Spray head frame of printer

A nozzle frame and printer technology, applied in printing, transfer materials, power transmission devices, etc., can solve problems such as large assembly errors, low adjustment efficiency and precision, and difficult to guarantee the dimensional accuracy of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The core of the present invention is to provide a printer nozzle frame to improve the assembly accuracy of its parts.

[0025] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

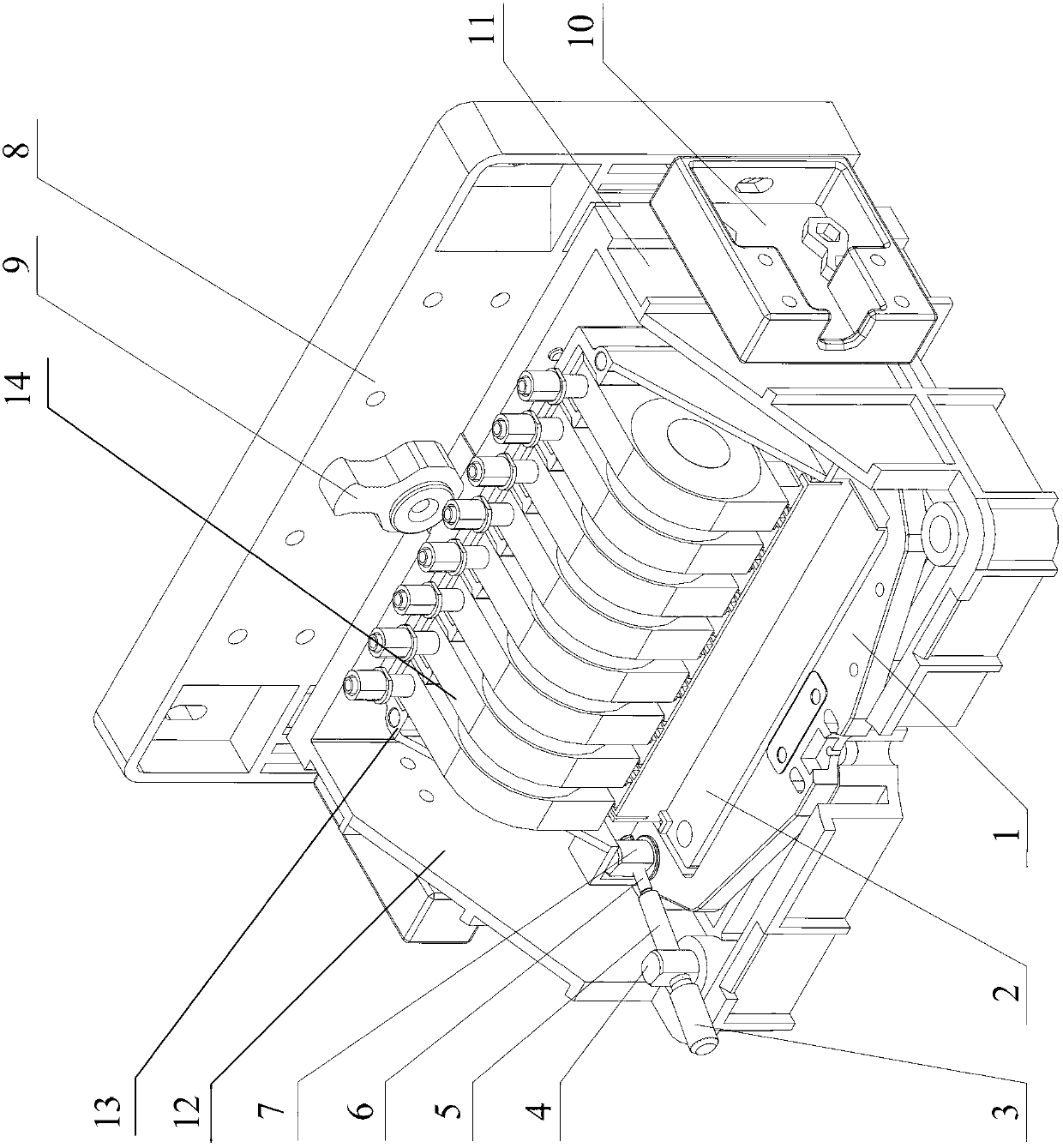

[0026] Please refer to figure 1 , figure 1 It is a schematic structural diagram of the first specific embodiment of the printer nozzle holder provided by the embodiment of the present invention.

[0027] The printer nozzle holder provided by the embodiment of the present invention includes a nozzle slide 8, a nozzle holder 12, a nozzle holder height adjustment device, an ink bag press 13, a nozzle adjustment plate 1 and a nozzle adjustment plate level adjustment device, wherein the nozzle holder 12 can It is slidable up and down on the nozzle slide 8. The nozzle holder height adjustment device is used to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com