Gallery underground cavity high side wall construction equipment and construction method

A technology for underground caverns and construction equipment, which can be applied to artificial islands, water conservancy projects, underwater structures, etc., and can solve problems such as increased construction risks for high-altitude operations, large engineering volume, and prone to misplaced platforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

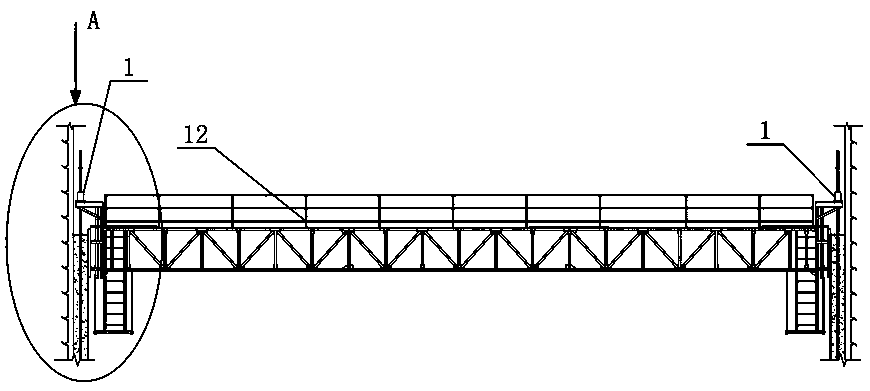

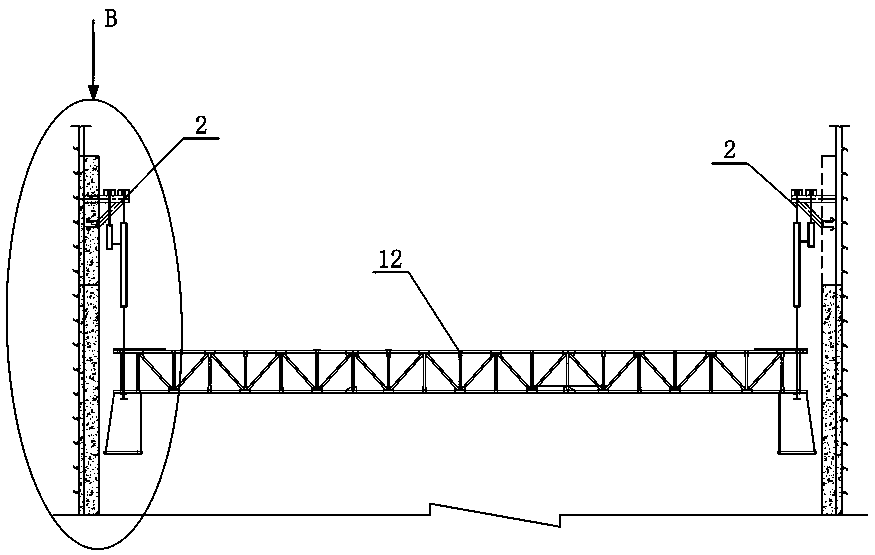

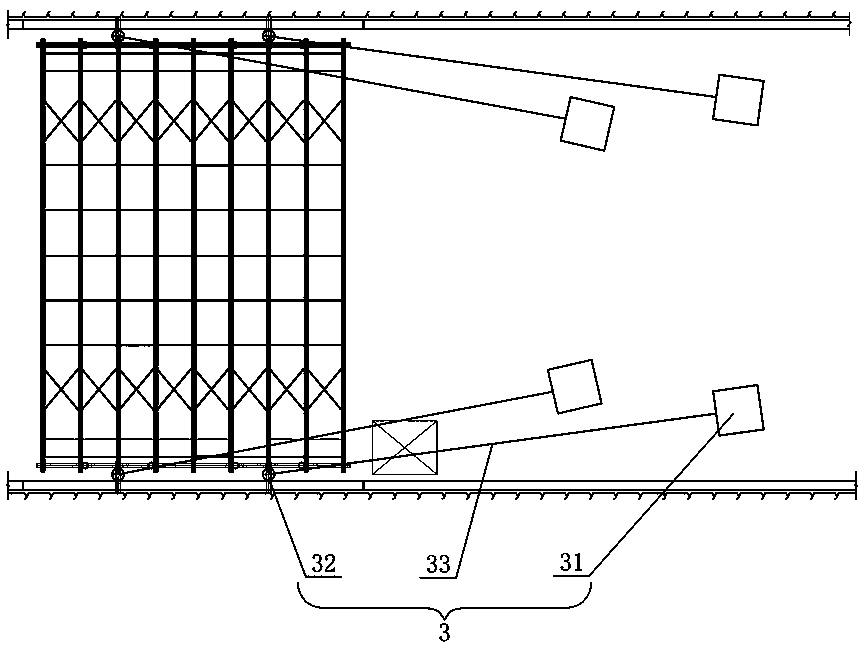

[0034] Figure 1 to Figure 7 The construction equipment for the high side wall of the long corridor underground cavern of this embodiment is shown, including a lifting slip form construction device 1, a wall top tensioning device 2 and a lowering device 3. The lifting slip form construction device 1 includes a truss construction platform 12. The truss construction platform 12 is set up between the side walls on both sides of the cavern. Both sides of the truss construction platform 12 are provided with slipforms 13, and vertical guide rods 11 are arranged between the slipforms 13 and the adjacent side walls. The straight guide rod 11 is equipped with a climbing rod hydraulic jack 14, and the truss construction platform 12 is fixed on each climbing rod hydraulic jack 14. When the top of the side wall is constructed, the wall top tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com