Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Reduce adjustment steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

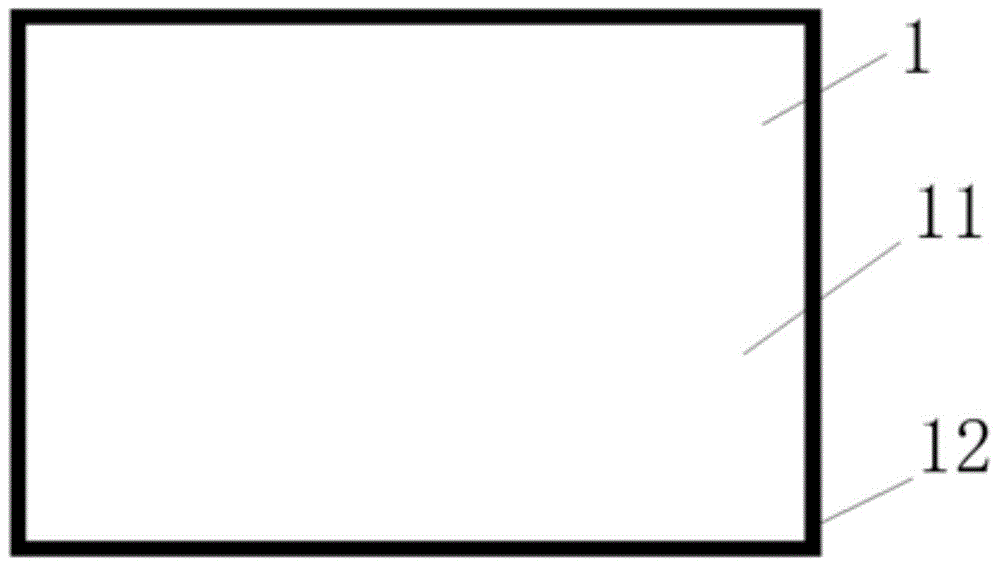

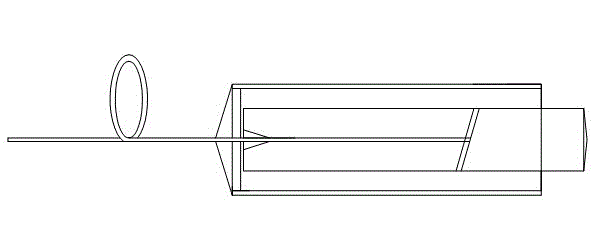

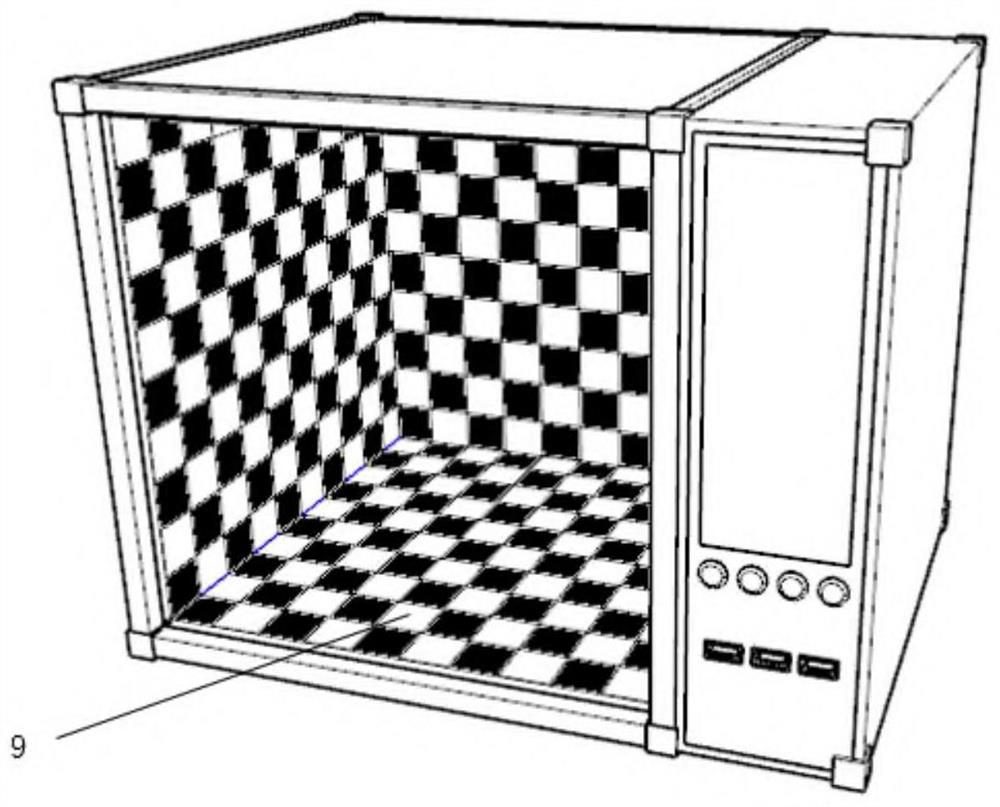

Display device

InactiveCN104464536AEliminate seamsDisplay images seamlesslyIdentification meansLensDisplay deviceMicro lens array

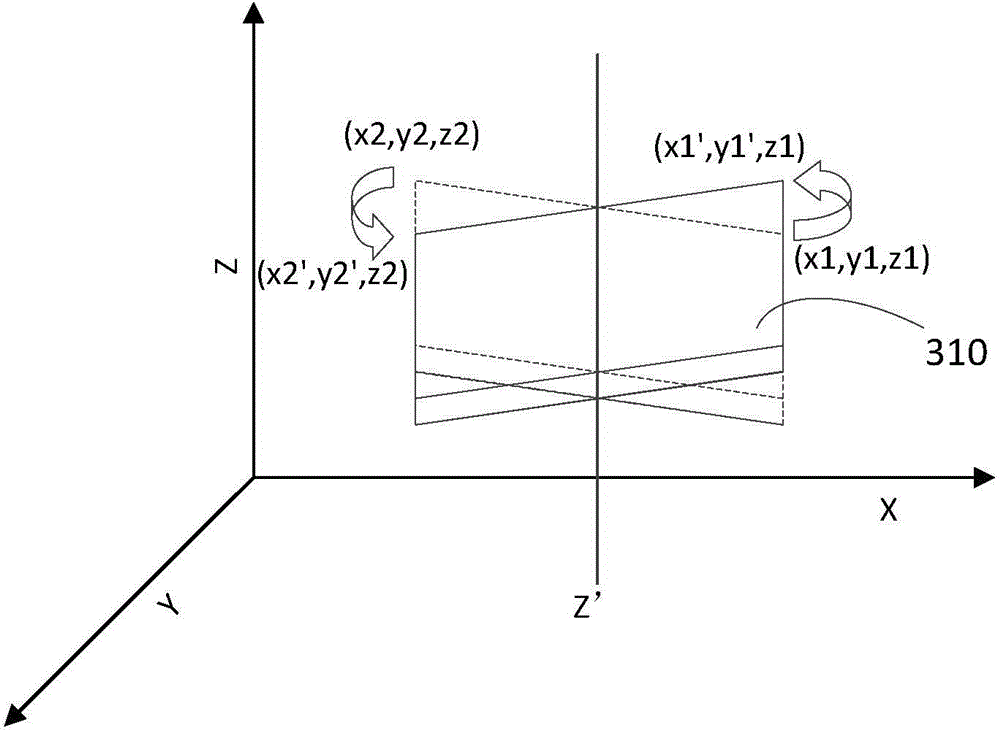

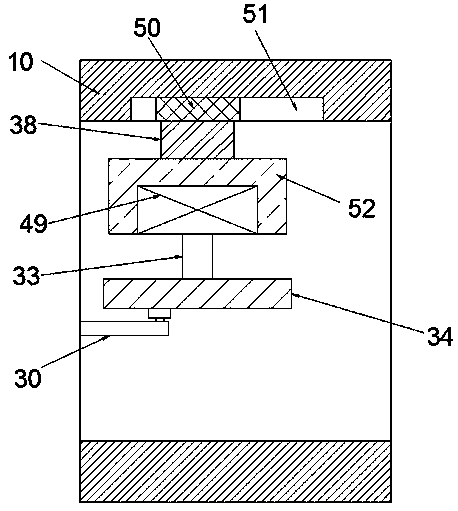

The invention relates to the field of display screens, in particular to a display device. The display device comprises a displayer provided with a display surface and a frame. An optical microlens array including a plurality of microlenses is arranged above the displayer. Light rays emitted from the displayer are irradiated into the optical microlens array from positions near to focal plane positions of the microlenses in the optical microlens array. A scattering screen is arranged above the optical microlens array. The display device has the advantages that the optical microlens array and the scattering screen are arranged on the surface of the displayer additionally, and image information from the displayer are shifted and amplified and can cover the frame of the displayer to shield the frame of the displayer, so that splicing seams among splicing units can be eliminated completely when the display device is applied to a spliced display screen, seamless splicing is achieved, and display images are complete, continuous and free from split sensation; on the basis of the scattering effect of the scattering screen, the complete and continuous image information can be still viewed and does not distorted when being viewed from wide angles.

Owner:GUANGDONG VTRON TECH CO LTD

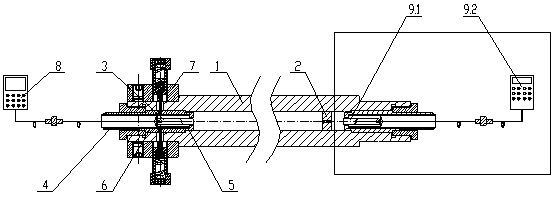

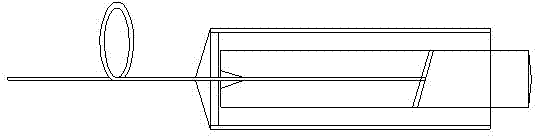

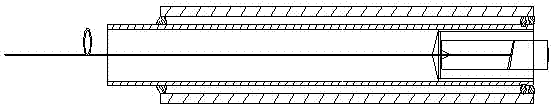

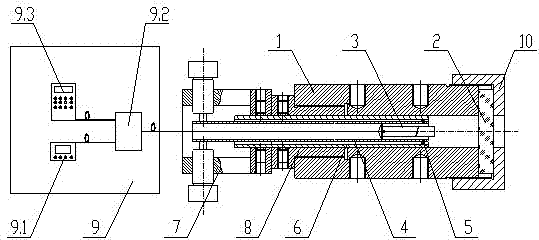

Method for reflectively adjusting optical-mechanical coaxiality of optical fiber collimator

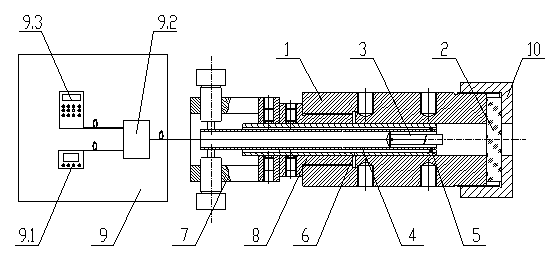

The invention relates to a method for reflectively adjusting optical-mechanical coaxiality of an optical fiber collimator. The method includes the steps: sequentially adjusting the position of the optical fiber collimator (3) up and down and front and back; and observing optical powers received by an optical power meter (9.3). When the optical powers in the up and down direction and in the front and back direction are simultaneously the highest, the emergent direction of a laser beam is perpendicular to a reflector (2), and the reflector (2) is perpendicular to a mechanical axis serving as a datum, so that optical-mechanical coaxiality is realized. An adjusting device is simple in structure, adjusting steps are fewer, the process is simple, the mechanical axis of the optical fiber collimator is used as the datum, the emergent direction of the laser beam is changed by adjusting the position of the optical fiber collimator up and down and front and back until the emergent direction of the laser beam is consistent with the direction of the mechanical axis serving as the datum, and accordingly, the optical fiber collimator has high-precision optical-mechanical coaxiality.

Owner:JIANGSU KANGLAITE TECH +1

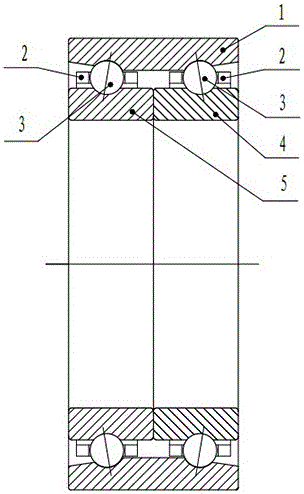

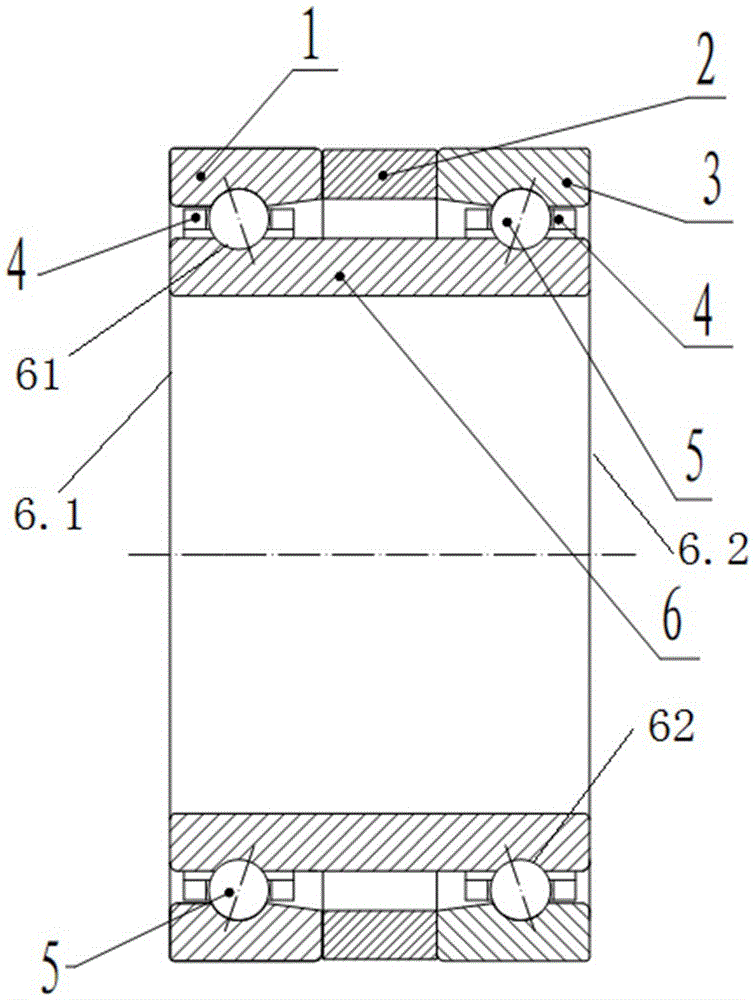

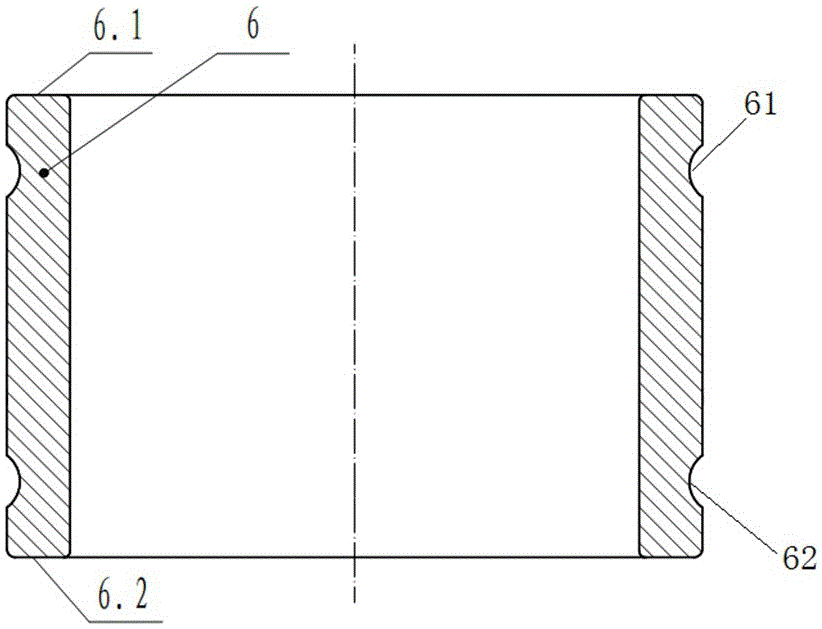

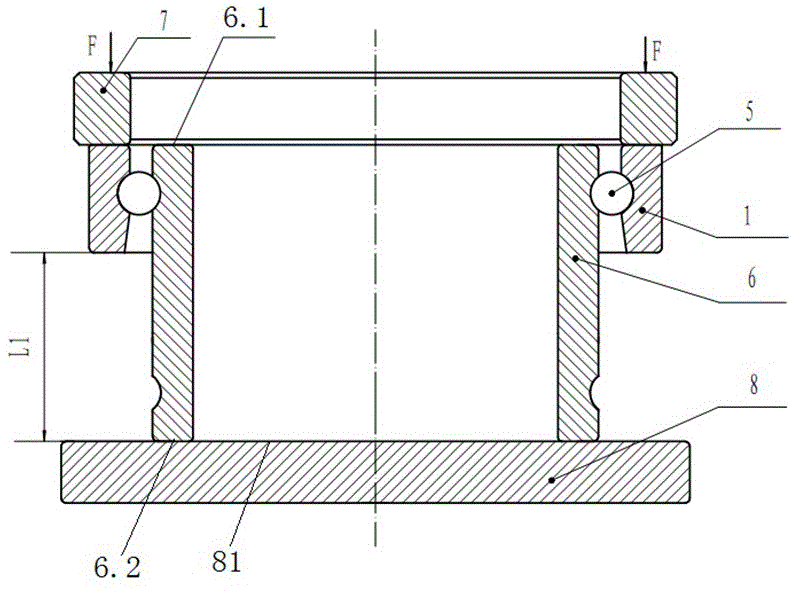

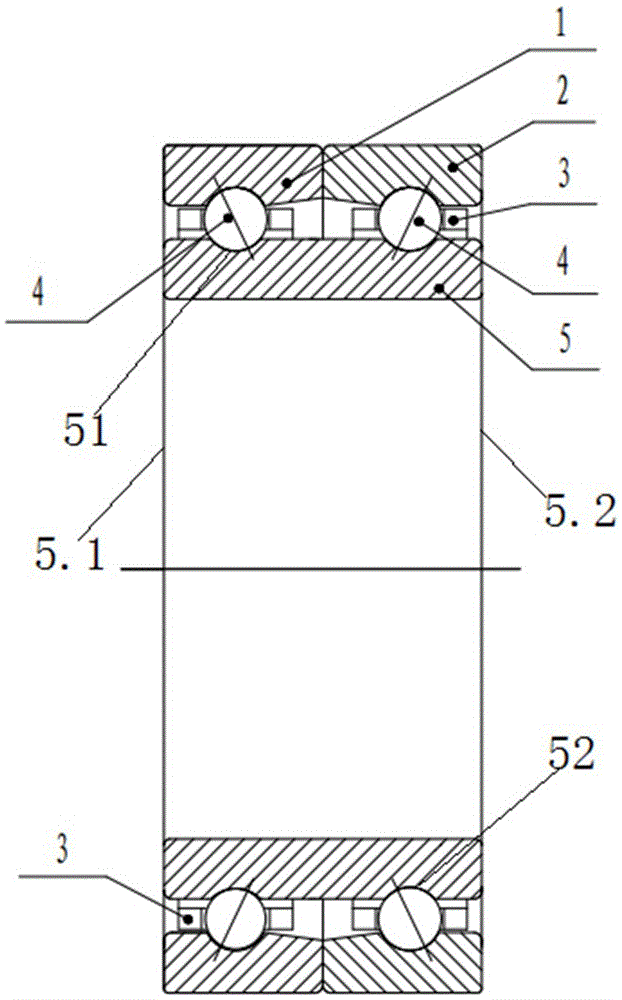

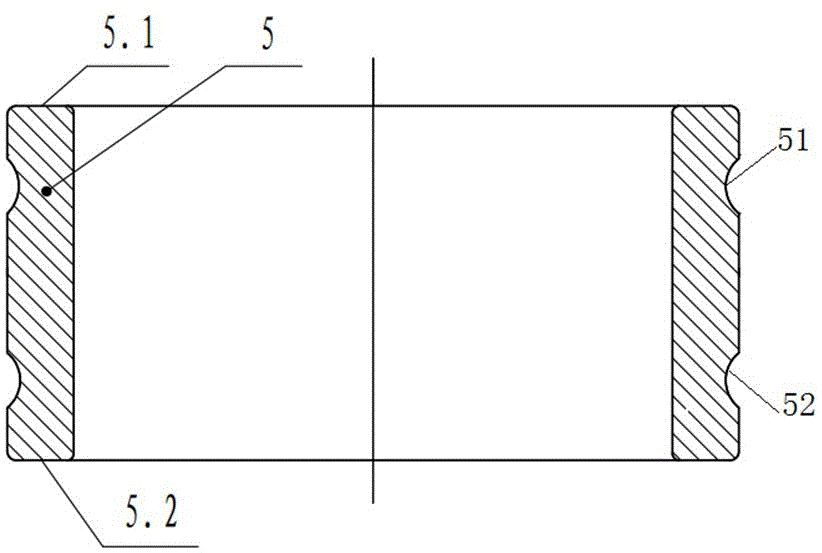

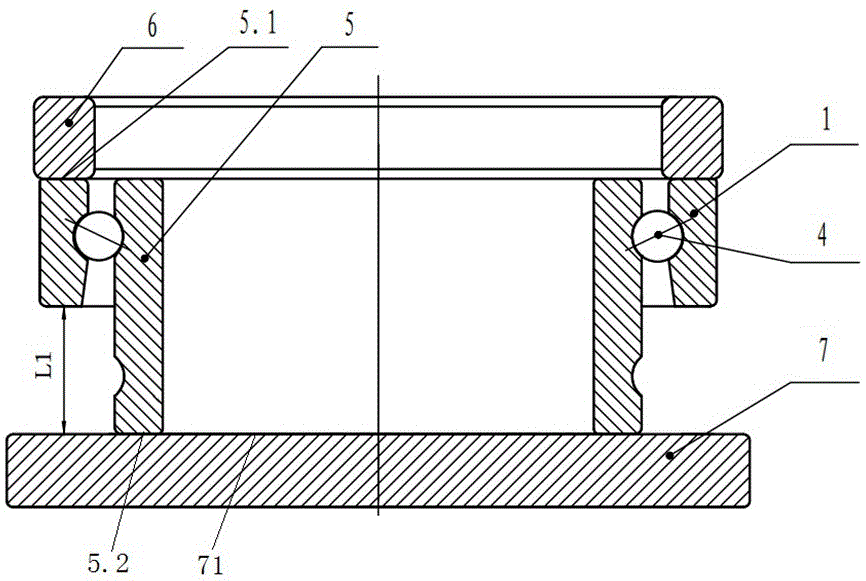

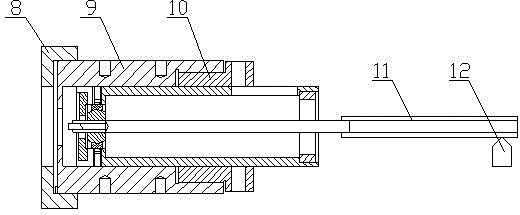

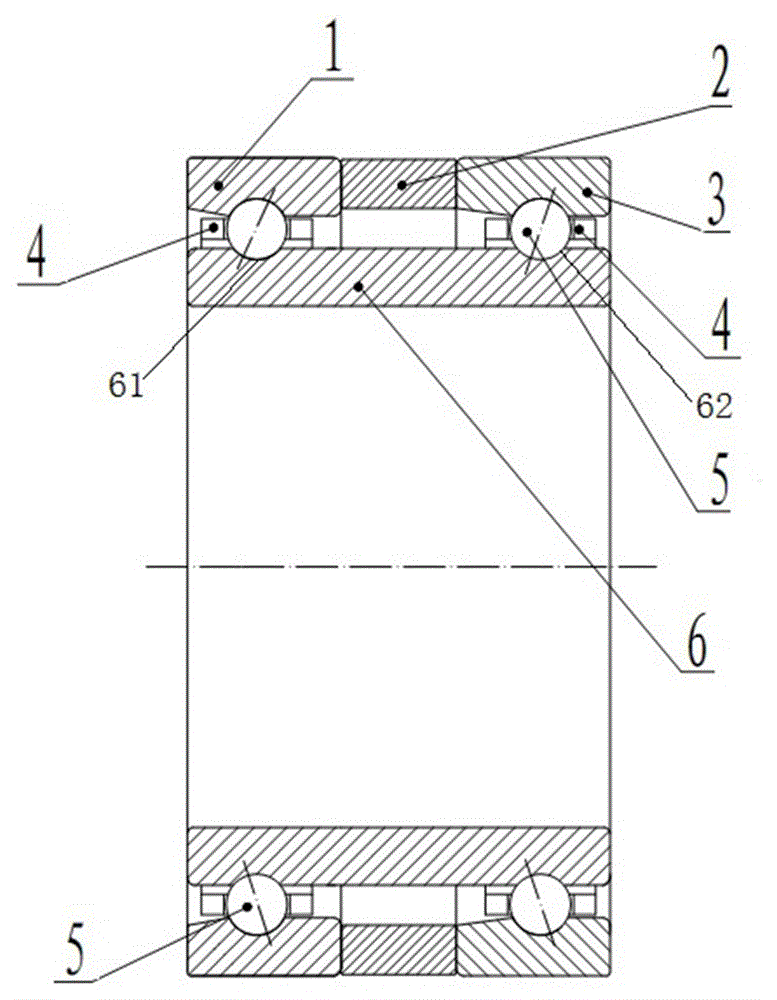

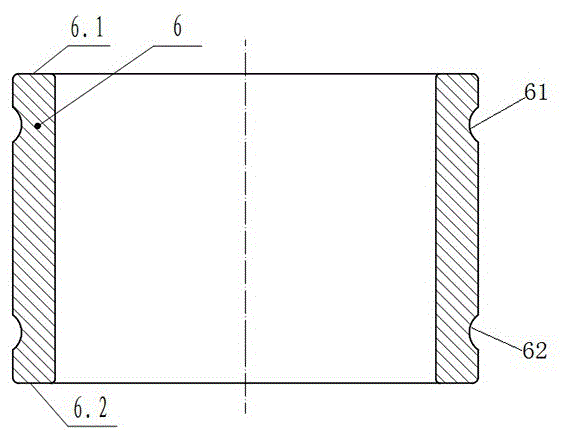

Back-to-back assembly type biserial angular contact ball bearing and assembling method thereof

ActiveCN105041855AIncrease stiffnessSimplify the installation processRolling contact bearingsBearing componentsBall bearingSteel ball

The invention provides a back-to-back assembly type biserial angular contact ball bearing and an assembling method thereof. The back-to-back assembly type biserial angular contact ball bearing comprises an outer ring, wherein a first inner channel and a second inner channel are formed in the inner circumferential surface of the outer ring, a first inner ring and a second inner ring are correspondingly arranged in the outer ring in a sleeved mode, and the two inner rings are arranged in sequence in the front-back direction and are in contact fit in an abutting mode; an outer channel is formed in the outer circumferential surface of each inner ring, steel balls are correspondingly arranged in the outer channels of the two inner rings and the two inner channels of the outer ring, and the hole wall at each of the two ends of the outer ring is of a conical structure which becomes smaller from outside to inside gradually to enable the two axial end faces of the outer ring to be narrow-side end faces arranged backing onto each other. Due to the fact that an inner partition ring and an outer partition ring are omitted, grinding of the inner partition ring and the outer partition ring is avoided, the assembly type biserial angular contact ball bearing pre-tightening force fitting technology is simplified, axial pre-tightening force adjusting time is shortened, and pre-tightening force adjusting efficiency is improved. Due to the adoption of the integral outer ring, the whole back-to-back assembly type biserial angular contact ball bearing can be installed easily and efficiently, complicated adjusting steps are omitted, and installation difficulty is reduced.

Owner:LUOYANG BEARING RES INST CO LTD

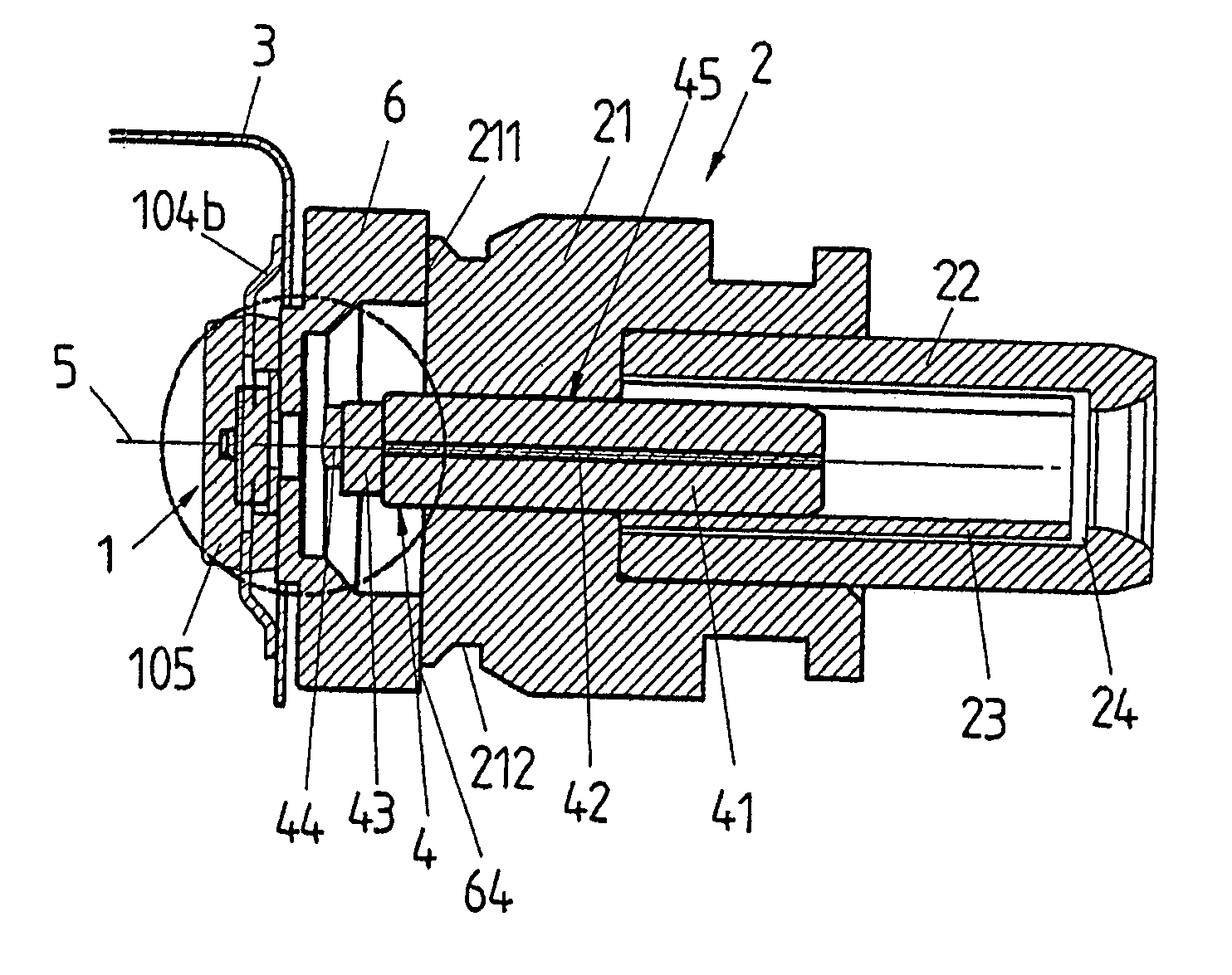

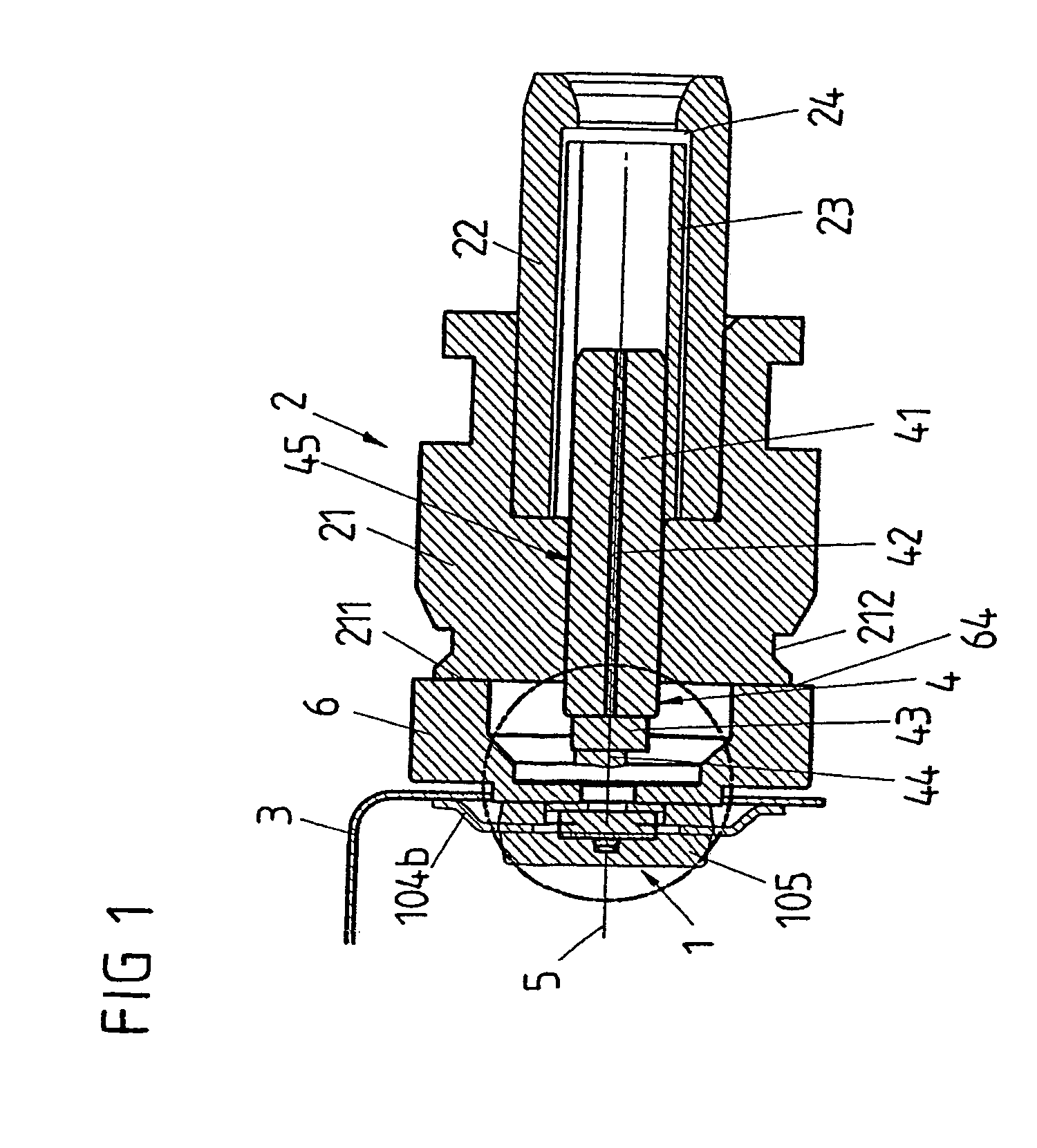

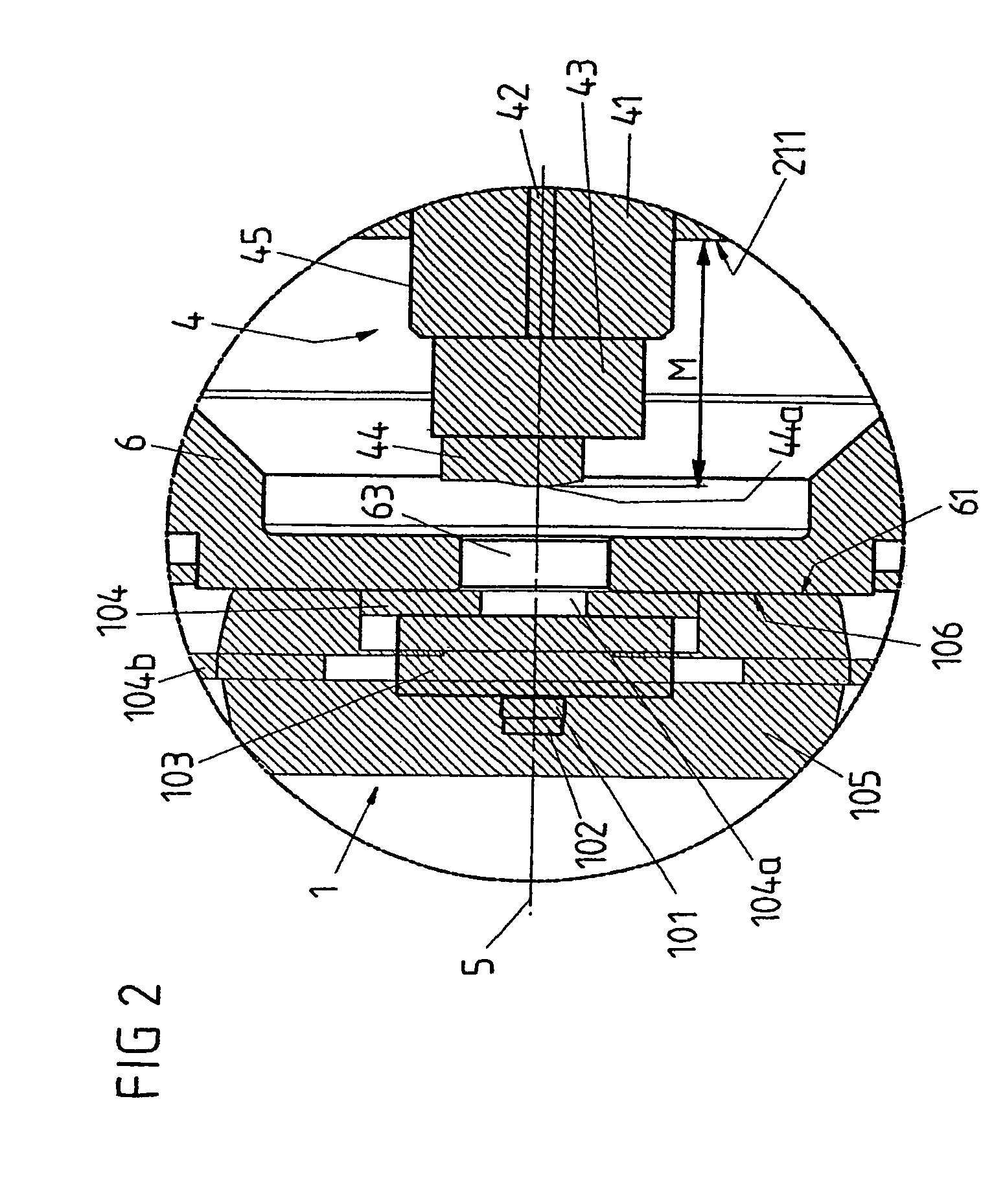

Optoelectronic transmission and/or reception arrangement

ActiveUS7270488B2Coupling efficiency is highProduced cost-effectivelyCoupling light guidesEngineeringOpto electronic

The invention relates to an optoelectronic transmission and / or reception arrangement. The arrangement includes a transmission and / or reception module containing an optoelectronic transmission and / or reception component, and a plug interface for the coupling of an optical fiber thereto. An optical waveguide section is arranged in the plug interface, and at one of its ends is optically coupled to the transmission and / or reception component. At its other end, the optical waveguide section is configured to be coupled to an optical fiber. The arrangement may further include a lens for optical coupling of the light between the optical waveguide section and the transmission and / or reception component. The lens and the optical waveguide section, in one example, are formed as a prefabricated subassembly, in which the lens is fixedly arranged at a defined distance from one end face of the optical waveguide section.

Owner:II VI DELAWARE INC

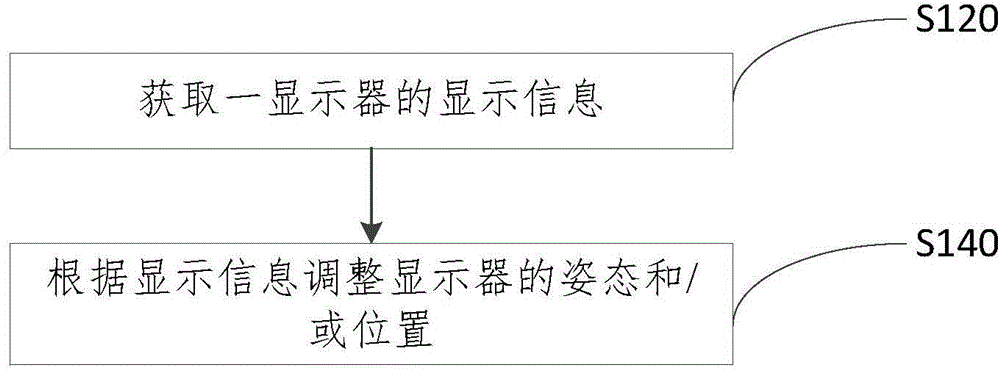

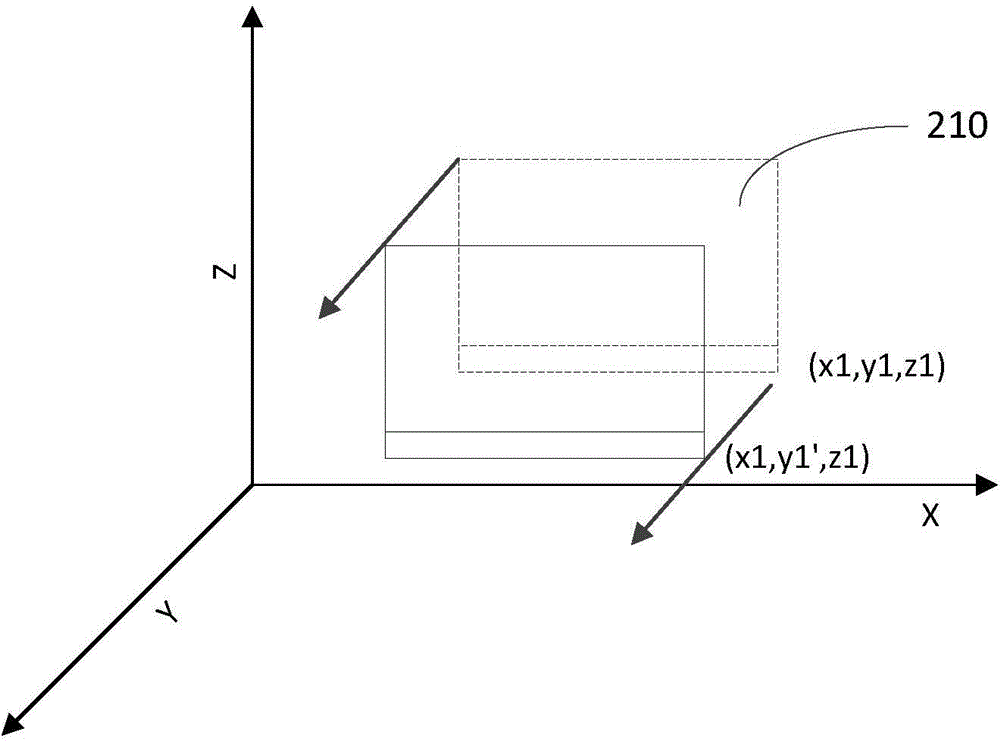

Display adjustment method and device

ActiveCN104635755AReduce adjustment stepsImprove experienceDetails for portable computersControl using feedbackDisplay deviceComputer engineering

Owner:BEIJING ZHIGU RUI TUO TECH

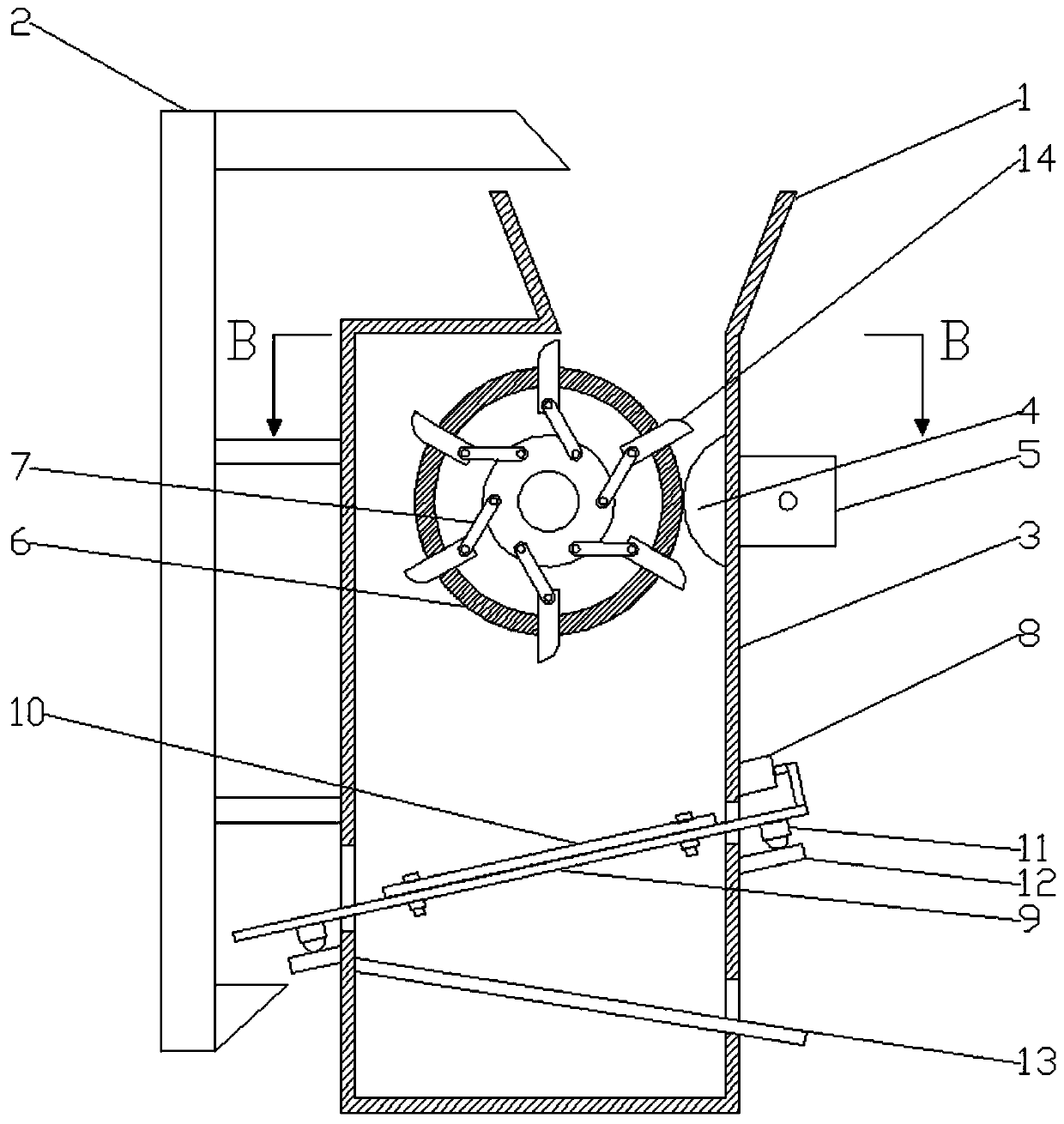

Crushing equipment with adjustable cutter

PendingCN109772520AImprove sliding fluencyMeet different usage needsGrain treatmentsPlastic recyclingFixed bearingEngineering

The invention discloses crushing equipment with an adjustable cutter. The crushing equipment with the adjustable cutter comprises a box body; the top of the box body is provided with a feed hopper; the upper end in the box body is provided with a roller; the two ends of the roller are provided with rotary shafts respectively; the outer walls of the front end and the back end of the box body are provided with first fixed bearings respectively; the rotary shafts are arranged in inner rings of the first fixed bearings respectively; rotating assemblies for driving the rotary shafts to rotate respectively are further arranged on the outer wall of the box body; the outer surface of the roller is provided with a plurality of rotary crushing assemblies at an equal interval in a length direction; each rotary crushing assembly comprises a plurality of rotary crushing teeth which are uniformly distributed in a circumferential direction of the roller; the rotary crushing teeth are connected with the roller in a sliding manner; the roller is internally provided with an adjusting assembly; the inner wall of one side of the box body is provided with a fixed crushing assembly; the fixed crushing assembly comprises a plurality of first fixed crushing teeth which are arranged in a staggered manner and a plurality of second fixed crushing teeth; the lower end in the box body is provided with an inclined discharge plate; and the lower end of the discharge plate extends out of the box body. The crushing equipment realizes crushing of wastes in different particle sizes so as to meet different subsequent use demands.

Owner:ANHUI FUYANG SHENGDA MACHINERY CO LTD

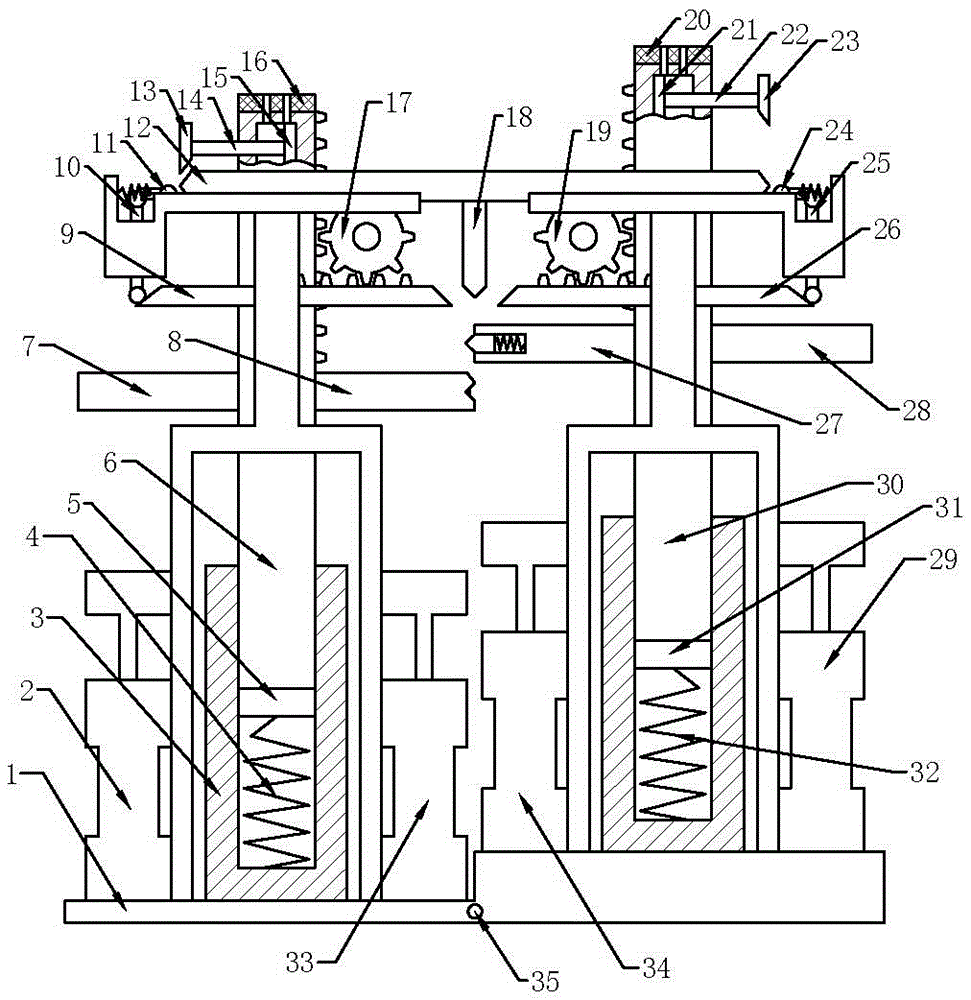

Base for steel plate cutting

InactiveCN106826309AImprove the efficiency of fixing and pressingImprove cut qualityLarge fixed membersPositioning apparatusSheet steelGear wheel

The invention discloses a base for steel plate cutting. The base comprises a frame; the frame is fixedly connected with two sliding cylinders; the sliding cylinders are provided with compression rods, namely a first compression rod and a second compression rod; negative pressure cavities are formed in the two compression rods, and are internally provided with pistons; the pistons are connected with a first wedge plate and a second wedge plate that are arranged at the exteriors of the negative pressure cavities; the first compression rod is engaged to a first gear; the first gear is engaged to a first rack; the first rack abuts against a first wedge rod; the first wedge rod abuts against a second wedge rod; the second compression rod is engaged to a second gear; the second gear is engaged to a second rack; the second rack abuts against a third wedge rod; the third wedge rod abuts against a fourth wedge rod; a fifth wedge rod which abuts against the first wedge plate and the second wedge plate is placed on the frame; the second wedge rod and the fourth wedge rod abut against the fifth wedge rod; the middle part of the fifth wedge rod is fixedly connected with a sixth wedge rod; and the first rack and the second rack abut against the sixth wedge rod. With the adoption of the base for the steel plate cutting, the adjustment efficiency and the cutting quality can be improved.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

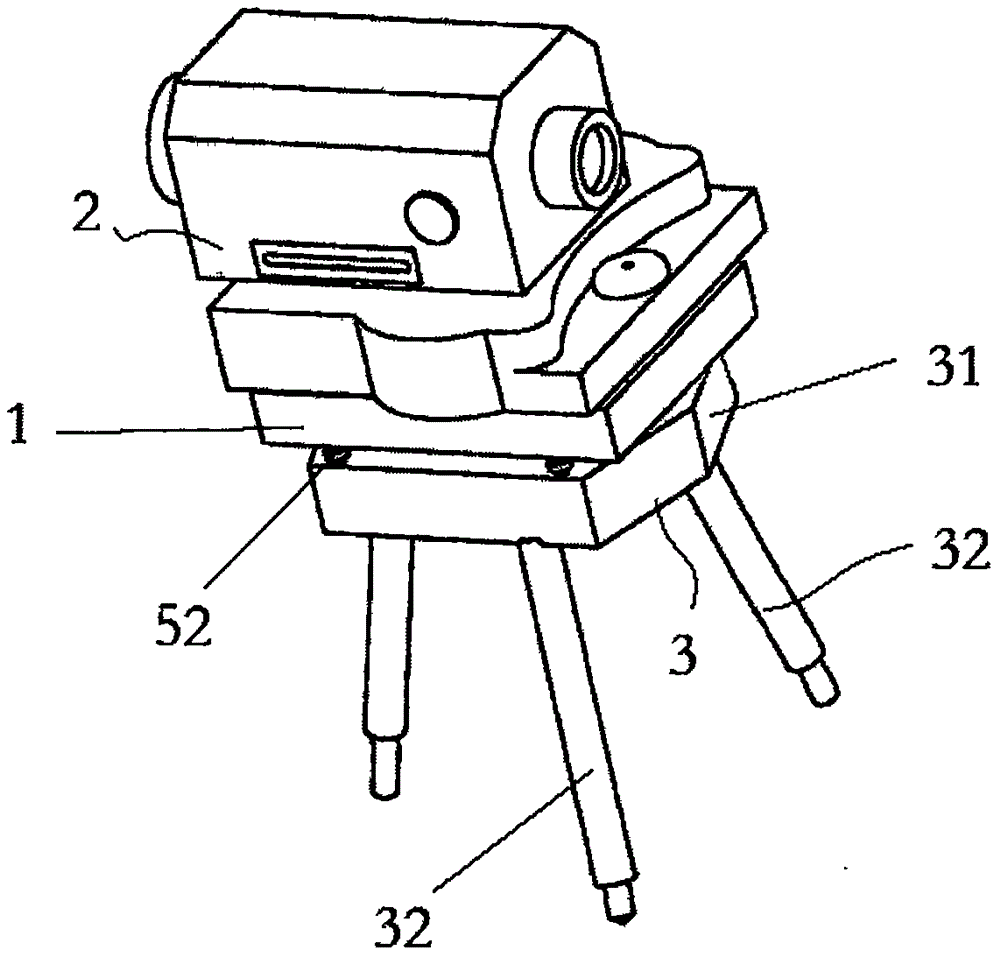

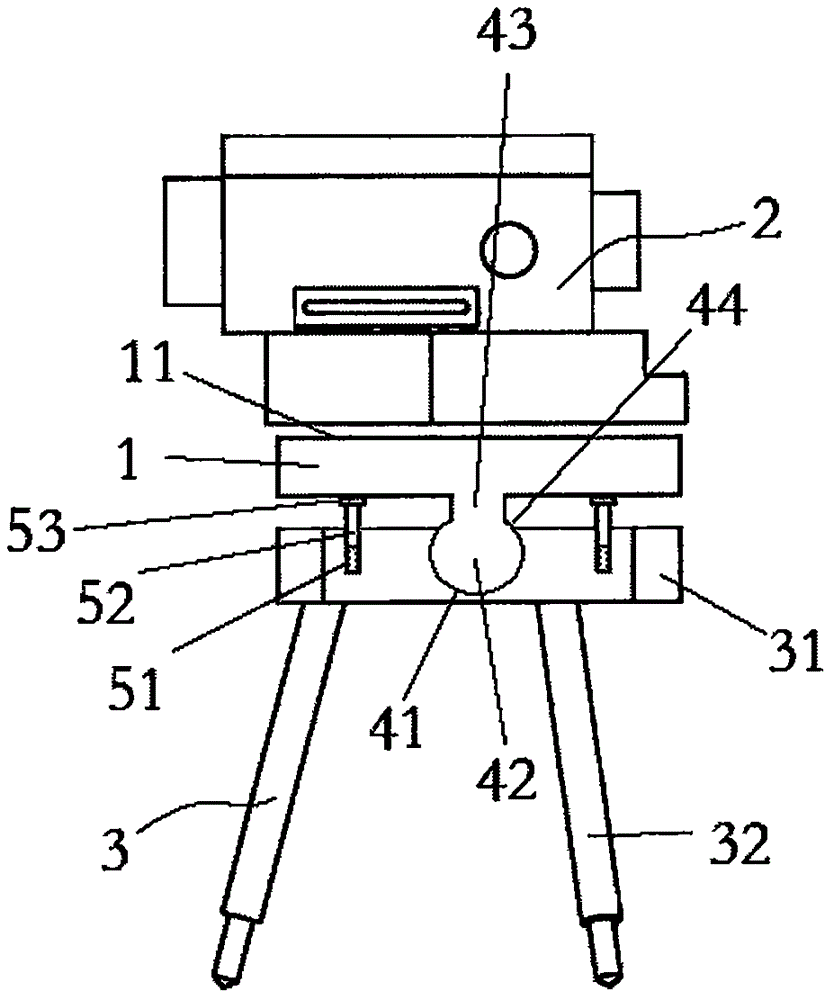

Level bracket structure and leveling method thereof

InactiveCN105805506ASimplify the adjustment processImprove regulation efficiencyHeight/levelling measurementStands/trestlesMechanical engineeringEngineering

Owner:SHANDONG GEO-SURVEYING & MAPPING INST

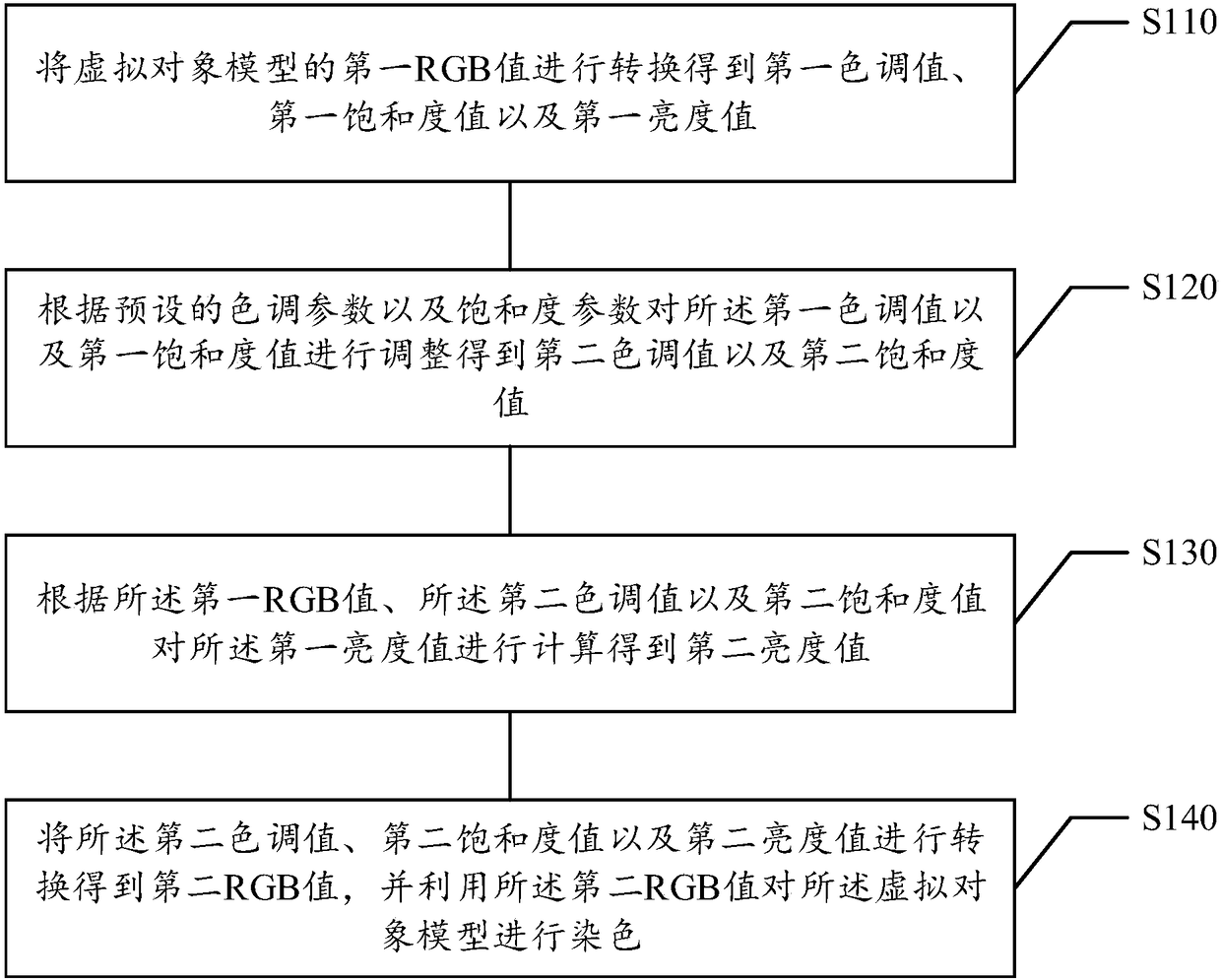

Method and device for dyeing virtual object model, storage medium and electronic equipment

ActiveCN108198250AImprove dyeing speedGuaranteed brightnessImage data processingHueComputer graphics

The invention relates to a method and device for dyeing virtual object model which belongs to the technical field of computer graphics. The method comprises: converting a first RGB value of a virtualobject model to obtain a first hue value, a first saturation value and a first brightness value; adjusting the first hue value and the first saturation value according to a preset hue parameter and asaturation parameter to obtain a second hue value and a second saturation value; calculating the first brightness value according to the first RGB value, the second hue value, and the second saturation value to obtain a second brightness value; converting the second hue value, the second saturation value, and the second luminance value to obtain a second RGB value, and dyeing the virtual object model using the second RGB value. The method reduces the step of adjusting the second brightness value, increases the speed of dyeing the virtual object model and saves the time cost.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

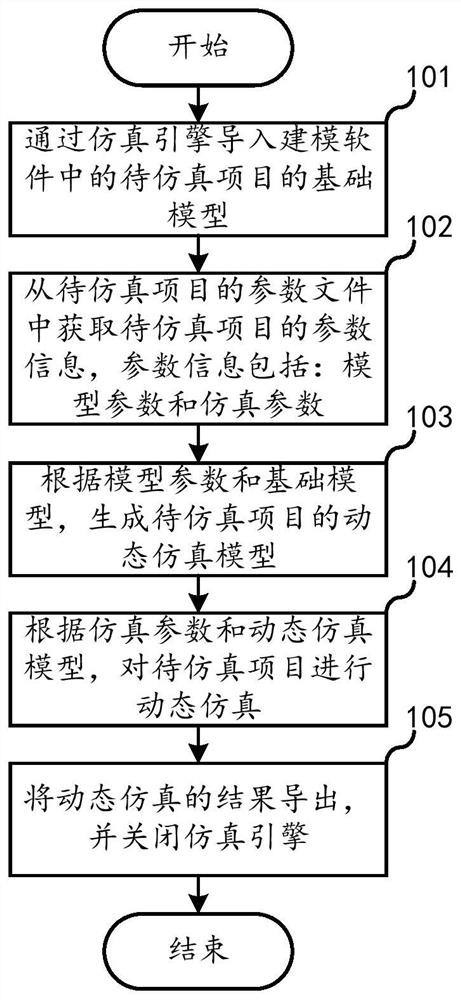

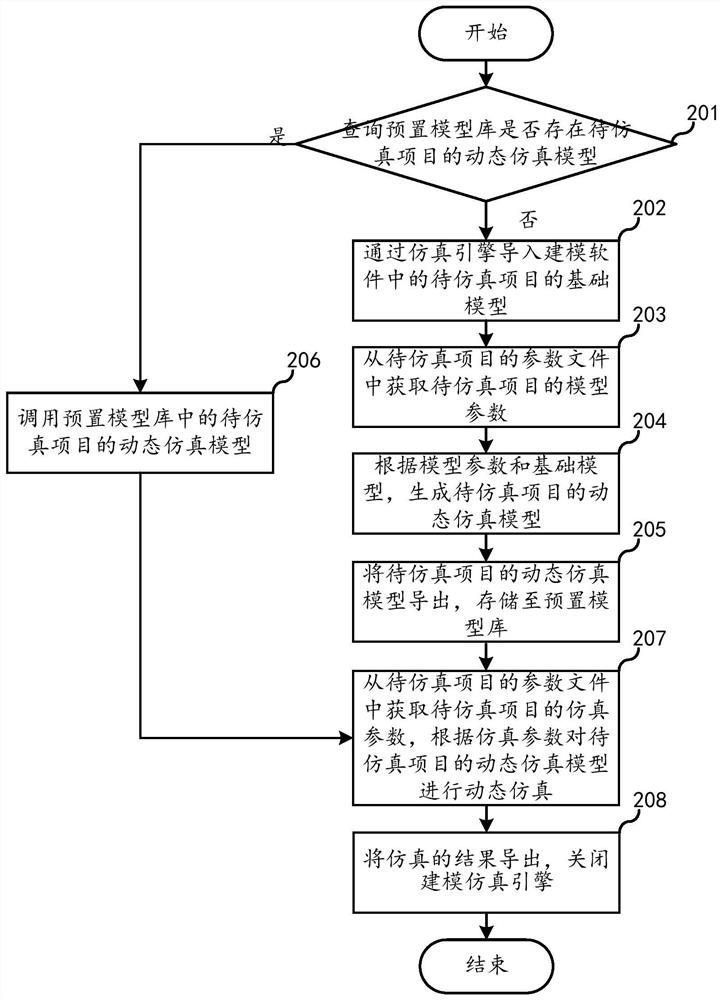

Simulation test method, device, electronic equipment and storage medium

PendingCN112668181AShorten the timeOptimizationDesign optimisation/simulationModelSimIndustrial engineering

The embodiment of the invention relates to the field of model simulation, and discloses a simulation test method, a device, electronic equipment and a storage medium. The method comprises the steps of importing a basic model of a to-be-simulated project in modeling software through a simulation engine; obtaining parameter information of the to-be-simulated project from the parameter file of the to-be-simulated project, wherein the parameter information comprises model parameters and simulation parameters; generating a dynamic simulation model of the to-be-simulated project according to the model parameters and the basic model; performing dynamic simulation on the dynamic simulation model according to the simulation parameters; exporting results of a simulation. In the embodiment of the invention, the basic model is imported through the simulation engine, so that the time for manually searching the basic model in the system folder is reduced; the parameter information is stored in the form of the parameter file and is directly read in the process of generating the dynamic simulation model, and parameters do not need to be input manually step by step, so that the parameter configuration process in the dynamic simulation process is optimized, the time and manpower investment in the simulation test process is reduced, and the user experience is improved.

Owner:SHANGHAI KELIANG INFORMATION ENG

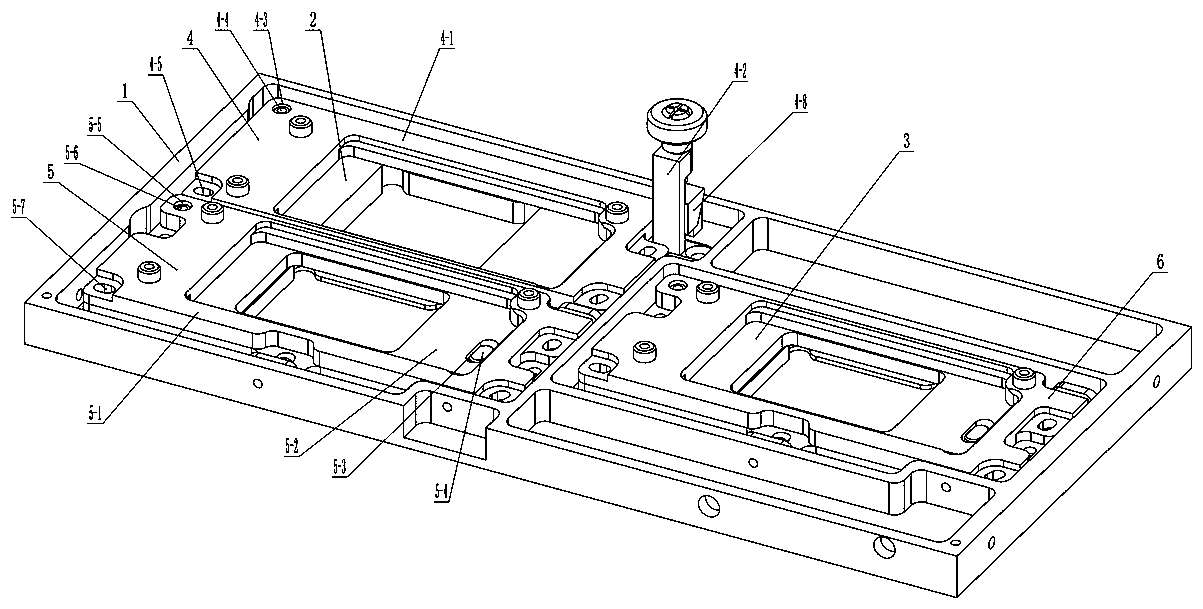

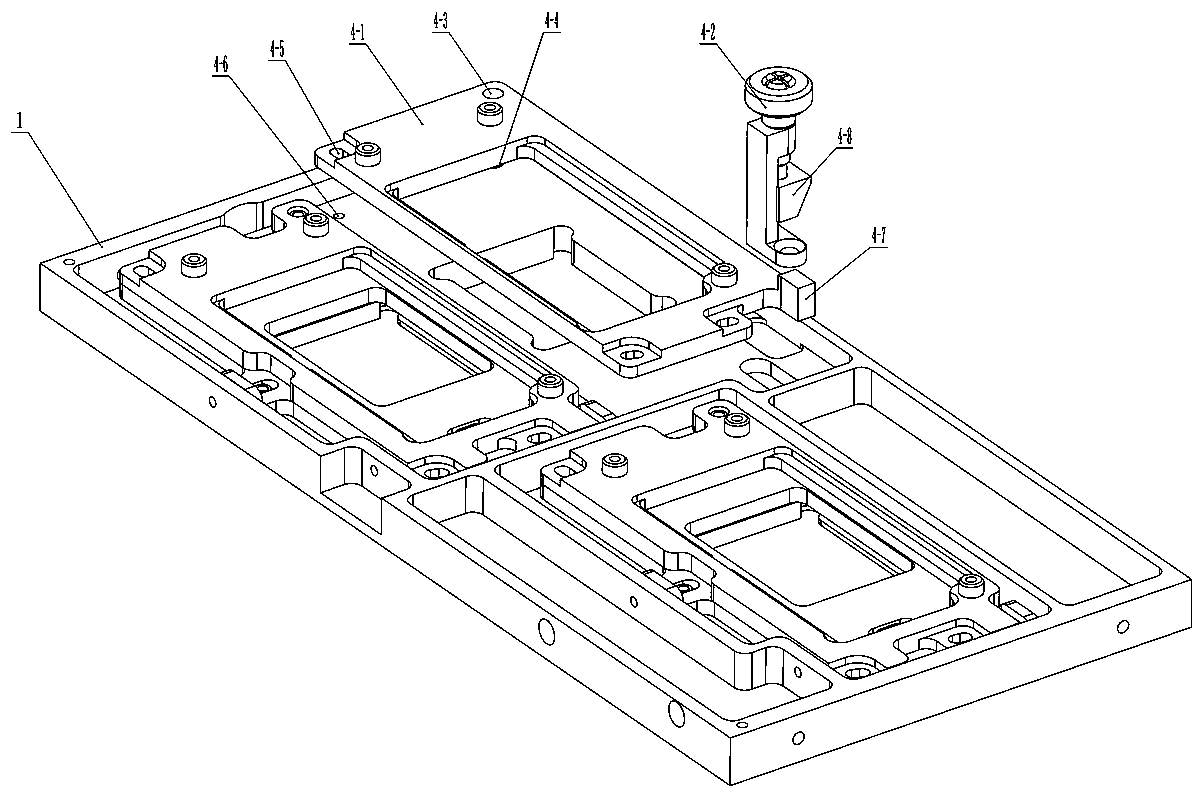

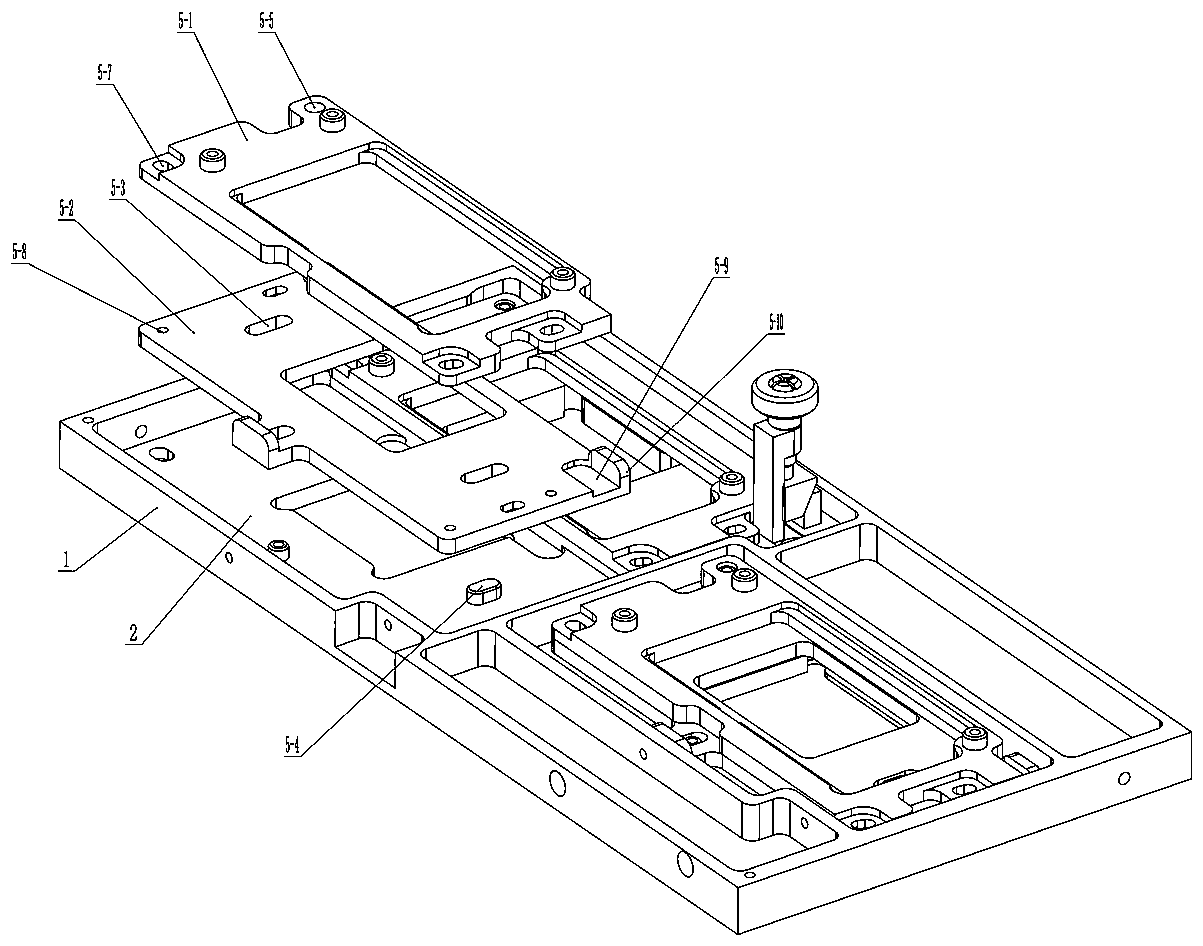

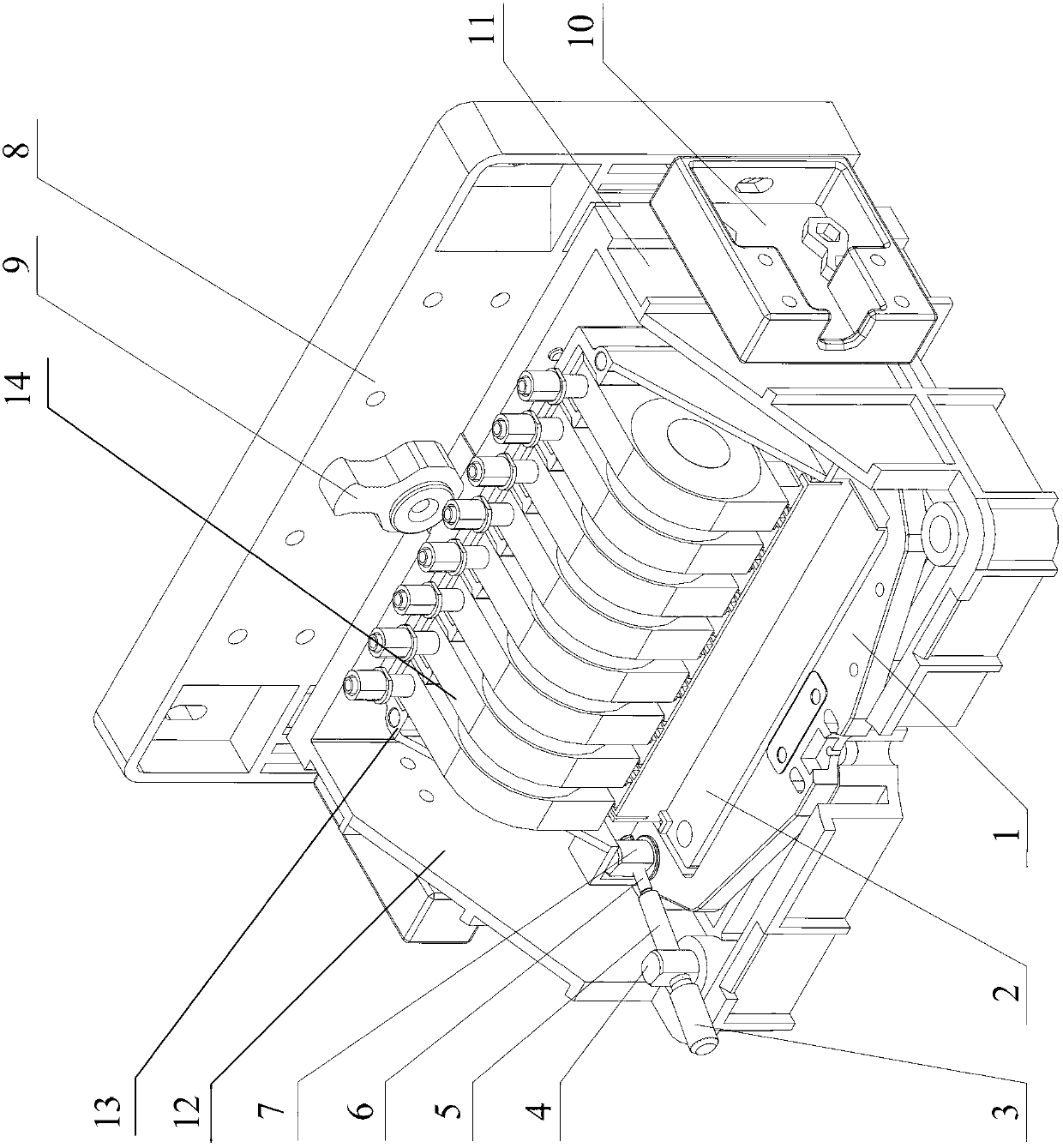

Nozzle angle fine-adjusting device for three-nozzle printer

The invention provides a nozzle angle fine-adjusting device for a three-nozzle printer. The nozzle angle fine-adjusting device comprises a base. The base is divided into a left adjusting groove and aright adjusting groove. A first nozzle adjusting device and a second nozzle adjusting device are longitudinally arranged in the left adjusting groove, and a third nozzle adjusting device is arranged in the right adjusting groove. The first nozzle adjusting device comprises a first adjusting plate and a fine adjusting knob. A first pin is arranged on the position, corresponding to a first circularhole, in the left adjusting groove. The first adjusting plate rotates around the first pin in a fine adjusting manner. First arc-shaped long holes are correspondingly formed in the second corner, thethird corner and the fourth corner which are sequentially arranged along the edge of the first adjusting plate. A fine adjusting cross bar extends transversely at the fourth corner. The fine adjustingknob is screwed on the base. The fine adjusting knob is sleeved with a bevel body structure. The bevel of the bevel body is abutted against the fine adjusting cross bar. The first pin is the center of the circle, and the angles of other corners can be adjusted; and meanwhile, the first nozzle adjusting device and the second nozzle adjusting device are adjusted together by using the fine adjustingknob and finally adjusted to the appropriate position.

Owner:NEW CENTURY DIGITAL PRINT TECH

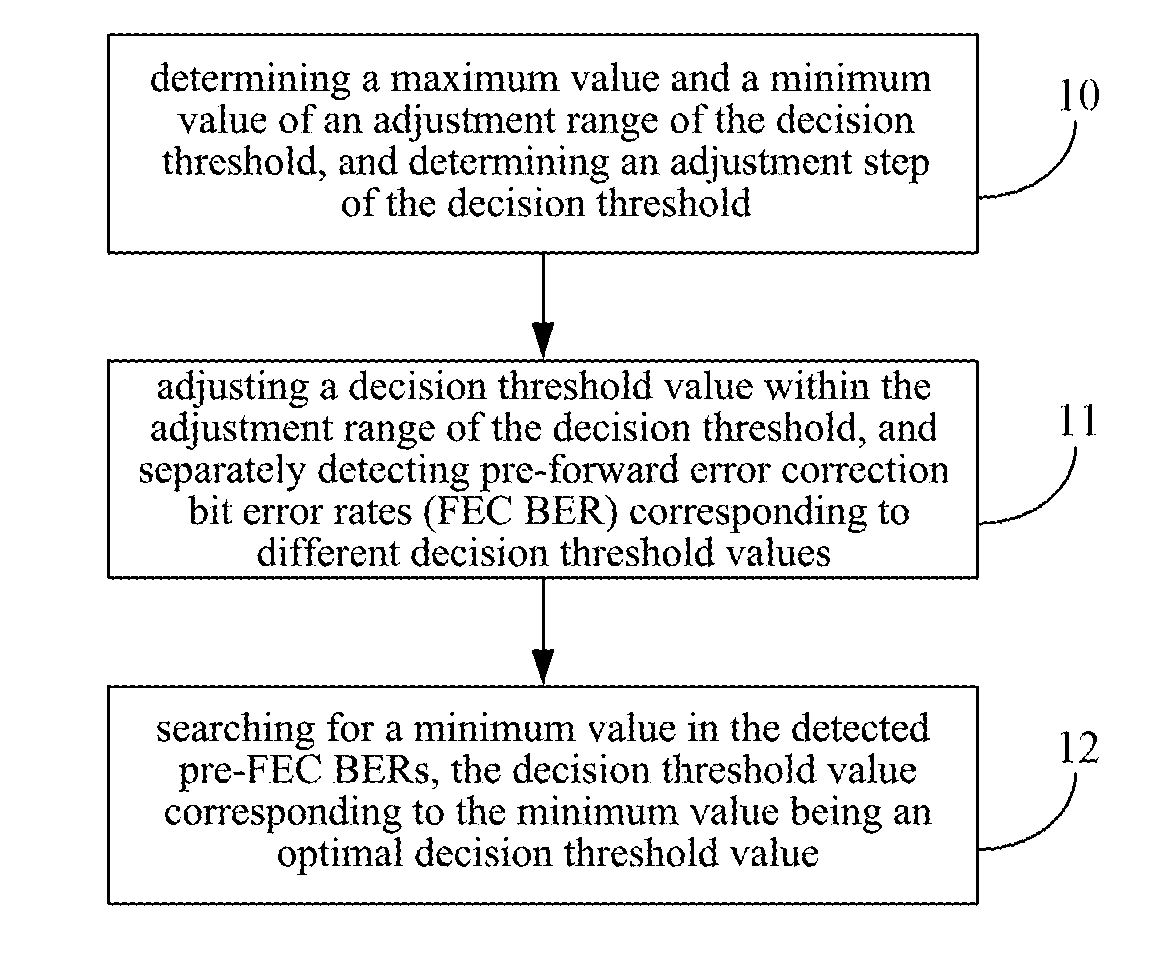

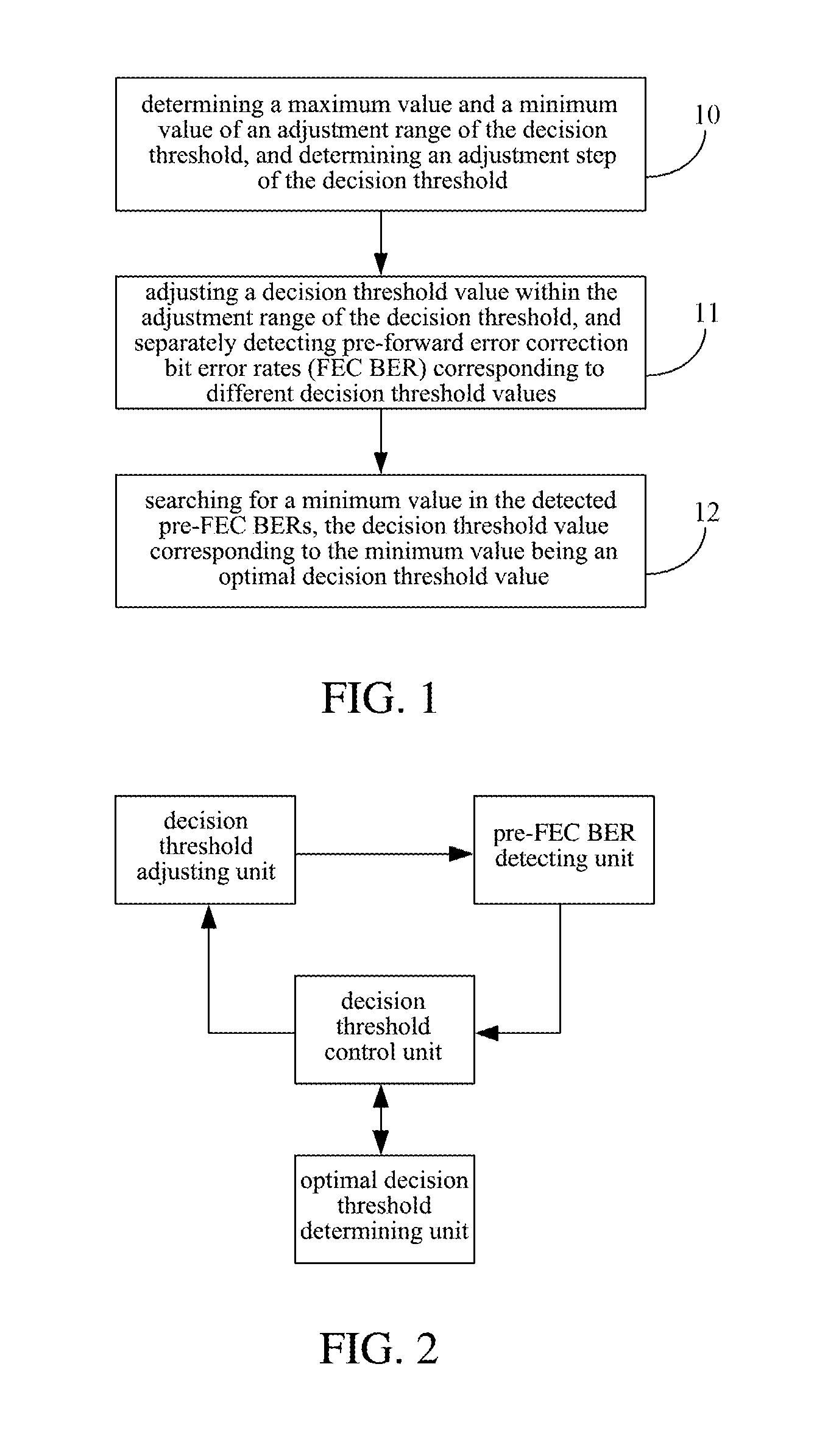

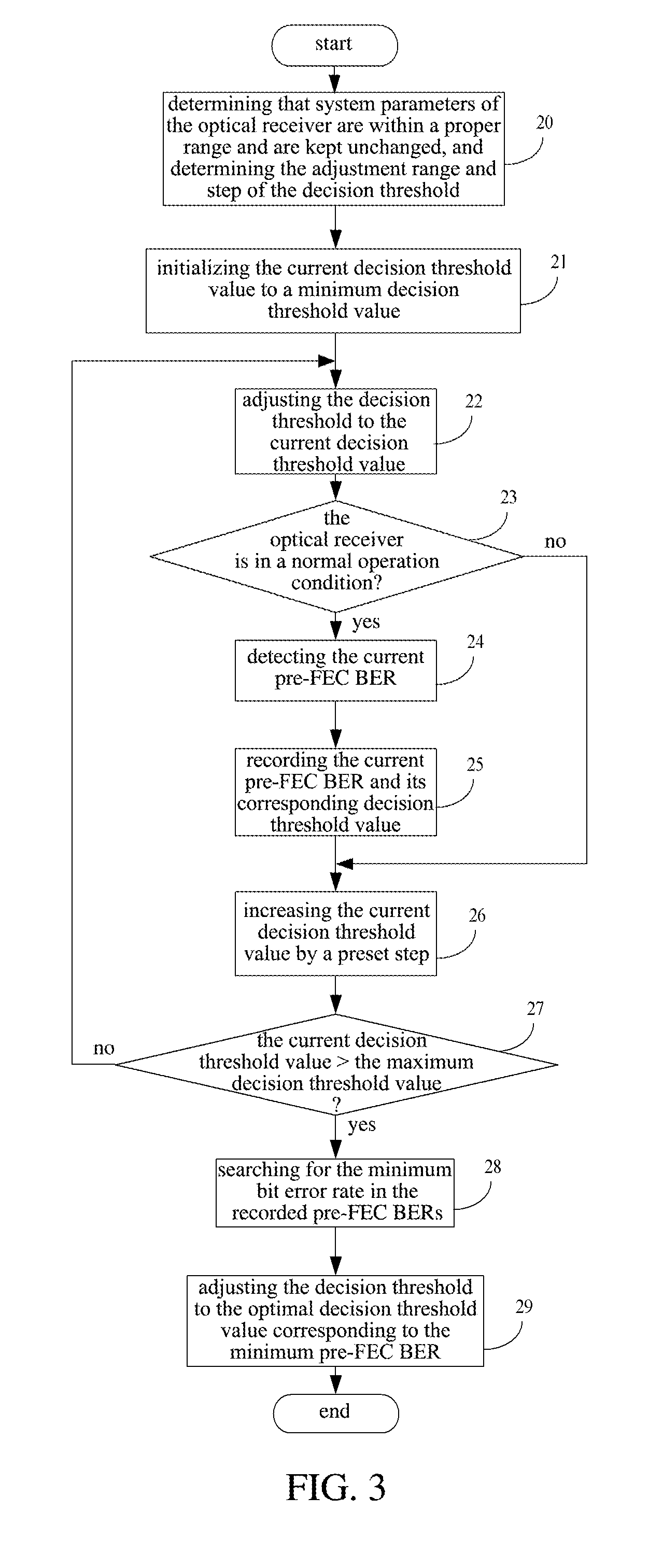

Method and apparatus optimizing decision threshold level of optical receiver

ActiveUS20110182574A1Less-gain adjustment rangeReduce adjustment stepsData representation error detection/correctionLaser detailsOptimal decisionSystem stability

method and apparatus for optimizing a decision threshold of an optical receiver is used to solve a problem of affecting system stability and reliability. The method comprises: determining a maximum value and a minimum value of an adjustment range of the decision threshold, and determining an adjustment step of the decision threshold (10); adjusting a decision threshold value within the adjustment range of the decision threshold, and separately detecting pre-FEC BERs corresponding to different decision threshold values (11); and searching for a minimum value in the detected pre-FEC BERs, a decision threshold value corresponding to the minimum value being an optimal decision threshold value (12). The apparatus comprises a decision threshold adjusting unit, a pre-FEC BER detecting unit, a decision threshold control unit and an optimal decision threshold determining unit.

Owner:ZTE CORP

Face-to-face matched angular contact ball bearing and matching method thereof

InactiveCN105041853ASimplify preload repair processSimplify the installation processRolling contact bearingsBearing componentsBall bearingEngineering

The invention provides a face-to-face matched angular contact ball bearing and a matching method thereof. The face-to-face matched angular contact ball bearing comprises an inner ring. The outer circumferential surface of the inner ring is provided with a first outer groove and a second outer groove. The inner ring is correspondingly sleeved with a first outer ring and a second outer ring. The two outer rings are arranged in a spaced mode in the front-and-back direction. An outer spacer ring is clamped between the two outer rings. The inner circumferential surfaces of the two outer rings are provided with inner grooves. The inner grooves of the two outer rings and the two outer grooves of the inner ring are correspondingly filled with steel balls. The two axial end faces of each outer ring are a wide-side end face and a narrow-side end face respectively. The narrow-side end face of the first outer ring and the narrow-side end face of the second outer ring are oppositely arranged. The narrow-side end face of the first outer ring and the narrow-side end face of the second outer ring make contact with the two axial end faces of the outer spacer ring correspondingly in an abutted fit mode. The axial play of the bearing can be adjusted just by grinding the outer spacer ring, grinding of an inner spacer ring is avoided, the pre-tightening force fitting process of the matched angular contact ball bearing is simplified, and the axial pre-tightening force adjusting time is shortened.

Owner:LUOYANG BEARING RES INST CO LTD

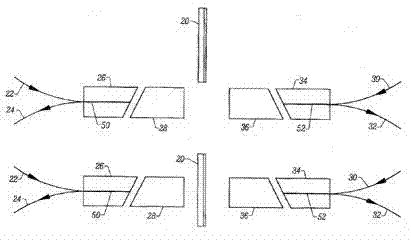

2*2 mechanical optical switch

The invention relates to the field of optical devices, in particular to a 2*2 mechanical optical switch. The 2*2 mechanical optical switch comprises two sets of four-fiber collimators, and glass prisms capable of being freely inserted and separated are arranged among the four-fiber collimators. In the separating state, light beams of a first optical fiber, a second optical fiber, a fifth optical fiber and a sixth optical fiber are directly coupled to a seventh optical fiber, an eighth optical fiber, a third optical fiber and a fourth optical fiber respectively. In the inserting state, after the light beams are deviated through the glass prisms, the first optical fiber is coupled to the third optical fiber, and at the same time, the second optical fiber is coupled to the fourth optical fiber. Besides, the fifth optical fiber is connected with the sixth optical fiber, and the eighth optical fiber is connected with the seventh optical fiber. A bypass loop is formed by leading the light to the other side from one side only through one displacement optical element. Therefore, the dimensionality of optical fiber alignment adjustment can be reduced, larger positions and angle allowances are allowed, the packing difficulty can be reduced, and the 2*2 mechanical optical switch is especially suitable for being produced on a large scale.

Owner:广西安捷讯电子科技有限公司

Face-to-face type assembled double-row angular contact ball bearing and assembling method thereof

InactiveCN105114447AIncrease stiffnessSimplify preload repair processRolling contact bearingsBearing componentsBall bearingEngineering

The invention provides a face-to-face type assembled double-row angular contact ball bearing and an assembling method thereof. The face-to-face type assembled double-row angular contact ball bearing comprises an inner ring, and a first outer channel and a second outer channel are formed in the peripheral face of the inner ring. The inner ring is correspondingly sleeved with a first outer ring and a second outer ring, the two outer rings are sequentially arranged in the front-back direction and are in jack-pressing contact fit, inner channels are formed in the inner circumferential faces of the two outer rings, and the inner channels of the two outer rings and the two outer channels of the inner ring are correspondingly filled with steel balls. The two axial end faces of each outer ring comprises a wide-edge end face and a narrow-edge end face, and the narrow-edge end face of the first outer ring is in corresponding contact and jack-pressing fit with the narrow-edge end face of the second outer ring. Due to the fact that an inner spacer ring and an outer spacer ring are omitted, the inner spacer ring and the outer spacer ring are prevented from being ground, a pretightening force repairing process for assembling the angular contact ball bearing is simplified, axial pretightening force adjusting time is saved, and the efficiency of pretightening force adjustment is improved. By means of the integral inner ring, the mounting process of the whole face-to-face type assembled double-row angular contact ball bearing is simple and efficient, complex adjusting steps are omitted, and the mounting difficulty of the bearing is lowered.

Owner:LUOYANG BEARING RES INST CO LTD

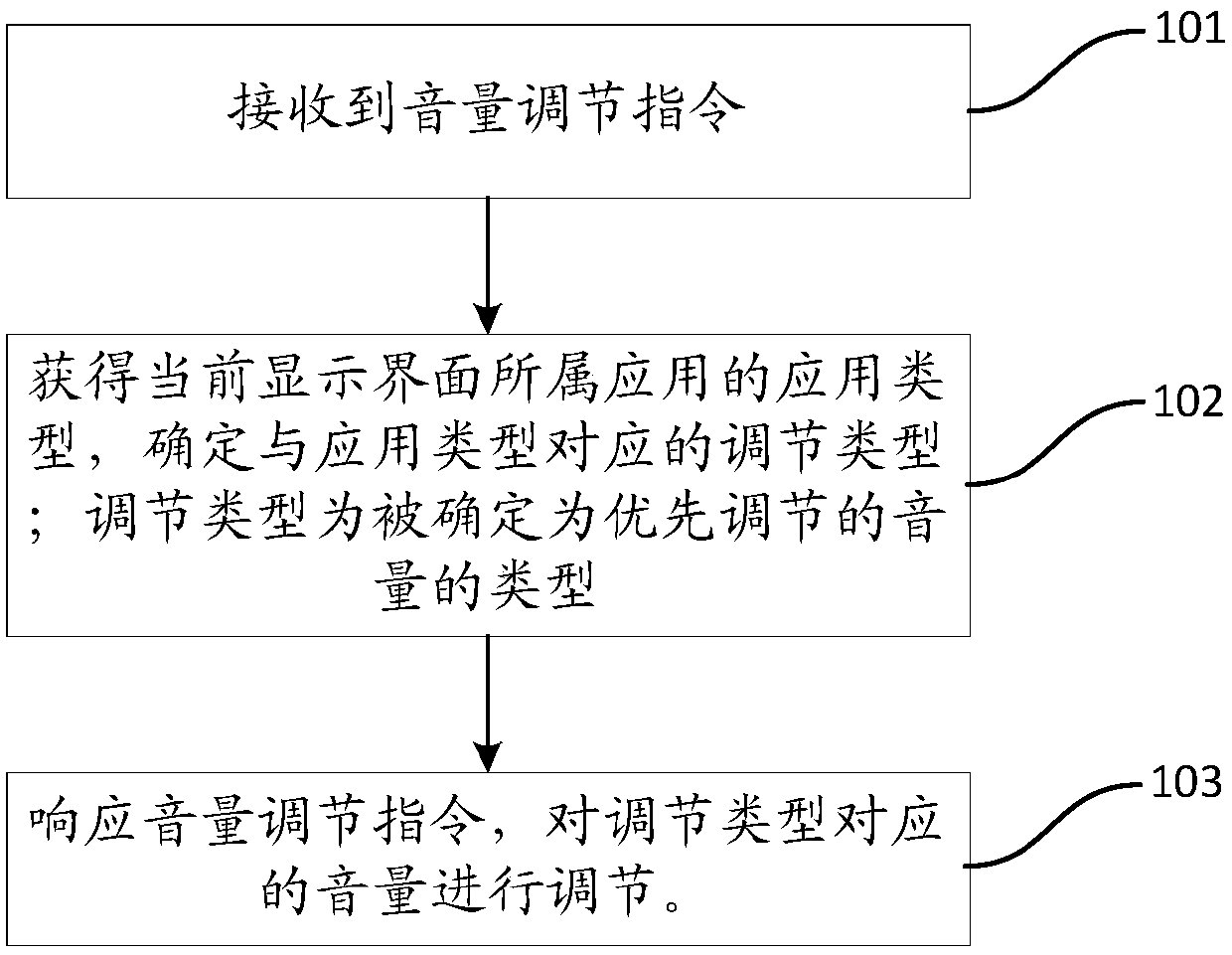

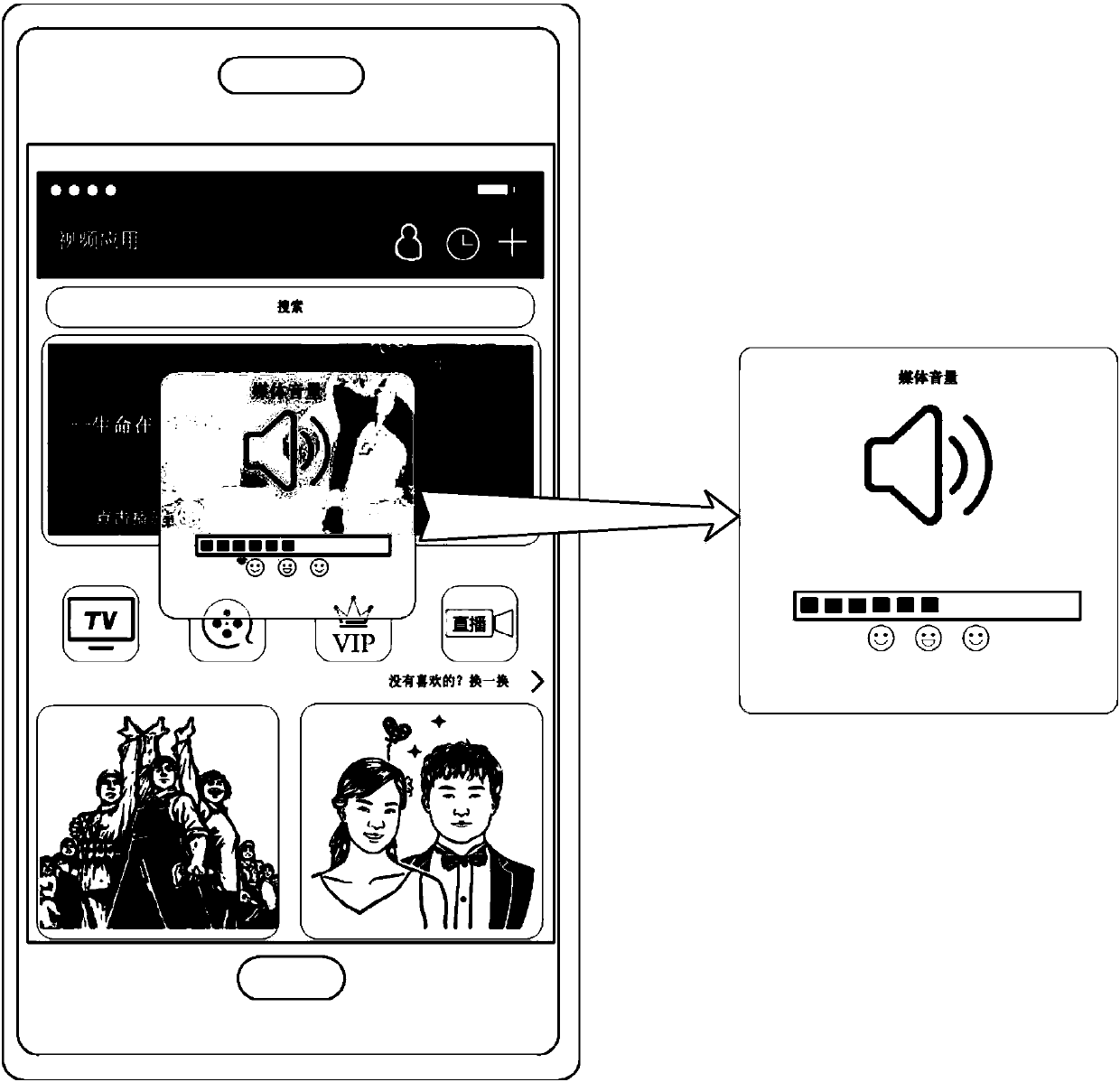

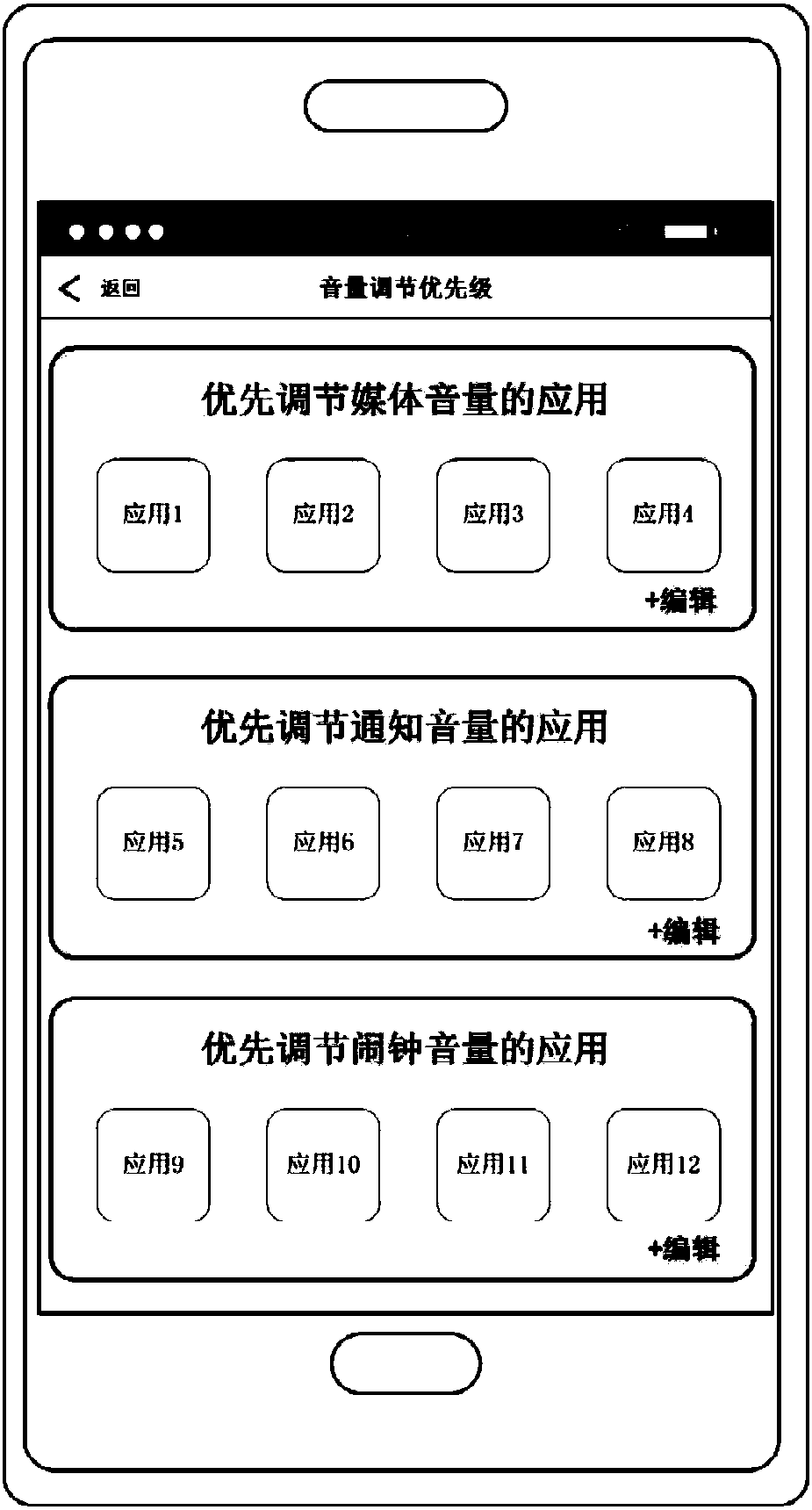

Volume adjustment method, terminal equipment and computer readable storage medium

InactiveCN108021301AReduce misuseFew stepsSubstation equipmentSound input/outputTerminal equipmentComputer engineering

The embodiment of the invention discloses a volume adjustment method, terminal equipment and a computer readable storage medium. The method comprises the following steps that: receiving a volume adjustment instruction; obtaining the application type of an application to which a current display interface belongs, and determining an adjustment type corresponding to the application type; determiningthe adjustment type as the type of the volume which is adjusted preferentially; and responding to the volume adjustment instruction to adjust the volume corresponding to the adjustment type. By use ofthe embodiment of the invention, the applications are classified into different application types, so that preferential volume adjustment types are different when the volume is adjusted under different application types, a volume adjustment misoperation can be reduced, in addition, a volume adjustment step is reduced, and the working efficiency of the terminal equipment is improved.

Owner:SHENZHEN GIONEE COMM EQUIP

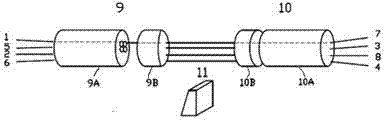

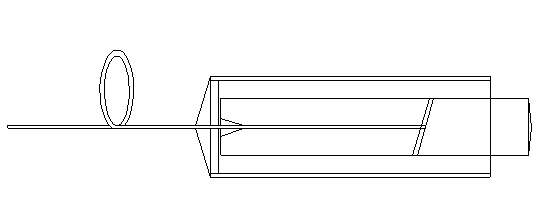

Method for adjusting coaxiality of optical machines of transmission-type optical fiber collimator

The invention relates to a method for adjusting coaxiality of optical machines of a transmission-type optical fiber collimator. The method comprises the steps that the position of the optical fiber collimator (3) is adjusted vertically and laterally in sequence while the optical power received by an instrument (9.2) is observed; and when the optical power in the vertical direction and the optical power in the lateral direction are the largest simultaneously, the center of a laser beam coincides with the center of a pinhole, the direction of the laser beam is parallel to a mechanical axis serving as the reference, and accordingly, the coaxiality of the optical machines is achieved. By means of the method for adjusting the coaxiality of the optical machines of the transmission-type optical fiber collimator, an adjusting device is simple in structure, adjusting steps are few, and the process is simple. Furthermore, the mechanical axis of the optical fiber collimator serves as the reference, the emission direction of the laser beam is changed by vertically and laterally adjusting the position of the optical fiber collimator until the emission direction of the laser beam coincides with the direction of the mechanical axis serving as the reference, and accordingly, the optical fiber collimator has high-accuracy optical machine coaxiality.

Owner:JIANGSU KANGLAITE TECH +1

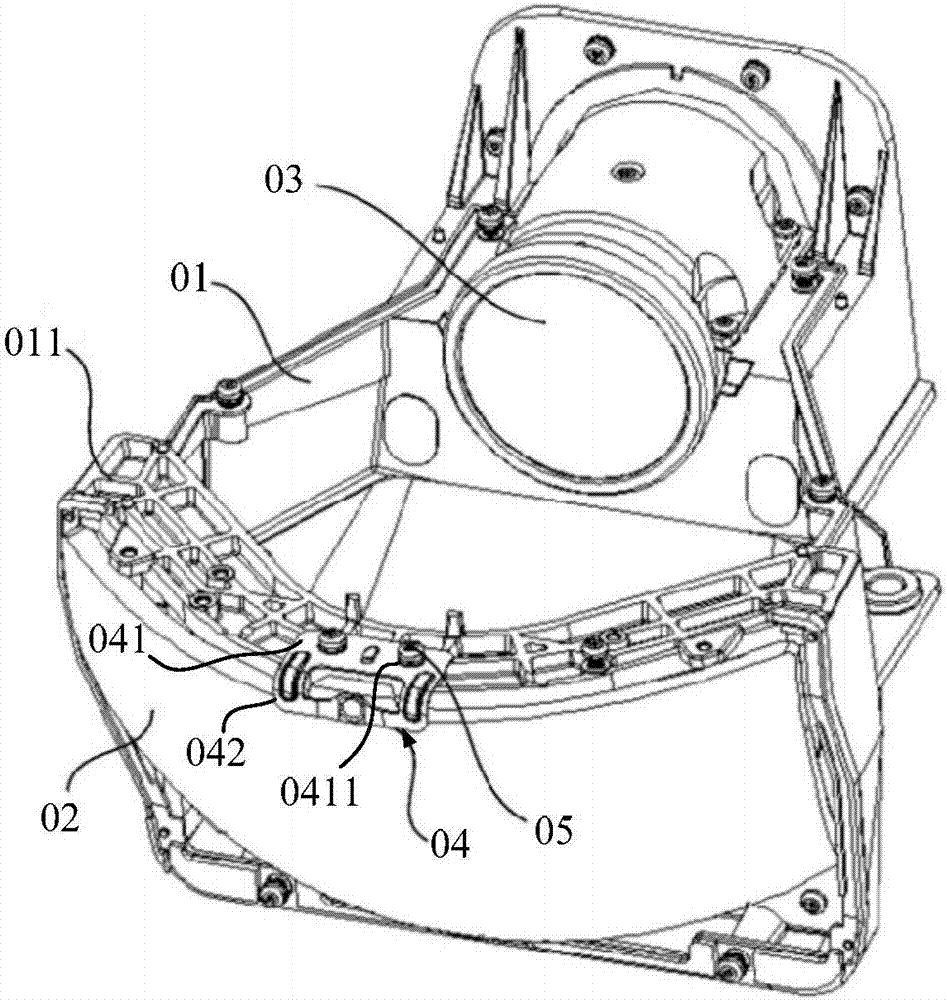

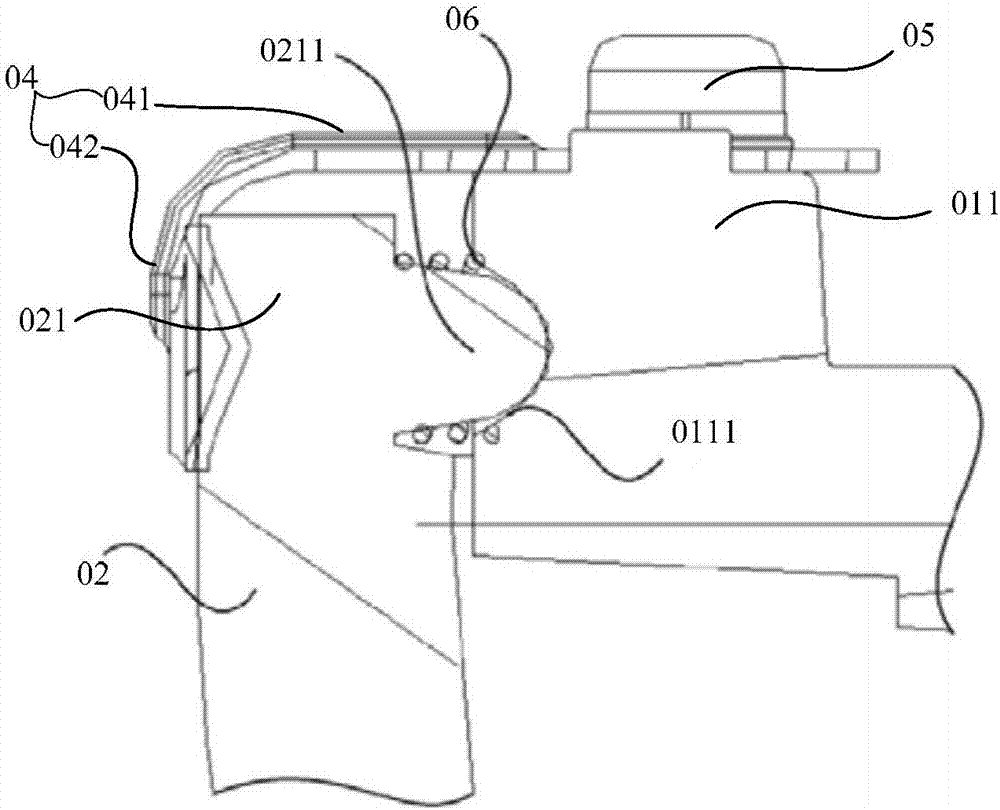

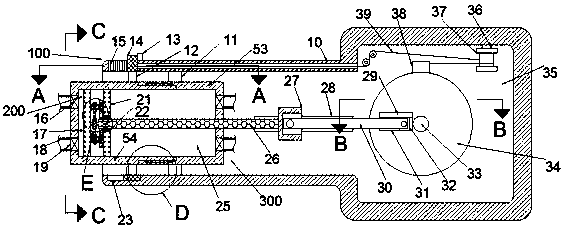

Adjusting mechanism of curved-surface reflection mirror in projector and projector

The invention discloses an adjusting mechanism of a curved-surface reflection mirror in a projector and the projector and relates to the technical field of projectors. The objective of the invention is to solve a problem that it is difficult to achieve precise adjustment when the current adjusting mechanism adjusts an upper end of a curved-surface reflection mirror. The adjusting mechanism comprises an installation support and a curved-surface reflection mirror. The upper end of the curved-surface reflection mirror is connected with a first adjusting beam through a fixed beam. The first adjusting beam is fixed on the upper end of the curved-surface reflection mirror. Two first through holes are arranged in the first adjusting beam in the length direction of the first adjusting beam. Two first adjusting screws are threaded in the first through holes respectively, and are in threaded connection with the fixed beam. An elastic piece is arranged between the first adjusting beam and the fixed beam. The contact point of the elastic piece and the first adjusting beam is arranged between the first through holes. The adjusting mechanism can be used for projectors.

Owner:HISENSE

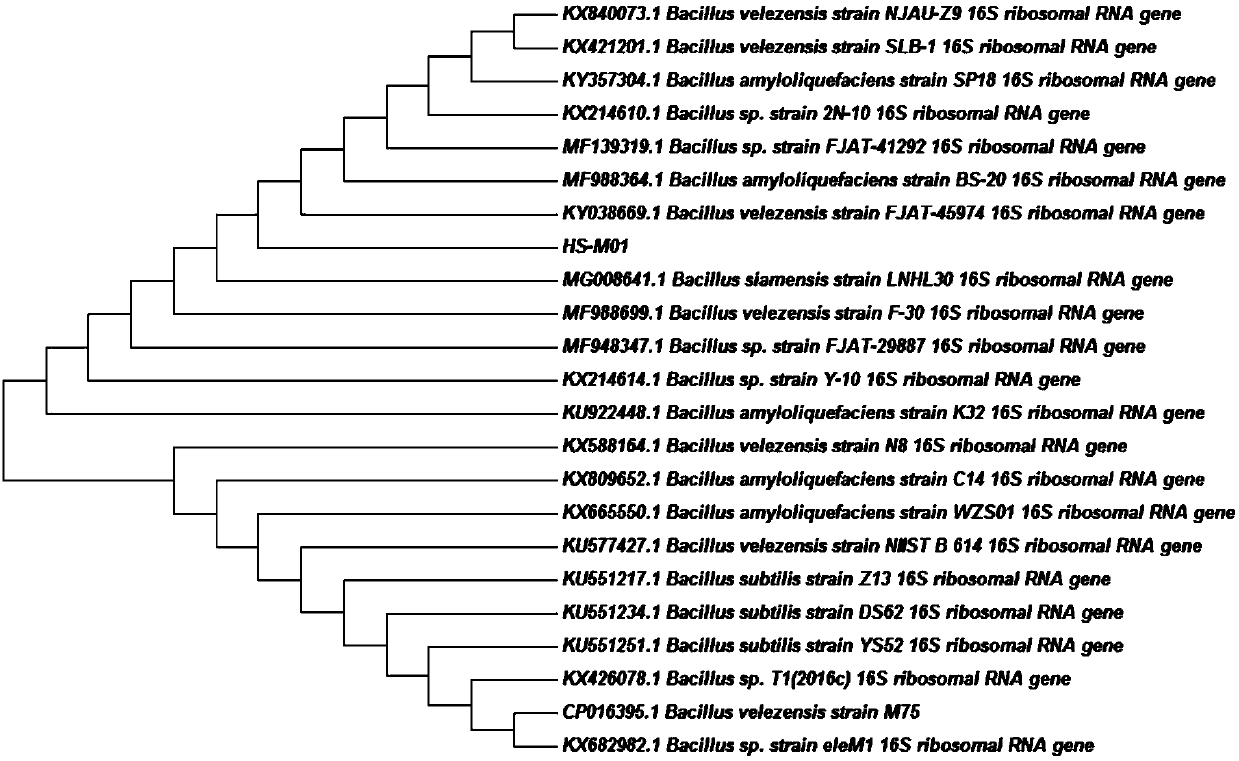

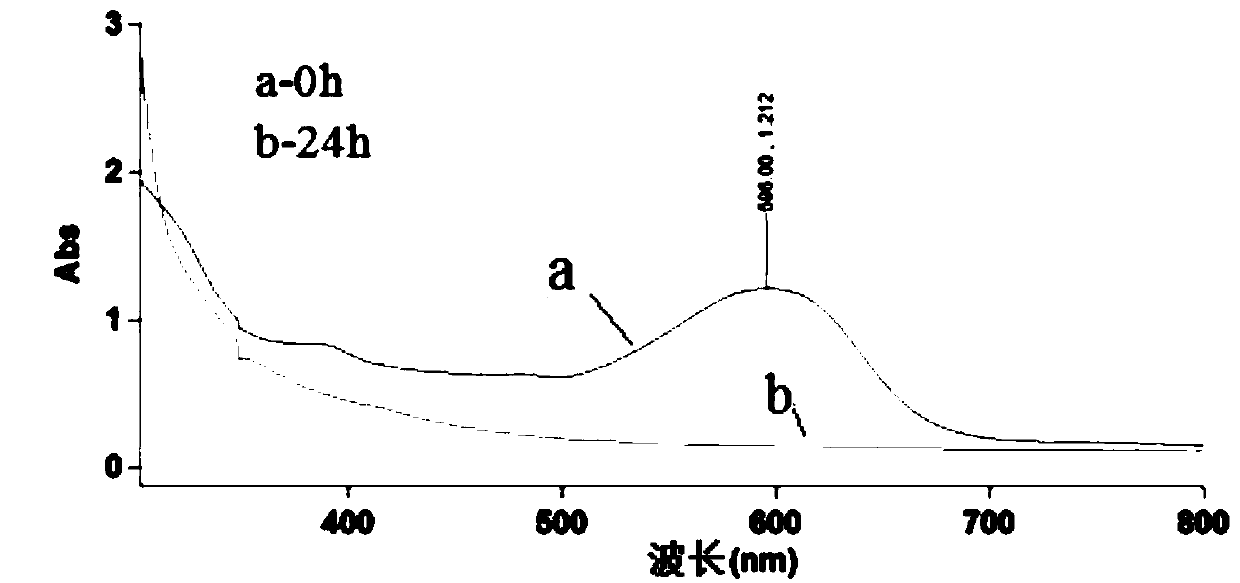

Bacterial strain of Bacillus spp. for high-efficient wide-spectrum decolorization and degradation of reactive dyes and application thereof

ActiveCN107841478ANo pollutionGood theoretical researchBacteriaMicroorganism based processesNitrate nitrogenWastewater

The invention discloses a bacterial strain of Bacillus spp. for high-efficient wide-spectrum decolorization and degradation of reactive dyes and an application thereof, and belongs to the fields of microorganisms and waste water treatment. The bacterial strain is Bacillus spp. HM01 (Bacillus spp. HM01), and the preservation number is CCTCC No:M2017558. The bacterial strain can be used for decolorization and degradation of a plurality of reactive dyes and is used as a nitrogen source required by growth, can avoid nitrogen pollution caused by accumulation of nitrate nitrogen in a dye degradationprocess, and can be applied to treatment of printing and dyeing waste water containing a plurality of reactive dyes; the product has wide pH adaptation range, and has good theatrical research valuesand production application prospects.

Owner:HUANGGANG NORMAL UNIV

Extensible positive displacement pump

ActiveCN109989902AEasy to adjustReduce adjustment stepsPositive displacement pump componentsFree piston pumpsImpellerEngineering

The invention discloses an extensible displacement pump. The extensible displacement pump includes a pump body and a work cavity, an air cylinder mechanism is arranged in the work cavity and includesa right shell body fixedly connected with the inner wall of the work cavity through a first fixing ring, a lower sliding groove is formed in the wall of the work cavity, a lower sliding block is slidably arranged in the lower sliding groove, a ring-shaped sliding groove is formed in the wall of the right shell body, a ring-shaped sliding block is slidably arranged in the ring-shaped sliding groove, and a left shell body is fixedly connected with the ring-shaped sliding block. According to the extensible positive displacement pump, when the pumping speed needs to be adjusted, power supply poweror the impeller speed does not need to be adjusted, the thickness of a piston can be adjusted and extension of an air cavity is adjusted, the adjusting process is simple and fast, steps required foradjusting are reduced, the adjusting difficulty is reduced, and practicability is improved greatly.

Owner:江苏博利源机械有限公司

Method for processing information and electronic equipment

ActiveCN104345881AImprove adjustment efficiencyShorten the timeInput/output for user-computer interactionGraph readingProcess informationElectronic equipment

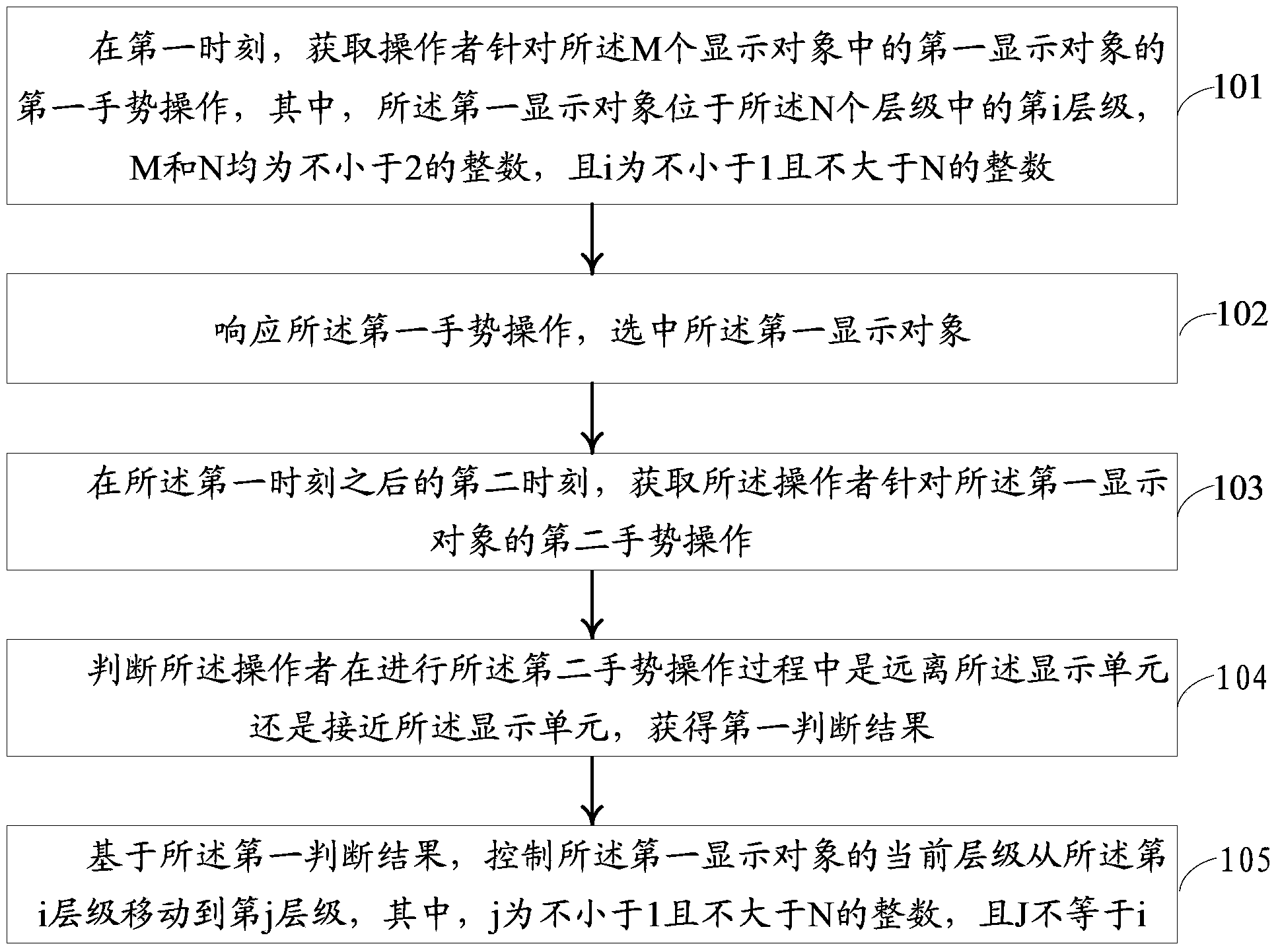

The invention discloses a method for processing information and electronic equipment. The electronic equipment is provided with a display unit, wherein M display objects which are arrayed in a stacked mode are displayed on the display unit and have N levels. The method comprises the following steps of acquiring a first gesture operation of an operation aiming at a first display object of the M display objects at the first time; responding the first gesture operation and selecting the first display object; acquiring a second gesture operation of the operation aiming at the first gesture operation at the second time after the first time; judging whether the operation is away from the display unit or close to the display unit or not in the process of performing the second gesture operation, and obtaining a first judgment result; controlling the current level of the first display object from the ith level to the jth level.

Owner:LENOVO (BEIJING) CO LTD

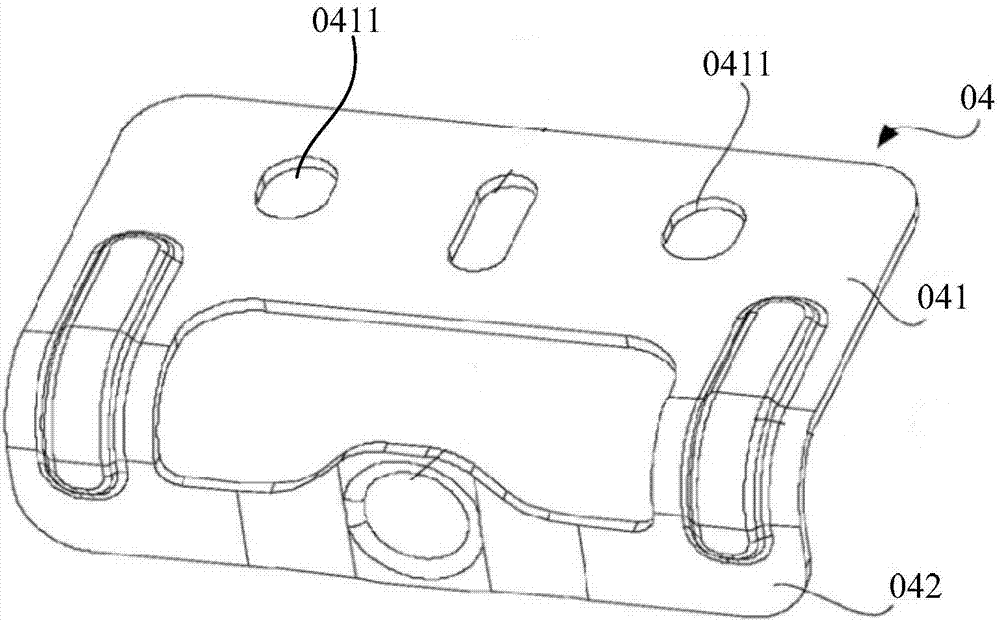

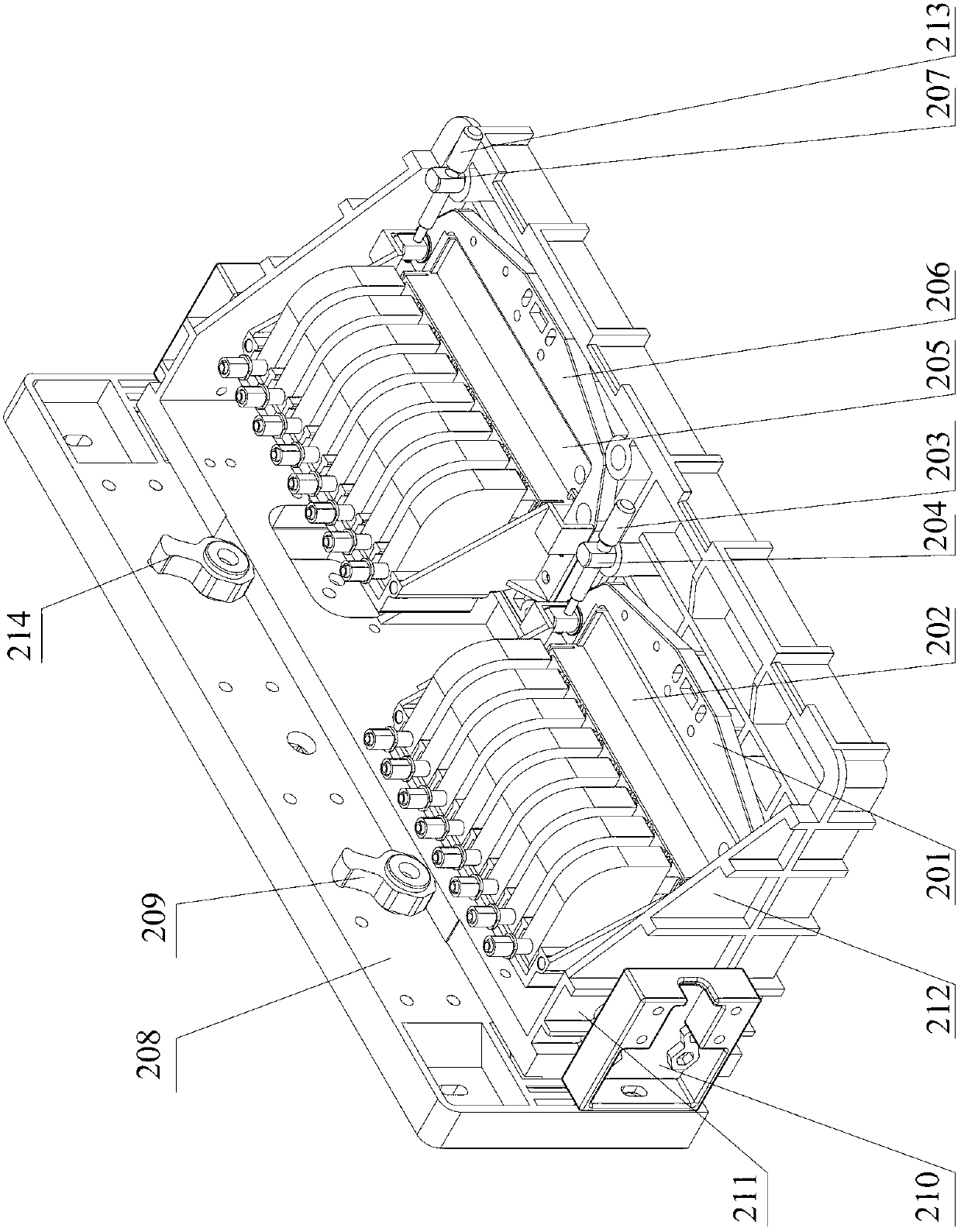

Spray head frame of printer

ActiveCN103101336AImprove assembly accuracyHigh accuracy consistencyPower drive mechanismsDie castingEngineering

The invention discloses a spray head frame of a printer. The spray head frame comprises a spray head sliding plate, a spray head frame body, a spray head frame height adjusting device, an ink bag pressing piece, a spray head adjusting plate and a spray head adjusting plate horizontal adjusting device, wherein the spray head frame body is arranged on the spray head sliding plate in a vertical sliding mode, the spray head frame height adjusting device is used for adjusting the height of the spray head frame body, the spray head adjusting plate is used for driving a spray head of the spray head frame of the printer to be parallel to the spray head sliding plate, the spray head adjusting plate is arranged on the spray head frame body in a horizontal sliding mode, the spray head adjusting plate horizontal adjusting device is used for adjusting the horizontal position of the spray head adjusting plate, the ink bag pressing piece is used for fixing an ink bag of the spray head frame of the printer, and the spray head sliding plate, the spray head frame body, the spray head frame height adjusting device, the ink bag pressing piece, the spray head adjusting plate and the spray head adjusting plate horizontal adjusting device are molded in an injection mode or a die-casting mode. The parts of the spray head frame of the printer are molded in the injection mode or the die-casting mode so that dimensional accuracy and dimensional consistency of the parts are improved, and therefore assembly accuracy of the parts is improved.

Owner:WENZHOU ACPASS DISPLAY EQUIP

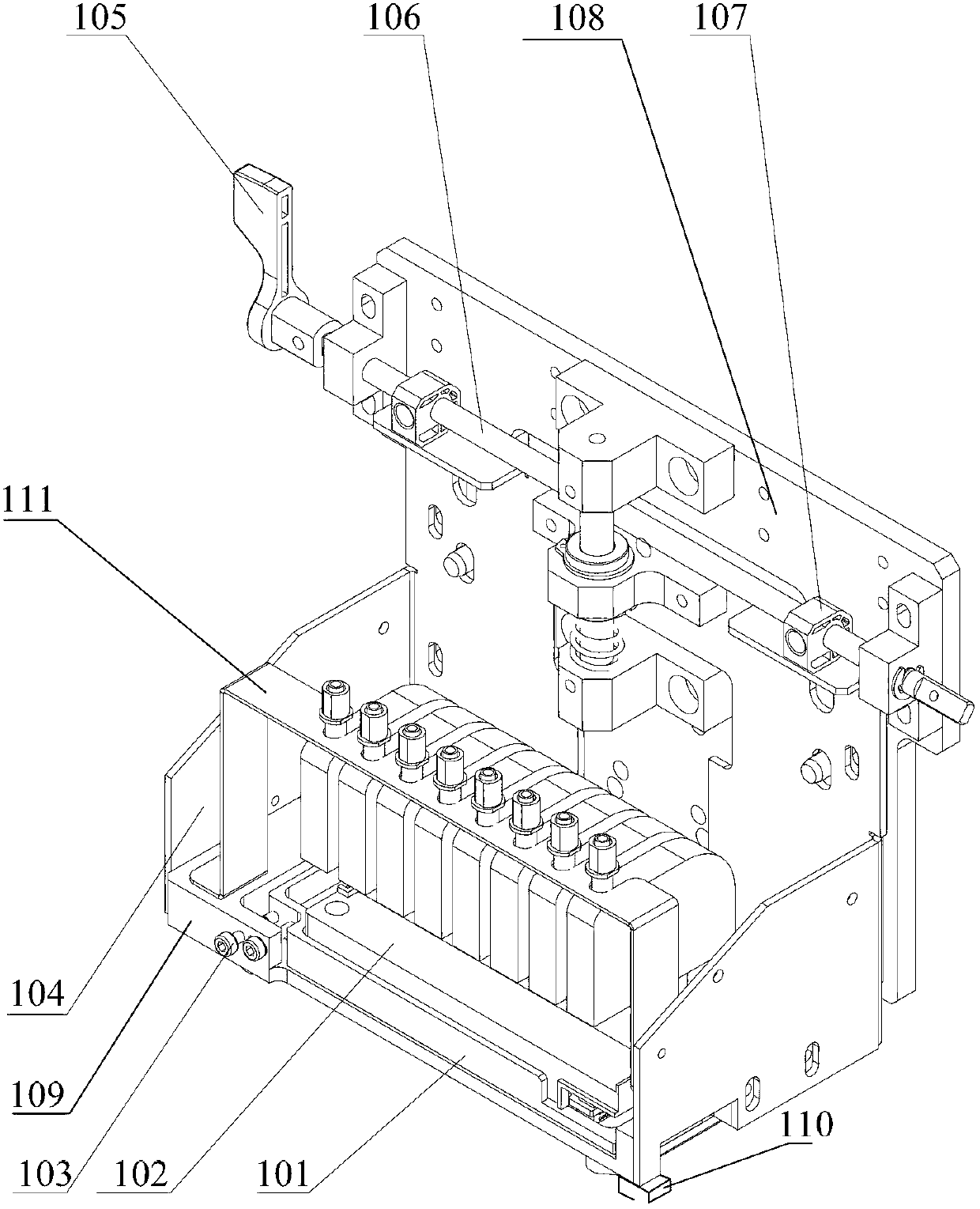

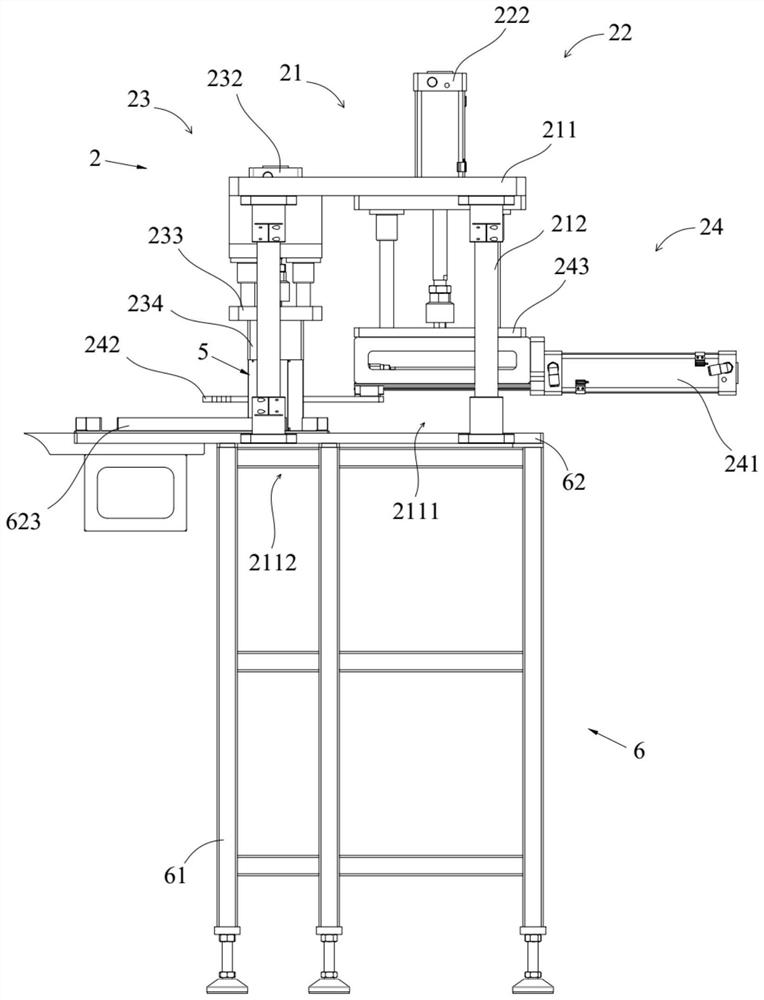

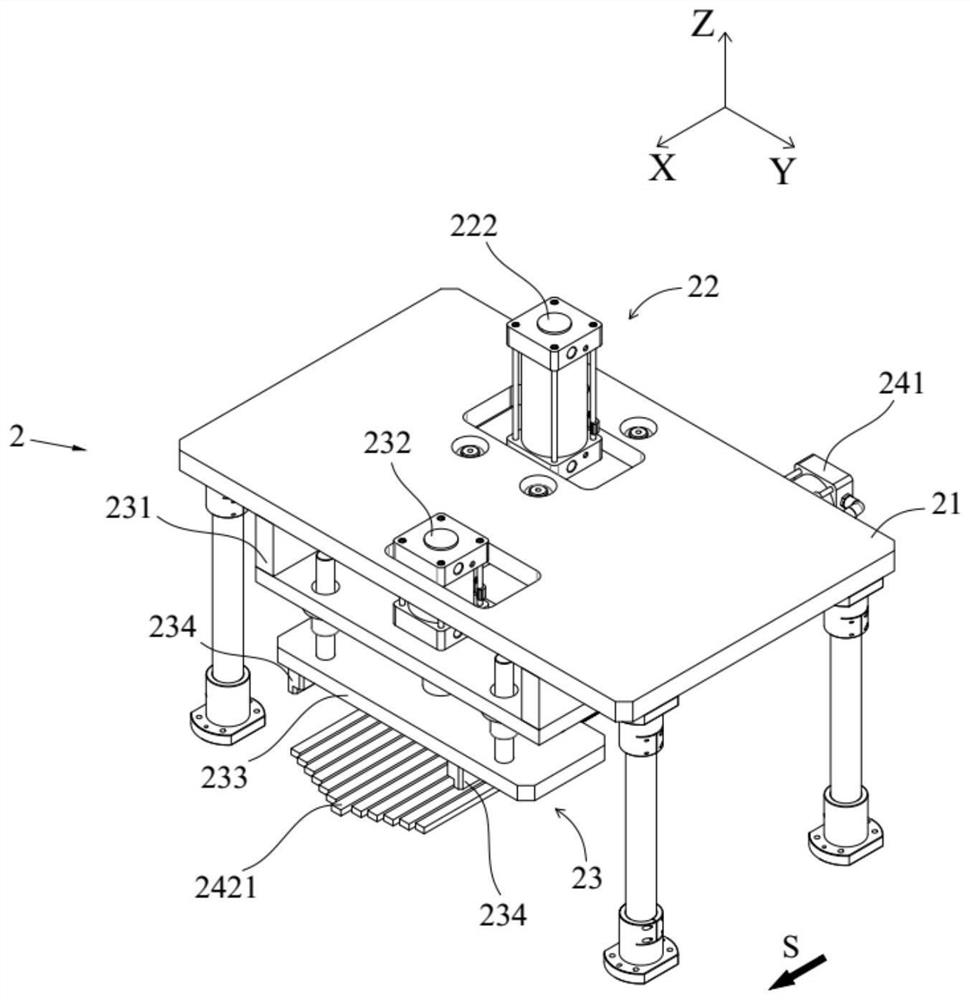

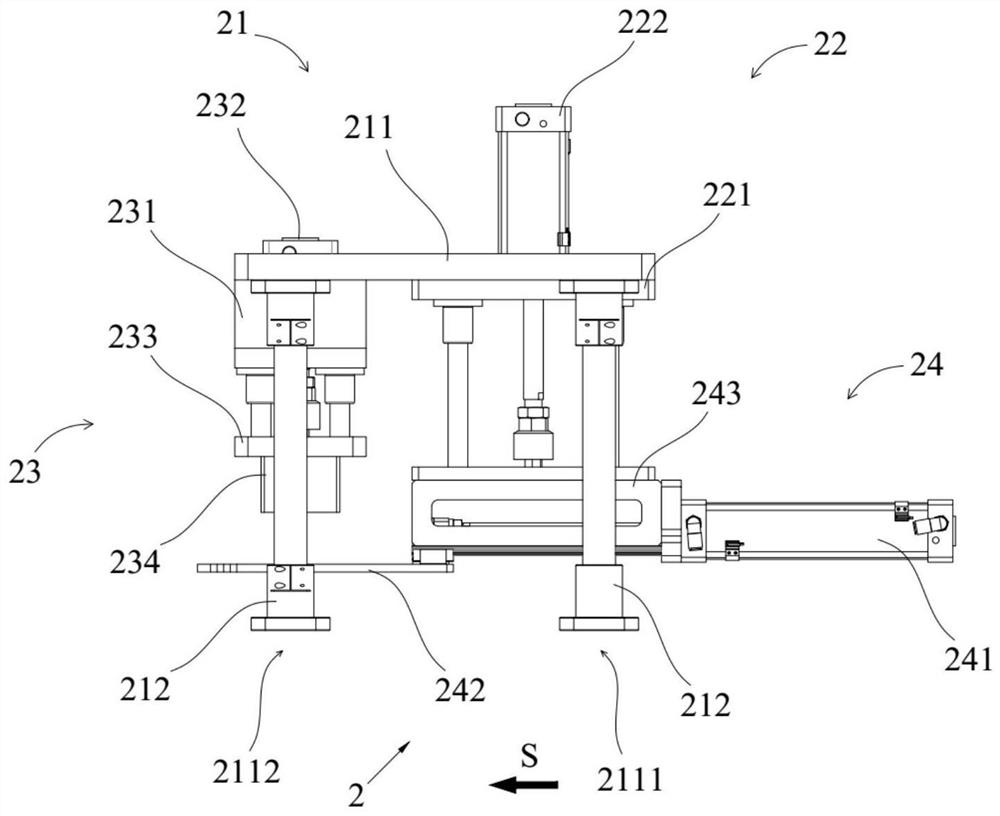

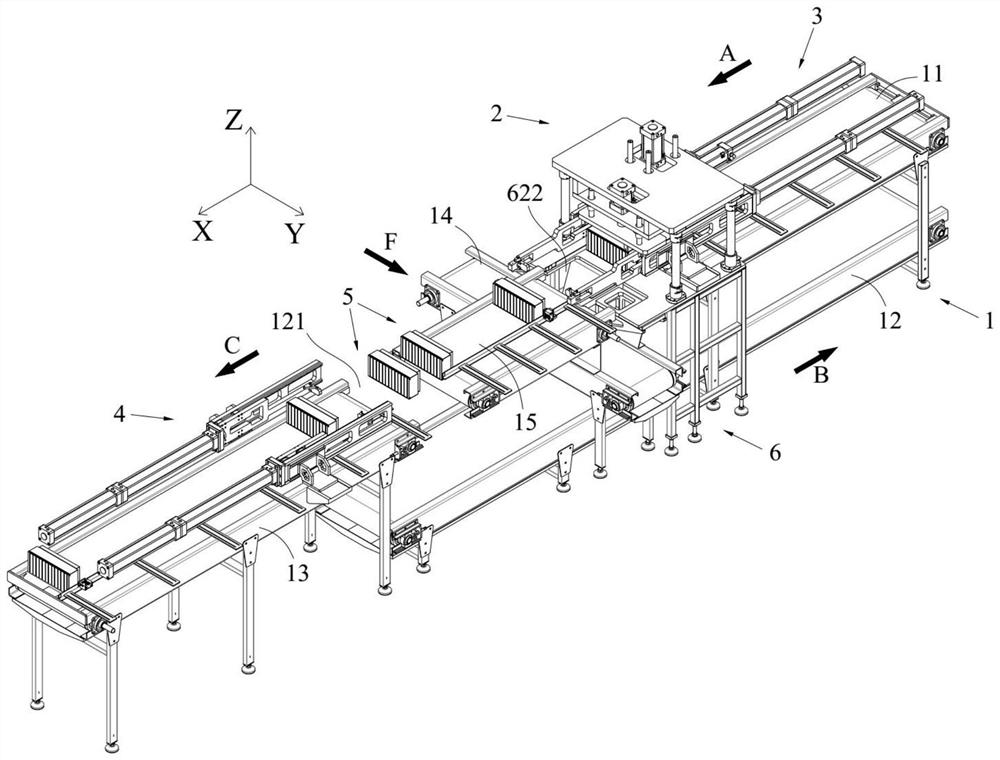

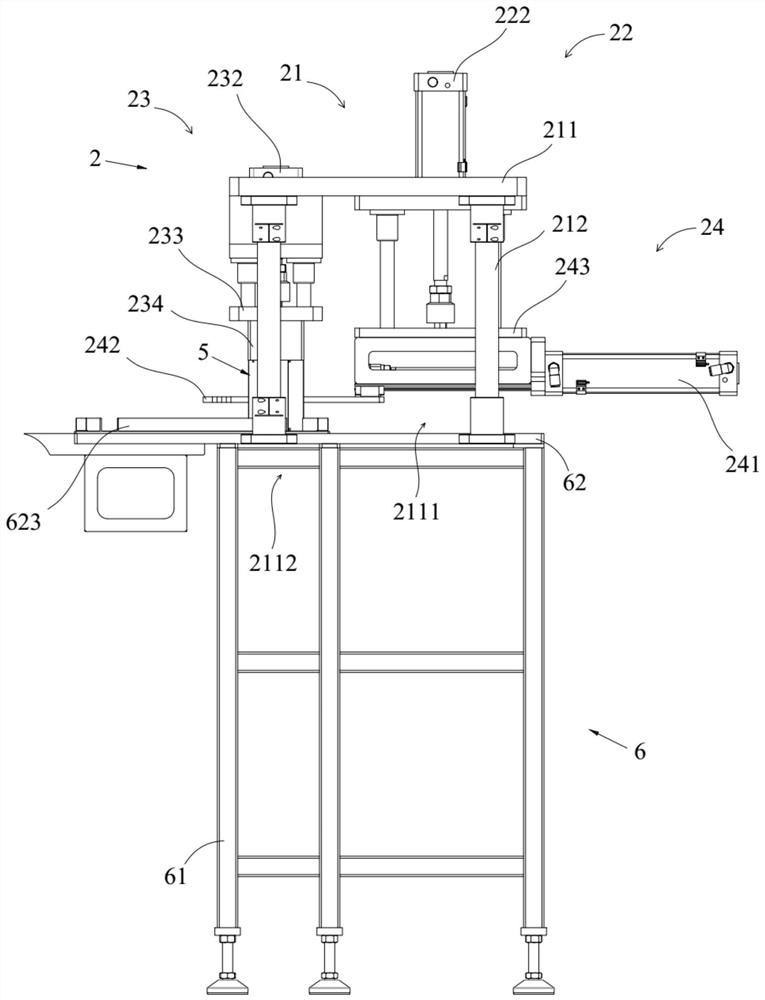

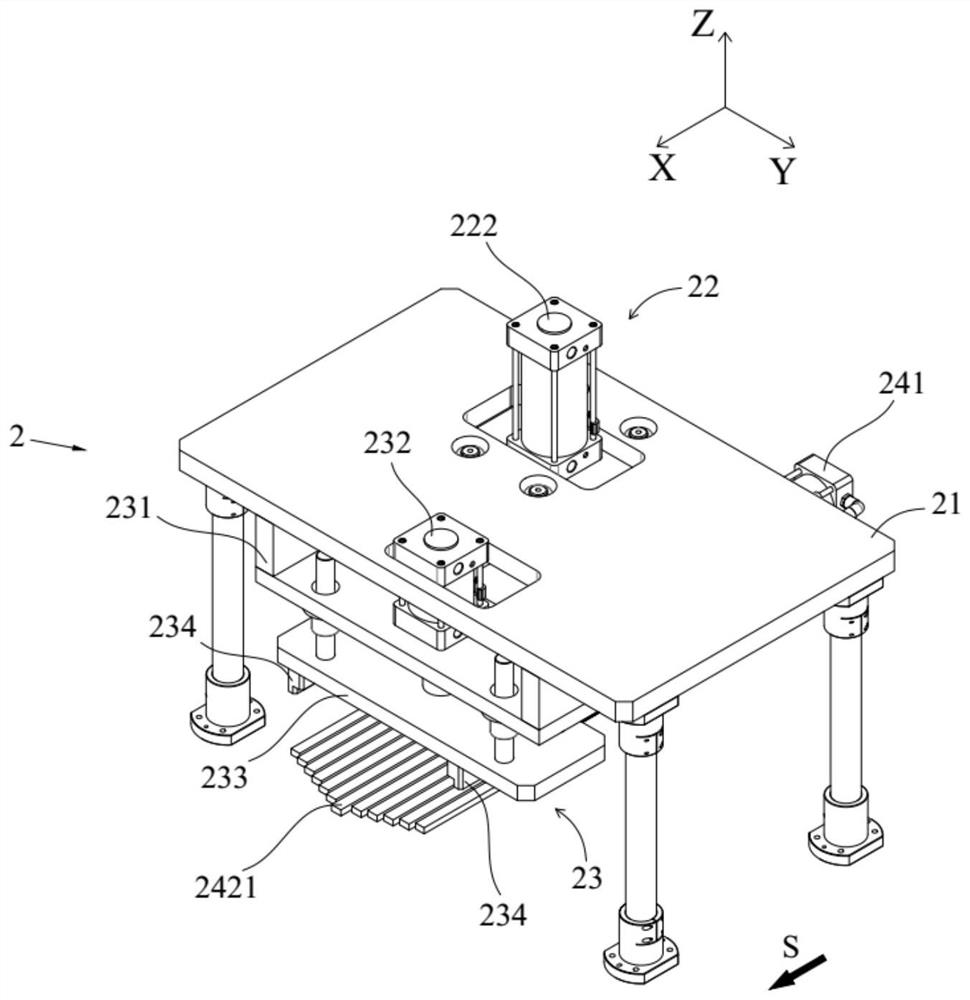

Storage battery cell pushing-out and recycling assembly line

ActiveCN111834688AImprove the efficiency of dismantling and recyclingCompact structureSolid waste disposalWaste accumulators reclaimingStructural engineeringSmall footprint

The invention discloses a storage battery cell pushing-out and recycling assembly line, which comprises a feeding conveying line, a shell conveying line, a battery cell bearing assembly and a batterycell push-out mechanism, wherein the feeding conveying line extends in the conveying direction of a storage battery; the shell conveying line is arranged at the downstream of the feeding conveying line; the battery cell bearing assembly is arranged between the feeding conveying line and the shell conveying line and is in butt joint with the feeding conveying line and the shell conveying line, andthe battery cell bearing assembly comprises a bearing support and a battery cell carrying table; the battery cell push-out mechanism is mounted on the battery cell carrying table; the battery cell push-out mechanism comprises a push-out rack, a lifting assembly and a push-out assembly; a lifting space is formed between the top of the push-out rack and the battery cell carrying table; the lifting assembly is mounted on the push-out rack; and the push-out assembly is arranged in the lifting space and is in transmission connection with the lifting assembly. According to the invention, the structure is compact, the occupied area is small, the automation degree is high, and the storage battery disassembling and recycling efficiency is improved.

Owner:BOZHON PRECISION IND TECH CO LTD

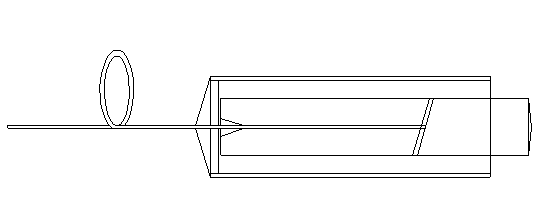

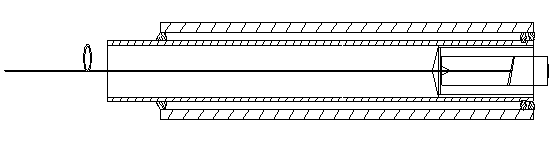

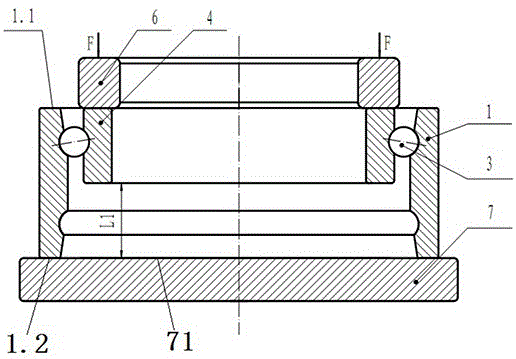

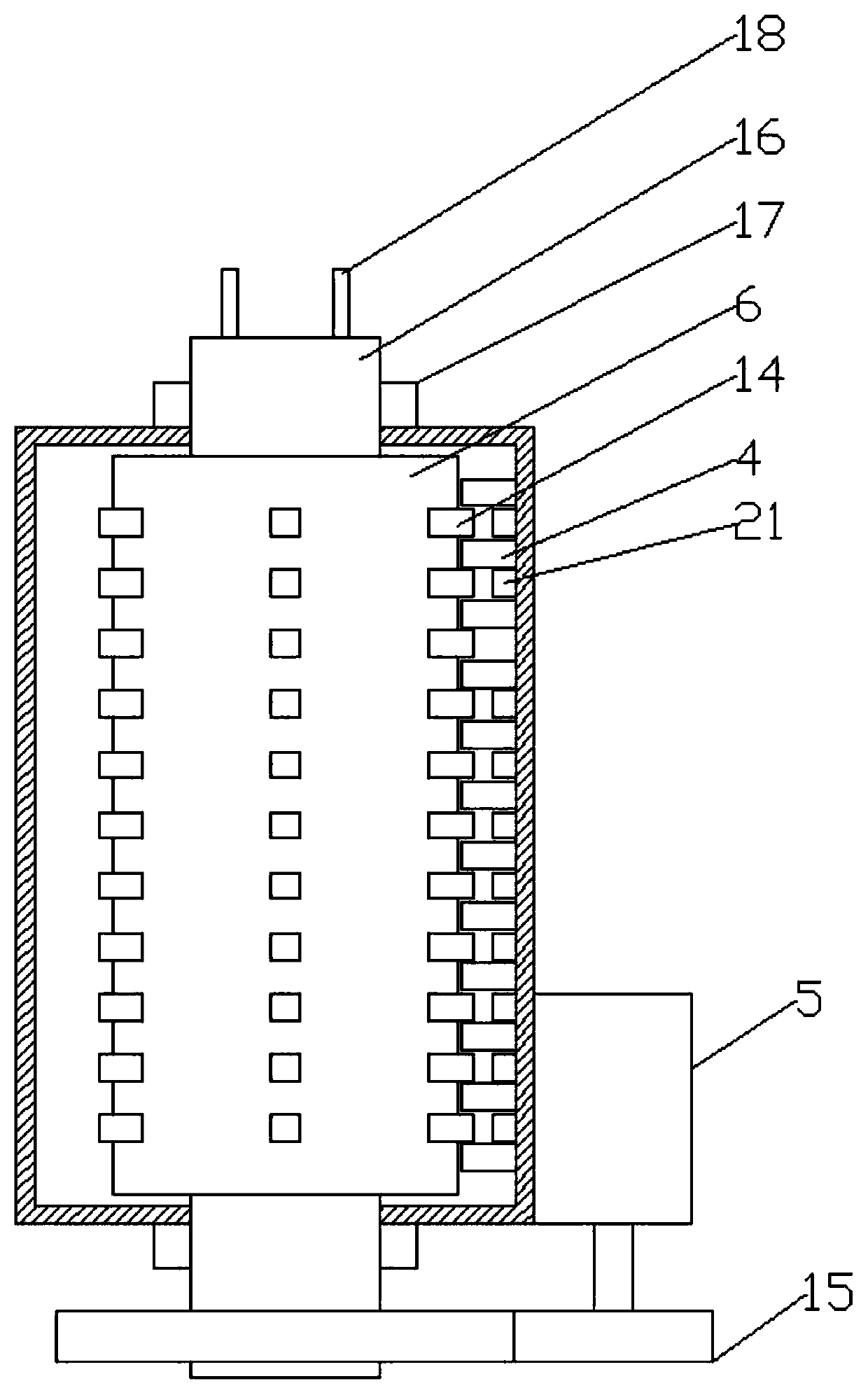

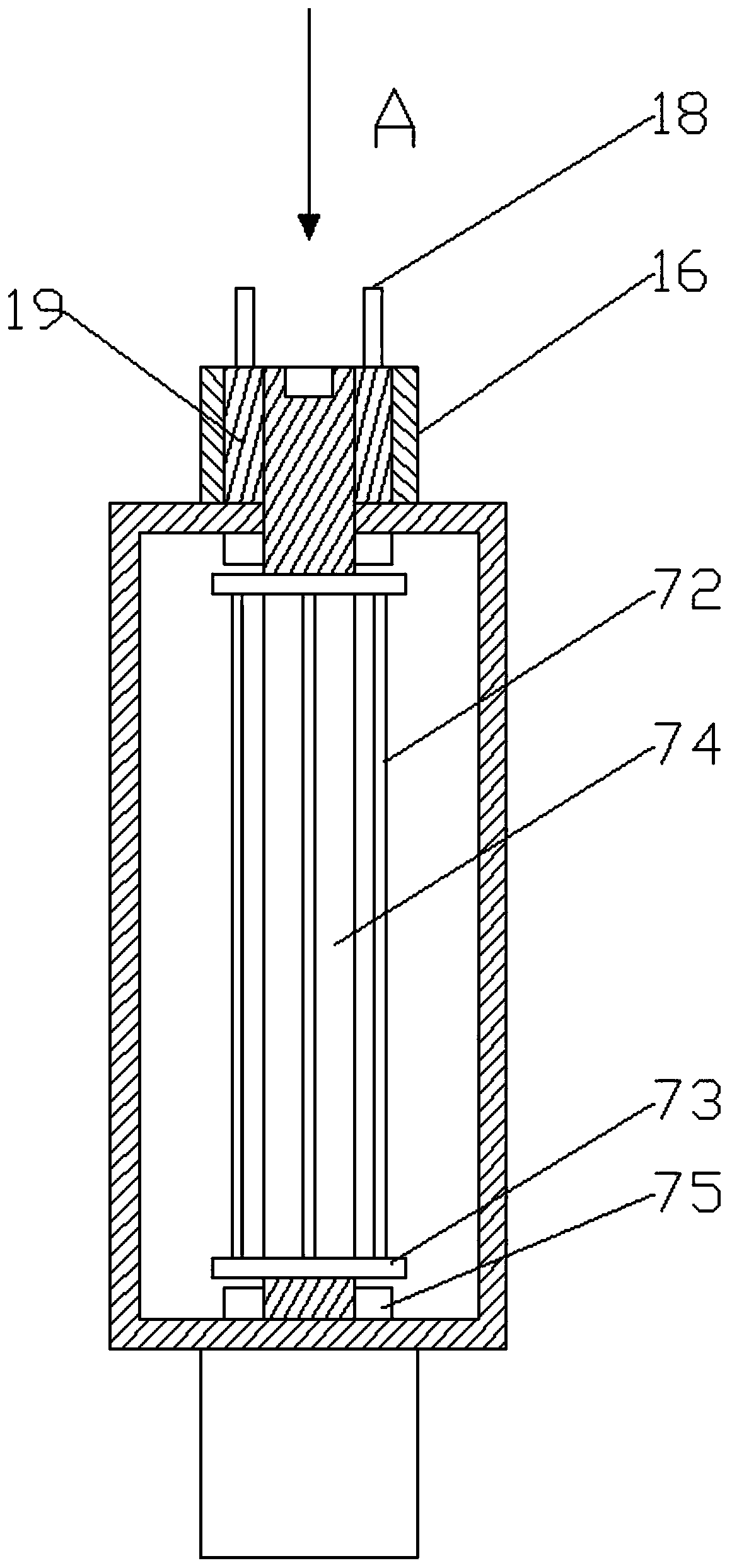

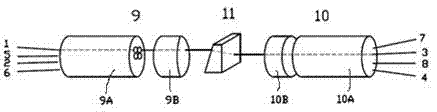

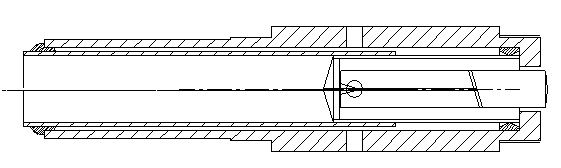

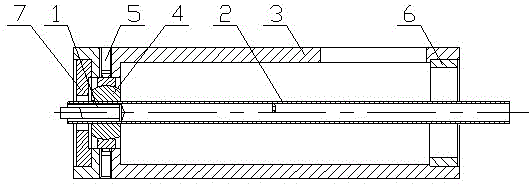

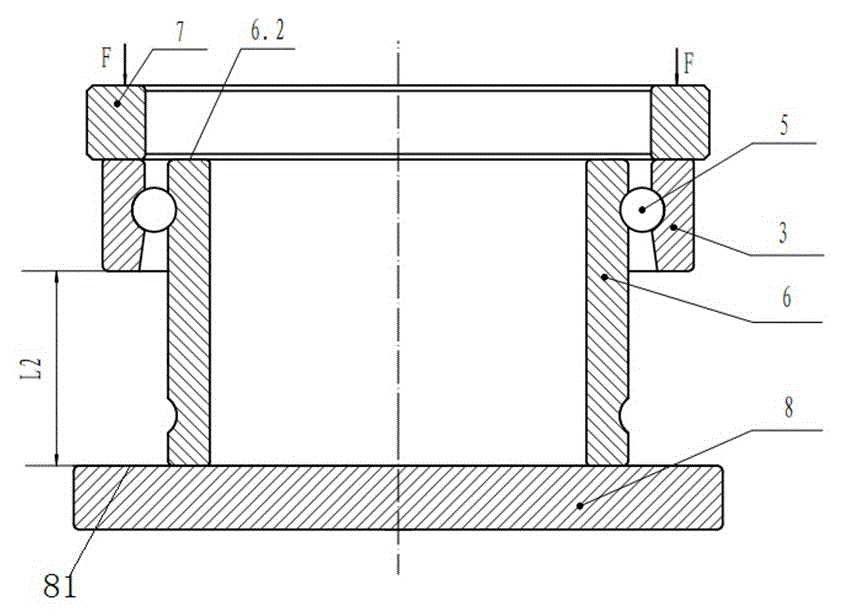

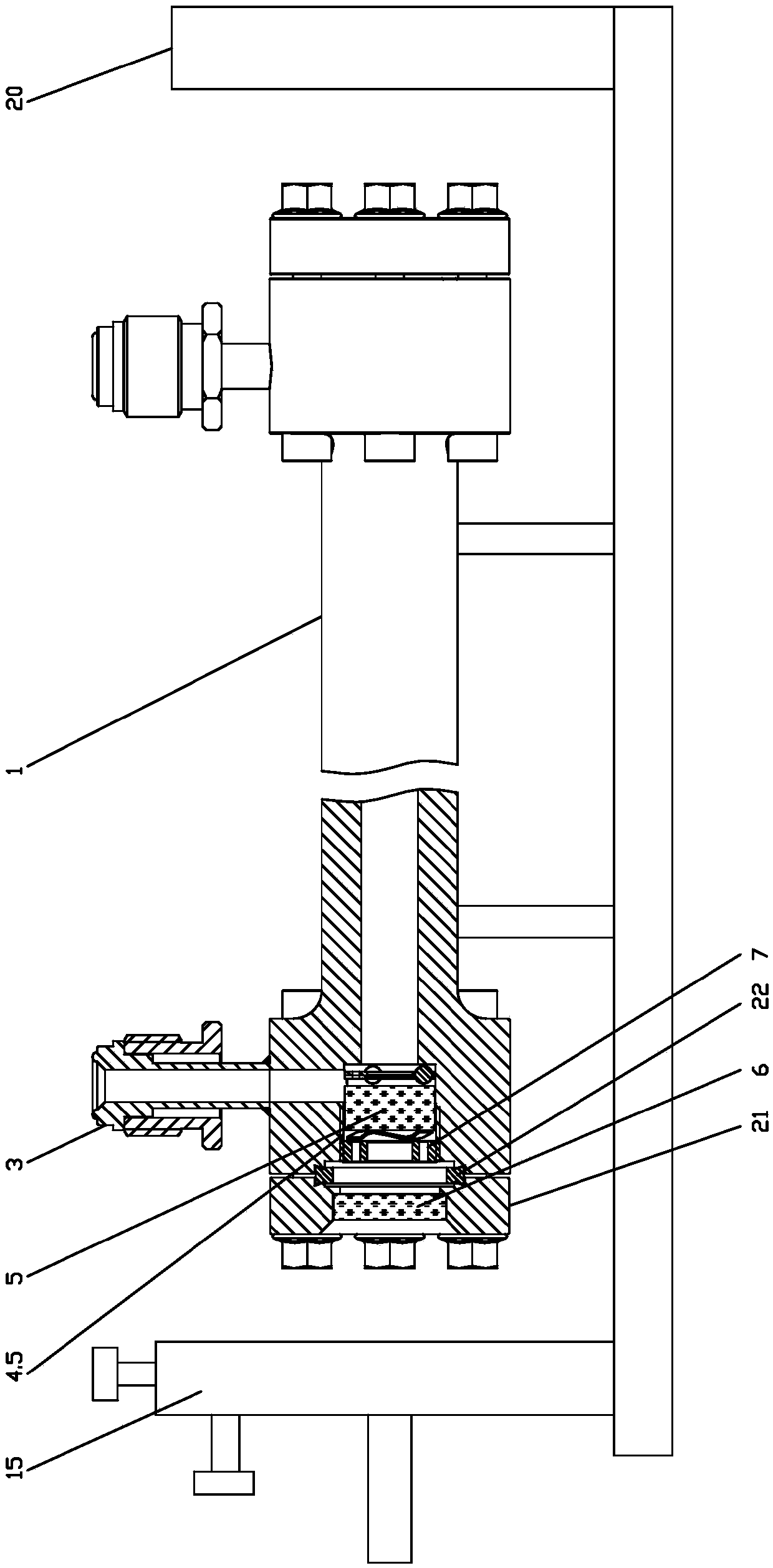

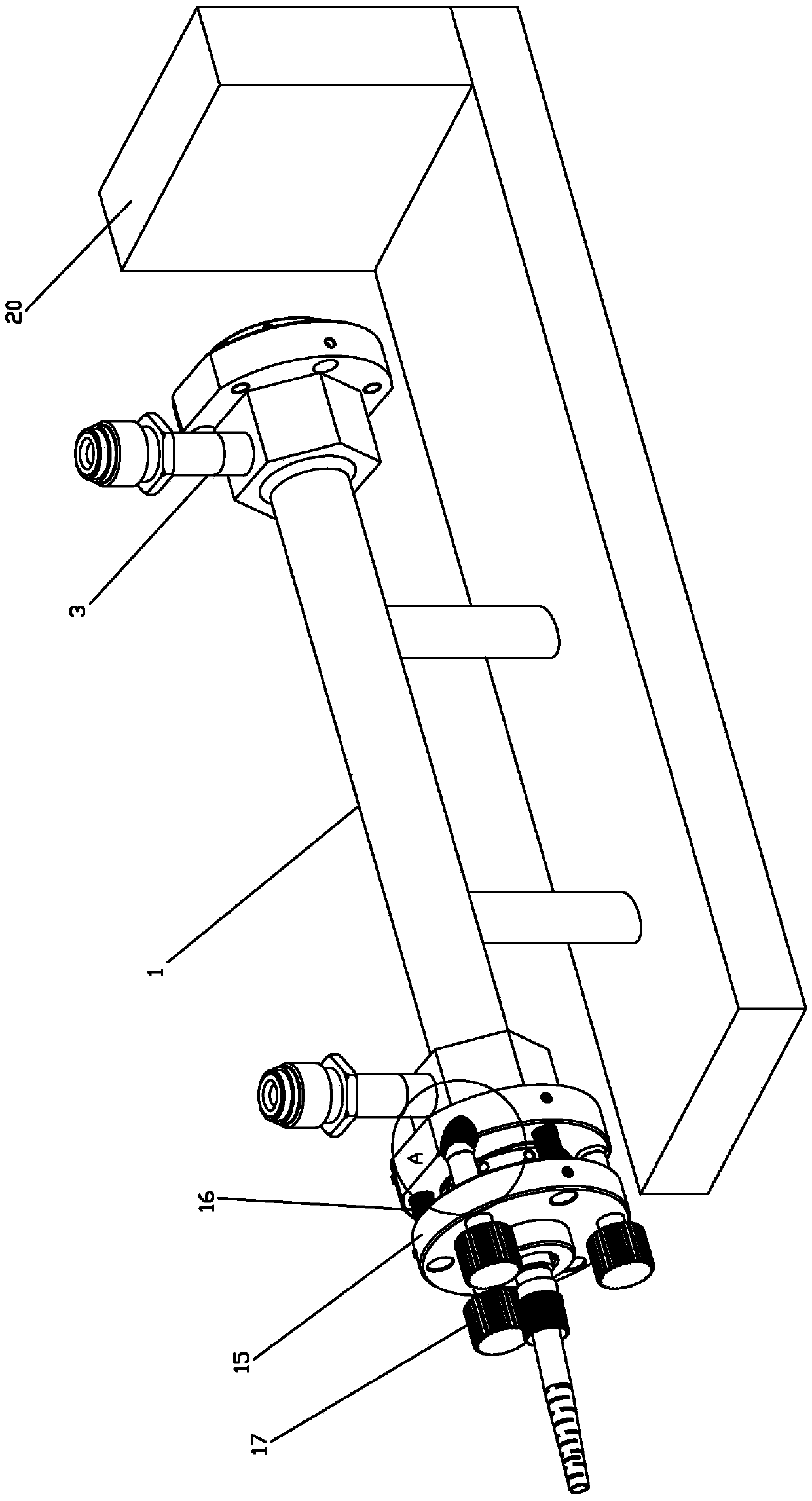

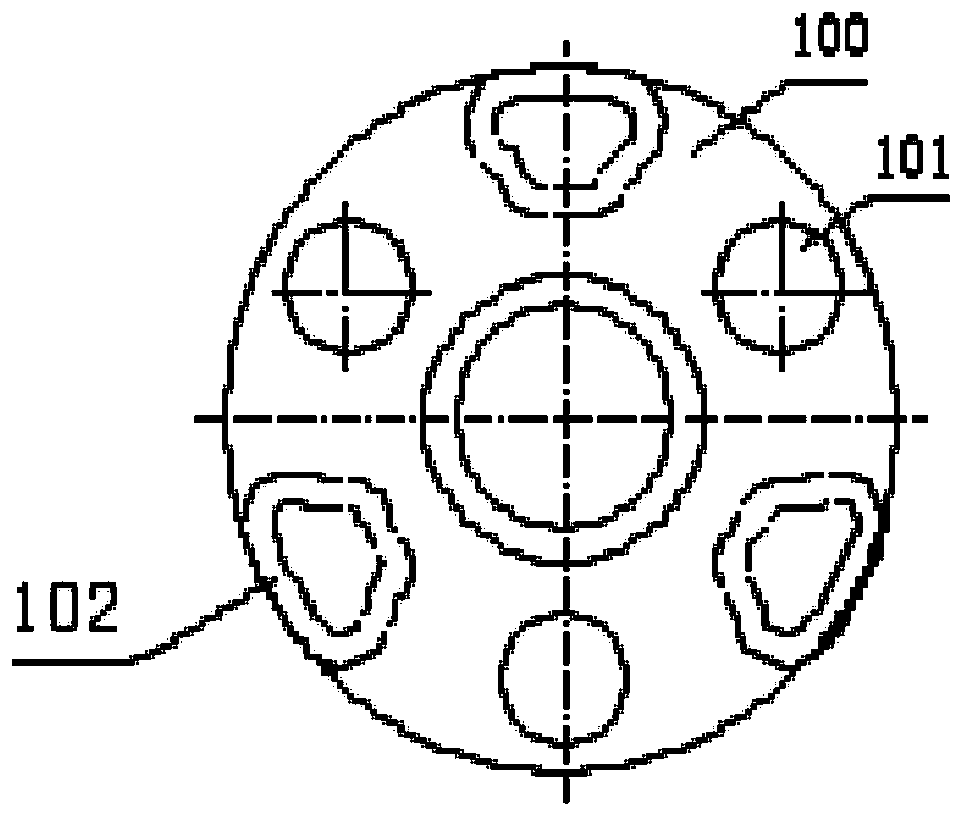

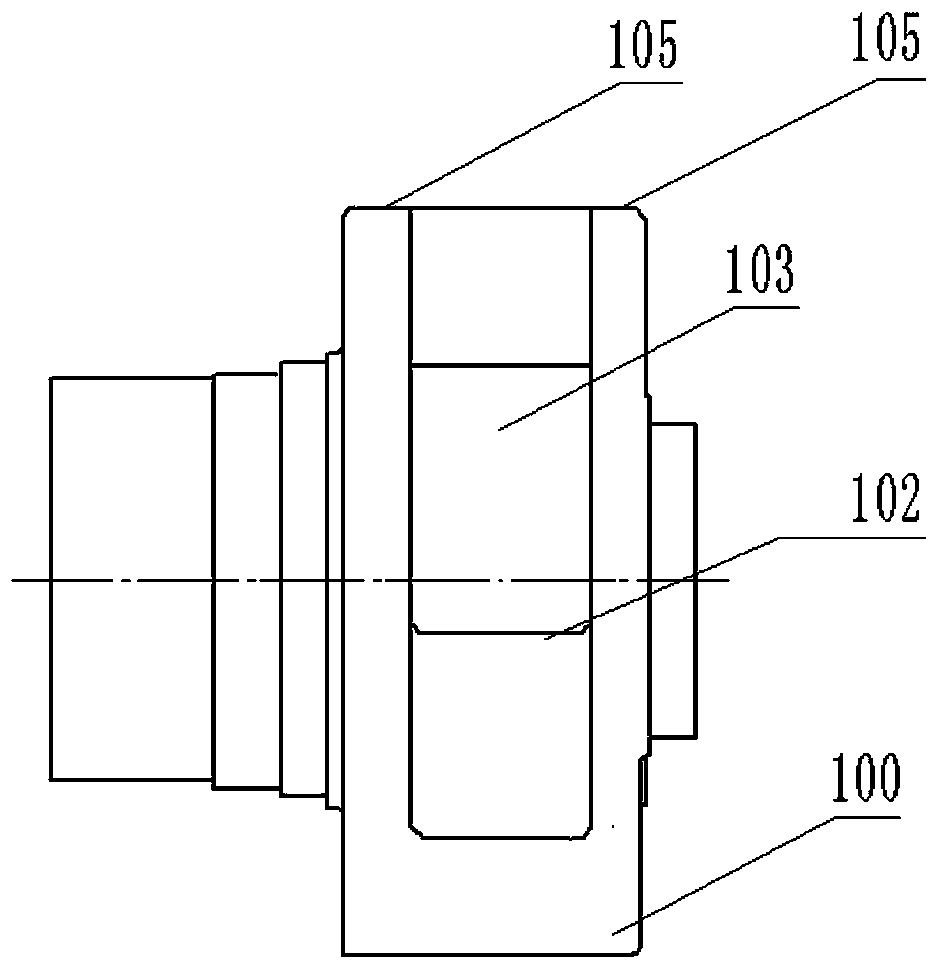

Fiber collimator having high-precision ray machine coaxiality, and assembling method thereof

ActiveCN104423056ASimple structureReduce adjustment stepsCoupling light guidesMountingsFiberEngineering

The invention relates to a fiber collimator having high-precision ray machine coaxiality, and an assembling method thereof. The fiber collimator is composed of a fiber collimator body (1), an inner casing tube (2) and an outer casing tube (3). The fiber collimator body (1) is arranged at the rear end of the inner casing tube (2); and the outer casing tube (3) sleeves the outer side of the inner casing tube (2). A collimator free end fixed element (6), a hinge (4), and a collimator joint end fixed element (7) are successively arranged between the inner casing tube (2) and the outer casing tube (3) from front to back; the collimator free end fixed element (6) is arranged at the front end of the outer casing tube (3); the collimator joint end fixed element (7) is arranged at the rear end of the outer casing tube (3); and the hinge (4) is arranged at the front side of the collimator joint end fixed element (7). According to the fiber collimator and the assembling method thereof, the structure is simple; the ray machine coaxiality is high; a few adjusting steps are arranged; and the assembling process is simple.

Owner:安徽新高电气有限公司

Storage battery disassembling and recycling assembly line

ActiveCN111834685AReasonable classification and collectionReduce structural complexitySolid waste disposalWaste accumulators reclaimingMechanical engineeringBattery cell

The invention discloses a storage battery disassembling and recycling assembly line, which comprises a rack, a shell conveying line, a battery cell bearing assembly, a battery cell push-out mechanismand a battery backflow conveying line, wherein a feeding conveying line and a shell recycling line are sequentially arranged in the rack from top to bottom in a stacked mode; the shell conveying lineis arranged at the downstream of the feeding conveying line; the battery cell bearing assembly is arranged between the feeding conveying line and the shell conveying line and is in butt joint with thefeeding conveying line and the shell conveying line, and the battery cell bearing assembly comprises a bearing support and a battery cell carrying table supported by the bearing support; the batterycell push-out mechanism is mounted on the battery cell carrying table; the battery backflow conveying line is arranged at the downstream of the shell conveying line; the battery backflow conveying line and the shell conveying line are arranged in a spaced mode so as to define a shell discharging channel located between the battery backflow conveying line and the shell conveying line; and the shellrecycling line extends to the position under the shell discharging channel. According to the invention, the automation degree and the disassembling and recycling efficiency are high.

Owner:BOZHON PRECISION IND TECH CO LTD

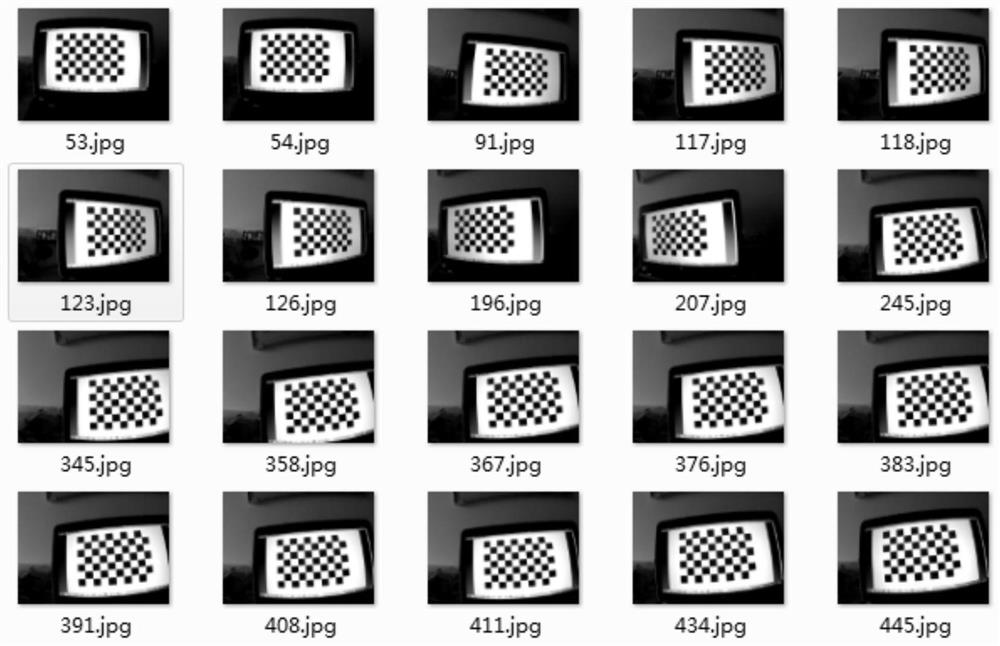

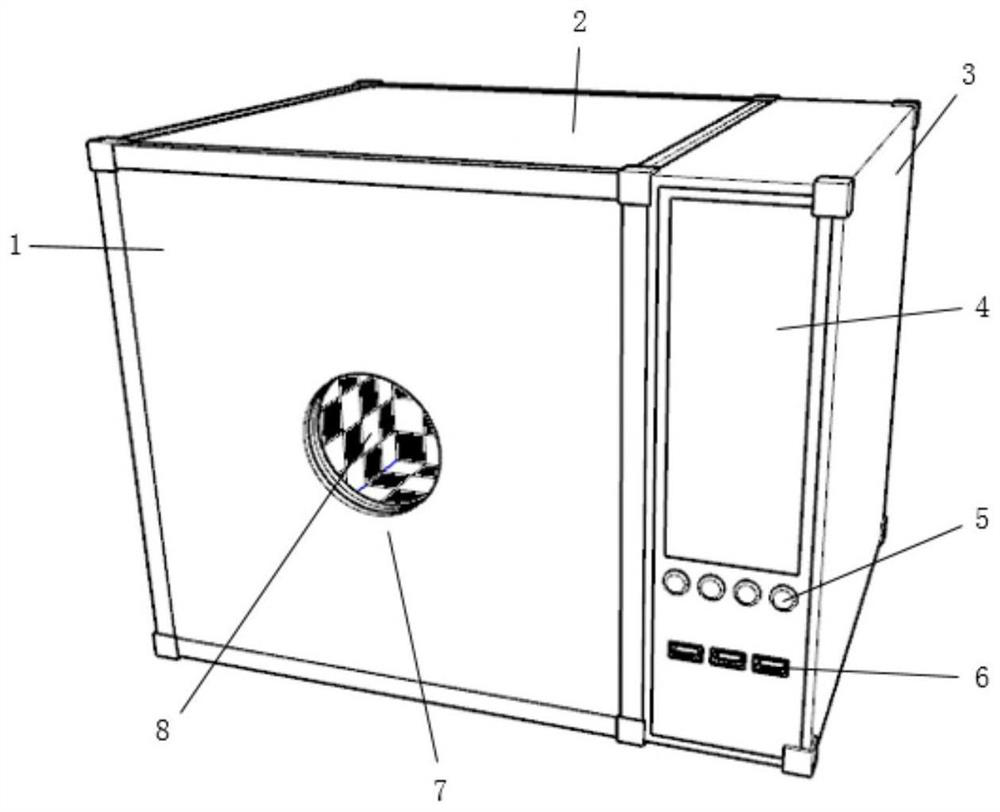

Camera debugging device and method

PendingCN112188191AApplicable Distortion AnalysisApplicable correctioTelevision systemsComputer hardwareCamera image

The invention discloses a camera debugging device and method. The camera debugging equipment comprises a front cover plate and a preset image display part, wherein the front cover plate and the presetimage display part form an internal space of a lamp box in a surrounding manner; a camera shooting opening is formed in the front cover plate, and the camera shooting opening can enable a to-be-debugged camera to shoot the internal space of the lamp box; and the preset image display part comprises a calibration plate located on the inner side and a light-emitting plate located on the outer side of the calibration plate, and a calibration pattern for camera debugging is preset on the inner side face of the calibration plate. According to the technical scheme, the novel camera debugging equipment is provided, the adjustment frequency can be reduced, camera image quality optimization tests and parameter tests such as chromatic aberration, contrast and white balance can be rapidly and efficiently achieved, and the novel camera debugging equipment is particularly suitable for distortion correction of the camera when the camera leaves a factory.

Owner:THUNDERSOFT

Tandem matched angular contact ball bearing and matching method thereof

ActiveCN105041852AIncrease stiffnessSimplify the installation processRolling contact bearingsBearing componentsBall bearingSteel ball

The invention relates to a tandem matched angular contact ball bearing and a matching method thereof. The tandem matched angular contact ball bearing comprises an inner ring which extends axially in the front-and-back direction. The outer circumferential surface of the inner ring is provided with a first outer groove and a second outer groove. The inner ring is correspondingly sleeved with a first outer ring and a second outer ring. The two outer rings are arranged in a spaced mode in the front-and-back direction. An outer spacer ring is clamped between the two outer rings. The inner circumferential surfaces of the two outer rings are provided with inner grooves. The inner grooves of the two outer rings and the two outer grooves of the inner ring are correspondingly filled with steel balls. The two axial end faces of each outer ring are a wide-side end face and a narrow-side end face respectively. The wide-side end face of the first outer ring and the narrow-side end face of the second outer ring are oppositely arranged. The wide-side end face of the first outer ring and the narrow-side end face of the second outer ring make contact with the two axial end faces of the outer spacer ring correspondingly in an abutted fit mode. The tandem matched angular contact ball bearing is simple in overall structure; the axial play of the whole bearing can be adjusted just by grinding and adjusting the outer spacer ring; pre-tightening operation is easy.

Owner:LUOYANG BEARING RES INST CO LTD

Method for reflectively adjusting optical-mechanical coaxiality of optical fiber collimator

The invention relates to a method for reflectively adjusting optical-mechanical coaxiality of an optical fiber collimator. The method includes the steps: sequentially adjusting the position of the optical fiber collimator (3) up and down and front and back; and observing optical powers received by an optical power meter (9.3). When the optical powers in the up and down direction and in the front and back direction are simultaneously the highest, the emergent direction of a laser beam is perpendicular to a reflector (2), and the reflector (2) is perpendicular to a mechanical axis serving as a datum, so that optical-mechanical coaxiality is realized. An adjusting device is simple in structure, adjusting steps are fewer, the process is simple, the mechanical axis of the optical fiber collimator is used as the datum, the emergent direction of the laser beam is changed by adjusting the position of the optical fiber collimator up and down and front and back until the emergent direction of the laser beam is consistent with the direction of the mechanical axis serving as the datum, and accordingly, the optical fiber collimator has high-precision optical-mechanical coaxiality.

Owner:JIANGSU KANGLAITE TECH +1

Gas detecting device with adjustable light path

PendingCN110346292ALow level of technical expertise requiredLow training input costColor/spectral properties measurementsLight pipeEngineering

The invention discloses a gas detecting device with the adjustable light path. The gas detecting device comprises a light pipe. Mirror group modules are plugged to gas chamber outlets at the two endsof the light pipe separately and movably in a split manner. Two gas path connecting pipes communicated with a gas chamber are arranged at the side wall of the light pipe. The mirror group modules include mirror group connectors, high reflection lenses, observation window lenses, and pressing rings. The gas detecting device has the following advantages: the mirror group modules are screwed to the ogas chamber outlets at the two ends of the light pipe; when the high reflection lenses need to be rotated to change light paths, the mirror group modules are rotated directly without dismounting theobservation window lenses, so that the operation becomes simple and the adjustment efficiency is high; the light pipe and an adjusting seat plate are connected by a tension spring and a fine adjustment screw and thus the position of the light path is limited in vertical and horizontal directions, so that the operation of adjusting the position of the light path in vertical and horizontal directions is avoided in the need of light path direction adjustment, so that the adjusting step is removed and thus the professional skill level requirement of the operator is reduced and the personnel training input cost is low.

Owner:内蒙古光能科技有限公司

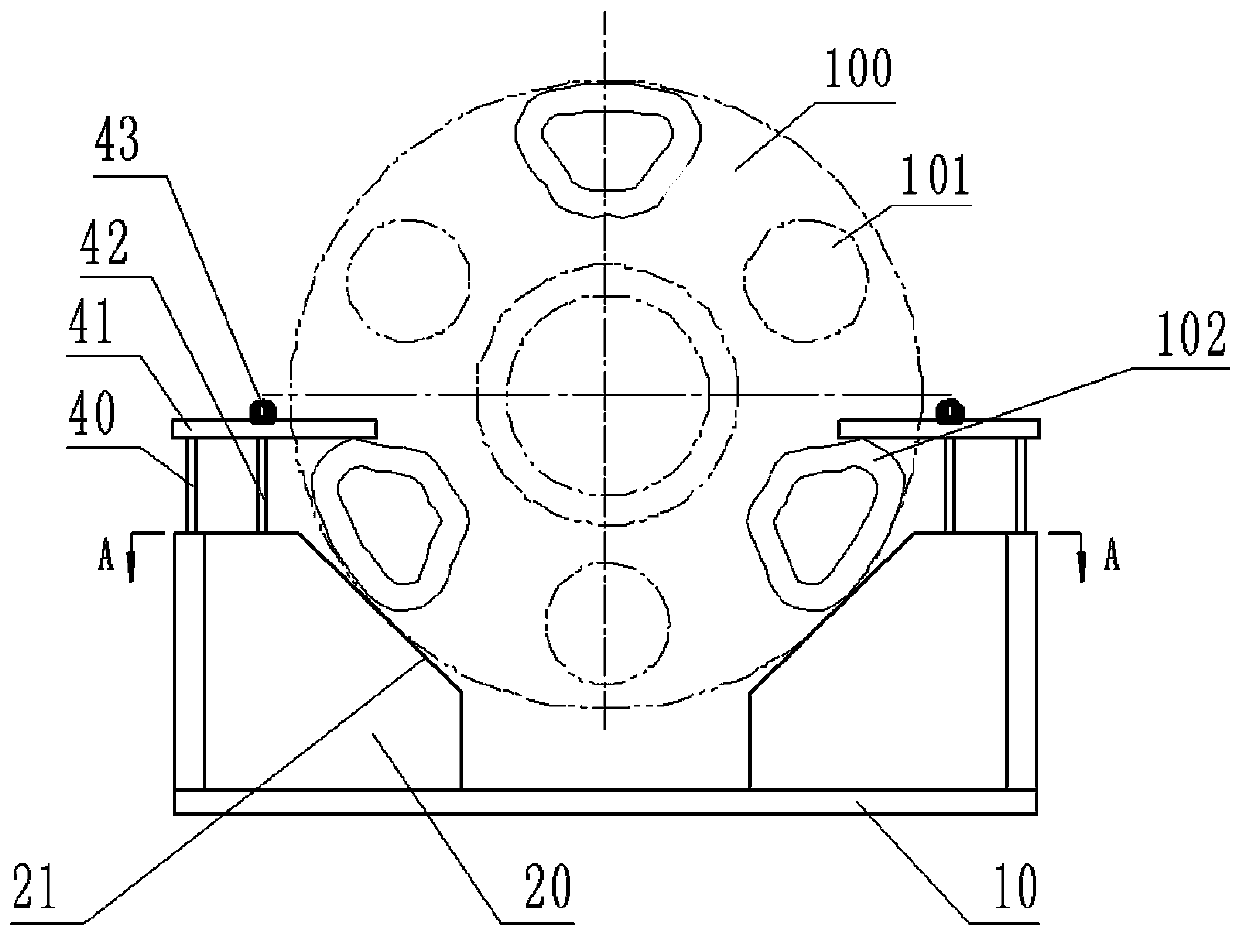

Clamp for machining planetary frame main body on horizontal machining center

PendingCN107775398AReduce adjustment stepsEasy to operatePositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a clamp for machining a planetary frame main body on a horizontal machining center. The clamp is characterized by further comprising two fine adjusting mechanisms located at front end; in each fine adjusting mechanism, a base comprises a base body and a connecting part, the top of the base body is an oblique plane, the connecting part vertically extends upwards from one endof the base body, a transverse hole with the aperture slightly larger than the outer diameter of an adjusting screw rod is formed in the connecting part, a slide seat comprises a slide seat body anda matched oblique plane arranged at the bottom of the slide seat body, the top surface of the slide seat is a plane, one end of the adjusting screw rod is connected with one end of the slide seat body, the other end of the adjusting screw rod penetrates through the transverse through hole in the connecting part of the base and stretches outwards, two nuts are screwed to the adjusting screw rod andare located on two sides of the connecting part of the base, the matched oblique plane arranged at the bottom of the slide seat body presses the oblique plane of the base body, and the top surface ofthe slide seat body is level with an oblique positioning surface of a positioning plate and is coplanar with an oblique positioning surface at the rear end of the corresponding positioning plate; andthe base body of the base is fixed on the positioning surface of the corresponding positioning plate.

Owner:CHONGQING WANGJIANG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com