Method for reflectively adjusting optical-mechanical coaxiality of optical fiber collimator

A fiber collimator and optical-mechanical coaxial technology, applied in optics, instruments, optical components, etc., can solve the problems of high cost of optical devices, complicated process, and restrictions on the use of optical fiber collimators, and achieve high-precision optical-mechanical coaxial Axis, less adjustment steps, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

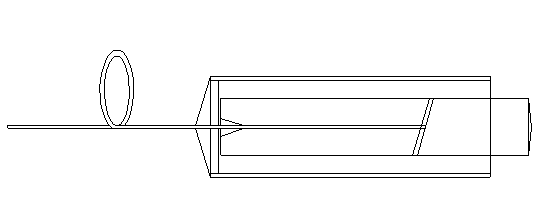

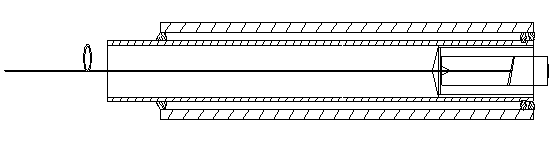

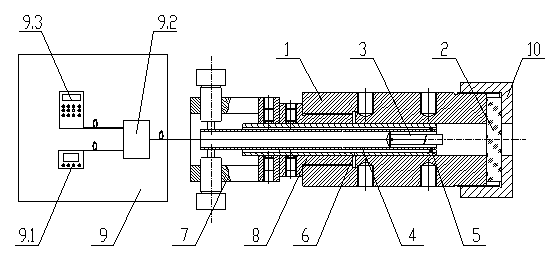

[0048] see image 3 , the present invention is a reflective method for adjusting the optical-mechanical coaxiality of an optical fiber collimator, which adjusts the optical-mechanical coaxiality of the optical fiber collimator through an adjustment device, and the adjustment device includes a base 1, a reflector 2, Optical fiber collimator 3, inner sleeve 4, hinge 5, outer sleeve 6, two-dimensional adjustment mechanism 7, collimator positioning and fixing mechanism 8, optical power monitoring system 9 and fastening cap 10, the optical power monitoring The system 9 is composed of a light source 9.1, a beam splitter 9.2 and an optical power meter 9.3, the base 1 is placed laterally, the reflector 2 is arranged at the rear end of the base 1 and fixed by a fastening cap 10, and the collimator is positioned The fixing mechanism 8 is arranged at the front end of the base 1, the two-dimensional adjustment mechanism 7 is arranged at the front end of the collimator and positioned at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com