Level bracket structure and leveling method thereof

A technology of support structure and level gauge, which is applied in the direction of machine platform/support, height/level measurement, instrument, etc., can solve the problems of cumbersome leveling process and low efficiency of the leveling instrument, and achieve the effect of improving adjustment efficiency and simplifying adjustment operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

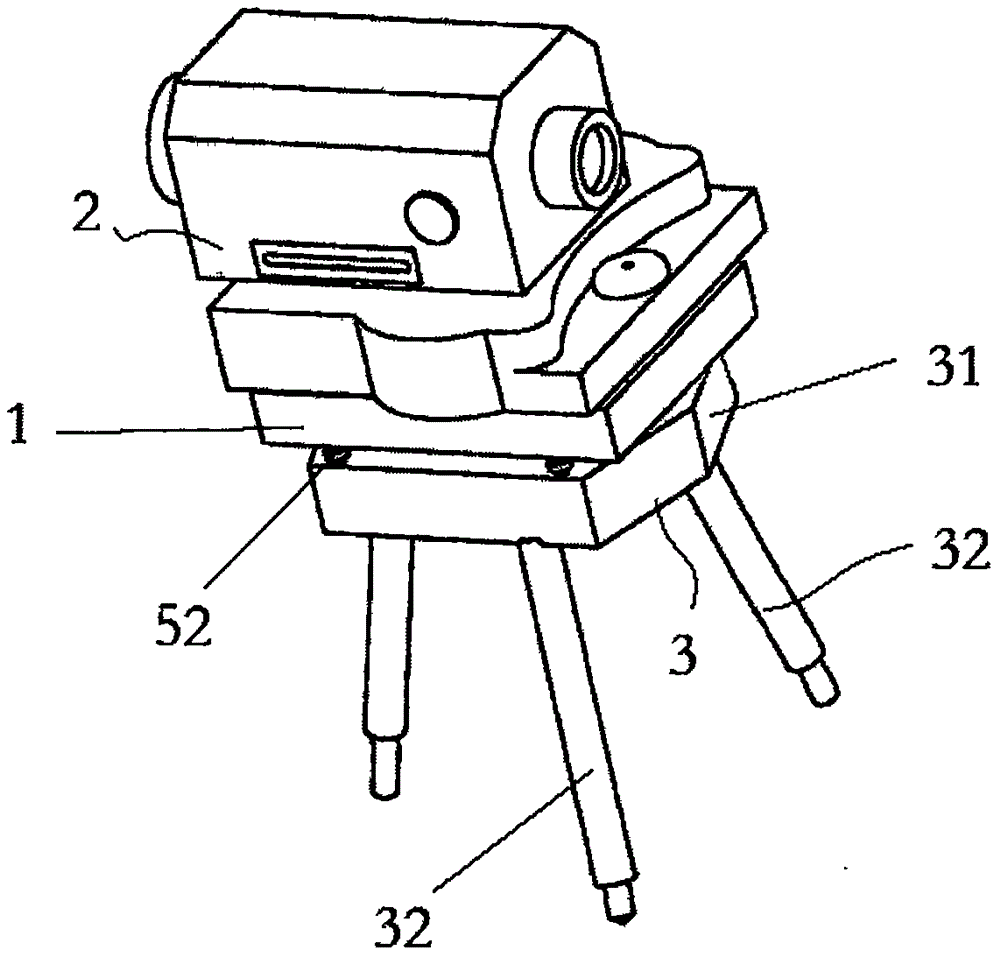

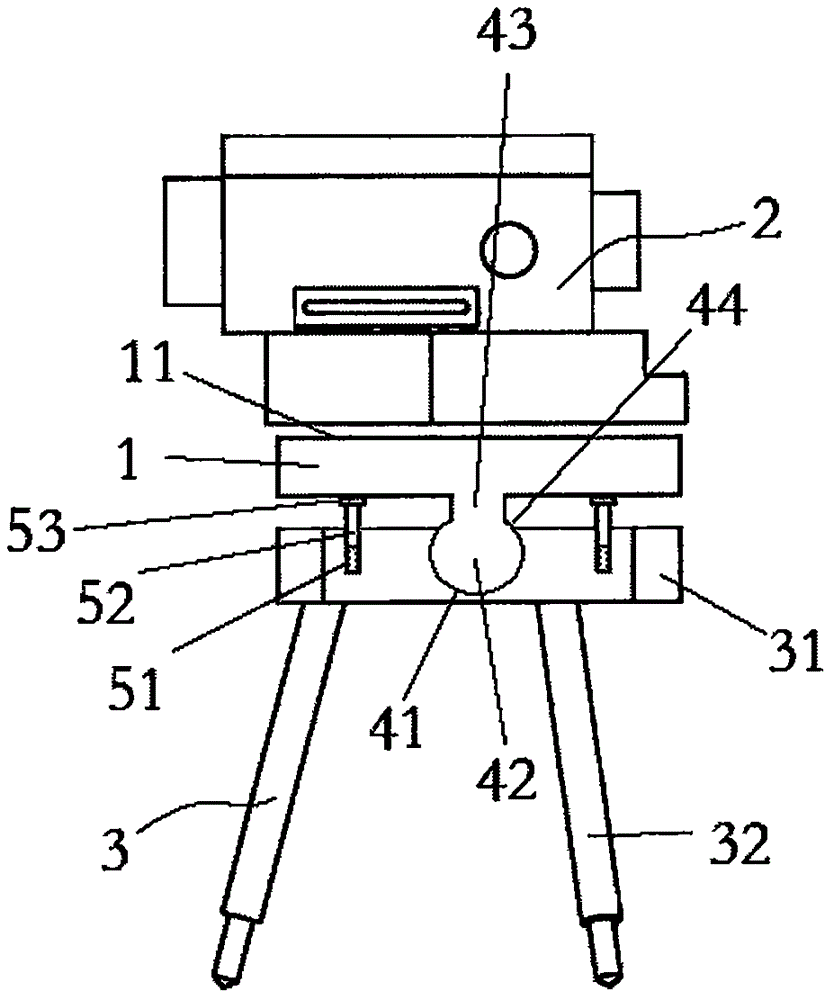

[0046] This embodiment provides a support structure for a level instrument, such as figure 1 and figure 2As shown, it includes: a base plate 1 with a mounting surface 11, on which a vertical axis (not shown) suitable for installing a level 2 is provided on the mounting surface 11, and the vertical axis is perpendicular to the mounting surface 11 The tripod 3 has a top plate 31, and is connected with the top plate 31 and is used to support three legs 32 of the top plate 31; the legs 32 can be fixed-length legs, or adjustable-length legs; the matching structure, It is arranged between the base plate 1 and the top plate 31, and is used to connect the base plate 1 and the top plate 31, so that the base plate 1 can be automatically adjusted when the level gauge 2 is not installed and is not fixed. , and then keep the installation surface 11 horizontal; the adjustable fixing structure is arranged on the top plate 31 and is used to fix the substrate 1 after the installation surface...

Embodiment 2

[0054] This embodiment provides a method for leveling the support structure of the level gauge. figure 1 and figure 2 shown, including the following steps:

[0055] 1) Separate the three legs 32 of the tripod 3, and support the top plate 31 at the target position;

[0056] 2) installing the base plate 1 on the top plate 31 through a matching structure, so that the base plate 1 is automatically adjusted to keep the mounting surface 11 horizontal;

[0057] 3) Adjust the adjustable fixing structure to fix the substrate 1 .

[0058] As a preferred solution, after the step 3, a step is further included: adjusting the adjustable fixing structure again to drive the whole base plate 1 to move vertically upward to a certain height.

[0059] The matching structure includes: a circular groove 41, set on the top plate 31, with a smooth inner wall; a circular protrusion 42, connected with the base plate 1 through a connecting part 43, with a smooth outer wall, used for installation int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com