Pouring formwork and construction method for once forming of bottom plate and pond wall of water treatment structure

A construction method and technology for structures, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, building type, etc., can solve the problems of poor apparent quality and weak quality control, and achieve construction Small difficulty, shortening construction period, and improving the effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

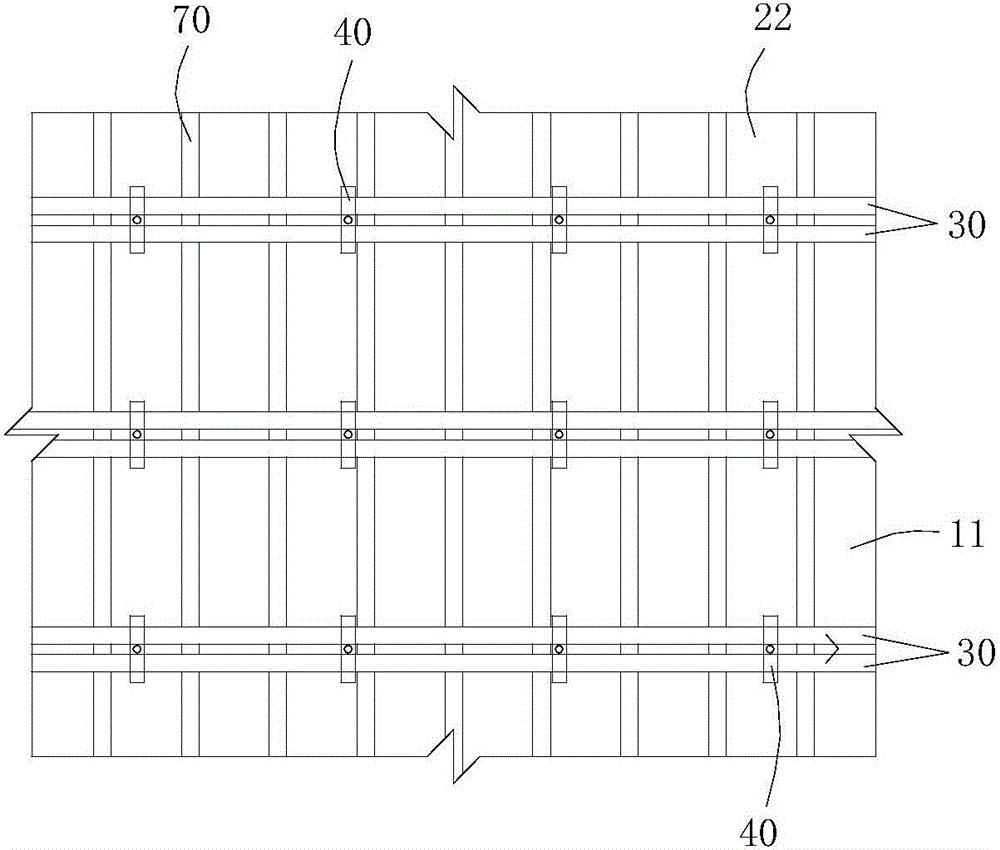

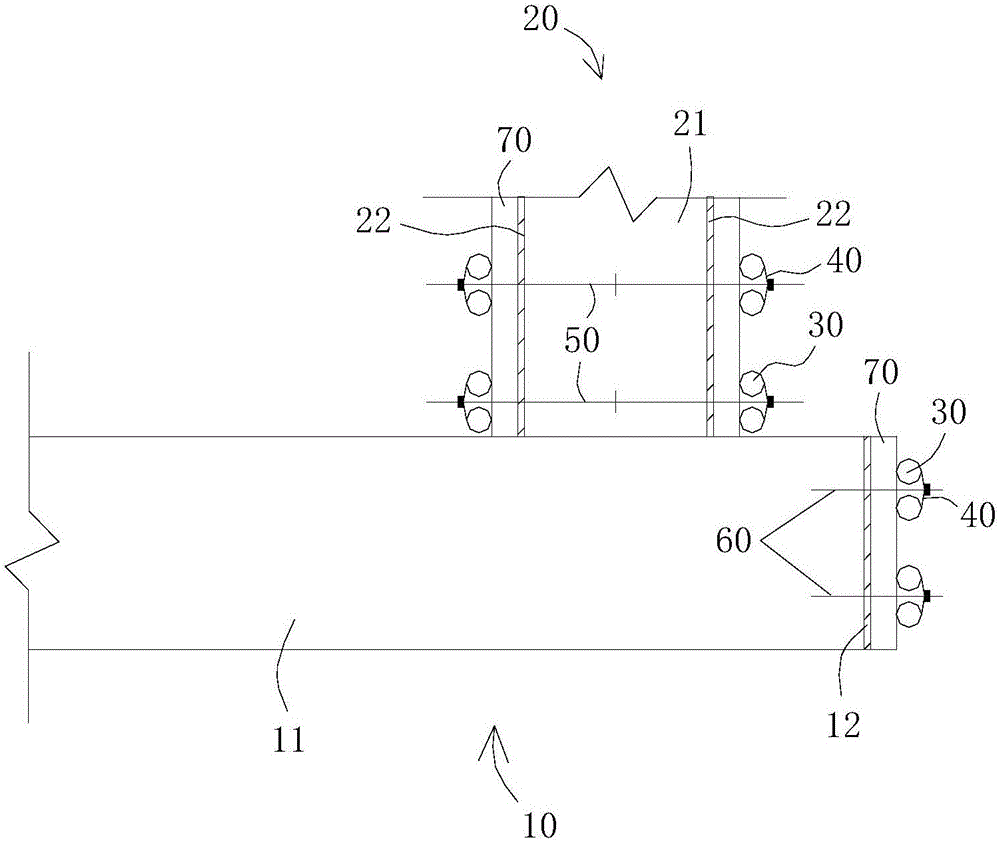

[0025] Such as figure 1 and 2 As shown, the pouring formwork includes a bottom plate mold 10 and a pool wall mold 20, which are respectively used for pouring the bottom plate and the pool wall, wherein the bottom plate mold 10 is surrounded by the first side plates 11 on both sides and the first sealing plate 12 at one end, The pool wall mold 20 is surrounded by two second side plates 21 and two second sealing plates 22 .

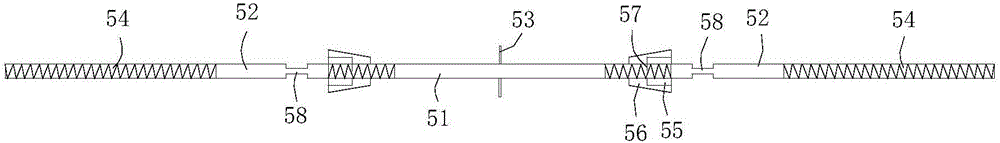

[0026] In order to increase the structural stability of the pouring formwork, a plurality of double cross ribs 30 and vertical ribs 70 are alternately arranged on the outer surfaces of the first sealing plate 12 and the second sealing plate 22, wherein the double ribs on the first sealing plate 12 The joint transverse rib and the first sealing plate are connected by a fastener 40 and a single-head bolt 60, and the double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com