third, carrying out secondary lining construction. The method is reasonable in design, simple and convenient to construct and good in use effect, the upper blasting area in the upper step and the middle blasting area on the middle step are separately subjected to blasting zone division, the arrangement position of each shot hole in each blasting zone is defined, the collapse of a tunnel face or the collapse ofa vault caused by large vibration generated by blasting when one-time loading of the large section is excessive can be effectively prevented, the safety and reliability of the tunnel excavation process are ensured, and the stability of the tunnel structure is ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

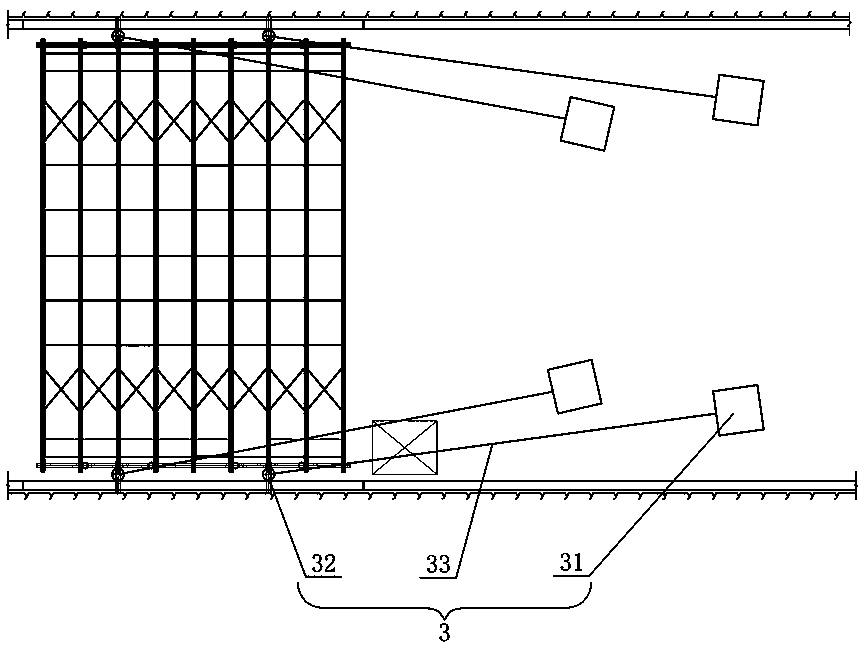

Gallery underground cavity high side wall construction equipment and construction method

InactiveCN109137969ASafe working environmentImprove construction efficiencyArtificial islandsForms/shuttering/falseworksEngineeringArchitectural engineering

The invention discloses gallery underground cavity high side wall construction equipment. The equipment comprises a lifting slide mold construction device, a wall top pull fixing device and a placingdevice; the lifting slide mold construction device comprises a truss construction platform; the truss construction platform is built between two side walls of a cavity; slide molds are arranged on twobackup wall sides of the truss construction platform; vertical guide rods are arranged between the slide molds and near side walls; climbing rod type hydraulic jacks sleeve the vertical guide rods; the truss construction platform is fixedly mounted on each climbing rod type hydraulic jack; when the tops of the side walls are constructed, the hung truss construction platform is tensioned by the wall top pull fixing device; and after the tops of the side walls are constructed, the truss construction platform is put down by the placing device. A construction method comprises the steps of building of the lifting slide mold construction device, casting of side wall concrete, mounting of the wall top pull fixing device, placement of the truss construction platform and shifting of the truss construction platform to adjacent construction places; and the steps are repeated. The construction equipment and the construction method have the advantages of safe operation, high construction efficiency and good construction quality.

Owner:SINOHYDRO BUREAU 8 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com