Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve pressure test efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

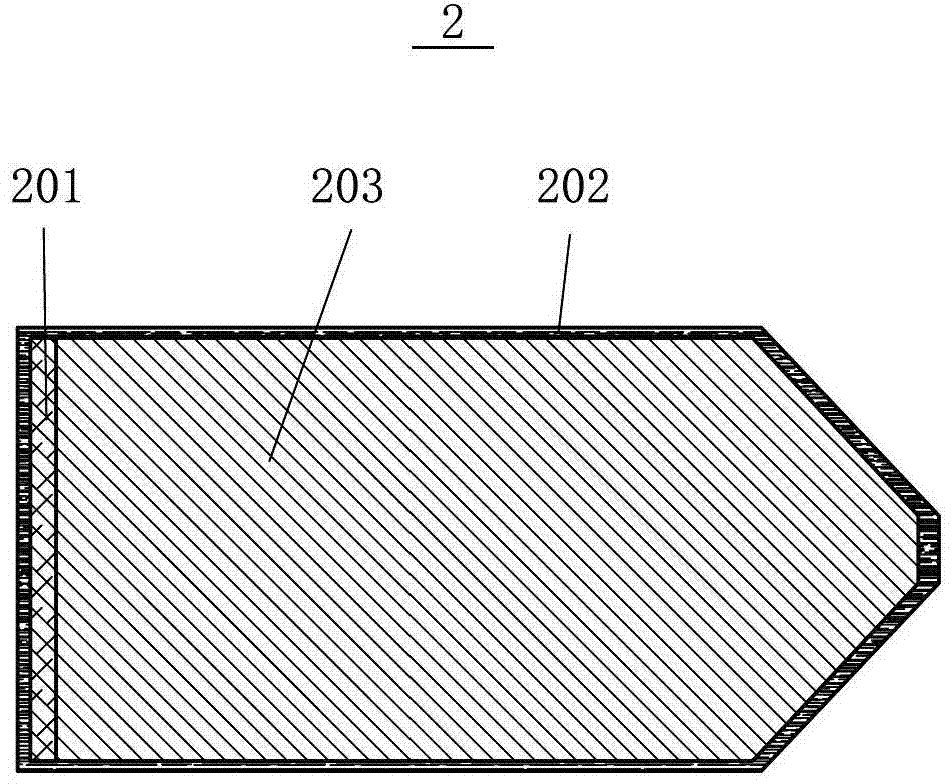

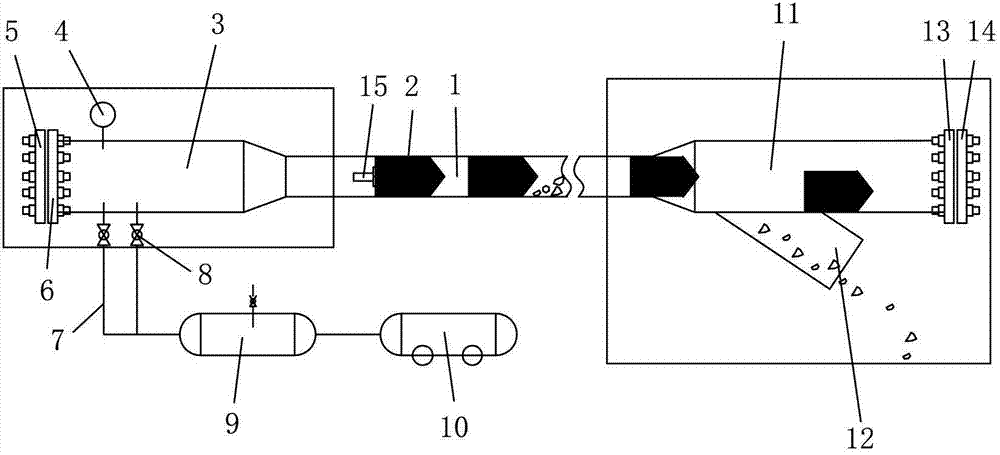

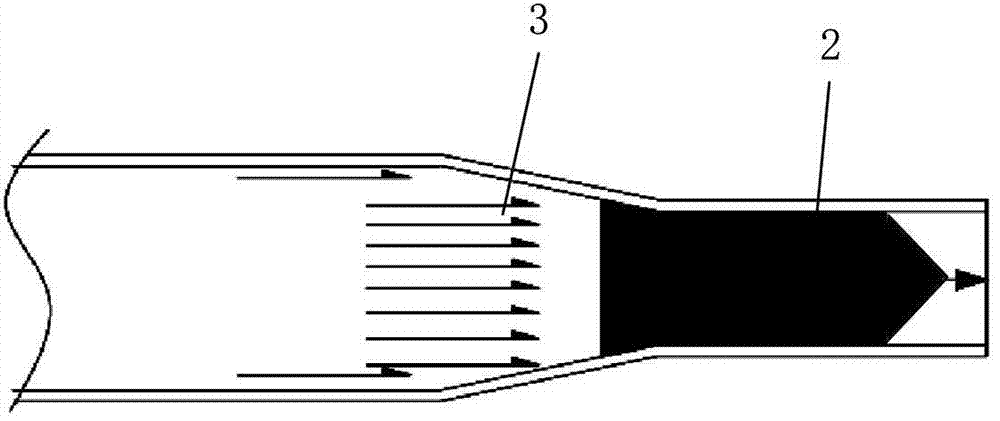

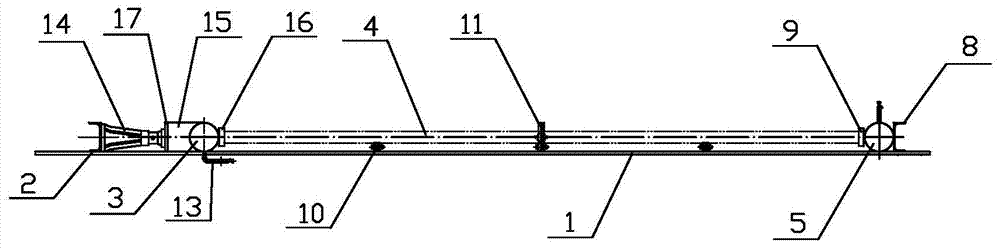

Elastic cleaning ball, cleaning device, cleaning method and pressure test device and method

InactiveCN103071653AImprove cleanlinessHigh strengthMeasurement of fluid loss/gain rateHollow article cleaningTest efficiencyElastic solids

The invention discloses an elastic cleaning ball, a cleaning device and a cleaning method and a pressure test device and a pressure test method for a pipeline. The elastic cleaning ball comprises an elastic solid core, an elastic reinforcing plate arranged on the rear surface of the elastic solid core and an elastic coating which wraps the elastic solid core and the elastic reinforcing plate. The cleaning device comprises a ball serving device and a ball receiving device which are connected to both ends of the pipeline, and at least one elastic cleaning ball. The elastic cleaning ball is compactly contacted with the inner wall of the pipeline in the cleaning process. According to the cleaning device and cleaning method provided by the invention, the pipeline for conveying ore pulp is efficiently cleaned. The pressure test device comprises a first end water injection device, a water injection pump and a rear end emptying device which are connected to both ends of the pipeline as well as the elastic cleaning ball for emptying air in the pipeline. According to the pressure test device and method provided by the invention, the efficient pressure test efficiency is realized, and air in the pipeline can be completely emptied.

Owner:PANGANG GRP ENG TECH

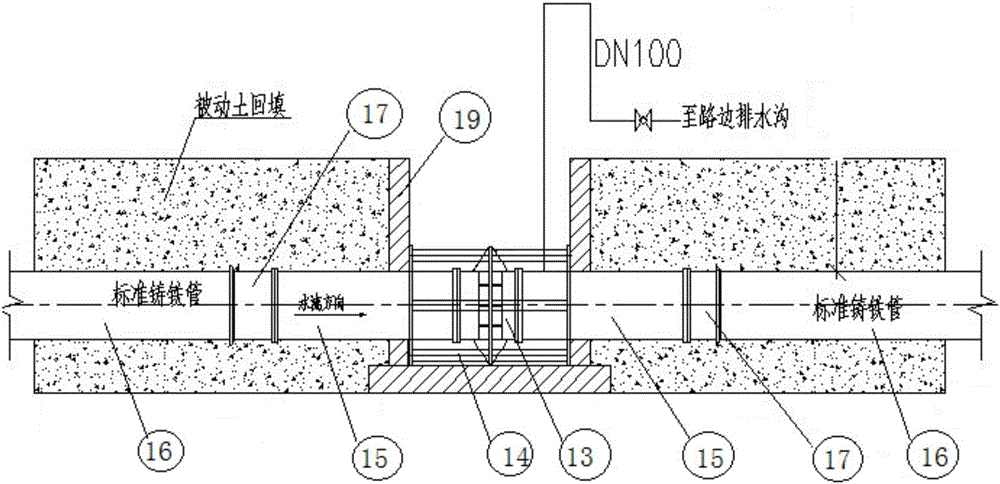

Pressure test pit

InactiveCN105605401ARealize automatic openingAchieve closureEngineering safety devicesArchitectural engineeringStructural engineering

Owner:SICHUAN NAUTILUS IND EQUIP OPERATION MANAGEMENT CO LTD

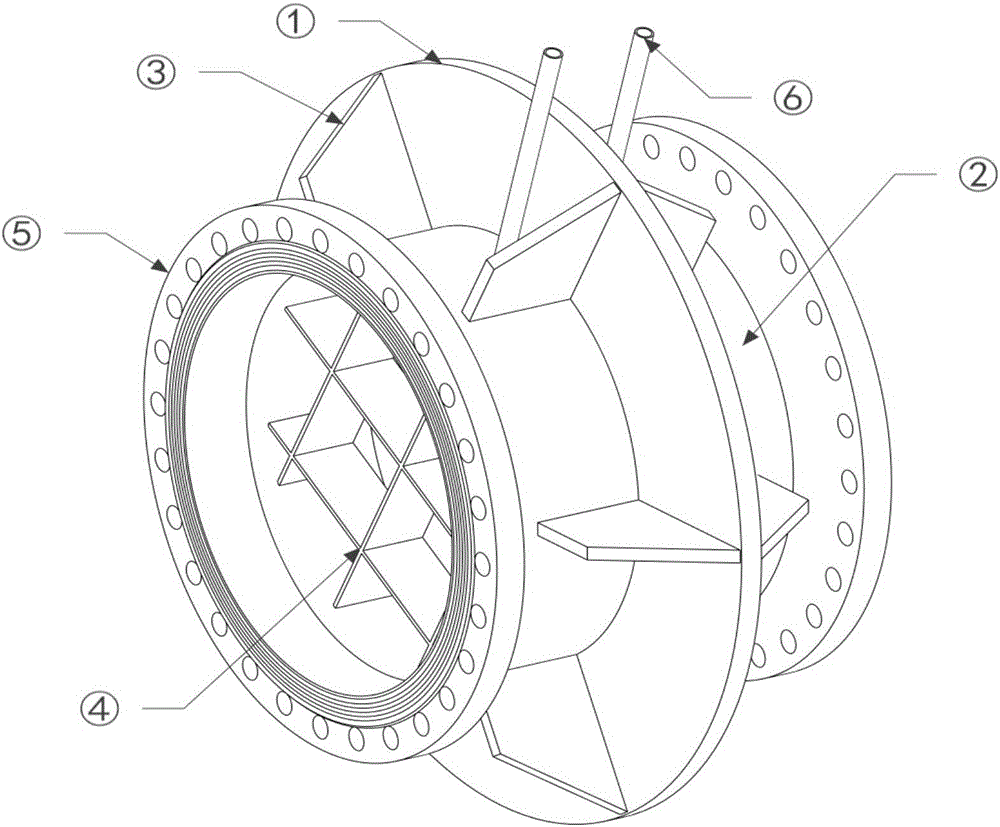

Clamping-ring-type welding-free pressure test plugging device

The invention discloses a clamping-ring-type welding-free pressure test plugging device. The device comprises a fixed ring installed at the end of a pipeline and a skid-resistance fastening pressing sheet which is installed between the fixing ring and the outer surface of the pipeline, wherein a plugging blind plate is further installed at the end of the pipeline; a pressure sealing ring is further installed in the plugging blind plate, so that a plane between a bevel face at the end of the pipeline and the pressure sealing ring achieves effective face sealing. The device is easy to operate, and the quality problem of welded plugging is solved; moreover, the problem that the installing construction period is too long is also solved, and the efficiency of a pipeline pressure test is greatlyimproved; moreover, the device can be repeatedly utilized, and the cost for installing and building the pipeline is reduced.

Owner:OFFSHORE OIL ENG QINGDAO +1

Pressure testing system and pressure testing method

InactiveCN102331329APlug firmlyFirmly connectedMeasurement of fluid loss/gain rateHydraulic cylinderEngineering

The invention relates to oil testing of petroleum, especially to a pressure testing system and a pressure testing method. The pressure testing system comprises a pressure testing tool; and the system is characterized in that: the system also comprises a solid choke plug, a hollow end socket and a nylon packing; one end of the solid choke plug is connected with an output end of the pressure tool and the other end of the solid choke plug is a solid joint; one end of the hollow end socket is connected with an input end of the pressure tool and the other end of the hollow end socket is a hollow joint; a liquid passing hole is arranged in the middle of the hollow end socket; one end of the nylon packing is capable of being connected with a hydraulic cylinder and the other end of the nylon packing is a sealed end face that is cooperatively docked with the hollow joint; and an inner bore that is communicated with the liquid passing hole is arranged at the nylon packing. In the prior art, it is difficult to carry out detection on a sealing effect of a pressure testing tool by a pressure testing machine and the detection effect is not good; however, the above-mentioned defects can be overcome with utilization of the pressure testing system and the pressure testing method provided in the invention.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

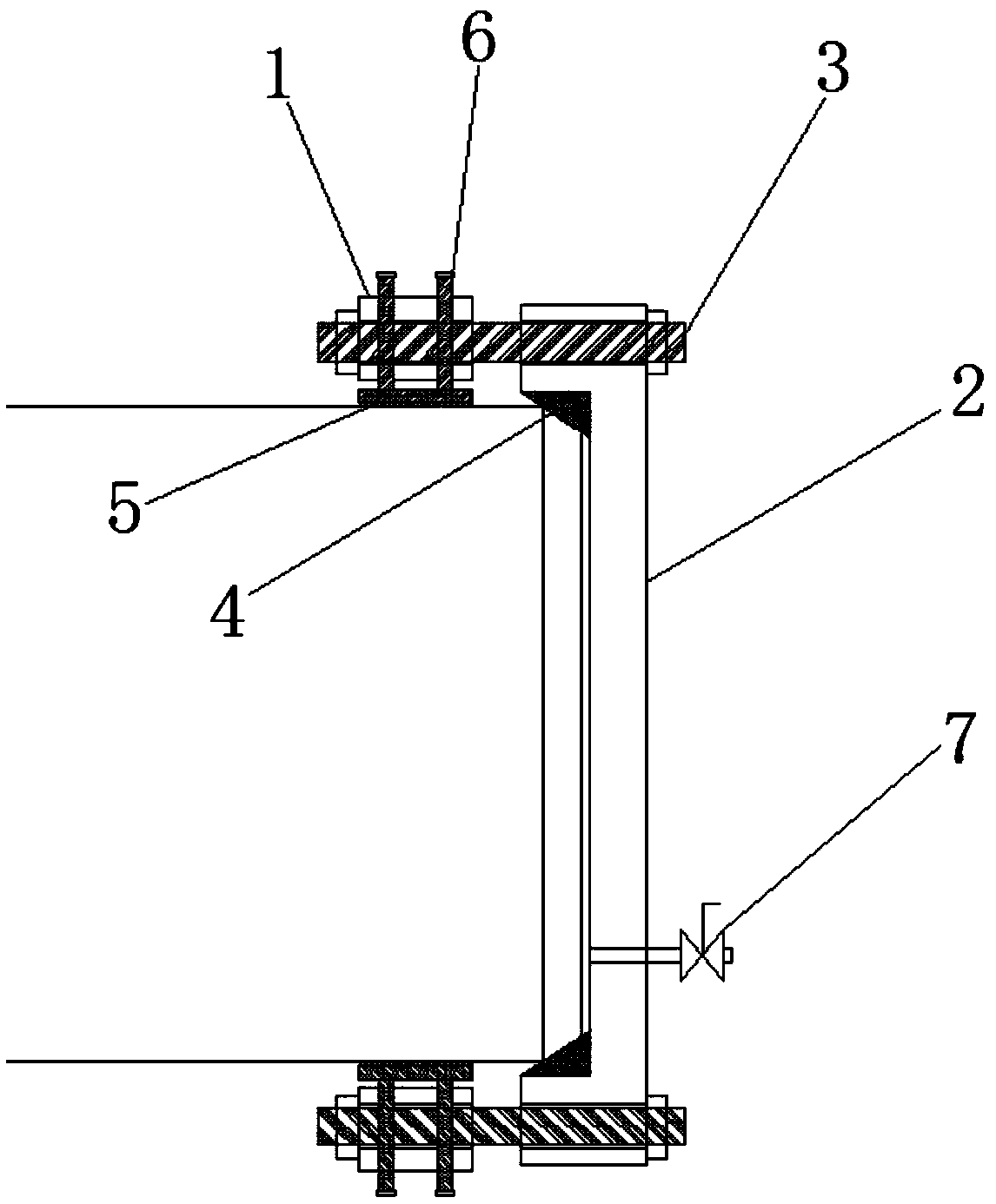

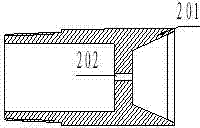

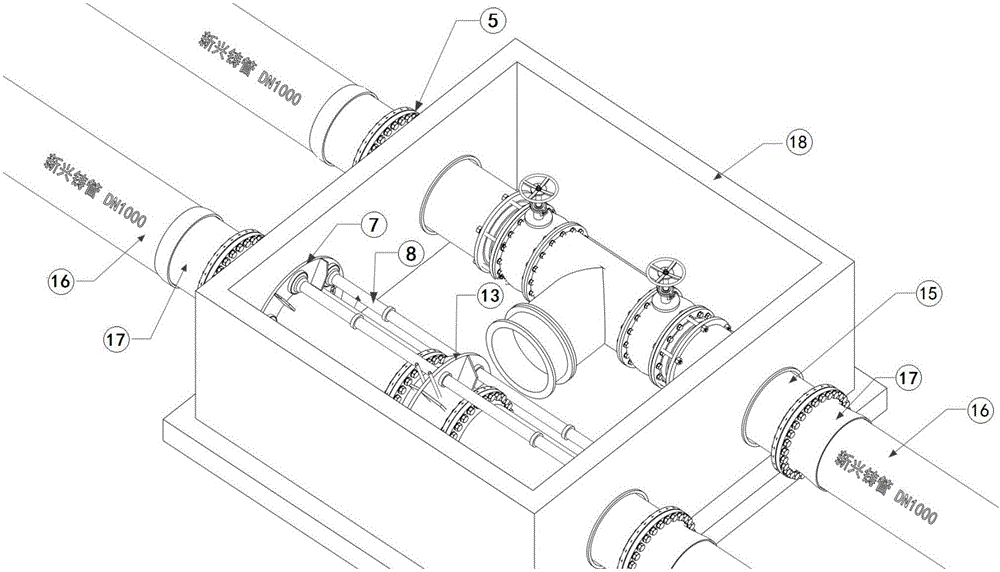

Large-caliber cast iron pipe pressure testing device without backrest, and large-caliber cast iron pipe pressure testing method without backrest

InactiveCN105890851AEasy to operateImprove pressure test efficiencyMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesCast ironCast iron pipe

The invention discloses a large-caliber cast iron pipe pressure testing device without a backrest, and a large-caliber cast iron pipe pressure testing method without a backrest. The large-caliber cast iron pipe pressure testing device without a backrest includes a pressure testing short pipe and a pressure release apparatus, wherein the pressure testing short pipe includes a partition-type blind plate; two sides of the partition-type blind plate are symmetrically provided with standard short pipes; two ends of the pressure testing short pipe are connected with two adjacent pipes waiting for pressure testing; the pressure release apparatus sleeves the pressure testing short pipe; and during the pressure testing process, the pressure difference at two sides of the partition-type blind plate is transmitted to the inner wall of a valve chamber through the pressure release apparatus. For the large-caliber cast iron pipe pressure testing device without a backrest, the partition-type blind plate is utilized to separate the adjacent two ends; and approximately equivalent pressure are generated from the two ends of the partition-type blind plate through pressure testing of the adjacent two segments of pipes waiting for pressure testing at the same time, so that the pressure are mutually cancelled out and the wall of the valve chamber can fully accept to enable pressure testing of the pipe to have no demand for setting a backrest and an anchored pier additionally. Therefore, the large-caliber cast iron pipe pressure testing device without a backrest is simple in operation, can improve the pressure testing efficiency and reduce the construction period for pressure testing so as to improve the construction continuity and reduce the consumed materials for the construction scheme, is high in universality, and is convenient for movement.

Owner:CHINA FIRST METALLURGICAL GROUP

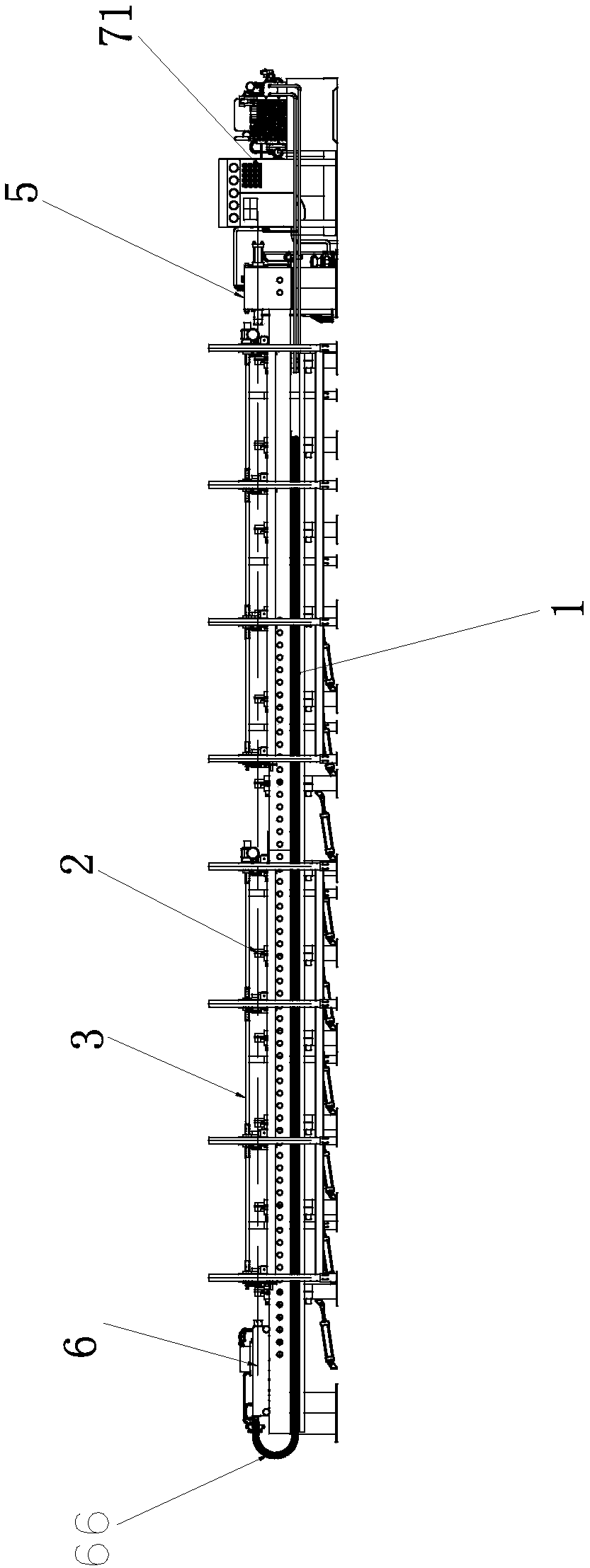

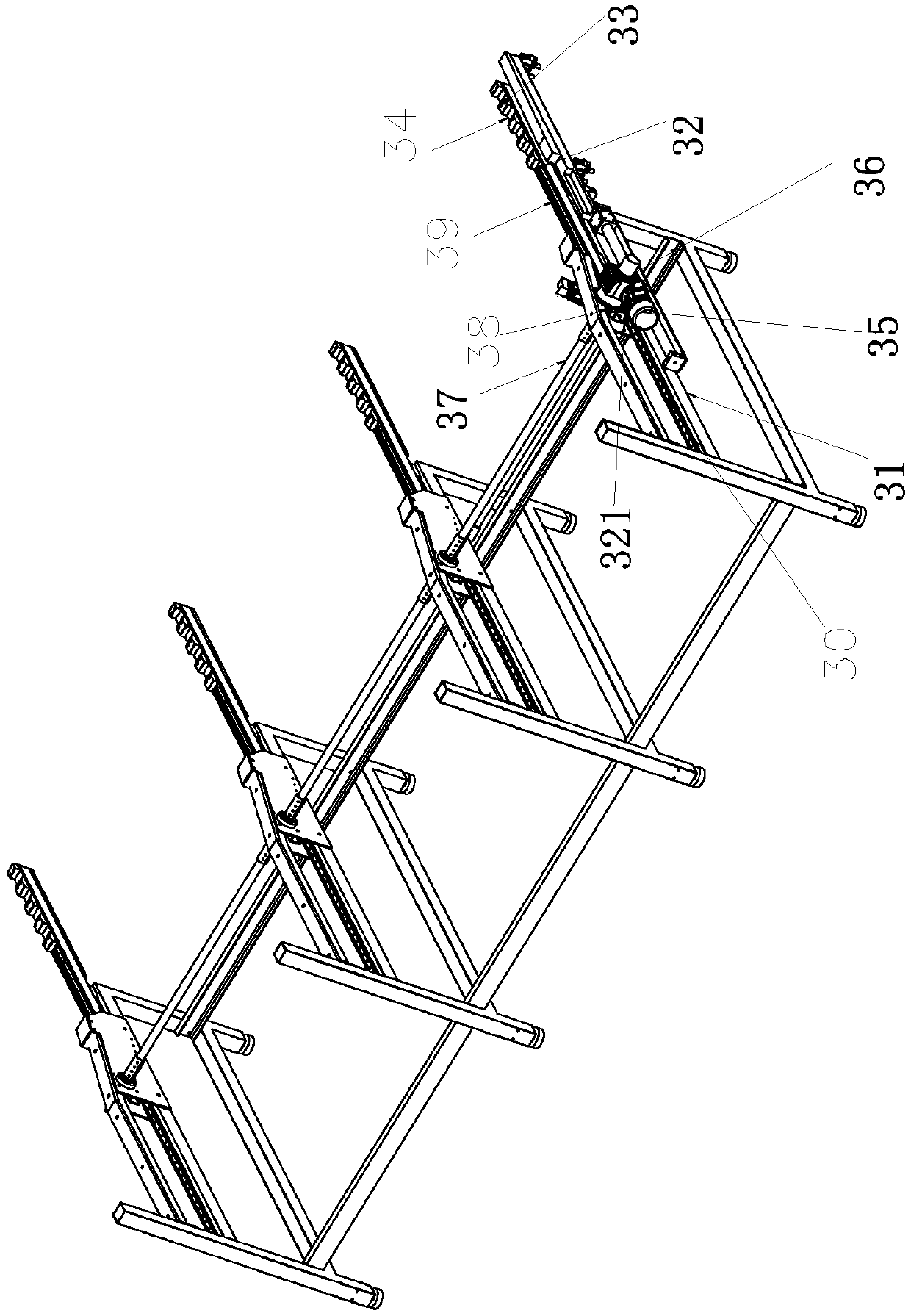

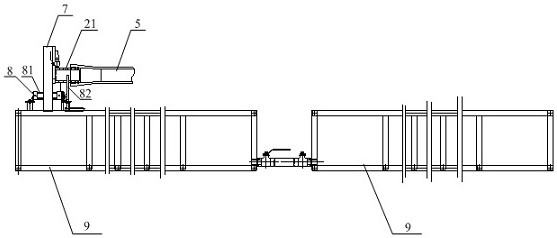

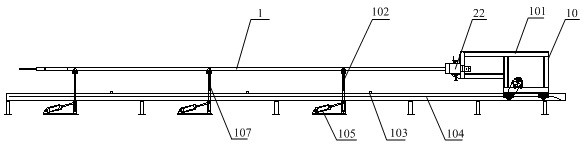

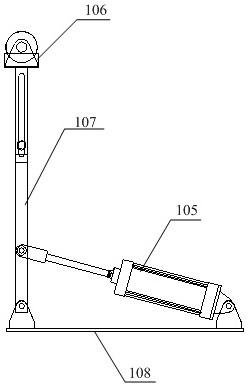

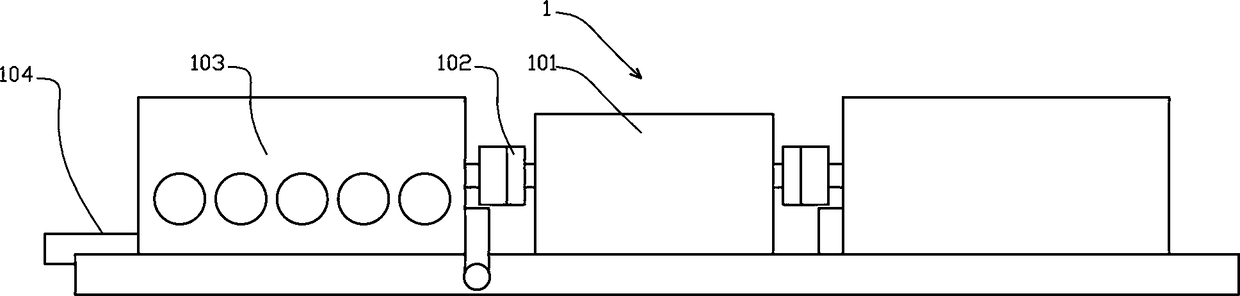

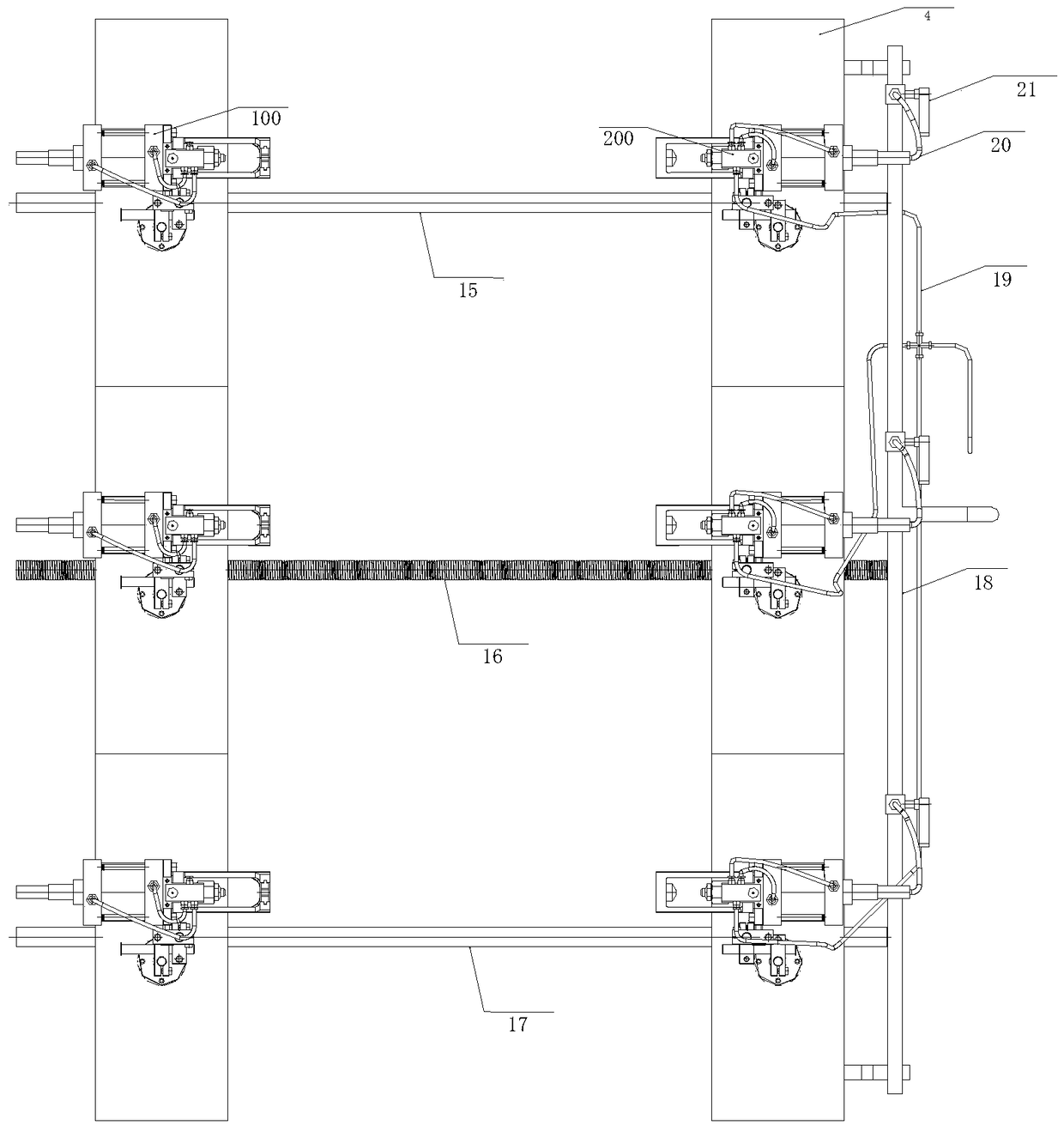

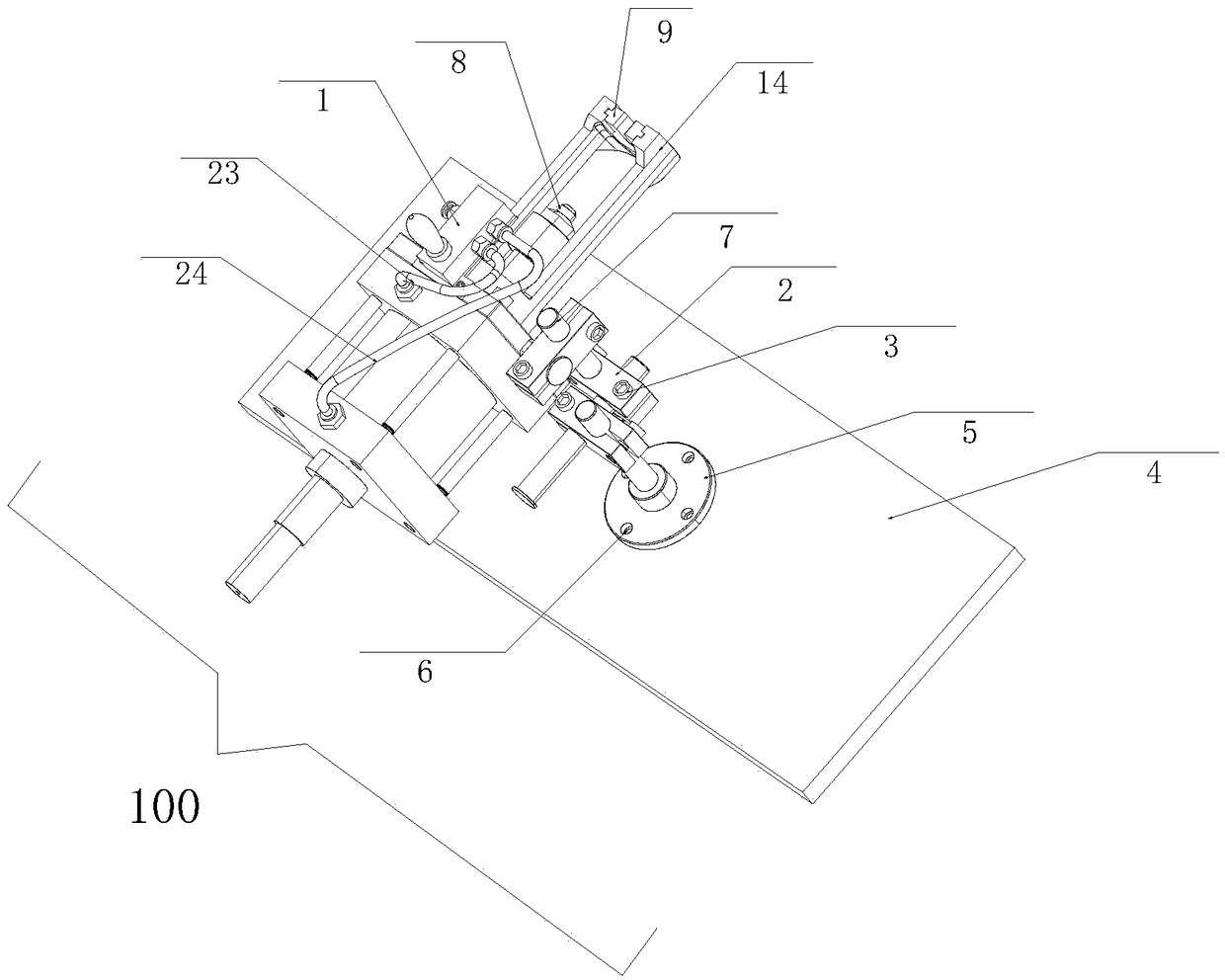

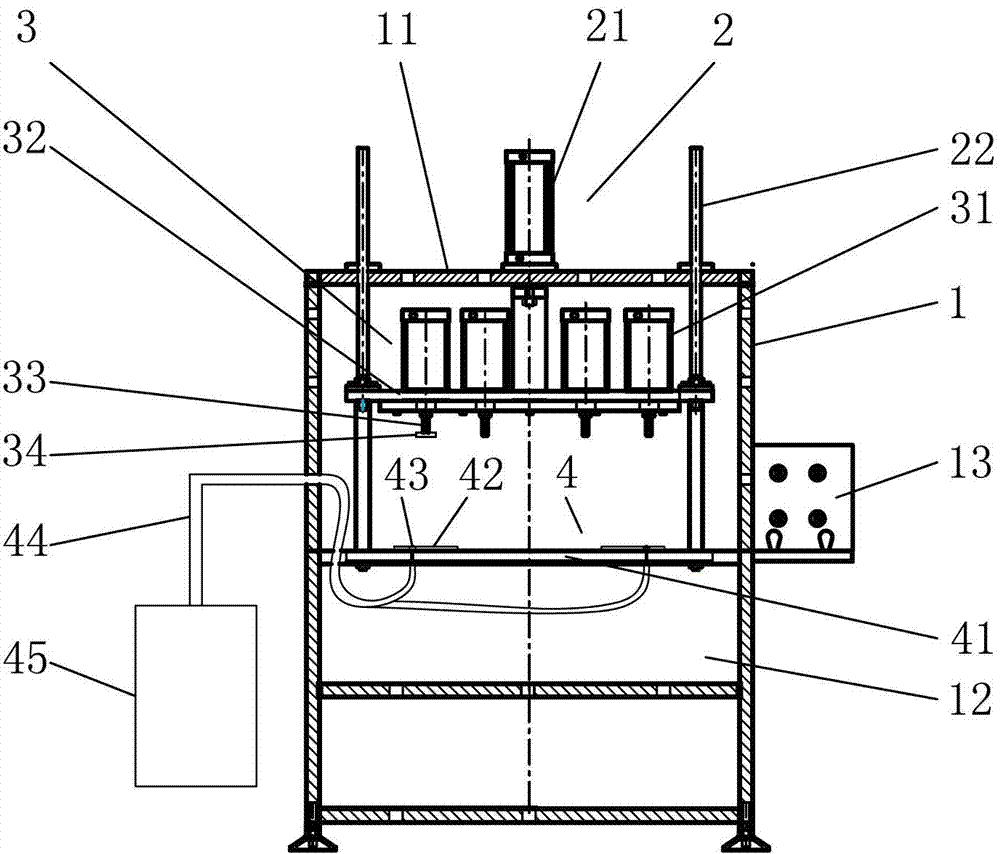

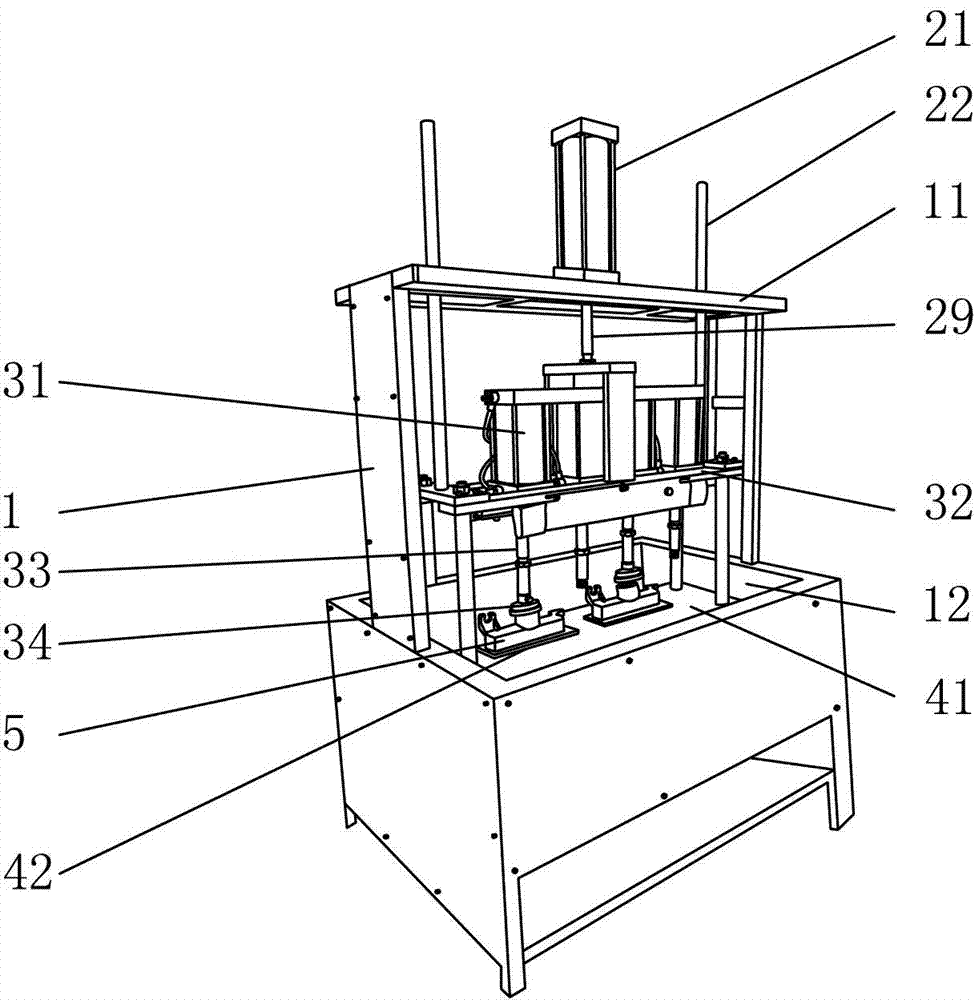

Multi-steel-pipe water pressure test machine

PendingCN109580340ATo achieve the purpose of hydrostatic testNo manual operation requiredMaterial strength using tensile/compressive forcesPipe waterEngineering

The invention relates to a steel pipe test machine, in particular to a multi-steel-pipe water pressure test machine. The multi-steel-pipe water pressure test machine comprises a machine frame, whereina plurality of clamping mechanisms used for clamping steel pipes are arranged in the machine frame; a feeding mechanism used for pushing and conveying the steel pipes to the clamping mechanisms is arranged at one side of the machine; a blanking mechanism is arranged at the other side; a fixing mechanism is arranged at one end of the machine frame; a moving mechanism for pushing the steel pipes tothe fixing mechanism to be fixed is arranged at the other end; and a water pressure system used for implementing pressurization on the steel pipes is arranged on the fixing mechanism. Each clamping mechanism comprises a base and two clamping plates arranged above the base; at least two L-shaped clamping blocks are respectively arranged on the two clamping plates; the directions of the L-shaped clamping blocks on the two clamping plates are opposite, so that a clamping groove is formed between the adjacent L-shaped clamping blocks on the two clamping plates; the two clamping plates are in staggered arrangement; and a regulating mechanism used for regulating the size of the clamping groove is arranged at the bottom of the two clamping plates.

Owner:青山钢管有限公司

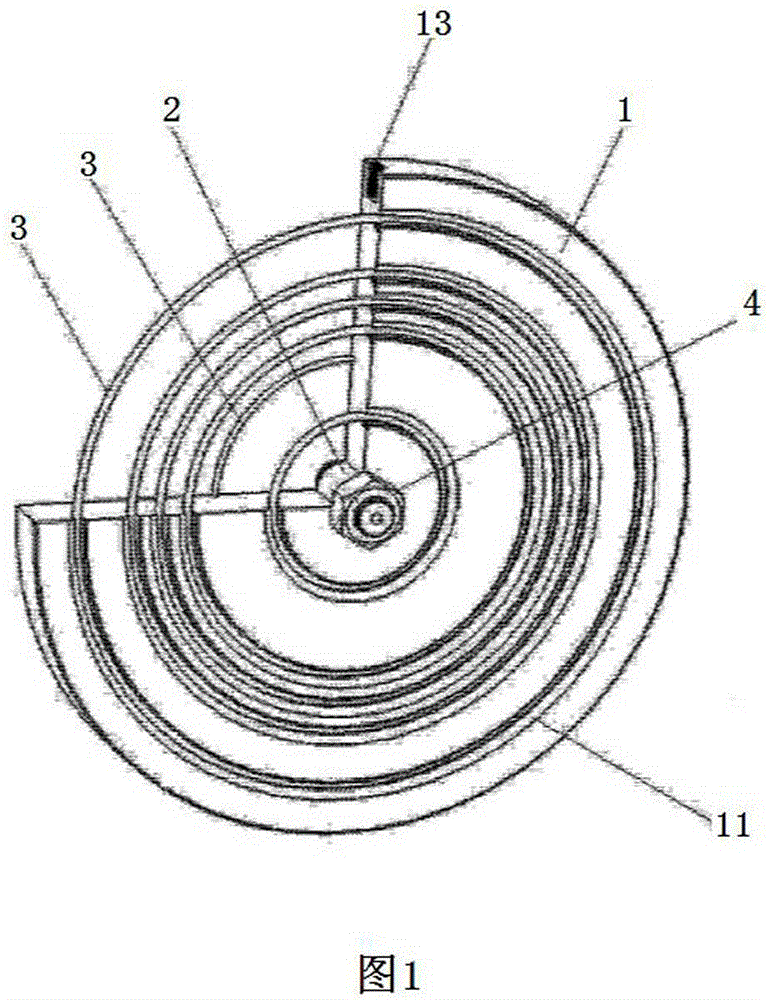

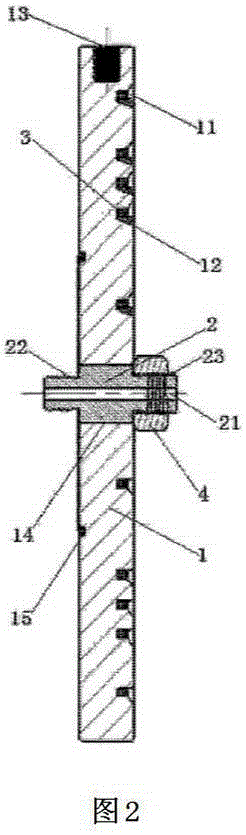

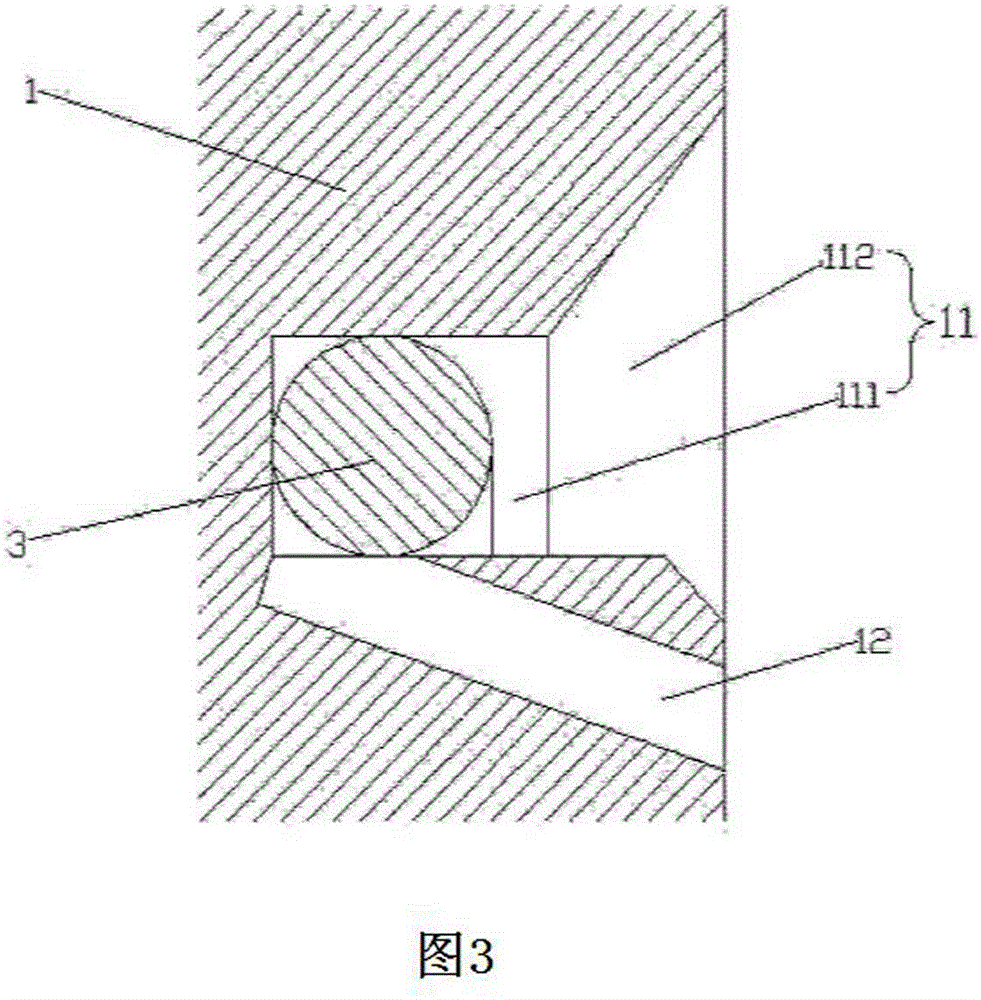

Pipeline pressure testing equipment

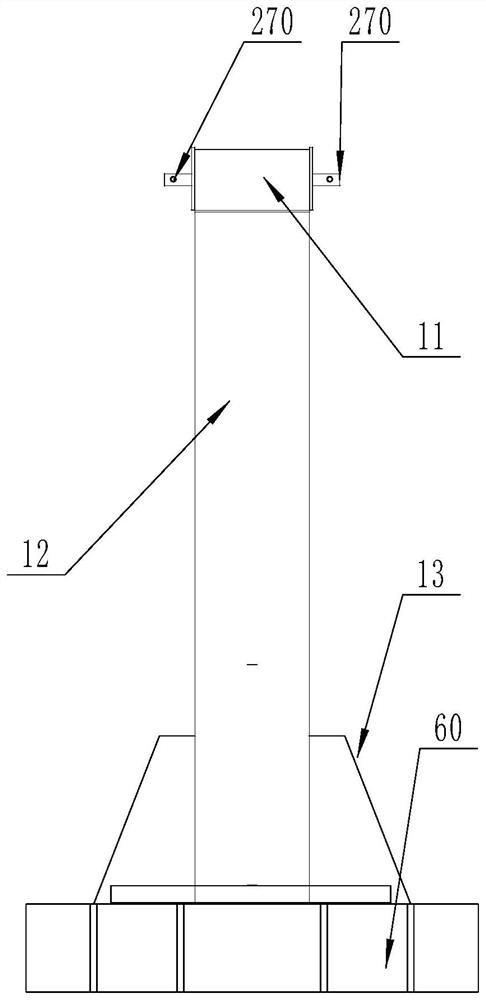

ActiveCN112161877AAvoid bendingImprove pressure test efficiencyMaterial strength using tensile/compressive forcesStructural engineeringMechanical engineering

The invention relates to the technical field of pressure testing, and especially relates to pipeline pressure testing equipment. The equipment comprises a supporting rod, a pipeline to be subjected topressure testing and two sealing parts. The supporting rod is arranged in the pipeline to be subjected to pressure testing in a penetrating mode. The two sealing parts are arranged at the two ends ofthe supporting rod respectively and are used for sealing the two ends of the supporting rod and the pipeline to be subjected to pressure testing respectively. Each sealing part is provided with an inlet for a pressure test liquid to flow into the pipeline to be subjected to pressure testing. According to the pipeline pressure testing equipment provided by the invention, in the pipeline pressure testing process, the supporting rod is located in the pipeline and plays a role in supporting the pipeline, so that the pipeline is prevented from being bent in the pressure test process, and the pressure testing efficiency is improved.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

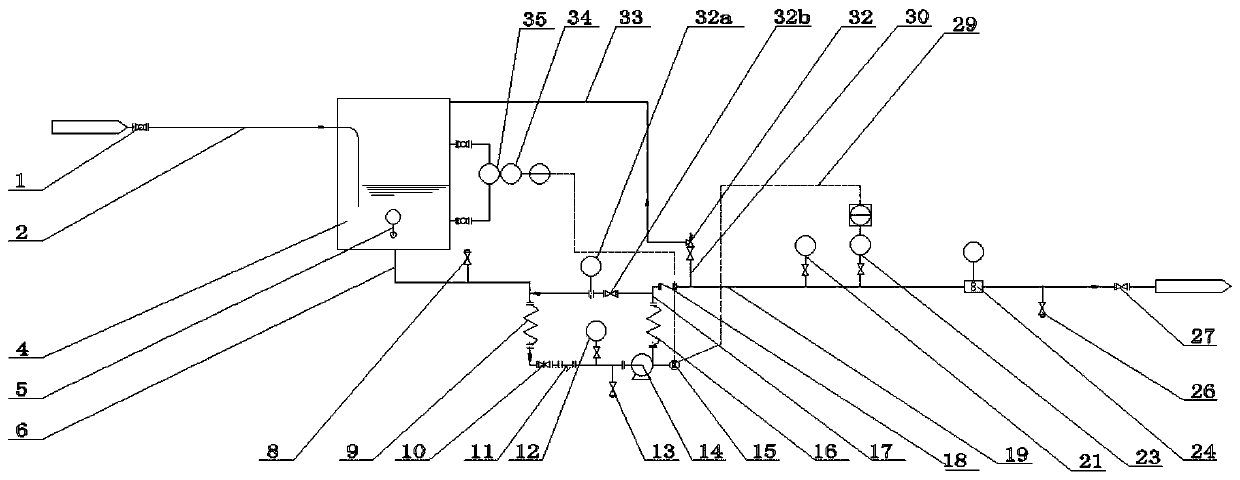

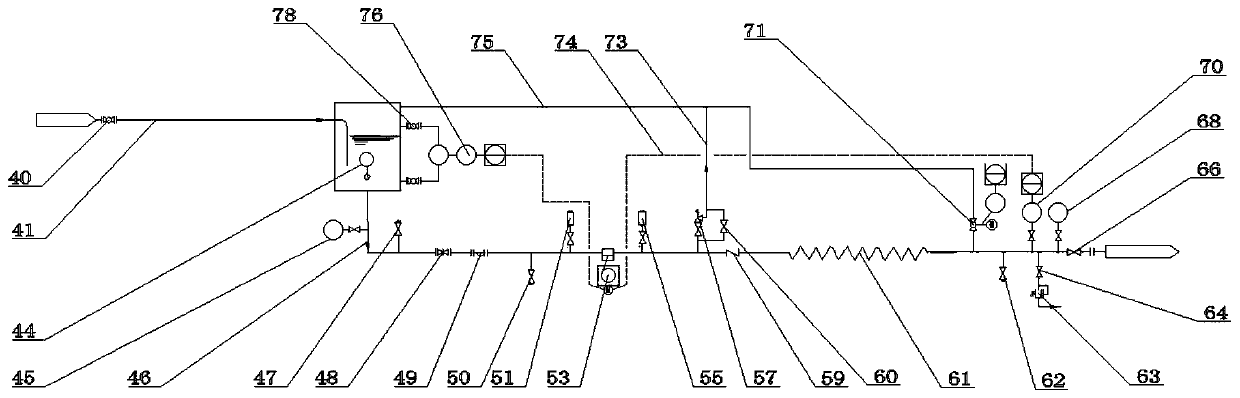

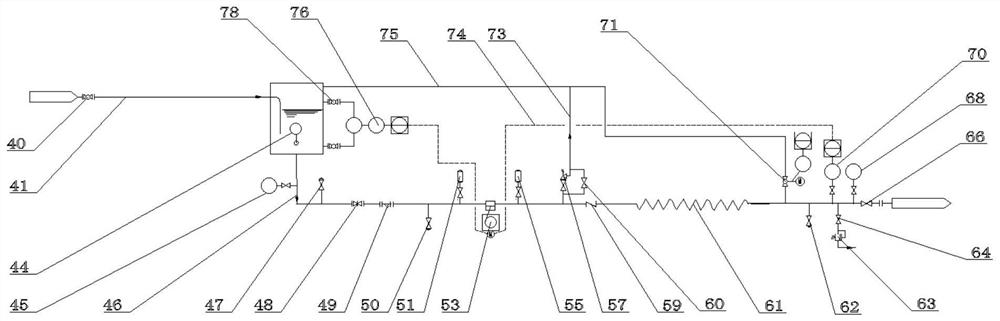

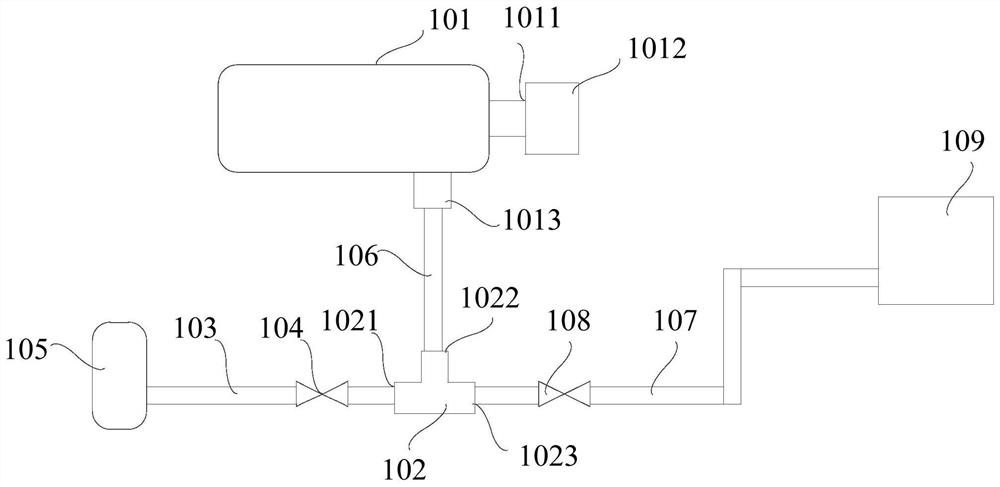

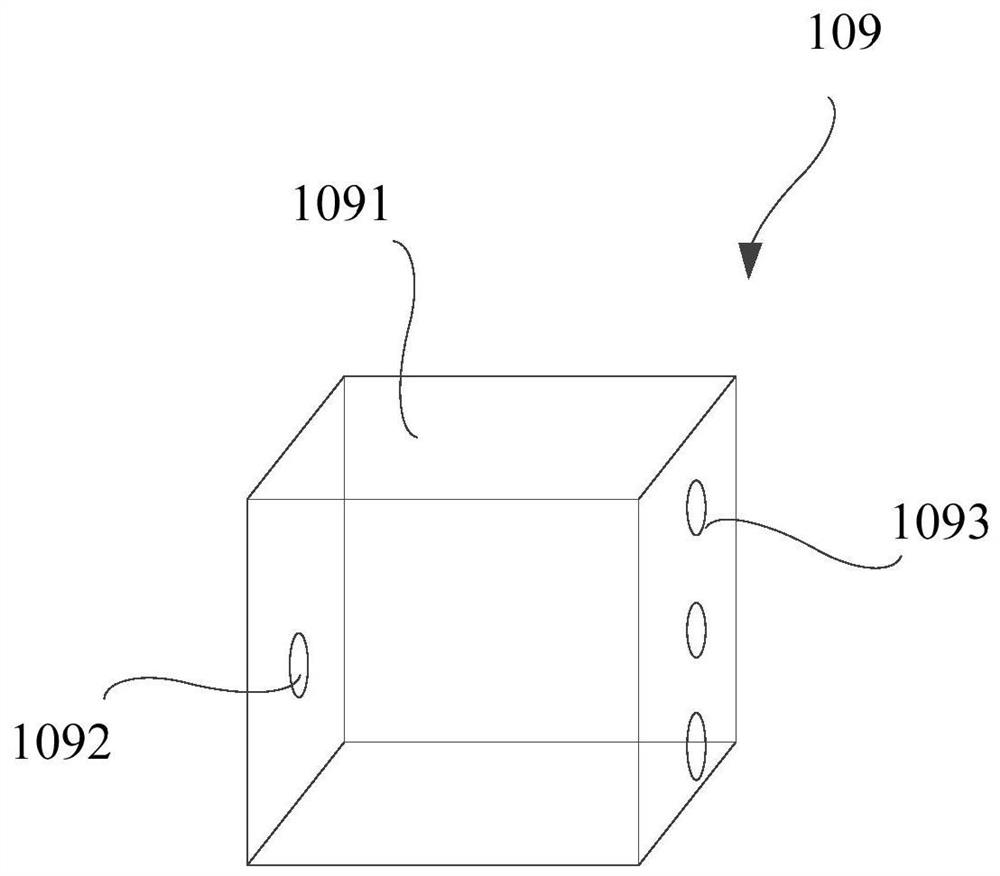

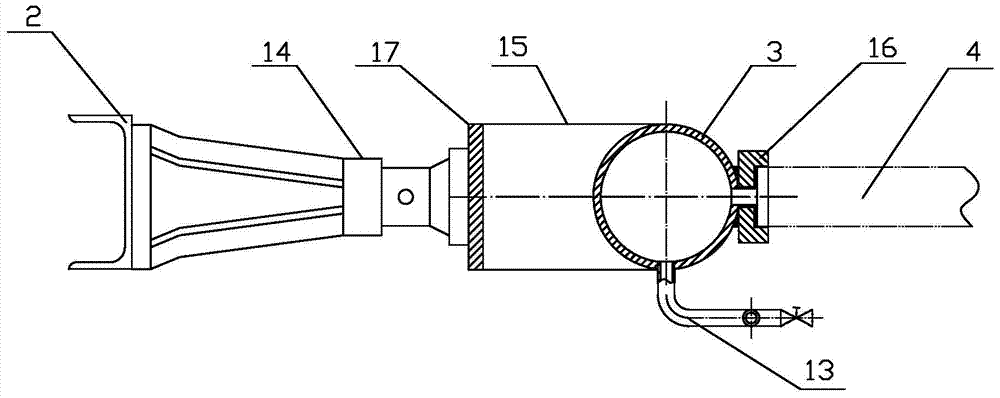

Pressure testing device and pressure testing method for long-distance pipeline

ActiveCN111503522AEasy to movePlay a shock absorbing effectPipeline systemsLine tubingStructural engineering

The invention relates to a pressure testing device for a long-distance pipeline. The pressure testing device comprises a water filling unit and a pressurizing unit which are respectively mounted on afirst base and a second base. The invention further relates to a pressure testing method adopting the pressure testing device. The long-distance pipeline comprises a plurality of conveying pipe sections, and valves are arranged at the joints of the conveying pipe sections. The pressure testing method comprises the steps of filling the first conveying pipe section with water by using the water filling unit, pressurizing the first conveying pipe section by using the pressurizing unit after water filling is completed, simultaneously filling other conveying pipe sections with water by using the water filling unit, simultaneously using the pressurizing unit and the water filling unit until the last conveying pipe section is filled with water, and stopping the water filling unit after the waterfilling is completed, and pressurizing the last conveying pipe section by the pressurizing unit. The water filling unit and the pressurizing unit are respectively arranged on the two bases and are respectively pried, the water outlet pipe sections of the water filling unit and the pressurizing unit respectively comprise a hose, the movement is more convenient, the water filling unit and the pressurizing unit can simultaneously fill water and pressurize different conveying pipe sections, the time is saved, and the pressure testing efficiency is improved.

Owner:JEREH OIL & GAS ENG

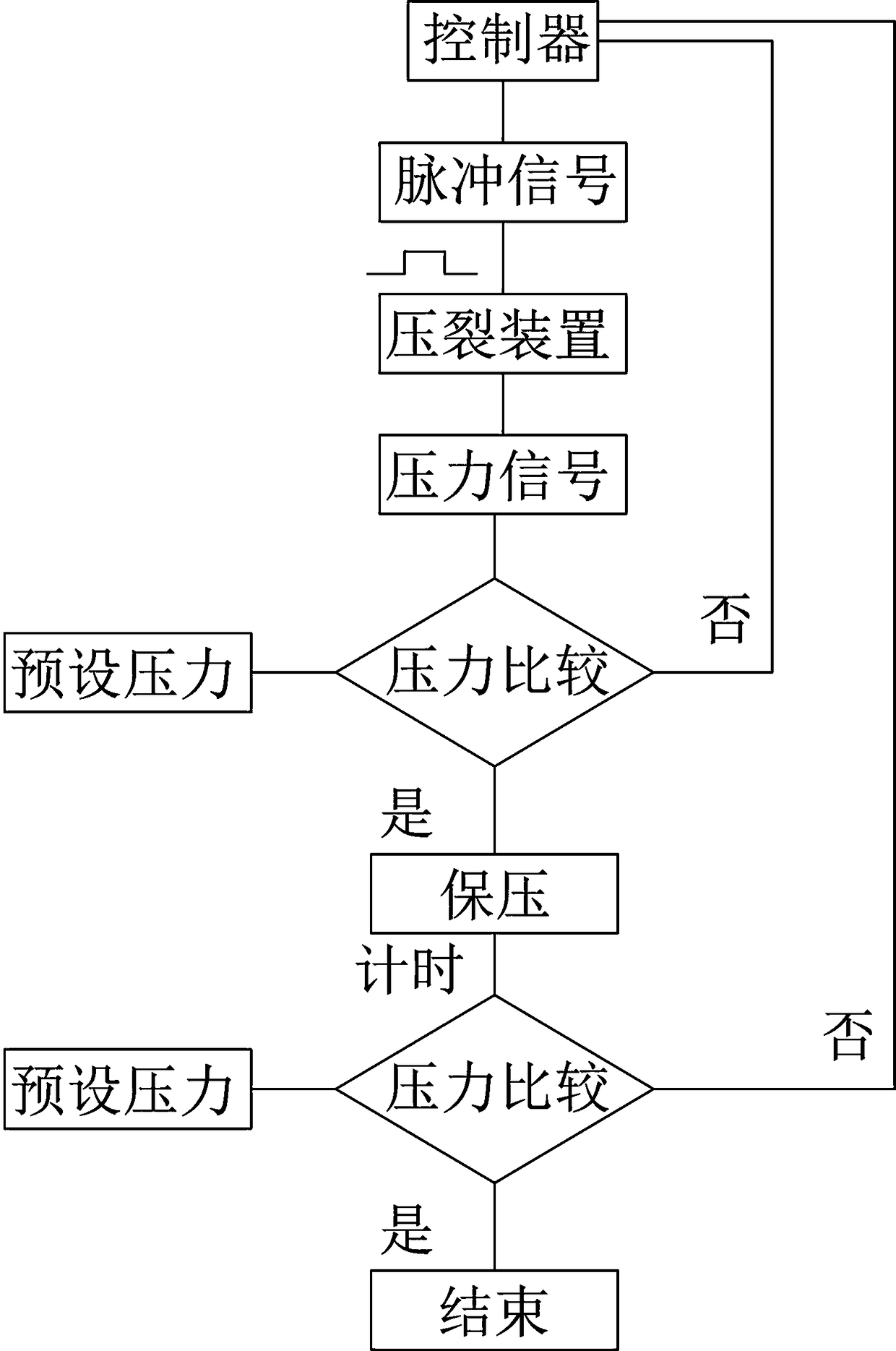

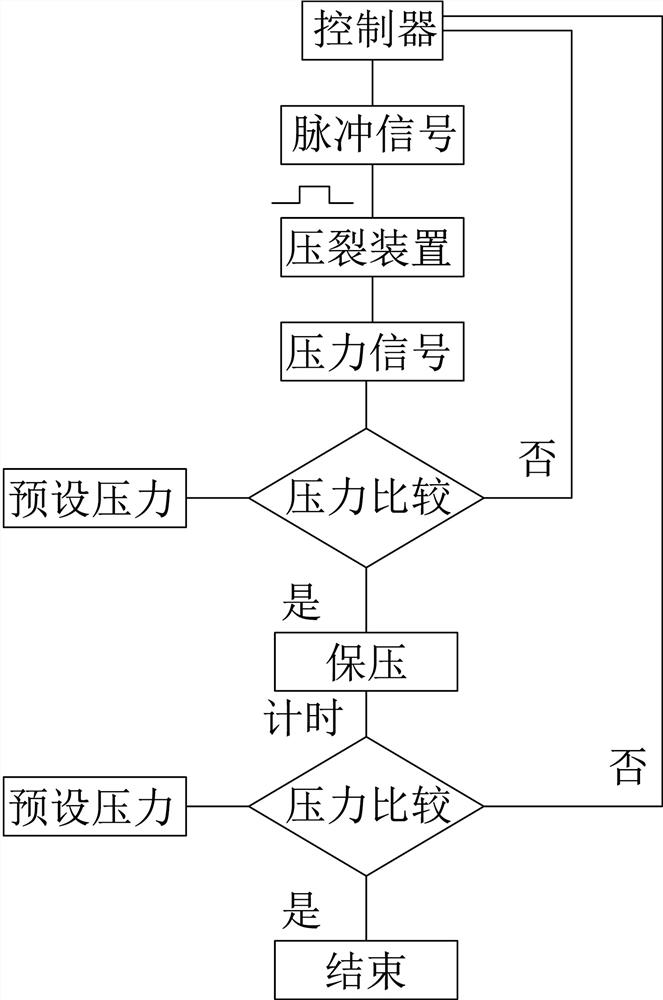

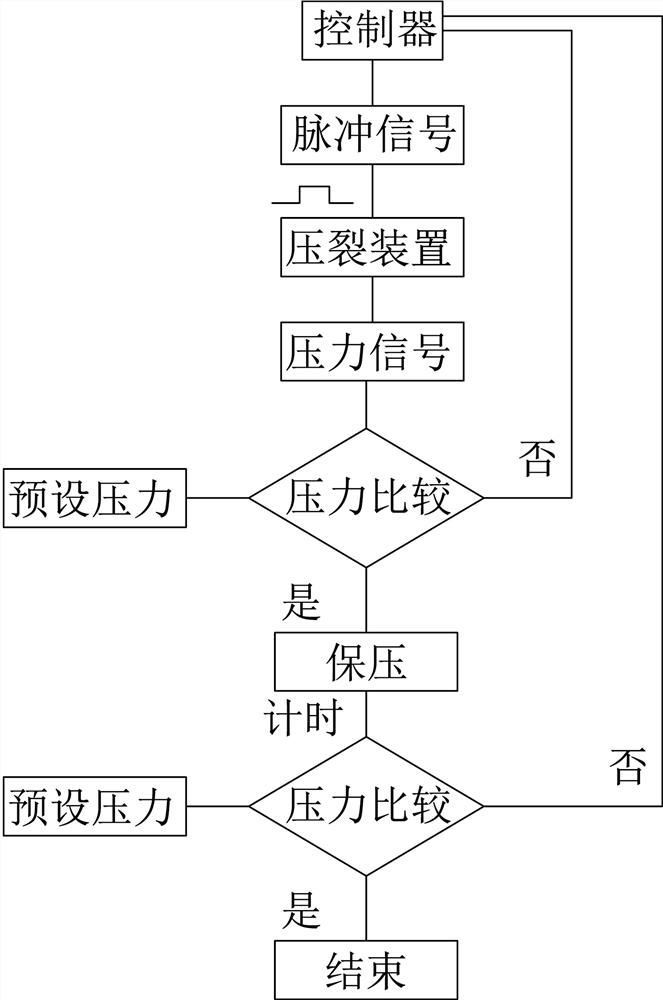

Fracturing system pressure test control method

ActiveCN109342100AImprove securityRapid positioningStructural/machines measurementSystem pressureEngineering

The invention provides a fracturing system pressure test control method, which includes the following steps: S1, the valve of the discharge pipeline of a fracturing device is closed; S2, a controlleroutputs a pulse signal to drive a motor of the fracturing device to rotate so as to increase the pressure of the discharge pipeline, and a pressure sensor of the discharge pipeline outputs a pressuresignal; and S3, the controller receives the pressure signal and compares the pressure signal with a preset pressure value; if the pressure reaches the preset pressure value, the pressure is maintained; and if the pressure does not reach the preset pressure value, the controller outputs a same pulse signal again to drive the motor of the fracturing device to rotate so as to increase the pressure ofthe discharge pipeline until the pressure reaches the preset pressure value. The pressure test operation of a fracturing system is realized through the steps. The fracturing system pressure test control method of the invention can greatly improve the safety of pressure test operation and improve the efficiency of pressure test.

Owner:中石化四机石油机械有限公司 +2

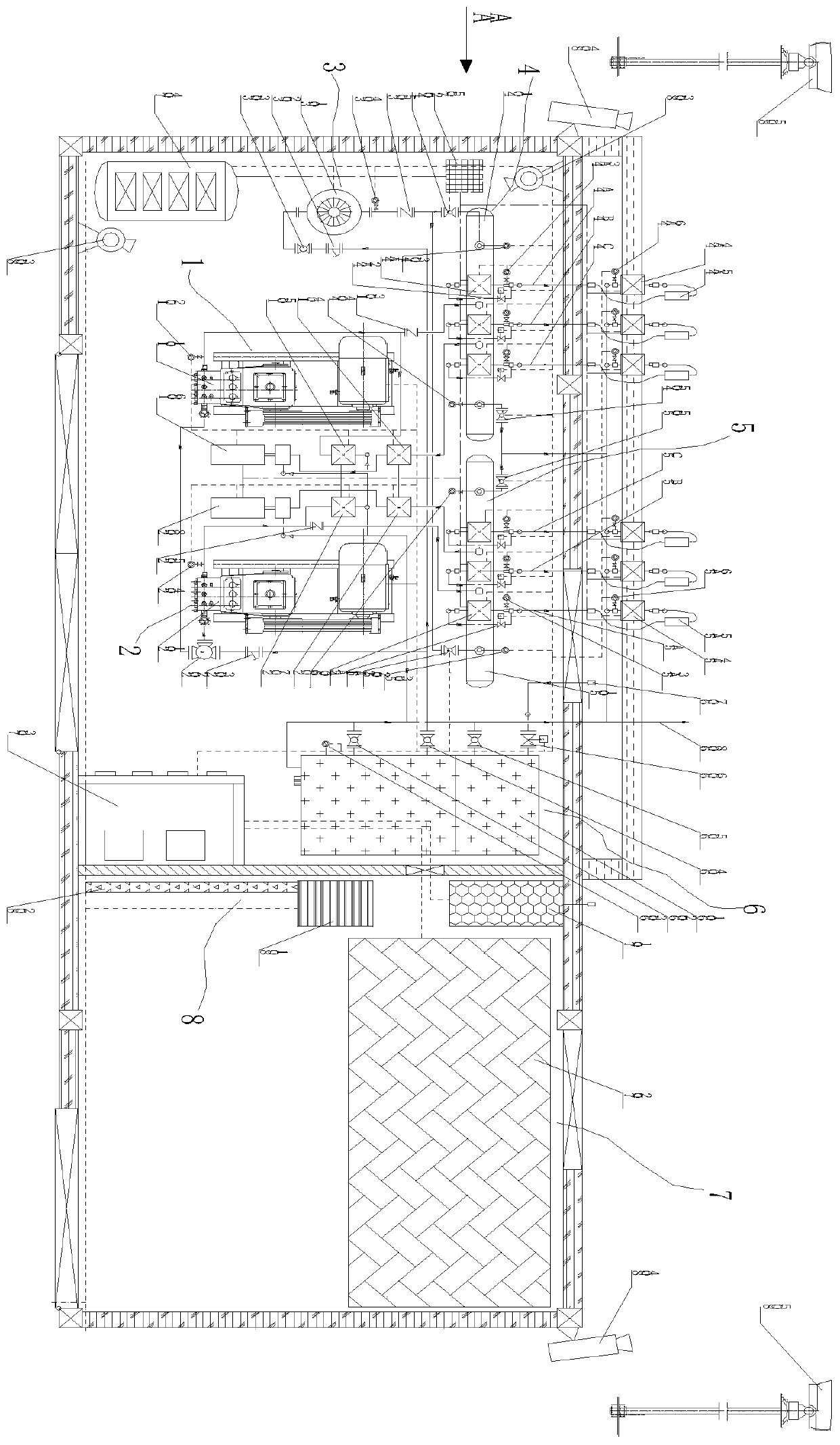

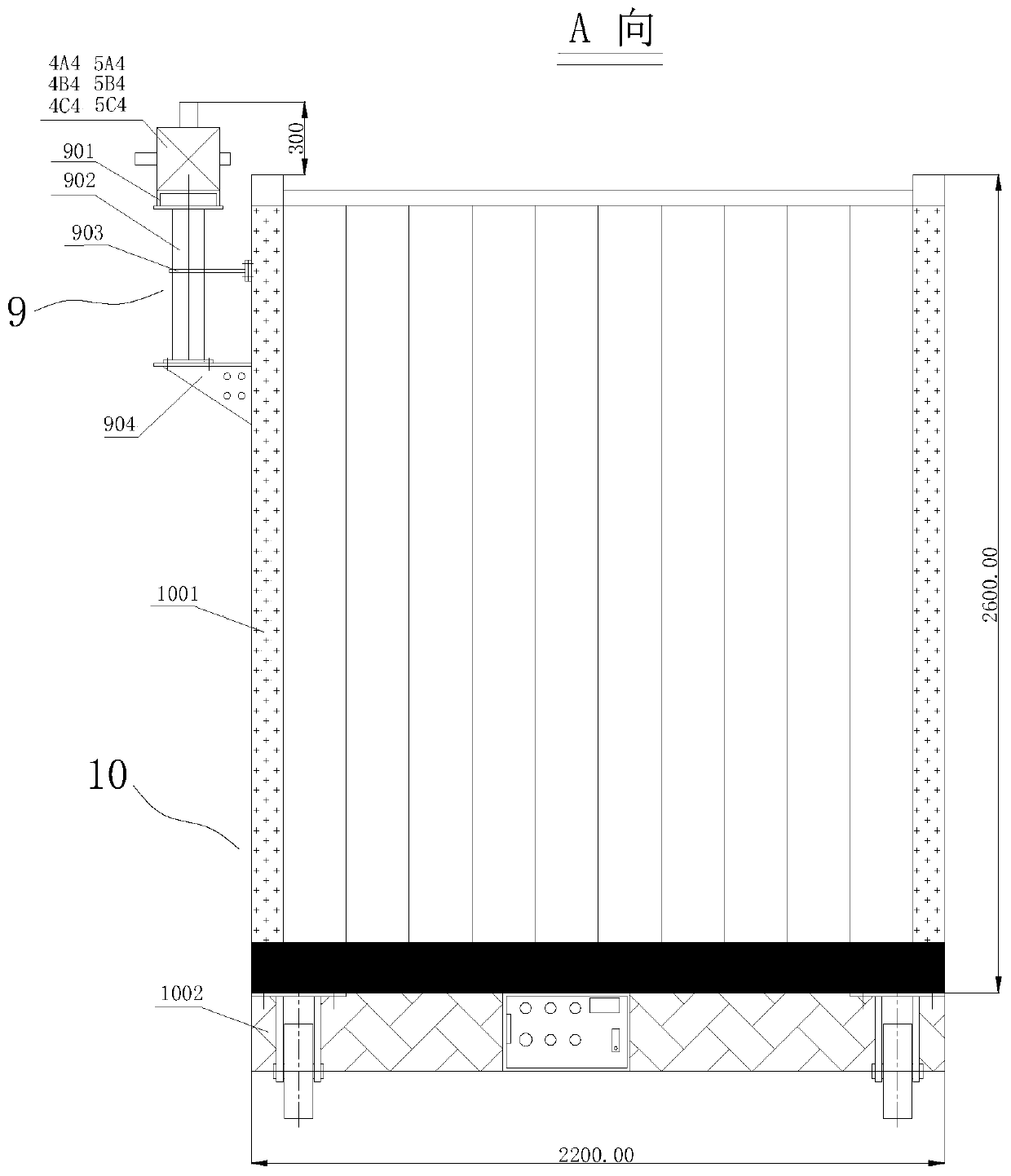

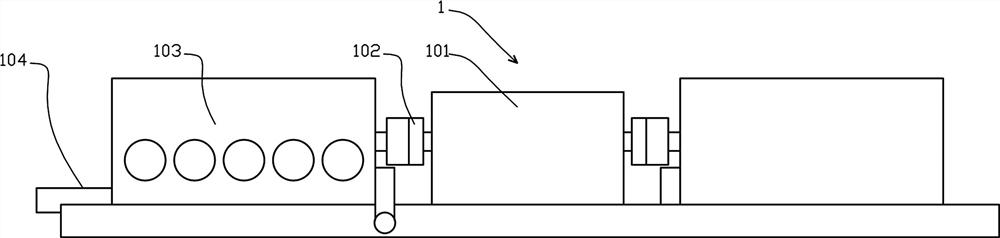

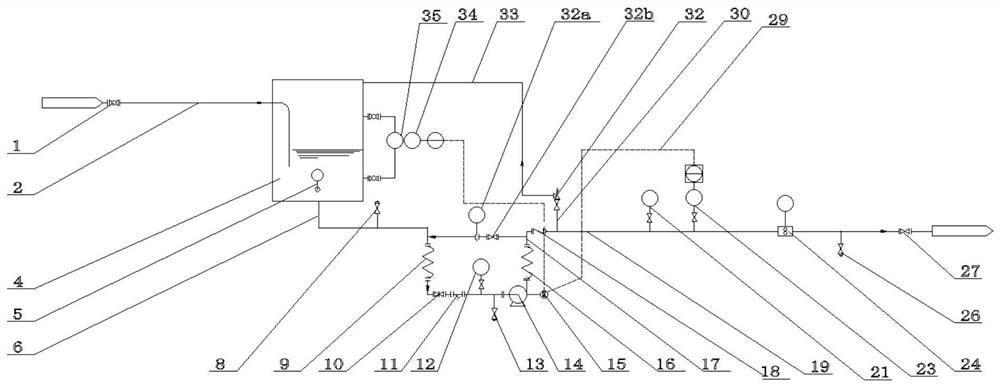

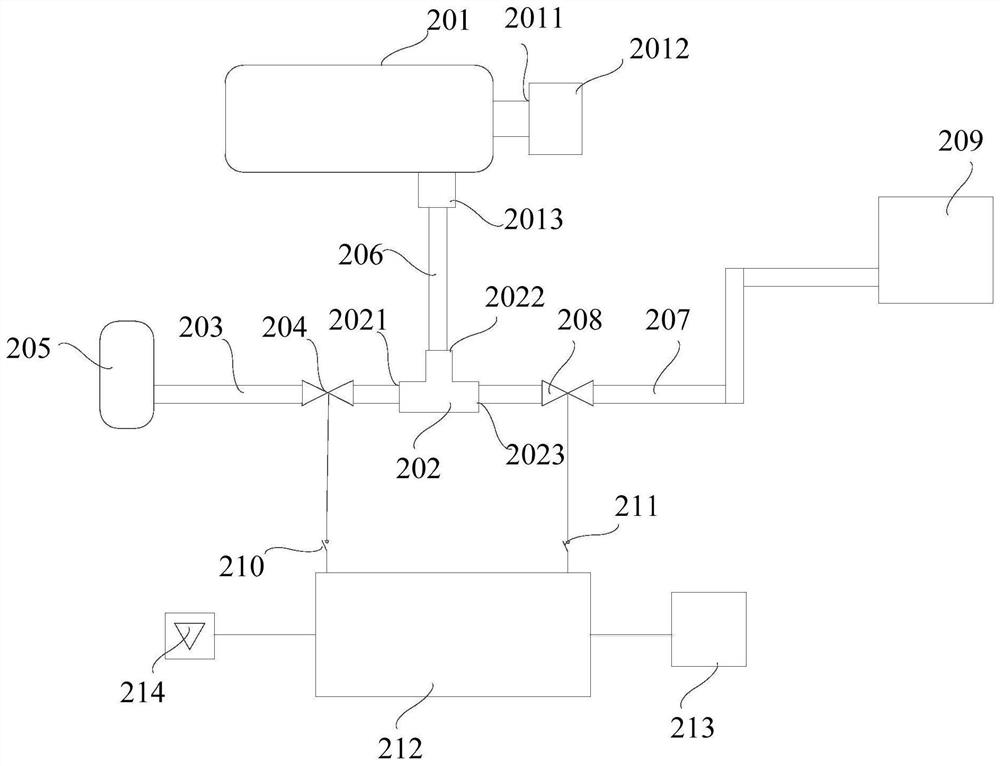

Integrated mobile intelligent pressure test integrated device

PendingCN111307604AHighly integratedHigh pressure holding accuracyMaterial strength using tensile/compressive forcesRemote controlControl cell

The invention belongs to the technical field of pressure test equipment of pressure-bearing equipment, and particularly relates to an integrated mobile intelligent pressure test integrated device. According to the invention, a first high-pressure pump unit, a second high-pressure pump unit, a water injection pump unit, a first water collecting and distributing device unit, a second water collecting and distributing device unit, a pressure test water tank unit and a pressure test monitoring control unit are organically arranged, so the integrated device integrating multi-station pressure test,test process man-machine separation, automatic remote control operation, automatic test data storage, automatic generation and printing of a pressure test report, pressure test area monitoring alarm and container type mobile intelligent pressure test is realized; therefore, the efficiency of the pipeline pressure test of the integrated device is improved, and the labor intensity of operators is reduced.

Owner:XIAN CHANGQING TECH ENG +1

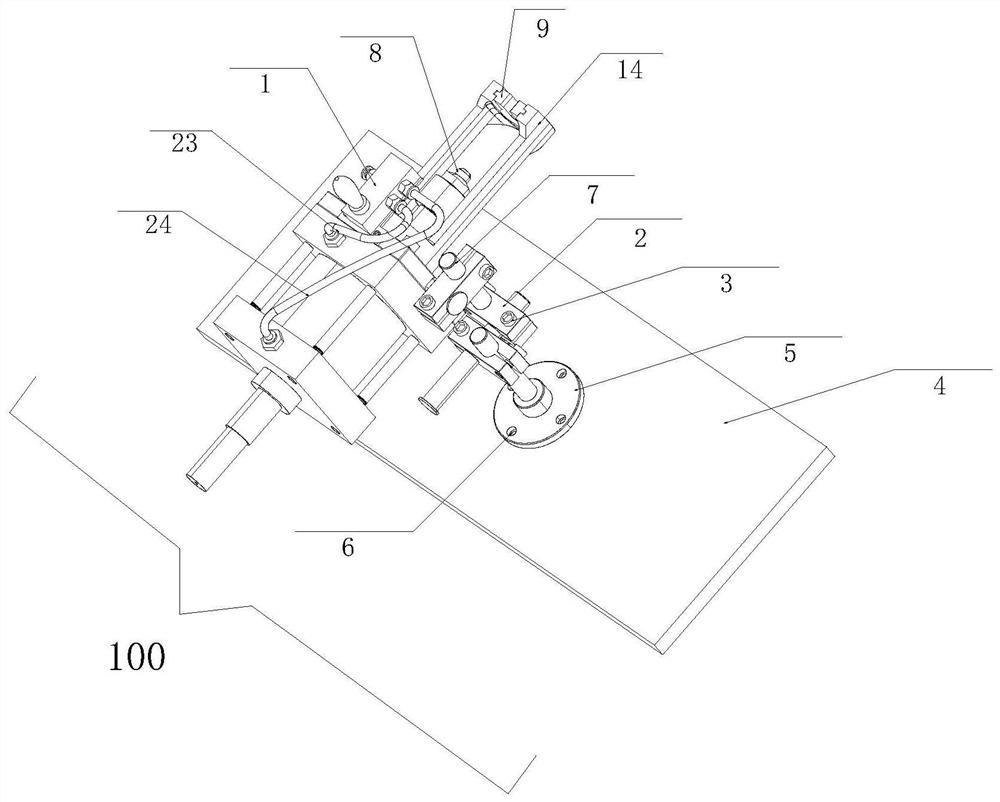

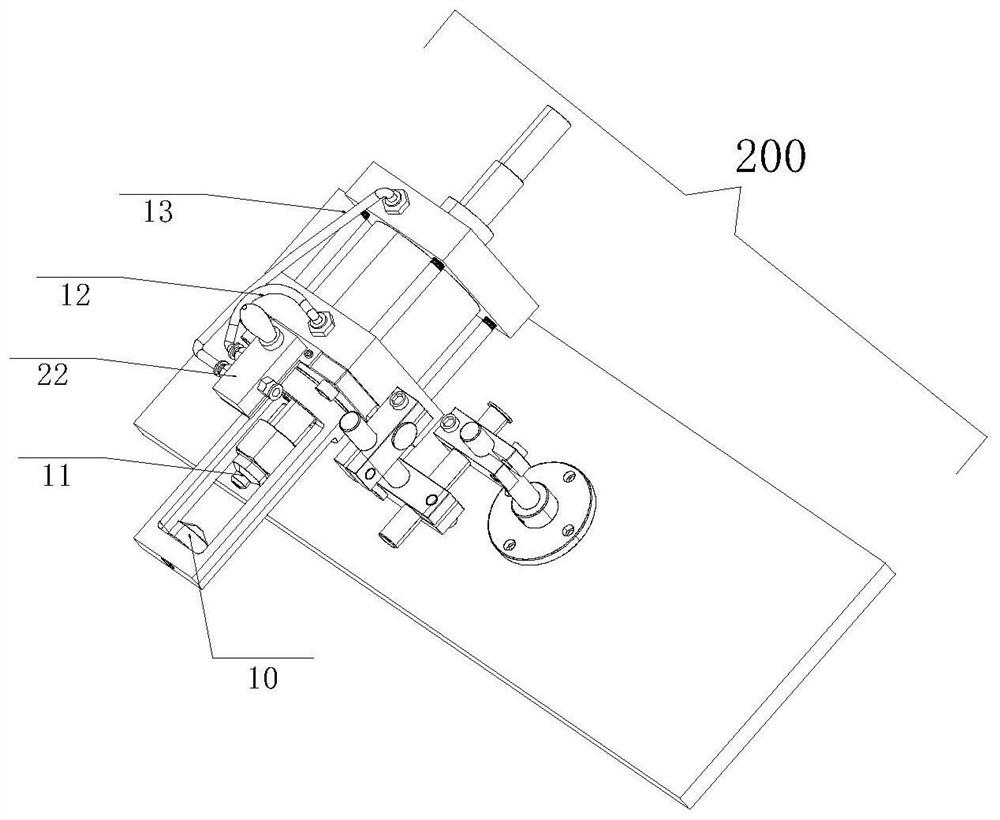

Tool device convenient for testing pressure of high-pressure oil pipe

ActiveCN109443939AEasy to operateEasy to installMaterial strength using tensile/compressive forcesHigh pressurePiston rod

The invention discloses a tool device convenient for testing pressure of a high-pressure oil pipe. The tool device comprises a left-side oil pipe fixing component, a right-side oil pipe fixing component, a bottom plate, a water incoming pipe, an air incoming pipe and a connection water pipe, the left-side oil pipe fixing component comprises a first manual valve, a first end cap, a retaining plate,a rotating seat, a first air pipe and a second air pipe, and the right-side oil pipe fixing component comprises a second end cap, a third end cap, a third air pipe, a fourth air pipe and a second manual valve. The first end cap and the third end cap are pushed by a piston rod to tightly clamp joints at two ends of the high-pressure oil pipe by pulling the first manual valve and the second manualvalve, so that operation is simple and convenient; for the high-pressure oil pipe different in length, proper distance is reached by adjusting a screw for the convenience of mounting; angle of a grooving position on a retaining plate is adjusted by utilizing the rotating seat for the convenience of mounting the oil pipe; distance and angle are adjusted through sliding of a clamping plate on a connection rod to realize adjusting on direction of the left-side oil pipe fixing component and the right-side oil pipe fixing component.

Owner:南京海王汽车零部件有限公司

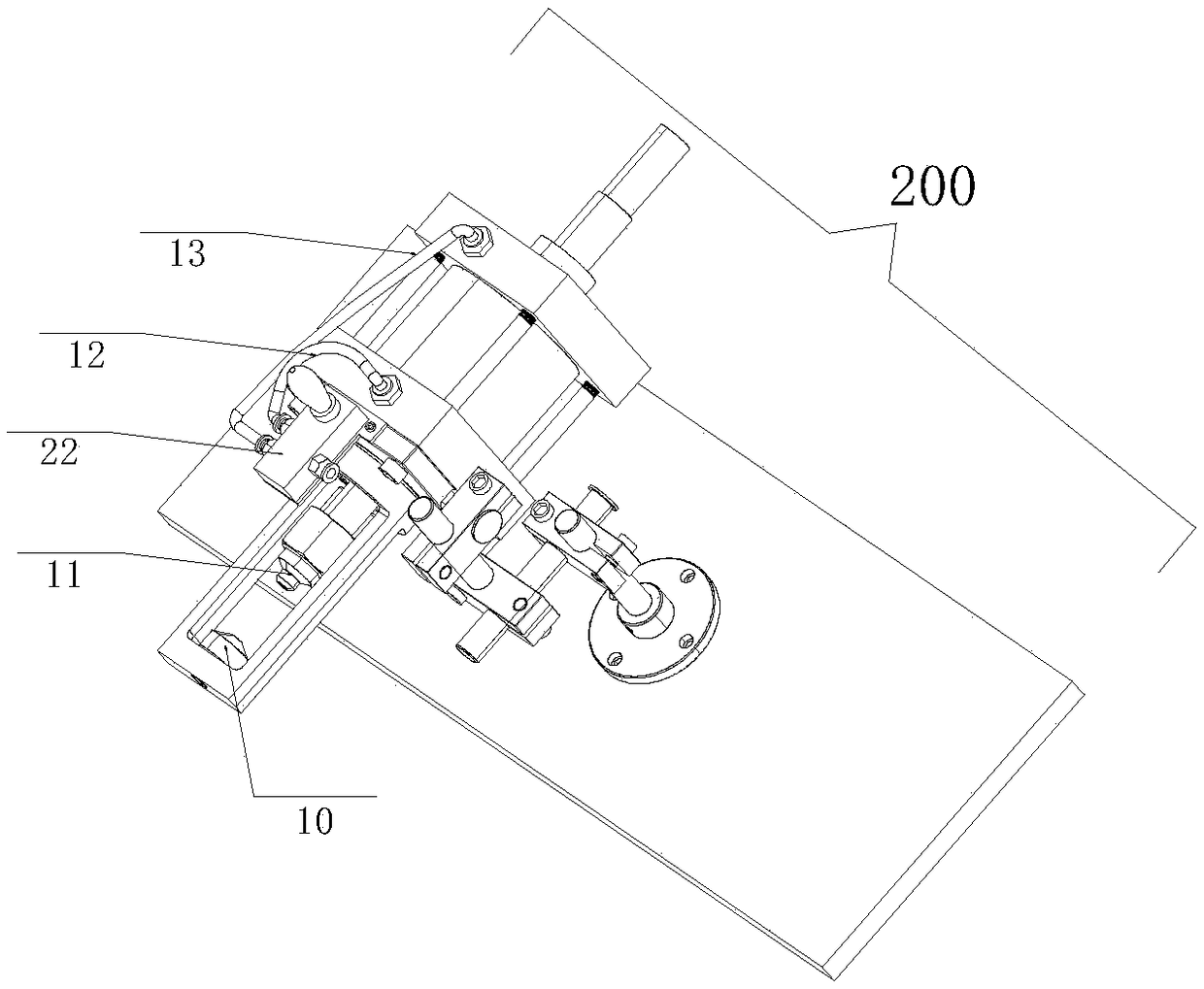

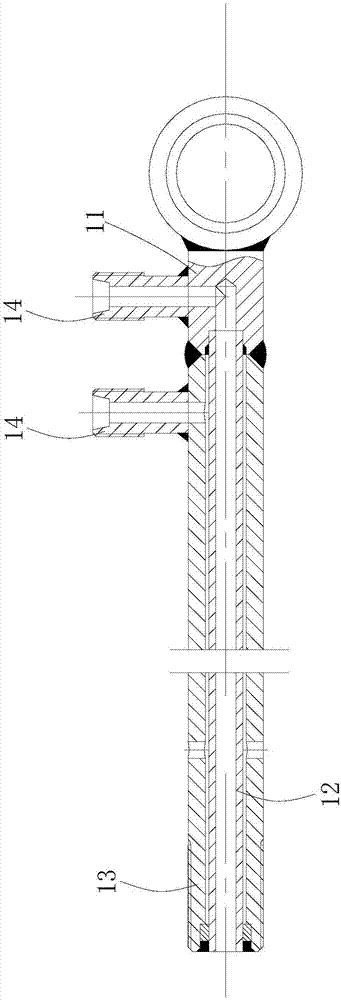

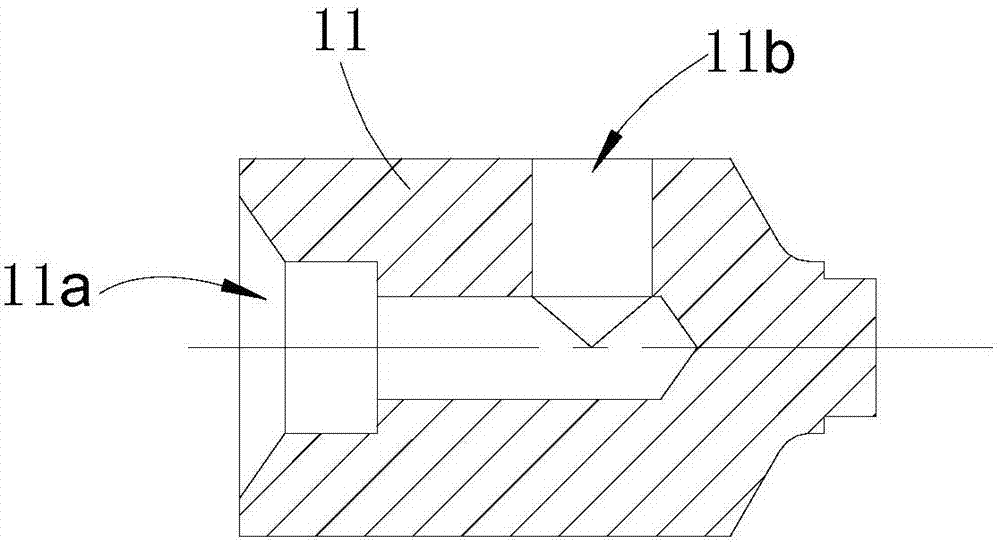

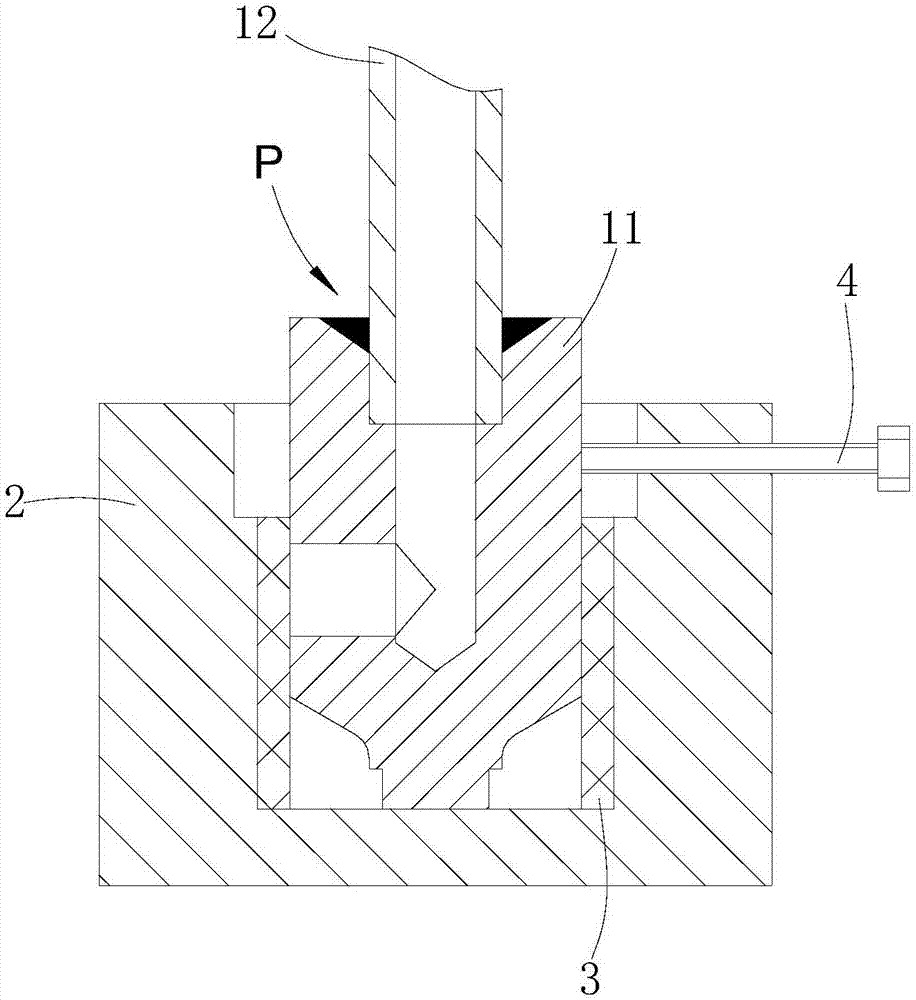

Welding positioning tool and pressure testing method for inner oil path type piston rod

PendingCN107984152AThe pressure test process is simple and clearImprove pressure test efficiencyDetection of fluid at leakage pointWelding/cutting auxillary devicesTest efficiencyEngineering

The invention provides a welding positioning tool for inner oil path type piston rod. The welding positioning tool comprises a fixing seat and sealing rings; positioning grooves matched with a pistonrod head are formed in the upper end surface of the fixing seat; the sealing rings sleeve in the positioning grooves; the piston rod head is matched with the fixing seat; and the piston rod head extends into the positioning grooves and the sealing rings seal oil ports of the piston rod head. The welding positioning tool has the beneficial effects that the problem of auxiliary positioning between the piston rod head and a core tube is solved; the welding operation of the inner oil path type piston rod is simplified, and the working efficiency is improved. The invention further provides a pressure testing method of the inner oil path type piston rod. The method comprises the following steps of matching the welded piston rod head and the core tube with the positioning tool; then placing the welded piston rod head, the core tube and the welding positioning tool of the inner oil path type piston rod into the water; enabling the end part of the core tube is communicated with a gas source; and observing whether the welding position between the piston rod head and the core tube is sealed or not. The pressure testing method has the beneficial effects that the pressure test process is simpleand clear, the pressure test efficiency is greatly improved, and the labor intensity is reduced.

Owner:BENGBU YELI MACHINERY

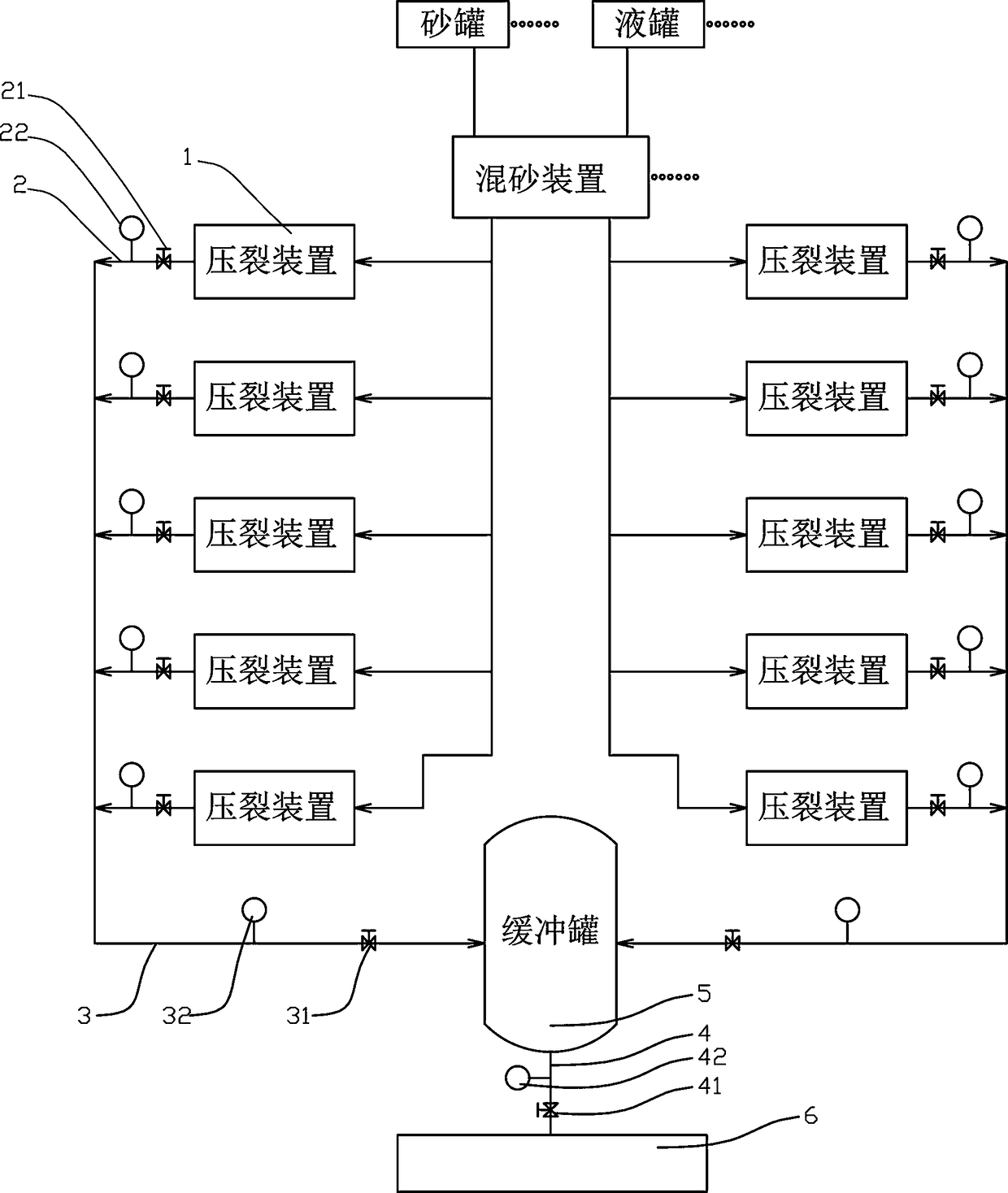

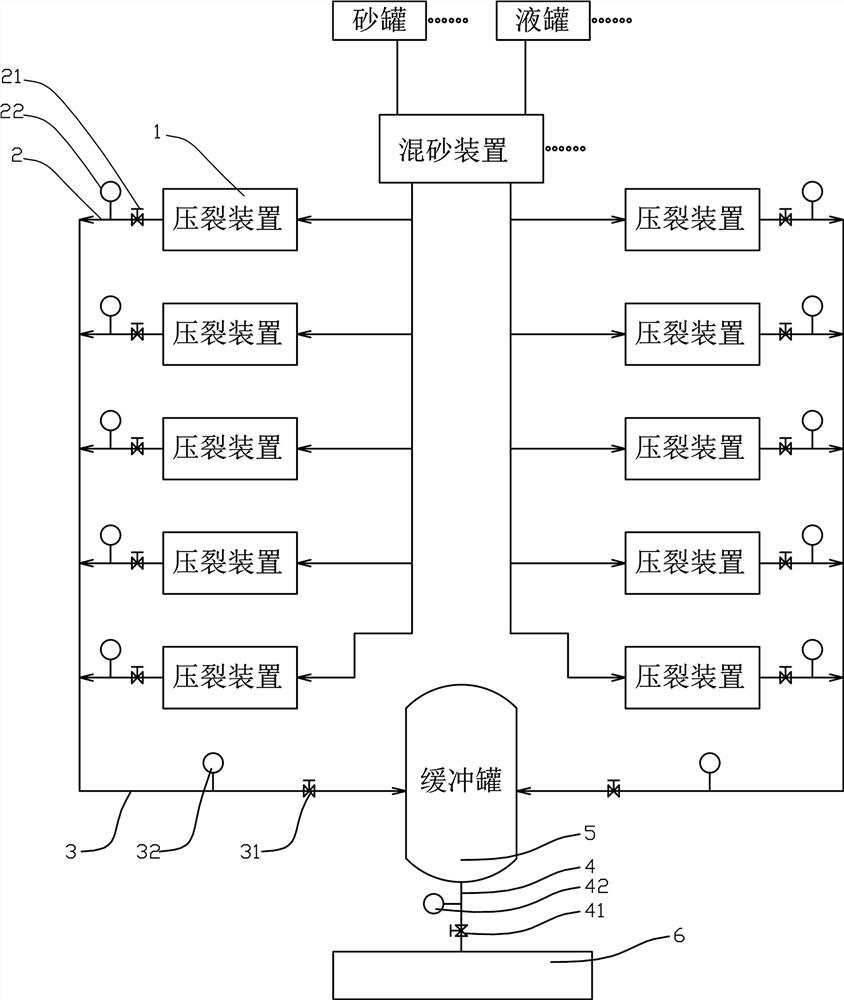

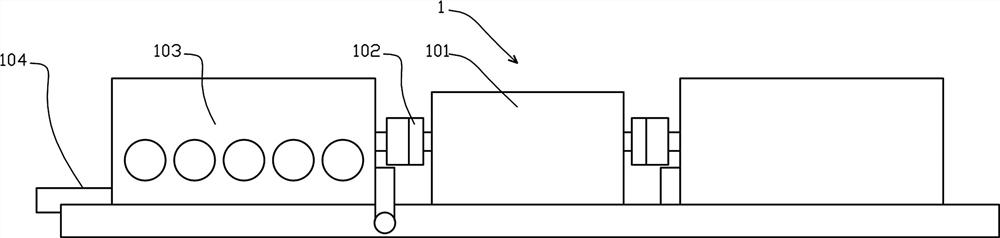

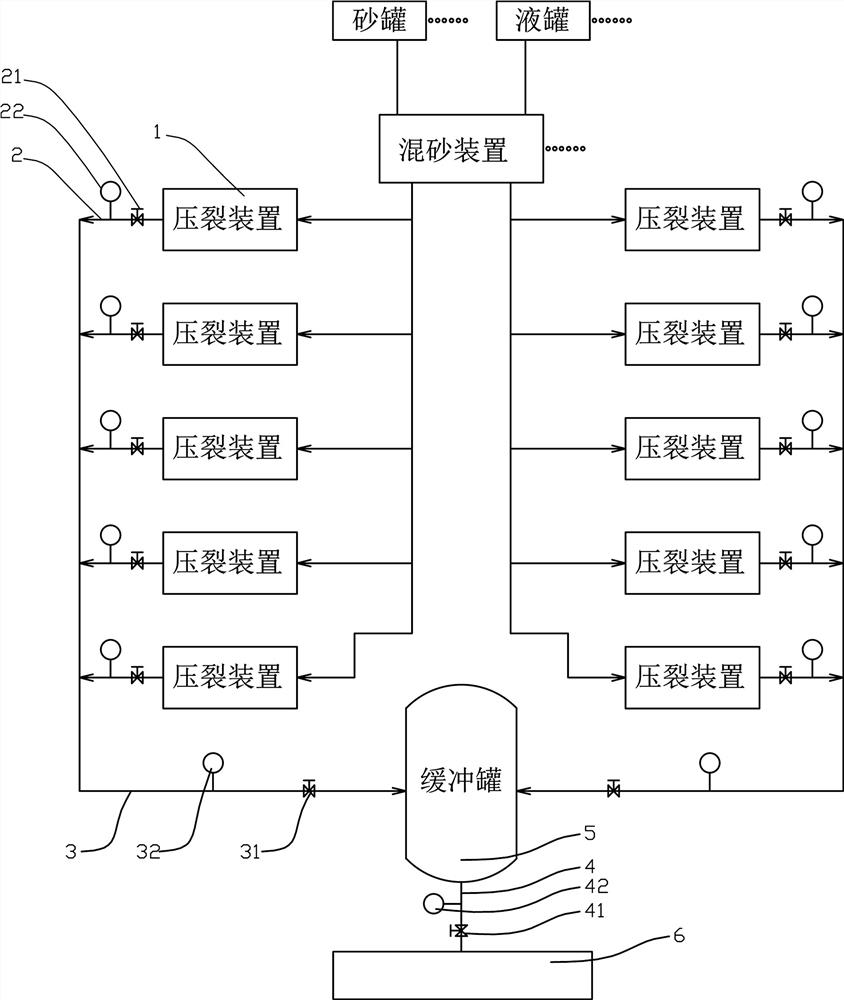

Rapid location method for pressure test failure of fracturing system

ActiveCN109632353BRapid positioningImprove securityStructural/machines measurementControl engineeringSystem pressure

The invention provides a fracturing system pressure test fault rapid positioning method. The method comprises the following steps that fracturing devices in the fracturing system are grouped for multiple times, the main controller gives out signals to enable the fracturing devices of all groups to output pressure, all the fracturing devices controlled by branch controllers participate in outputting pressure; when pressure fed back by a bus pressure sensor reaches a set value, the pressure is maintained; after a period of pressure maintaining, a current pressure signal output by the bus pressure sensor is read and compared with the preset pressure value, and if the current pressure value is within the setting range of the preset pressure value, the pressure test is completed; if the currentpressure value exceeds the setting range of the preset pressure value, a fault alarm is output, a fault positioning step is started, and fracturing system pressure test fault rapid positioning is realized. According to the method, the safety of the pressure testing operation is greatly improved, pressure testing efficiency is improved, and by adopting a scheme of grouping and calibrating a pressure increase curve, a fault point can be quickly positioned.

Owner:中石化四机石油机械有限公司 +2

Pressure test control method for fracturing system

ActiveCN109342100BImprove securityRapid positioningStructural/machines measurementElectric machineryControl theory

The present invention provides a pressure test control method for a fracturing system, comprising the following steps: S1, closing the valve of the discharge pipeline of the fracturing device; S2, the controller outputs a pulse signal to drive the motor of the fracturing device to rotate to discharge The pressure of the pipeline rises, and the pressure sensor of the discharge pipeline outputs a pressure signal; S3. The controller receives the pressure signal and compares it with the preset pressure value. If it reaches the pressure, it maintains the pressure, and if it does not reach it, it outputs the same pulse again The signal drives the motor of the fracturing device to rotate, so that the pressure of the discharge pipeline increases until it reaches the preset pressure value; the pressure test operation of the fracturing system is realized through the above steps. The invention can greatly improve the safety of the pressure test operation and improve the pressure test efficiency.

Owner:中石化四机石油机械有限公司 +2

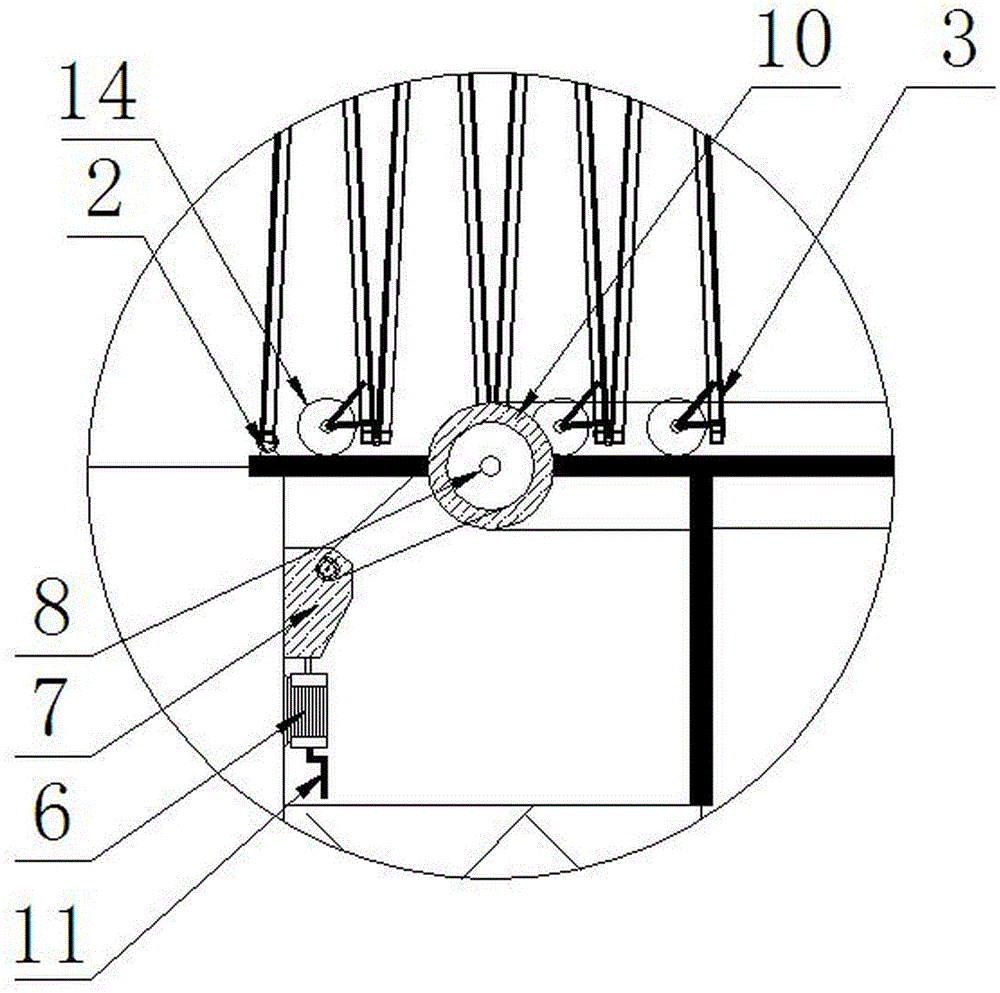

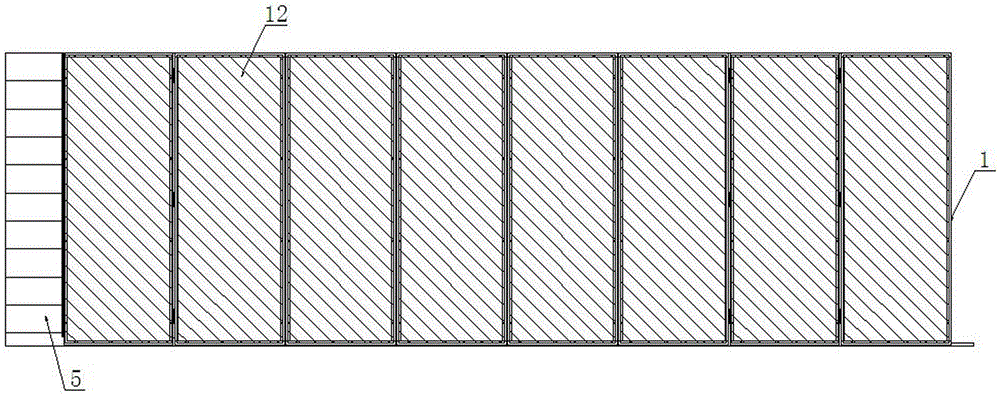

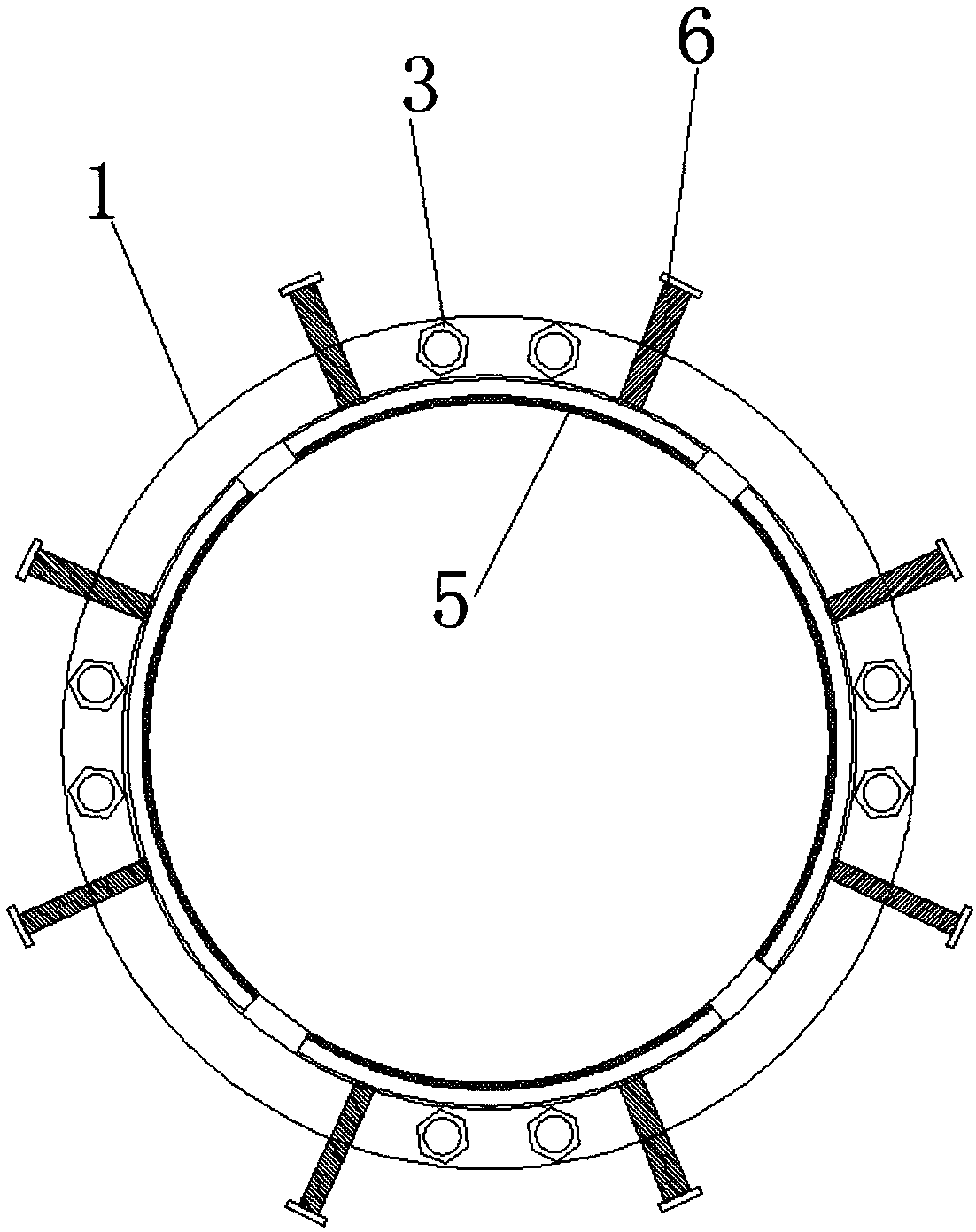

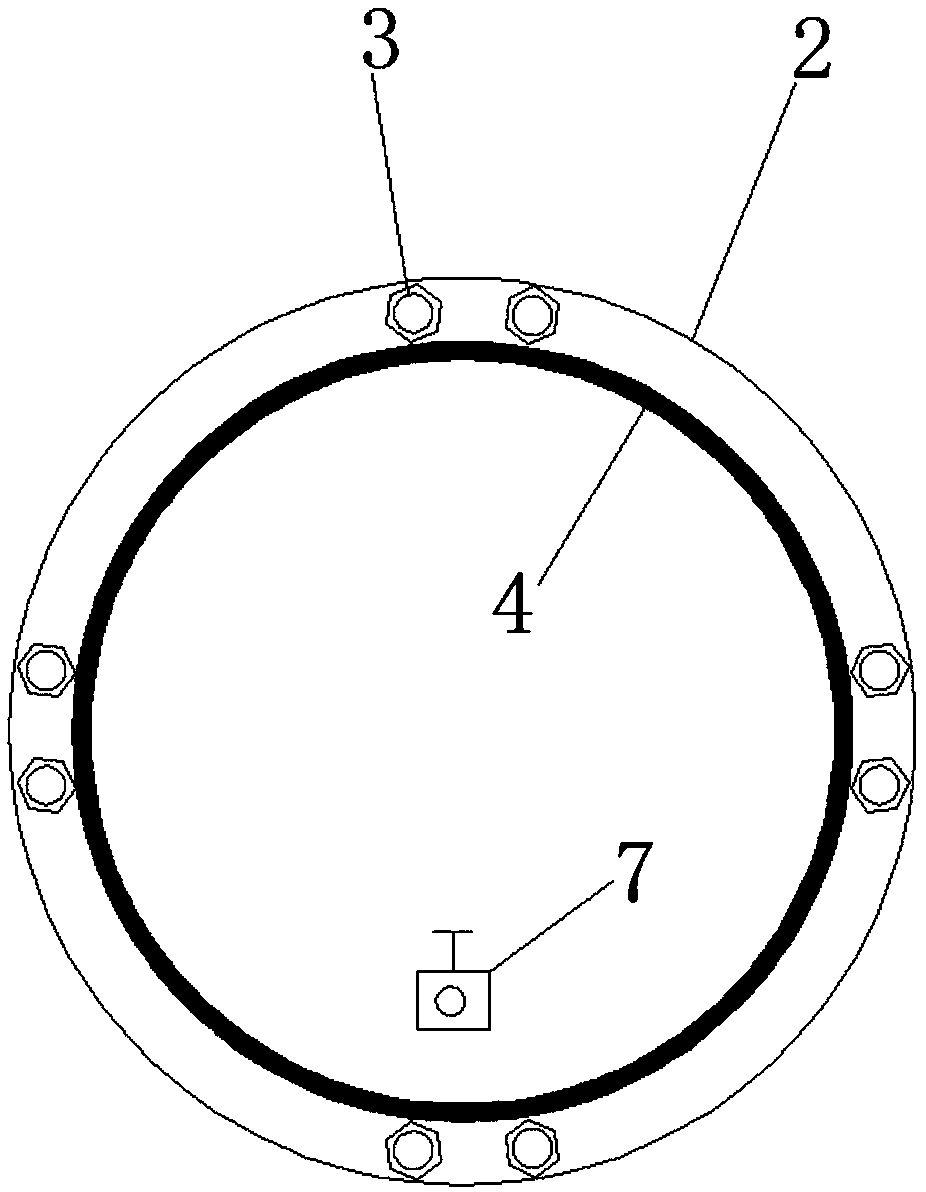

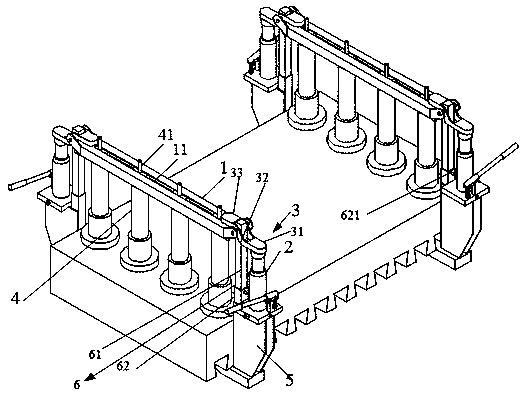

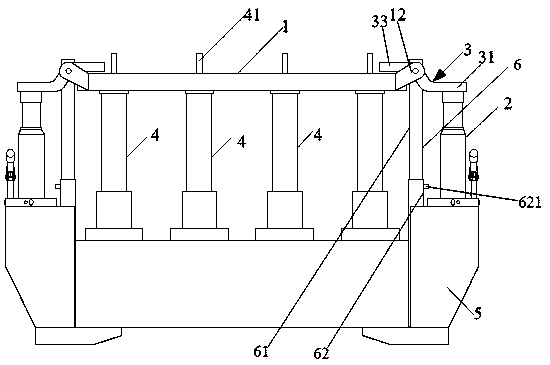

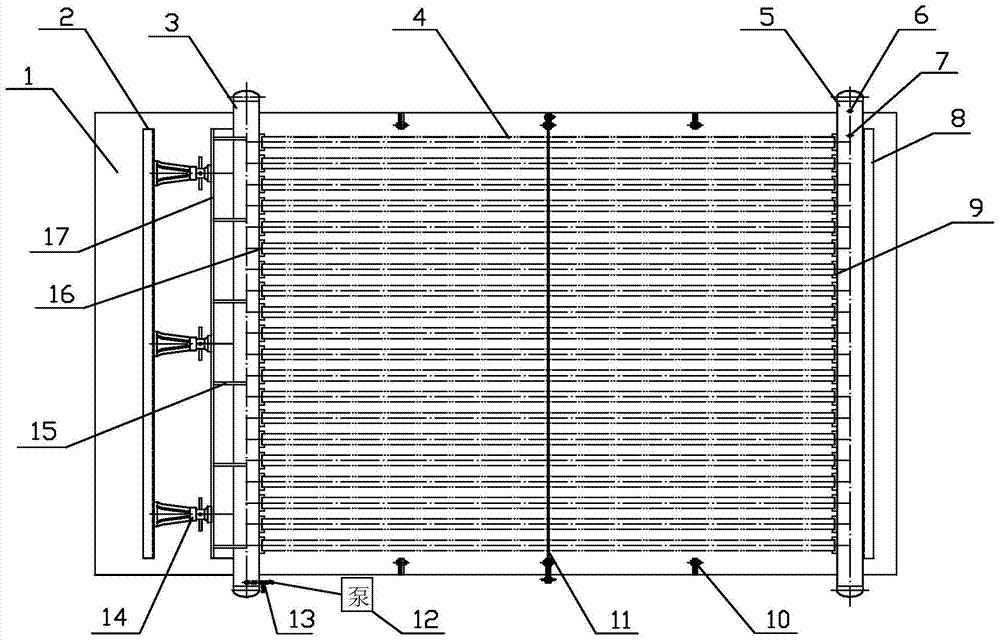

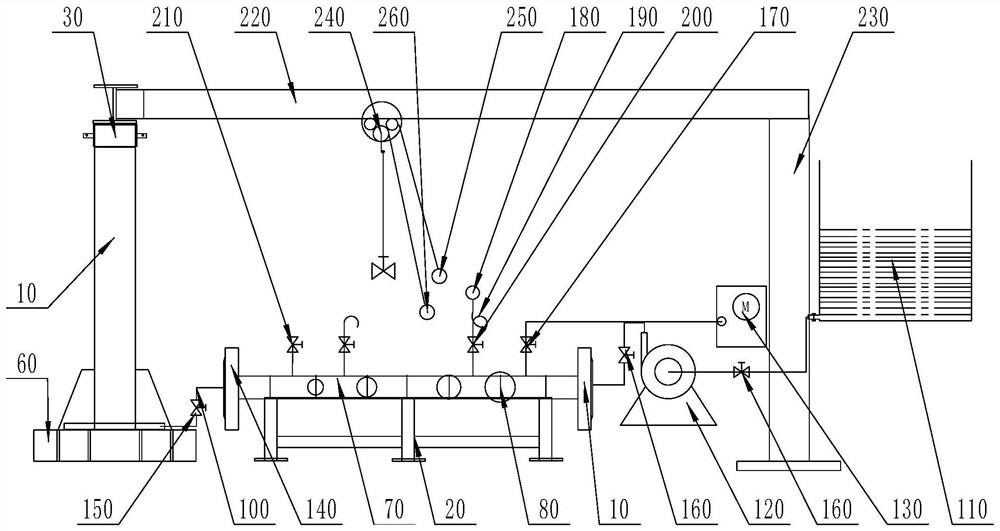

Pressure testing device and method of cooling wall of blast furnace

ActiveCN110283954AImprove pressure test efficiencySolve the problem of water seepageCooling devicesChecking devicesTest efficiencyEngineering

The invention provides a pressure testing device and method of a cooling wall of a blast furnace. The device comprises a pressing plate, hoisting mechanisms, supporting columns and connecting rod structures, wherein the hoisting mechanisms, the supporting columns and the connecting rod structures are arranged at two ends of the pressing plate; the supporting columns are arranged between the end part of the pressing plate and the hoisting mechanisms; the connecting rod structures penetrate through the supporting columns; the driving ends, hinged with the hoisting mechanisms, of the supporting columns are connected to the first ends of the connecting rod structures and are used for driving the first ends of the connecting rod structures to up and down reciprocate; and the second ends of the connecting rod structures are pressed to the pressing plate and are rotatably connected to the pressing plate, and the second ends of the connecting rod structures are used for applying downward pressure to the pressing plate while the first ends of the connecting rod structures upwards move so as to compress a plurality of water cooling pipes through the pressing plate. According to the device, the top parts of the plurality of water cooling pipes are pressed through the pressing plate, and a hoisting mechanism set and a connecting rod structure set are arranged at each of two sides of the pressing plate; the hoisting mechanisms and the connecting rod structures are matched to apply pressure to the pressing plate from two ends, and thus the plurality of water cooling pipes can be synchronously compressed so as to perform pressure test on a workpiece, and as a result, the pressure test efficiency is greatly improved.

Owner:CHINA FIRST METALLURGICAL GROUP

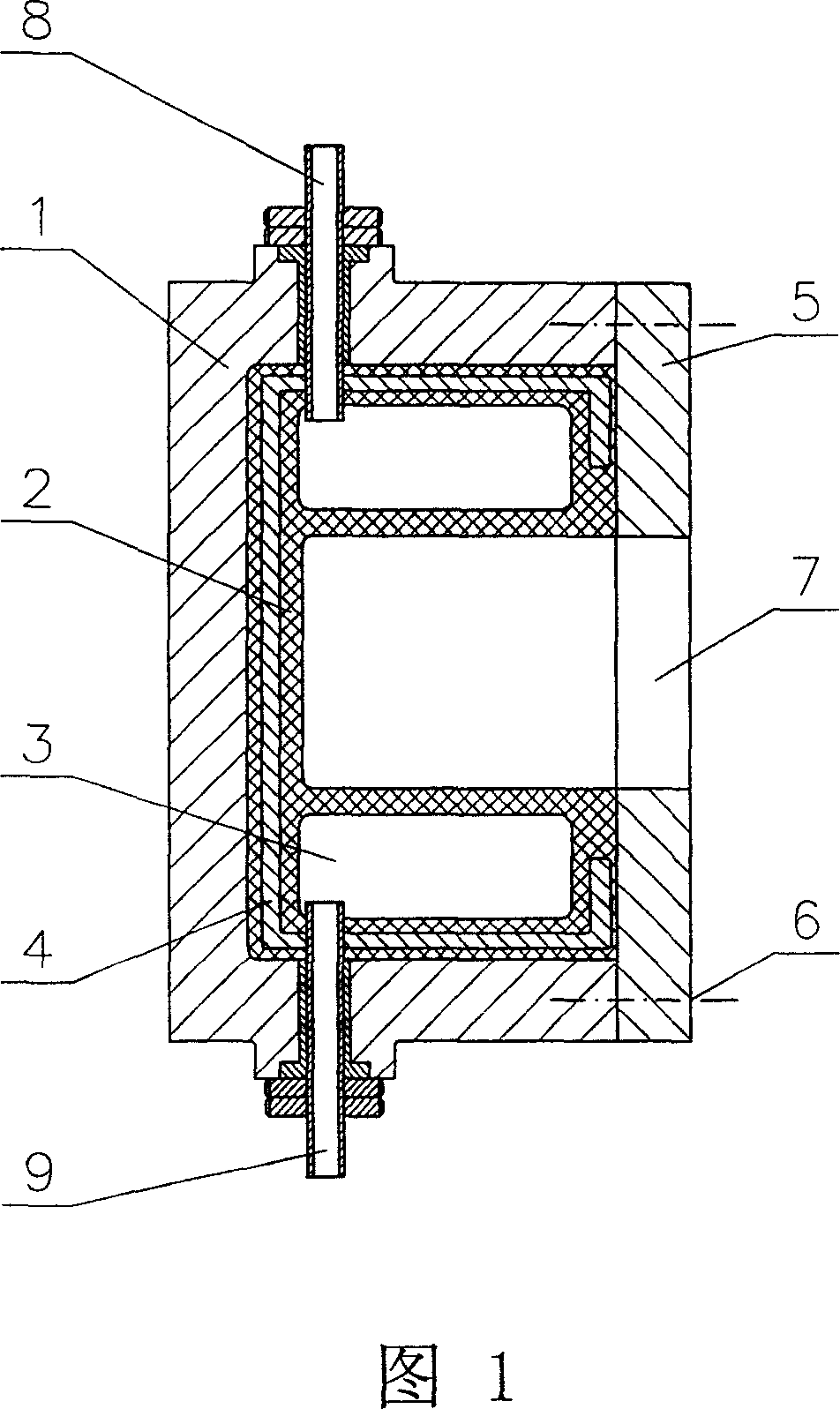

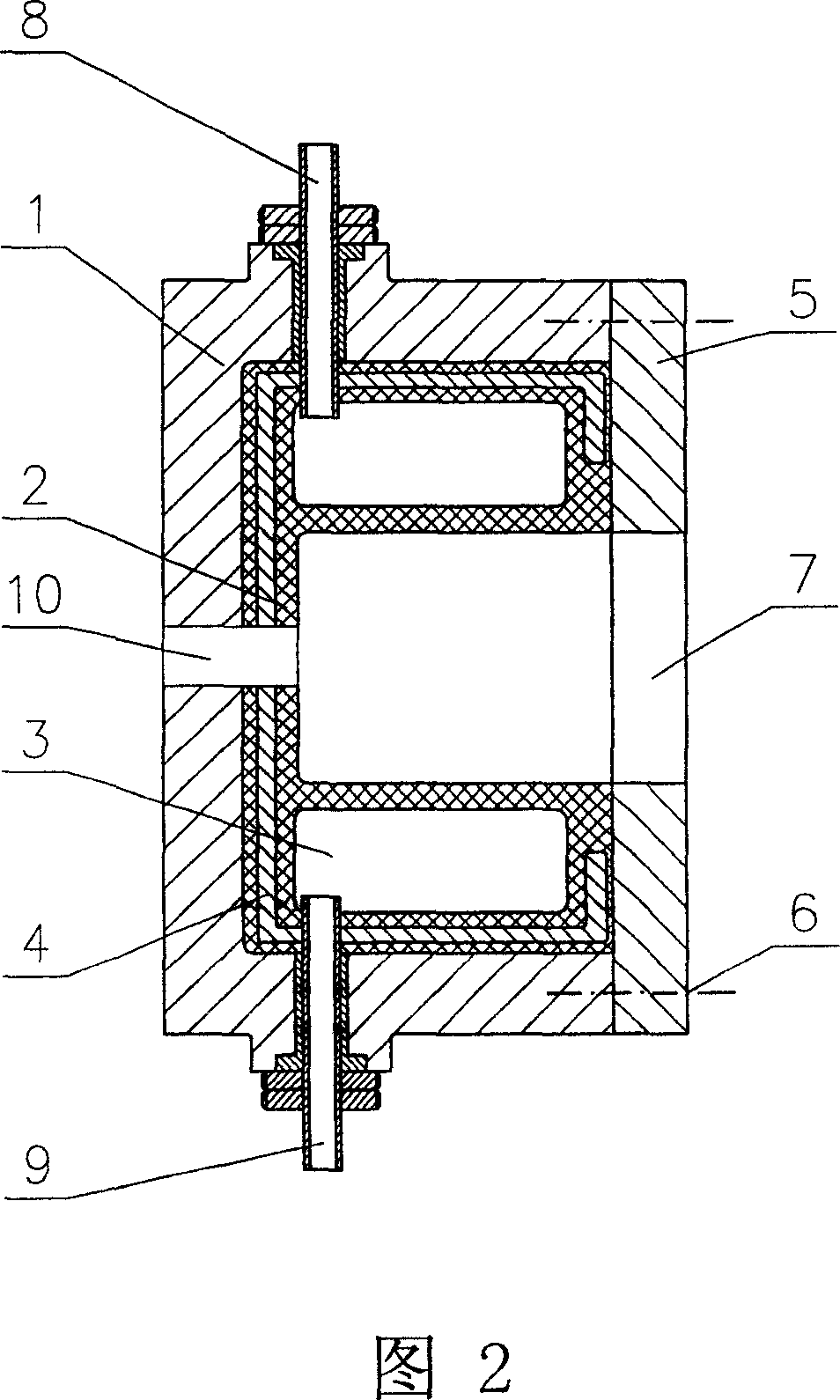

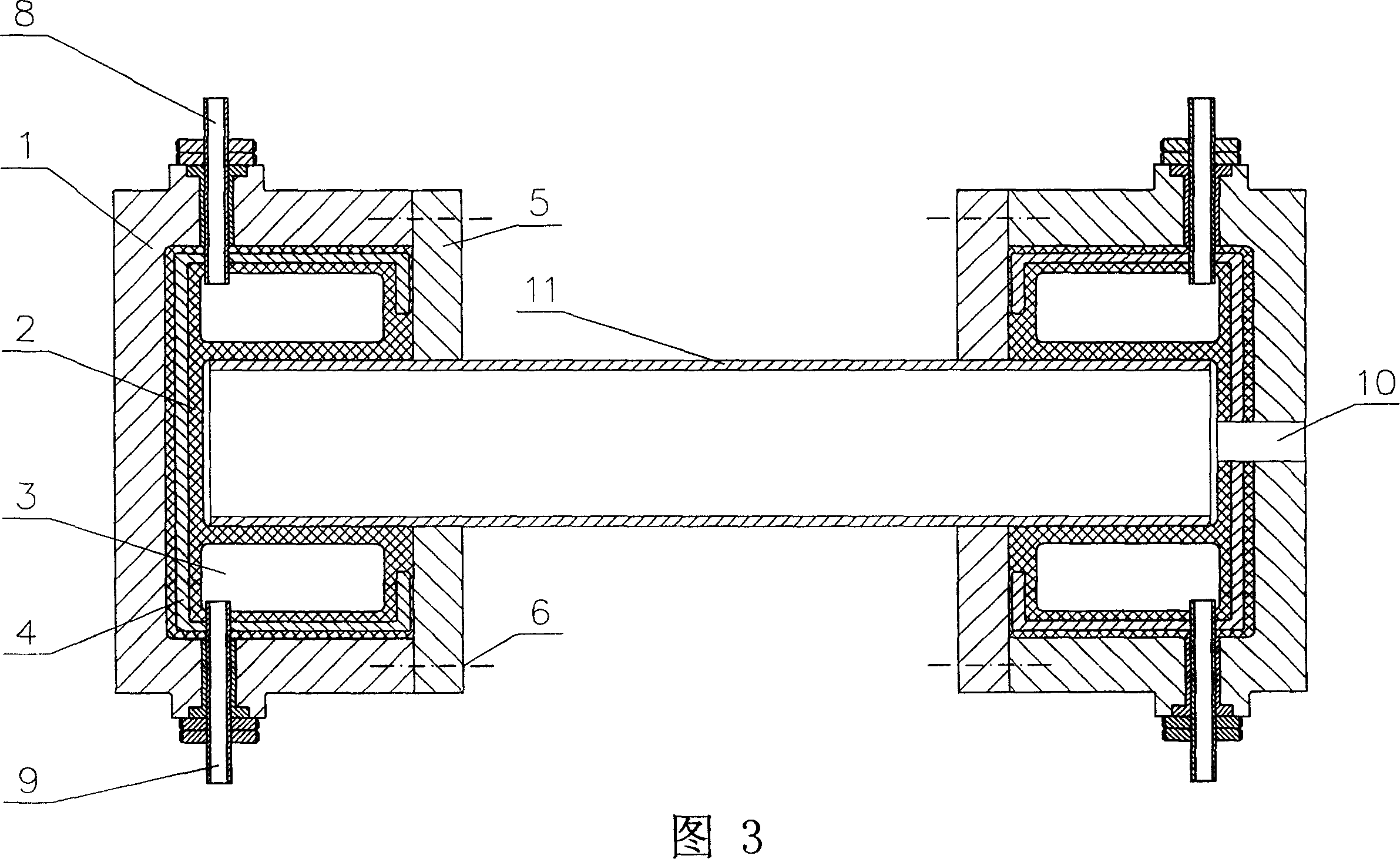

Sealing device

InactiveCN1314912CImprove pressure test efficiencyGuaranteed tightnessEngine sealsMetallic enclosureEngineering

The invention relates to a sealing device, including: a metallic case with a n-shaped section; a rubber layer with a n-shaped section in which there is an annular rubber cell; a metallic frame with a C-shaped section, set in the rubber layer outside the rubber cell; a guard board connected at the inner end of the metallic case and set with a through hole in the center directly corresponding to a seal component; an oil inlet and outlet pipe, respectively connected with the rubber cell and fixed with the metallic case. Its sealing function is implemented by deformation of the rubber cell, i.e. when the high-pressure oil is charged in the rubber cell, the rubber cell deforms to closely adhere to the tool so as to play a role in sealing, and when the high-pressure oil is drained, the rubber cell can rapidly returns to set aside a space for taking the tool out, therefore the rubber cell can not be damaged by friction, the sealing effect good and the pressure measuring efficiency high and the service life is effectively prolonged. It can be used in pressure-testing device of oil tool and also widely used in other sealing devices with higher pressure pipelines.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

A pressure test method for ultra-large waste heat boiler pipes based on BIM technology

ActiveCN106354933BImprove pressure test efficiencyReduce the influence of human factorsGeometric CADSpecial data processing applicationsPressure systemEngineering

The invention discloses a BIM(building information modeling) technology based ultra-large steel making exhausted heat boiler pipeline pressure testing method which includes the steps of converting construction drawings into a BIM technology based three-dimensional model, importing the three-dimensional model of an ultra-large steel making exhausted heat boiler pipeline system to a Fluent fluid simulation software, determining positions for installation of communicating pipes and the highest point by the Fluent fluid simulation software, installing on an actual construction site and taking pressure testing measures of the testing pressure system, and carrying out pressure test by the system. By the BIM technology, the conventional construction drawings are converted into the three-dimensional construction drawings, and the specific positions, needing pressure testing measures, of the ultra-large steel making exhausted heat boiler pipeline system, can be determined by the aid of the Fluent fluid simulation software.

Owner:CHINA MCC17 GRP

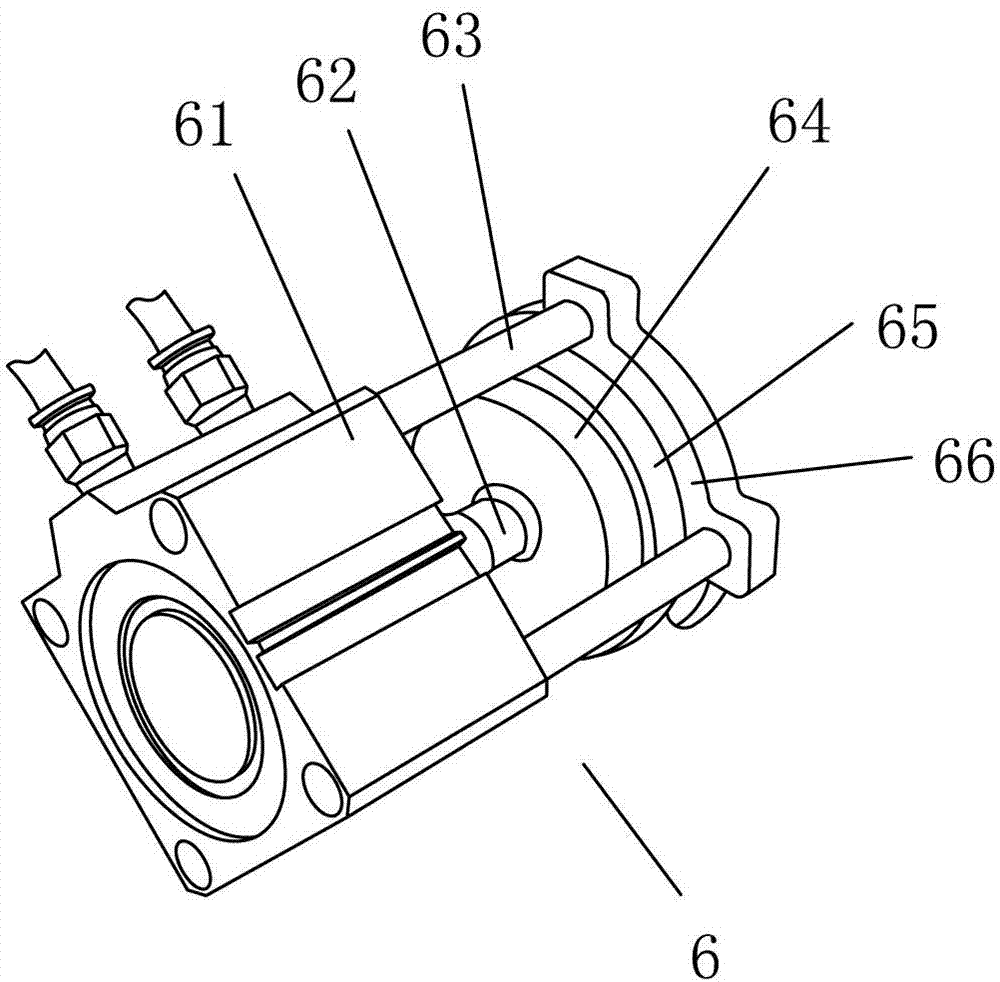

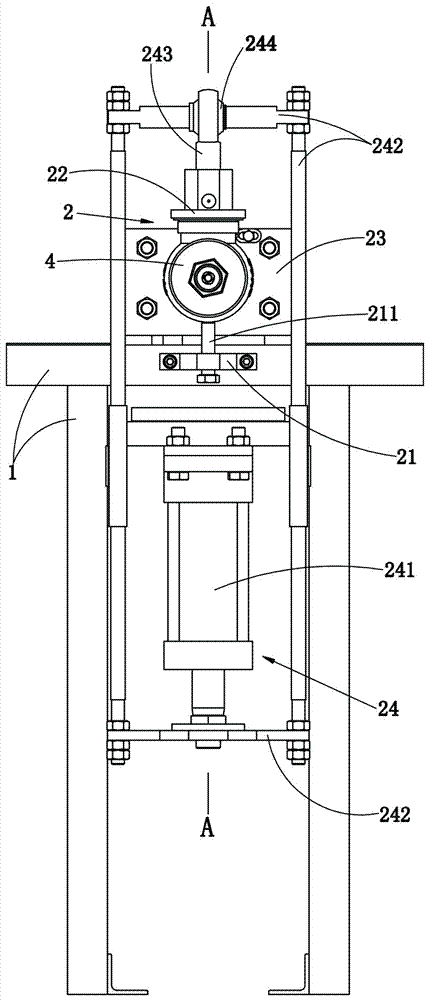

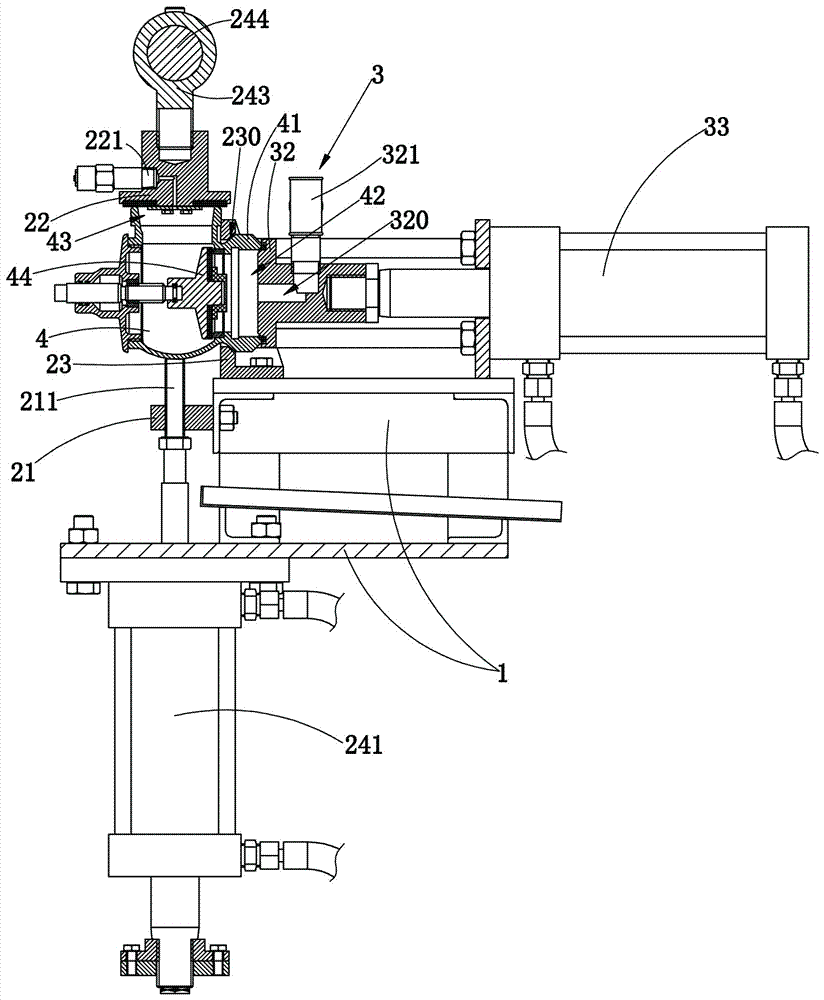

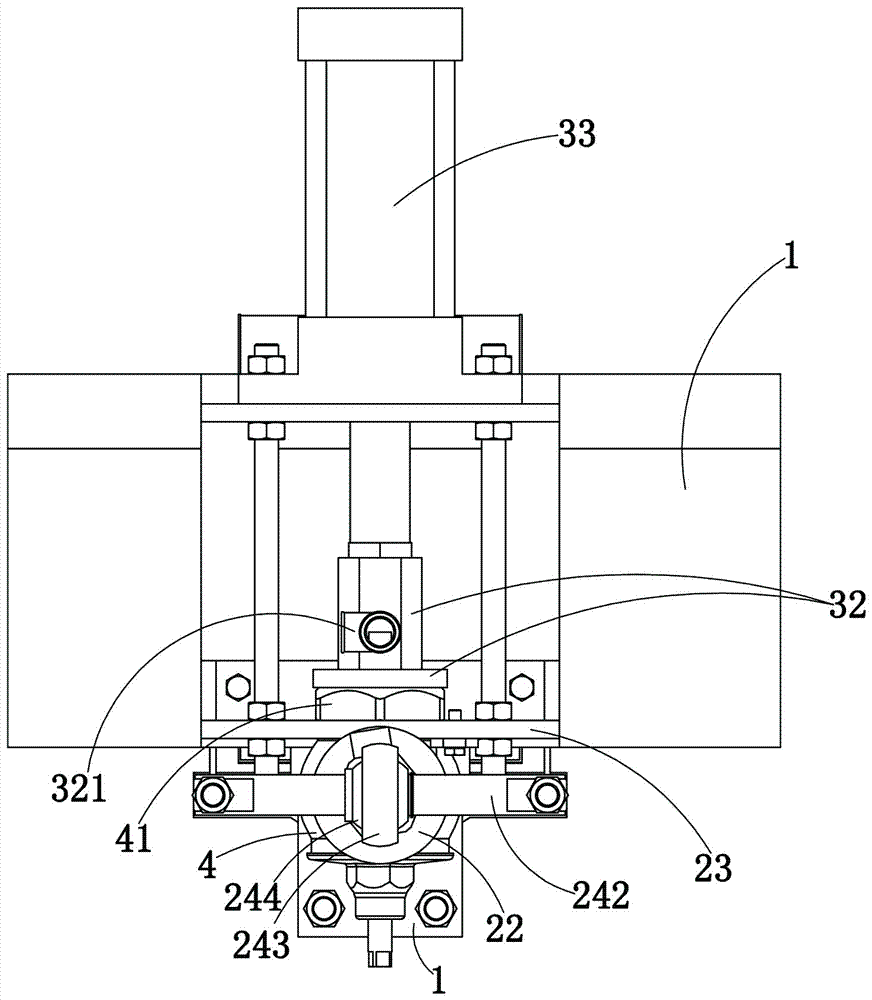

Static pressure testing device for integrated packaging mechanical seal

PendingCN109115426AAvoid manualStable pressure outputMeasurement of fluid loss/gain rateHydraulic cylinderInlet valve

The invention discloses a static pressure testing device for an integrated packaging mechanical seal, which comprises a rack, and is characterized in that the bottom end of the rack is fixedly provided with an integrated packaging mechanical seal, the top end of the rack is fixedly provided with an oil cylinder, a piston rod of the oil cylinder is fixedly connected with the top end of a ventilating disc through a flange, the middle part of the ventilating disc is fixedly provided with an air inlet pipe, one end of the air inlet pipe is fixedly provided with an air inlet valve, the other end ofthe air inlet pipe is fixedly provided with a pressure meter, the middle part of the air inlet pipe is provided with an air outlet, and the bottom end of the ventilating disc is fixedly provided witha cavity. According to the static pressure testing device for the integrated packaging mechanical seal, the ventilating disc, the cavity and the integrated packaging mechanical seal are compressed through extending the piston rod of the oil cylinder so as to quickly form a sealed cavity, the air pressured is charged for testing, the pressure of the hydraulic oil cylinder is provided by a hydraulic station, and the pressure output is stable, so that manual bolt locking is avoided, and the pressure testing efficiency if improved so as to meet the requirement of batch production of the integrated packaging mechanical seal.

Owner:昆山福步工业设备有限公司

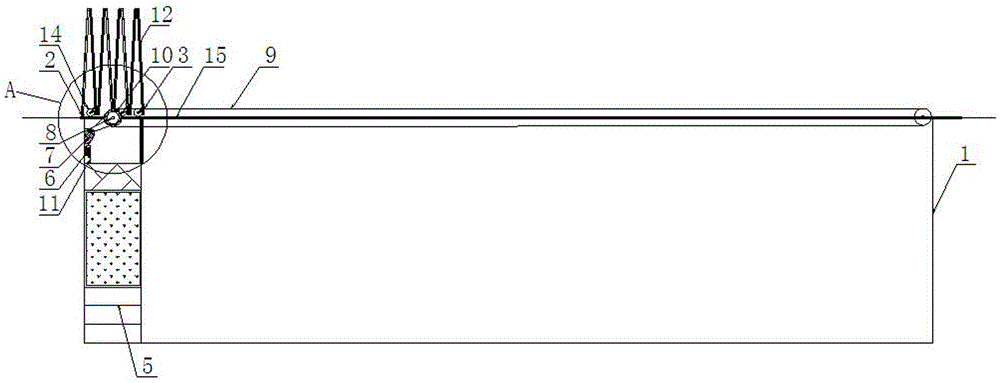

A pressure test device and a pressure test method for a long-distance pipeline

ActiveCN111503522BEasy to movePlay a shock absorbing effectPipeline systemsLine tubingStructural engineering

The present invention relates to a pressure test device for long-distance pipelines, which includes a water filling unit and a booster unit respectively installed on the first base and the second base; The pipeline includes multiple conveying pipe sections, and valves are installed at the joints between multiple conveying pipe sections; the pressure test method is as follows: use the water filling unit to fill the first conveying pipe section with water, and after the water filling is completed, use the booster unit to fill it with water. Pressurize, and at the same time, the water filling unit fills other conveying pipe sections with water. The pressurizing unit and the flushing unit are used at the same time until the last conveying pipe section. Supercharging; the water filling unit and the supercharging unit are respectively arranged on two bases, which are separately skidded, and the water outlet pipe sections of the water filling unit and the supercharging unit both contain hoses, which are more convenient to move, and can make the water filling unit and the booster unit The pressure unit fills and pressurizes different conveying pipe sections at the same time, which saves time and improves the efficiency of pressure testing.

Owner:JEREH OIL & GAS ENG

Air inlet and exhaust device

PendingCN112664738AImprove pressure test efficiencyShorten pressure test timeMachine part testingOperating means/releasing devices for valvesThermodynamicsEngineering

The invention belongs to the technical field of water heaters, and particularly relates to an air inlet and exhaust device. The air outlet end of an air inlet pipeline and the air inlet end of an exhaust pipeline are connected to a first connector and a third connector of a three-way connector correspondingly, and a first valve and a second valve are arranged on the air inlet pipeline and the exhaust pipeline correspondingly; meanwhile, a middle pipeline is in communication between the second connector of the three-way connector and a pressure testing opening of a water heater inner container so that when the water heater inner container is still located in water, exhaust work can be conducted in the mode that a second valve is opened; and in other words, after pressure maintaining is finished, and when the water heater inner container starts to be lifted, gas in the water heater inner container can be exhausted into air from the middle pipeline and the exhaust pipeline, the pressure testing time is effectively saved, and therefore the pressure testing efficiency of the water heater inner container is improved.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

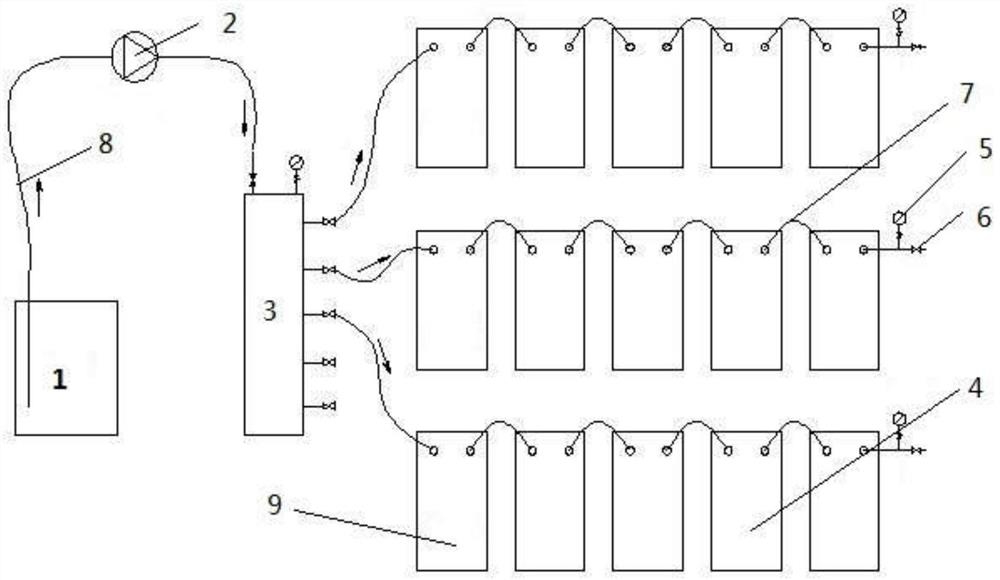

Rapid pressure test device and method for cooling wall of blast furnace

PendingCN114635001AIncrease the capacity of pressure test mediumImprove pressure test efficiencyCooling devicesChecking devicesThermodynamicsExhaust valve

The invention provides a rapid pressure testing device and method for a blast furnace cooling wall, and belongs to the technical field of blast furnace cooling walls. The device comprises a water source, a pressure stabilizing unit, a pressure testing pump used for connecting the water source and the pressure stabilizing unit, and a testing unit used for testing the cooling wall; the pressure stabilizing unit is used for distributing water of a water source to each testing unit; the test unit comprises more than two cooling walls which are connected in series; in the testing unit, the water inlet of the cooling wall at the front end is connected with the pressure stabilizing unit, and the water outlet of the previous cooling wall is connected with the water inlet of the next cooling wall through a testing connecting pipe; a pressure gauge and an exhaust valve are arranged at the water outlet of the cooling wall at the tail end; the method has the technical effects of reducing the pressure test cost and improving the pressure test efficiency.

Owner:CHINA HUAYE GROUP +1

Pressure test tool for sealing pressure vessel welding beveled edges

InactiveCN105092361AImprove sealingMeet the pressure test functionMaterial strength using tensile/compressive forcesEngineeringPressure vessel

The invention discloses a pressure test tool for sealing pressure vessel welding beveled edges. The pressure test tool comprises a pressure test tool body and a pressure test connector. The right side face of the pressure test tool body is provided with annular welding beveled edge sealing grooves. Each welding beveled edge sealing groove comprises a sealing ring containing portion and a welding beveled edge matching portion. The welding beveled edge matching portions of the welding beveled edge sealing grooves are matched with the welding beveled edges of a pressure vessel. The sealing ring placing portions are internally provided with O-shaped sealing rings. The center of the pressure test tool body is provided with an assembling hole. The pressure test connector is assembled in the assembling hole of the pressure test tool body. The left end of the pressure test connector is further connected with a pressure device. The center of the pressure test connector is provided with a pressure conduction hole. The right side face of the pressure test tool body is provided with inclined holes communicated with the welding beveled edge sealing grooves. While the pressure test function is met, the problems that through a traditional pressure test method, welding beveled edges are prone to deformation and damage by bumping are solved, the whole structure is higher in safety, the cost is saved, and the pressure test tool is higher in using efficiency and simple and easy to operate.

Owner:REFONE AUTO POWER

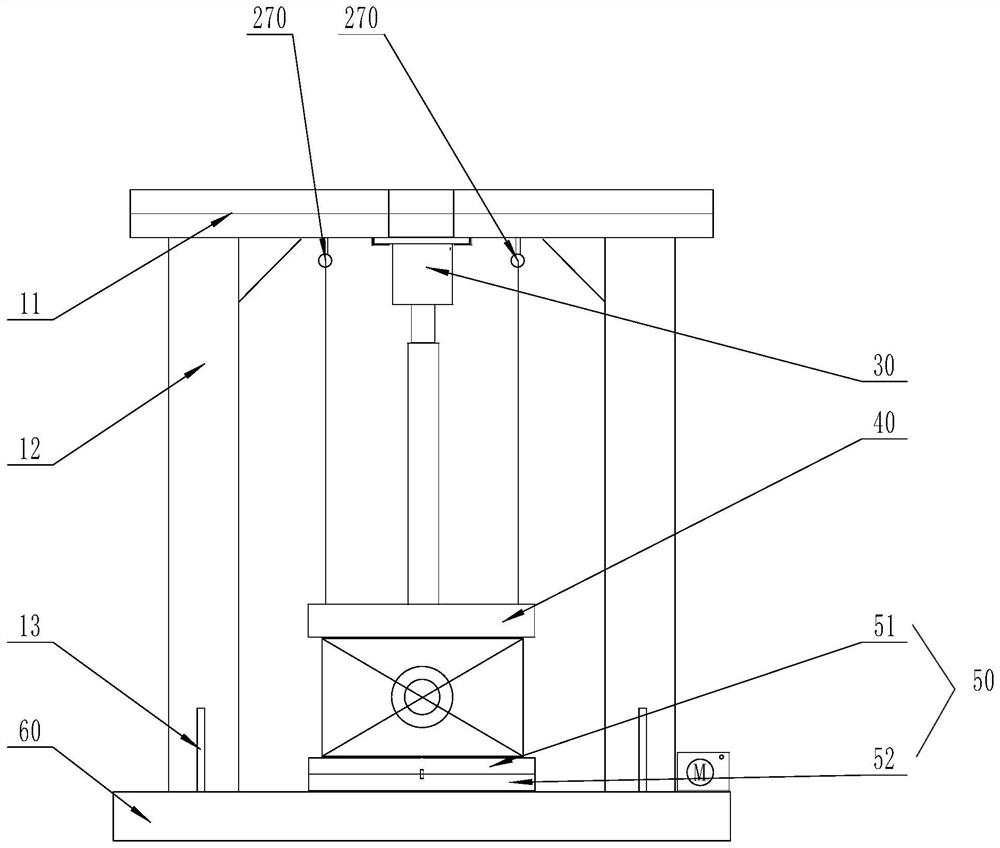

Automated sealing test machine

ActiveCN103196632BOperating physical exertion is smallLong holding timeDetection of fluid at leakage pointIntercoolerEngineering

The invention belongs to the technical field of sealing test machines and relates to an automated sealing test machine. A sealing test pond is arranged at the lower portion of a frame, a lifting device is arranged at the upper portion of the frame, the lower side of the lifting device is provided with a product placing rack and a product pressing device, a pipe opening cap is arranged on the product pressing device or on one side of the product placing rack, the lifting device can drive the product placing rack and the product pressing device to extend into the sealing test pond, and a controller controls actions of the lifting device and the pressing device and performs air supply or exhausting of the pipe opening cap. The automated sealing test machine has the advantages of being small in consumed strength, long in pressure holding time, high in pass percent of test products and high in production efficiency and is suitable for sealing tests of intercooler end caps in automobiles and like products.

Owner:TIANTAI YINXING MECHANICAL CASTING

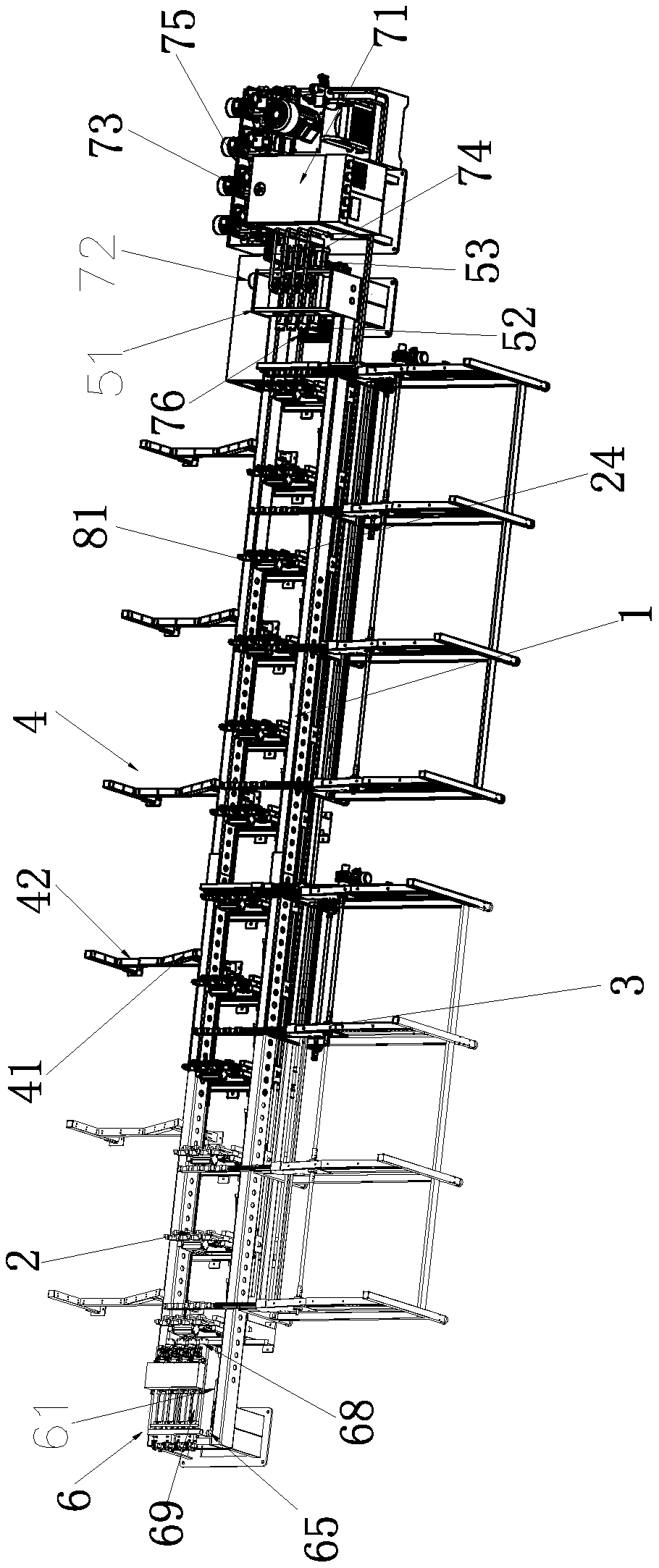

Batch steel pipe pressure test device

ActiveCN105181467BImprove pressure test efficiencyEasy to install and disassembleMaterial strength using tensile/compressive forcesEngineeringMean pressure

Owner:广西建工集团第二安装建设有限公司

Valve pressure testing device

PendingCN114252212ASolve the technical problem of low pressure test efficiencyGuaranteed accuracyMeasurement of fluid loss/gain rateFluid supplyVALVE PORT

The invention relates to the technical field of valve detection, in particular to a valve pressure testing device. The valve pressure testing device comprises a first supporting frame, a second supporting frame, a jack, an upper blind plate, a lower blind plate, a base, a pressure testing main pipe, a pressure testing branch pipe, a first connecting piece, a combined pipeline and a pressure testing fluid supply device. The base is connected with the bottom of the first supporting frame, the lower blind plate is connected with the base, the jack is connected between the top of the first supporting frame and the upper blind plate, and the upper blind plate and the lower blind plate are oppositely arranged at intervals. The pressure test main pipe is connected with the second supporting frame, the number of the pressure test branch pipes is multiple, one end of each pressure test branch pipe is communicated with the pressure test main pipe, and the other end of each pressure test branch pipe is provided with a first connecting piece; the lower blind plate is provided with a fluid inlet, one end of the pressure test main pipe is communicated with the fluid supply device, the other end of the pressure test main pipe is communicated with one end of the combined pipeline, and the other end of the combined pipeline is communicated with the fluid inlet.

Owner:CHINA ELEVENTH CHEM CONSTR

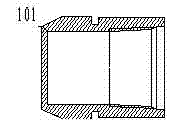

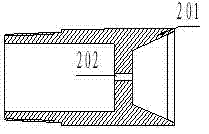

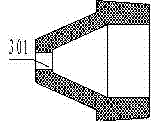

Pressure testing system and pressure testing method

InactiveCN102331329BPlug firmlyFirmly connectedMeasurement of fluid loss/gain rateHydraulic cylinderEngineering

The invention relates to oil testing of petroleum, especially to a pressure testing system and a pressure testing method. The pressure testing system comprises a pressure testing tool; and the system is characterized in that: the system also comprises a solid choke plug, a hollow end socket and a nylon packing; one end of the solid choke plug is connected with an output end of the pressure tool and the other end of the solid choke plug is a solid joint; one end of the hollow end socket is connected with an input end of the pressure tool and the other end of the hollow end socket is a hollow joint; a liquid passing hole is arranged in the middle of the hollow end socket; one end of the nylon packing is capable of being connected with a hydraulic cylinder and the other end of the nylon packing is a sealed end face that is cooperatively docked with the hollow joint; and an inner bore that is communicated with the liquid passing hole is arranged at the nylon packing. In the prior art, it is difficult to carry out detection on a sealing effect of a pressure testing tool by a pressure testing machine and the detection effect is not good; however, the above-mentioned defects can be overcome with utilization of the pressure testing system and the pressure testing method provided in the invention.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

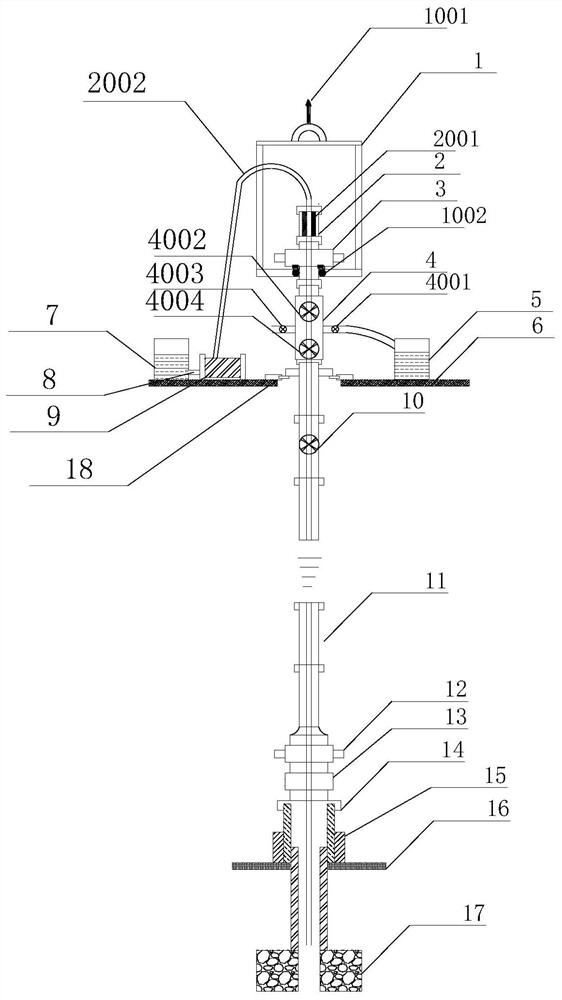

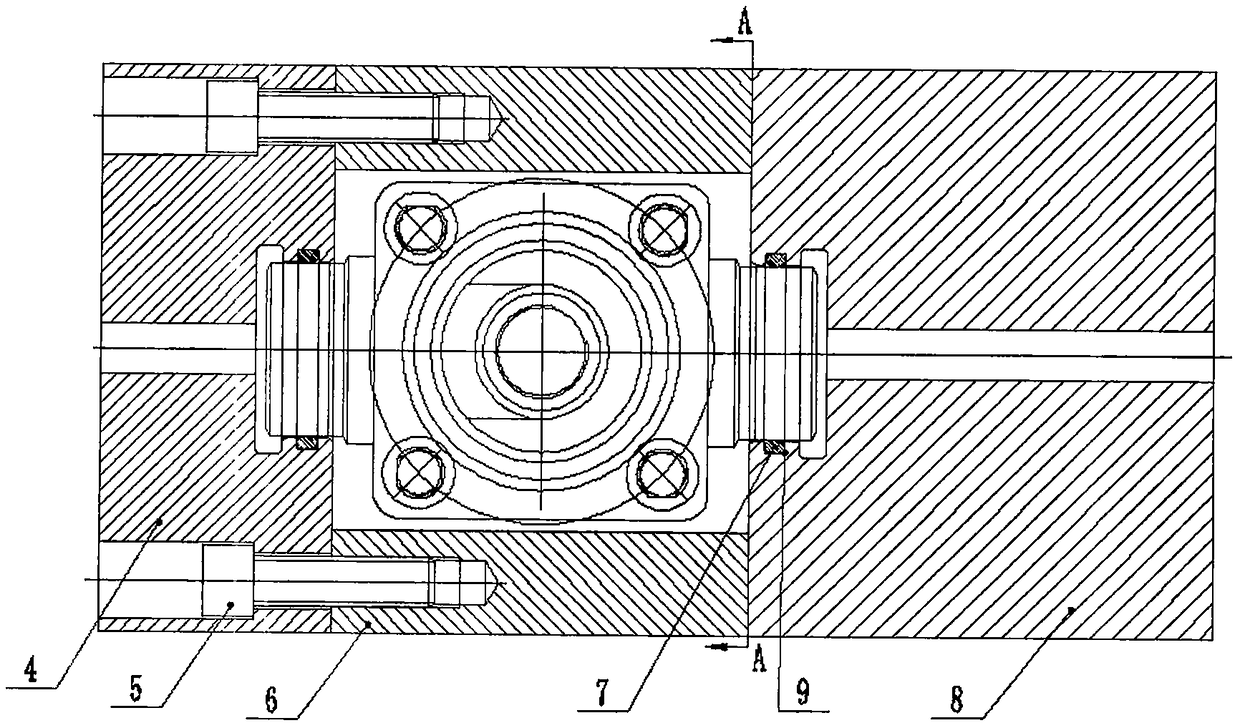

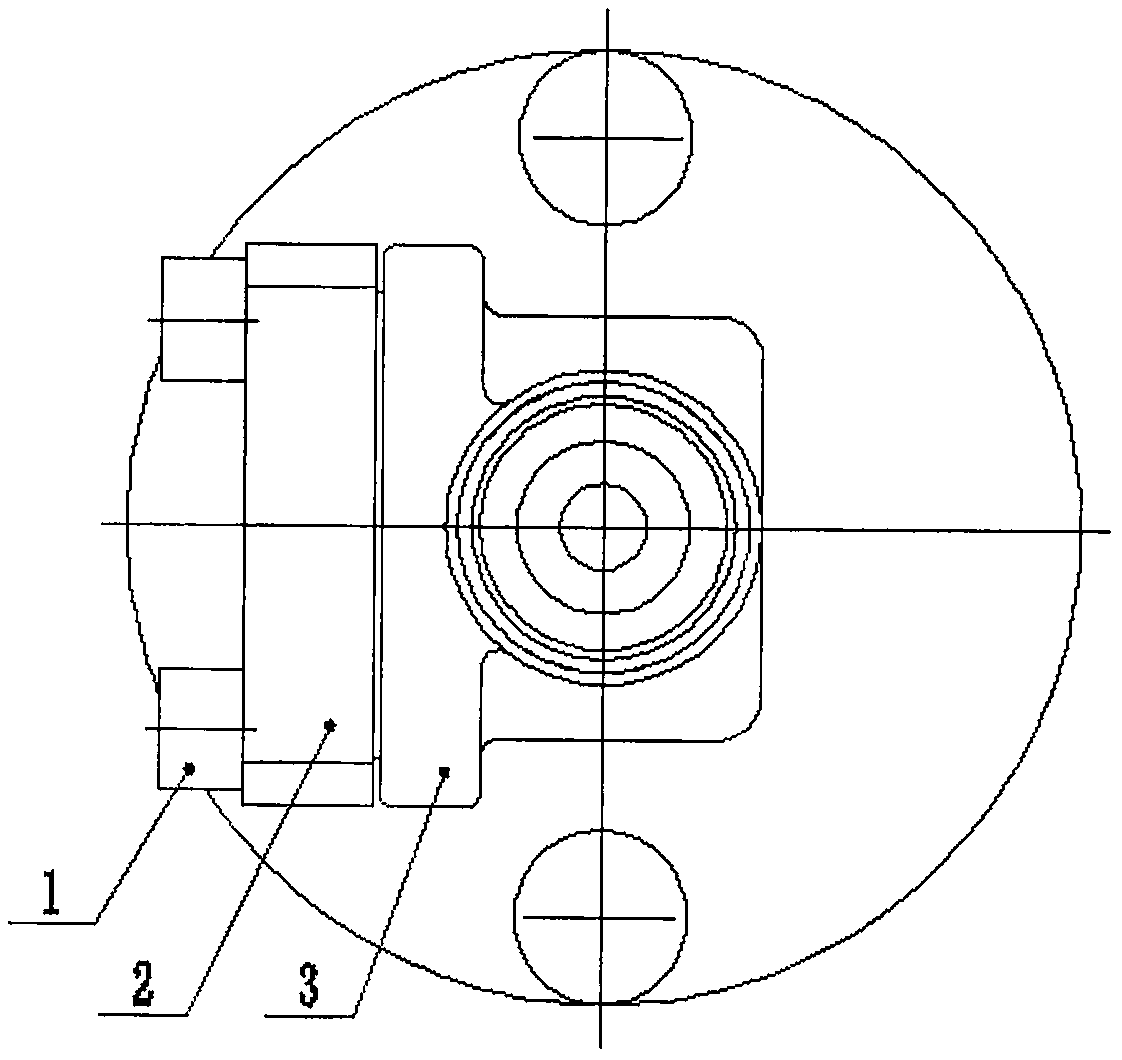

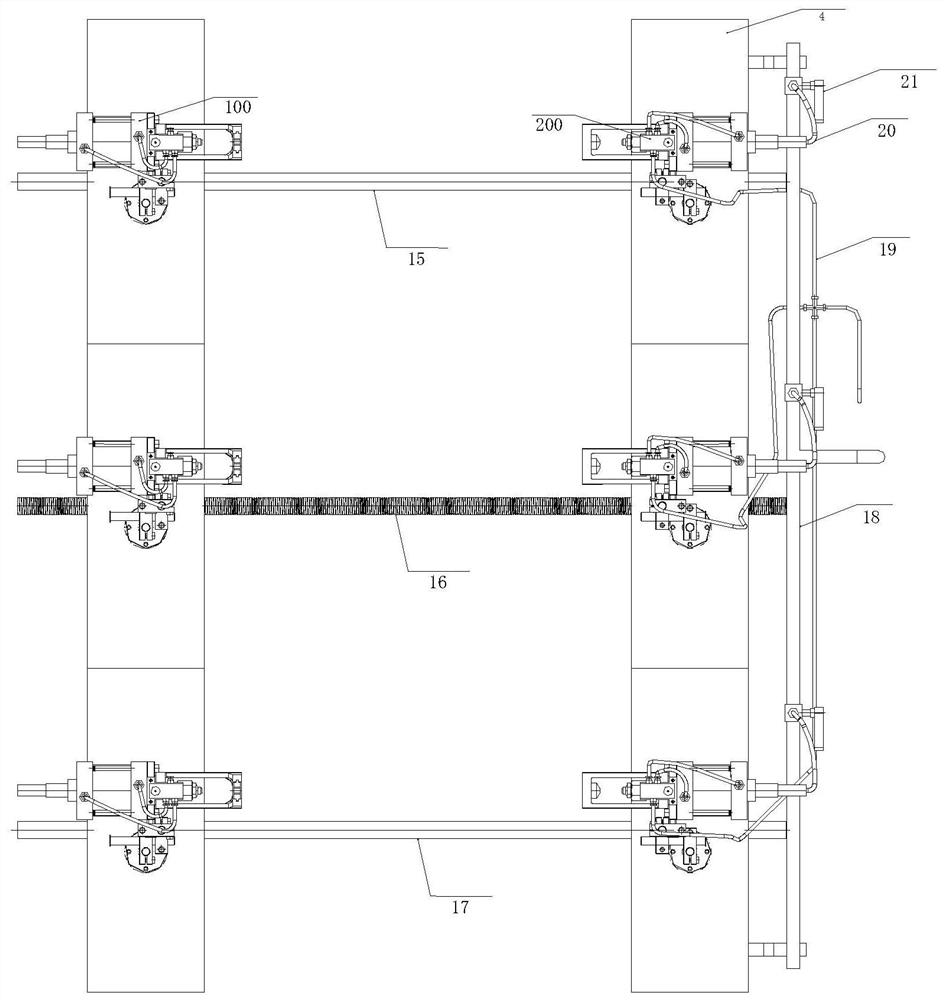

A liquid drainage and gas extraction operation system and operation method suitable for engineering ships

ActiveCN111561299BThe overall structure is light in weightConvenient on-site operationDrilling rodsFluid removalLine tubingMarine engineering

The invention discloses an operating system and an operating method for liquid drainage and gas extraction suitable for engineering ships. The liquid drainage and gas recovery operation system includes a high-pressure riser and a coiled tubing; one end of the high-pressure riser is connected to an underwater wellhead, and an underwater blowout preventer is arranged at the underwater wellhead; the other end of the high-pressure riser extends to the engineering ship; continuous The tubing is set in the high-pressure riser, one end of the coiled tubing extends to the wellbore, and the other end extends to the outside of the high-pressure riser; the annulus formed between the high-pressure riser and the coiled tubing and the coiled tubing form a liquid drainage and gas production mechanism. Circulation channel; the high-pressure riser is equipped with a cross, the third branch of the cross is connected with the liquid recovery tank, and the fourth branch is connected with the choke and kill pipeline; the free end of the coiled tubing is connected with the liquid storage tank . The invention can be used not only on conventional drilling operation ships but also on engineering ships, has strong adaptability, flexible and convenient operation, and can be widely used in drilling, completion and workover operations of deep-water oil and gas fields adopting the underwater wellhead development mode.

Owner:CHINA NATIONAL OFFSHORE OIL (CHINA) CO LTD +1

Flangeless thin-walled workpiece pressure test tool

InactiveCN108120642ASolve the deformationSave assembly and pressure test tooling timeMaterial strength using tensile/compressive forcesTest efficiencyMechanical equipment

The invention discloses a flangeless thin-walled workpiece pressure test tool relating to the technical field of mechanical equipment. The flangeless thin-walled workpiece pressure test tool comprisesa bolt II, a pressure test plate III, a pressure test plate I, a bolt I, a pressure test support, O-shaped sealing rings, a pressure test plate II and sealing grooves, wherein parts are fixed on thepressure test plate III by virtue of bolts II; the sealing grooves are formed in the pressure test plate I and the pressure test plate II; the O-shaped sealing rings are arranged in the sealing grooves; one ends of the parts are arranged in the sealing groove in the pressure test plate II; the other ends of the parts are arranged in the sealing groove of the pressure test plate I; the pressure test plate I is connected with the pressure test support by virtue of the bolt I; and the pressure test support and a section of the pressure test plate II are in contact. The pressure test tool assembling time is saved, the pressure test efficiency is improved, the deformation of the parts in the pressure test process can be avoided, and the practicality is high.

Owner:ANHUI YINGLIU ELECTROMECHANICAL

Easy-to-use high-pressure oil pipe pressure test tooling device

ActiveCN109443939BEasy to operateEasy to installMaterial strength using tensile/compressive forcesMechanical engineeringPiston rod

Owner:南京海王汽车零部件有限公司

Semi-automatic pressure testing machine for indoor bolts and its pressure testing method

ActiveCN104815409BSimple structureOptimize structure layoutFire rescueFluid-tightness measurement using fluid/vacuumSemi automaticEngineering

Owner:FUJIAN SEA WHALE FIRE PROTECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com