Large-span arch bridge empty case cast-in-situ arch ring template system and construction method thereof

A technology of long-span arch bridge and formwork system, applied in the direction of arch bridges, bridges, bridge forms, etc., can solve the problems of troublesome installation and removal of cover formwork, many concrete construction joints, and difficulties in on-site construction, so as to achieve the reduction of concrete construction joints, simple construction, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

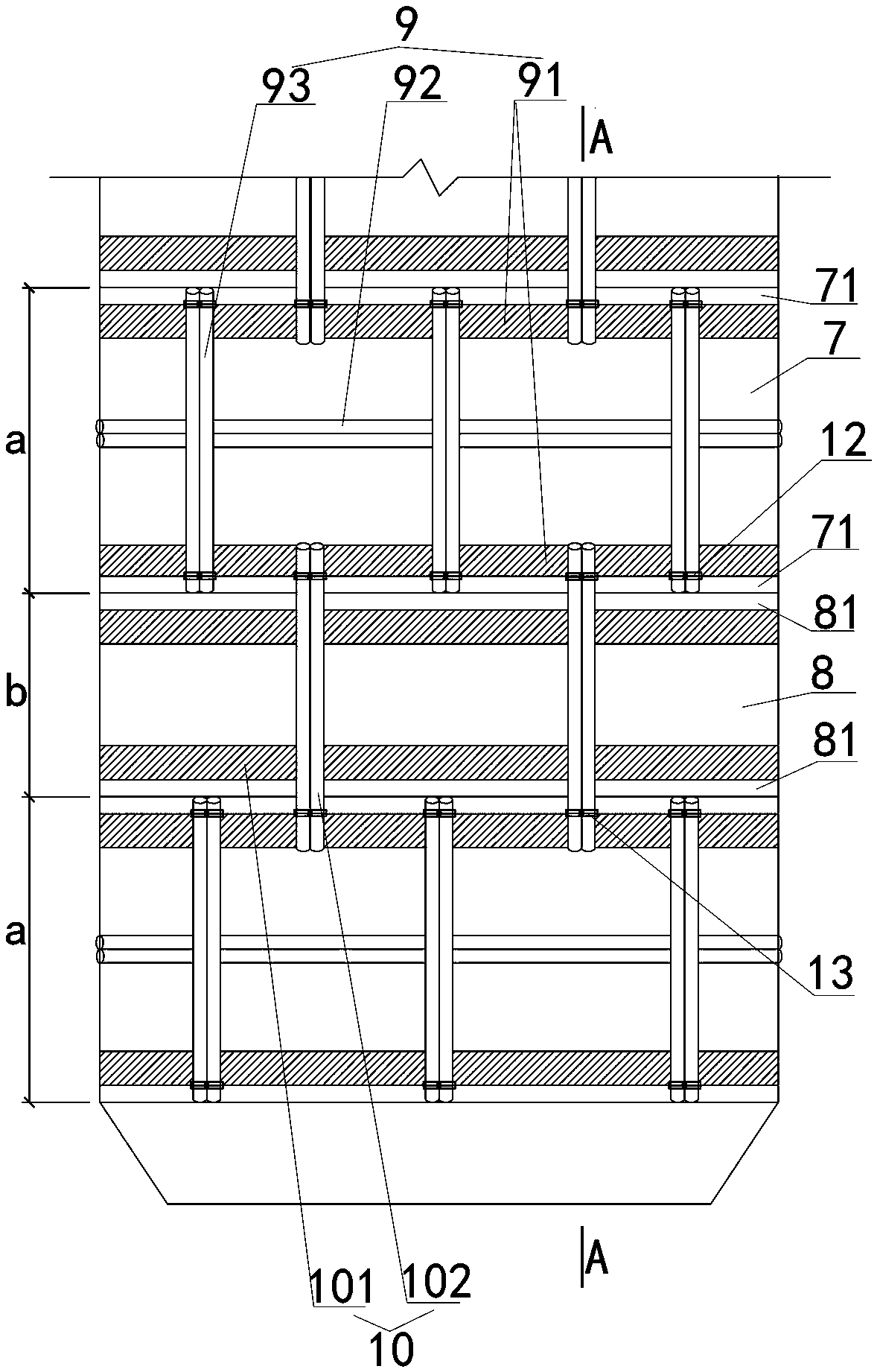

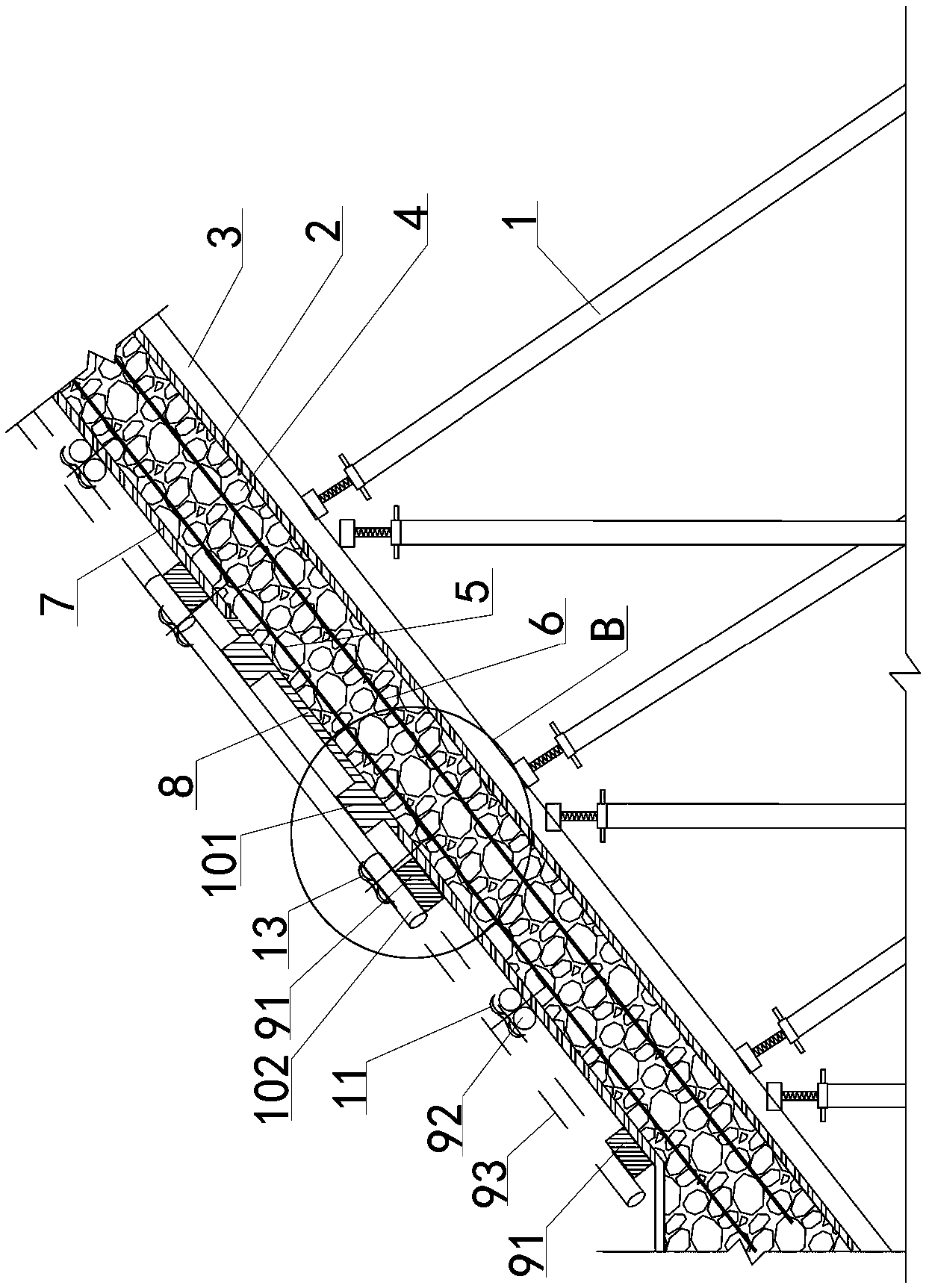

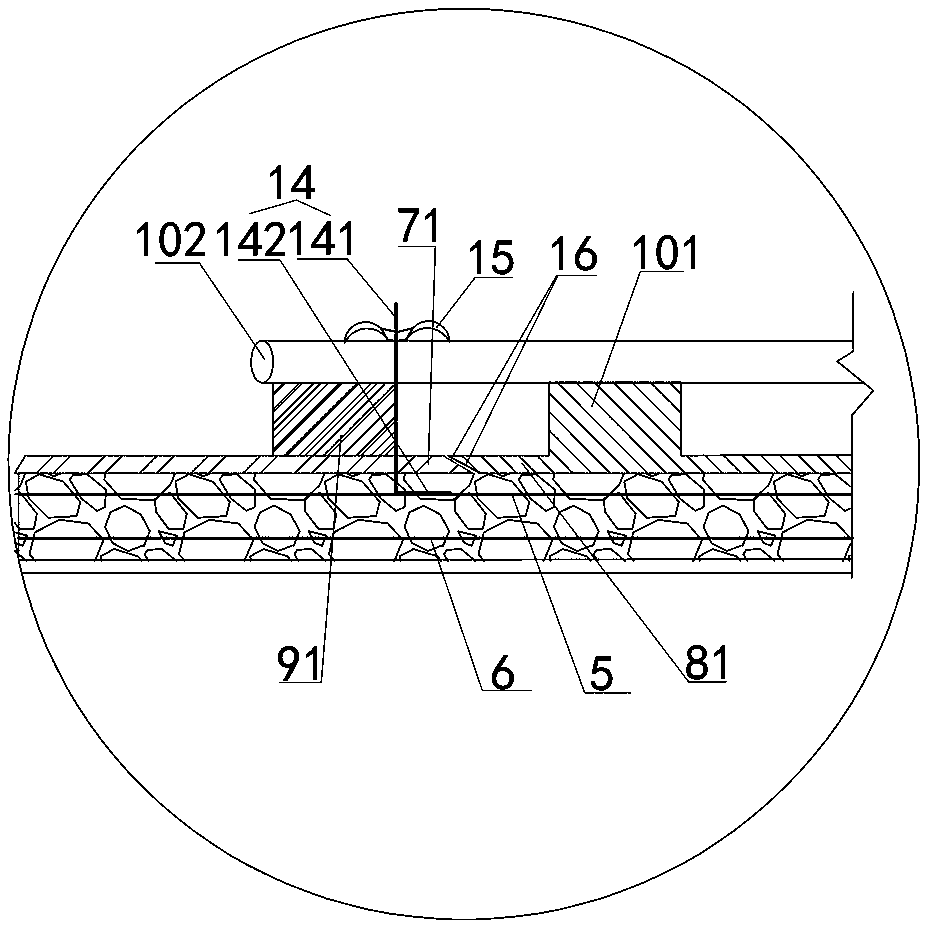

[0040] Examples see Figure 1-3 As shown, a large-span arch bridge hollow box room cast-in-situ arch ring formwork system includes a formwork structure, a support frame body 1 and an arch ring constructed between the formwork structures. The formwork structure includes a bottom formwork 2 and a bottom formwork keel 3 And cover formwork and cover formwork keel, the bottom of described support frame body 1 stands on the ground, the top is supported on the bottom formwork keel 3, and described arch ring comprises arch ring concrete 4, arch ring upper layer steel bar 5 and arch ring lower layer steel bar 6.

[0041] The cover formwork includes fixed pre-set formwork units 7 and movable rear formwork units 8 alternately arranged at intervals from the bottom to the top, and the cover formwork keel includes a pre-set keel fixed on the upper side of the fixed pre-set formwork unit 7 Unit 9 and the rear keel unit 10 fixed on the upper side of the movable rear formwork unit 8 .

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com