Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Realize placement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

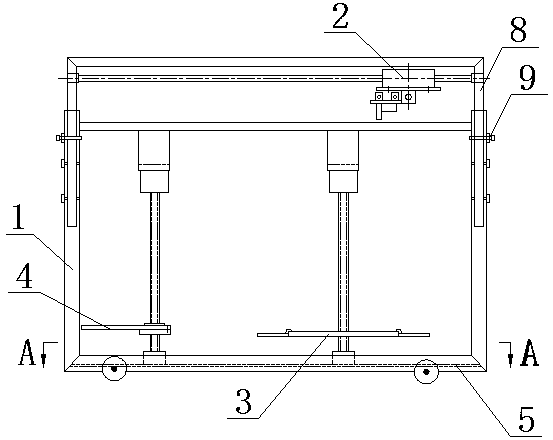

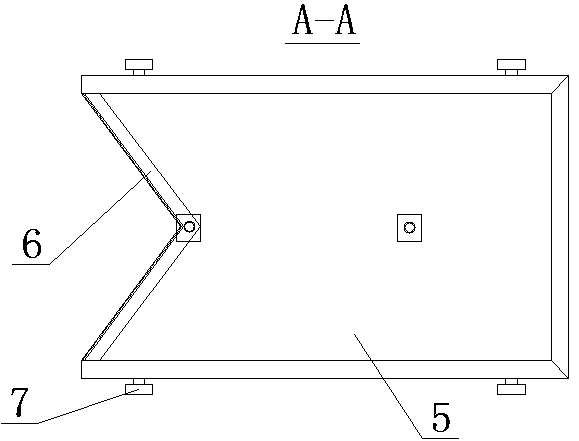

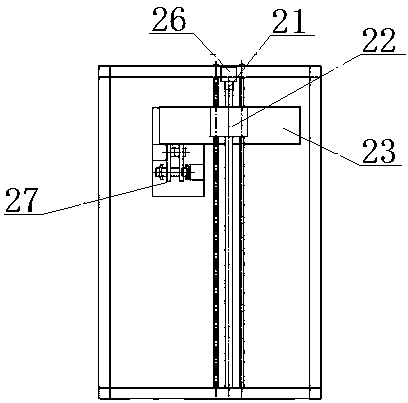

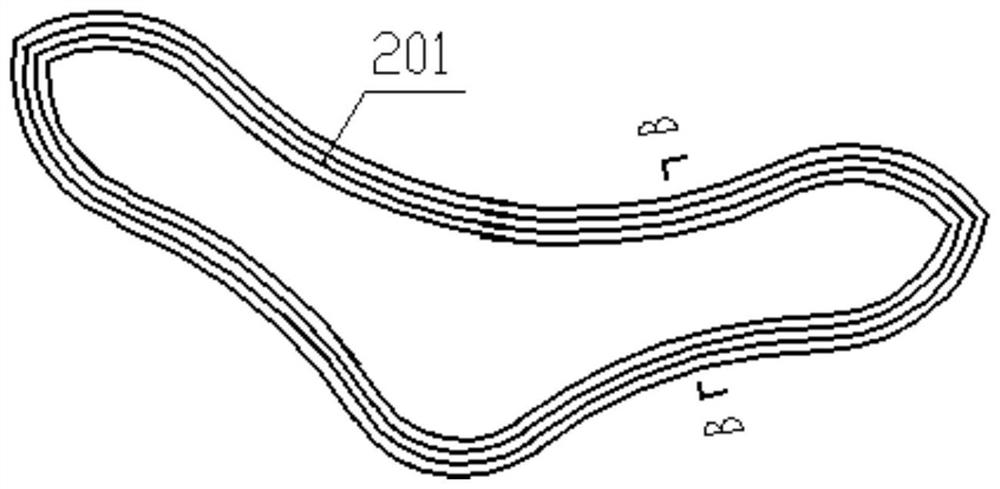

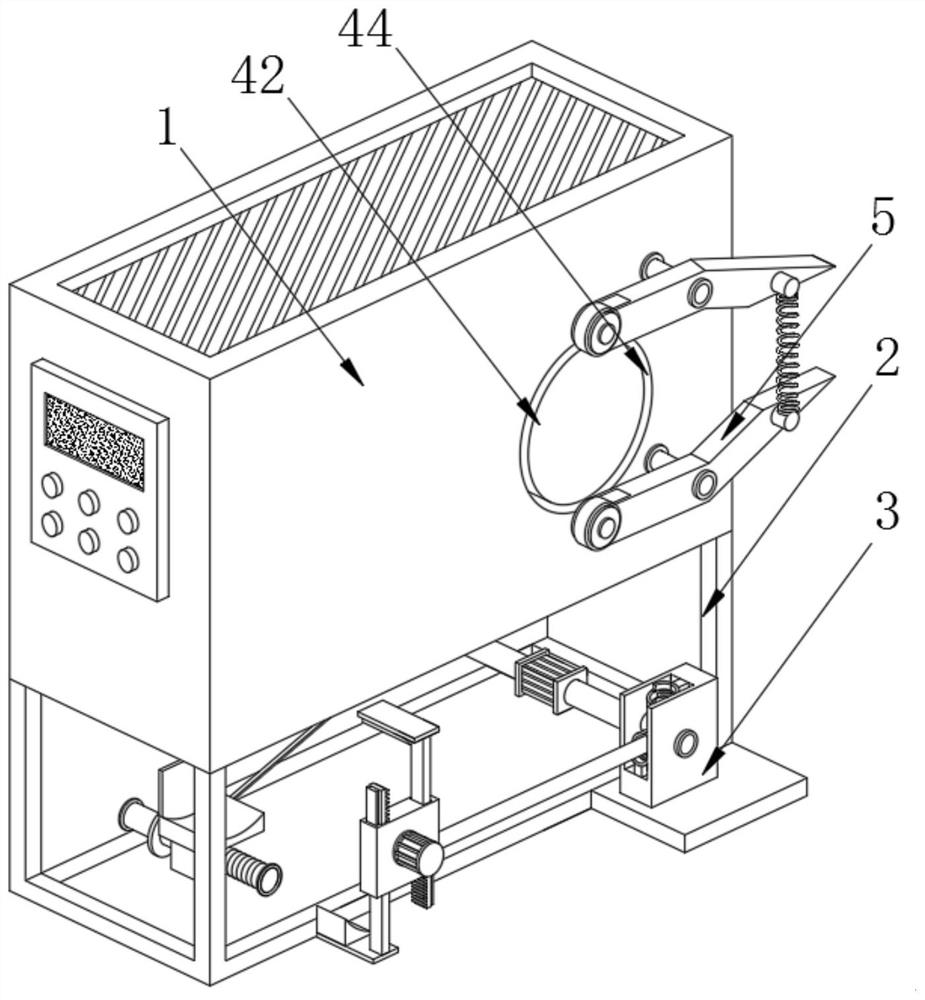

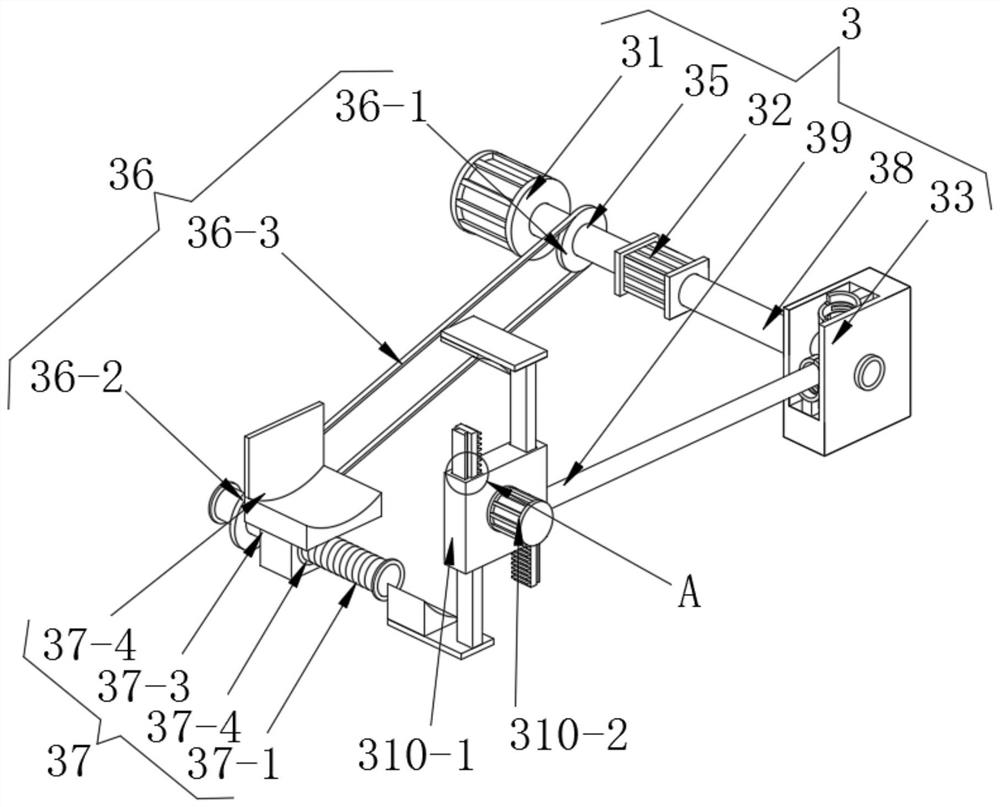

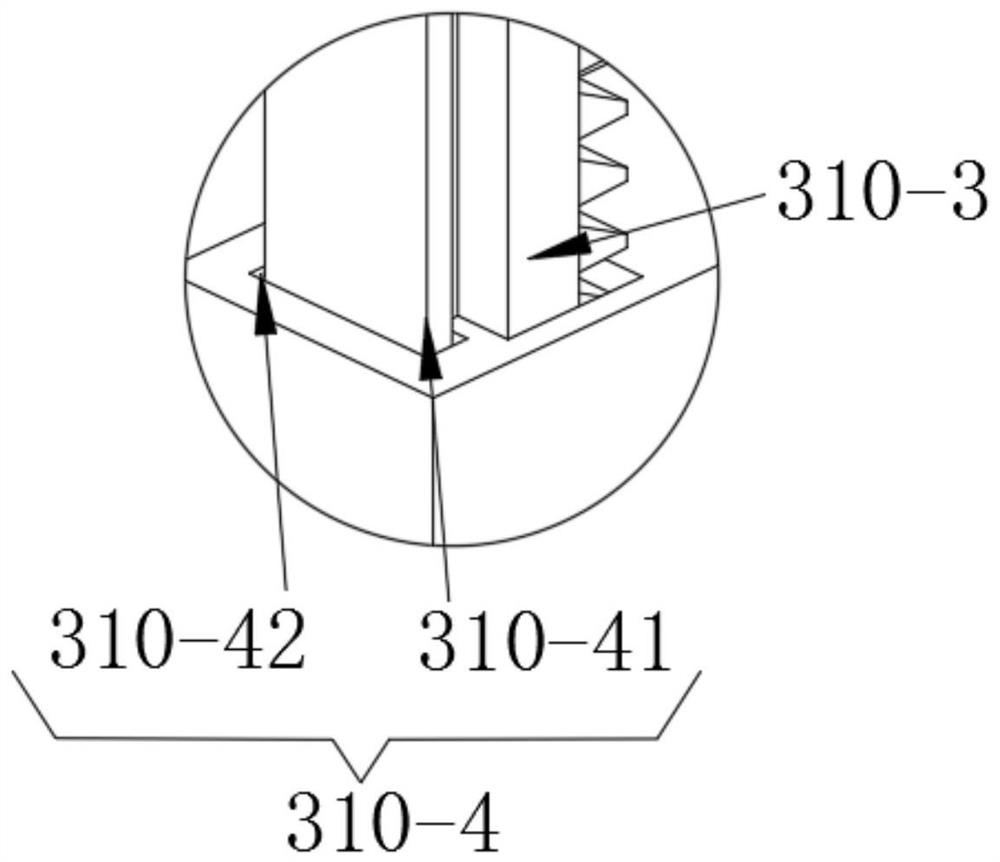

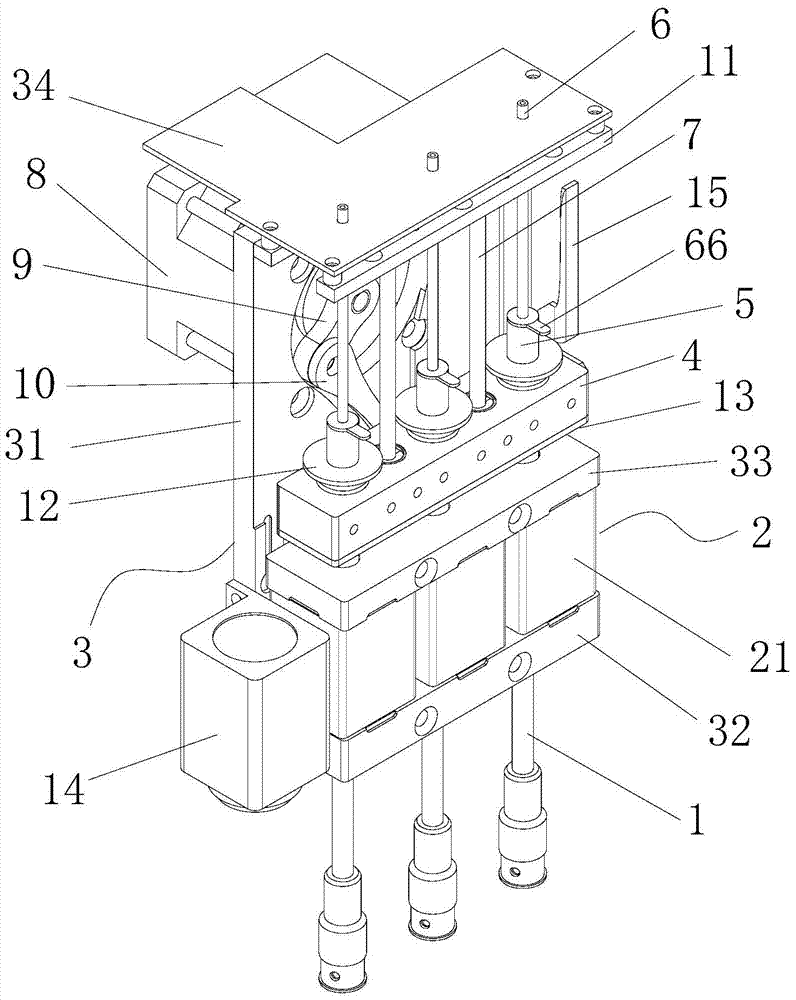

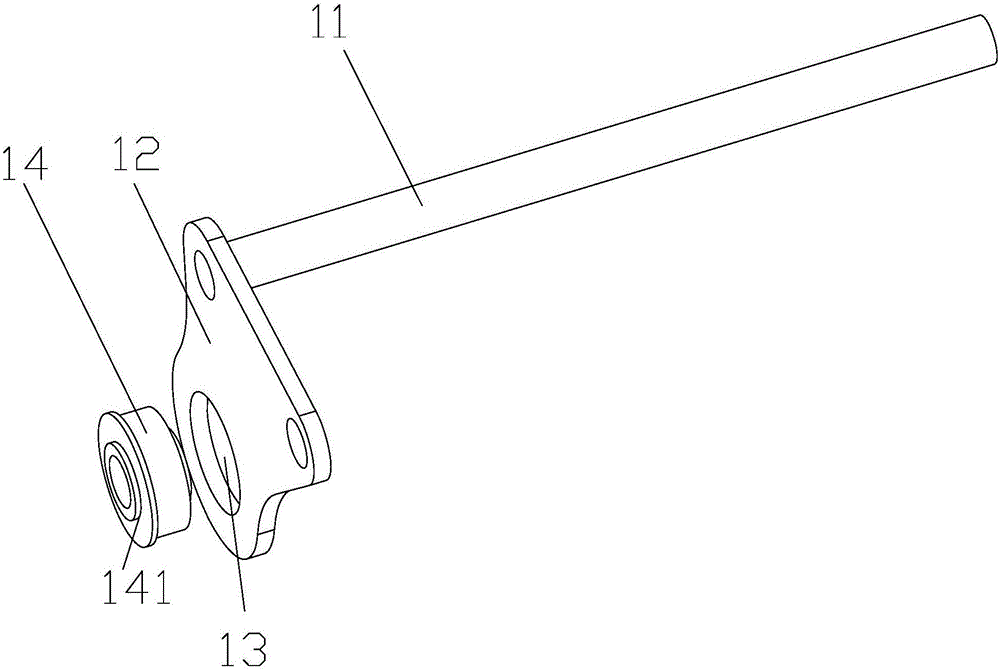

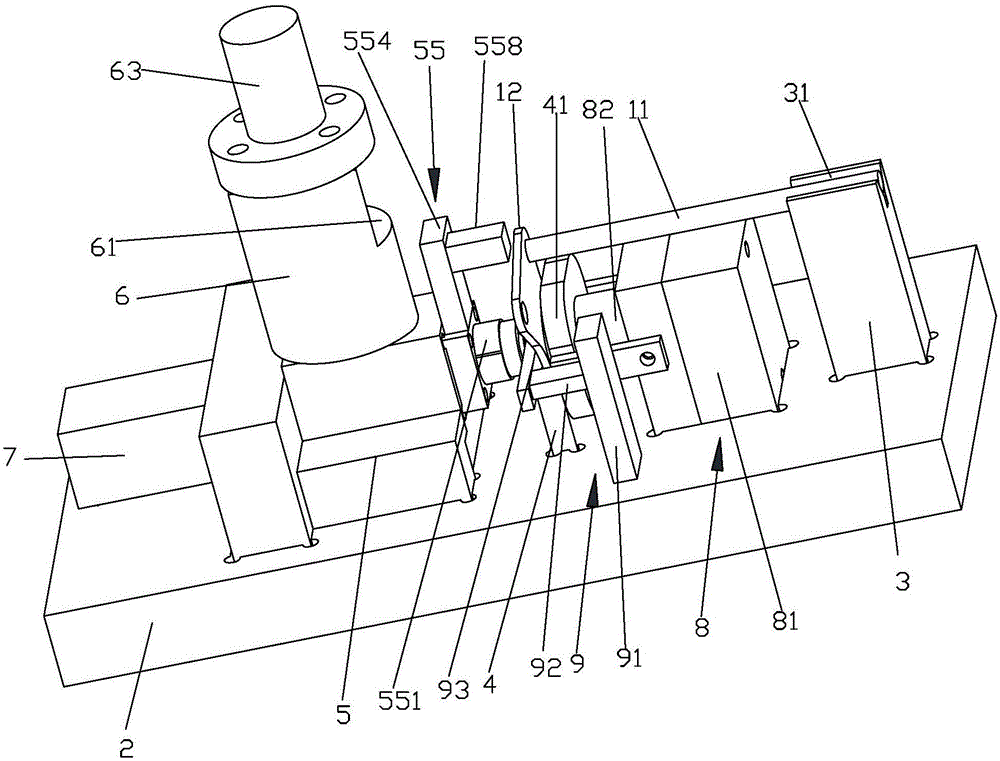

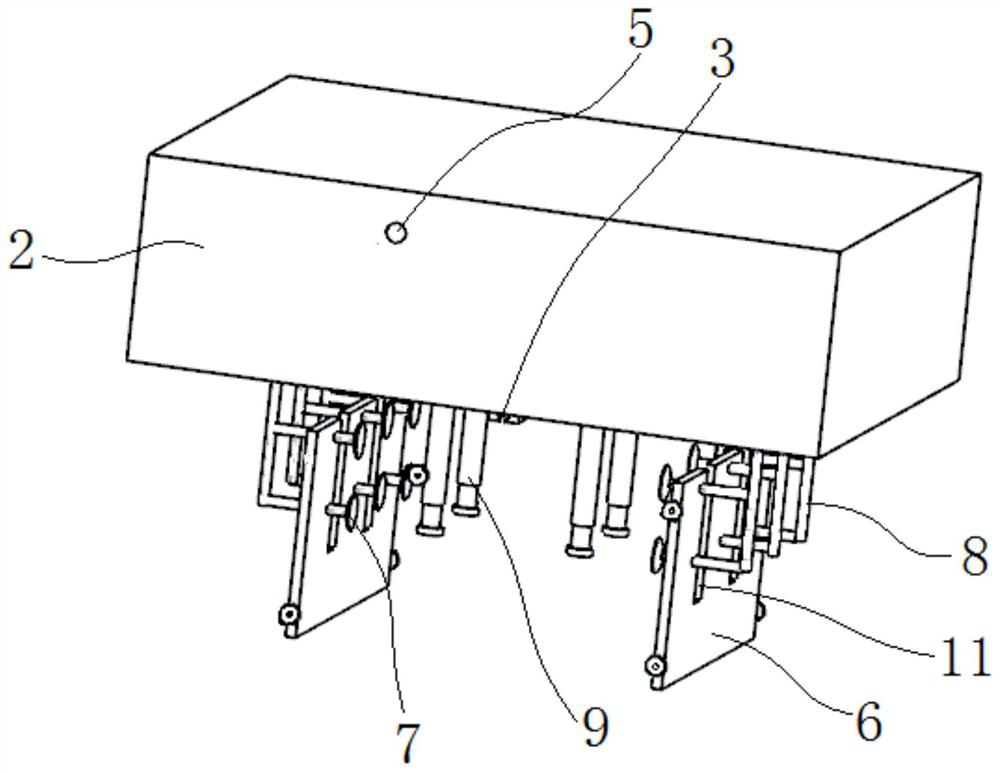

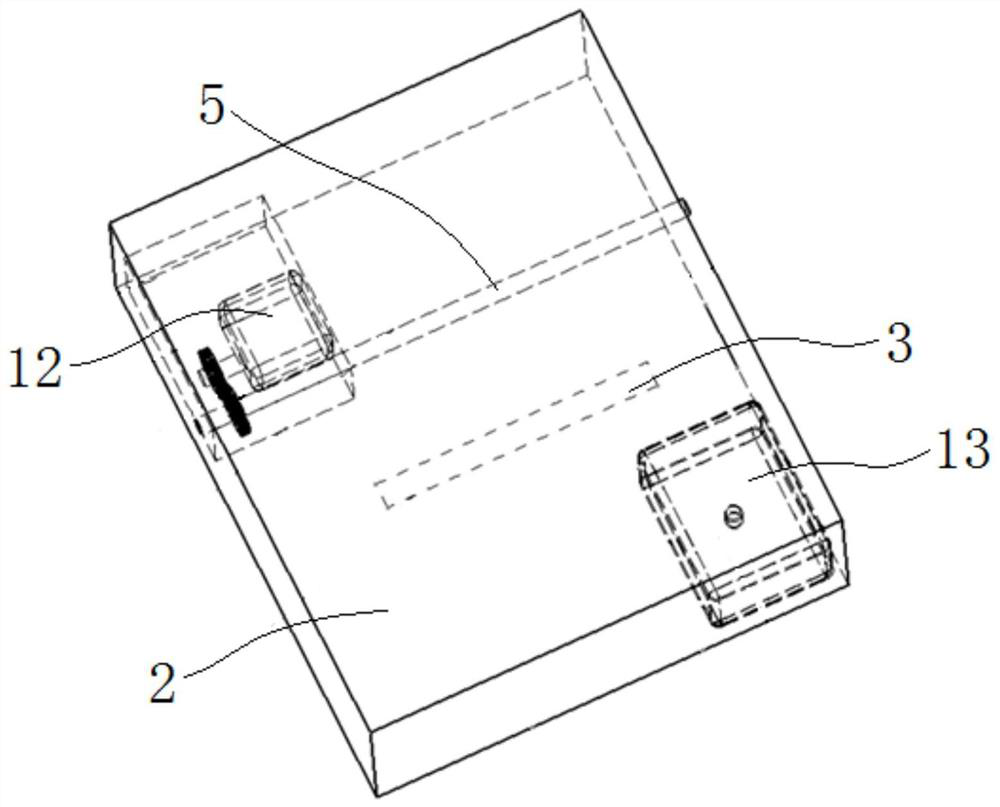

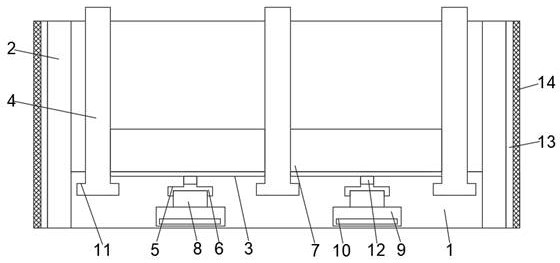

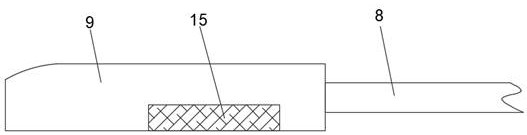

Wrap angle laying method applied to ceramic chip group packaging and wrap angle laying device

InactiveCN103979171AImplement extractionAchieve positioningClosuresStructural engineeringMechanical engineering

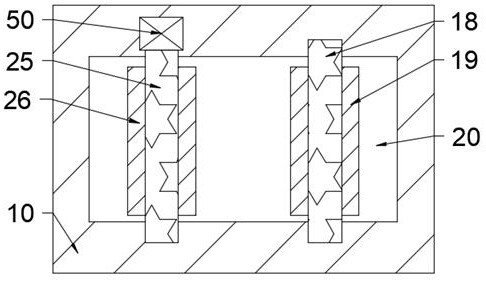

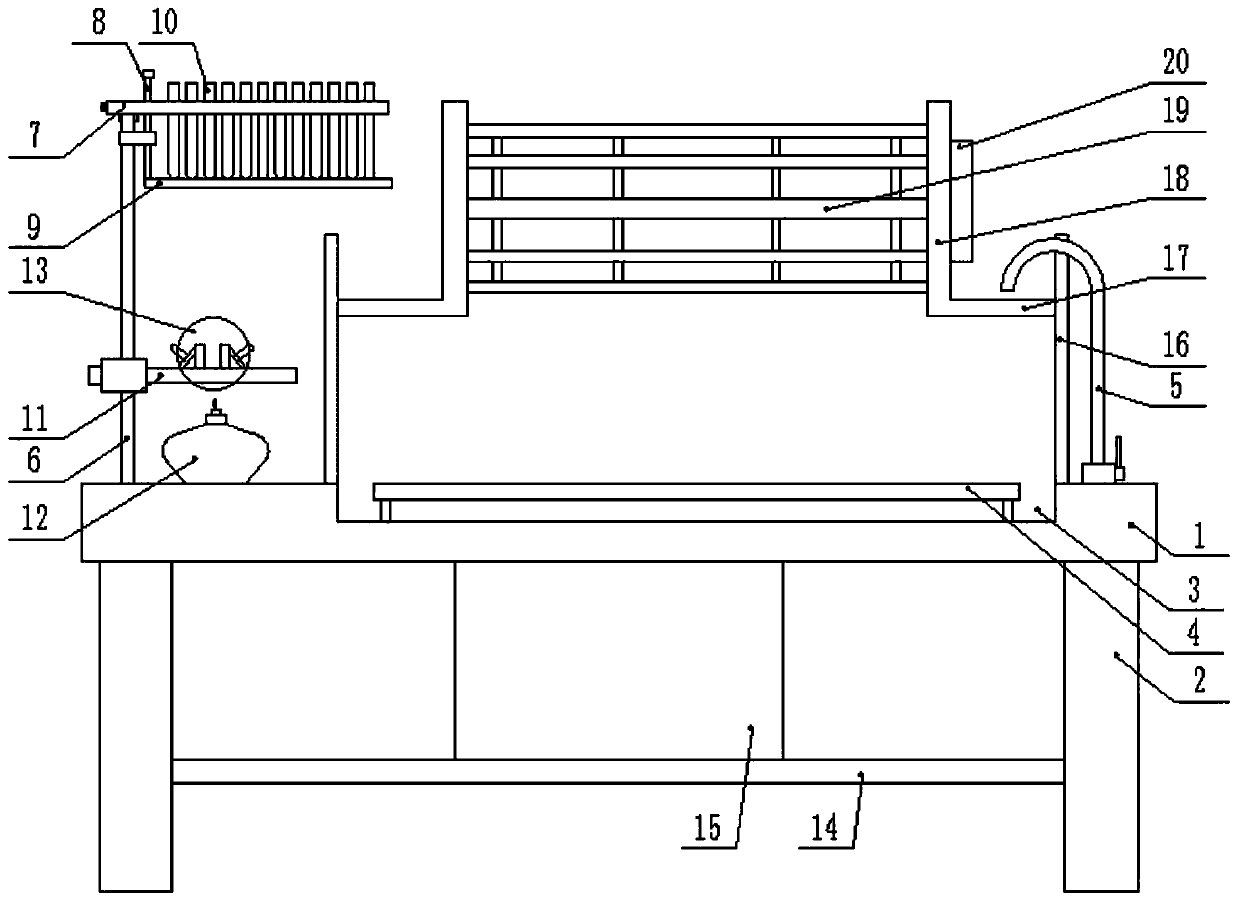

The invention relates to the field of packaging equipment inserting accessories onto a packing material, and discloses a wrap angle laying method applied to ceramic chip group packaging, which is used for automatically laying a wrap angle with protective strips onto a corner of a ceramic chip group, and preferably the wrap angle with the protective strips is laid and positioned on the corner of the ceramic chip group through a wrap angle conveying device. The method comprises the concrete steps of taking out the wrap angle through a wrap angle adsorption component, then changing the horizontal position of the wrap angle to be a vertical position through a wrap angle rotating component, and finally pushing the wrap angle to the corner of the ceramic chip group through a wrap angle pushing component. The invention also discloses the wrap angle laying device based on the method. The wrap angle laying device comprises a wrap angle conveying device body and a wrap angle, wherein the wrap angle adopts a double protective strip structure; the wrap angle conveying device body comprises the wrap angle rotating component, the wrap angle adsorption component arranged at the front end of the wrap angle rotating component, and the wrap angle pushing component driving the wrap angle adsorption component to move forward and backward. Compared with the prior art, the device has the characteristics of simple structure, good packaging effect and high production efficiency.

Owner:佛山市科信达机器人技术与装备有限公司 +1

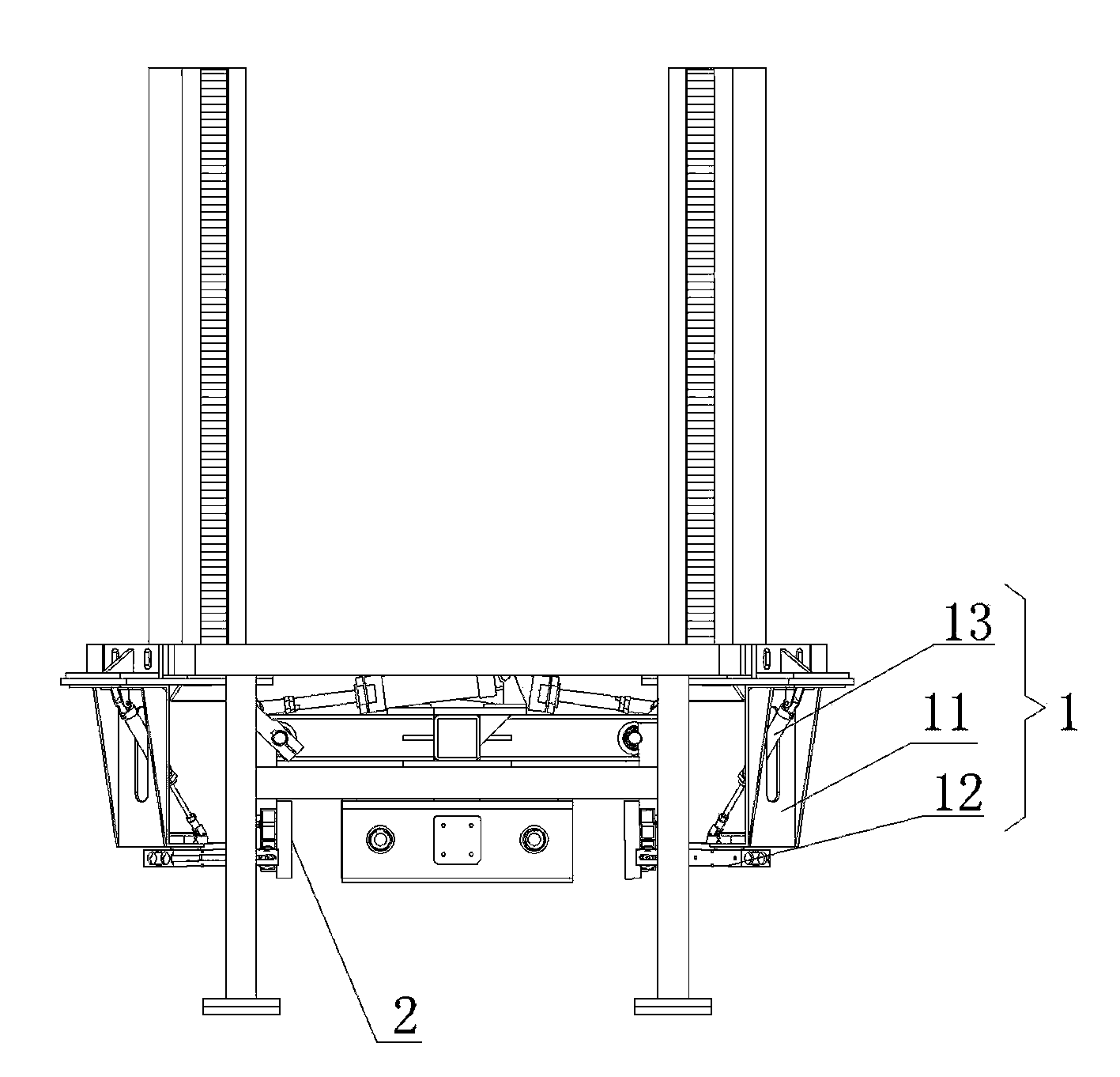

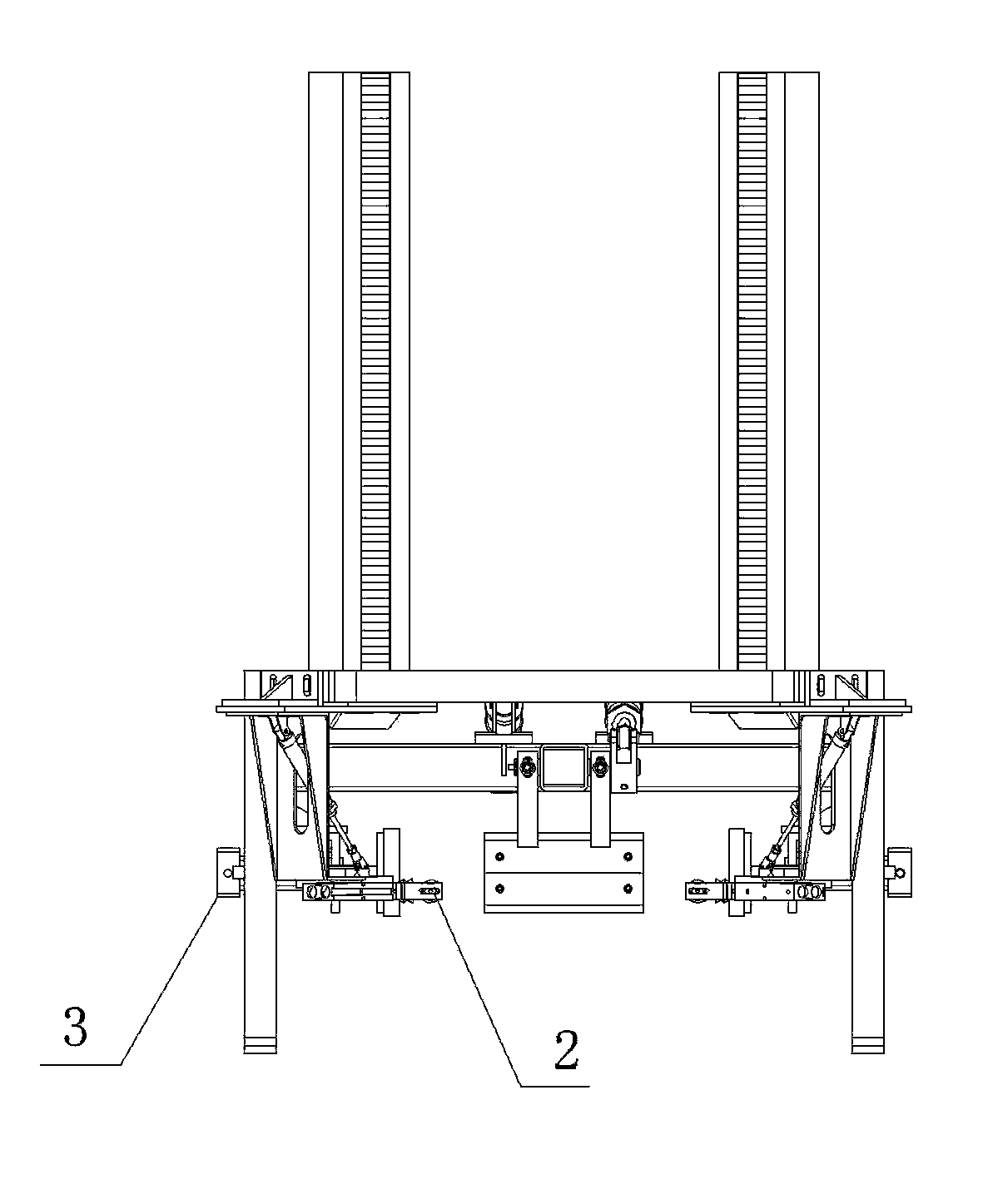

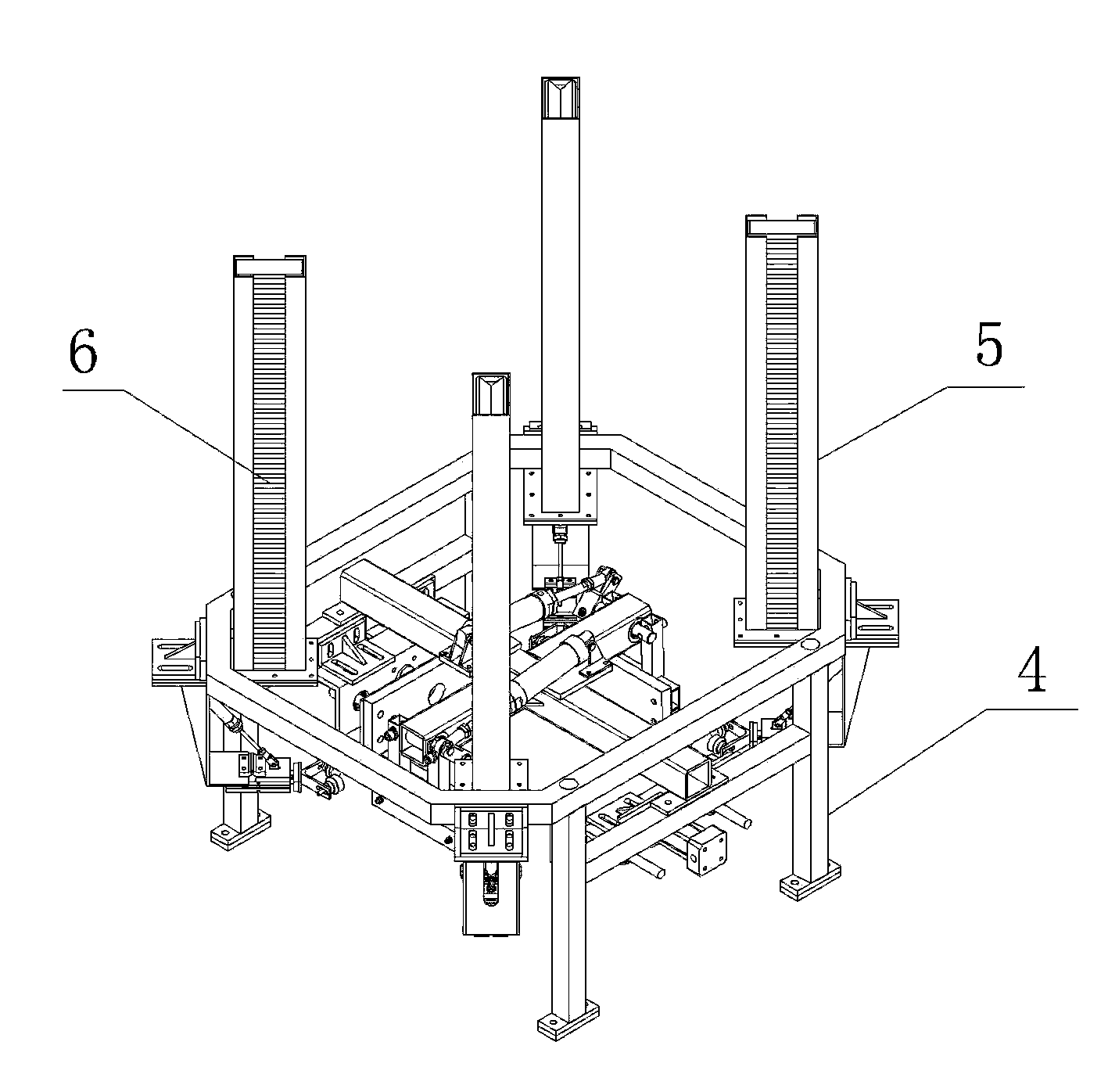

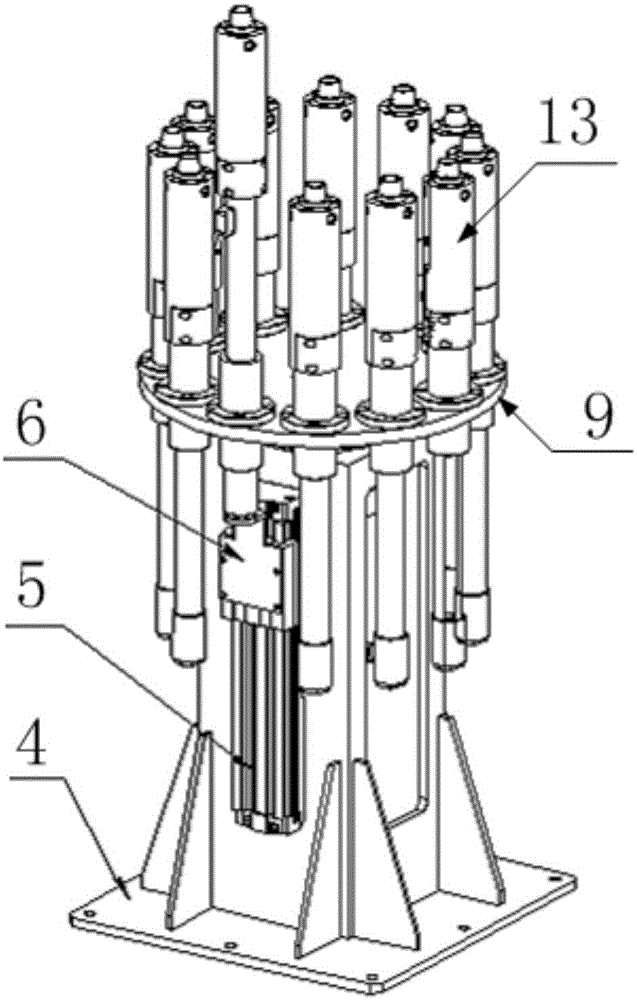

Tool changer and mobile robot drilling-riveting equipment comprising same

InactiveCN106826333AHigh positioning accuracyGuaranteed uptimeFeeding apparatusOther manufacturing equipments/toolsEngineeringRotating disc

The invention discloses a tool changer and mobile robot drilling-riveting equipment comprising the same. The tool changer comprises a tool base, a plurality of liftable tool fixing seats, a tool rotating disc, a rotating device for rotating the tool rotating disc and a lifting device for lifting the tool fixing seats, wherein the rotating device is fixed on the tool base, the tool rotating disc is arranged on the rotating device, the tool fixing seats are arranged on the tool rotating disc, a tool is arranged in a central hole of each tool fixing seat, and the lifting device is fixed on the tool base and located below the tool fixing seats. The tool changer is compact in structure, convenient to control, simple to adjust and high in efficiency.

Owner:上海奇灏特自动化工程有限公司

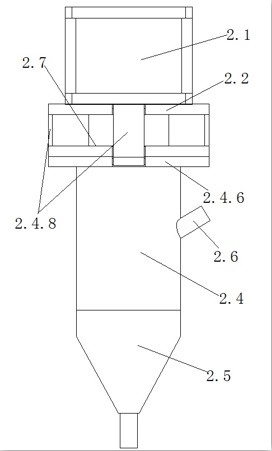

Smoking behavior recorder with cigarette smoke particulate matter trapping function

PendingCN111750913AEasy to holdEasy to useRecording apparatusWithdrawing sample devicesFlue gasElectrical and Electronics engineering

The utility model discloses a smoking behavior recorder with a cigarette smoke particulate matter trapping function. The smoking behavior recorder comprises a handheld holder, and a recorder and a flue gas trapping device which are fixed on the holder, wherein two ends of the recorder are respectively provided with a suction nozzle end and a plug port; the plug port is connected with the trappingdevice; the trapping device comprises a trapping container, and a filter disc and a filter disc baffle which are arranged in an inner cavity of the trapping container; the trapping container is formedby combining a left part and a right part through threaded connection; the left half side of the trapping container is provided with a closing bottleneck section and is connected with a smoke inlet of the recorder through a connecting pipe, the right half side of the trapping container is provided with a cigarette inserting hole, the right side of the handheld holder is provided with a cigaretteash collecting hopper, and the collecting hopper is located under a cigarette; and a handheld support and a base are fixedly connected to the lower end of the holder. The invention has the beneficialeffects that the smoke particulate matter trapping device is connected to the plug port of the smoking behavior recorder, so the purpose of trapping particulate matters in cigarette smoke in the actual smoking process of a smoker can be achieved while smoking behavior parameters are tested.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

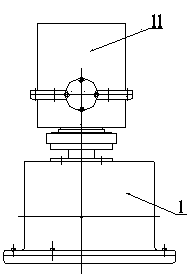

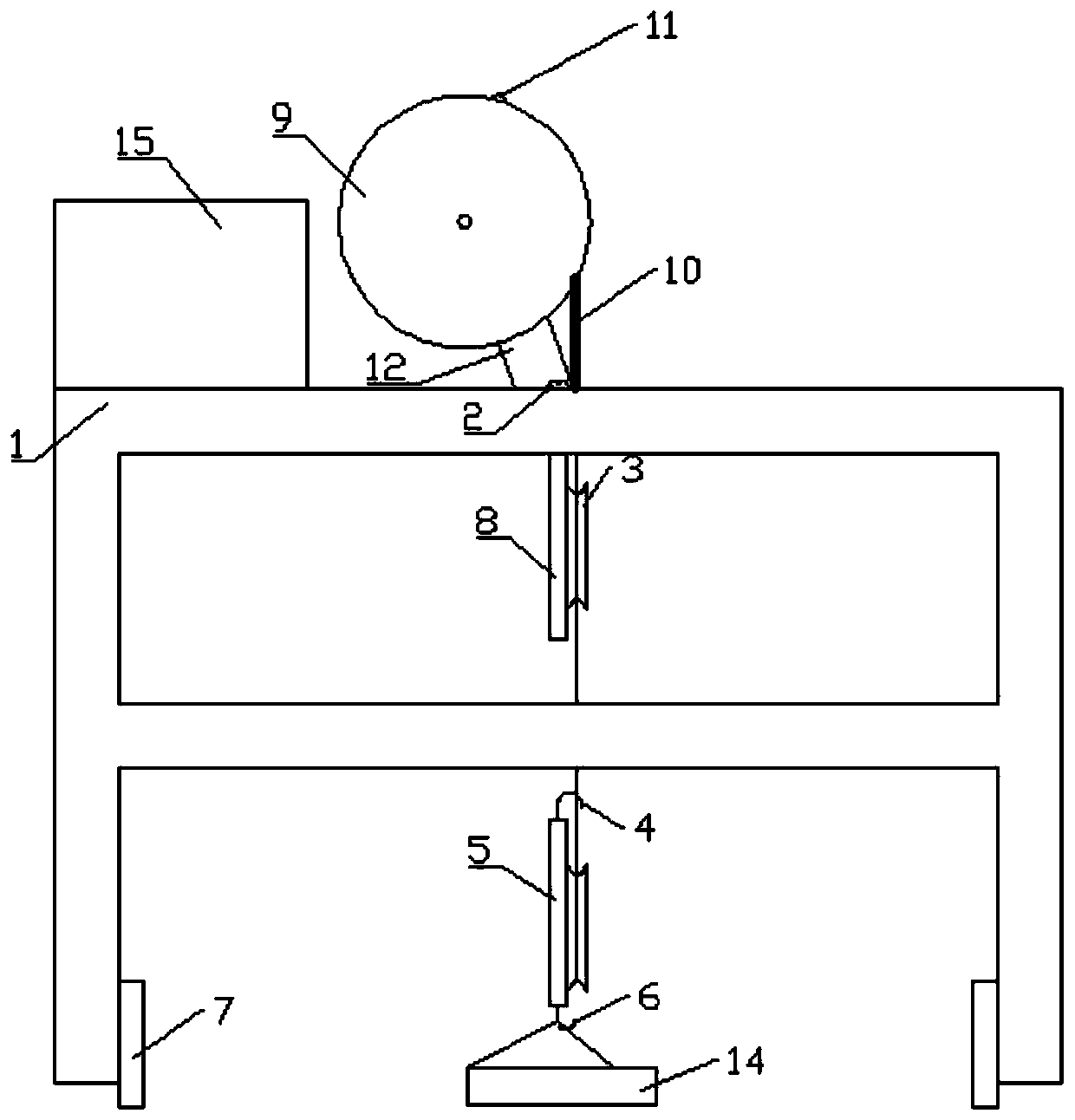

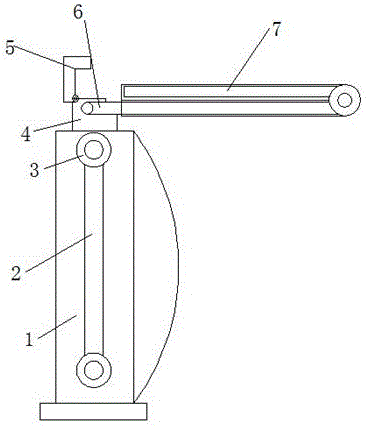

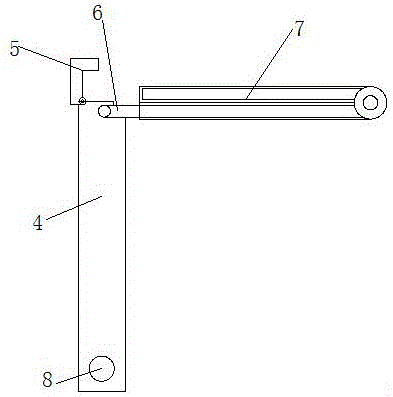

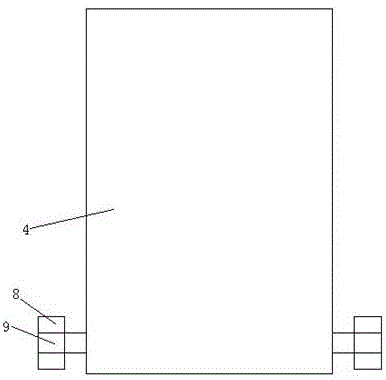

Workpiece auto-carry device

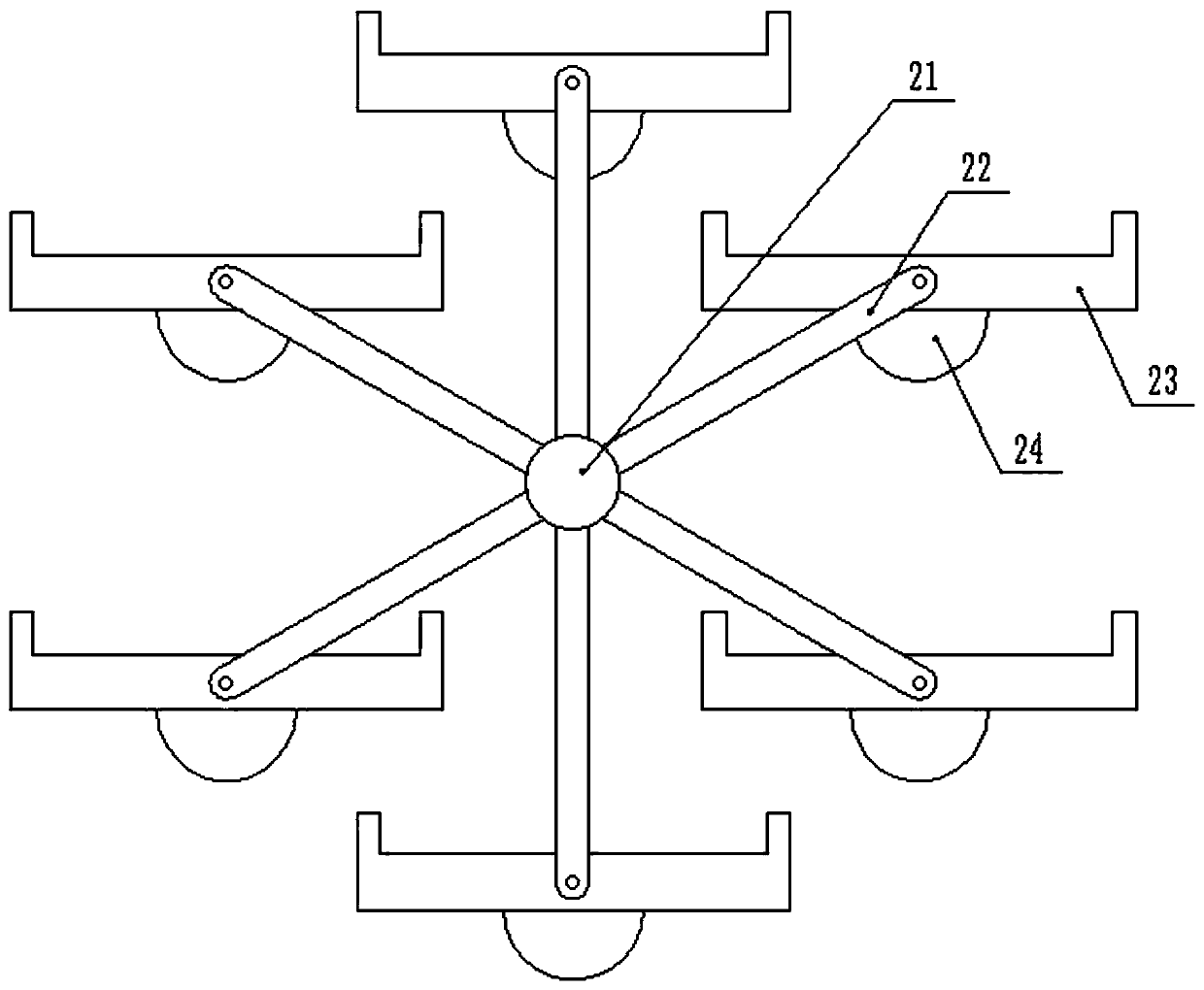

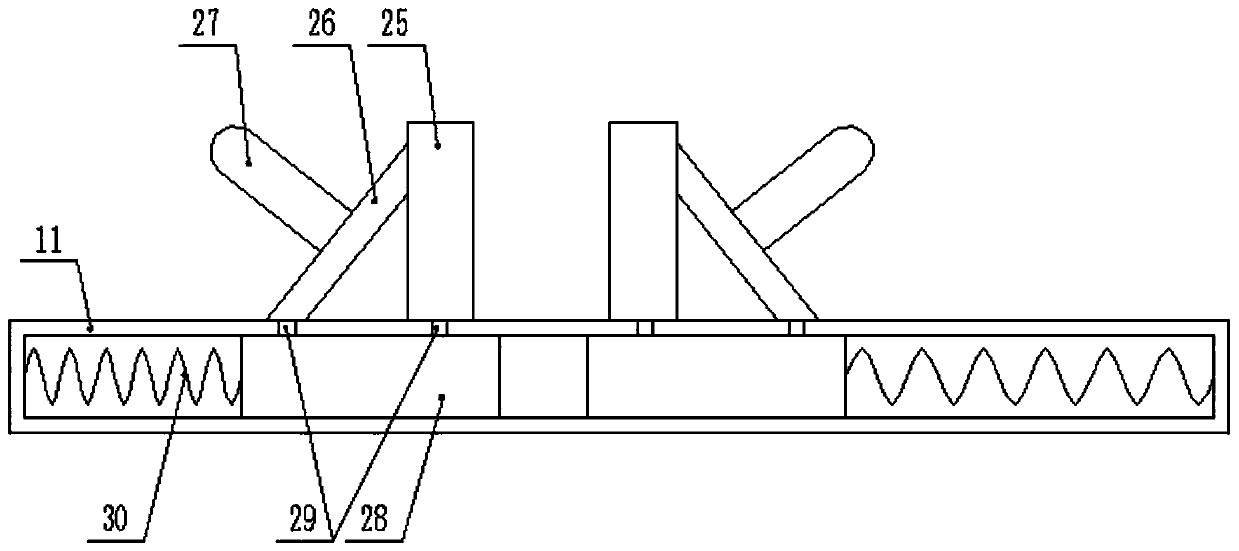

InactiveCN103522284AHas crawlWith placementProgramme-controlled manipulatorThrough transmissionEngineering

A workpiece auto-carry device has two degrees of freedom including telescopic motion of a manipulator front arm and rotational motion around the vertical axis of a base. The motions are major motions of a manipulator and controlled by two motors. The motors are connected with an actuator through transmission mechanisms such as a gear so as to transmit motions. In addition, during the whole acting process, opening and closing of a claw are involved. The workpiece to be clamped is light and can be clamped at ease just with a pneumatic pump.

Owner:江苏剑桥涂装工程股份有限公司

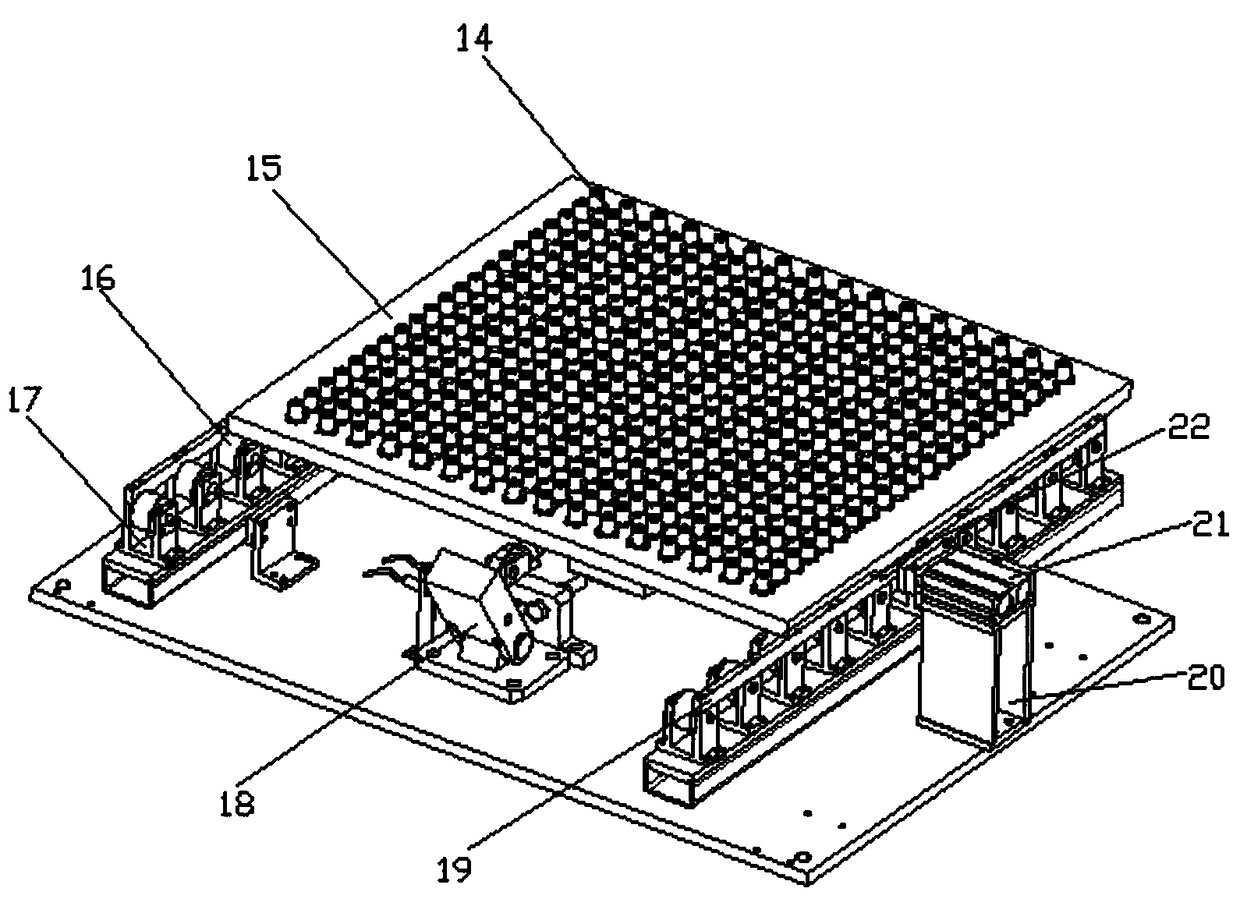

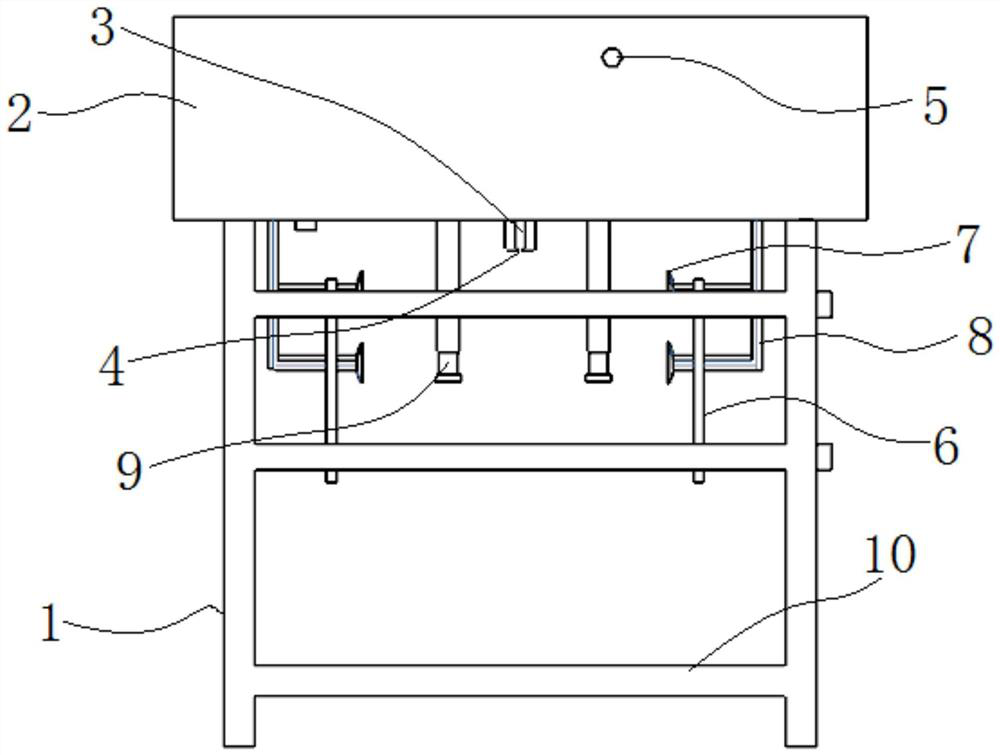

Full-automatic EPB assembling machine

InactiveCN108080947ANo deflectionRealize double-station workAssembly machinesMetal working apparatusDistribution controlButt joint

The invention relates to a full-automatic EPB assembling machine. The machine comprises a machine frame and a power distribution control box arranged in the machine frame; a conveying belt device is arranged at the upper end of the machine frame, a nut feeding device and a screw rod feeding device are symmetrically arranged on the two sides of the starting end of the conveying belt device, a plurality of sets of jig assemblies are movably placed at the upper end of the conveying belt device, and a jig jacking device which is in butt joint with each jig assembly is arranged below the conveyingbelt device; and a pressing device, a detection device, an OK material discharging device and a NG material discharging device are sequentially arranged on one side of the conveying belt device from left to right. According to the machine, two nut fixing blocks are arranged on each jig assembly, so that double-station operation is realized, and the working efficiency is greatly improved; the nut fixing blocks are provided with receding holes matched with one ends of EPB nuts, so that accurate positioning on the EPB nuts is achieved; and lifting matching holes formed in jig bottom plates are matched with jig matching pins of the jig jacking device, so that the position of each jig assembly after rising can not be deflected, and the machining precision is further improved.

Owner:DONGGUAN UNIV OF TECH

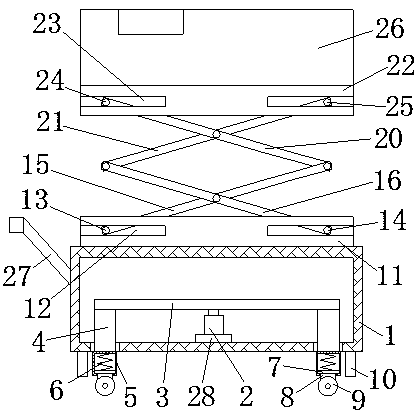

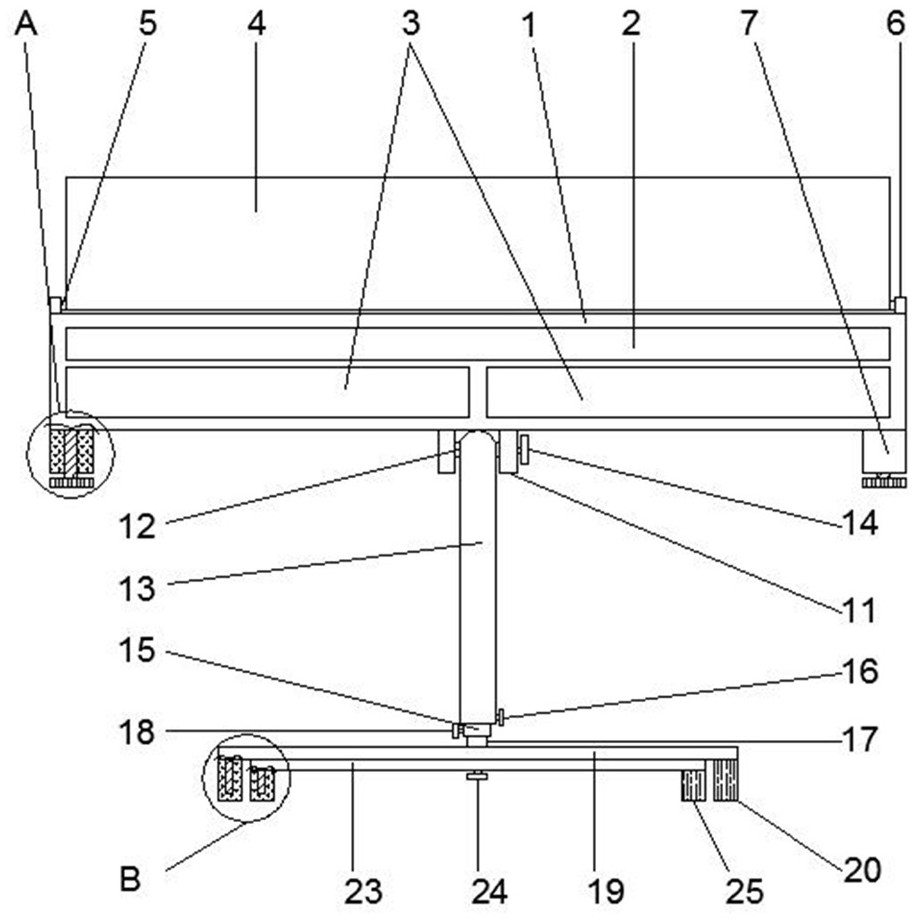

Mounting support for stage lighting

PendingCN108644578AHeight adjustmentImprove usabilityLighting applicationsLighting support devicesEngineeringStage lighting

The invention discloses a mounting support for stage lighting. The mounting support for the stage lighting comprises a box body, wherein a first electric telescoping rod is fixedly connected to the bottom part of an inner cavity of the box body; a transverse plate is fixedly connected to the output end of the first electric telescoping rod; supporting rods are fixedly connected to two sides of thebottom part of the transverse plate; and the bottom parts of the supporting rods penetrate the bottom part of the inner cavity of the box body. According to the mounting support for the stage lighting, a first sliding rod, a second sliding rod, a first adjusting rod, a second adjusting rod, a first supporting block, a second supporting block, a second electric telescoping rod, a third adjusting rod, a fourth adjusting rod, a second vertical plate, a second chute, a third sliding rod and a fourth sliding rod are matched to achieve of the purposes of adjusting the height and conveniently movingthe mounting support for the stage lighting; the height of the support can be adjusted, and the support can conveniently move, so that the usability of the support is improved; and the problems thatthe height cannot be adjusted and the mounting support for the stage lighting inconveniently moves can be solved.

Owner:佛山市第七感文化传播有限公司

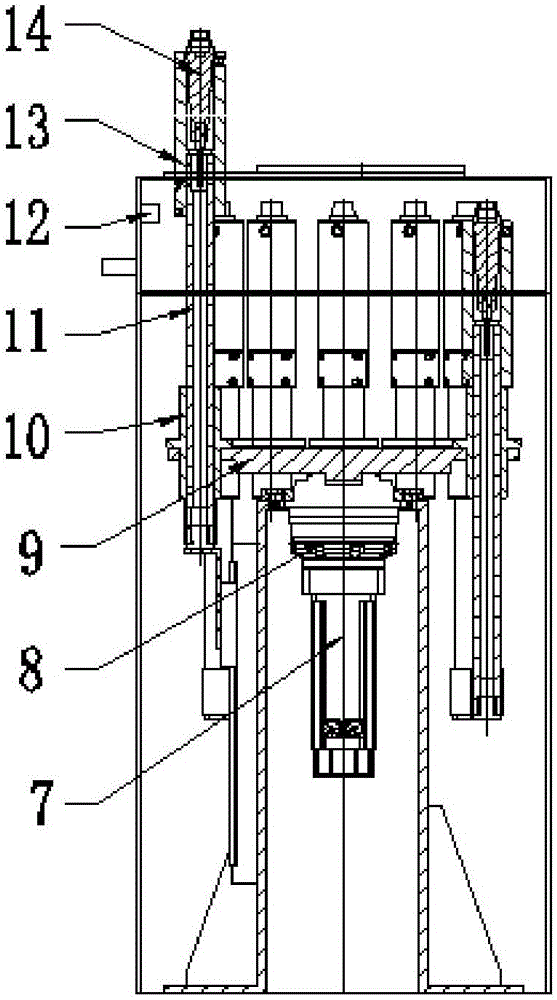

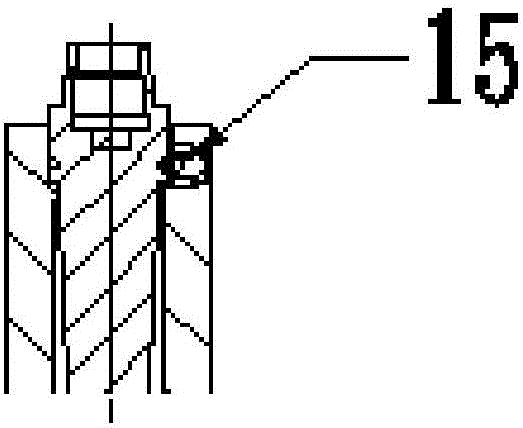

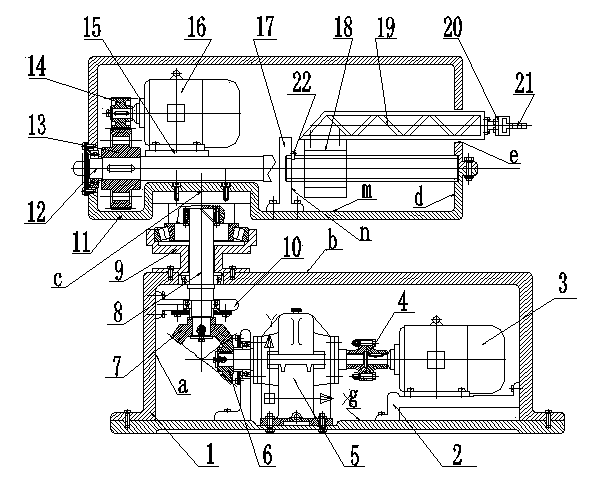

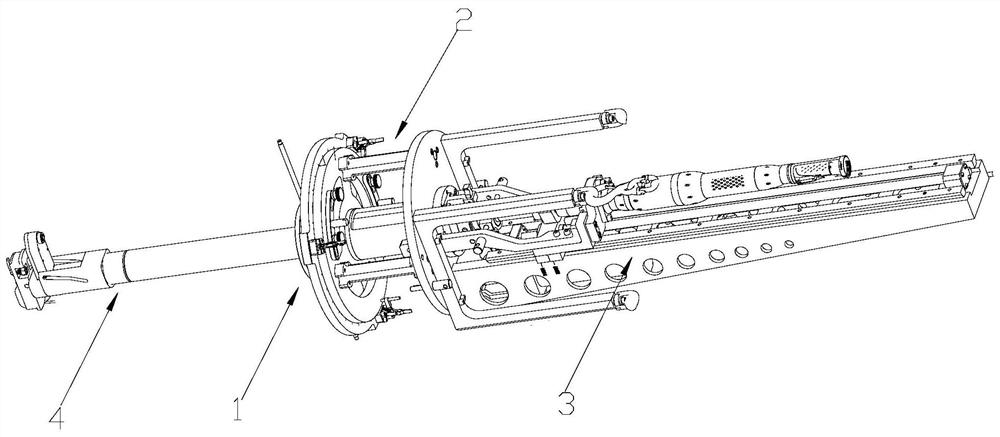

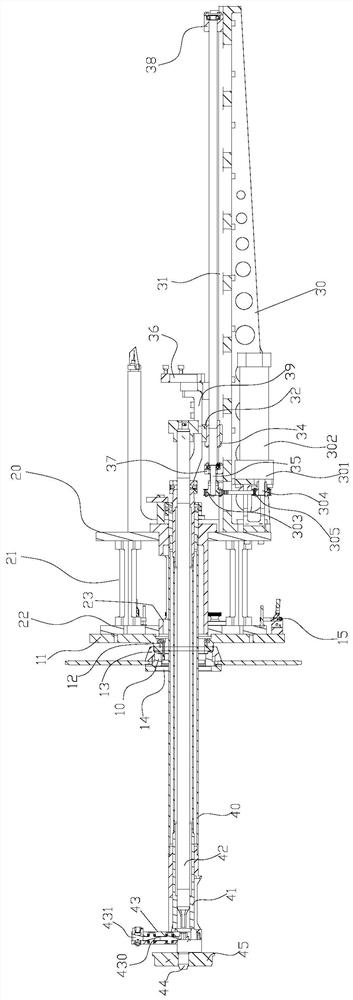

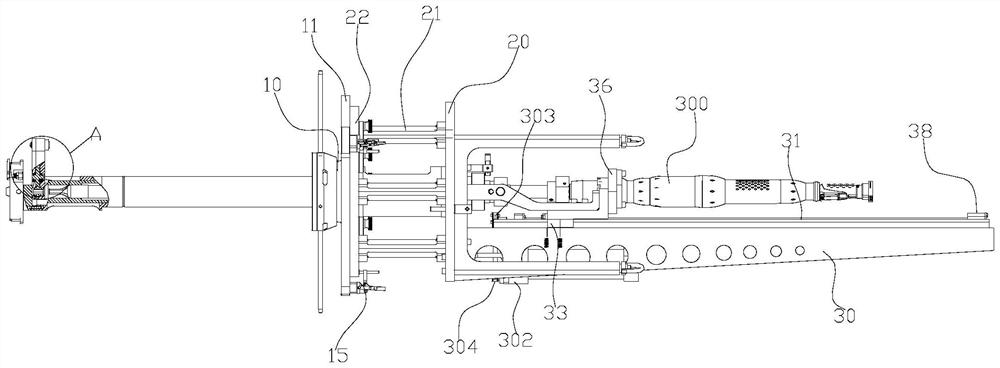

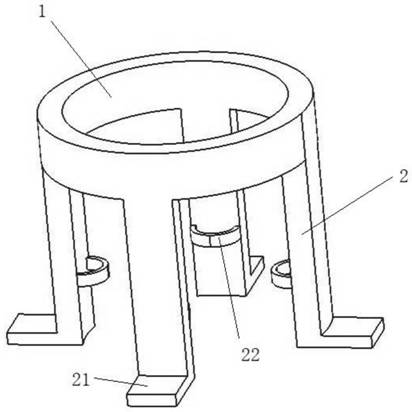

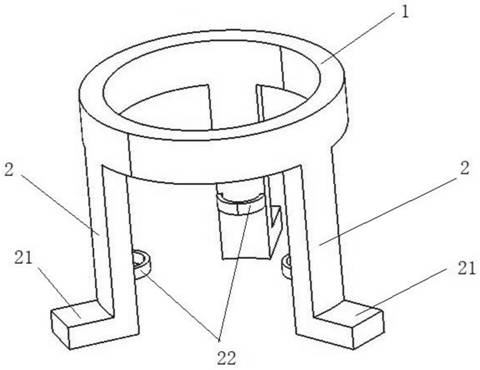

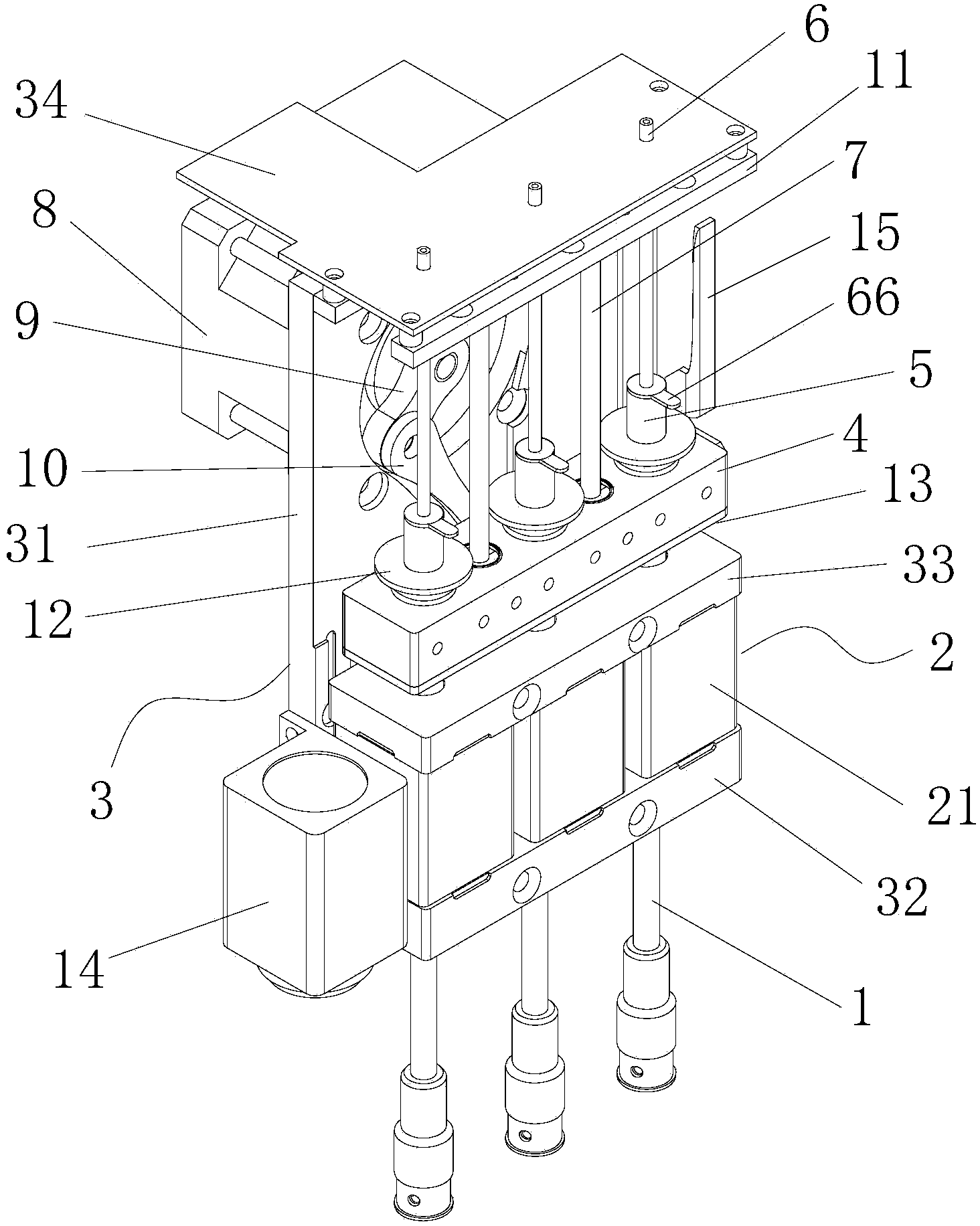

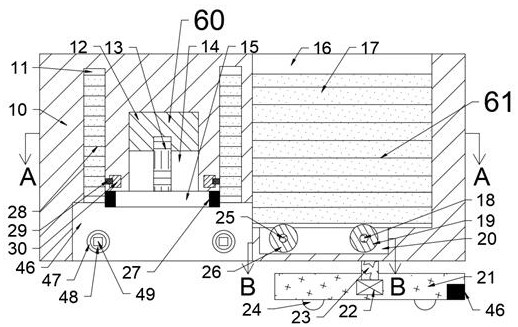

Engine high-pressure rotor narrow and small space connecting nut assembly device and operation method

ActiveCN111660085AMeet assembly operationsRealize placementMetal working apparatusControl engineeringRotor (electric)

The invention discloses an engine high-pressure rotor narrow and small space connecting nut assembly device and an operation method. The engine high-pressure rotor narrow and small space connecting nut assembly device comprises a locating and pressing mechanism, an angular indexing mechanism, a lifting and locating mechanism, a track folding torque input mechanism, a nut and turbine shaft end tooth initial angular locating mechanism, an auxiliary locating seat placing and taking mechanism and a rotor assembly simulation assembly torque measurement mechanism. The track folding torque input mechanism is assembled on the angular indexing mechanism and is matched and connected with an electric wrench. The angular indexing mechanism is matched and connected with the upper end face of the locating and pressing mechanism. The lifting and locating mechanism is perpendicularly connected to the upper end face of the angular indexing mechanism. The engine high-pressure rotor narrow and small space connecting nut assembly device is reliable in structure, convenient to operate and good in usability, can effectively meet the requirements for assembly operation of connecting nuts in a narrow andsmall space, can also accurately control the output torque while greatly improving the assembly efficiency and reduces the labor intensity of an operator.

Owner:AECC AERO SCI & TECH CO LTD

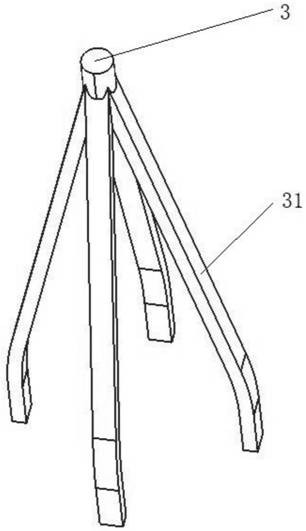

Functional near-infrared device for pushing aside hair in head cap hole

PendingCN113397537AImprove placement efficiencyAvoid replyDiagnostic recording/measuringSensorsHead scalpForceps

The invention relates to a functional near-infrared device for pushing aside hair in a head cap hole. The functional near-infrared device comprises a device ferrule and device deflector rods connected with the device ferrule, wherein the device deflector rods have elasticity; a near-infrared light electrode can be placed in the device ferrule; deflector sheets are arranged at end parts of free ends of the device deflector rods and are L-shaped with the deflector rods; deflector rings are further arranged at inner sides of the device deflector rods and are arranged at positions 1 / 3 away from single sides of the free ends of the device deflector rods, so that the device deflector rods are conveniently operated to be gathered inwards; and in order to conveniently operate the device disclosed by the invention, mounting forceps with forceps rods are further arranged, the forceps rods correspond to the device deflector rods in number and angle, and free ends of the forceps rods are matched with the deflector rings and can be detachably connected with the deflector rings. The device has the advantages that a scalp can be accurately, simply, conveniently and rapidly exposed, the hair is prevented from rebounding, the near-infrared light electrode is rapidly mounted, thus, near-infrared light can be in direct contact with the scalp, interference of the hair to signals is reduced, clinical and scientific researchers can better carry out functional near-infrared related research, and the working efficiency is improved.

Owner:SHANGHAI TONGJI HOSPITAL

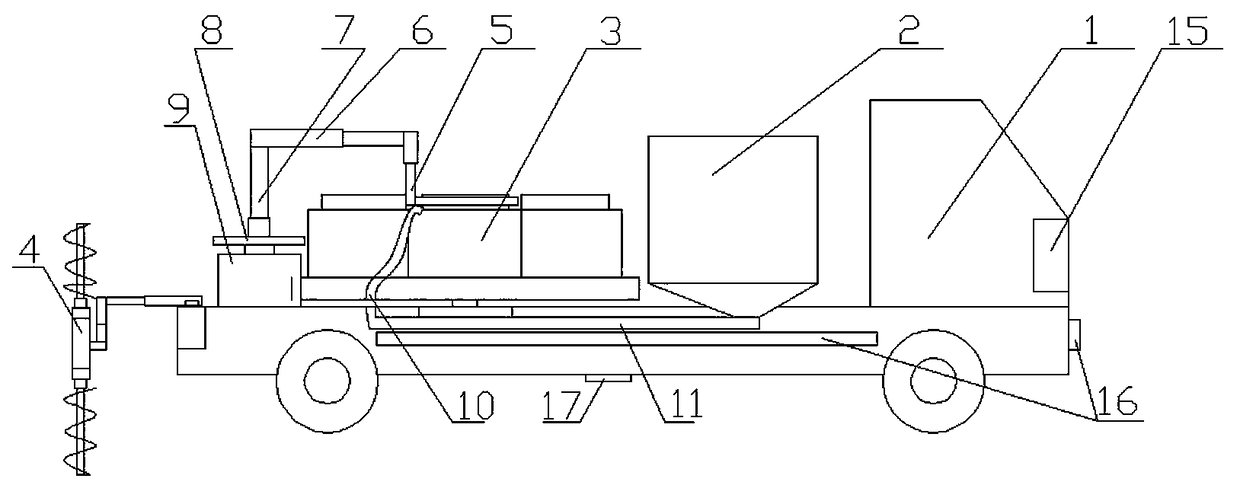

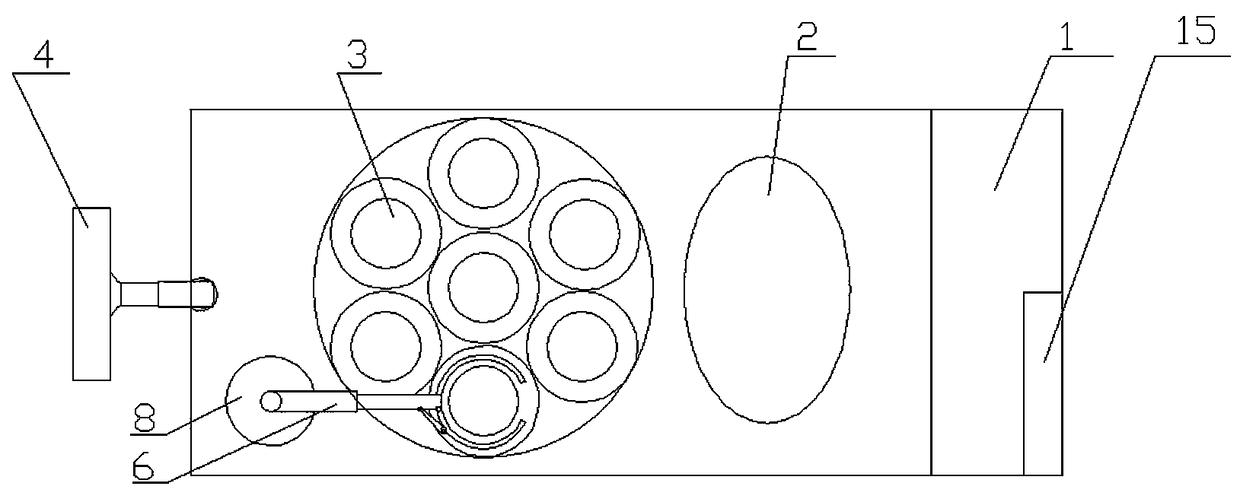

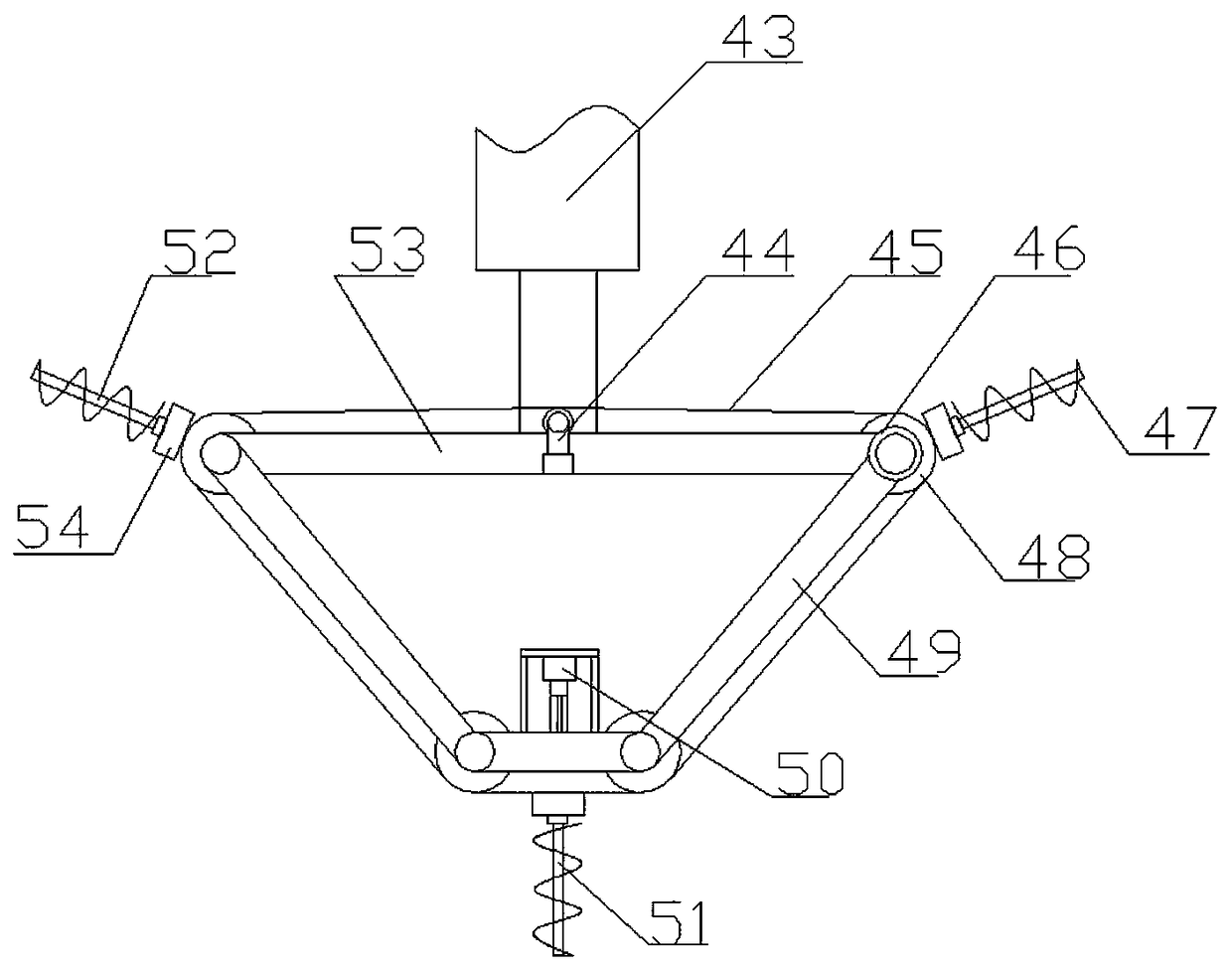

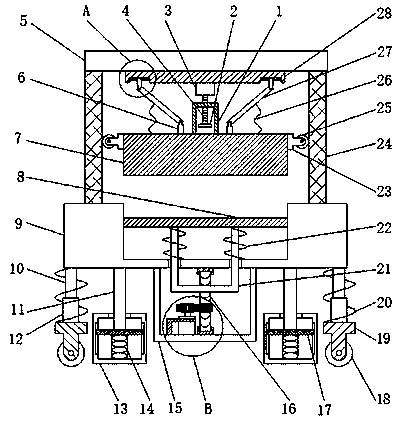

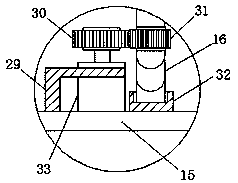

Power tower pole base installation device

The invention provides a power tower pole base installation device, and relates to the technical field of tower pole erection equipment. The power tower pole base installation device comprises a moving trolley, a foundation pit excavation mechanism, a bearing bin, an installation mechanism, a balancing mechanism, a casting mechanism and a control mechanism, wherein the foundation pit excavation mechanism is arranged on the moving trolley, the bearing bin is arranged on the moving trolley, the installation mechanism is arranged on the moving trolley and is matched with the bearing bin, the balancing mechanism is arranged on the moving trolley and is matched with the foundation pit excavation mechanism, the casting mechanism is arranged on the moving trolley and is matched with the installation mechanism, and the control mechanism is arranged on the moving trolley and is used for controlling the foundation pit excavation mechanism, the installation mechanism, the balancing mechanism andthe casting mechanism. By the power tower pole base installation device, the number of constructors can be reduced, foundation pit excavation can be efficiently, stably, safely and rapidly performed,base casting can be achieved in a site, so that a tower pole base with a stable structure is obtained.

Owner:国网河南省电力公司兰考县供电公司 +2

Furniture shaping device

InactiveCN108858647AAvoid shakingHave the effect of acceleratingWood working apparatusFlat articlesEngineeringAbsorption effect

The invention discloses a furniture shaping device, and relates to the technical field of furniture processing equipment. The furniture shaping device comprises a bottom plate. A storage groove is formed in the upper side of the bottom plate, a support plate is arranged in the storage groove, side plates are fixedly connected with two sides of the storage groove, a squeezing plate is arranged between the two side plates and is matched with the storage groove, slide devices are arranged between two sides of the squeezing plate and the corresponding side plates, the upper ends of the two side plates are fixedly connected with each other by a cover plate, a control panel is fixed to the bottom of the cover plate, a first servo motor is fixedly connected with the bottom of the control panel, afirst screw is fixedly connected with the tail end of an output shaft of the first servo motor, and a first movable block sleeves the first screw in a threaded manner. The furniture shaping device has the advantages that the furniture shaping device is novel in structure, sawdust can be conveniently and quickly shaped and processed by the furniture shaping device with the simple structure, and integral procedures are easy to operate; shock absorption effects can be realized by the furniture shaping device, and the furniture shaping device can conveniently move.

Owner:孝感市凯馨智能家居设计有限公司

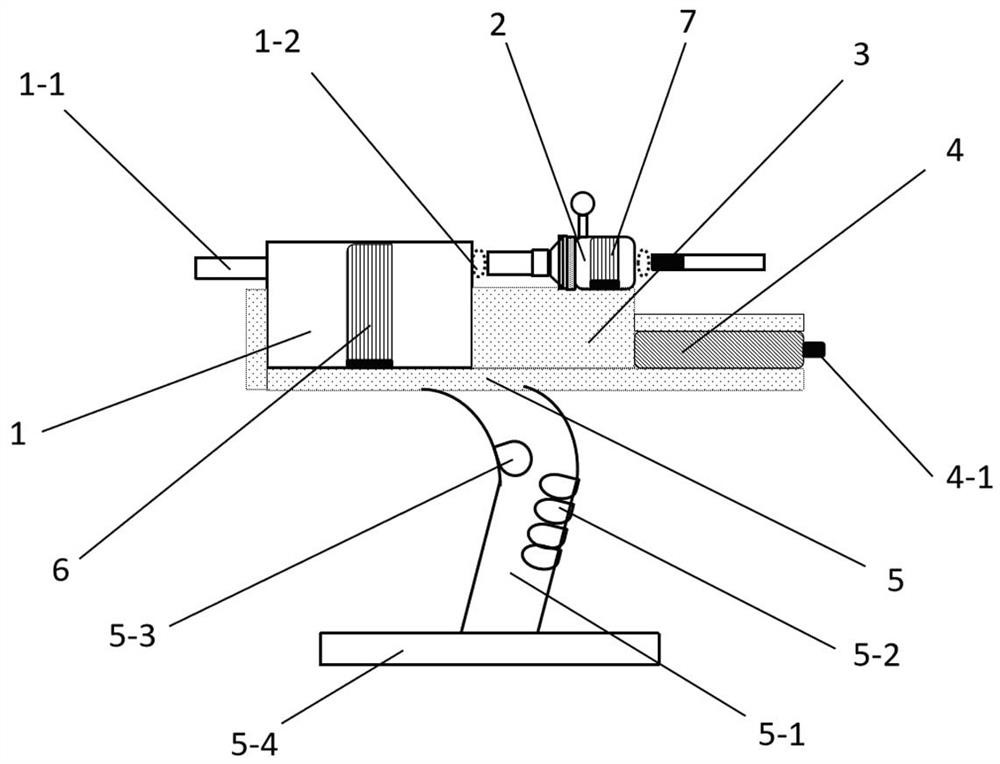

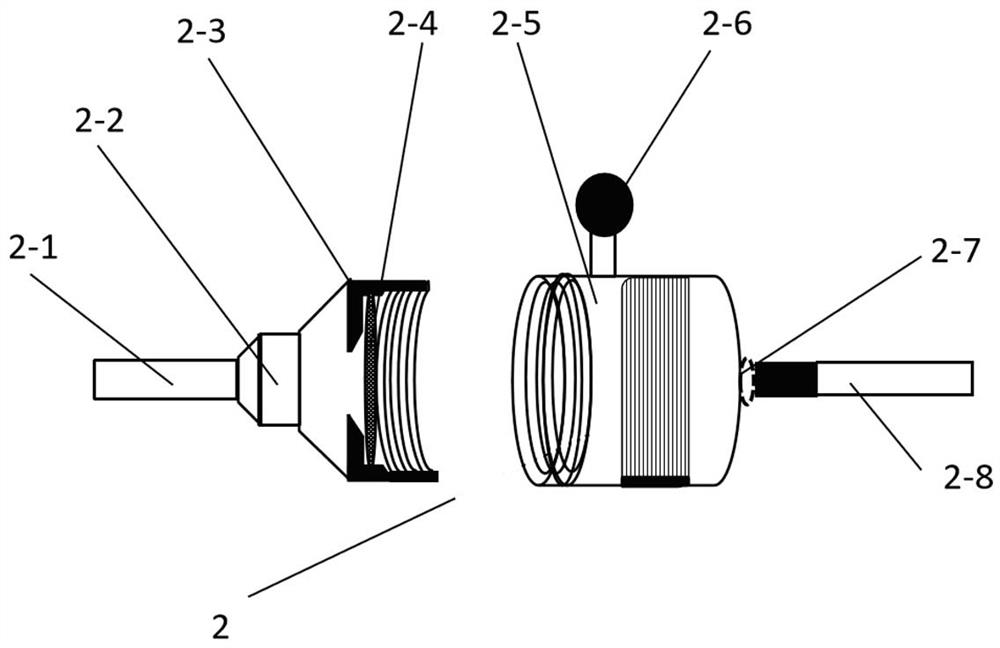

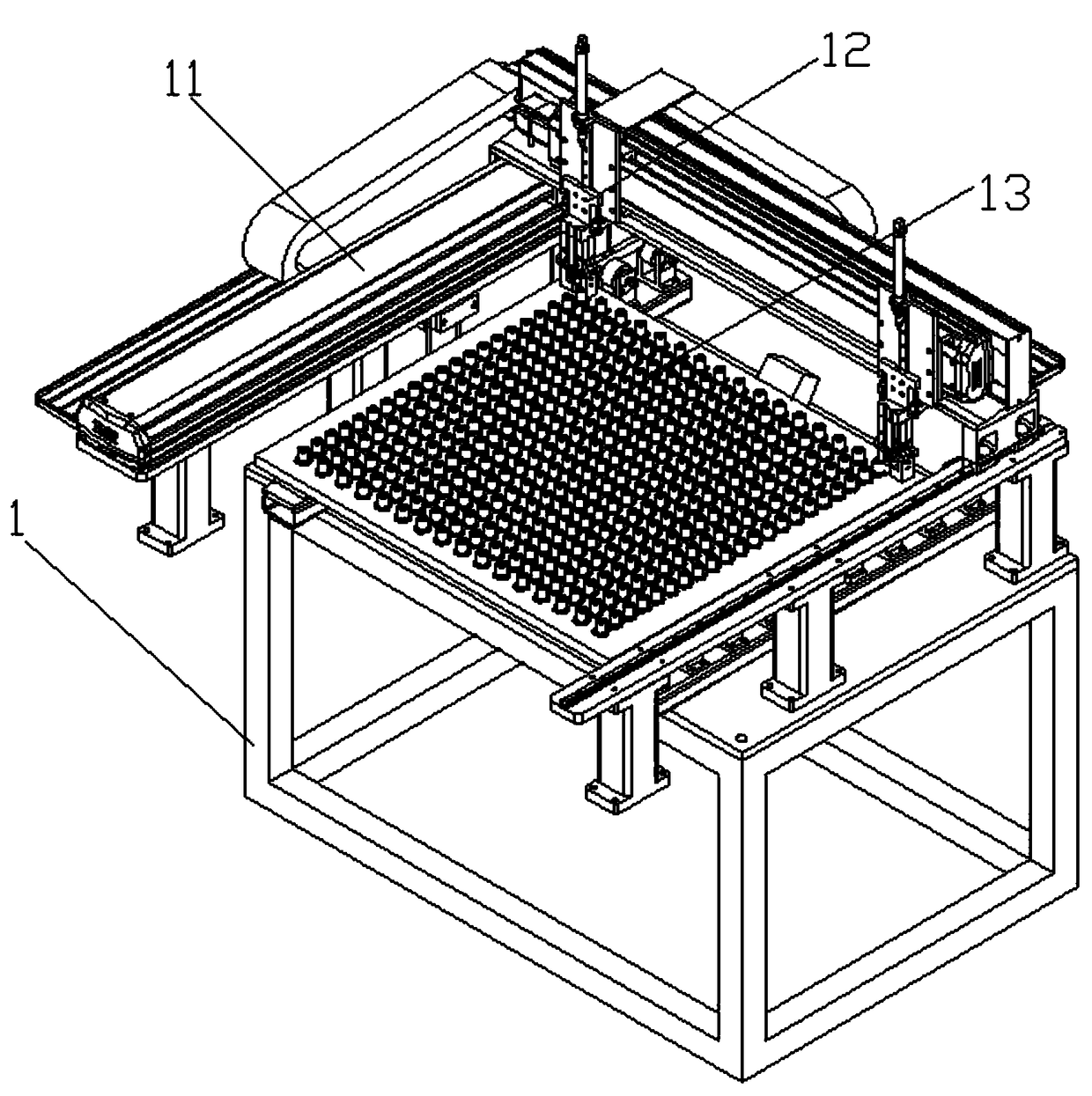

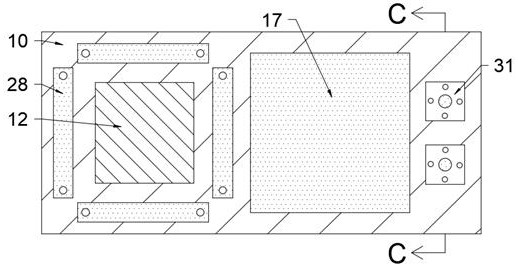

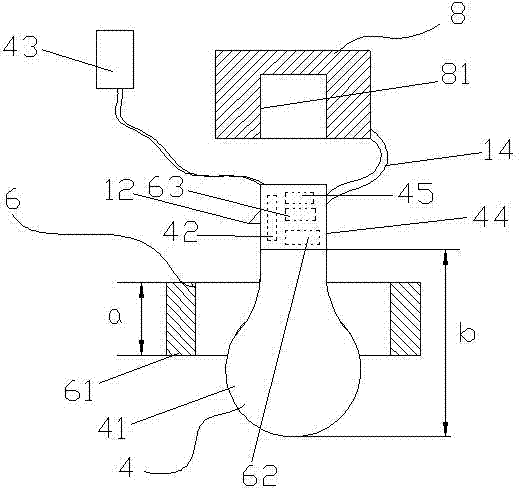

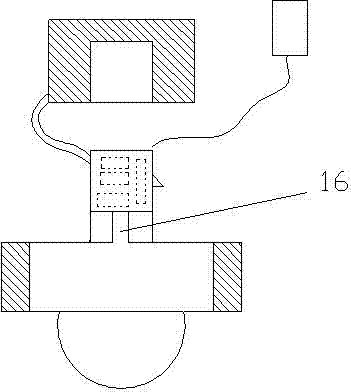

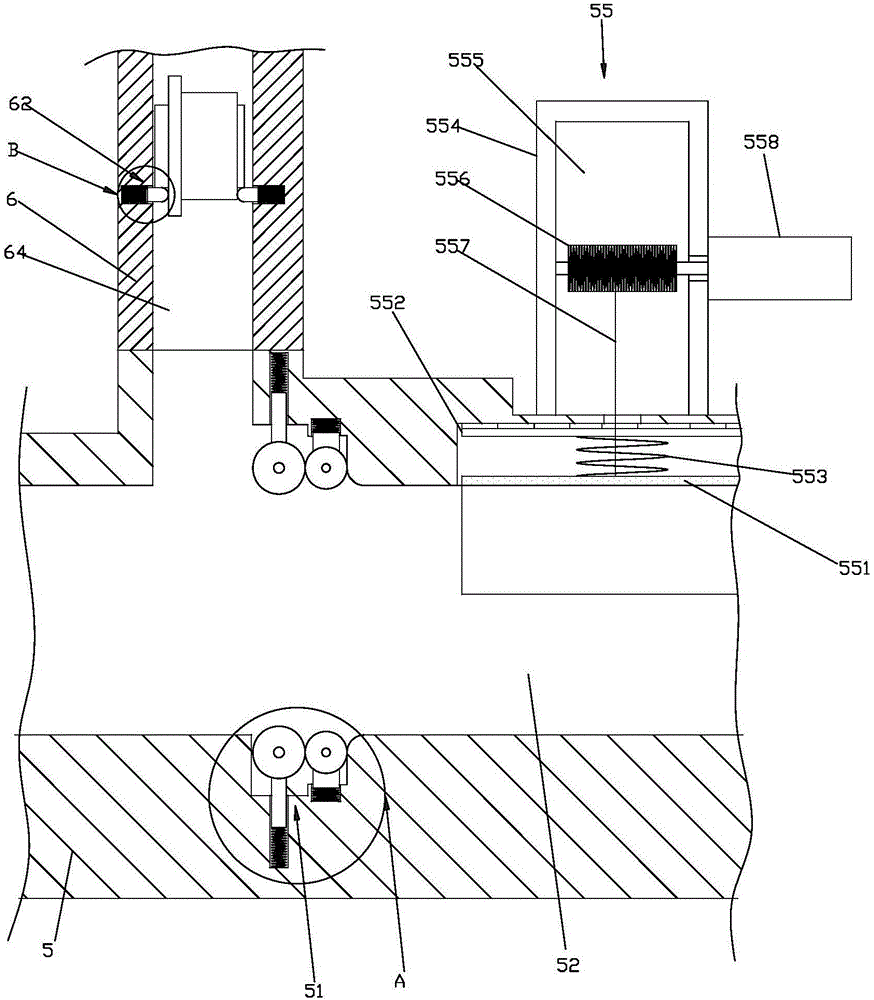

Novel chip mounting head and chip mounting machine

ActiveCN104023482AAchieve absorptionRealize placementPrinted circuit assemblingControl theoryComputer hardware

The invention discloses a novel chip mounting head and a chip mounting machine. The novel chip mounting head comprises a vertical suction rod and a horizontal rotating motor for driving the suction rod to rotate in the horizontal direction. The horizontal rotating motor comprises a motor body and an output shaft, wherein the suction rod serves as the output shaft of the horizontal rotating motor, the suction rod can slide relative to the motor body in the vertical direction. The novel chip mounting head is simple in structure, high in speed and high in efficiency, and movable units are small in quality.

Owner:BEIJING TORCH CO LTD

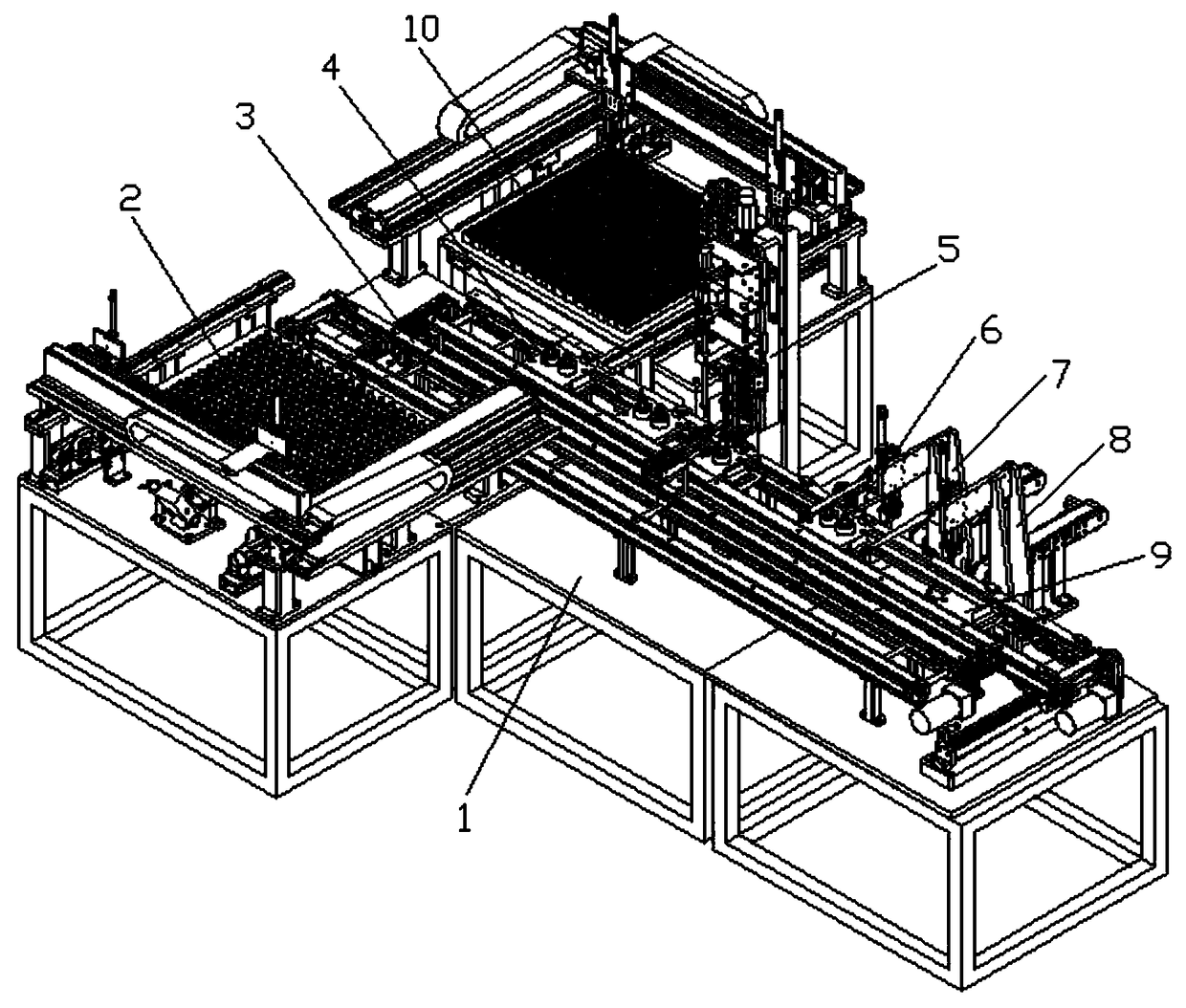

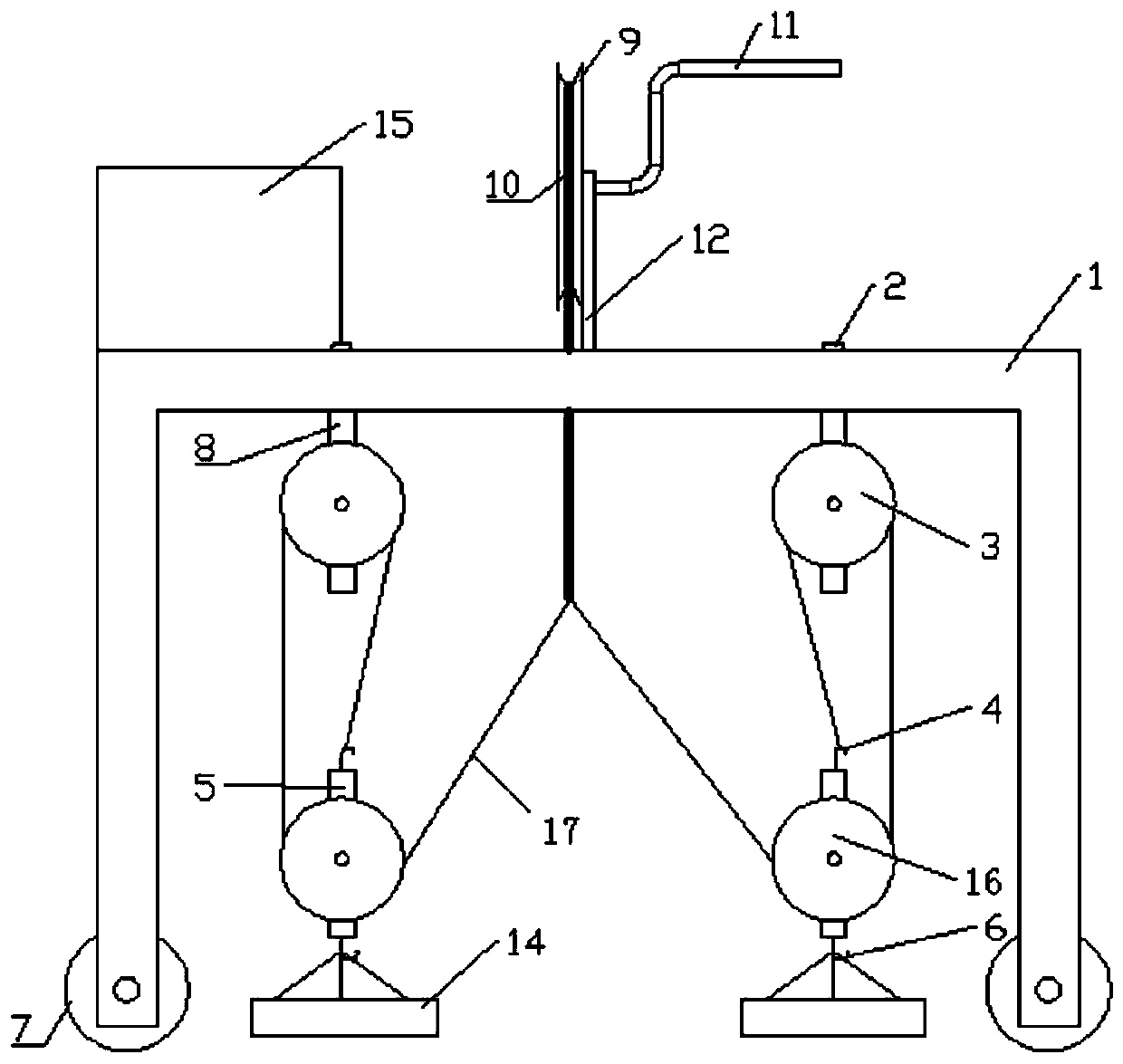

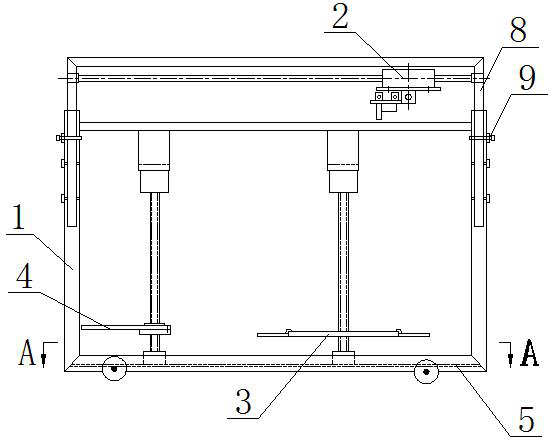

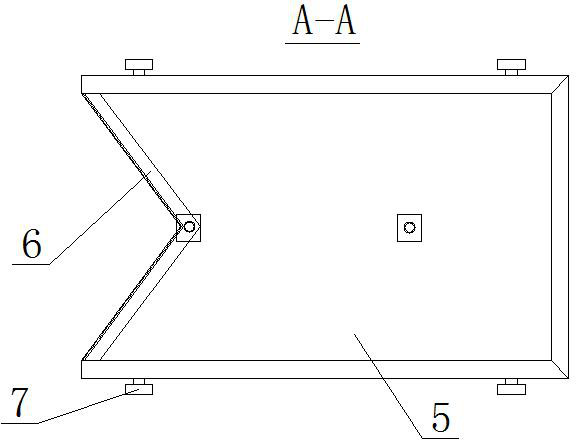

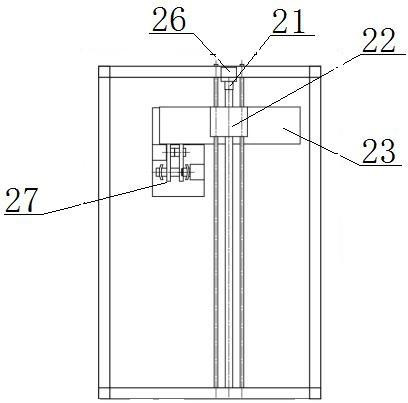

Placing and retracting device for road traffic cone

A placing and retracting device for a road traffic cone comprises a frame; a bucket taking device is arranged at the upper end of the frame; a bottom plate is arranged under the bucket taking device;the bottom plate is fixedly connected to the lower end of the frame; a cone bucket storage device and a bucket collecting device are arranged between the bottom plate and the bucket taking device; thebucket taking device is arranged at the edge of the frame; and the bucket taking device moves between the cone bucket storage device and the bucket collecting device in a reciprocating manner. According to the placing and retracting device for the road traffic cone, stretching, folding, placing and retracting of the road traffic cone can be realized, manual direct operation can be replaced, the working efficiency can be enhanced, and dangers of personal injuries in the case of normal passing of vehicles on expressways can be avoided.

Owner:江苏鼻豆科技有限公司

Packaging tool for logistics

The invention discloses a packaging tool for logistics. The packaging tool comprises a base, a cutting piece, suction cup components and a rotating device; a shell-shaped lower cutter is arranged on the upper surface of the base in a protruding manner; the shape of an inner cavity of the lower cutter is matched with that of a lower shell of a V-shaped cavity; the rotating device comprises a pedestal, a sleeve, a rotating shaft and two cantilever rods; the sleeve is rotationally arranged in the pedestal; the rotating shaft is a stepped shaft; the position, located in the sleeve, of the rotating shaft is provided with a fan-shaped sliding cavity; a positioning screw pin comprises a threaded section and a smooth pin shaft section; one end of each cantilever rod is provided with a suction cup component; and the suction cup component connected with the cantilever rod on the rotating shaft can transfer the cutting piece to the position over the inner cavity of the lower cutter. By means of the packaging tool, blanking and discharging of packaging skin during wrapping can be rapidly achieved.

Owner:运易通科技有限公司

Automatic laying device for anti-static raised floor

The invention discloses an automatic laying device for the anti-static raised floor. The device comprises a placement block, four steel frame placement cavities with downward openings are formed in the placement block in an annular array mode, and steel frame mounting mechanisms are arranged in the steel frame placement cavities. The steel frame mounting mechanisms are used for steel frame mounting. A floor placement cavity with upward and leftward openings is formed inside the placement block. A floor mounting mechanism is arranged inside the floor placement cavity. According to the anti-static floor laying device, anti-static floors can be automatically laid, the time of constructors is saved, construction is rapid, support installation is completed through the support installation mechanism, and positioning is accurate. The steel frame is mounted through the steel frame mounting mechanism, labor is saved greatly, the floor is placed through the floor mounting mechanism, and the placing process is stable and rapid.

Owner:温州根旭电子科技有限公司

Multifunctional operation platform for chemical experiments

The invention discloses a multifunctional operation platform for chemical experiments, which relates to the field of chemical experiment, including a platform, wherein landing lags are fixedly connected with four corners respectively at the bottom of the platform; a drainage trough is provided at the top of the platform; the drainage trough is arranged with an operating platform; the operating platform is fixedly connected with the platform; a fixing rod is fixedly connected with the top end of the platform; a first placing rack is fixedly connected with the top of the fixing rod, and the first placing rack is perforated with a lifting rack; a second placement rack is fixedly connected with the bottom of the lifting rack. The first placement rack is provided with a placement hole and a test tube. The multifunctional operation platform for the chemical experiments realizes the placement of test tubes and the heating of liquids in the container by setting the first, second and third shelves on the fixed rod, facilitates the discharge of liquids on the platform by setting the operating table and the drainage tank, and realizes all kinds of containers and articles for the chemical experiments by setting the placement device, which has the advantages of being easy to place and take, and occupying a small space, thereby making the chemical experiment very convenient.

Owner:杨中乾

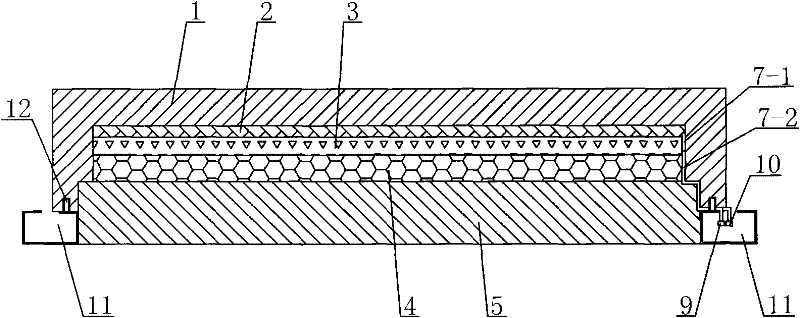

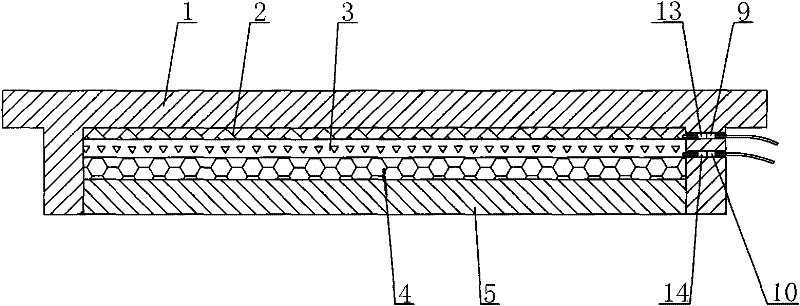

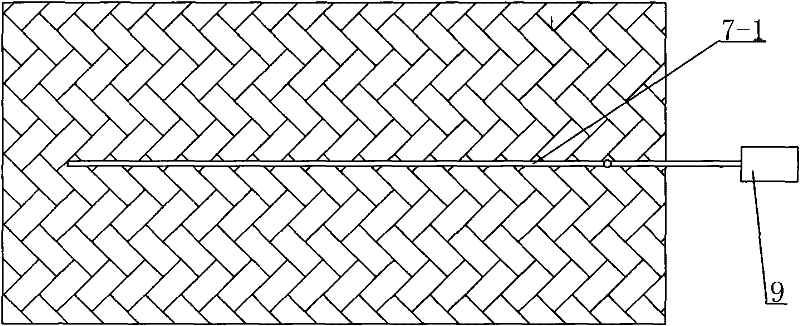

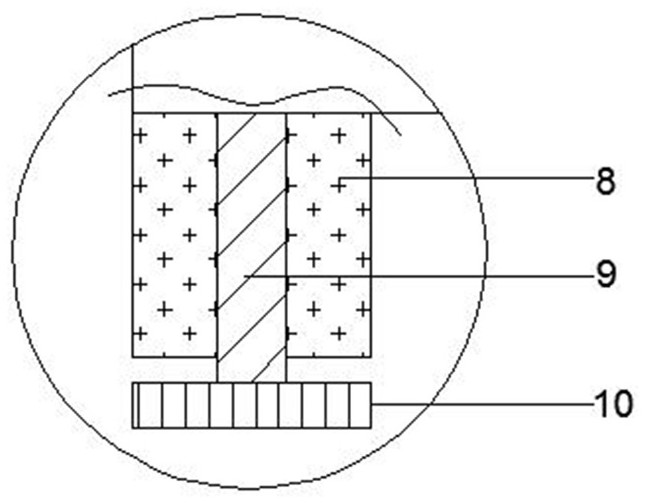

Low-carbon heating thermal-insulation floor tile

InactiveCN101799187BReasonable layoutReasonable structural designLighting and heating apparatusElectric heating systemThermal insulationEngineering

The invention discloses a low-carbon heating thermal-insulation floor tile comprising a surface plate layer with an inverted concave shape or a phi shape, and an anti-static anti-interference layer, an electric heating layer and a thermal-insulation material layer which are filled in the surface plate layer in sequence, wherein the middle part of the anti-static anti-interference layer is provided with an anti-static metal conducting wire; one end of the anti-static metal conducting wire is connected with an anti-static metal plug; the left side and the right side of the electric heating layer are symmetrically provided with electrode copper sheets; one end of each electrode copper sheet, being near the anti-static metal plug, is connected with a temperature-resistance waterproof power lead; one end of the temperature-resistance waterproof power lead, being near the electrode copper sheets, is provided with a temperature switch, and the other end is connected with a waterproof seal power plug; the waterproof seal power plug and the anti-static metal plug are led out of the surface plate layer or are respectively arranged in a small hole arranged at one side of the surface plate layer; and the lower part of the thermal-insulation material layer is provided with an inorganic material thermal-insulation seal layer connected with the thermal-insulation material layer. The invention has reasonable design, convenient and simple use, safety, reliability, no pollution, high temperature rise speed and good thermal-insulation effect.

Owner:段小龙

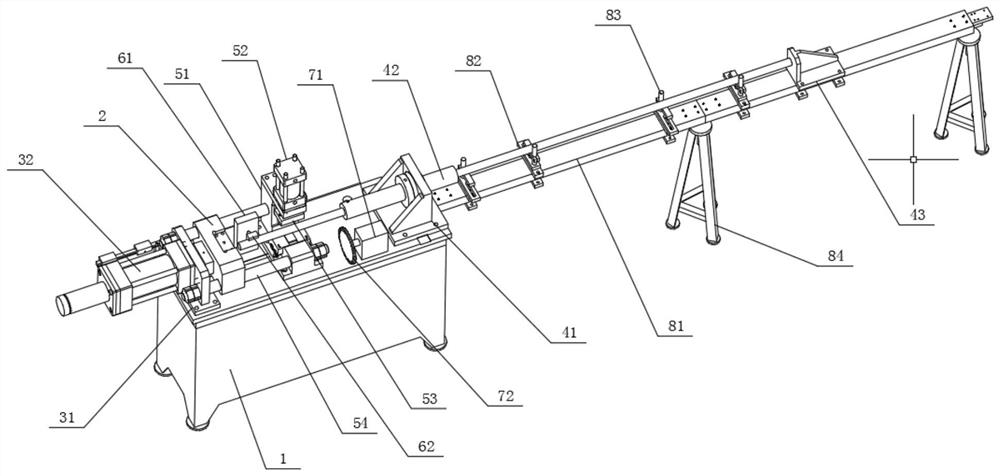

Brand-new automatic pipe shrinking machine

ActiveCN112589183AAvoid misalignmentAvoid deformationMetal-working feeding devicesTube shearing machinesMachineWorkbench

The invention discloses a brand-new automatic pipe shrinking machine. The brand-new automatic pipe shrinking machine comprises a workbench, a pipe shrinking device arranged at the head end of the workbench and used for shrinking a cylindrical pipe, a driving assembly for driving the pipe shrinking device to move along the workbench, a guiding and fixing assembly arranged at the tail end of the workbench and a fixing and clamping assembly arranged in the middle of the workbench. The pipe is fixed through the guiding and fixing assembly and the fixing and clamping assembly, the necking process is conducted on the pipe through a necking device, front-back movement of the necking device is achieved through the driving assembly, the pipe is prevented from being dislocated with the necking device when taken down, and the purposes of avoiding deformation of a pipe opening and guaranteeing the machining quality of the pipe are achieved.

Owner:东台市冉丹机械制造有限公司

Winding roller placing method for degradable polymer film

InactiveCN113460759AImprove efficiency when windingRealize automatic feedingWebs handlingElectric machineEngineering

The invention discloses a winding roller placing method for a degradable polymer film. In the first step, placing equipment comprises a treatment box and a support fixedly mounted at the bottom of the treatment box, the support is provided with an upper roller mechanism, the treatment box is internally provided with a positioning mechanism, the outer surface of the treatment box is provided with an anti-wrinkling mechanism, the upper roller mechanism comprises a driving motor, a first air cylinder and a limiting box. According to the winding roller placing method for the degradable polymer film, the upper roller mechanism and an angle limiting unit are arranged, a driving motor is used for driving a driving rotating shaft to rotate, a lifting rotating shaft rotates along with the driving rotating shaft, a first air cylinder is matched to drive the limiting box to move, and the rotation between an arc plate and a first limiting plate and the rotation between the arc plate and a second limiting plate are matched; and automatic feeding of a winding roller is achieved, the rotating angle can be well limited, more accurate positioning and placing are achieved, and therefore the efficiency of film winding is improved.

Owner:余春庆

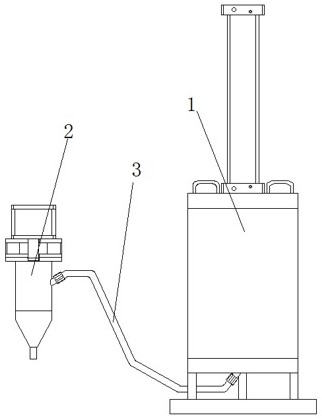

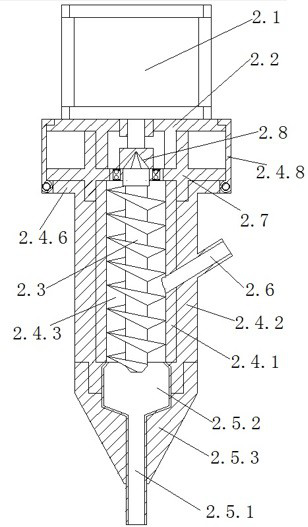

Feeding mechanism special for ceramic 3D printer

InactiveCN112497422AEasy to cleanMeet wire diameter requirementsAdditive manufacturing apparatusFeeding arrangmentsComputer printingElectric machinery

The invention belongs to a ceramic strengthening method, and particularly relates to a feeding mechanism special for a ceramic 3D printer. The feeding mechanism comprises a feeding barrel, a printinghead and a feeding hose, and the printing head comprises a conveying motor assembly, a conveying screw, a conveying pipe, a discharging head and a connecting seat; the conveying screw is rotatably connected with the axis position of the connecting seat, the top of the connecting seat is detachably connected with the conveying motor assembly, the top of the conveying pipe is detachably connected with the connecting seat, the discharging head is detachably connected with the bottom of the conveying pipe, and a feeding port is formed in the side face of the conveying pipe; and the feeding barrelcomprises a mud pressing plate, a base, a barrel body and a top cover with an air cylinder, the top cover and the base are detachably connected with the barrel body, and the mud pressing plate is arranged in the barrel body and detachably connected with a push rod of the air cylinder. According to the technical scheme, the problems that in the prior art, a feeding mechanism is too closed and inconvenient to clean are solved, stable feeding conditions and a reliable printing basis are provided for the ceramic 3D printer, and the quality of ceramic green bodies can be ensured to the maximum extent.

Owner:康硕(德阳)智能制造有限公司

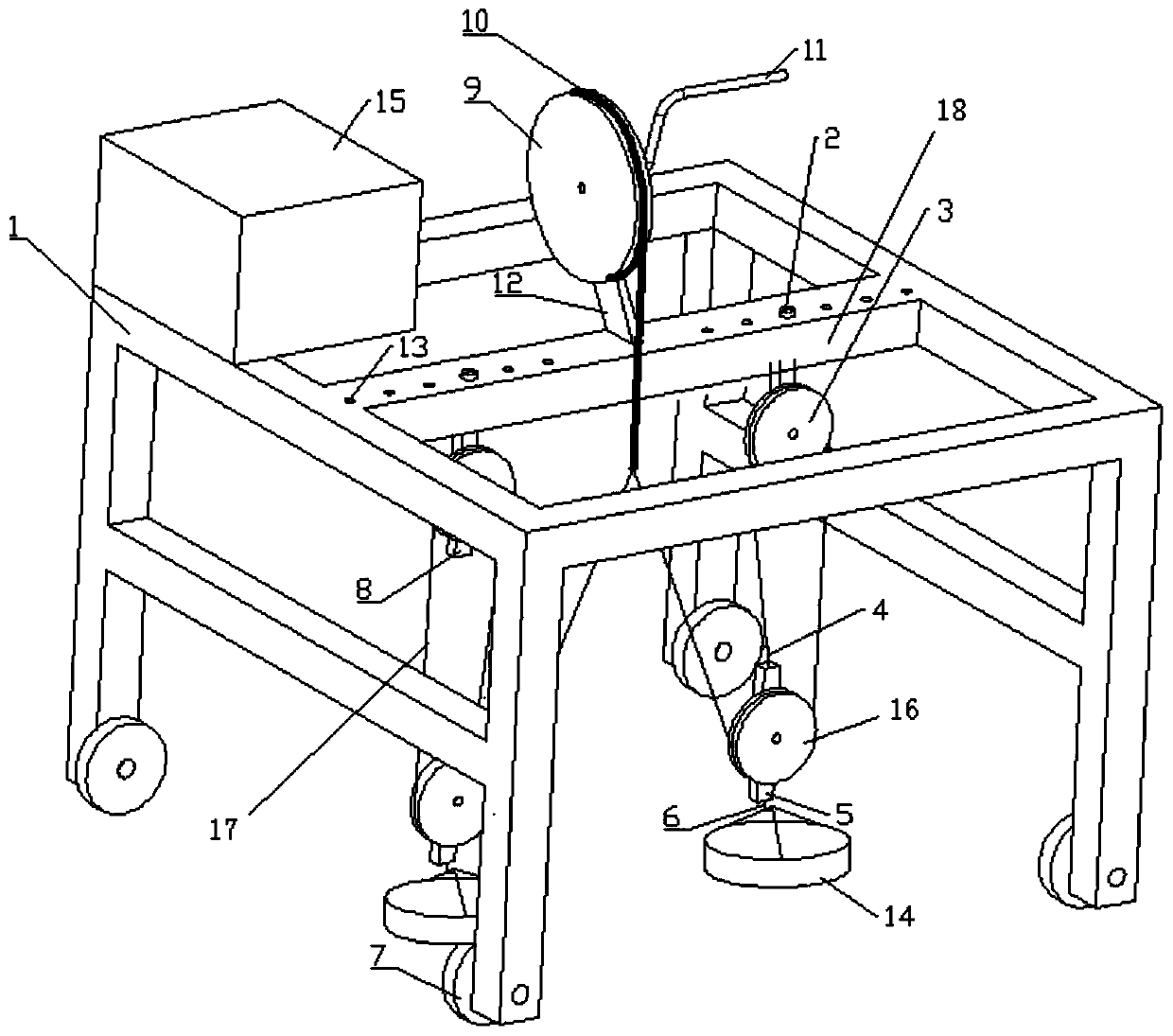

Manhole cover electromagnetism uncovering trolley

InactiveCN110817724ARealize placementSuction fastPortable liftingLoad-engaging elementsVehicle frameCrank

The invention discloses a manhole cover electromagnetism uncovering trolley. The manhole cover electromagnetism uncovering trolley comprises a trolley frame, four trolley wheels, an upper fixing block, a lower fixing block, a movable pulley, a fixed pulley, a traction main rope, a traction auxiliary rope, a rope coiling wheel, a fixing blot, an electromagnetic chuck and a power source, wherein thefour trolley wheels are fixed at bottoms of four supporting legs of the trolley frame, a cross beam horizontally arranged is fixed on the trolley frame, a supporting block is fixed in the middle of the cross beam, the rope coiling wheel is connected onto the supporting block through a middle shaft, the traction main rope is wound around the rope coiling wheel, and the lower end of the traction main rope is connected with a pulley block mechanism, and connected with the electromagnetic chuck through the pulley block mechanism. The manhole cover electromagnetism uncovering trolley drives a pulley block to perform transmission by shaking the rope coiling wheel through a crank handle, realizes the effect of sucking up and placing a manhole cover by utilizing rising and falling of the tractionmain rope, saves time and labor, cannot damage the manhole cover, and improves safety and stability of the manhole cover when the manhole cover is carried.

Owner:浙江音乐学院

Foldable lifting sunshade device for water entertainment vehicle

Owner:安徽长极机械工业科技有限公司

A chip mounter and a chip mounter

ActiveCN104023482BAchieve absorptionRealize placementPrinted circuit assemblingElectric machineEngineering

The invention discloses a new type of placement head and a placement machine, wherein the new type of placement head includes a vertically arranged suction rod and a horizontal rotating motor that drives the suction rod to rotate in the horizontal direction, and the horizontal rotating motor includes a motor body and an output shaft, wherein The suction rod is the output shaft of the horizontally rotating motor, and the suction rod can slide relative to the motor body in the vertical direction. The novel placement head of the invention has the advantages of simple structure, small mass of the moving unit, high speed and high efficiency.

Owner:BEIJING TORCH CO LTD

Self-cleaning lamp for spinning

InactiveCN103925520AEasy to cleanHigh speedLighting support devicesElectric circuit arrangementsEngineeringElectrical and Electronics engineering

The invention relates to a self-cleaning lamp for spinning. The self-cleaning lamp comprises a lamp body, and the lamp body comprises a bulb and an illuminating circuit device and a power supply which are electrically connected with the bulb. The self-cleaning lamp is characterized in that a bladless air fan is arranged on the periphery of the bulb; the bladless air fan comprises an annular member sleeving the periphery of the bulb and an air fan circuit device which is electrically connected to the annular member and the power supply. According to the self-cleaning lamp for spinning, by arranging the bladless air fan on the periphery of the bulb, air-force cleaning of the outer wall of the bulb can be implemented, cleaning effect is fine, speed is high, polishing scratches are avoided, and excellent illuminating quality is retained accordingly.

Owner:WUJIANG JIUMEI MICROFIBER WEAVING

Efficient equipment for pressing bearing into rear axle

The invention provides efficient equipment for pressing a bearing into a rear axle. The efficient equipment comprises a working platform, a placing seat, a supporting seat, a workpiece supplying seat, a workpiece transmitting barrel and a first air cylinder, wherein the placing seat is arranged on the surface of the working platform, and the surface of the placing seat is sunken inwards to form a placing groove; the supporting seat is arranged on the surface of the working platform and is positioned near the placing seat, and a bearing plate for supporting mounting plate in a horizontal direction is arranged on one side, close to the placing seat, of the supporting seat; the workpiece supplying seat is fixed on the working platform and is positioned on one side, far away from the placing seat, of the supporting seat; a workpiece outlet hole penetrating the workpiece supplying seat is formed in the workpiece supplying seat; the workpiece transmitting barrel is arranged at the top of the workpiece supplying seat, and a workpiece transmitting hole is formed in the workpiece transmitting barrel and is used for vertically placing a plurality of bearings; the workpiece transmitting hole is communicated with the workpiece outlet hole, and the center line of the workpiece transmitting hole is vertical to the center line of the workpiece outlet hole; the first air cylinder is arranged on the side face, far away from the workpiece supplying seat, of the workpiece supplying seat. The efficient equipment has the advantage of realizing the fact that the bearing is automatically pressed into an axle hole of the mounting plate under the premise of ensuring the automatic feeding of the bearing.

Owner:重庆越发机械制造有限公司

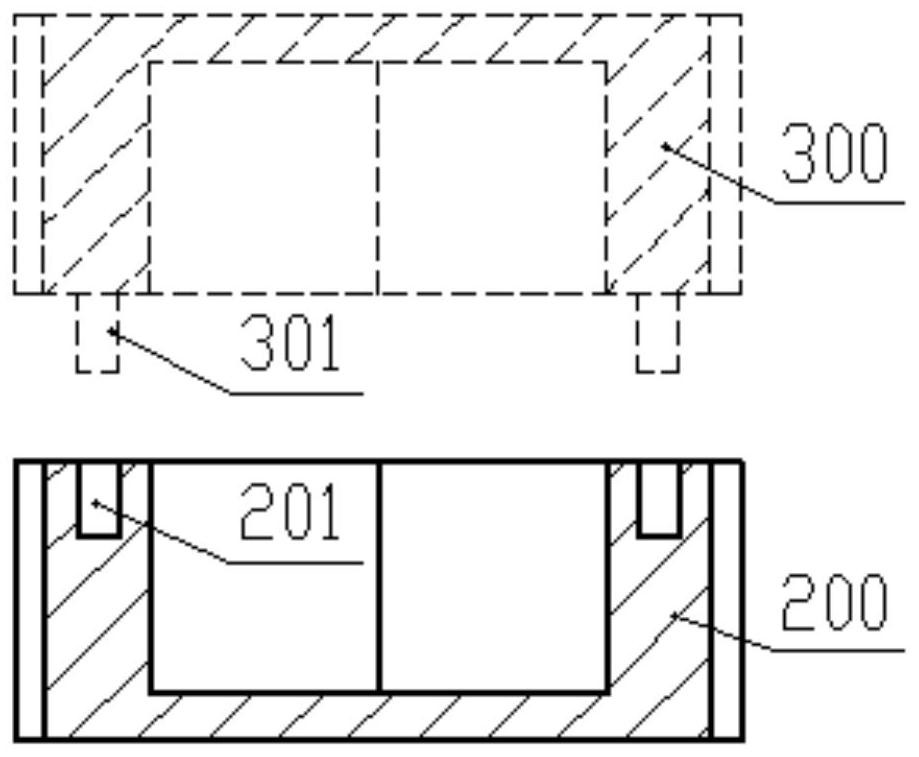

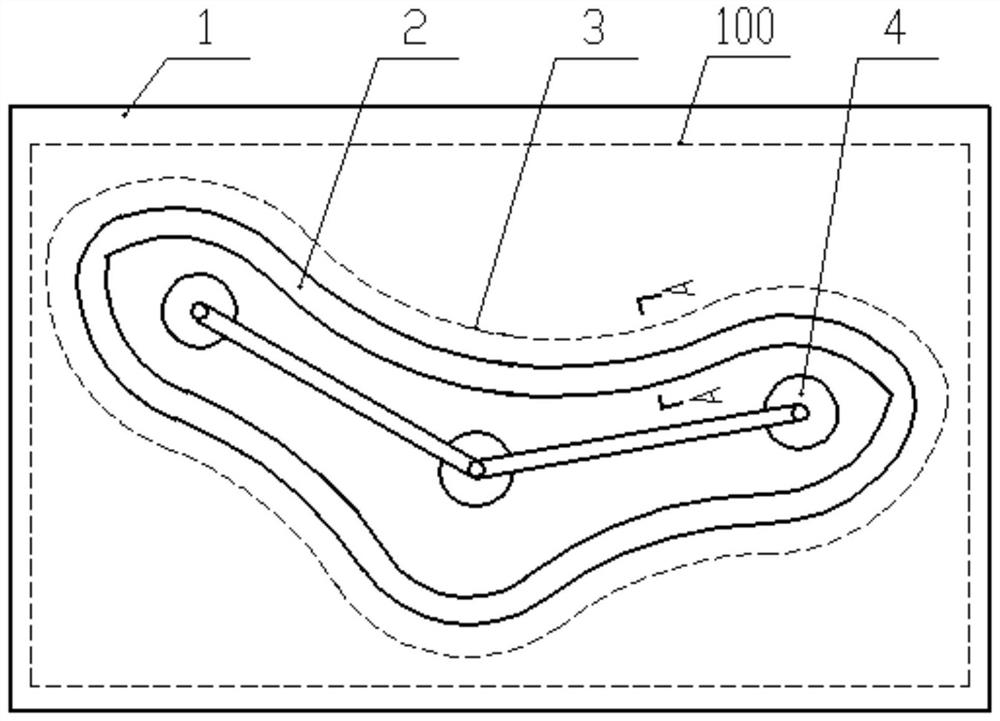

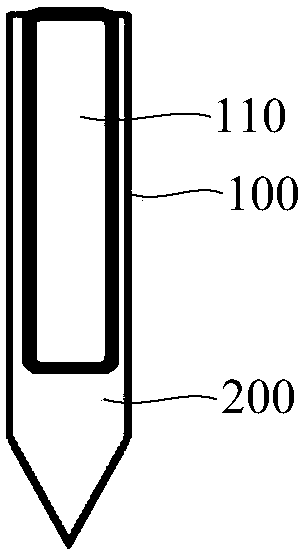

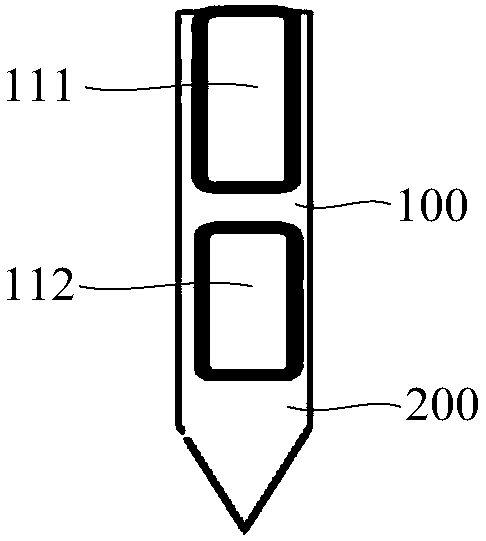

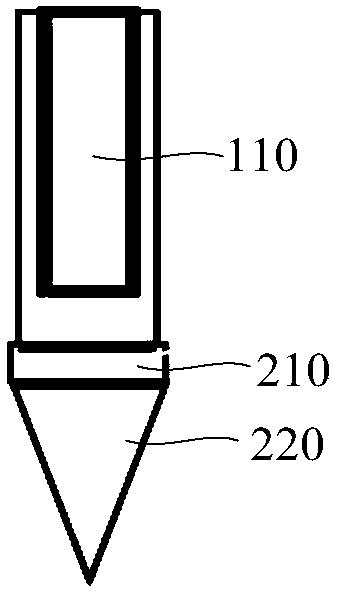

Planting carrier and planting method

The invention discloses a planting carrier, which comprises a bearing part (100) and a carrier insertion tip (200) fixedly connected with the bearing part (100). One end, with a larger cross section,of the carrier insertion tip (200) is fixedly connected with the bearing part (100); the bearing part (100) is provided with accommodating space (110) for accommodating a plant (a), a substrate (b) and soil (c); and the planting carrier is made of a degradable, soluble or mechanically crushed material. The above scheme can solve the problem of inconvenient planting caused as a thin film coats thesoil during a planting process at present. The invention also discloses a planting method.

Owner:吉林省一方水土贸易有限公司

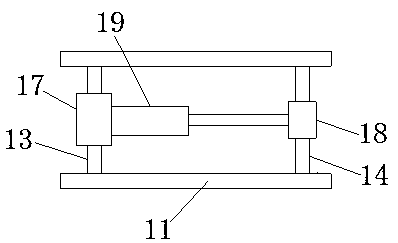

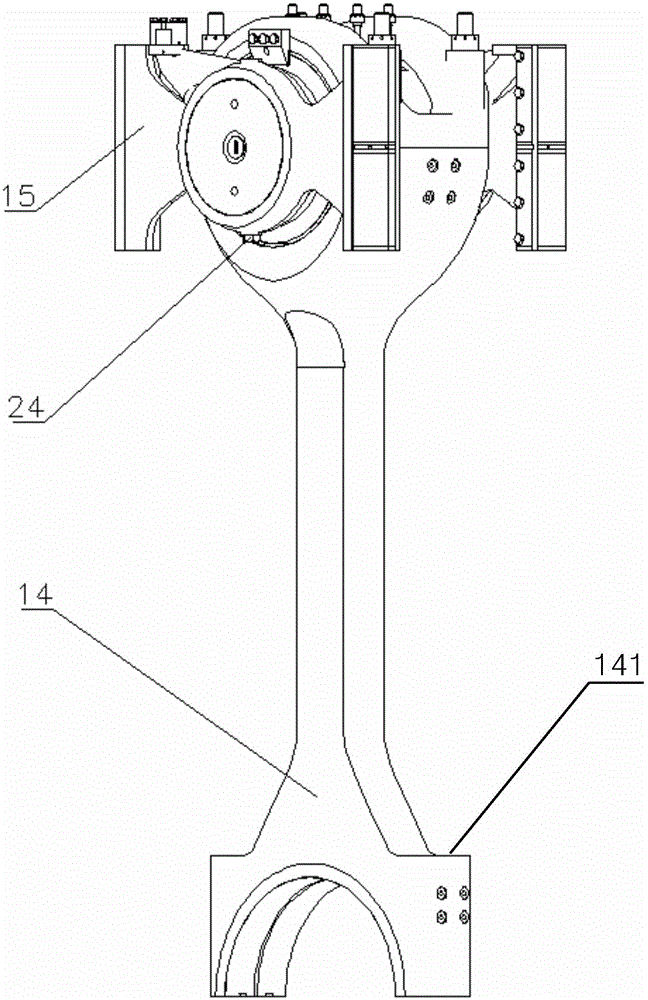

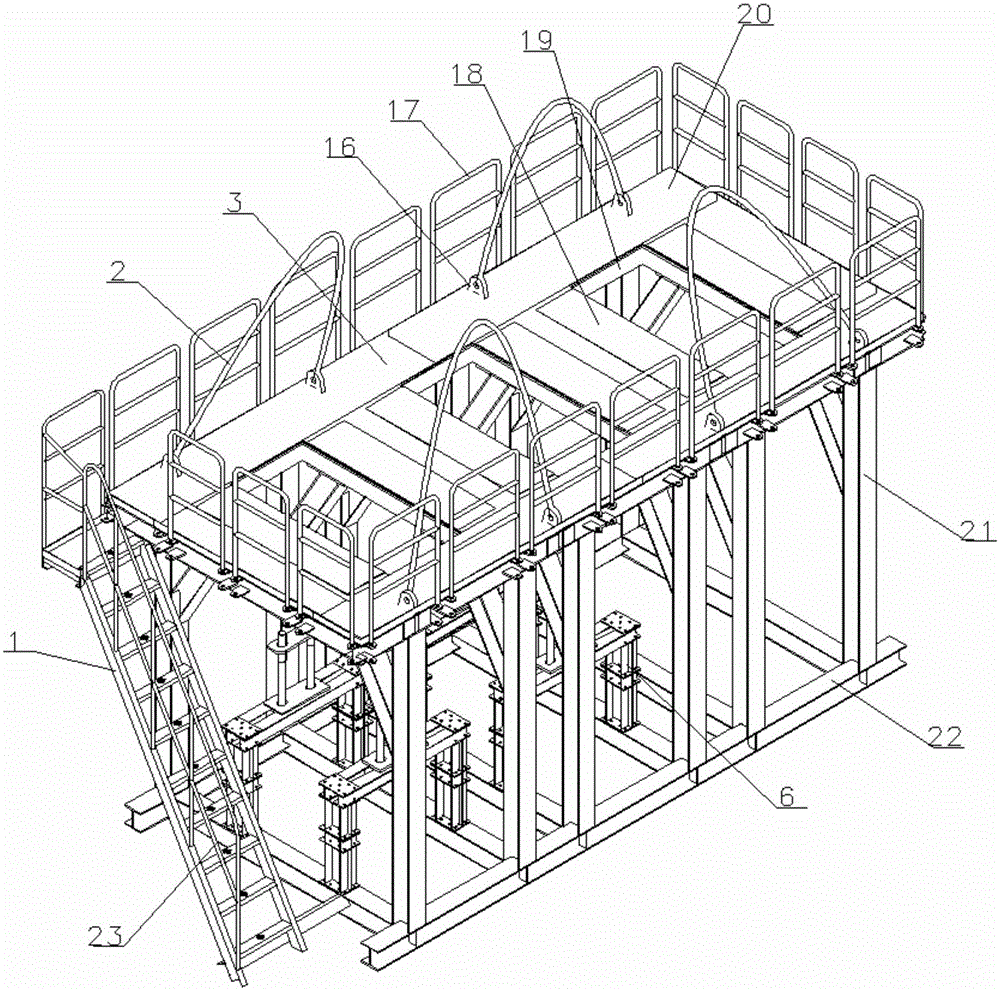

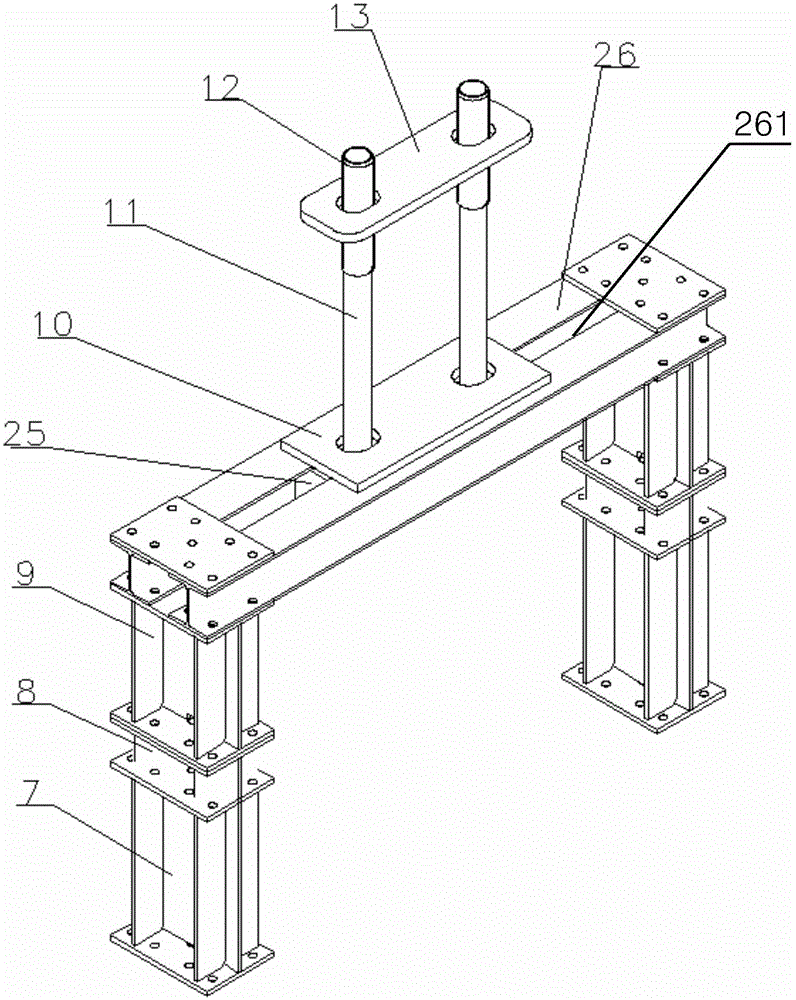

Operating device and method for connecting rod crosshead assembly of marine low-speed diesel engine

ActiveCN103600267BReduce waiting timeAvoid downtime waiting pit problemsWork benchesWork tools storageLow speedEngineering

Owner:CSSC MES DIESEL

A retractable device for road traffic cones

ActiveCN109555041BAchieve stretchAchieve foldingTraffic signalsRoad signsSimulationStructural engineering

A retractable device for road traffic cones, comprising a frame, the upper end of the frame is provided with a barrel taking device, the bottom of the barrel taking device is provided with a bottom plate, and the bottom plate is fixedly connected to the lower end of the frame; a cone barrel is arranged between the bottom plate and the barrel taking device The storage device and the barrel retracting device, the barrel taking device is set on the edge of the frame, and the barrel taking device makes a reciprocating movement between the cone barrel storage device and the barrel collecting device. This device can realize the stretching, folding, placing and retracting of the traffic cone. It replaces manual direct operation, improves work efficiency, and avoids the danger of personal injury when vehicles pass normally on the expressway.

Owner:江苏鼻豆科技有限公司

A garbage bag automatic loading and unloading machine

ActiveCN109649889BRealize placementHigh degree of automationRefuse receptaclesStructural engineeringBin bag

The invention discloses an automatic garbage bag loading and unloading machine, which comprises: a frame; a bracket, which is arranged on the upper end of the frame, a bag outlet is arranged in the middle, and two blades are arranged at the lower end of the bag outlet; a rotating shaft , which is erected on the bracket in a rotatable manner; the rotating shaft is used to install the continuous-roll garbage bag and release the garbage bag downward from the bag outlet through rotation; the suction cup seat plate, two suction cup seat plates are arranged in a relatively distributed left and right on the frame; the bag outlet is located between two suction cup base plates; each suction cup base plate is provided with at least two layers of suction cups from top to bottom; Between the two suction cup seat plates; all telescopic rods form a polygon surrounding the bag outlet. The invention can firstly release and stretch the garbage bag automatically, and then automatically place the stretched garbage bag in the garbage bin, so as to improve the automation degree of loading and placing the garbage bag in the garbage bin.

Owner:GUANGXI UNIV

Financial file folder taking-out device

PendingCN112869407ARealize placementRealize take outBook cabinetsFurniture partsStructural engineeringSliding contact

The invention discloses a financial file folder taking-out device which comprises a supporting bottom plate with the L-shaped section, limiting baffles are arranged on the two sides of the supporting bottom plate correspondingly, a plurality of file taking-out assemblies are evenly arranged on the inner bottom face of the supporting bottom plate, and a partition plate is detachably arranged between every two adjacent file taking-out assemblies; the file taking-out assembly comprises a shifting sliding groove formed in the supporting bottom plate, a supporting sliding base is arranged in the shifting sliding groove in a sliding mode, an L-shaped taking-out push plate is arranged on the supporting sliding base, a driving soft strip is connected to the bottom of the supporting sliding base, and the driving soft strip is in sliding contact with the inner wall of the shifting sliding groove. Driving pieces are fixedly connected to outer end of the driving soft strip, and adjusting holes are formed in the driving pieces. According to the invention, the structural design is reasonable, financial file folders can be rapidly placed and taken out, and great convenience is brought to financial staff to sort out the financial file folders.

Owner:JIANGSU MARITIME INST

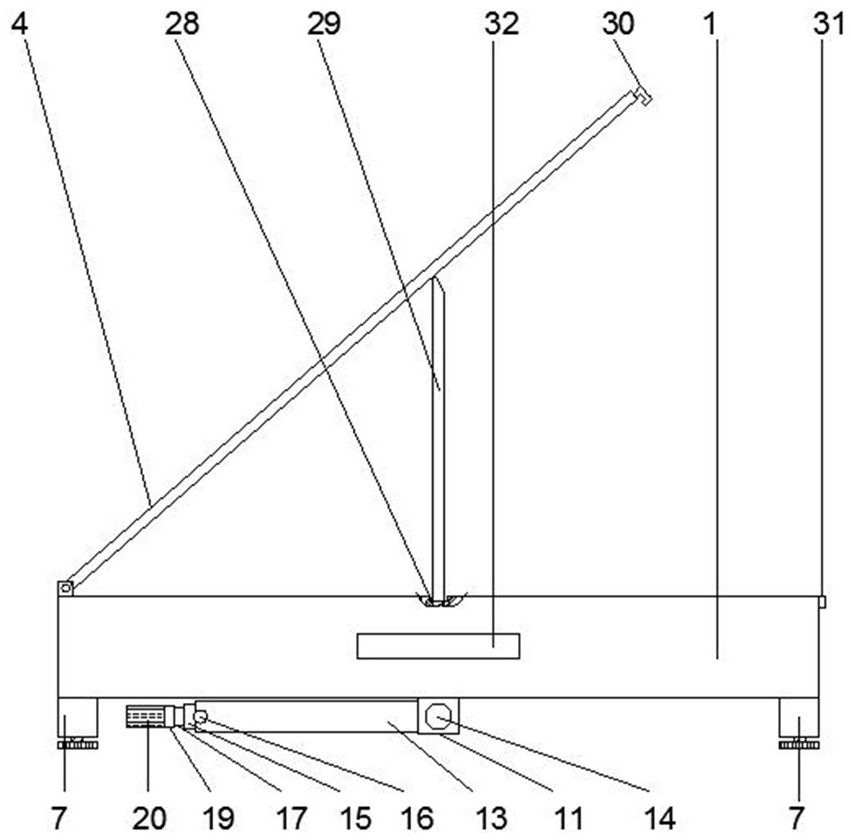

Art tool box convenient to carry

PendingCN112976915AToolbox stays steadyRealize placementOther artistic work equipmentsStructural engineeringDrawing board

The invention discloses an art tool box convenient to carry. The box comprises a box body, a drawing board, fine adjustment supporting legs and a first support, the front side of the upper end of the box body is rotatably connected with the front side of the drawing board, a limiting groove is formed in the middle of the upper end of the box body, and a supporting rod is arranged between the back face of the drawing board and the upper end of the limiting groove. The back surface of the drawing board is of an anti-skid rough structure. The tool box can be installed on the ground, the height of the box can be adjusted according to the height of a user, drawing can be directly conducted on the drawing board arranged on the box, specifically, after a sleeve is rotated to be perpendicular to the box body, the sleeve is fixed through a first fixing button, then a first telescopic pipe and a second telescopic pipe extend to the proper length, the first telescopic pipe and the second telescopic pipe are fixed through a second fixing button and a third fixing button respectively, then a second support is rotated to be perpendicular to the first support, the second support is fixed through a fourth fixing button, and therefore the tool box can be placed on the ground.

Owner:李英姿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com