A circular saw blade welding machine

A welding machine and circular saw blade technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low precision, high experience requirements, low adjustment efficiency, etc., and achieve the effect of improving the docking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

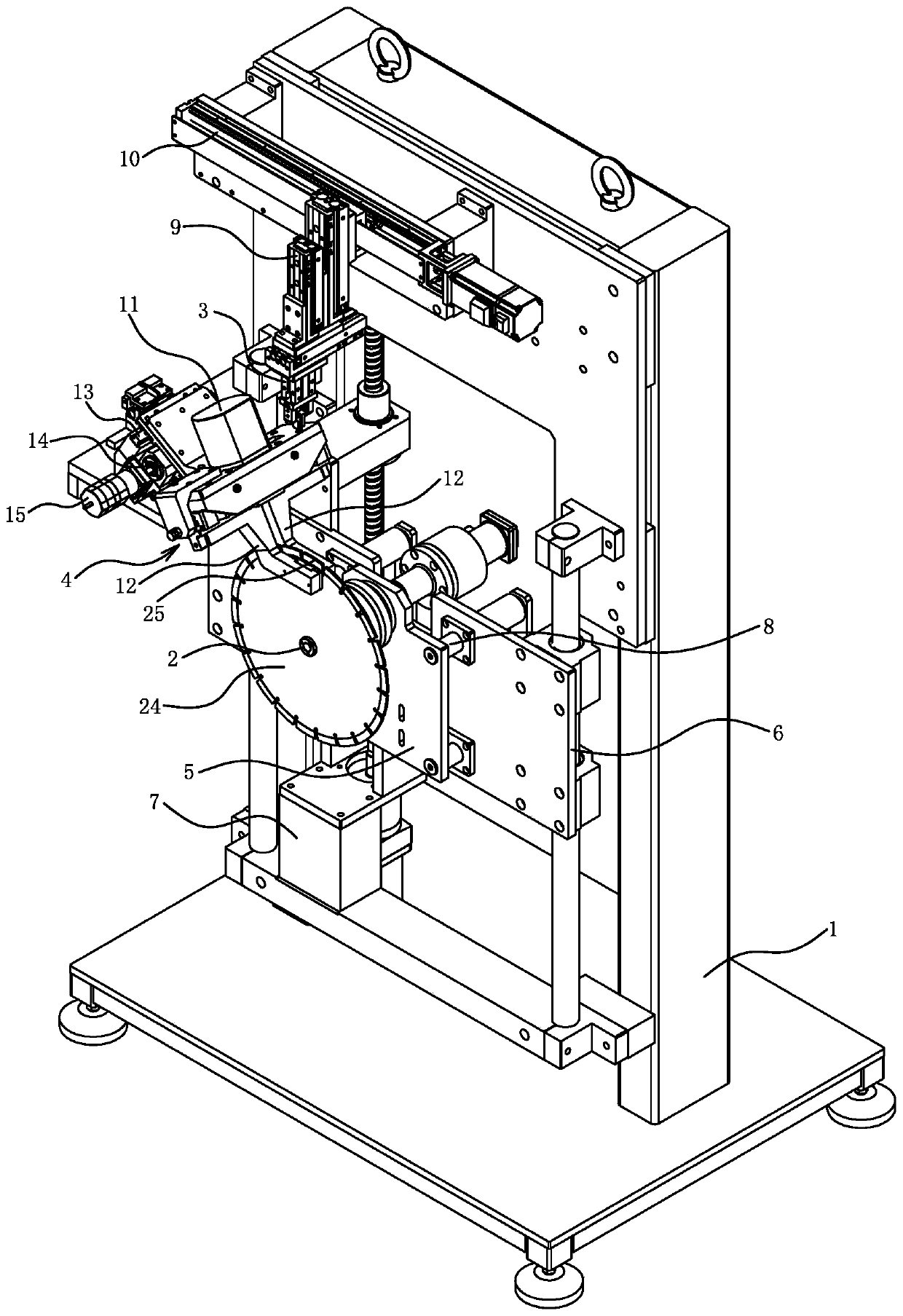

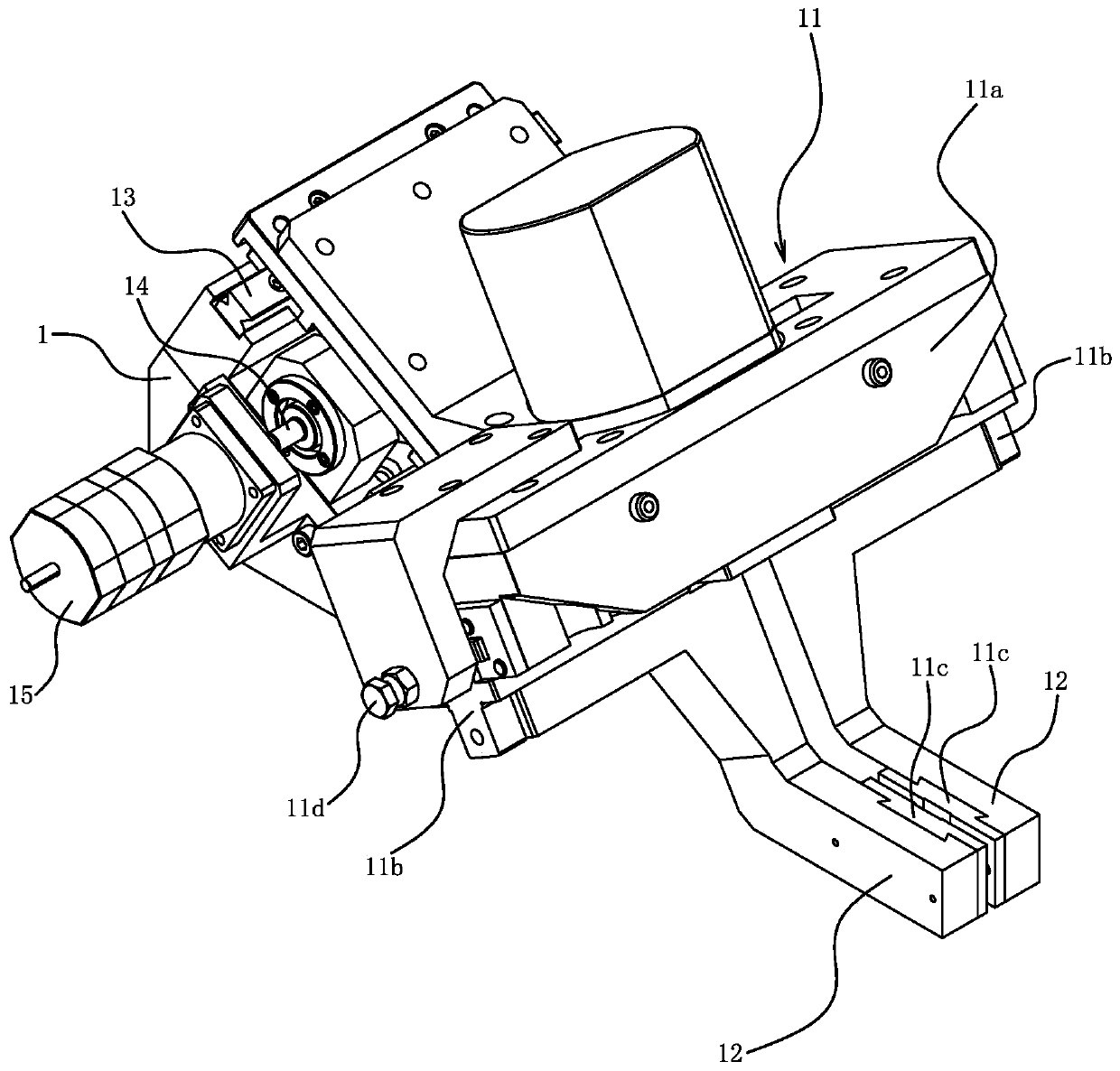

[0017] A circular saw blade welding machine includes a frame 1 , a base clamp 2 , a cutter head clamping manipulator 3 and a base clamping positioning device 4 . The frame 1 is a basic component, and the substrate fixture 2 and the substrate clamping and positioning device 4 are installed on the frame 1 .

[0018] The base clamp 2 is used to position the saw blade base 24. The base clamp 2 includes a base backer. A central positioning column is installed at the center of the base backer. The saw blade base 24 positioned on the base clamp 2 is in a vertical state.

[0019] A floating plate 5 and a lifting plate 6 are installed between the base backer and the frame 1, and the lifting plate 6 and the frame 1 are connected by a lifting drive structure 7 that can make the lifting plate 6 vertically lift. The floating plate 5 is positioned at the front side of the lifting plate 6, and is connected by a plurality of horizontal guide rail assemblies 8 between the floating plate 5 and ...

Embodiment 2

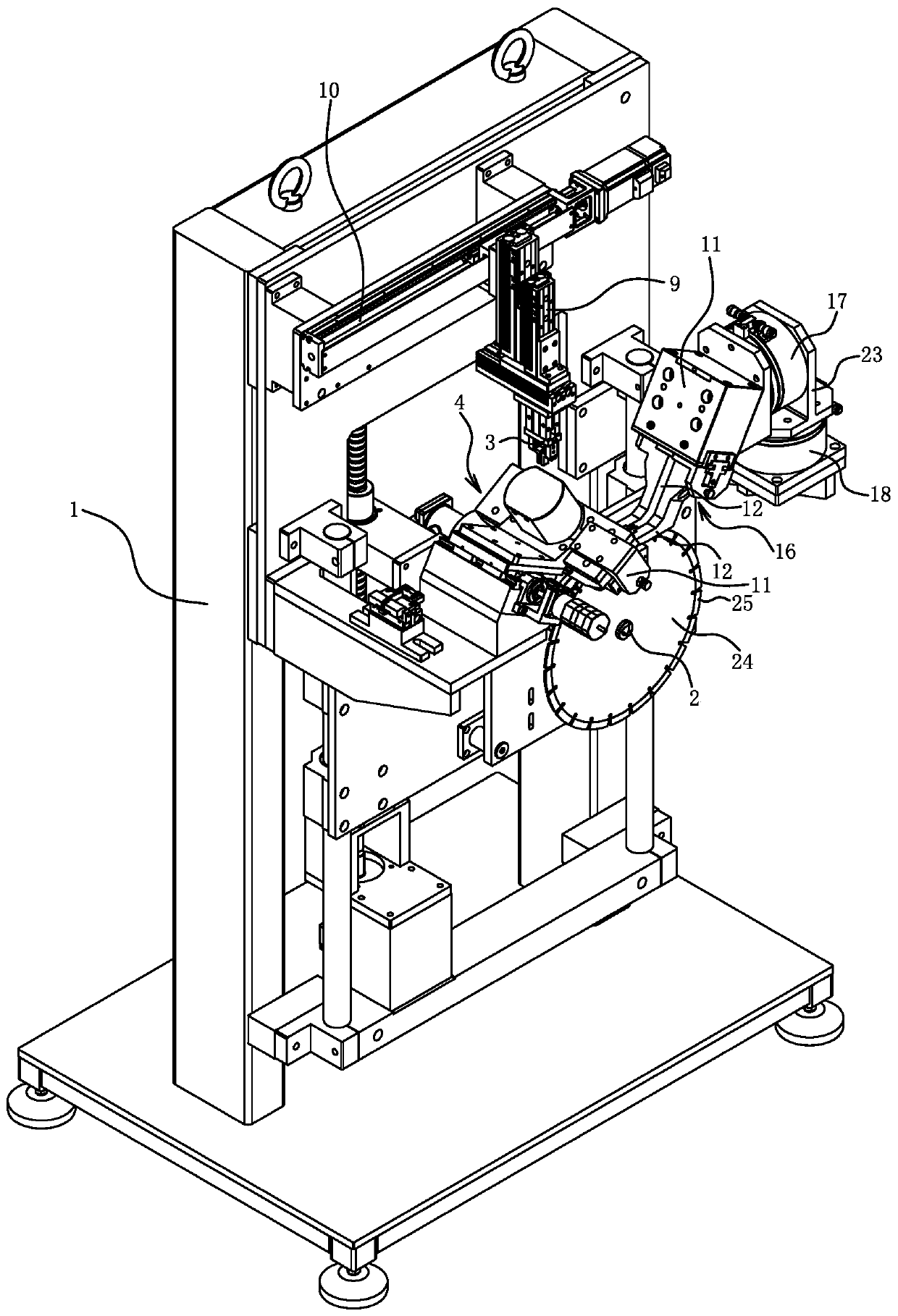

[0035] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described redundantly, only the differences will be described, and the differences lie in: There is also a cutter head clamping and positioning device 16 for clamping and positioning the saw blade cutter head 25. The structure of the cutter head clamping and positioning device 16 is the same as that of the substrate clamping and positioning device 4, and will not be described redundantly here.

[0036] The clamping arm 12 of the cutter head clamping and positioning device 16 is positioned above the clamping arm 12 of the substrate clamping and positioning device 4; On one side of the horizontal arm 12, the clamping driver 11 of the substrate clamping and positioning device 4 is positioned at the other side of the horizontal clamping arm 12 of the cutter head clamping and positioning device 16; Adjustment has the advantage of reasonable ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com