2*2 mechanical optical switch

An optical switch and mechanical technology, applied in the coupling of optical waveguides, etc., can solve the problems of low reliability and high production cost, achieve good stability and durability, reduce requirements, and reduce dimensionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

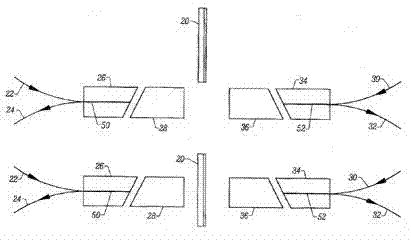

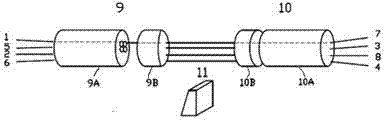

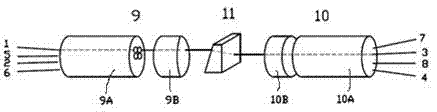

[0022] Such as figure 2 , image 3 Shown: 2×2 mechanical optical switch,

[0023] 1) Including the first optical fiber group and the second optical fiber group, the first optical fiber group gathers the first optical fiber 1, the second optical fiber 2, the fifth optical fiber 5 and the sixth optical fiber 6 together in the axial direction through the capillary glass tube 9A, The second optical fiber group gathers the third optical fiber 3 , the fourth optical fiber 4 , the seventh optical fiber 7 and the eighth optical fiber 8 along the axial direction through another capillary glass tube 10A;

[0024] 2) In the first fiber group and the second fiber group, the first collimator 9 and the second collimator 10 of the four-fiber collimator respectively arranged at the end are facing each other, so that the first fiber 1 and the second fiber 2. The light beams of the fifth optical fiber 5 and the sixth optical fiber 6 are directly coupled to the seventh optical fiber 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com