Air filtering device

An air filter device and air technology, applied in the direction of dispersed particle filtration, transportation and packaging, and separation of dispersed particles, can solve the problems of mesh blockage, time-consuming disassembly and installation operations, and adverse effects on the life of filter components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The air filter device involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0028]

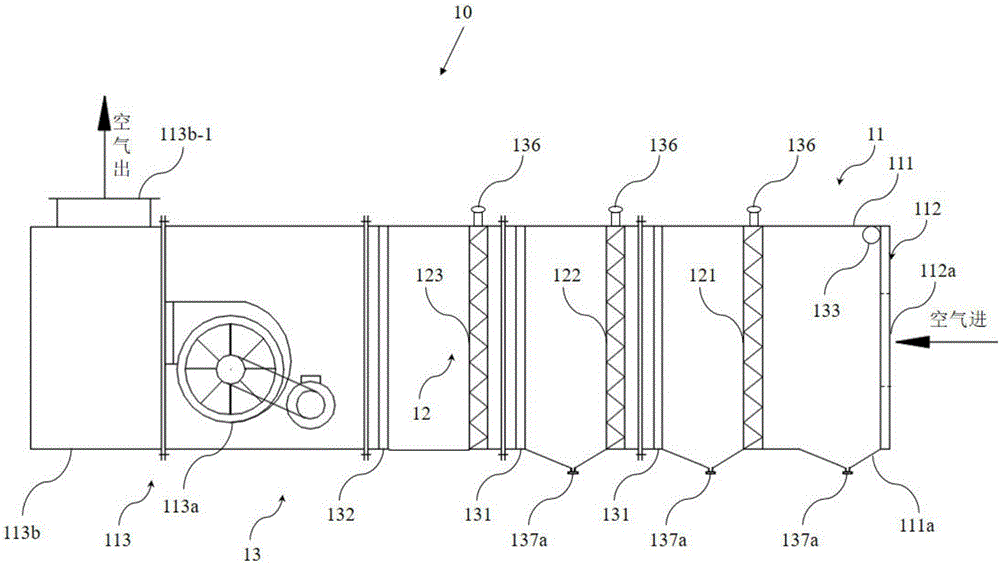

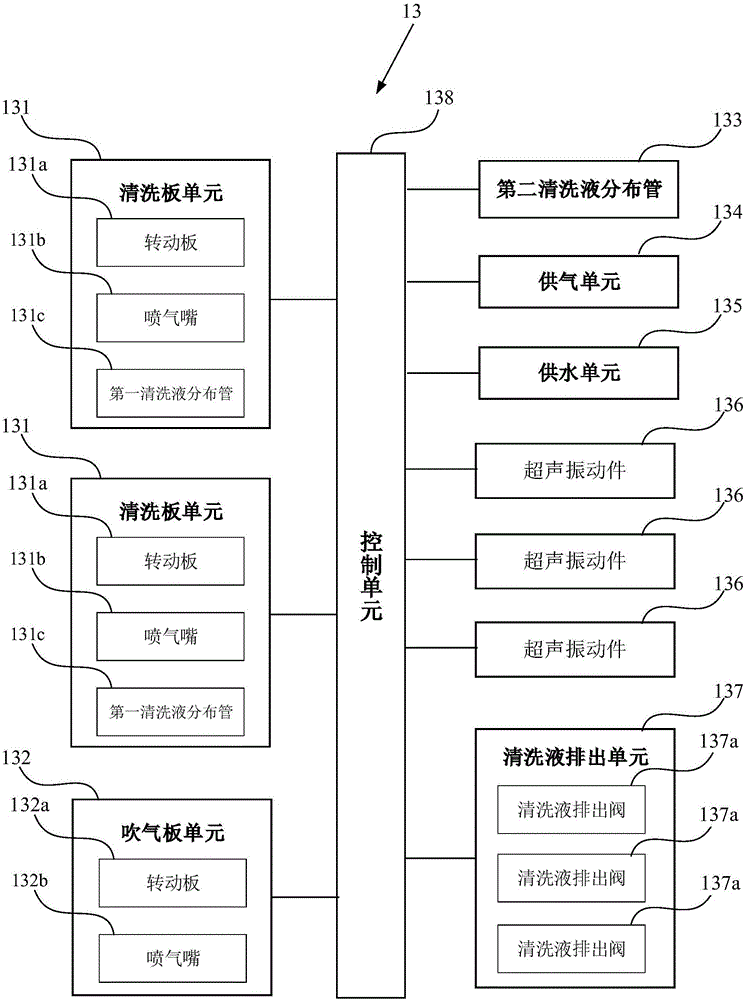

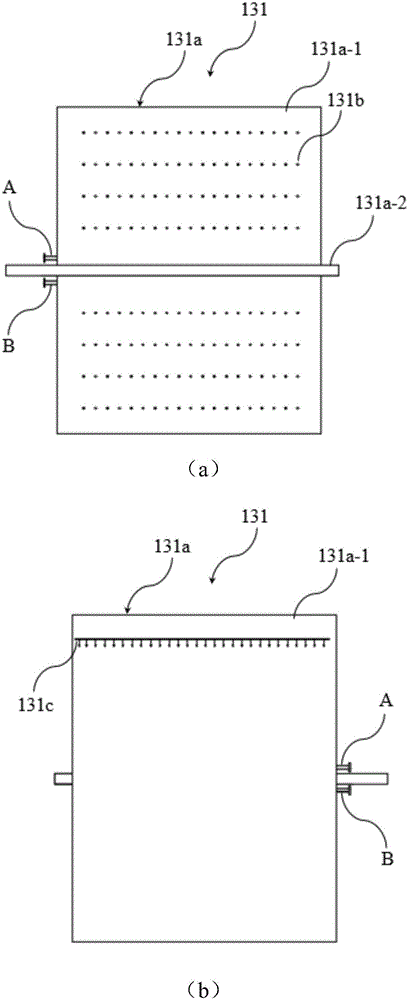

[0029] figure 1 It is a structural schematic diagram of the air filter device involved in the present invention in an embodiment.

[0030] Such as figure 1 As shown, the air filter device 10 is used to filter various particles such as dust in the air, and it has a housing 11 , three filter components 12 and a cleaning component 13 .

[0031] The housing 11 is made of stainless steel (sprayed with PTFE material on the surface) or plastic material, and has no magnetism. It includes a housing body 111 , an air inlet portion 112 and an air outlet portion 113 . The shell body 111 is a hollow structure.

[0032] The air inlet part 112 is located on the right side of the shell body 111, and it includes an air inlet 112a and a sealing cover (not shown in the figure). The air inlet 112a is used to allow air to enter the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com