Comprehensive pretreatment method for shaft penetration in mined-out area stratum

A goaf and wellbore technology, applied in wellbore lining, shaft equipment, mining equipment, etc., can solve problems such as limited treatment scope, impact on excavation construction, water inrush from water gushing face, etc., to achieve high construction safety and continuous construction. The effect of shortening performance and high construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

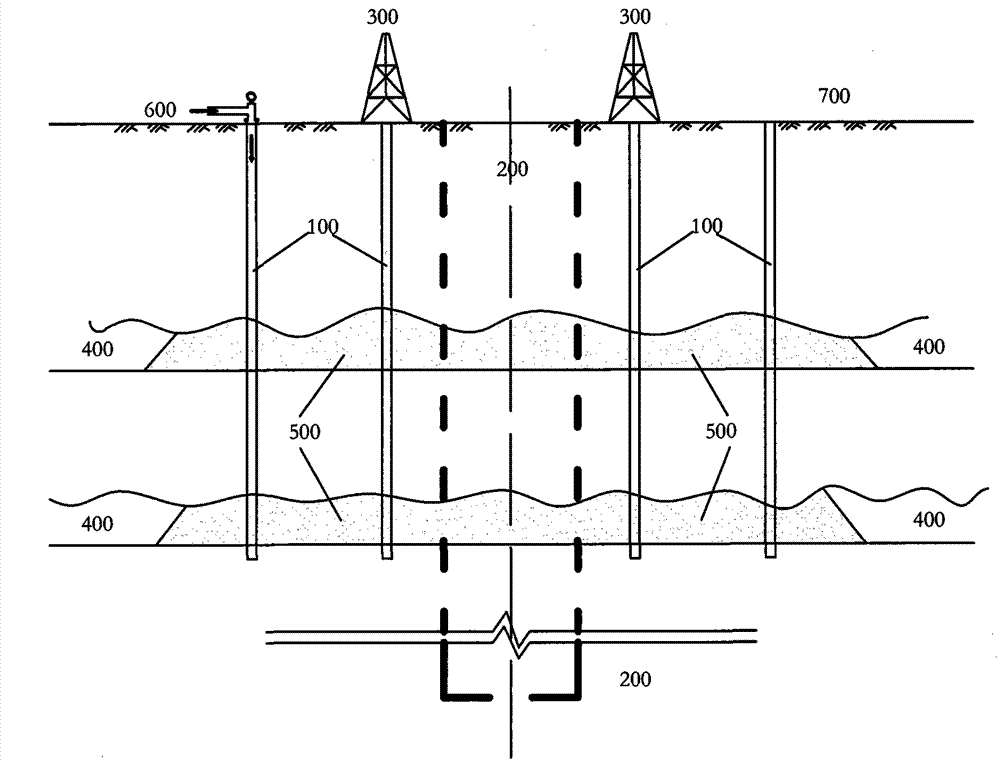

[0031] Such as figure 1 and figure 2 As shown, it is assumed that the net diameter of the proposed wellbore is 8.0m, and there are two goafs in the lower part, and the technical solution of the present invention is described by taking this as an example.

[0032] (1) With the center of the proposed wellbore as the center, two circles of treatment boreholes are arranged on the ground around the proposed wellbore. There are 6 treatment boreholes (1-1~1-6) in the inner circle, and the diameter of the inner circle is 24m; Drill 12 holes (2-1~2-12), the diameter of the outer ring is 50m, set a center hole J, as the final quality inspection hole and supplementary hole. On the same circle: the distance between adjacent treatment boreholes is 15m. Drilling rigs are used to make holes and put down casings. A Φ127-168mm casing is selected for each treatment drilling hole. The bottom of the casing should exceed the depth of the Quaternary system and can ensure repeated hole sweeping; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com