Large-caliber cast iron pipe pressure testing device without backrest, and large-caliber cast iron pipe pressure testing method without backrest

A technology of large pipe diameter and pressure relief device, which is used in measuring devices, fluid tightness testing, and machine/structural component testing. , reduce the use of materials, easy to move the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

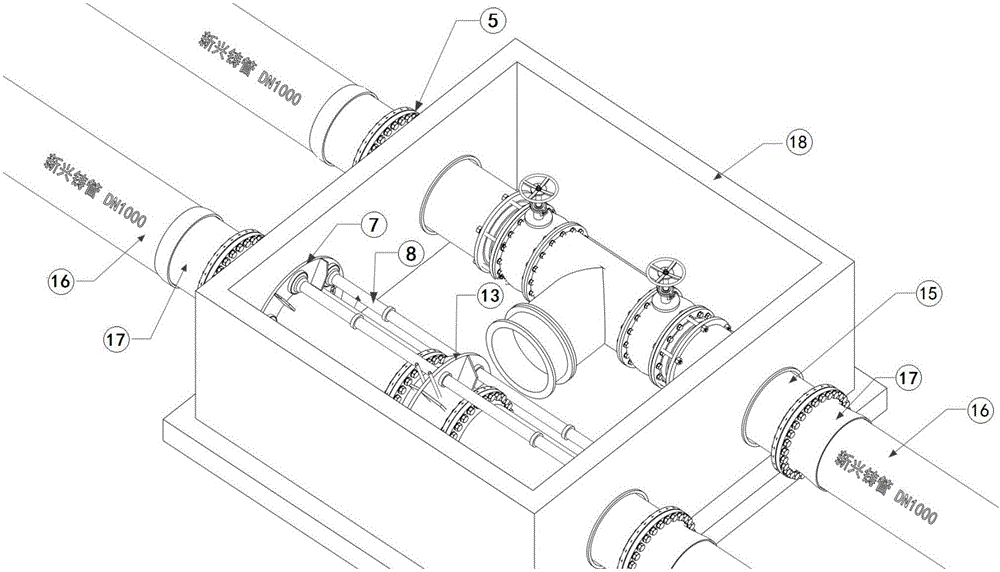

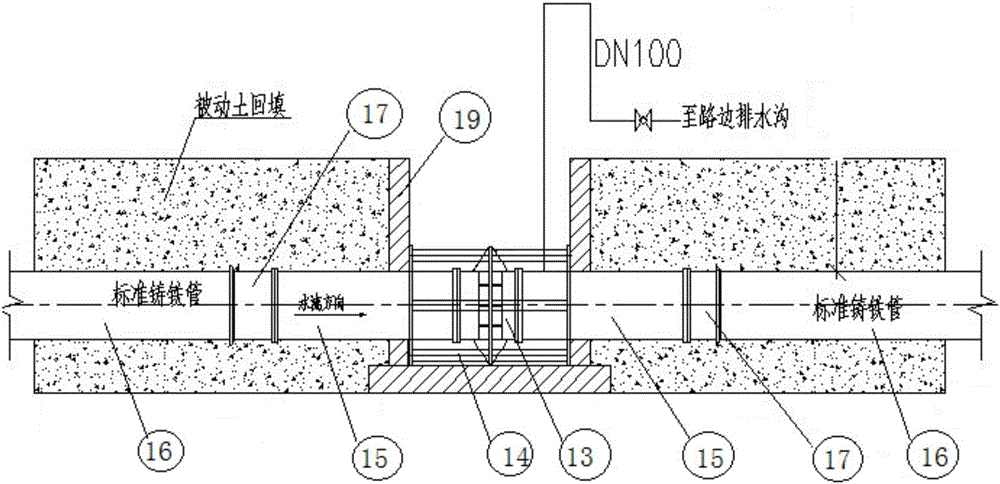

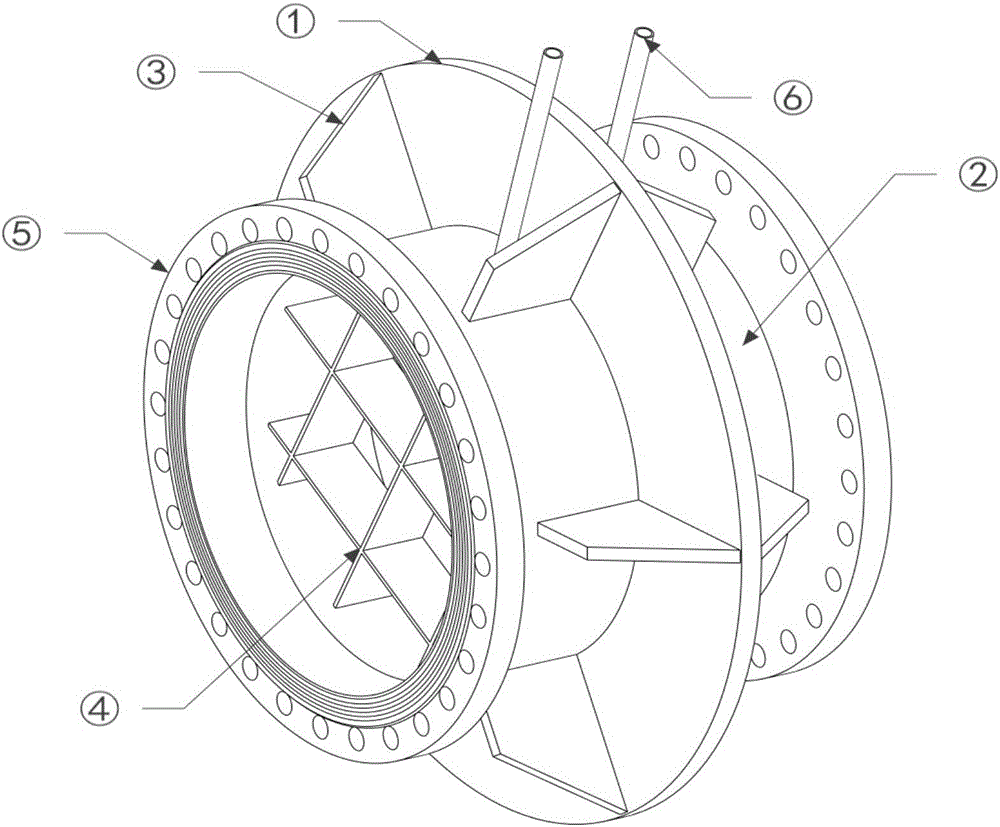

[0039] Such as Figure 1 to Figure 8 As shown, the large-diameter cast iron pipeline in an embodiment provided by the present invention has no back pressure test device, including a pressure test short pipe 13 and a pressure relief device 14, such as Figure 2 ~ Figure 3 As shown, the short pressure test pipe 13 includes a partition blind plate 1, and standard short pipes 2 are arranged symmetrically on both sides of the partition blind plate 1, and flanges 5 are provided on the outer ends of the standard short pipes 2 on both sides. , the short pressure test pipe 13 is placed in the valve well 18, the two ends of the short pressure test pipe 13 are respectively connected to the adjacent two ends of the pressure test pipeline through the flange 5, and the pressure relief device 14 is ring-sleeved on the short pressure test pipe 13 One end of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com