Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Normal filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

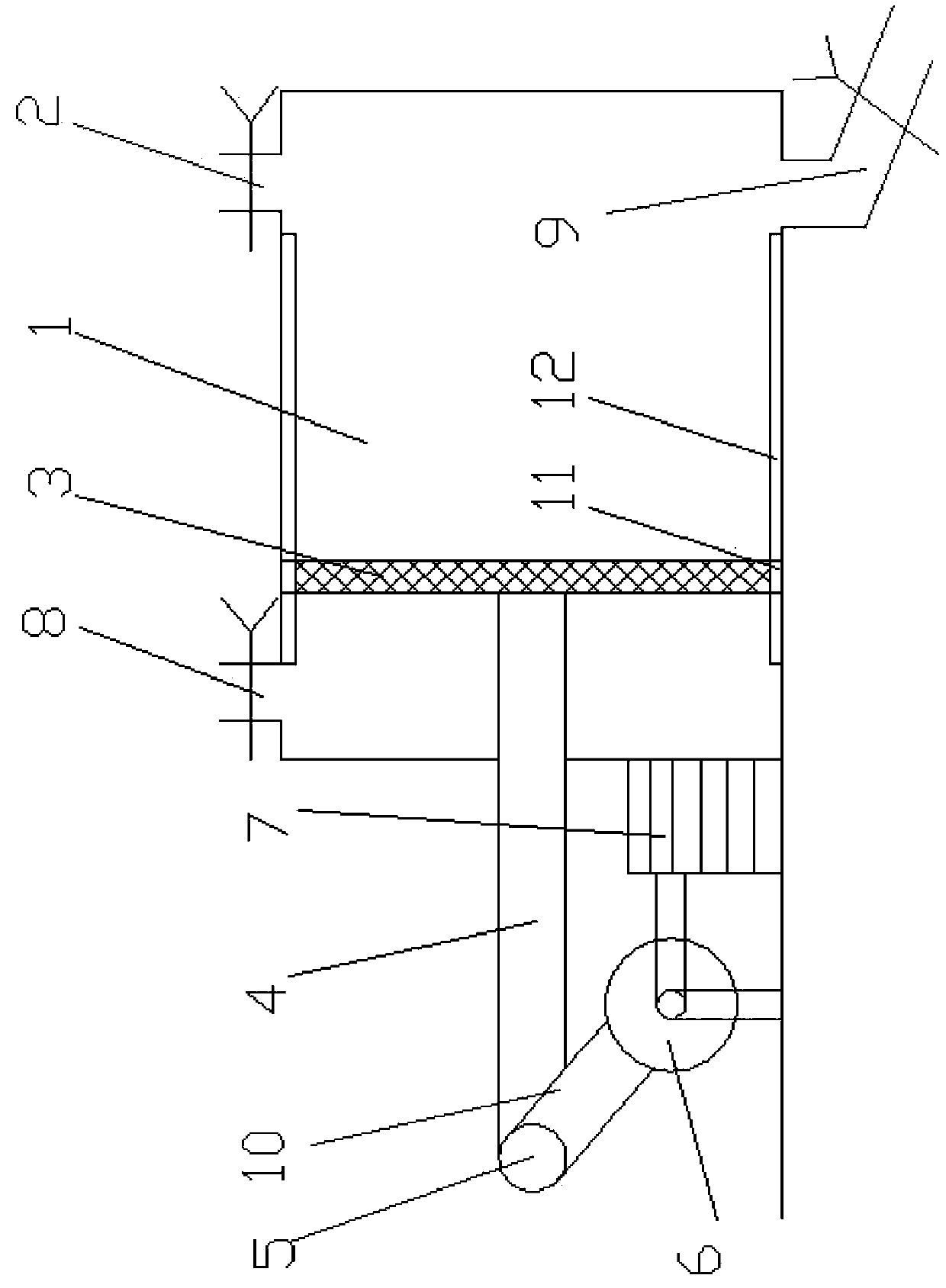

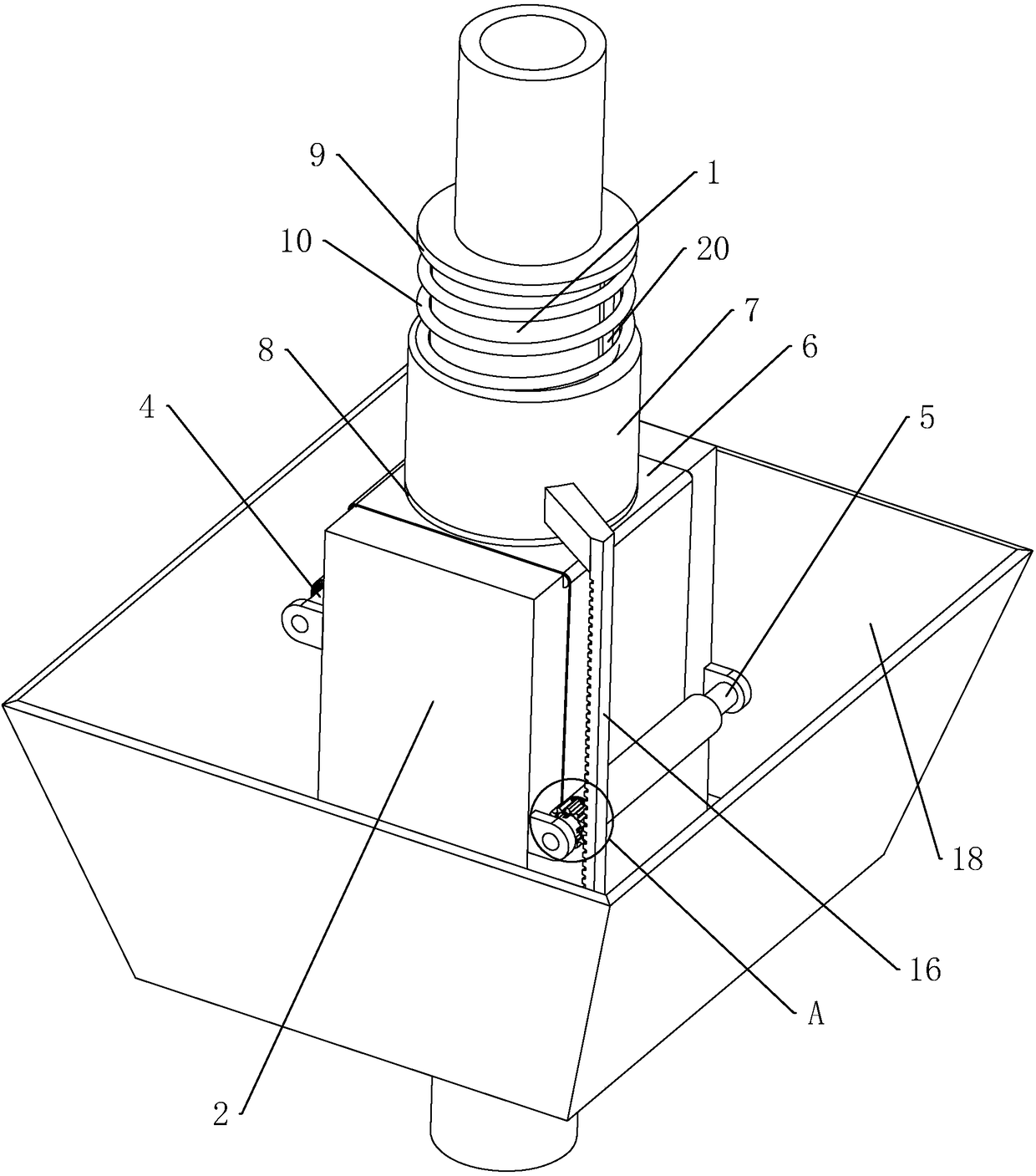

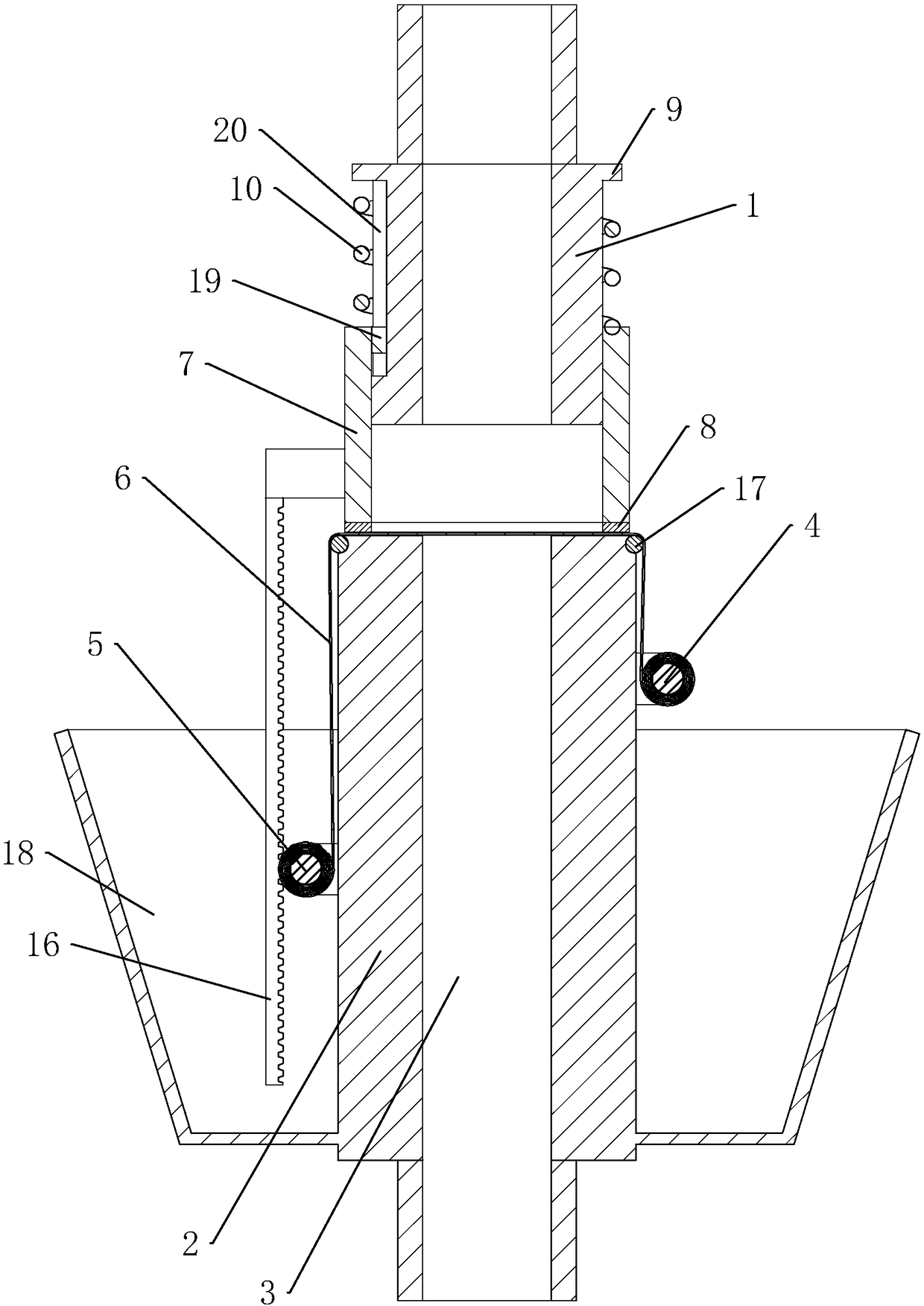

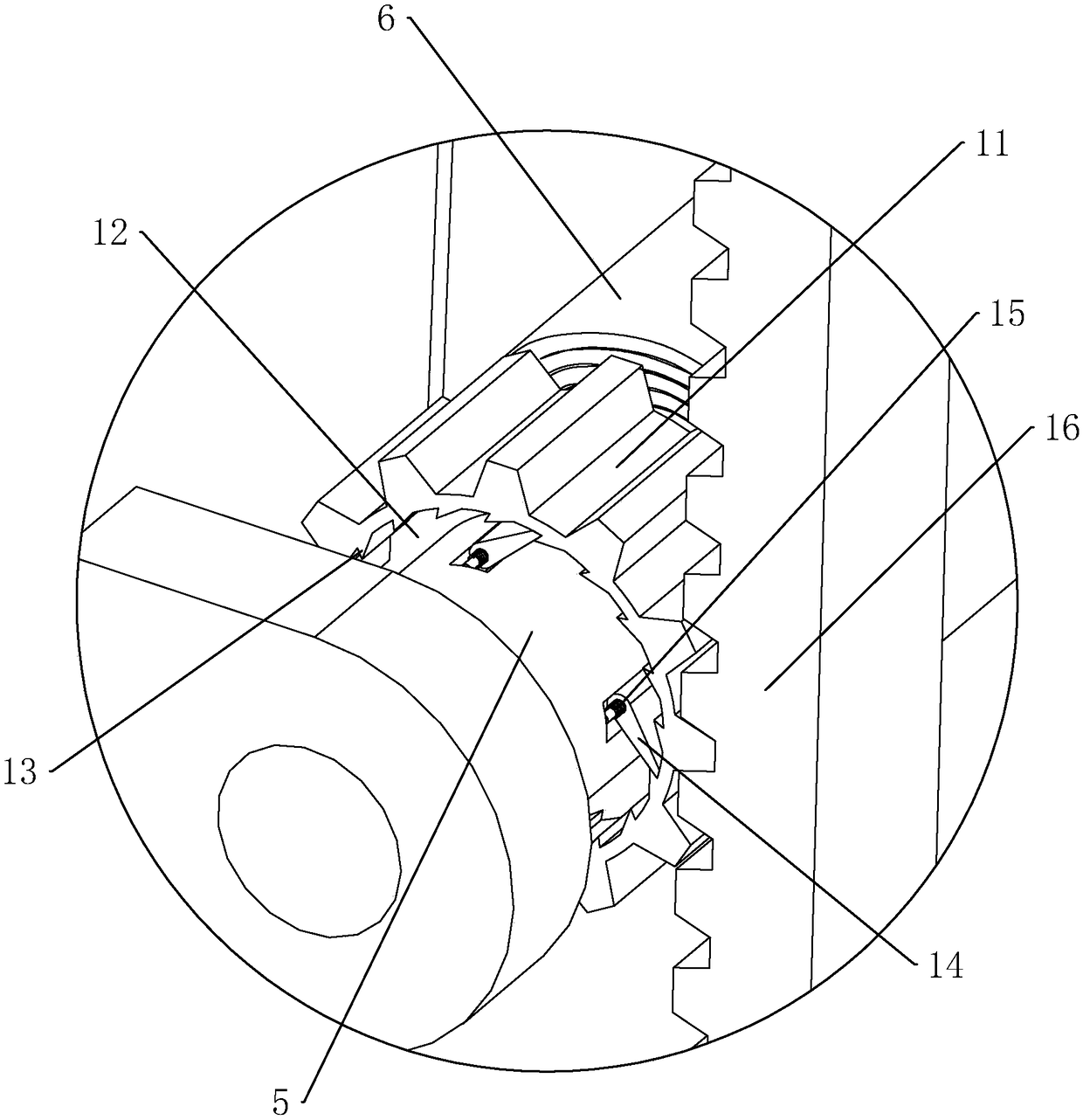

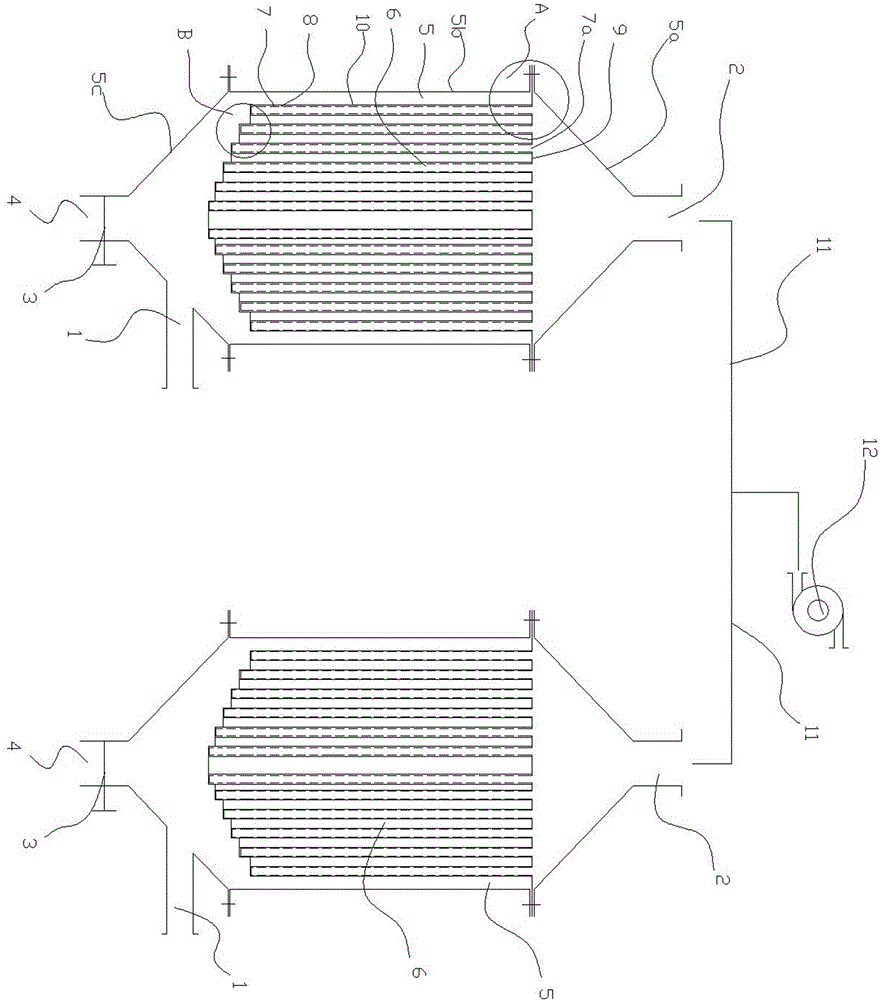

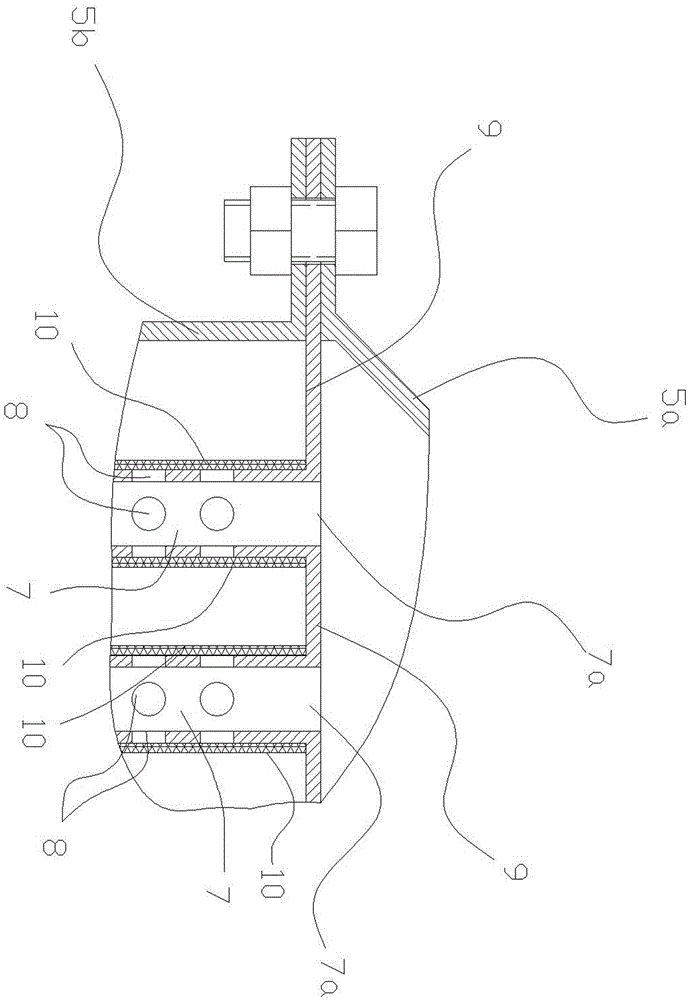

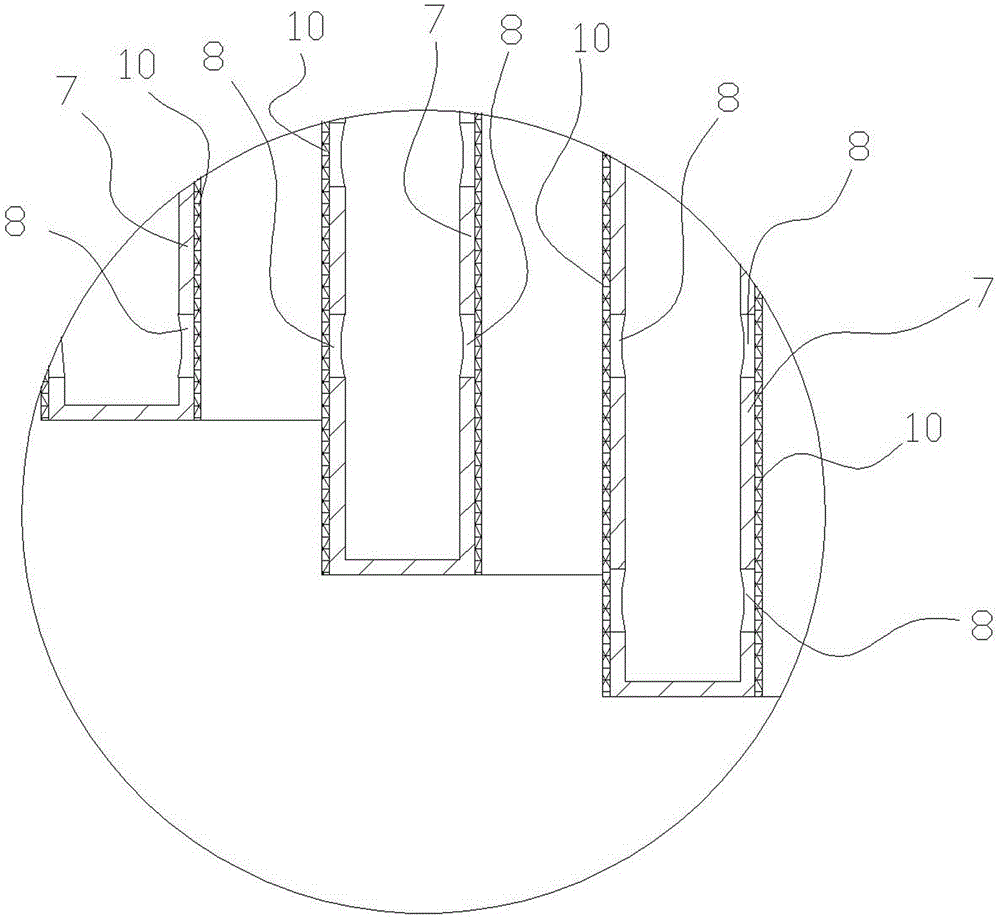

Wastewater filtering and purifying treatment device

ActiveCN108821475ANormal filterImprove filtration efficiencyTreatment involving filtrationMultistage water/sewage treatmentWastewaterEngineering

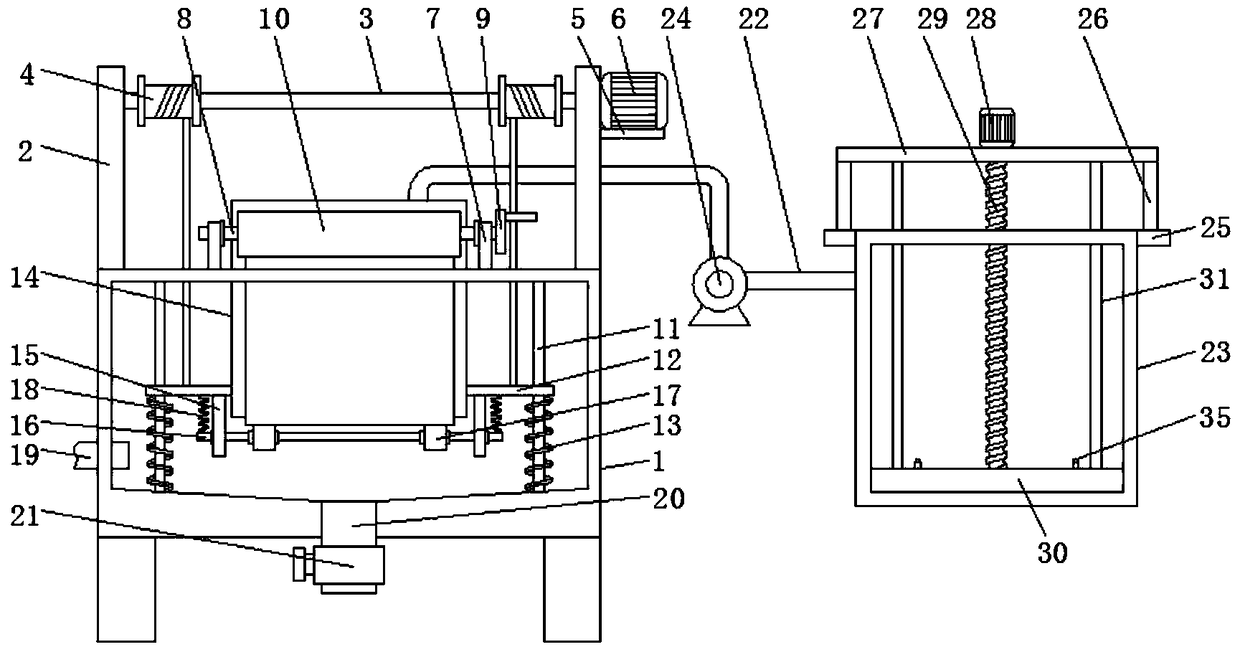

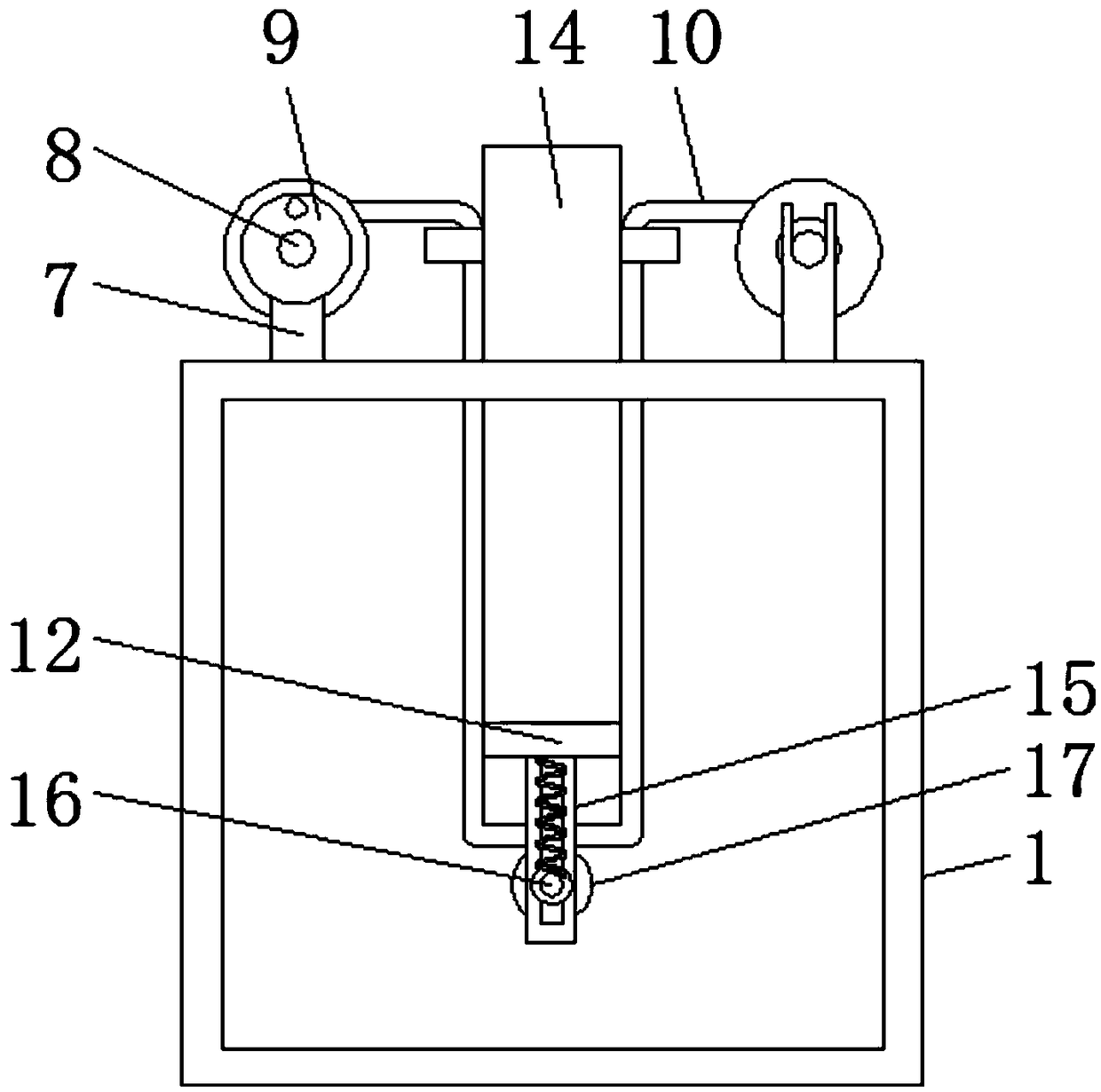

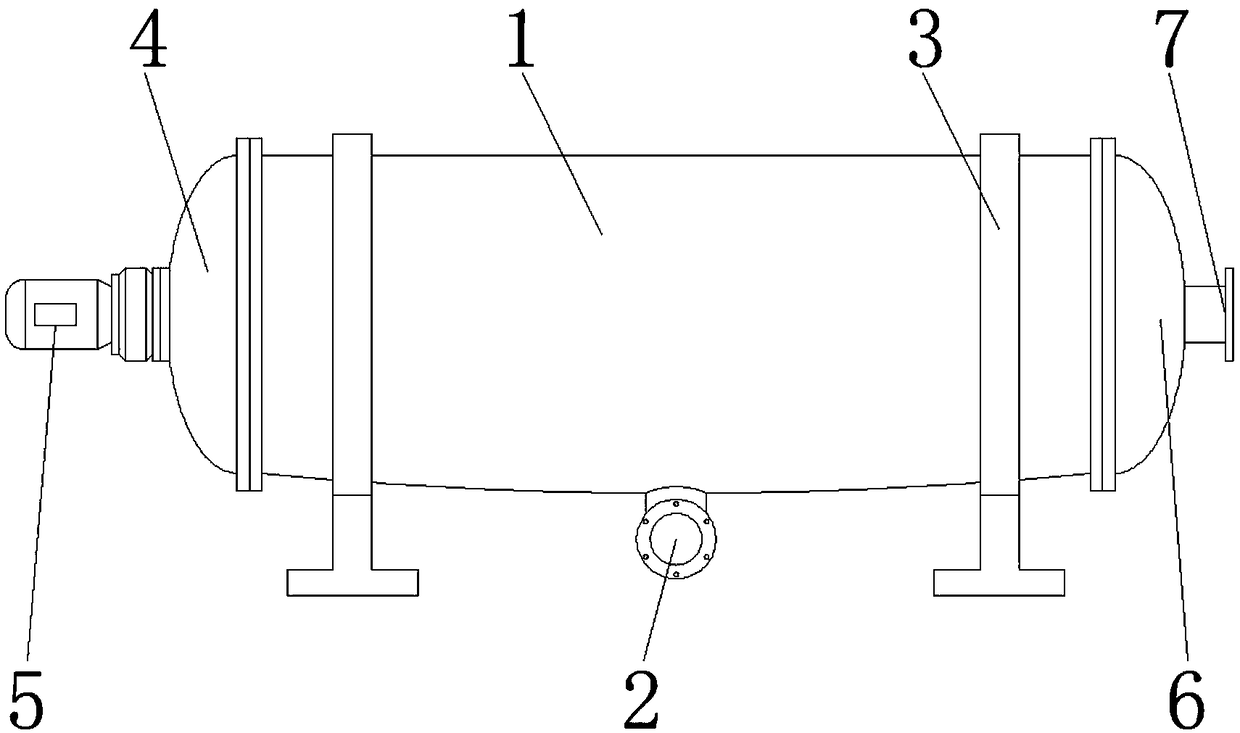

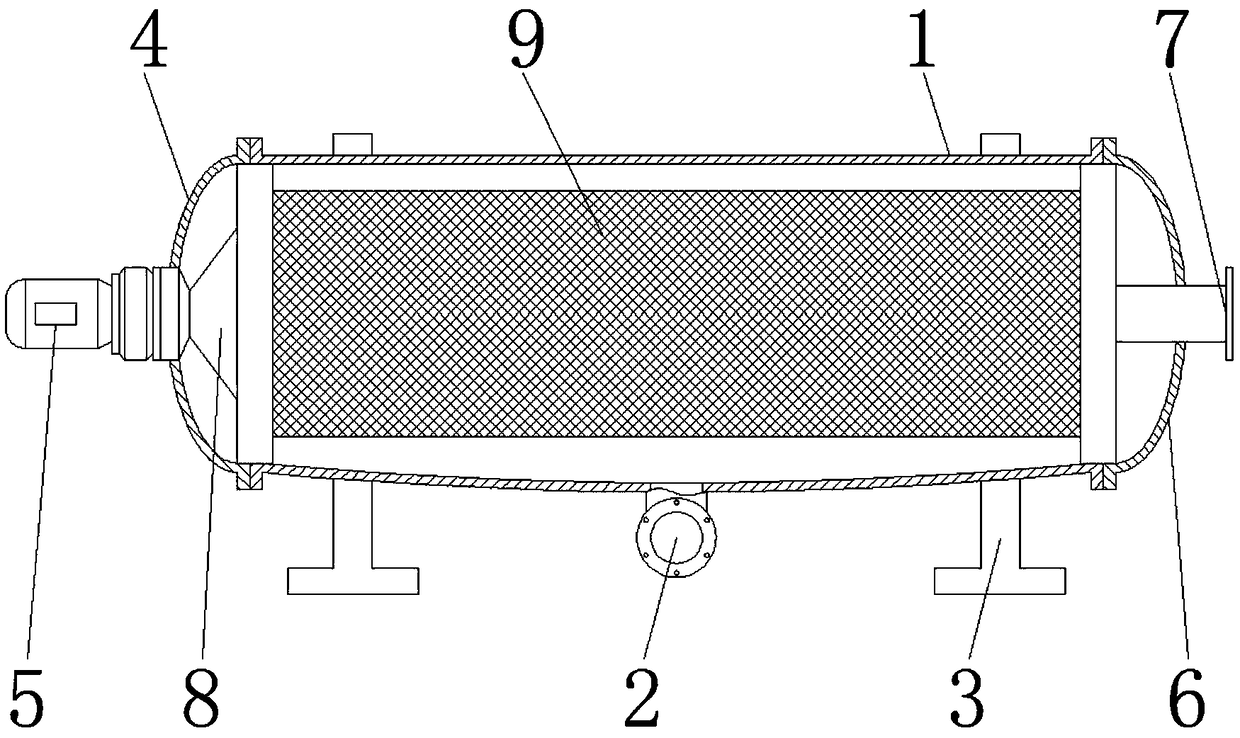

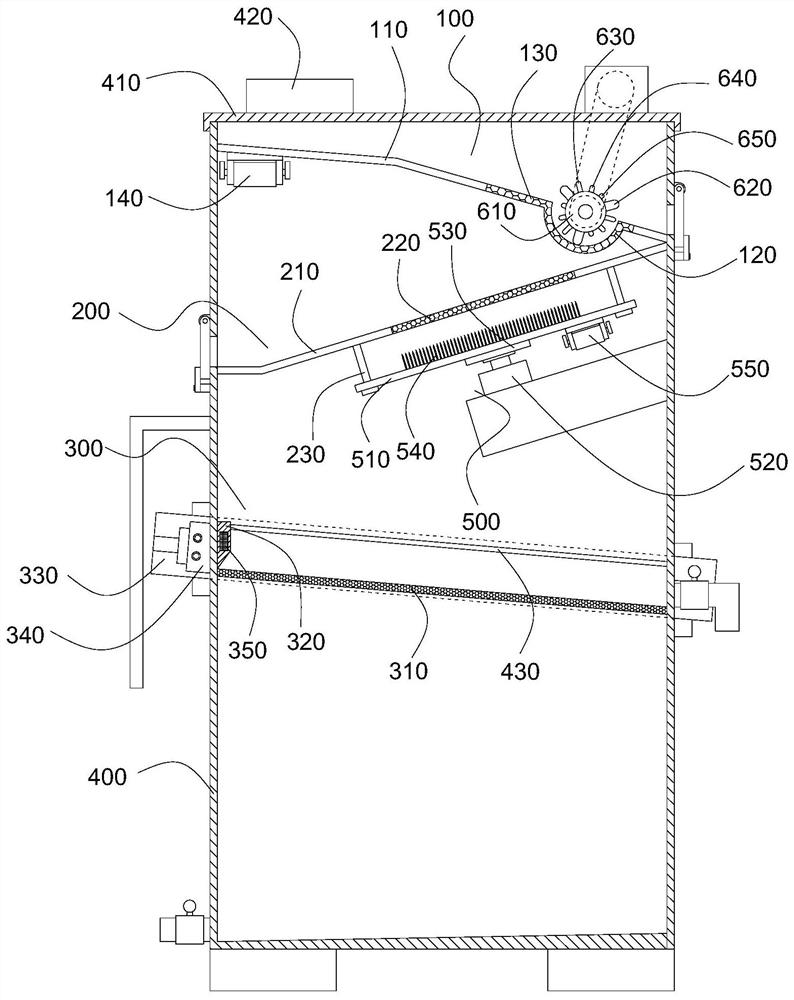

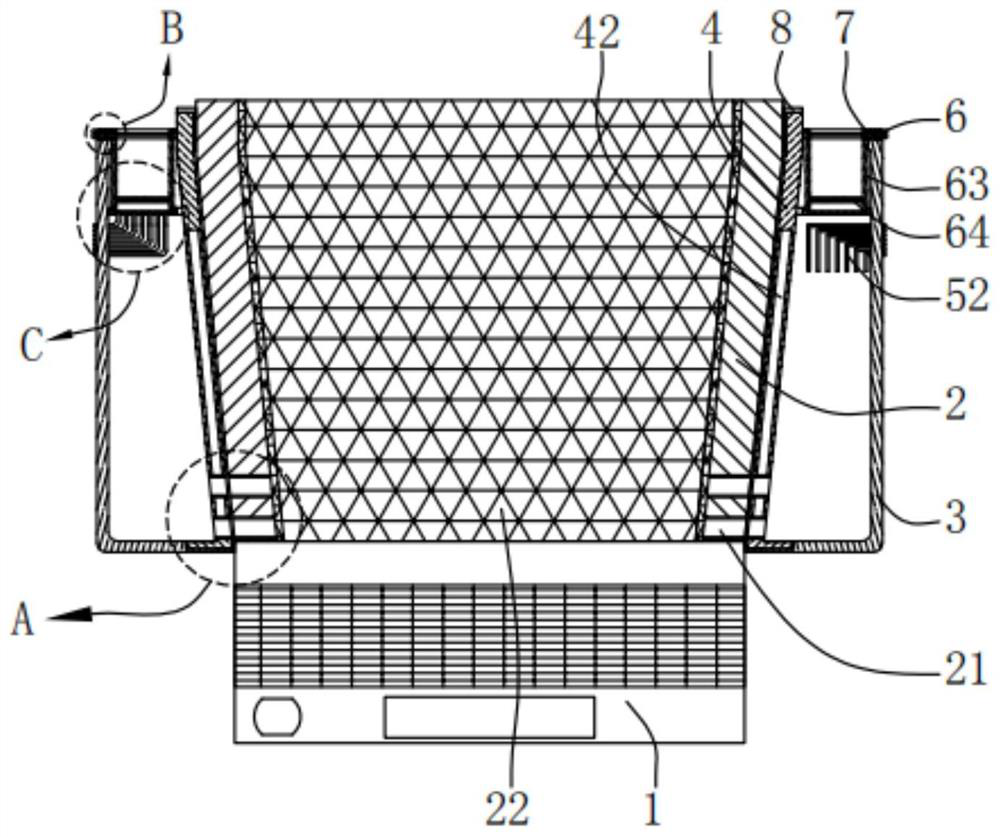

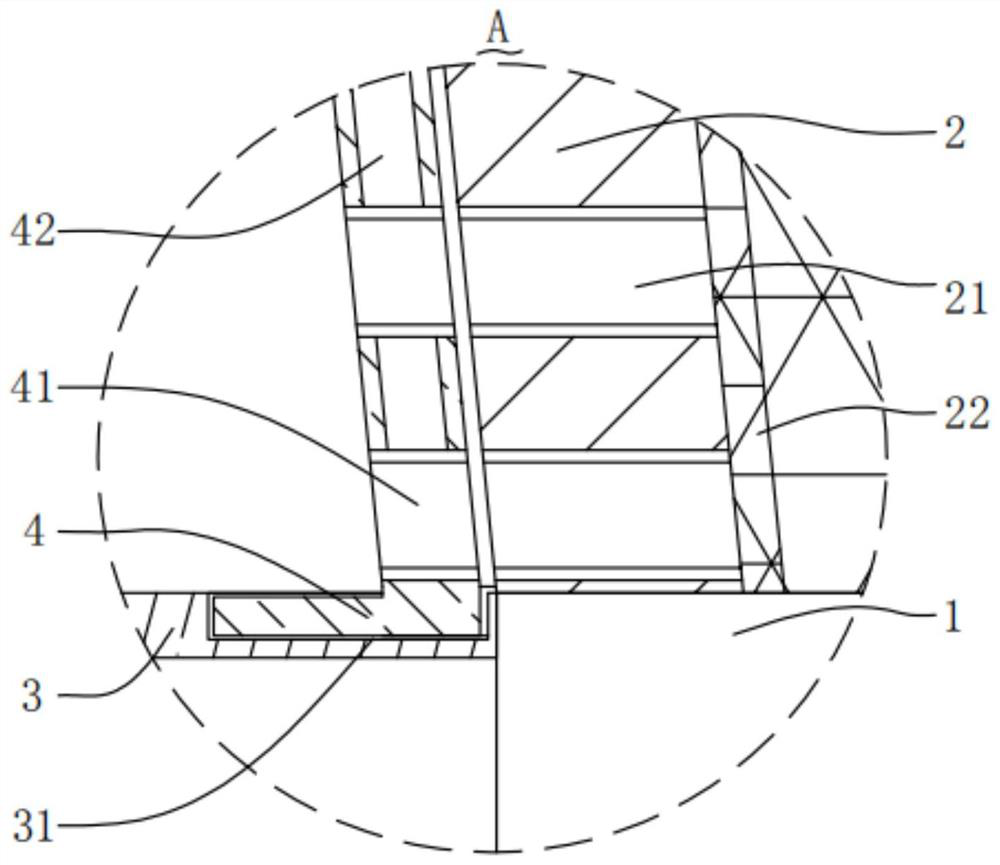

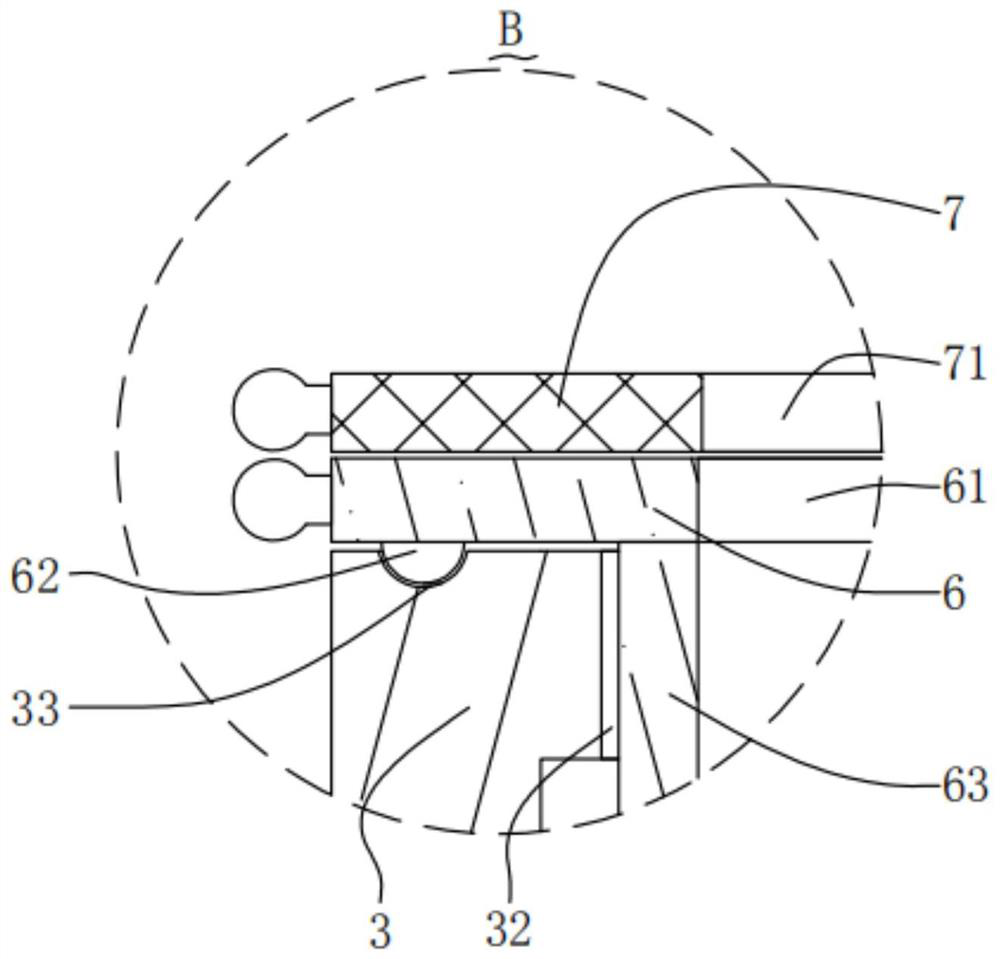

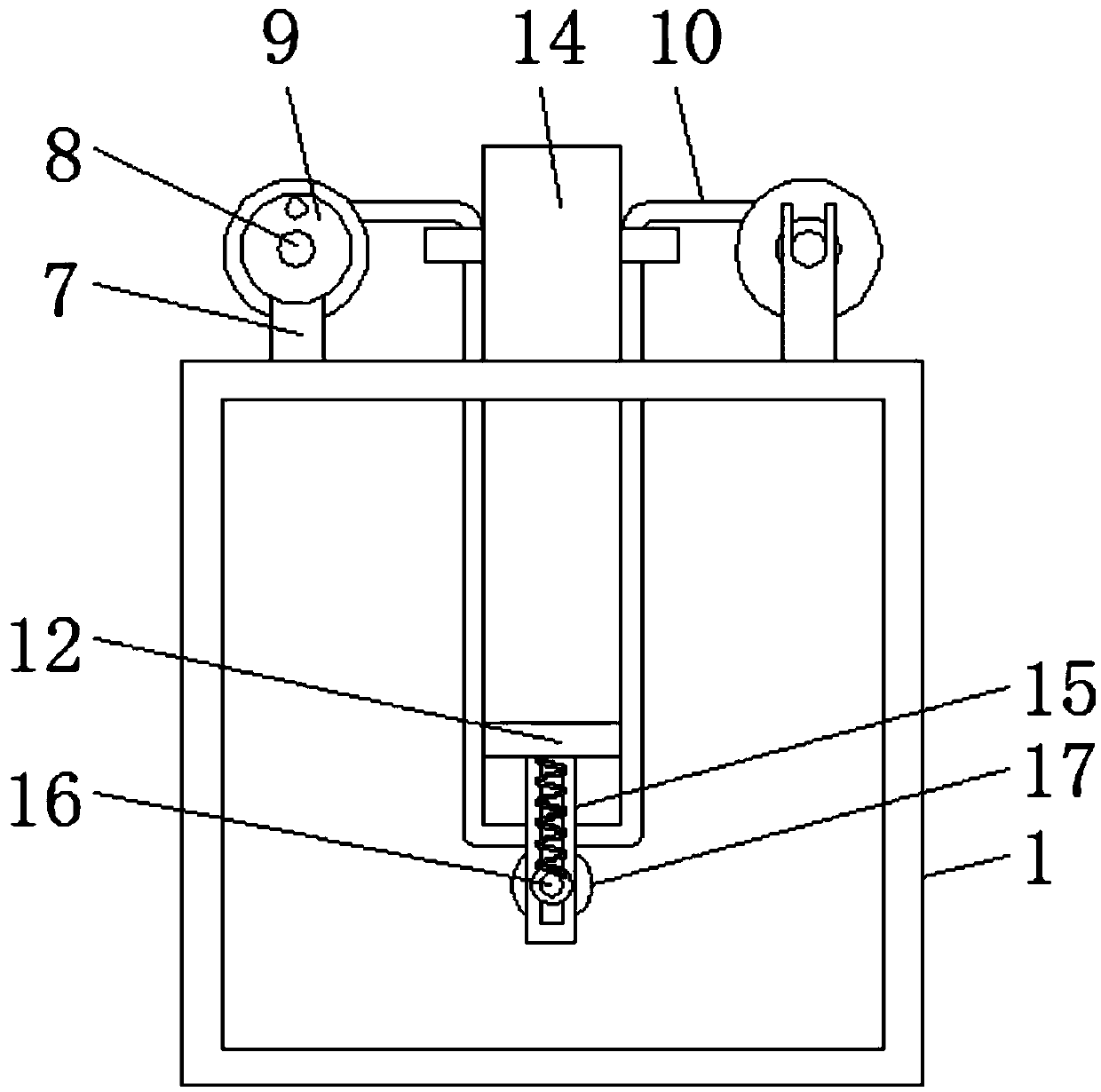

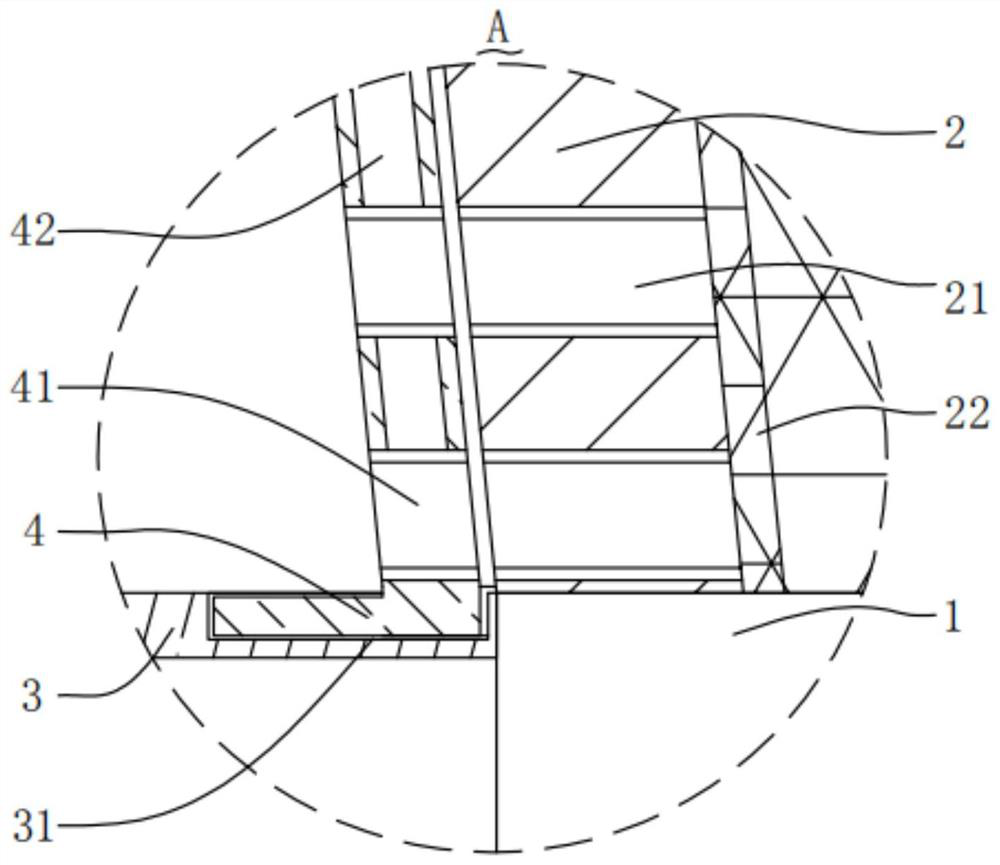

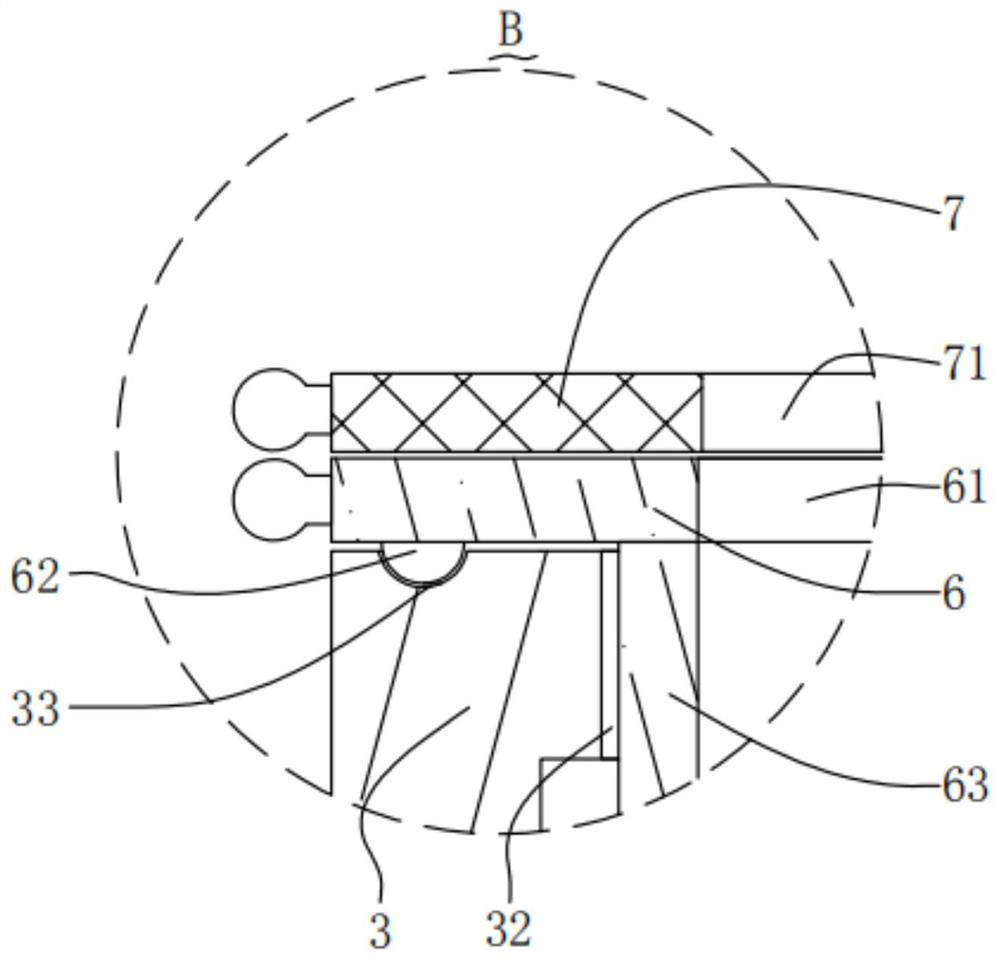

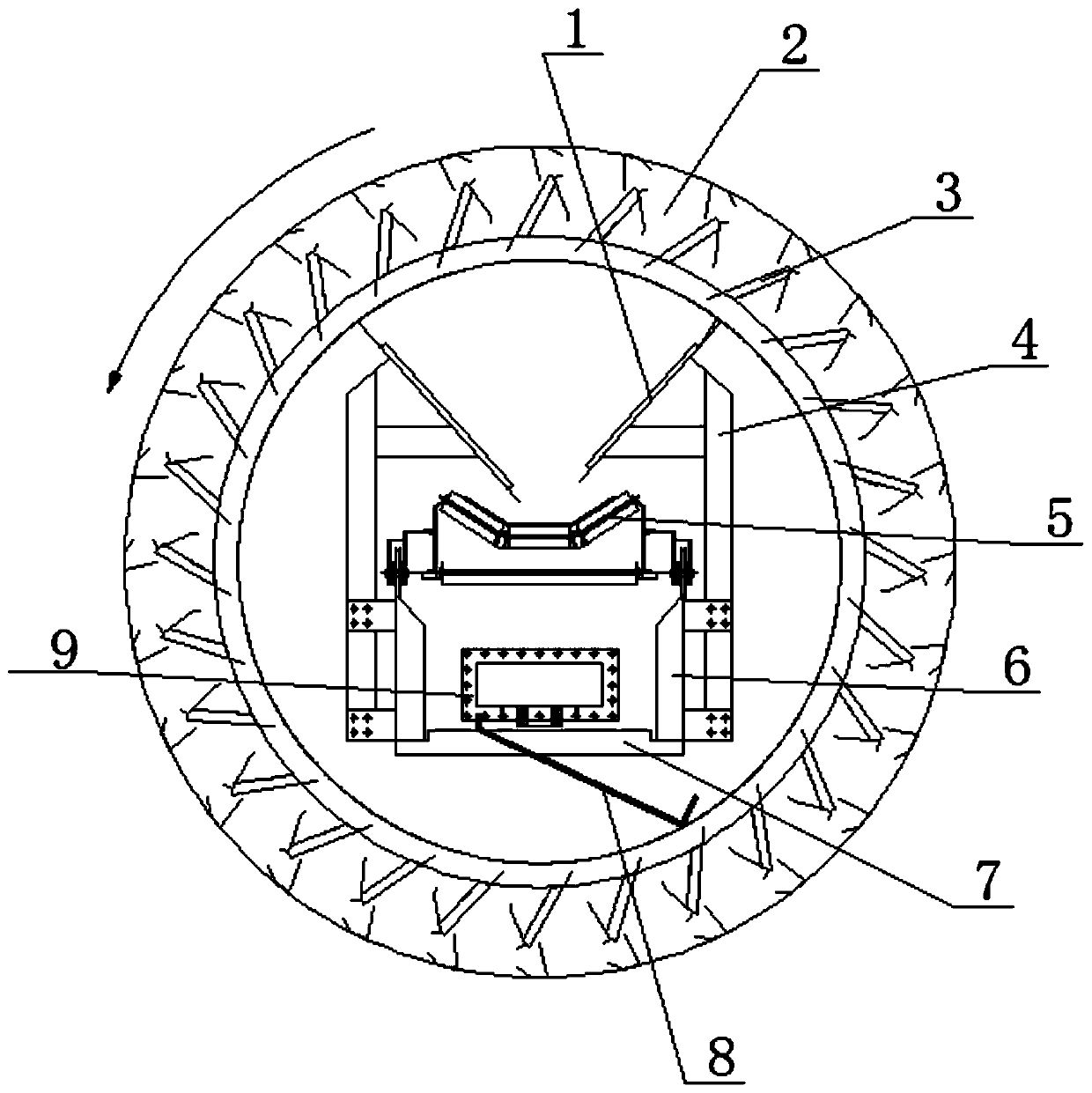

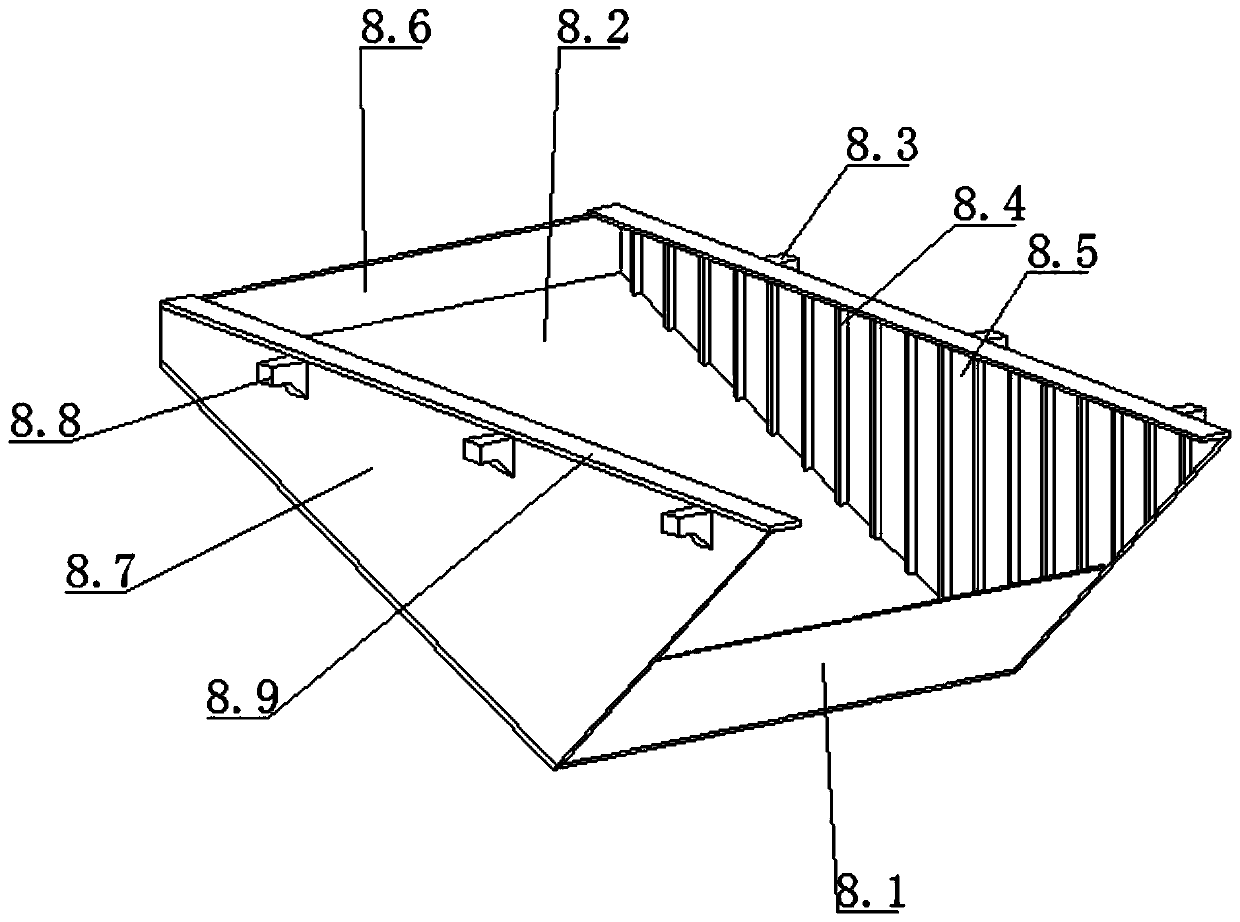

The invention relates to the technical field of wastewater treatment devices, and discloses a wastewater filtering and purifying treatment device. The wastewater filtering and purifying treatment device comprises a filtering box. Two sides of the top of the filtering box are fixedly connected with support plates. The top ends of the two support plates are moveably sleeved with a rotation shaft. Two ends of the rotation shaft are fixedly sleeved with a reel positioned between the two support plates. The top of the side face of one of the support plates is fixedly connected with a supporting plate. The top of the supporting plate is fixedly provided with a driving motor. An output shaft of the driving motor is fixedly connected with one end of the rotation shaft. The top of the filtering boxis fixedly connected with a vertical plate. The wastewater filtering and purifying treatment device is capable of, through enabling a filter screen to cross a port at the bottom of a filtering watertank, in a process of filtering wastewater, rotating a rolling shaft so that a new filter screen is moved to the port of the filtering water tank, thereby preventing garbage in the wastewater from blocking the filter screen in a continuous filtering process of the wastewater, ensuring that the wastewater is normally filtered, and improving filtering efficiency of the wastewater.

Owner:洛阳蓝源环保科技有限公司

Oil filtering system and method

PendingCN110252007AEasy extractionAvoid stockpilingGravity filtersStationary filtering element filtersFilter effectOil filter

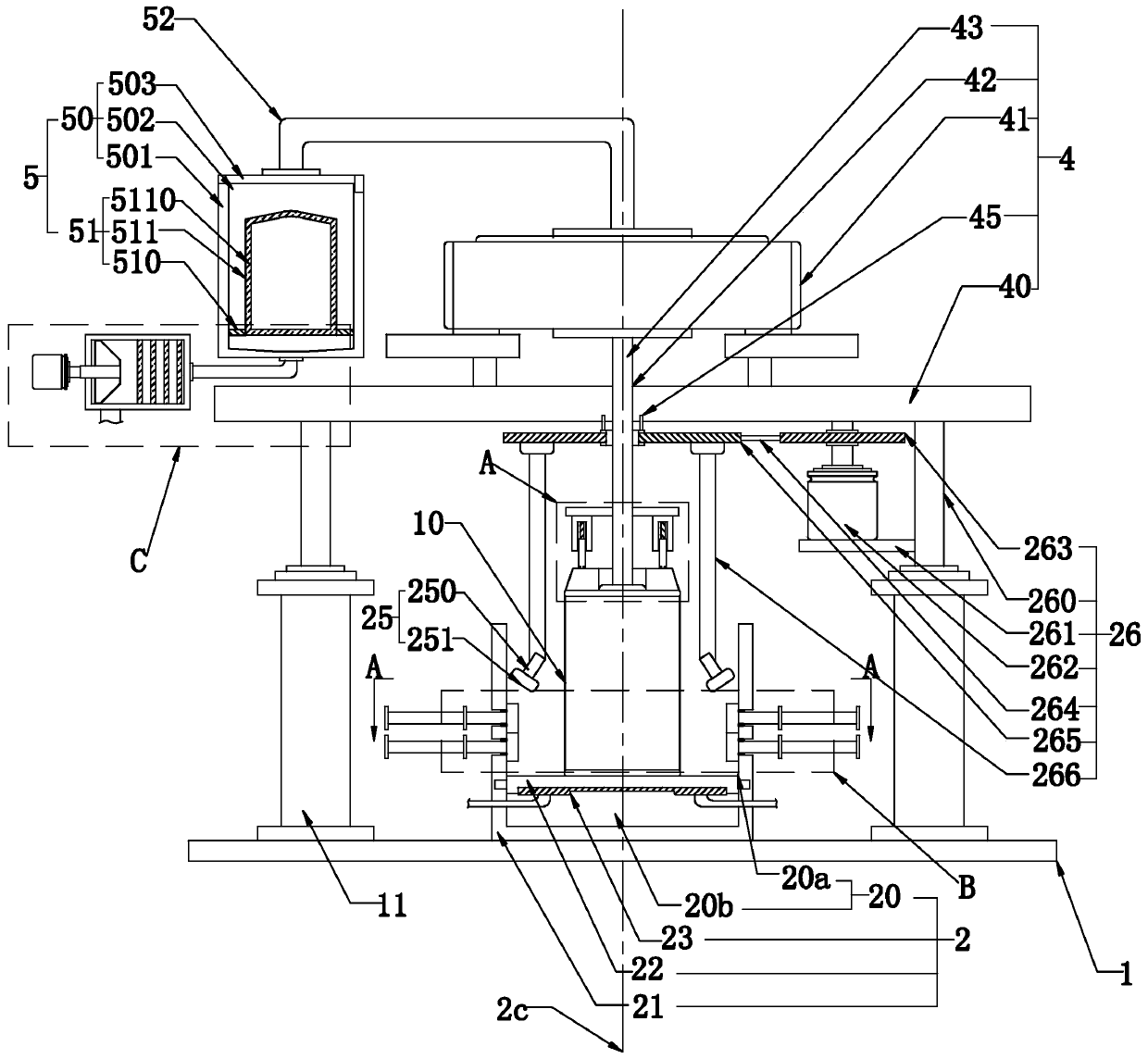

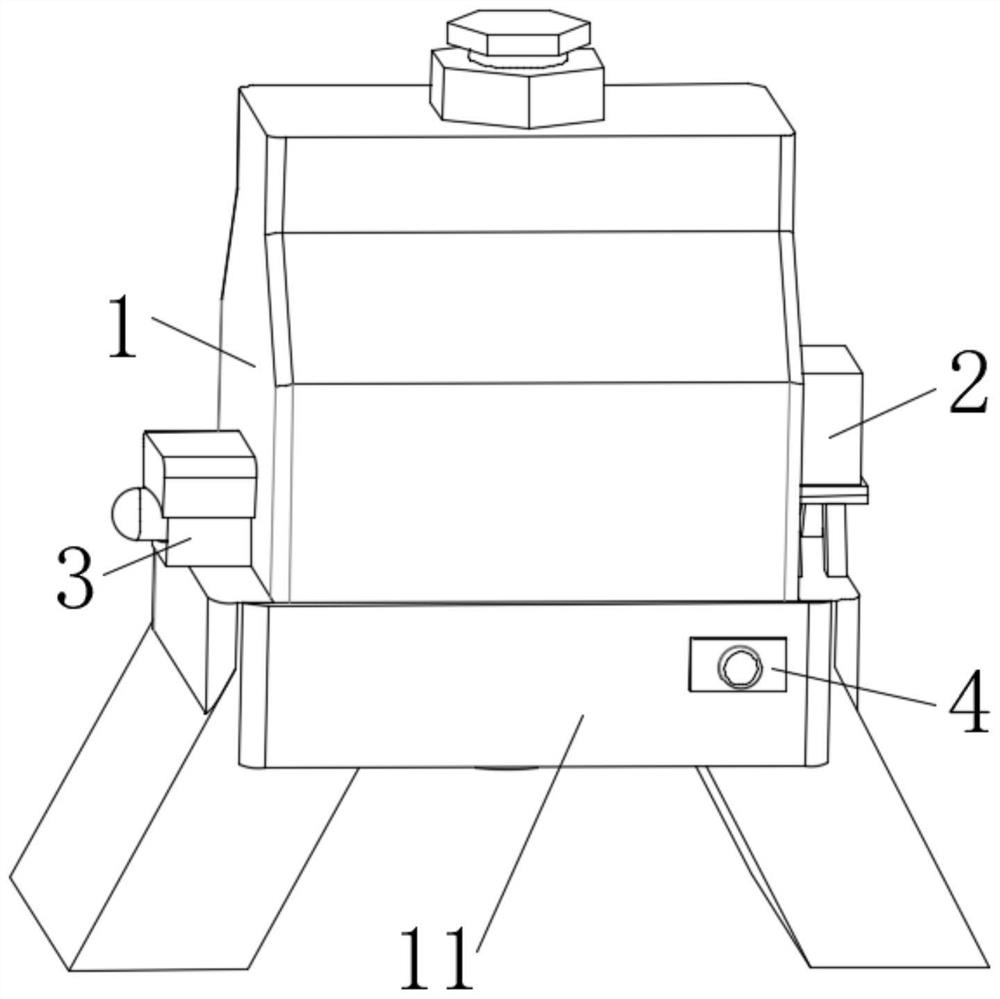

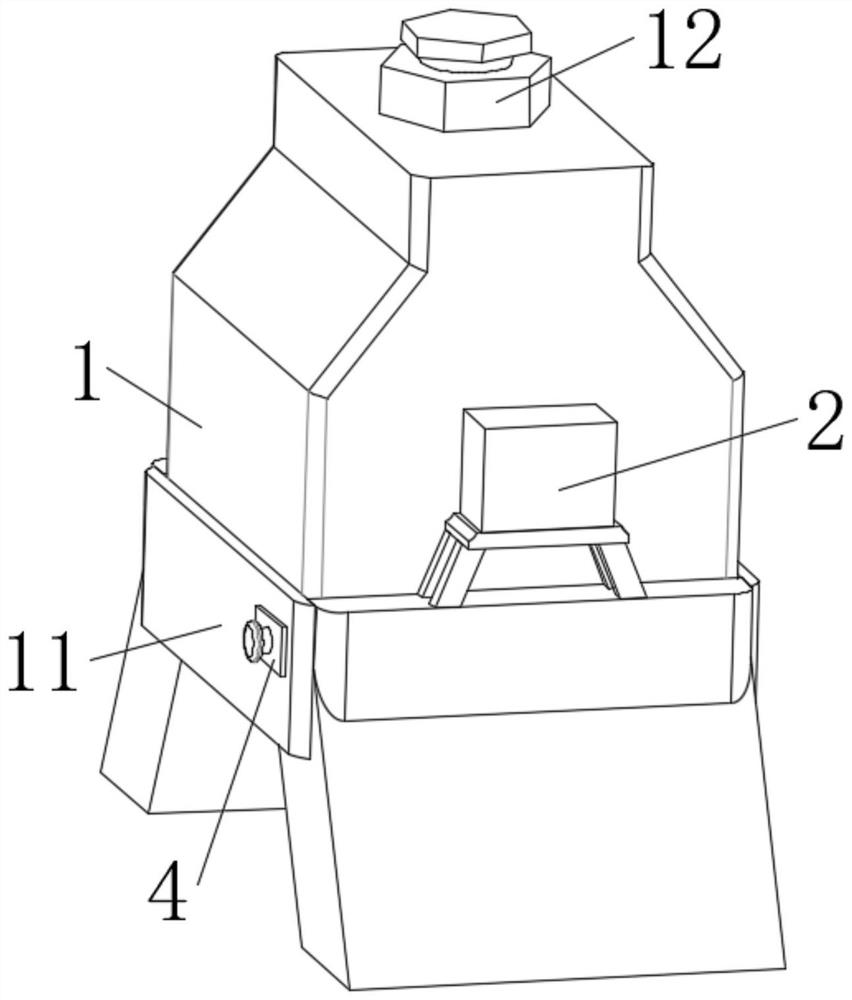

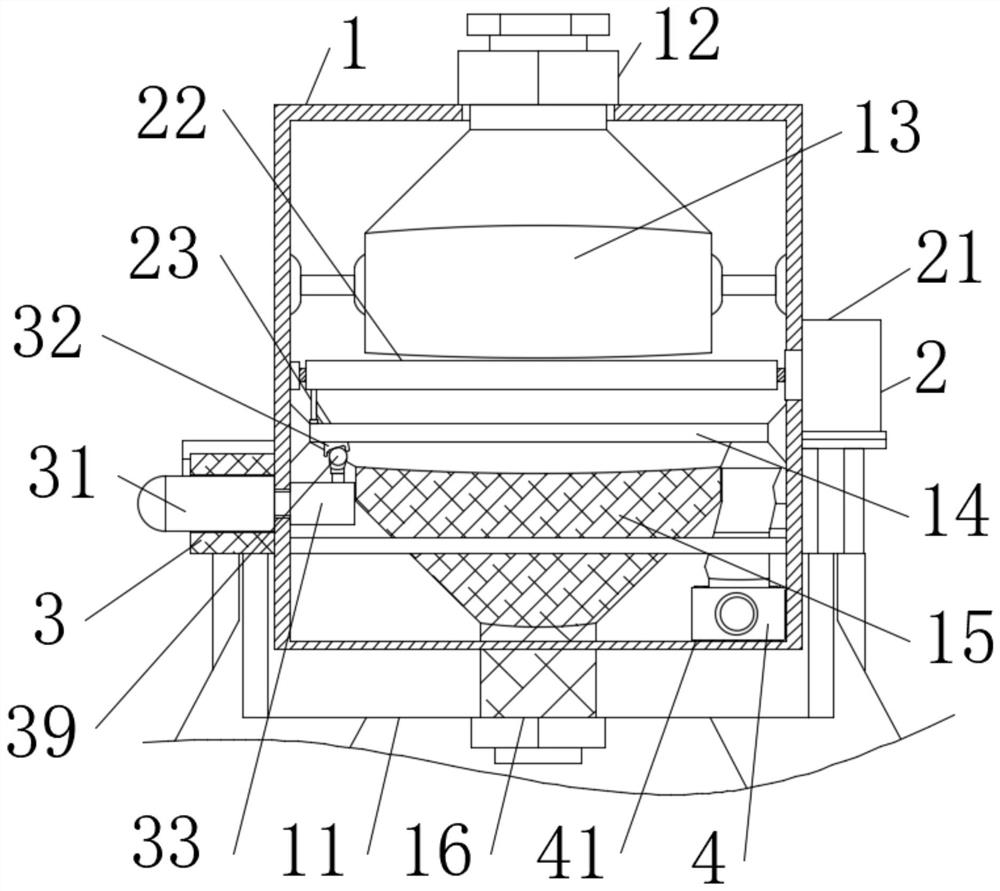

The invention relates to an oil filtering system and method. The oil filtering system comprises a frame and is characterized by comprising a preheating module mounted on the frame for placing a lubricating oil storage tank, an extruding module partly arranged inside the preheating module for pressing the outer wall of the lubricating oil storage tank from bottom to top, a feeding module at least driven by an air cylinder to move and down and arranged right above the preheating module for sucking lubricating oil, and a filtering module communicated with the feeding module for receiving and filtering the lubricating oil. The oil filtering method comprises S1, storage tank installation, S2, preheating treatment, S3, water draining extrusion and S4, repeated extrusion. The oil filtering system and method has the advantages of being good in filtering effects and high in filtering efficiency.

Owner:浙江安贝实业有限公司

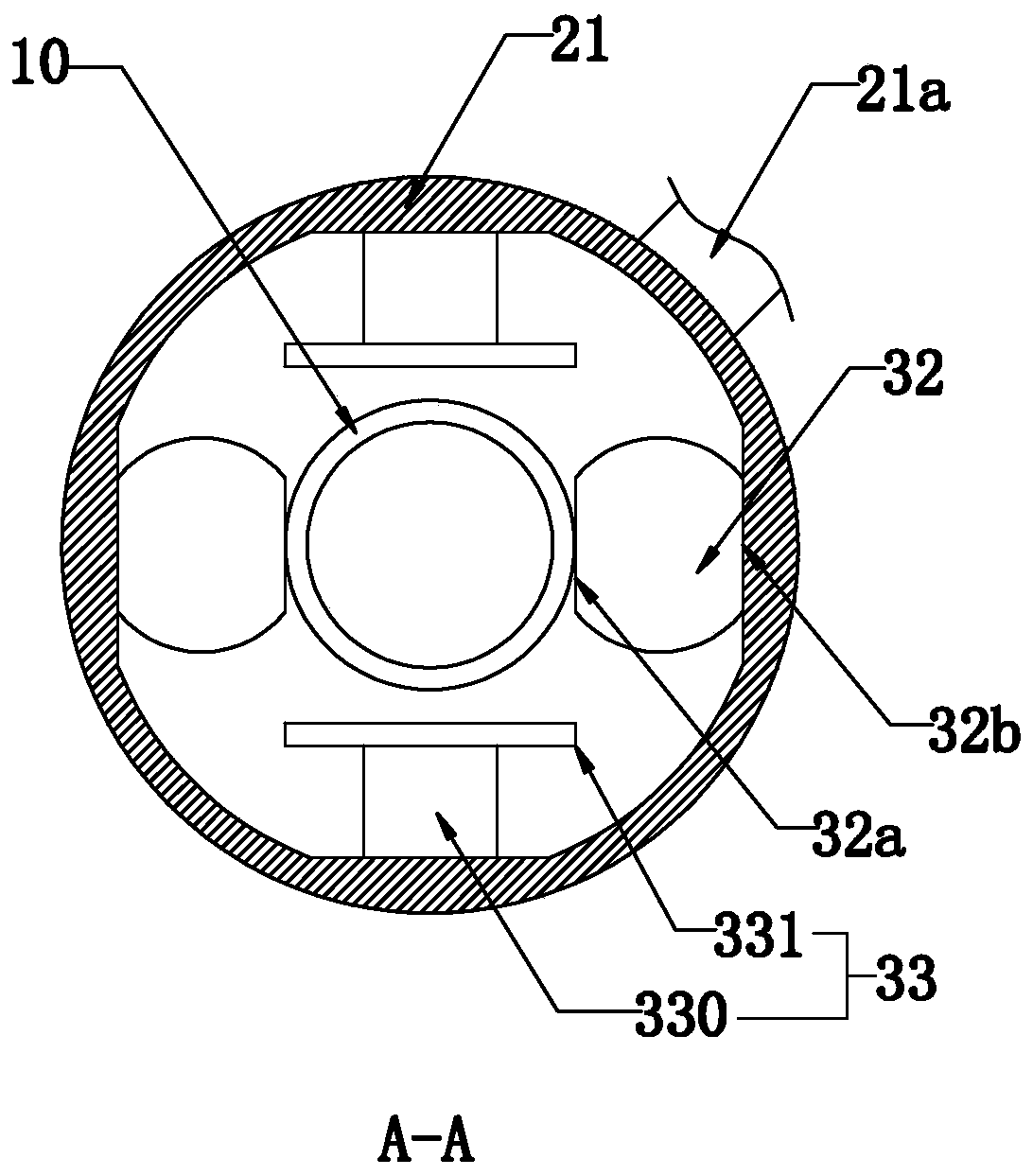

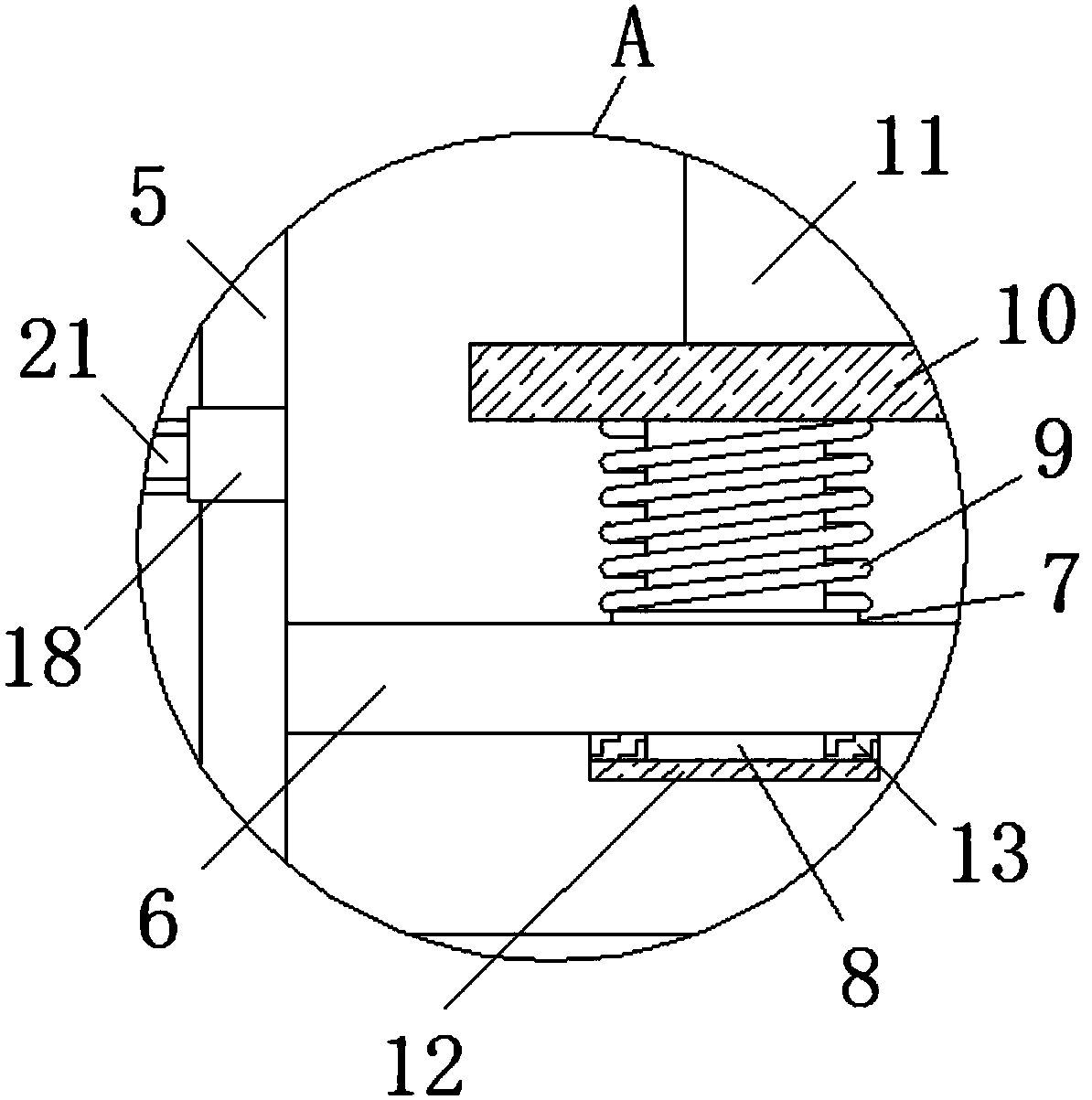

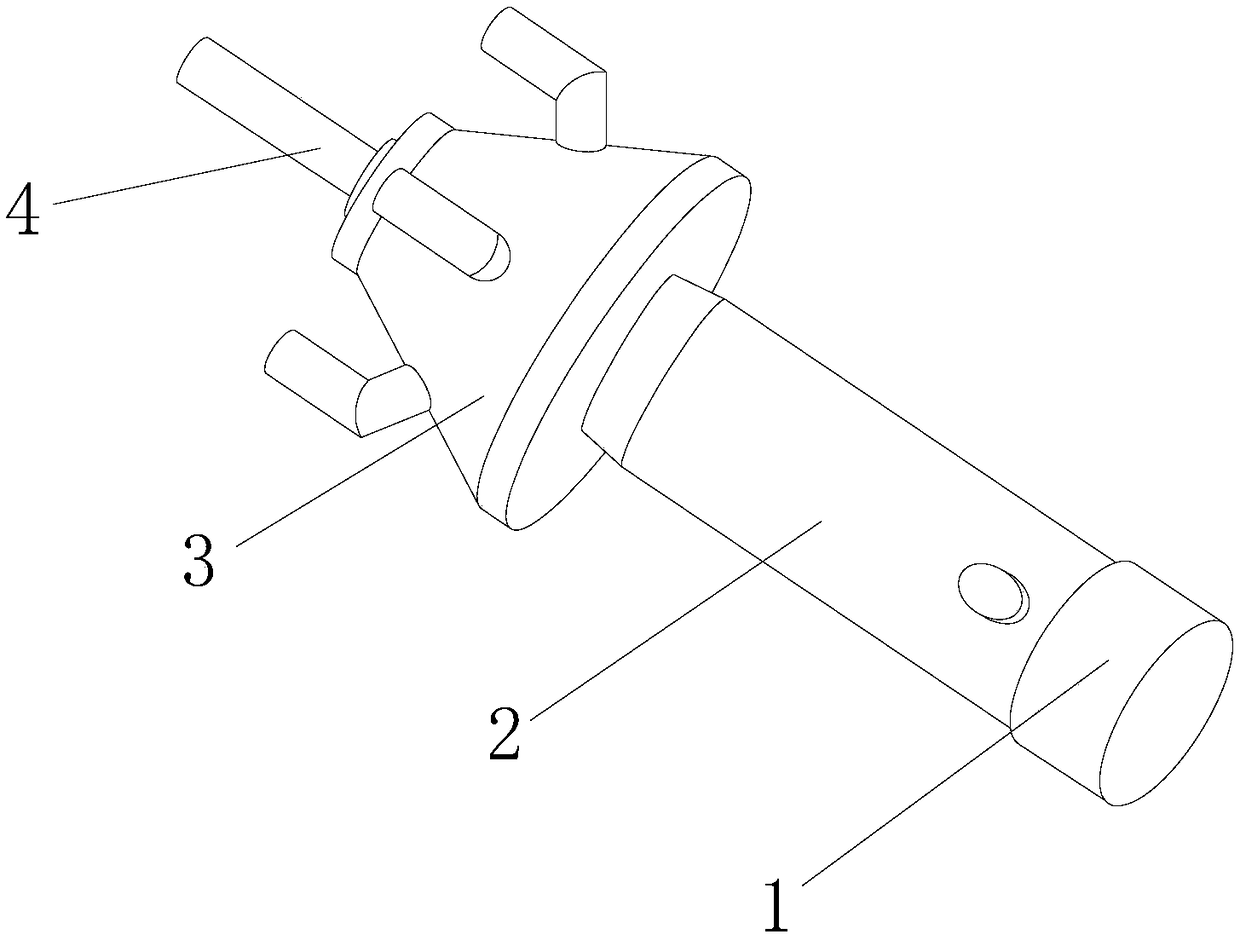

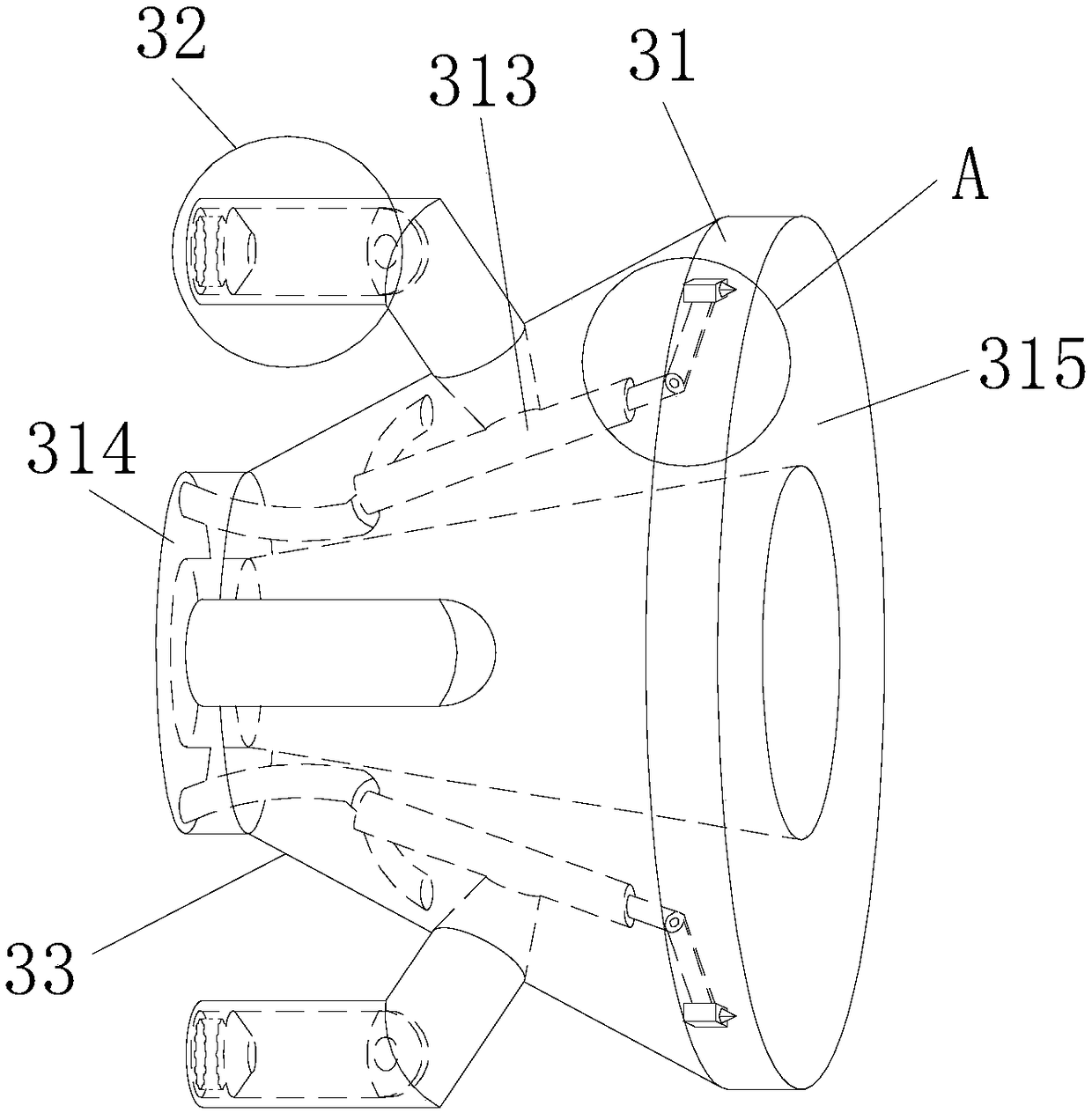

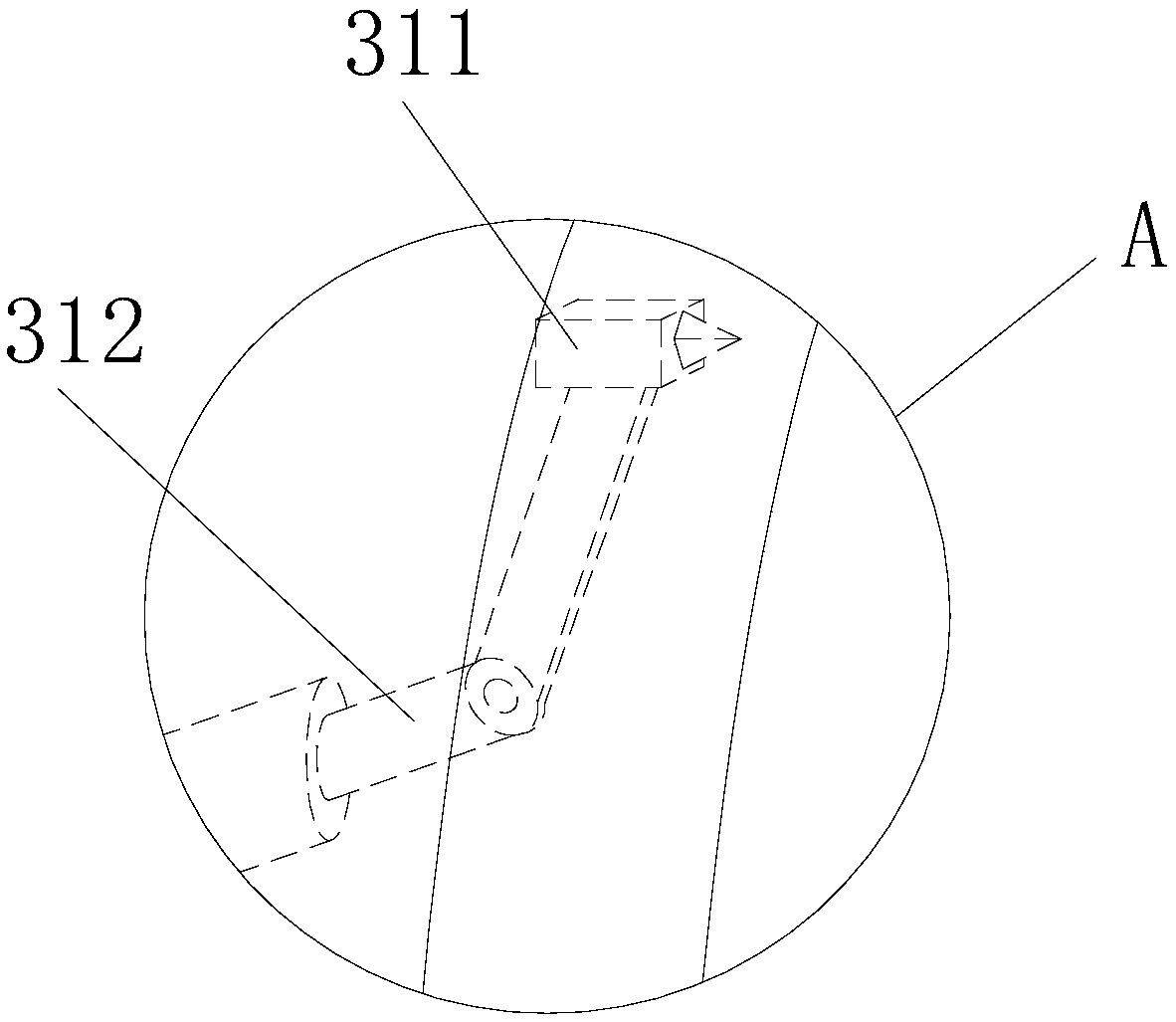

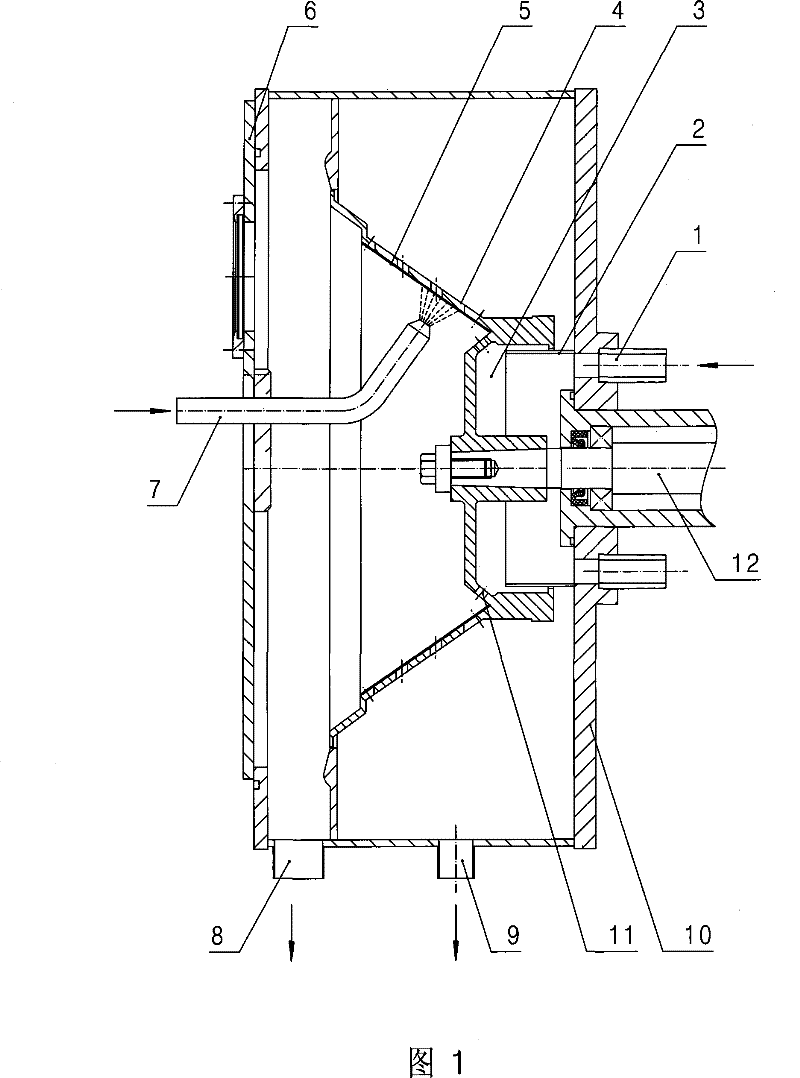

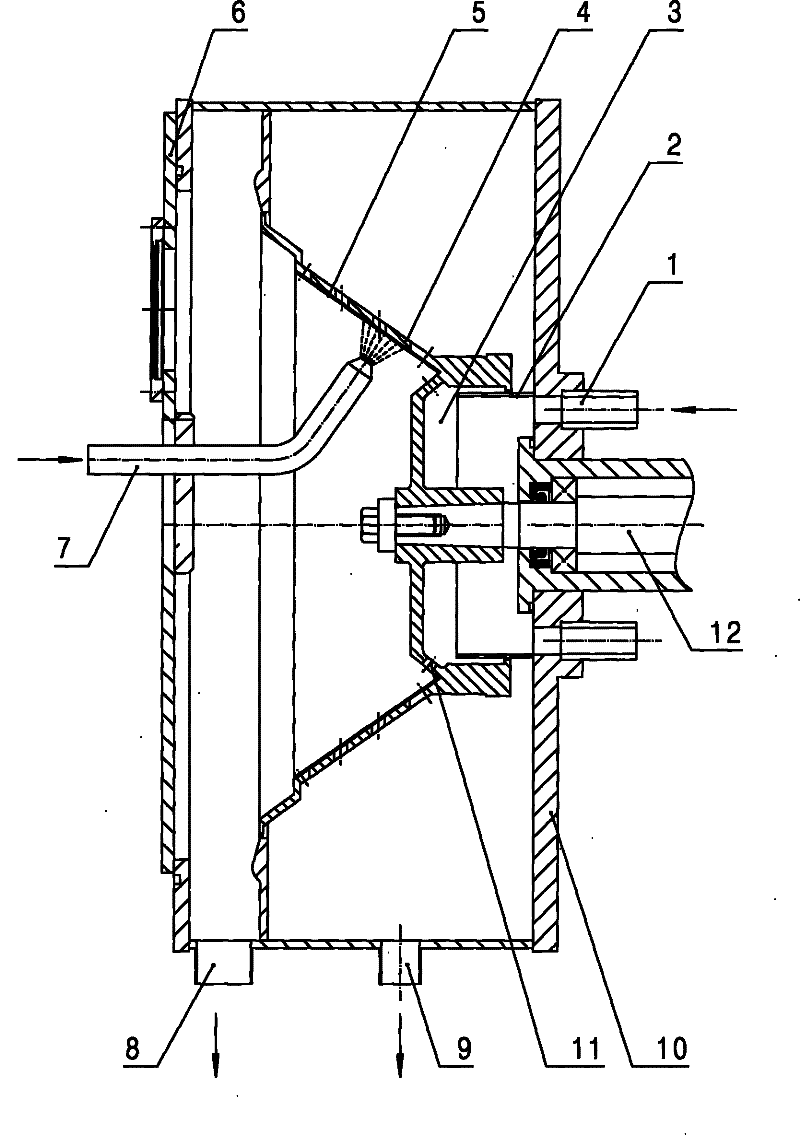

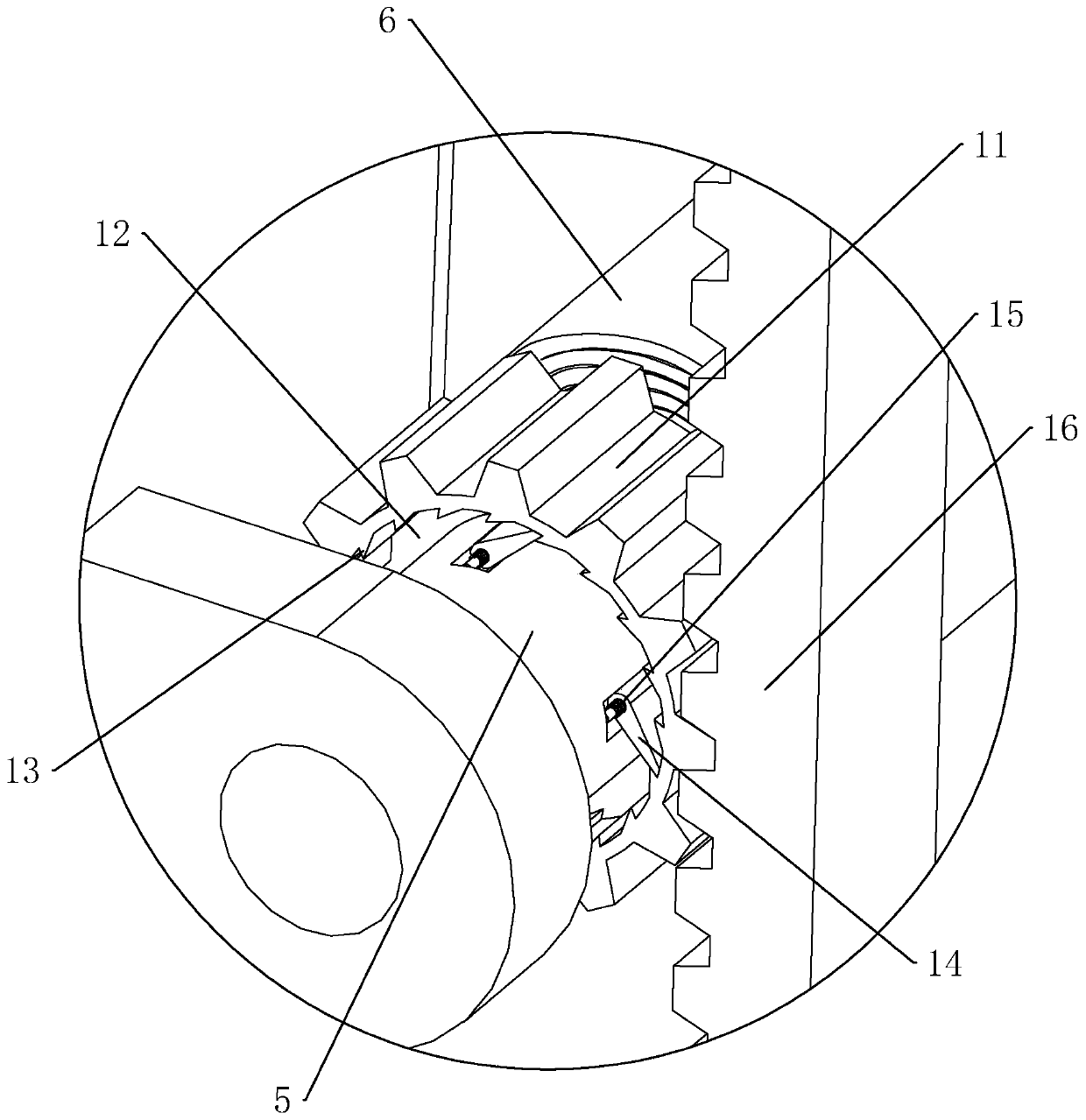

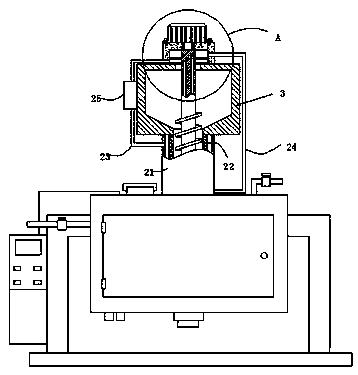

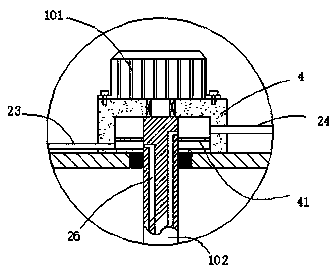

Feeder unit of the centrifugal discharging type centrifugal machine

The present invention discloses a feeding device in an unloading centrifuge, which can make a suspension distribute evenly along a circumference of a small end of a rotary drum. The present invention comprises a machine shell. A rotating principal axis is arranged in the machine shell and is equipped with the rotary drum. The external side of the bottom of the drum is concave inwards to form a material silo. The bottom of the material silo communicates with a plurality of material holes evenly arranged on the same circumference at the bottom of the drum. The interior wall of the machine shell is equipped with a material discharge hopper cooperating with the material silo, and the material discharge hopper communicates with a plurality of feed pipes going through the machine shell. The feeding device of the present invention can make the centrifuge operate smoothly in the working course, so as to ensure the normal operation of filtering, spinning, unloading and other courses of the centrifuge and reduce the mechanical problems greatly.

Owner:JIANGSU PEONY CENTRIFUGE MFG

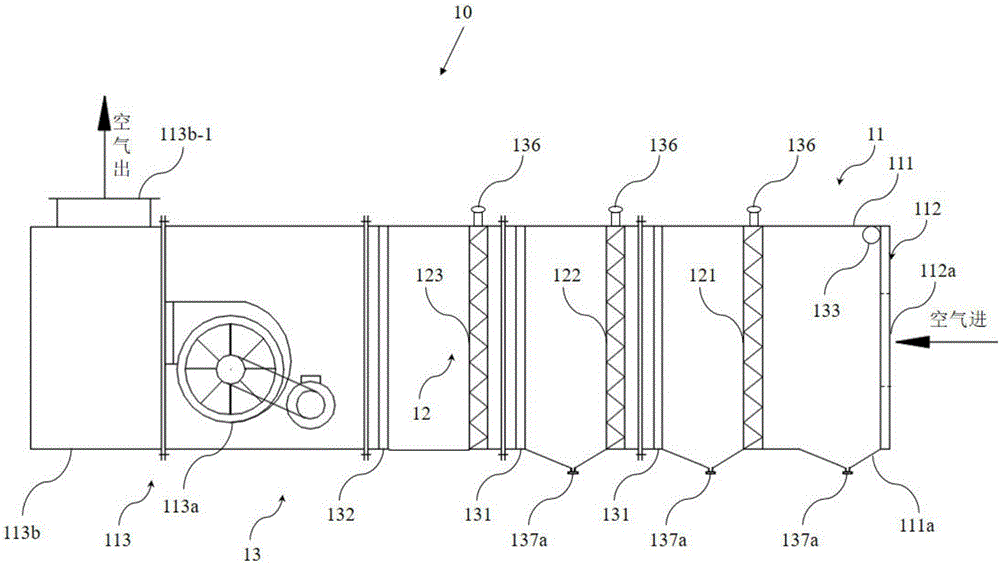

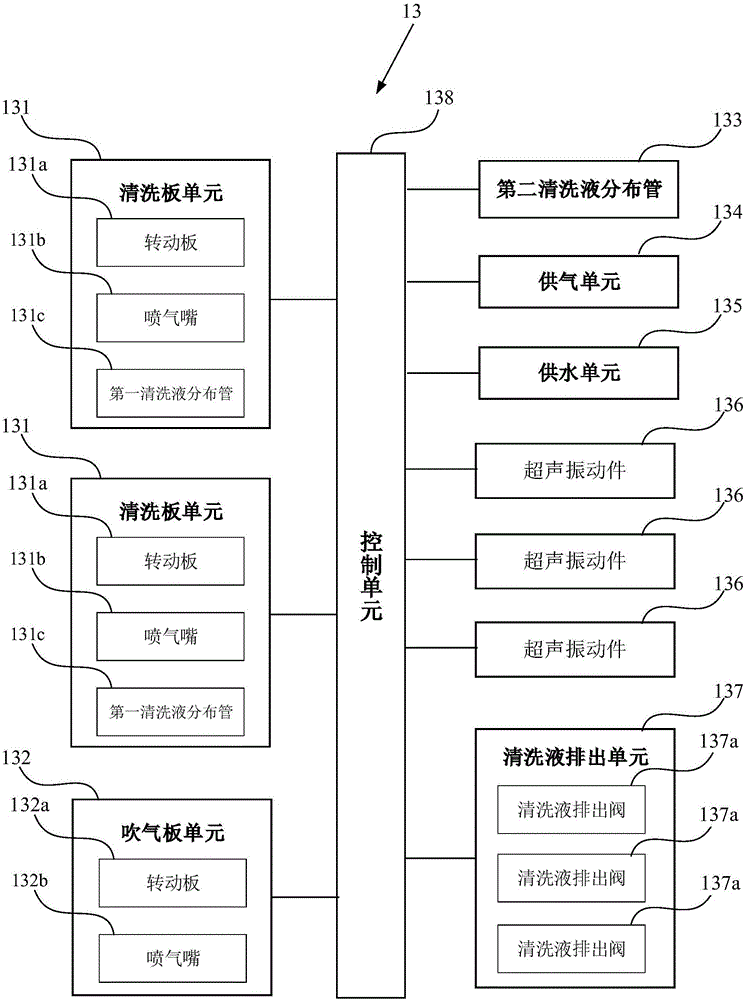

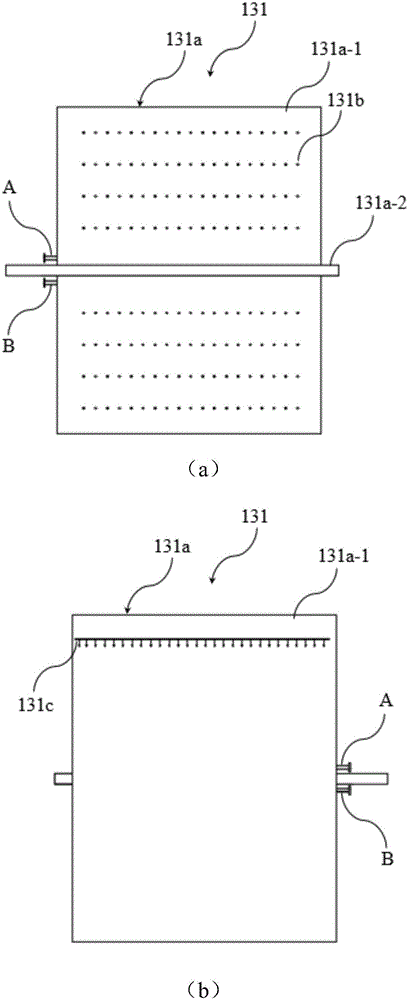

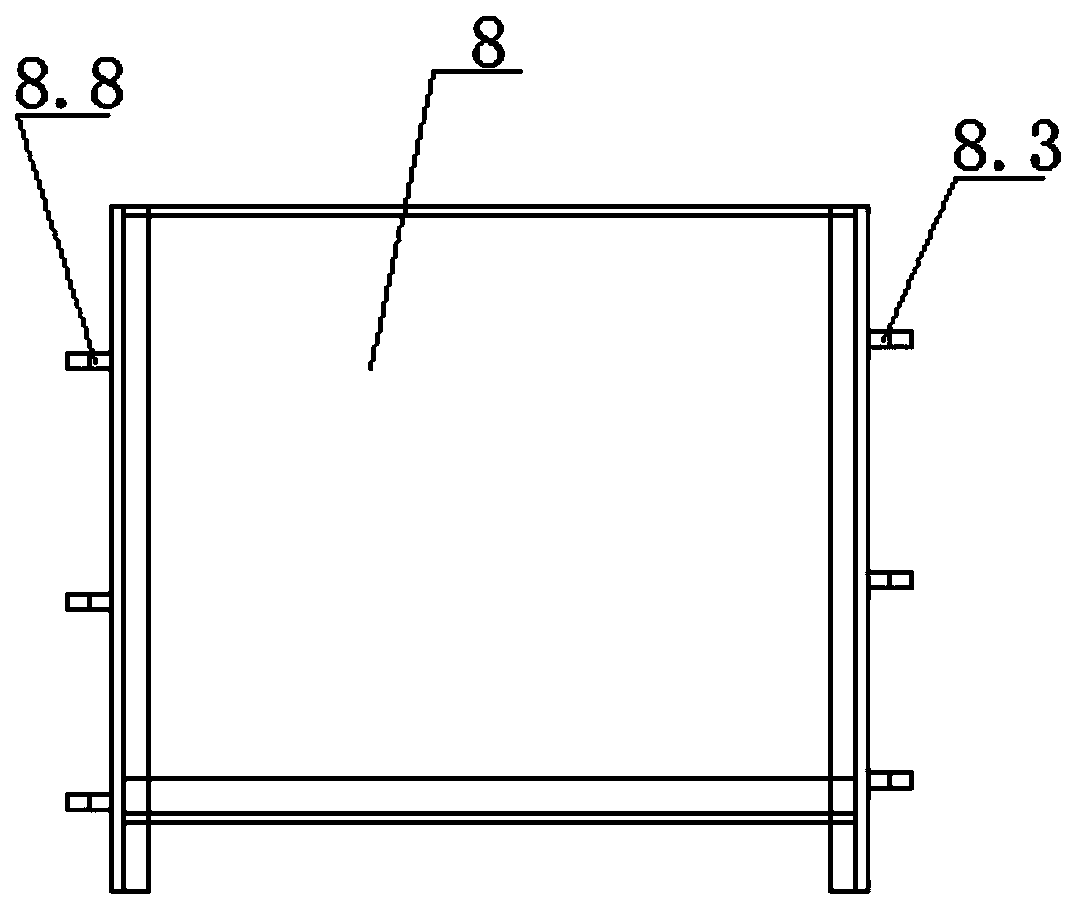

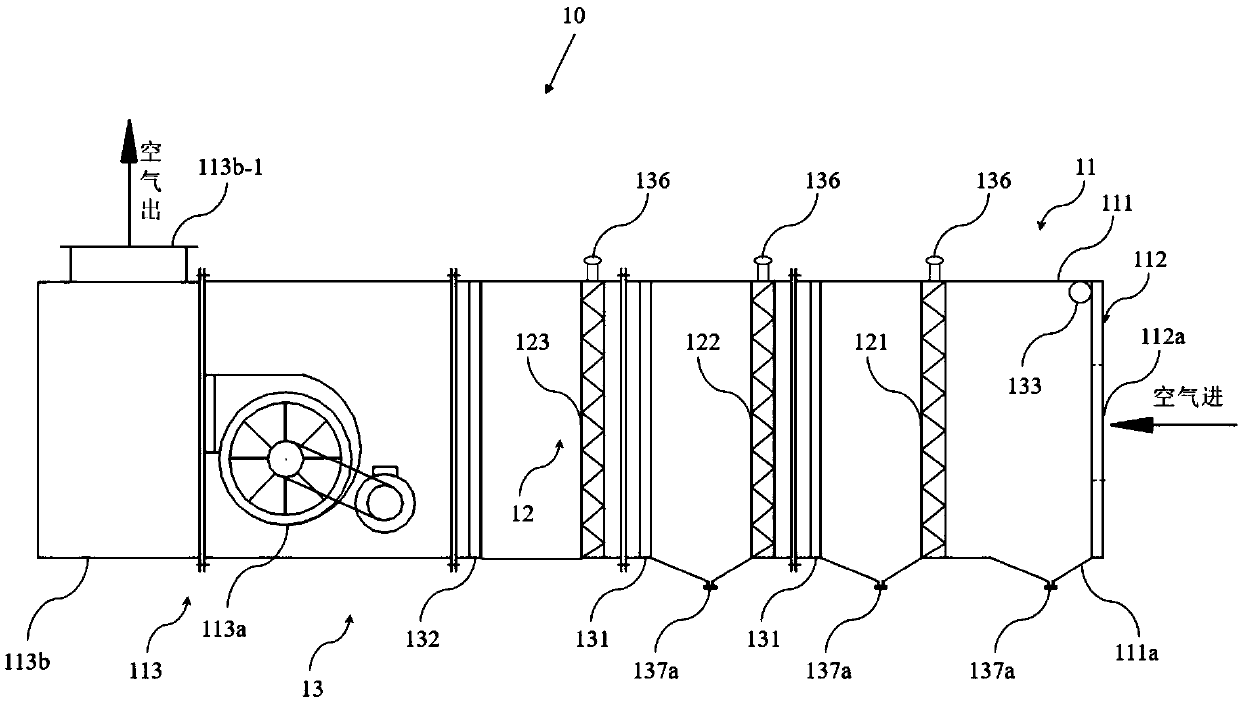

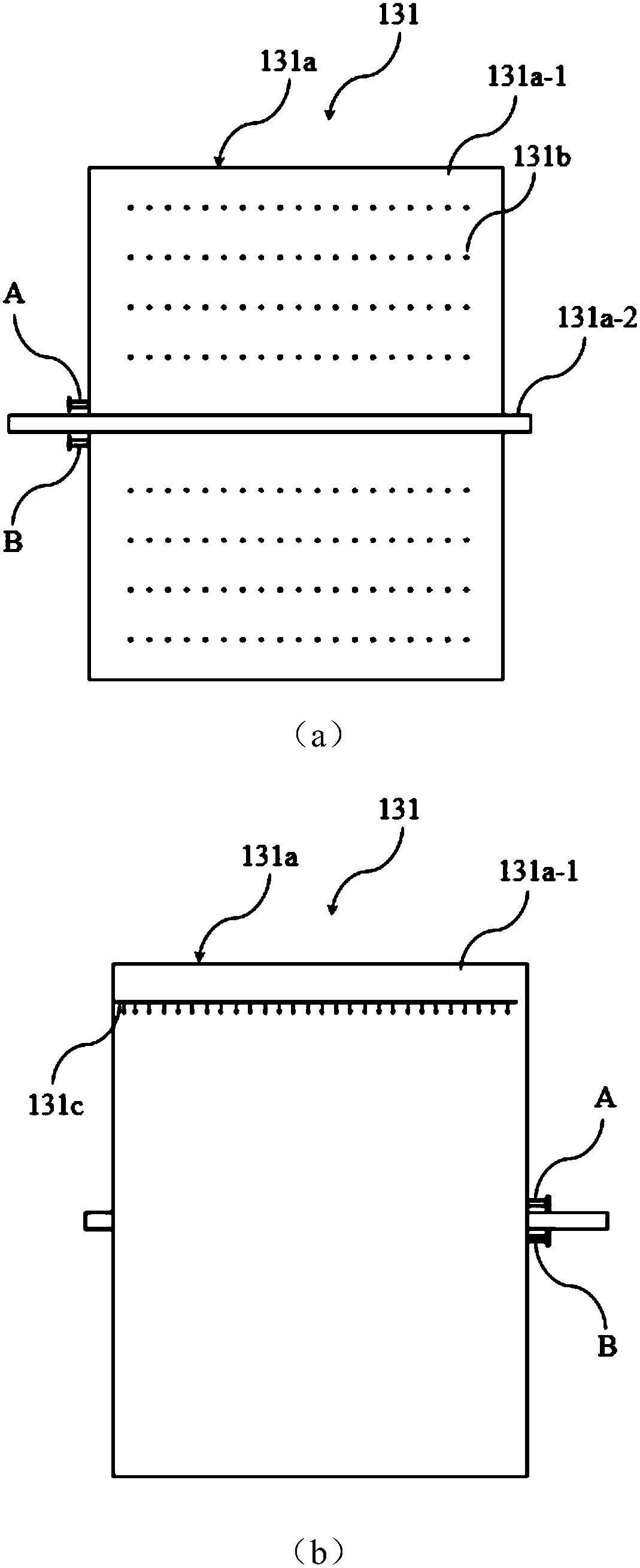

Air filtering device

ActiveCN106345196AEfficient removalEasy to cleanDispersed particle filtrationTransportation and packagingParticulatesForeign matter

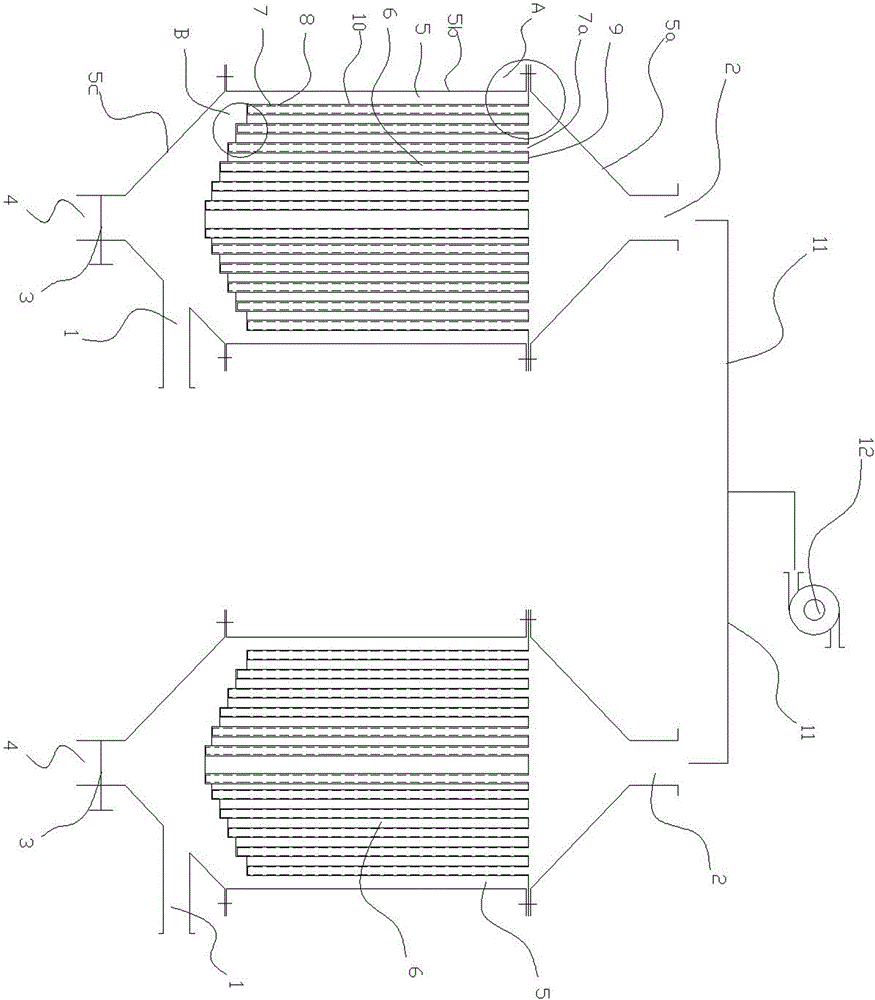

The invention provides an air filtering device which can effectively remove magnetic foreign matters, effectively clean a filtering net component and guarantee the filtering effect. The air filtering device provided by the invention is used for filtering grains in air and is characterized by comprising a shell, at least two filtering components and a cleaning component, wherein each filtering component comprises multiple layers of filtering nets; at least one layer of filtering net in at least one filtering component is arranged as a magnetic filtering net; the cleaning component comprises at least one cleaning plate unit which is arranged in the shell; each cleaning plate unit is located between two adjacent filtering components; the air filtering device is equipped with a rotating plate, a plurality of air nozzles, a first cleaning liquid distribution pipe, an air blowing plate unit, a control unit and a cleaning liquid draining unit; the cleaning liquid draining unit is arranged at the bottom of the shell and is used for draining the cleaning liquid attached with the grains from the interior of the shell.

Owner:JINGMEN GEM NEW MATERIAL

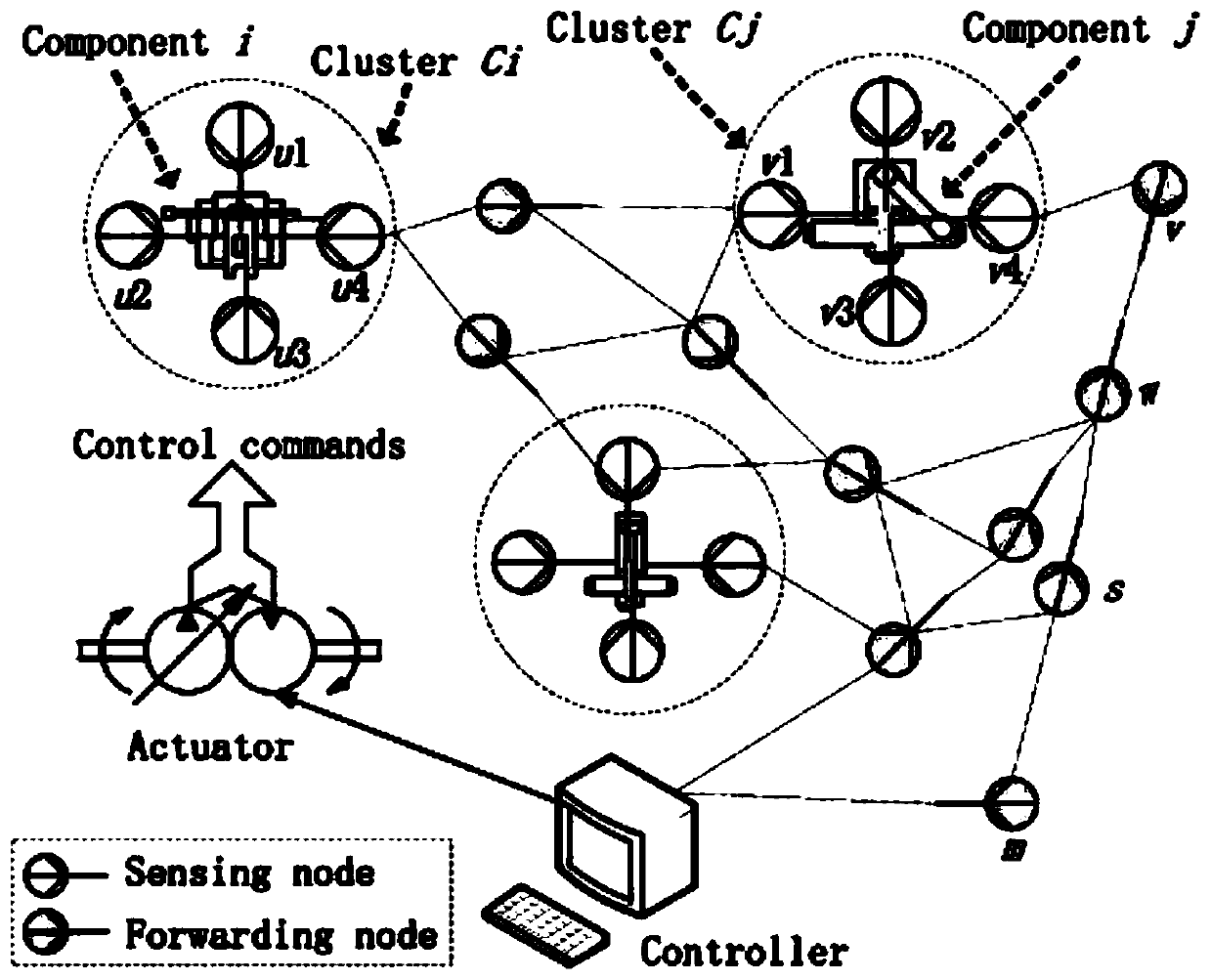

False data filtering and detecting method for information physical convergence network

The invention discloses a false data filtering and detecting method for an information physical convergence network. The method comprises the following steps: firstly, constructing a node cluster; distributing authentication information to each sensing node in each node cluster; encrypting the measurement data and the information authentication code of each sensing node to form measurement information, and sending the measurement information to a cluster head node; the cluster head node fuses the received measurement information of the T different sensing nodes and sends the fused informationto a controller; in the sending process, detecting and filtering the fusion information received by each transmission node; under the condition that a large amount of extra information does not need to be added, it is ensured that false measurement information is detected and filtered in the network transmission process; the additional information load of the network is reduced, and the service life of the sensor is prolonged; the influence of T-threshold limitation is avoided. According to the method, static routing and node positioning are avoided, and the method is more suitable for solvingthe network security problem of an information physical convergence network system.

Owner:XI AN JIAOTONG UNIV

Graded filtering device for water purification treatment of waterworks

PendingCN109481975AEasy to disassemble and overhaulImprove efficiencyStationary filtering element filtersFiltrationTap water

The invention discloses a graded filtering device for water purification treatment of waterworks. The graded filtering device comprises a device main body, a driving motor and a graded filtering mainbody, wherein a water outlet is fixed at the lower side of the device main body; a support frame is arranged at the outer side of the device main body; a first sealing cover is arranged at one end ofthe device main body; the driving motor is arranged at the outer side of the first sealing cover; a second sealing cover is fixed at the other end of the device main body; a water inlet is formed in the outer side of the second sealing cover; the front end of the driving motor is connected to a rotatable connecting cover; the front end of the rotatable connecting cover is connected to the graded filtering main body through a first baffle plate; a rotating shaft is arranged inside the graded filtering main body; and a first scraping plate is fixed at the outer side of the rotating shaft. According to the graded filtering device for water purification treatment of waterworks, the surface of the graded filtering main body can be cleared through the rotation of the first scraping plate and a second scraping plate, so that the working efficiency of follow-up water filtration and the filtration effect are ensured.

Owner:GUIZHOU UNIV

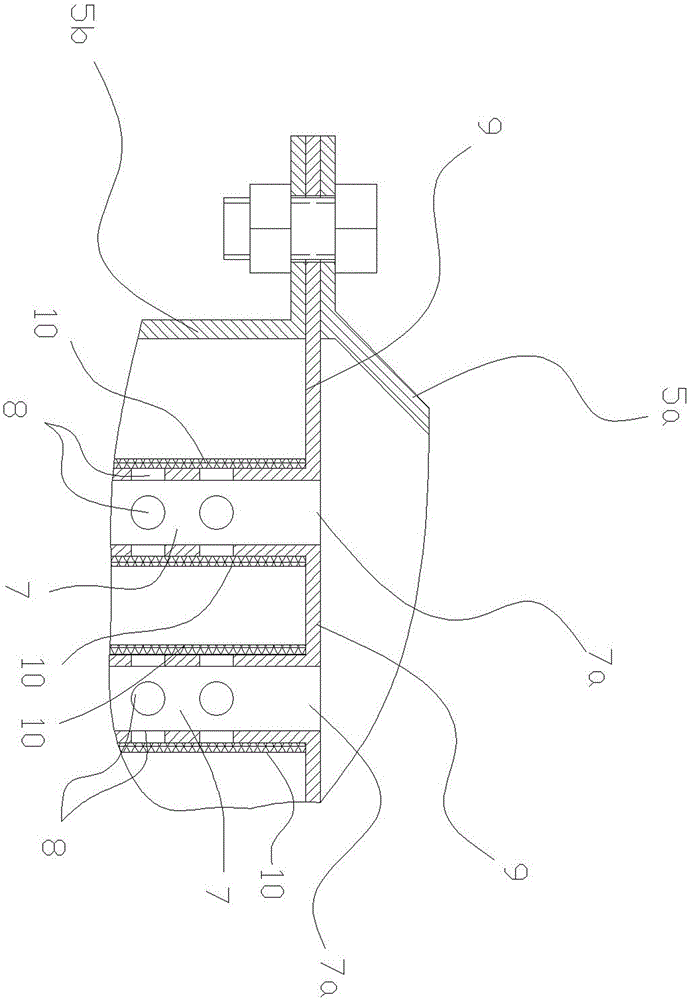

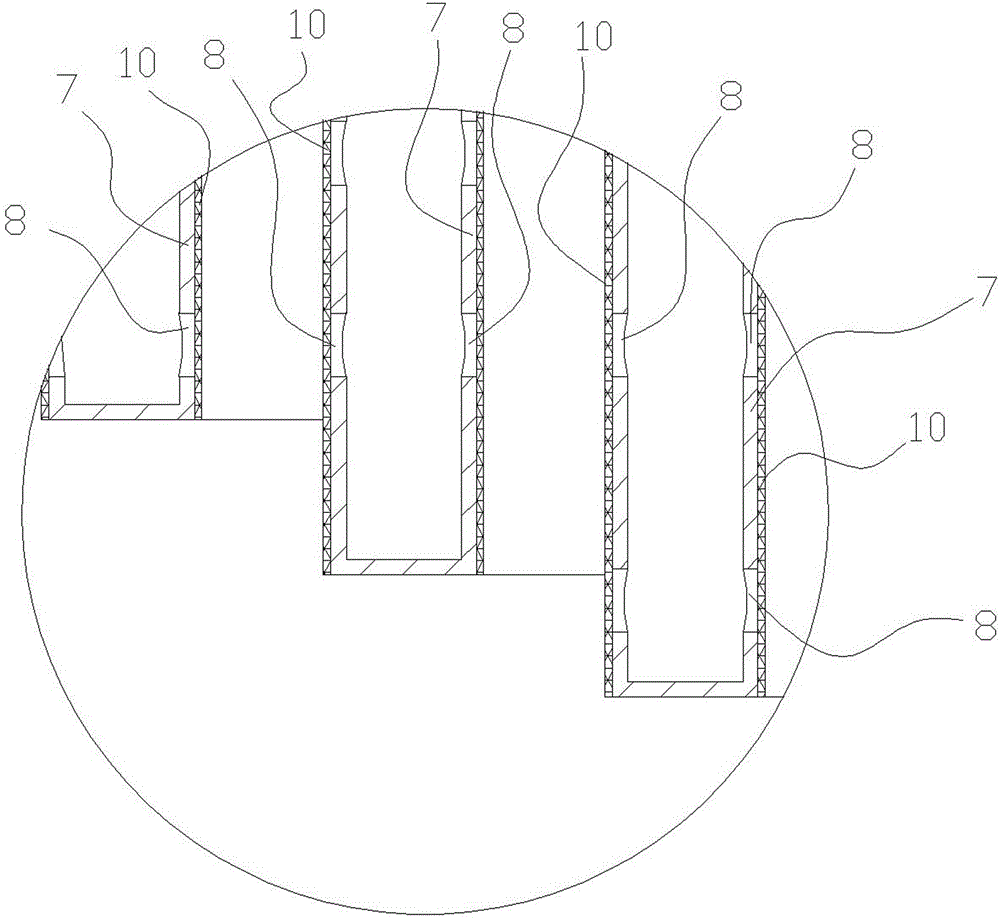

Filtering device

InactiveCN109745755AAvoid cloggingNormal filterMoving filtering element filtersFiltrationPulp and paper industry

The invention relates to the field of chemical equipment, in particular to a filtering device, which comprises a cylinder body, a filtering screen arranged in the cylinder body, a feeding port and a discharging port formed in the top of the cylinder body, wherein the feeding port and the discharging port are formed in two sides of the filtering screen; guide rails are formed in the top and the bottom of the cylinder body, sliding blocks are fixed to the edges of the filtering screen, and the sliding blocks are hermetically matched with the guide rails; and the filtering screen is fixedly connected with one end of a fixing shaft, the other end of the fixing shaft extends from one side of the cylinder body and is connected with one end of a rotary shaft through a hinge, the other end of therotary shaft is fixedly connected with a rotary wheel, and the rotary wheel is in transmission connection with a motor. After the structure is adopted, the blockage of mesh of the filtering screen isavoided, and the normal filtration is ensured; and the practicability of the device is greatly increased.

Owner:丹阳市日晟工业设备有限公司

Electric cabinet with high dustproof effect

PendingCN107658707AImprove dustproof effectKeep the inside cleanSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsGas pipelineEngineering

The invention discloses an electric cabinet with high dustproof effect. The electric cabinet comprises a base. The top of the base is fixedly connected with a filtering box and a supporting block successively from left to right. One end, which is far from the base, of the supporting block is fixedly connected with a cabinet body. An air inlet at one side of the cabinet body is fixedly connected with a suction fan. The top of the filtering box is fixedly connected with a fixing leg, a blower fan and an air inlet pipe successively from left to right. The air outlet of the blower fan is fixedly connected with an air transferring pipe. One end, which is far from the blower fan, of the air transferring pipe, penetrates through and extends into the inner chamber of the filtering box. One end, which is far from the filtering box, of the air inlet pipe is fixedly connected with one side of the suction fan. According to the electric cabinet with high dustproof effect, through matching among thefiltering box, the blower fan, the air inlet pipe and the air transferring pipe, dust in the air is totally eliminated, thereby ensuring high sanitation in the cabinet body, ensuring no dust on innercomponents in the cabinet body, improving heat radiation effect of the inner components in the cabinet body, and furthermore ensuring normal operation of the inner components in the cabinet body.

Owner:绍兴柯桥雷霄机械科技有限公司

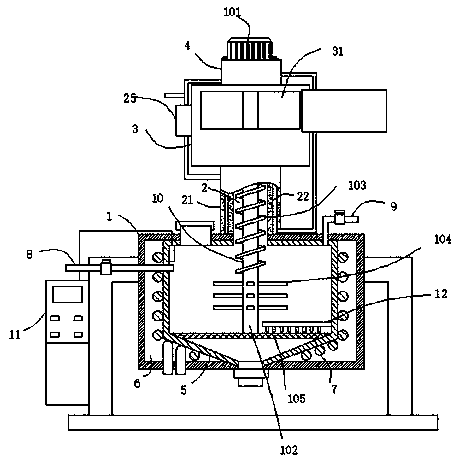

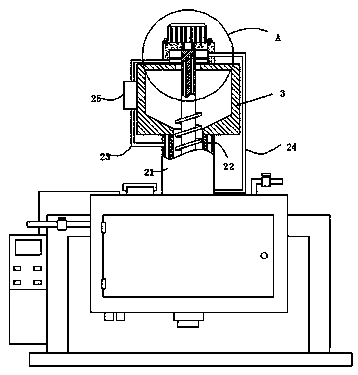

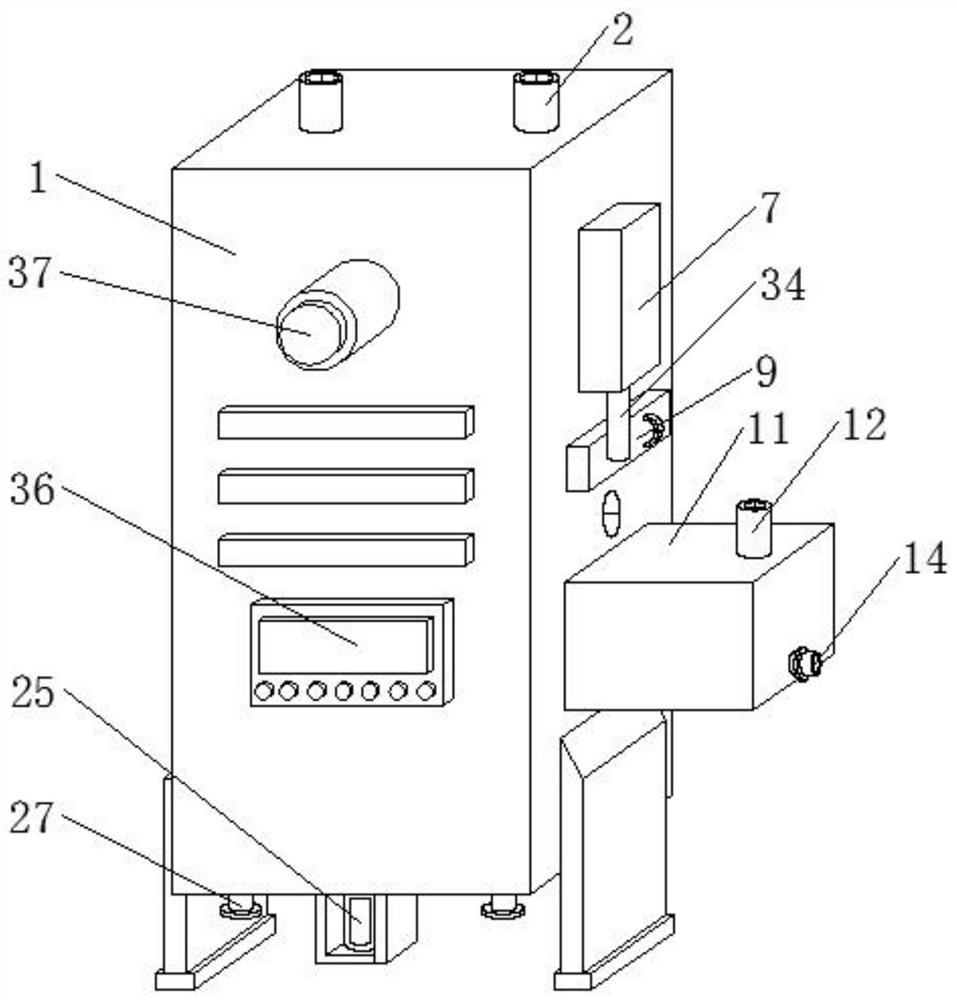

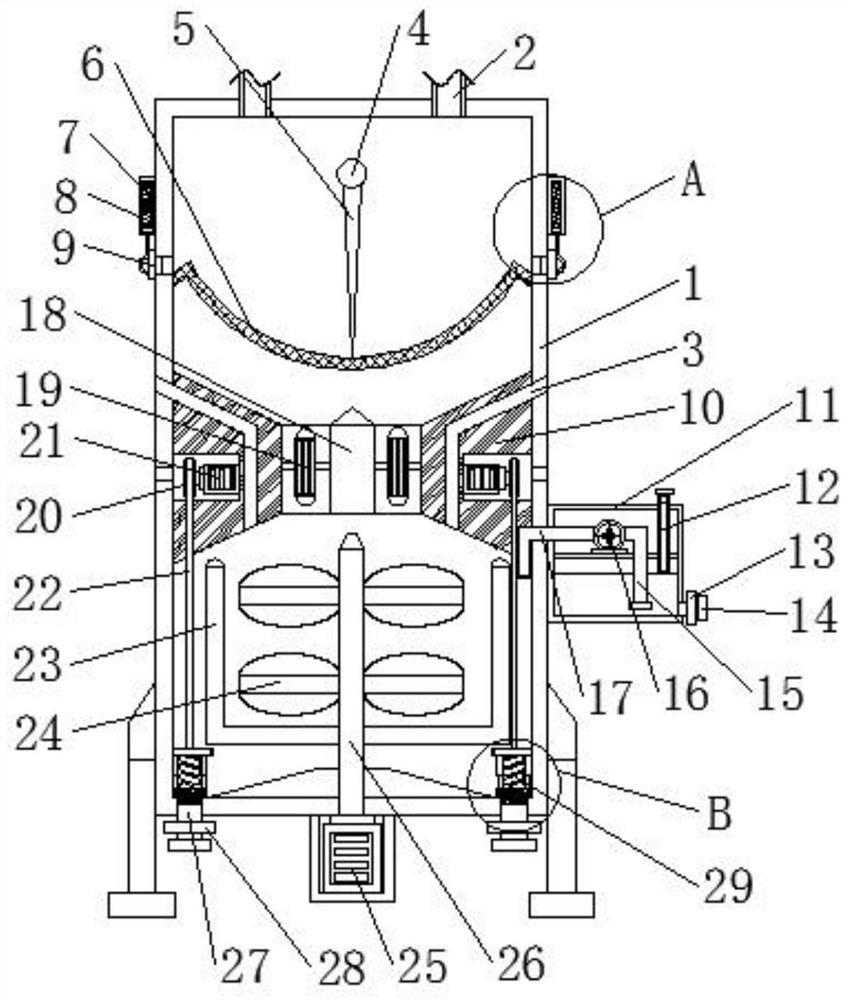

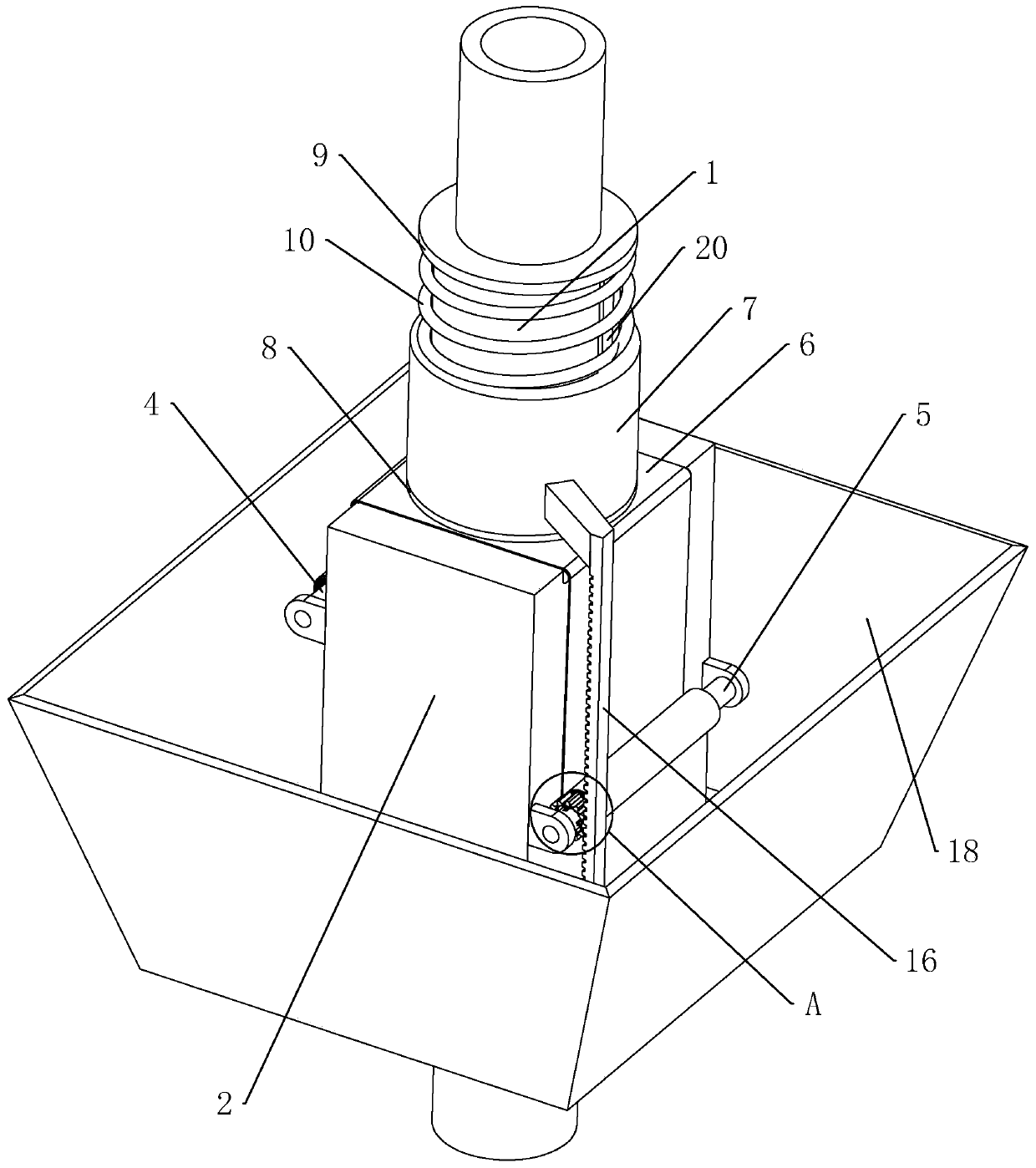

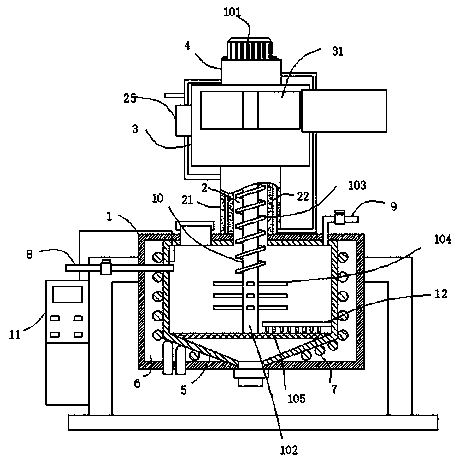

High-strength aluminum alloy production equipment

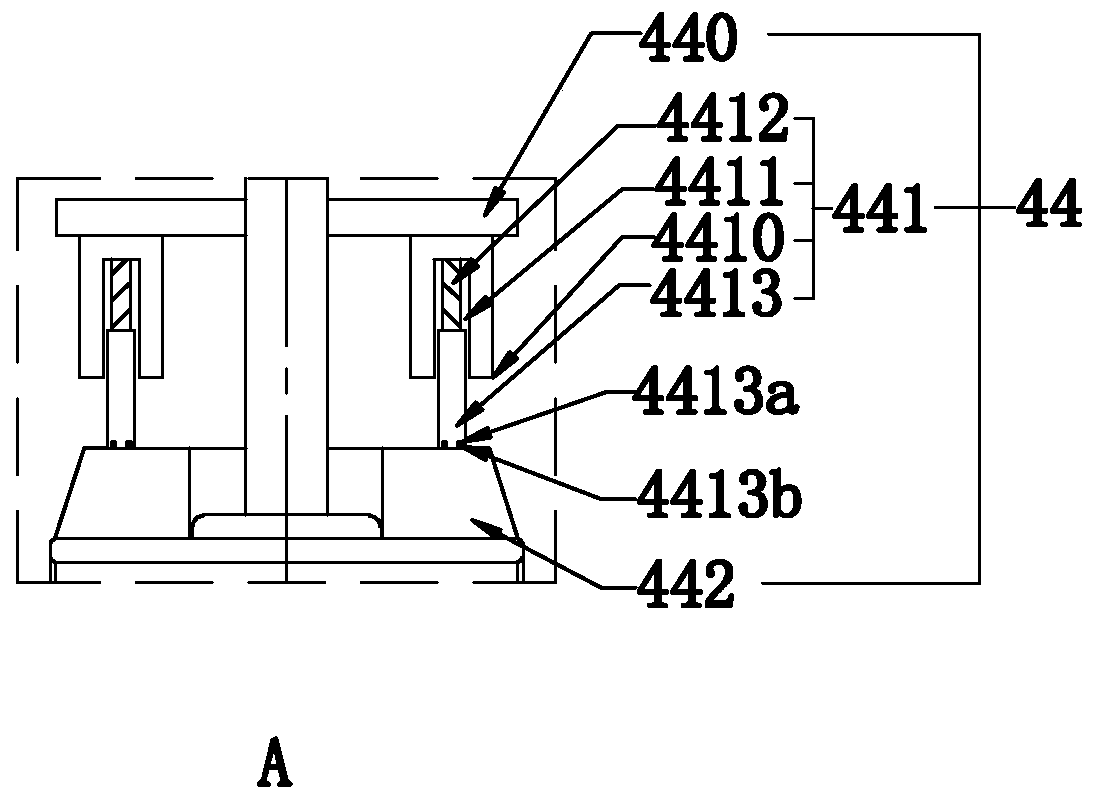

InactiveCN109631576AImprove processing efficiencySpeed up meltingCharge treatment typeCrucible furnacesHigh intensityMachining

The invention belongs to the field of aluminum alloy machining, in particular to high-strength aluminum alloy production equipment. To solve the problems that an existing aluminum alloy smelting furnace is not good enough in smelting effect, the smelting speed is low, and consequentially the aluminum alloy machining efficiency is low, a solution is put forward, wherein a production body and a control assembly which are arranged on a supporting frame are included, the production body comprises a furnace body, the furnace body is internally and fixedly provided with a pot body, a vacuum heatingcavity is formed between the pot body and the furnace body, an electric heating coil wound on the pot body is fixedly arranged in the vacuum heating cavity, the furnace body is provided with a gas charging pipe and a gas discharging pipe which communicate with the pot body, and the top of the furnace body is fixedly provided with a material guiding and preheating mechanism. According to the aluminum alloy production equipment, by means of a hollow material mixing rod, gas ports, a gas inlet pipe, a gas outlet pipe, a circulating air pump, an outer cylinder and an inner cylinder, hot air can begenerated through heat energy of the furnace body, raw materials are preheated through the hot air, the smelting speed of the raw materials is increased, energy is saved, and the production efficiency can be improved.

Owner:安徽辰隆铝业有限公司

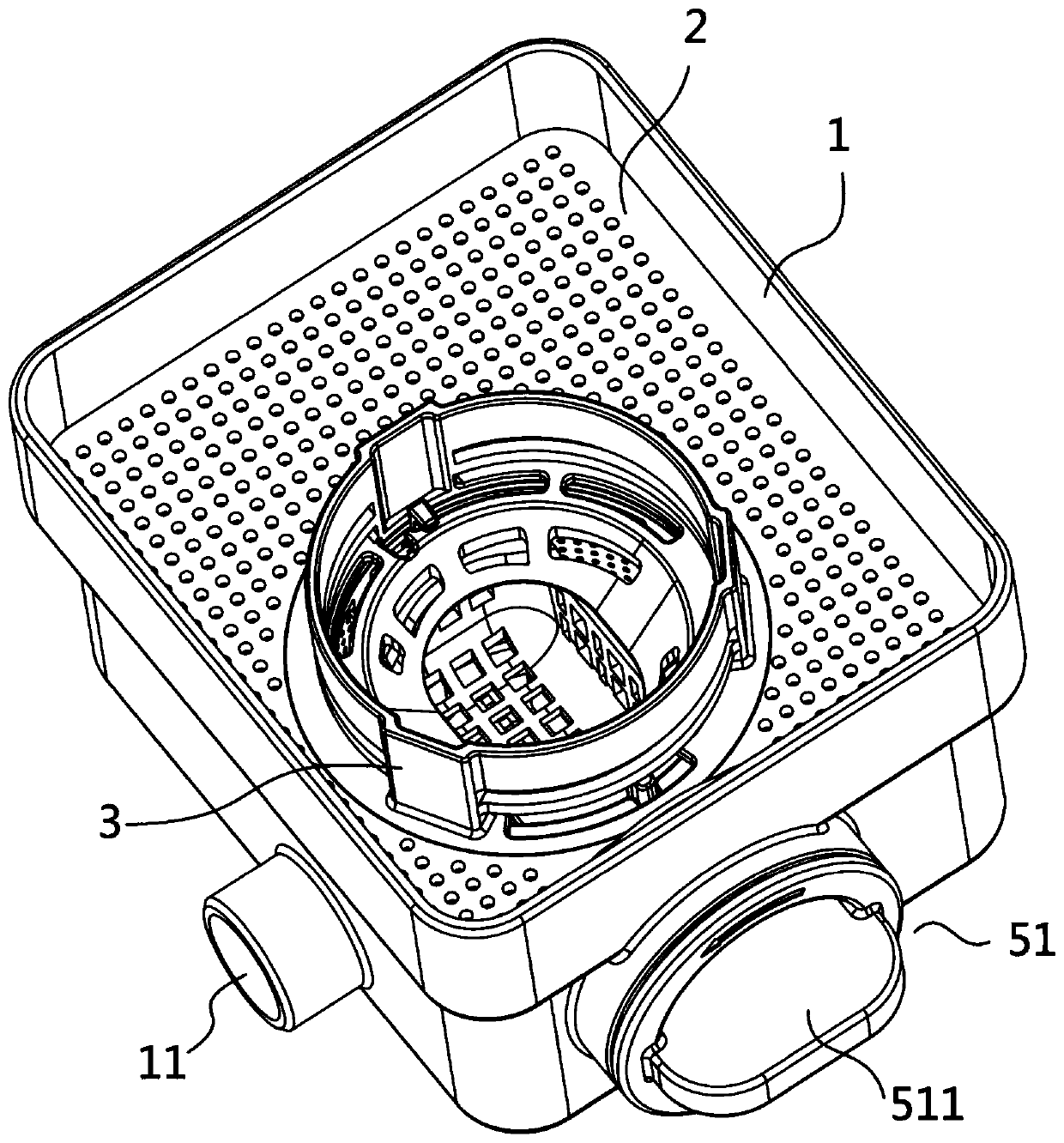

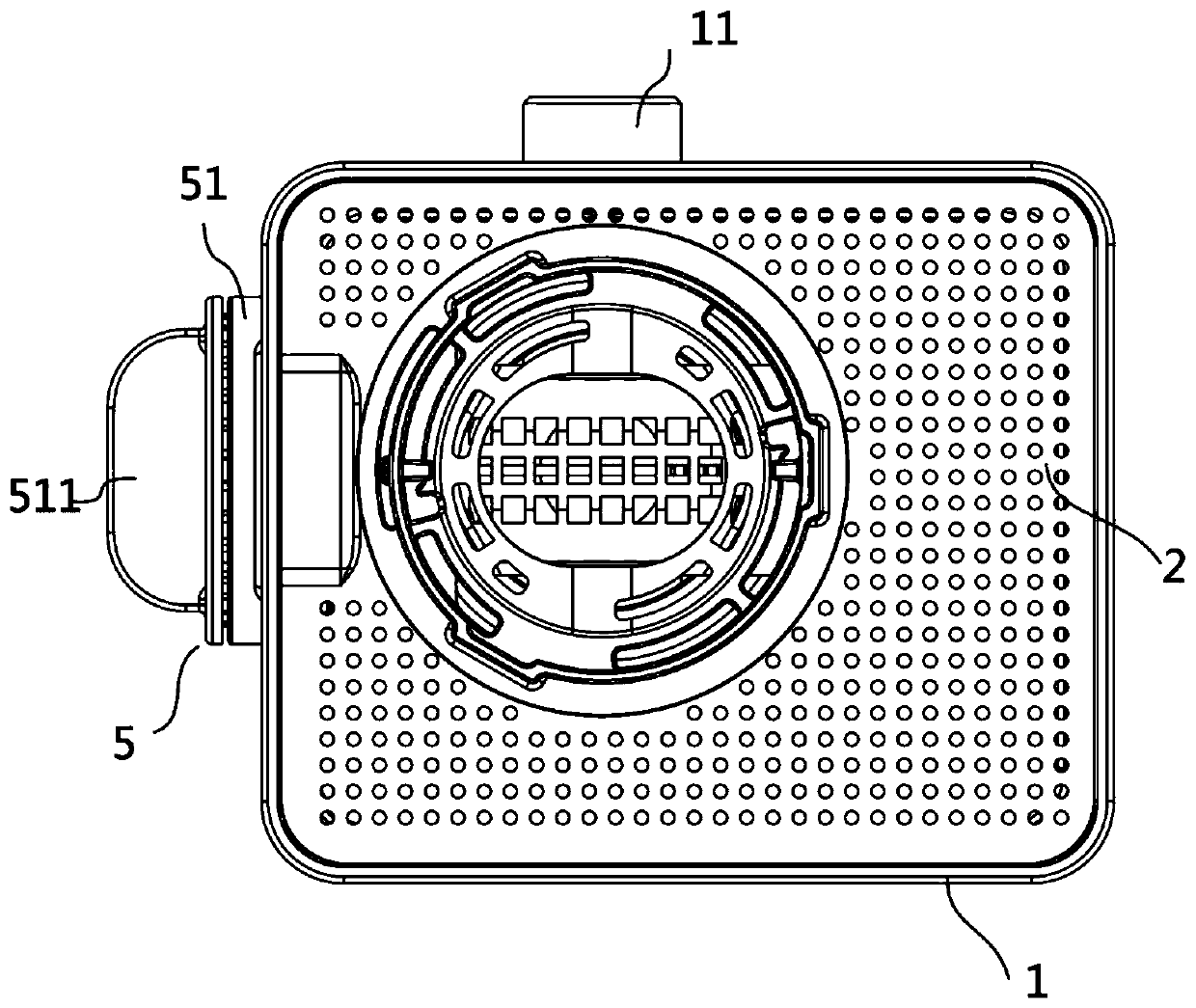

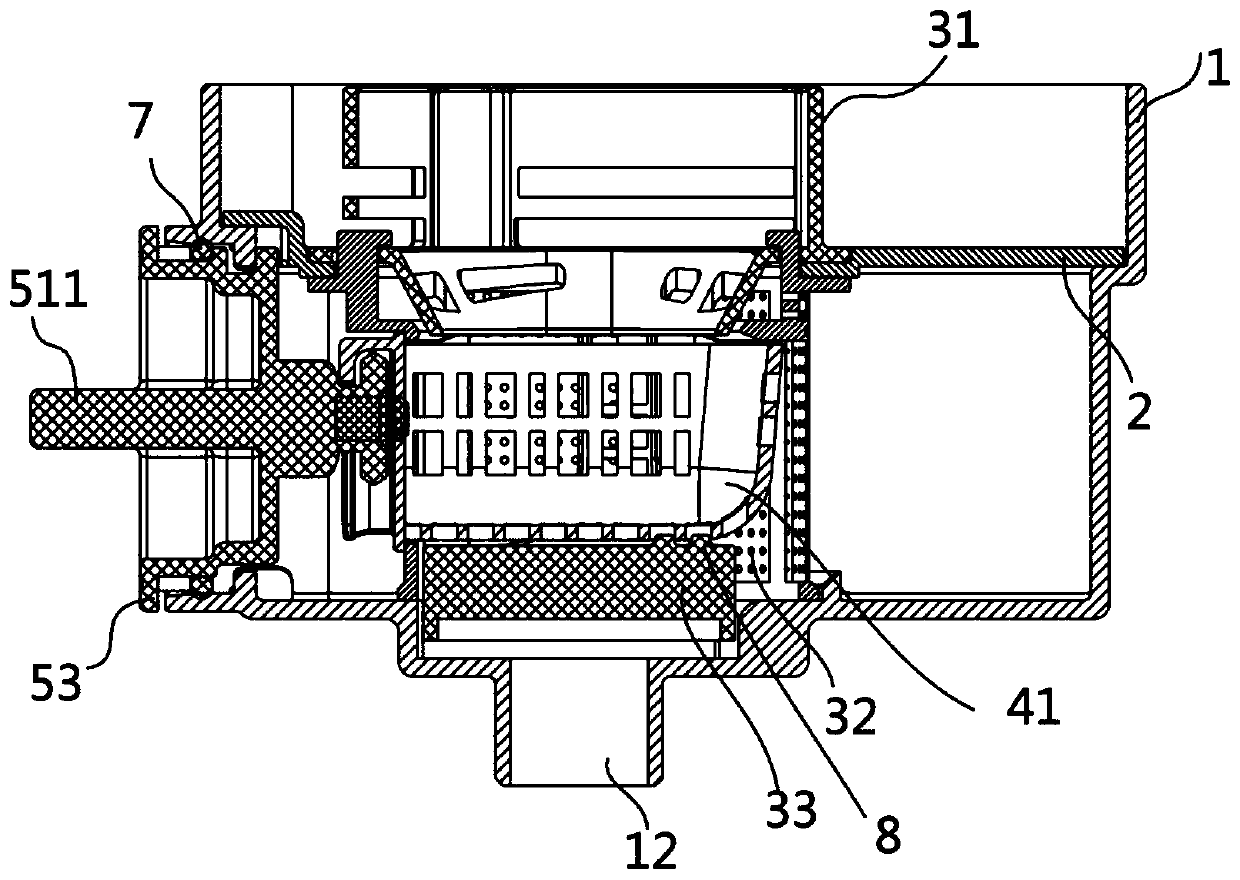

Cyclone cylinder, dust cup assembly and dust collector

PendingCN110301861ANormal filterGuaranteed Filtration EfficiencyCleaning filter meansSuction filtersCycloneEngineering

The invention belongs to the technical field of dust removal equipment, and particularly relates to a cyclone cylinder, a dust cup assembly and a dust collector. The cyclone cylinder comprises a cyclone cylinder body, at least one first cleaning part and a driving unit, wherein a plurality of filtering holes and a through groove which at least partially penetrates through the circumferential sidewall are formed in the circumferential side wall of the cyclone cylinder body; each first cleaning part at least partially extends out of the peripheral side wall through the through groove; and the driving unit is connected with the first cleaning parts, and the driving unit drives the first cleaning parts to move along the extending direction of the through groove. According to the cyclone cylinder, hairs wound on the outer surface of the cyclone cylinder can be effectively removed, so that the filtering holes of the cyclone cylinder body are not blocked by the hairs, and normal ventilationof the cyclone cylinder can be guaranteed, and the filtering efficiency of air is guaranteed; and the dust cup does not need to be opened in the cleaning process, all the cleaning processes are carried out inside the dust cup, and the pollution to the environment can be effectively reduced.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

Wall-attached stabilizing device for hydraulic engineering concrete tester

InactiveCN109490065AIncrease the areaWon't skewInvestigating material hardnessPneumatic pressureInternal pressure

The invention discloses a wall-attached stabilizing device for a hydraulic engineering concrete tester. The wall-attached stabilizing device structurally comprises a rear carrier sleeve, a body, a wall-attached stabilizing unit, and an elastic impact rod. An outer rotating ring is rotated to drive conical base rails to rotationally contract; arc connection rods are moved leftward so that inner pressure of communicating pipes varies to push pushing connection discs; the pushing connection discs push pasting discs to drive tough needles to extend out; the multiple tough needles on a combinationdisc extend out at the same time to slightly lock the surface of a concrete wall; the combination of the tough needles is in ring shape, so that area of contact with the surface of concrete is enlarged; the elastic impact rod never skews when a concrete resiliometer performs detecting; it is ensured that the elastic impact rod never crushes a seal ring to cause deformation; the seal ring allows normal filtering of concrete dust; normal discs help temporarily prevent slip on dry concrete walls; the elastic impart rod never slips when detecting dry concrete; the elastic impact rod never damages;the surface of the dry concrete wall is never damaged.

Owner:王世洛

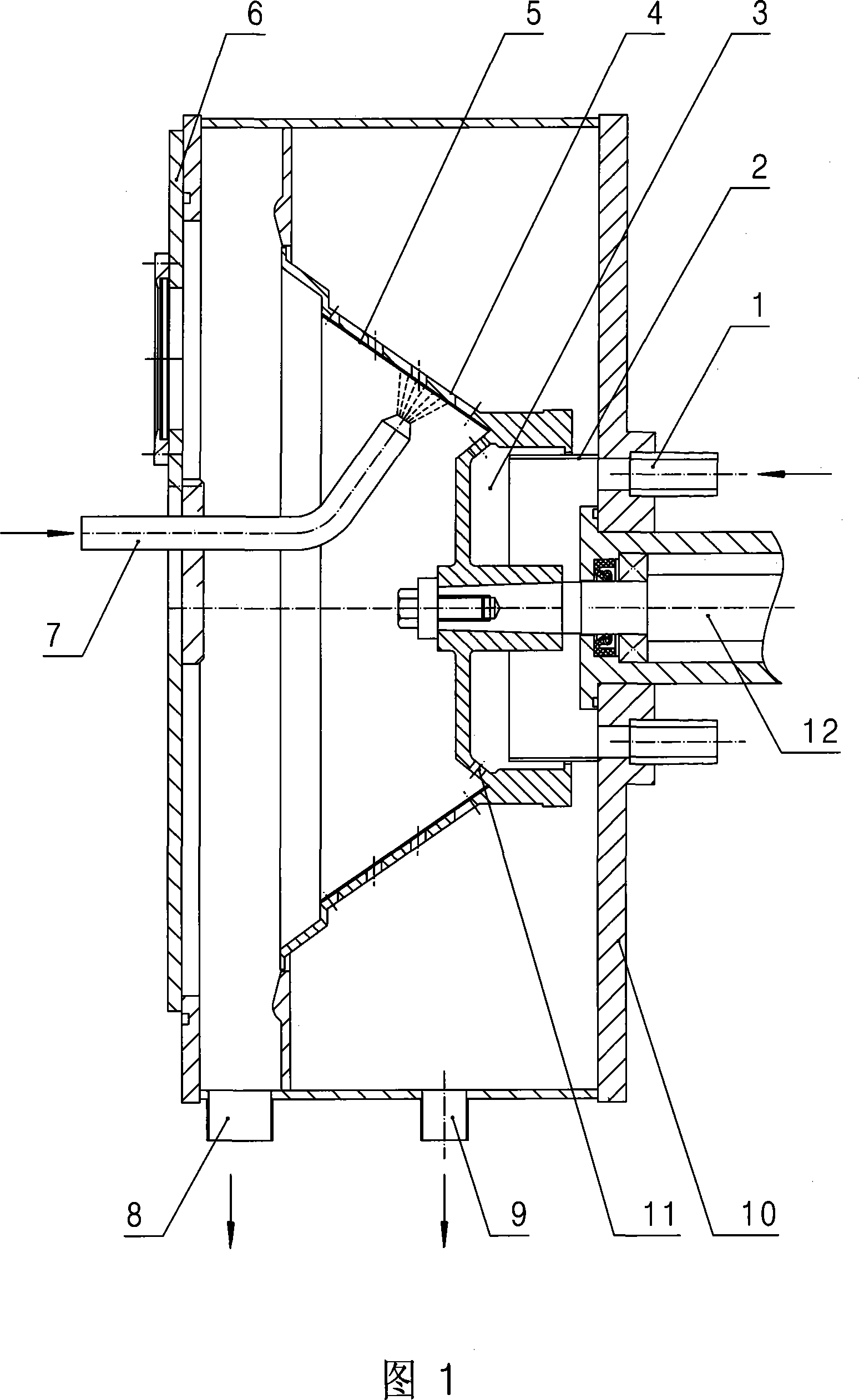

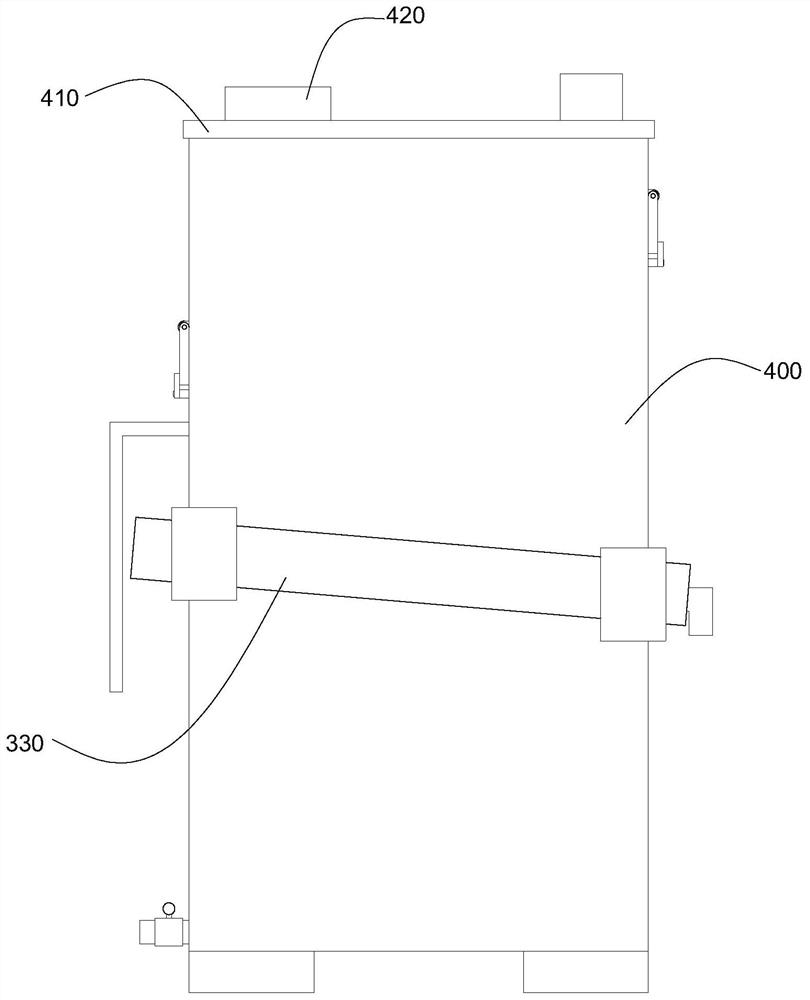

Biomass gas making furnace dedusting apparatus and dedusting method thereof

InactiveCN105779004AEfficient dust removalContinuous dust removal effectCombination devicesCombustible gas productionWater storageFiltration

The invention discloses a biomass gas making furnace dedusting apparatus and a dedusting method thereof. The biomass gas making furnace dedusting apparatus is characterized in that the spray nozzle of a spray head is upward, the upper end of the spray head is provided with a cylindrical latticed water storage frame, and the cylindrical latticed water storage frame is formed through closed wrapping of an upper dustproof and waterproof breathable film and a lower dustproof and waterproof breathable film, and is full of clear water; and the cylindrical latticed water storage frame is fixedly arranged in a dedusting tube through a lower flange and an upper flange. The method comprises the following steps: opening a ball valve, and upward spraying 65-90DEG C hot water to the end surface of the lower end of the cylindrical latticed water storage frame in a mist manner from the spray head. The apparatus and the method are suitable for dedusting of biomass gas making furnaces, and realize efficient and continuous dedusting effects through filtration of the cylindrical latticed water storage frame and water mist treatment.

Owner:罗福仲

Anti-blocking sewage treatment device

PendingCN114146464AAvoid cloggingNovel structureStationary filtering element filtersSewageSewage treatment

The invention provides an anti-blocking sewage treatment device which comprises a box body and a box cover, a feeding hopper is arranged on the box cover, and a first filtering structure, a second filtering structure and a third filtering structure are sequentially mounted in the box body from top to bottom; the first filtering structure is used for filtering large-particle impurities; the second filtering structure is used for filtering medium particle impurities, the second filtering structure comprises a second filtering plate, a cleaning mechanism is arranged below the second filtering plate, and the cleaning mechanism can clean filtering holes of the second filtering plate; the third filtering structure is used for filtering small-particle impurities, the third filtering structure comprises a third filtering plate, a first scraping plate is arranged above the third filtering plate, the first scraping plate is driven by a driving mechanism and abuts against the third filtering plate to slide, and the first scraping plate can conduct scraping and brushing cleaning on the third filtering plate; the multi-stage sewage treatment device is novel in structure, can perform multi-stage treatment on sewage, can clean filtering parts of small and medium particle impurities, effectively prevents the filtering parts from being blocked, and maintains a relatively good filtering effect.

Owner:清远市科博环保技术有限公司

Filtering and residue removing device for edible oil processing and use method of filtering and residue removing device

PendingCN114681976AImprove food qualityAvoid cloggingFatty-oils/fats refiningStationary filtering element filtersElectric machineProcess engineering

The invention discloses a filtering and residue removing device for edible oil processing, the filtering and residue removing device comprises a filtering box and a filtering net plate, the right side of the filtering box is provided with a cleaning mechanism, the cleaning mechanism comprises a bidirectional motor and a cleaning brush plate, the left side of the bidirectional motor is movably provided with a threaded rod, and the outer side of the threaded rod is provided with a threaded seat; an inclined scraping plate is mounted at one end of the sweeping brush plate, the filter screen plate is fixedly mounted in the filter box, the left side of the bidirectional motor is fixedly mounted on the right side surface of the filter box, and the upper end of the sweeping brush plate is fixed to the lower end of a threaded seat. According to the edible oil filtering device, oil residues falling on the filter screen plate and edible oil can be filtered, the oil residues on the filter screen plate can be cleaned, so that the eating quality of finished edible oil in the later period is improved, the oil residues blocked in holes of the filter screen plate can be cleaned, the filter screen plate is prevented from being blocked by the oil residues, and the edible oil filtering effect is improved. The filtering efficiency of the edible oil is improved.

Owner:安徽金葵食品科技有限公司

A speaker-type flower pot with adaptive temperature to control watering

ActiveCN112243731BEasy to coverImprove filtering effectDomestic cooling apparatusLighting and heating apparatusWater storageAgricultural engineering

The invention provides a speaker-type flowerpot capable of self-adapting temperature to control watering. The speaker-type flowerpot capable of adjusting and watering by adapting to the temperature includes: a speaker frame; The inner surface of the basin body is fixedly connected with an inner partition net; a water storage box, the water storage box is fixed on the outer side of the sound box frame, the bottom of the inner wall of the water storage box is provided with a sliding groove, and the water storage box is The top of the water storage box is provided with a mounting hole, and one side of the top of the water storage box is provided with a sealing groove. The speaker-type flower pot with self-adapting temperature to control watering provided by the invention has the advantages of convenient filtering and cooling of the remaining hot tea in the office, avoiding unnecessary damage to green plants caused by direct pouring of hot tea into the flower pot, and separating the The remaining tea leaves are easy to clean and maintain, ensure the cleanliness and normal filtration inside the connecting cover, and avoid the phenomenon of clogging after the tea leaves are accumulated.

Owner:福建省德化县腾艺陶瓷有限公司

a dust filter

ActiveCN104826425BWill not deformNot easy to damageDispersed particle filtrationAir filtrationFilter material

A dust filtering apparatus is characterized by comprising a gas inlet, a gas outlet, a tank provided with a dust outlet, and a filtering structure arranged in the tank. The filtering structure comprises a plurality of annular skeletons with increasing diameters, the annular skeleton with a smaller diameter is arranged in the annular skeleton with a bigger diameter, the cross section of each annular skeleton is in a U shape, the wall of each annular skeleton is provided with a plurality of through holes; annular sealing plates are arranged between the upper openings of annular skeletons, and the upper opening of the biggest annular skeleton and the tank; filter cloth is paved on the external lateral wall of each annular skeleton, the gas outlet is arranged in the top part of the tank, the gas inlet is arranged in the lower part of the tank, the dust outlet provided with a valve is arranged in the bottom of the tank, and the gas outlet is connected to an exhaust fan through a pipeline. Compared with the prior art, the provided dust filtering apparatus has the advantages that the air filtration capacity is large and the filter material cannot be destroyed easily.

Owner:FOSHAN XINGLI ENVIRONMENTAL PROTECTION EQUIP CO LTD

Wastewater purification system for red brick production workshop

PendingCN112225365AImprove purification effectQuick clean upWater/sewage treatment by irradiationSpecific water treatment objectivesProcess engineeringDrive shaft

The invention discloses a wastewater purification system for a red brick production workshop, and relates to the field of red brick production wastewater treatment. The wastewater purification systemcomprises a device main body; and fixing plates are fixed above both sides of the device main body. Through arrangement of a third motor, a driving shaft, a material turning plate, a discharging opening, a sealing plug and a limiting rod, when impurities on a filter screen need to be cleaned, a user pushes the limiting rod upwards, the limiting rod moves upwards to drive a sliding block to move upwards, the sliding block moves upwards to extrude a spring, and the spring is stressed and compressed; after the limiting rod does not contact with the sealing plug any more, a user takes out the sealing plug from the discharging opening, then the user starts the third motor through an operation table; the third motor works to drive the driving shaft to rotate; the driving shaft rotates to drive the material turning plate to rotate; and due to the fact that the bottom of the material turning plate makes contact with the filter screen, the impurities on the filter screen can be brought up whenthe material turning plate rotates; when the material turning plate rotates to one side of the discharging opening, impurities located at the top of the material turning plate can slide to the discharging opening, and the impurities are discharged through the discharging opening.

Owner:岳阳县星浩环保砖有限公司

Sewer pipe filtering device

InactiveCN108187385ANormal filterEasy to moveStationary filtering element filtersRubber ringEngineering

The invention discloses a sewer pipe filtering device. The technical scheme is characterized in that the sewer pipe filtering device comprises an upper connecting seat and a lower connecting seat which are connected with a sewer pipe, wherein a filtering unit is arranged between the upper connecting seat and the lower connecting seat and comprises a first connecting shaft horizontally and rotationally connected to the side wall of the lower connecting seat, a second connecting shaft rotationally connected to the side wall of one side, away from the first connecting shaft, of the lower connecting seat, a filter net, a sleeve glidingly connected to the upper connecting seat in the vertical direction, a rubber ring fixedly connected to the lower end surface of the sleeve and butted against the filter net as well as a spring nested on the upper connecting seat and pushing the sleeve to move downwards, one end of the filter net winds around the first connecting shaft, the other end of the filter net winds around the second connecting shaft, and a driving mechanism driving the second connecting shaft to rotate is arranged between the sleeve and the second connecting shaft. By means of the scheme, the filter net can be unchoked without dismounting the upper connecting seat and the lower connecting seat, and blocking of the filter net is prevented.

Owner:李美珍

Filter paper filtering method in chemical experiment

The invention discloses a filter paper filtering method in a chemical experiment. The method comprises the following steps: folding filter paper to be conical, directly putting the folded filter paper on a tall beaker, and filtering pulp. The method is easy to perform, convenient, quick and good in filtering effect, and few utensils are used.

Owner:ANHUI SCI & TECH UNIV

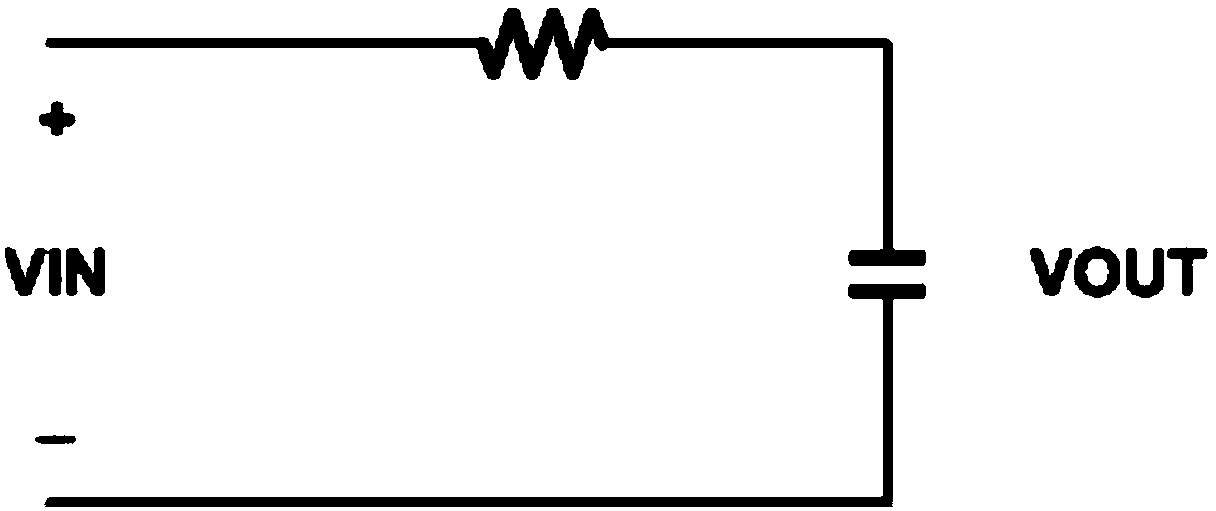

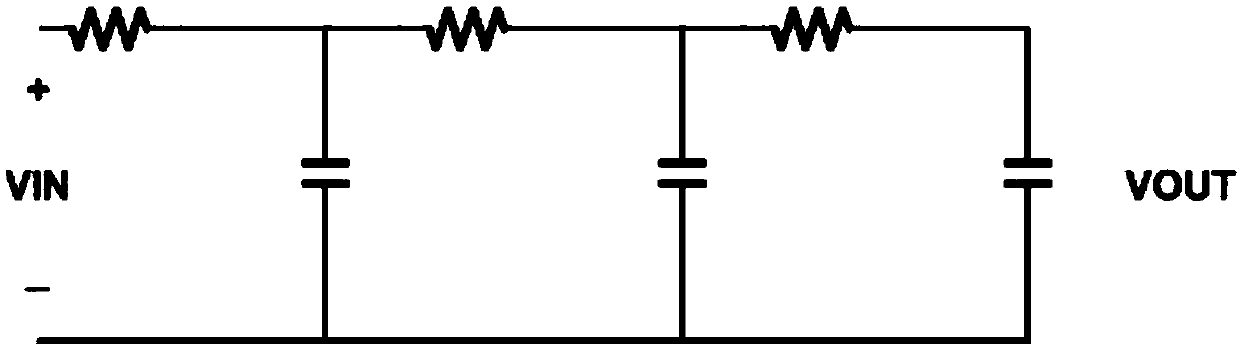

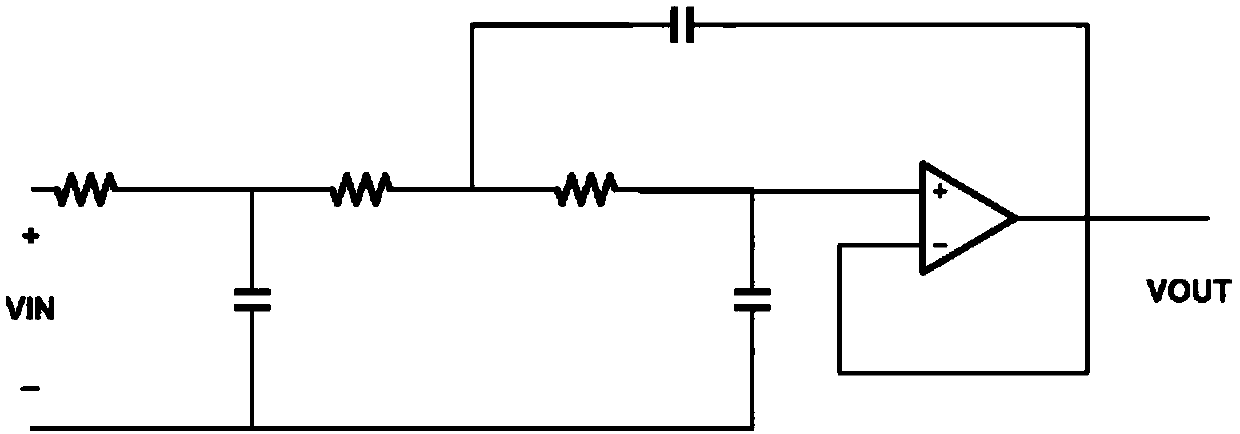

High-speed reaction type low-pass filter, filter circuit and control method

InactiveCN109687838ARapid responseNormal filterFrequency selective two-port networksCapacitanceBand-pass filter

The invention discloses a high-speed reaction type low-pass filter, comprising an operational amplifier U1 and a switch phib1, a switch phia1, a switch phib2, a switch phia2, a switch phib3 and a switch phia3 that are sequentially connected in series, wherein the front end of the switch phib1 serves as the input end of the low-pass filter, the rear end of the switch phib1 is grounded through a capacitor C1, the rear end of the switch phia1 is grounded through a capacitor C2, the rear end of the switch phib2 is grounded through a capacitor C3, the rear end of the switch phib3 is grounded through a capacitor C4, the rear end of the switch phia3 is connected to the non-inverting end of the operational amplifier U1, the rear end of the switch phia2 is connected to the output end of the phase of the operational amplifier U1 through a capacitor C5, and the output end and the inverting end of the operational amplifier U1 are connected to each other to serve as the output end of the low-pass filter. According to the scheme of the invention, the angular frequency of low-pass filtering is reduced in the case of not reducing the channel switching speed, and thus the adverse influence of noiseon signals can be further reduced.

Owner:SHENZHEN BETTERLIFE ELECTRONICS SCI & TECH

A waste water filtration and purification treatment device

ActiveCN108821475BNormal filterImprove filtration efficiencyTreatment involving filtrationMultistage water/sewage treatmentFiltrationWastewater

The invention relates to the technical field of wastewater treatment devices, and discloses a wastewater filtering and purifying treatment device. The wastewater filtering and purifying treatment device comprises a filtering box. Two sides of the top of the filtering box are fixedly connected with support plates. The top ends of the two support plates are moveably sleeved with a rotation shaft. Two ends of the rotation shaft are fixedly sleeved with a reel positioned between the two support plates. The top of the side face of one of the support plates is fixedly connected with a supporting plate. The top of the supporting plate is fixedly provided with a driving motor. An output shaft of the driving motor is fixedly connected with one end of the rotation shaft. The top of the filtering boxis fixedly connected with a vertical plate. The wastewater filtering and purifying treatment device is capable of, through enabling a filter screen to cross a port at the bottom of a filtering watertank, in a process of filtering wastewater, rotating a rolling shaft so that a new filter screen is moved to the port of the filtering water tank, thereby preventing garbage in the wastewater from blocking the filter screen in a continuous filtering process of the wastewater, ensuring that the wastewater is normally filtered, and improving filtering efficiency of the wastewater.

Owner:洛阳蓝源环保科技有限公司

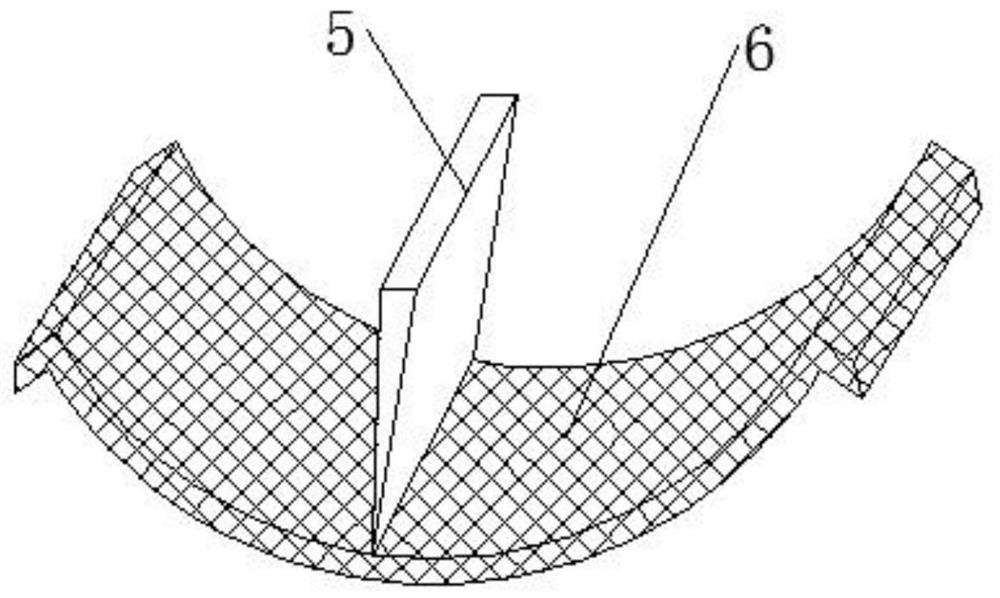

Feeder unit of the centrifugal discharging type centrifugal machine

The present invention discloses a feeding device in an unloading centrifuge, which can make a suspension distribute evenly along a circumference of a small end of a rotary drum. The present invention comprises a machine shell. A rotating principal axis is arranged in the machine shell and is equipped with the rotary drum. The external side of the bottom of the drum is concave inwards to form a material silo. The bottom of the material silo communicates with a plurality of material holes evenly arranged on the same circumference at the bottom of the drum. The interior wall of the machine shellis equipped with a material discharge hopper cooperating with the material silo, and the material discharge hopper communicates with a plurality of feed pipes going through the machine shell. The feeding device of the present invention can make the centrifuge operate smoothly in the working course, so as to ensure the normal operation of filtering, spinning, unloading and other courses of the centrifuge and reduce the mechanical problems greatly.

Owner:JIANGSU PEONY CENTRIFUGE MFG

A sewage filter device

InactiveCN108187385BNormal filterEasy to moveStationary filtering element filtersRubber ringStructural engineering

The invention discloses a sewer pipe filtering device. The technical scheme is characterized in that the sewer pipe filtering device comprises an upper connecting seat and a lower connecting seat which are connected with a sewer pipe, wherein a filtering unit is arranged between the upper connecting seat and the lower connecting seat and comprises a first connecting shaft horizontally and rotationally connected to the side wall of the lower connecting seat, a second connecting shaft rotationally connected to the side wall of one side, away from the first connecting shaft, of the lower connecting seat, a filter net, a sleeve glidingly connected to the upper connecting seat in the vertical direction, a rubber ring fixedly connected to the lower end surface of the sleeve and butted against the filter net as well as a spring nested on the upper connecting seat and pushing the sleeve to move downwards, one end of the filter net winds around the first connecting shaft, the other end of the filter net winds around the second connecting shaft, and a driving mechanism driving the second connecting shaft to rotate is arranged between the sleeve and the second connecting shaft. By means of the scheme, the filter net can be unchoked without dismounting the upper connecting seat and the lower connecting seat, and blocking of the filter net is prevented.

Owner:李美珍

Dust filtering apparatus

ActiveCN104826425ANot easy to damageLarge air filtration capacityDispersed particle filtrationAir filtrationFilter material

A dust filtering apparatus is characterized by comprising a gas inlet, a gas outlet, a tank provided with a dust outlet, and a filtering structure arranged in the tank. The filtering structure comprises a plurality of annular skeletons with increasing diameters, the annular skeleton with a smaller diameter is arranged in the annular skeleton with a bigger diameter, the cross section of each annular skeleton is in a U shape, the wall of each annular skeleton is provided with a plurality of through holes; annular sealing plates are arranged between the upper openings of annular skeletons, and the upper opening of the biggest annular skeleton and the tank; filter cloth is paved on the external lateral wall of each annular skeleton, the gas outlet is arranged in the top part of the tank, the gas inlet is arranged in the lower part of the tank, the dust outlet provided with a valve is arranged in the bottom of the tank, and the gas outlet is connected to an exhaust fan through a pipeline. Compared with the prior art, the provided dust filtering apparatus has the advantages that the air filtration capacity is large and the filter material cannot be destroyed easily.

Owner:FOSHAN XINGLI ENVIRONMENTAL PROTECTION EQUIP CO LTD

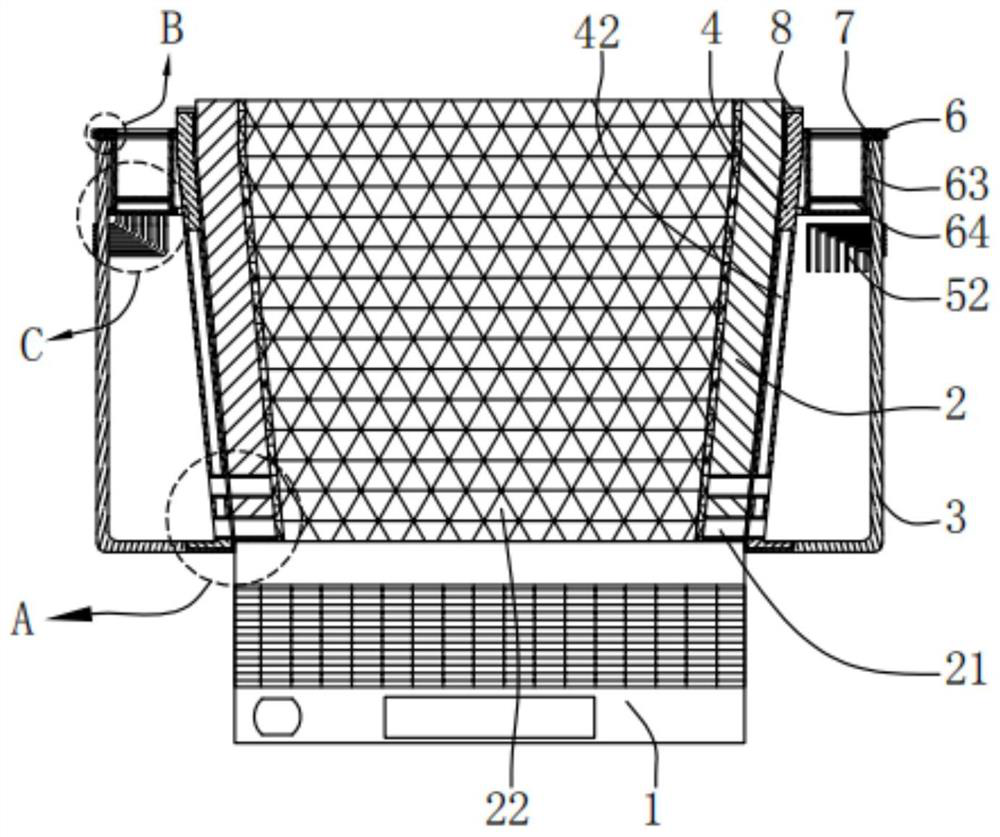

An easy-to-clean dishwasher

ActiveCN107307828BEasy to cleanEasy to operateTableware washing/rinsing machine detailsKitchen equipmentWater flowFilter effect

The invention provides a dish-washing machine convenient to clean. A residue collector is made to detachably stretch into a lifting cup to be fixed by making a via hole used for installing the residue collector formed in the side of the lifting cup; on one hand, the residue collector and the lifting cup are made to form two parts respectively, the structural complexity of the lifting cup body and a mold is simplified, and machine shaping is conducted conveniently; on the other hand, the residue collector can be installed in the lifting cup, the residue collecting efficiency is not affected, and the residue collector can be removed from the lifting cup to make cleaning work of the residue collector and the lifting cup convenient to operate, so that the residue collector is detachable in two directions of the lifting direction, facing the lifting cup relative to a circulating water cup, of the residue collector and the lifting cup side direction. A fine filter screen is located on the periphery of the residue collector, secondary filtration is conducted on circulating washing water flowing out of the residue collector so as to further improve the cleanliness of the circulating washing water, and the filtering effect is improved conveniently.

Owner:JOYOUNG CO LTD

Loudspeaker box type flowerpot capable of adjusting and controlling watering by self-adapting to temperature

ActiveCN112243731AEasy to coverImprove filtering effectDomestic cooling apparatusLighting and heating apparatusSound boxTea leaf

The invention provides a loudspeaker box type flowerpot capable of adjusting and controlling watering by self-adapting to temperature. The loudspeaker box type flowerpot capable of adjusting and controlling watering by self-adapting to the temperature comprises a loudspeaker box frame, a basin body and a water storage box; the bottom of the basin body is fixed to the top of the loudspeaker box frame, a connecting hole is formed in the bottom of the surface of the basin body, and an inner separation net is fixedly connected to the inner surface of the basin body; and the water storage box is fixed to the outer side of the loudspeaker box frame, a sliding groove is formed in the bottom of the inner wall of the water storage box, a mounting hole is formed in the top of the water storage box,and a sealing groove is formed in one side of the top of the water storage box. The loudspeaker box type flowerpot capable of adjusting and controlling watering by self-adapting to the temperature hasthe advantages that residual hot tea water in an office can be filtered and cooled conveniently, unnecessary damage to green plants due to the fact that the hot tea water is directly poured into theflowerpot is avoided, and separated tea leaves are convenient to clean and maintain; and the cleanliness and normal filtration in a connecting cover are guaranteed, and the phenomenon that tea leavesare blocked after being accumulated is avoided.

Owner:福建省德化县腾艺陶瓷有限公司

Device and method for improving filtering capacity of INBA rotary drum for dealing with foam slags

InactiveCN111057805ASmall particlesSmall filter resistanceRecycling and recovery technologiesBuffer tankSlag

The invention provides a device and method for improving the filtering capacity of an INBA rotary drum for dealing with foam slags. The device involves the rotary drum, wherein a distributor is arranged in the rotary drum, a buffer tank is fixed to the lower portion of the distributor, a bottom plate of the buffer tank is gradually inclined from top to bottom, and the inclination direction of thebottom plate is consistent with the rotation direction of the drum body, below the bottom plate, of the rotary drum. According to the device and method, slurry flows into one side of the rotary drum after being guided by the buffer tank, and due to the fact that the bottom plate of the buffer tank is gradually inclined from top to bottom, in the rotary lifting stage of the rotary drum, water flowsback to the lowest point of the rotary drum, and water granulated slag is followingly lifted by the combination of a slag lifting net and a filter screen so that the water and the slag can be quicklyseparated, and the overflow phenomenon is avoided.

Owner:RIZHAO STEEL HLDG GROUP

air filter

ActiveCN106345196BEfficient removalEasy to cleanDispersed particle filtrationTransportation and packagingForeign matterAir filtration

The invention provides an air filter device capable of effectively removing magnetic foreign objects, effectively cleaning filter screen components, and ensuring the filtering effect. The air filter device involved in the present invention is used to filter particulate matter in the air, and is characterized in that it has: a housing; at least two filter components; a cleaning component, wherein the filter component includes a multi-layer filter screen, at least one filter At least one layer of filter screen in the component is a magnetic filter screen, and the cleaning component includes: at least one cleaning plate unit installed in the housing, each cleaning plate unit is located between two adjacent filter components, and has: a rotating plate; and a first cleaning liquid distribution pipe; an air blowing plate unit; a control unit; and a cleaning liquid discharge unit, which is installed at the bottom of the shell body and discharges the cleaning liquid with particulate matter from the shell body.

Owner:JINGMEN GEM NEW MATERIAL

A high-strength aluminum alloy production equipment

InactiveCN109631576BSpeed up meltingIncrease productivityCharge treatment typeCrucible furnacesAir pumpExhaust pipe

Owner:安徽辰隆铝业有限公司

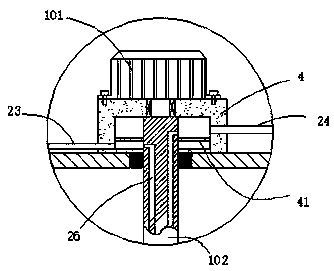

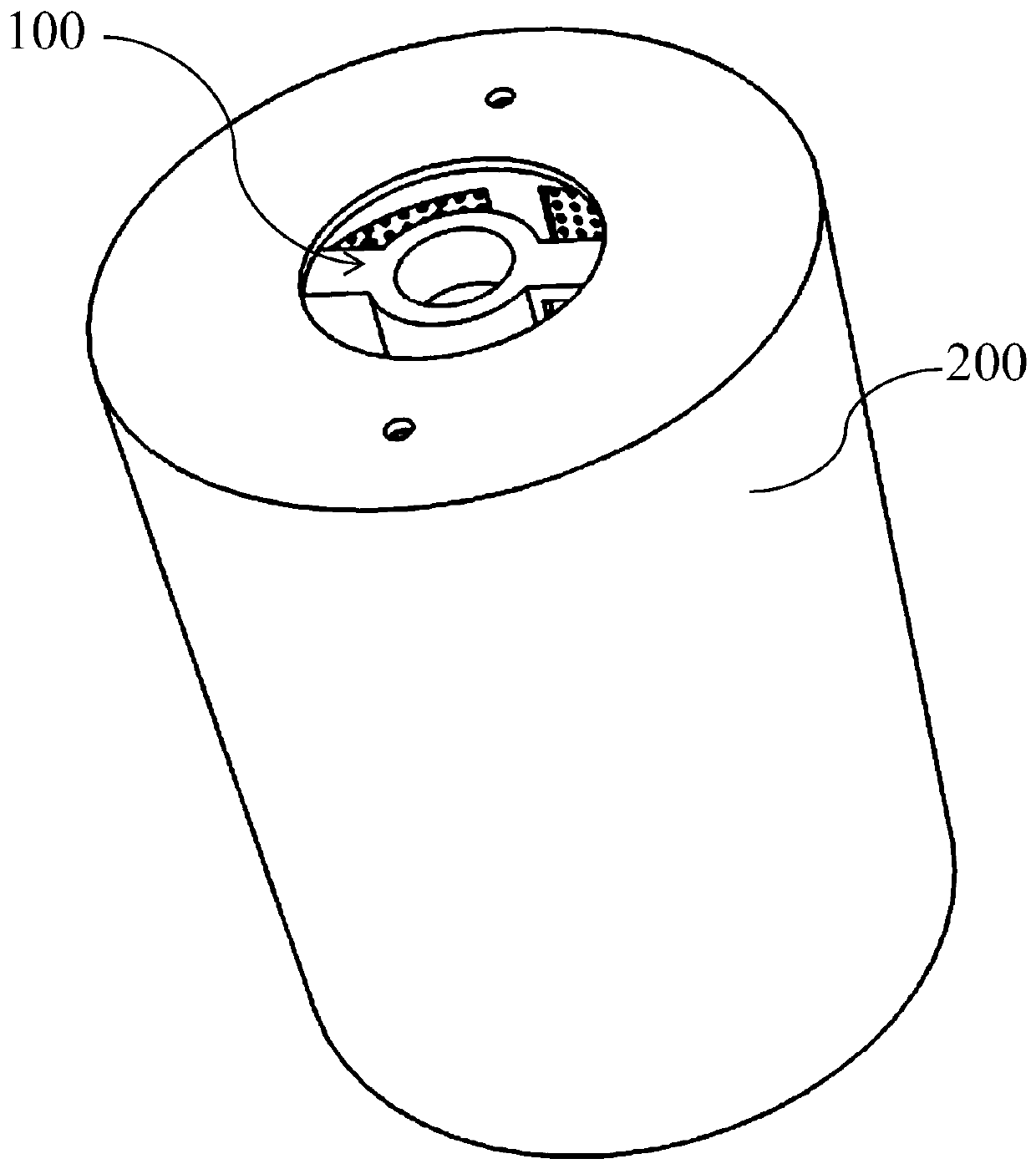

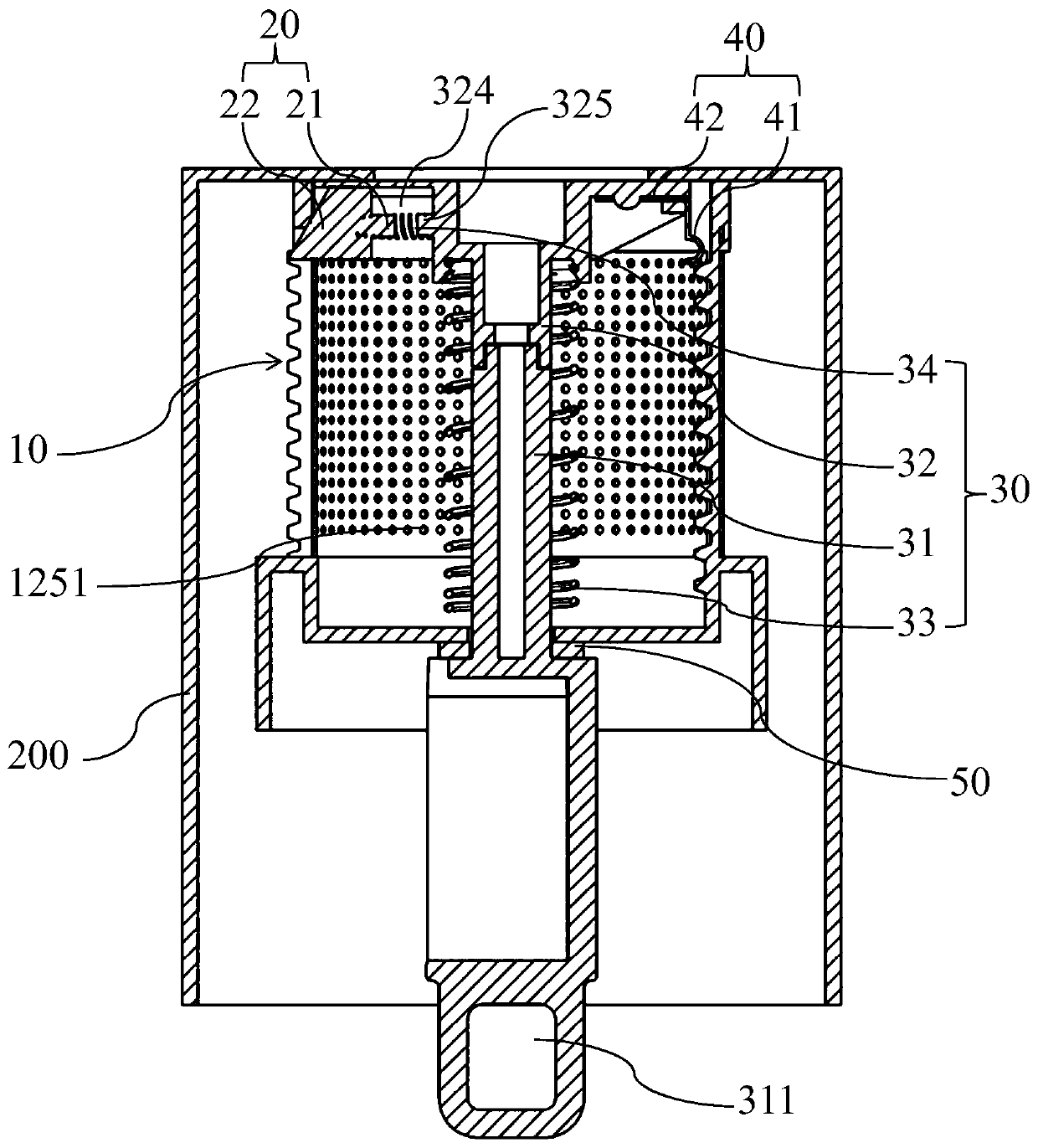

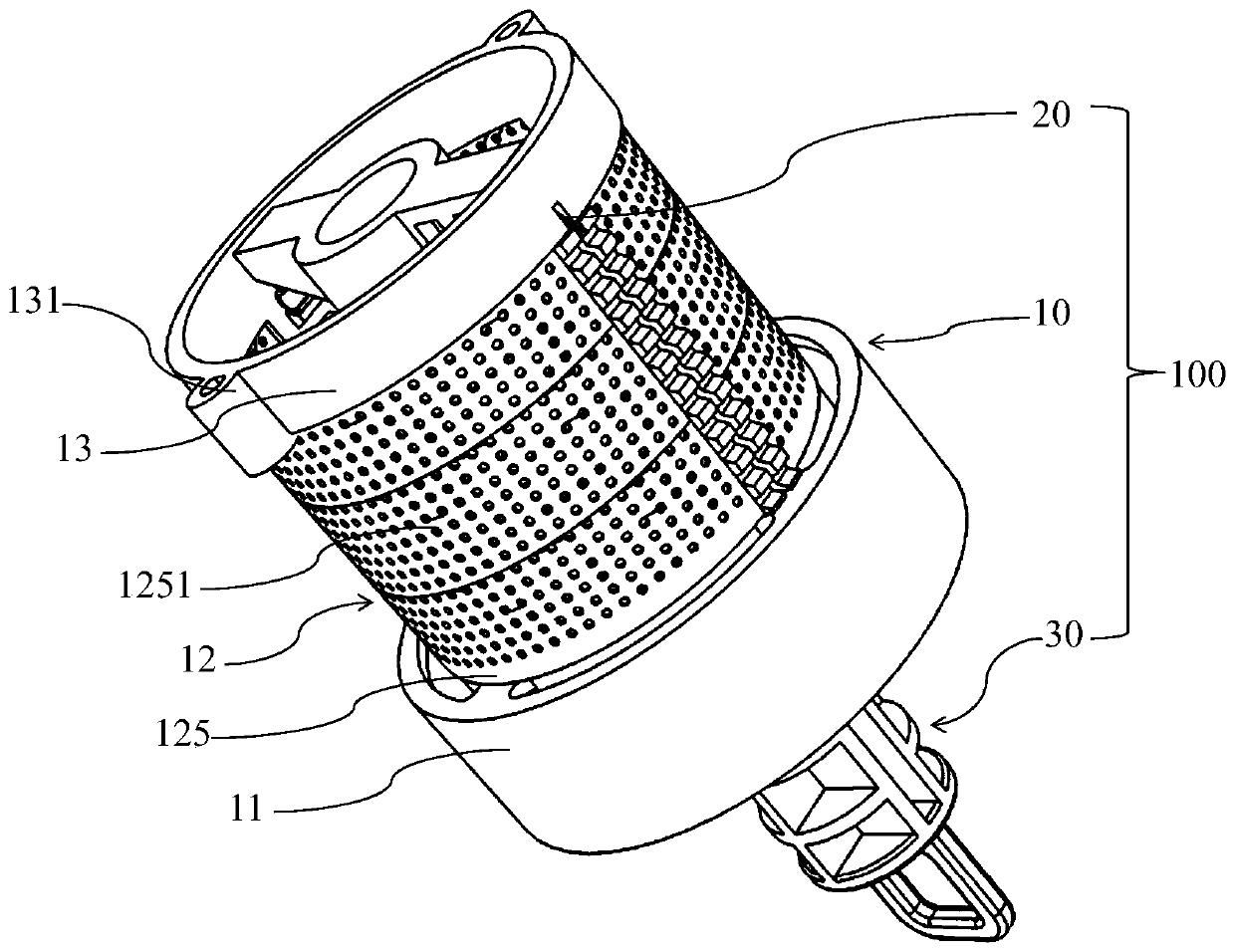

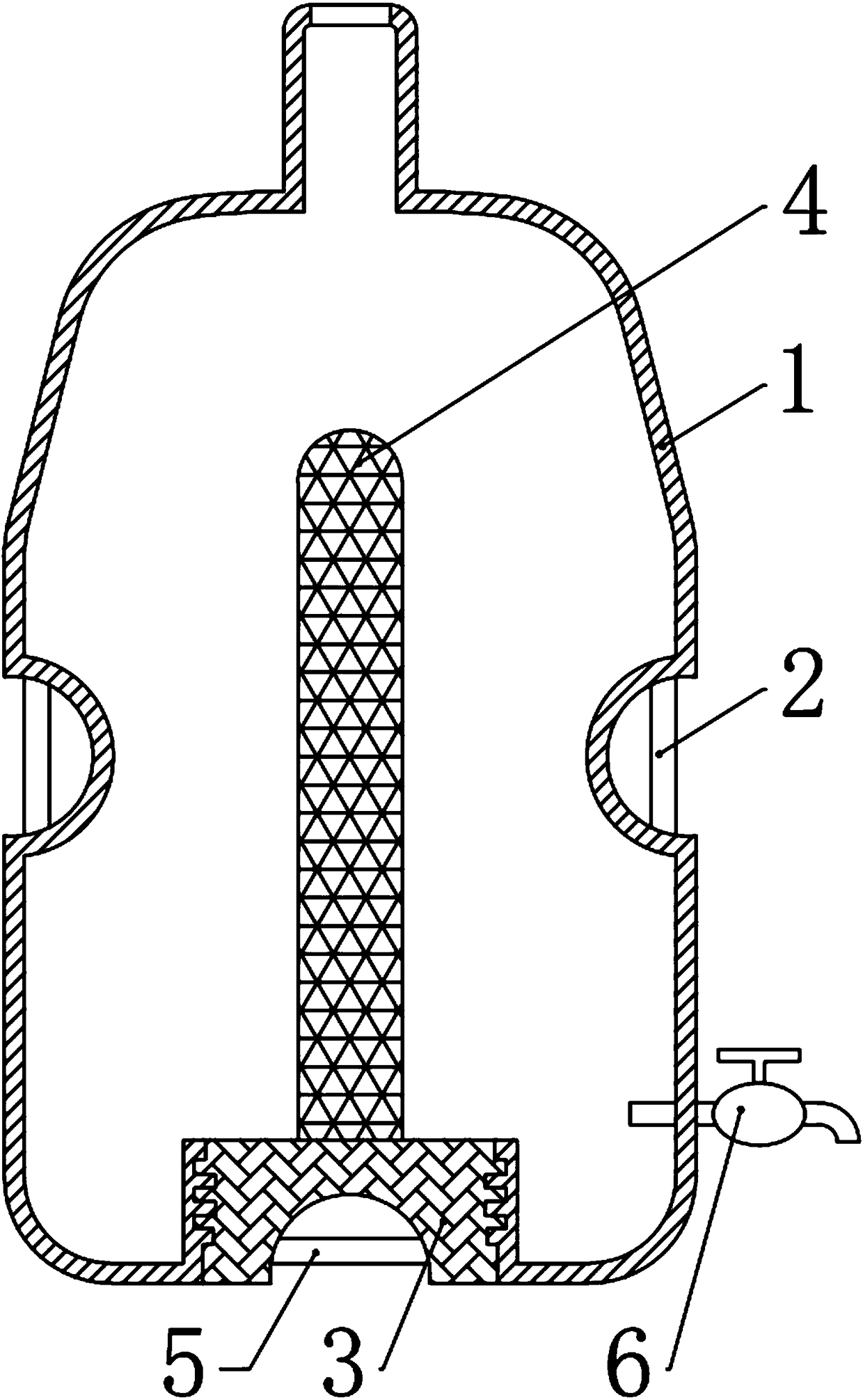

Water dispenser bucket

InactiveCN108146810AThe function of adsorbing impurities is normalEasy to carryWater treatment locationDischarging meansBiochemical engineeringWater quality

The invention discloses a water dispenser bucket comprising a bucket body (1) and further comprising a base (3). The bucket walls of the bucket body (1) are inwards sunken; first handles (2) are arranged in the sunken positions of the bucket walls; the base (3) is of a cylindrical structure, and a filter element (4) is arranged at the top of the base (3); the bottom of the base (3) is sunken, anda second handle (5) is arranged in the sunken position of the base (3); the base (3) is connected with the bottom of the bucket body (1) in a threaded mode, and when the base (3) is connected with thebucket body (1), the bottom of the base (3) is flush with the bottom of the bucket body (1); and a tap (6) is arranged on the lower portion of the bucket body (1). According to the water dispenser bucket, the multiple handles are arranged, and thus carrying is facilitated; the filter element is arranged, so that the drinking water quality is improved; and the tap is arranged and can be separatedfrom a water dispenser to be used, so that the requirement of people outdoor is met.

Owner:PANZHIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com