Rapid location method for pressure test failure of fracturing system

A positioning method and pressure test technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problem of high risk of equipment and personnel, achieve low probability of equipment loss, improve pressure test efficiency, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

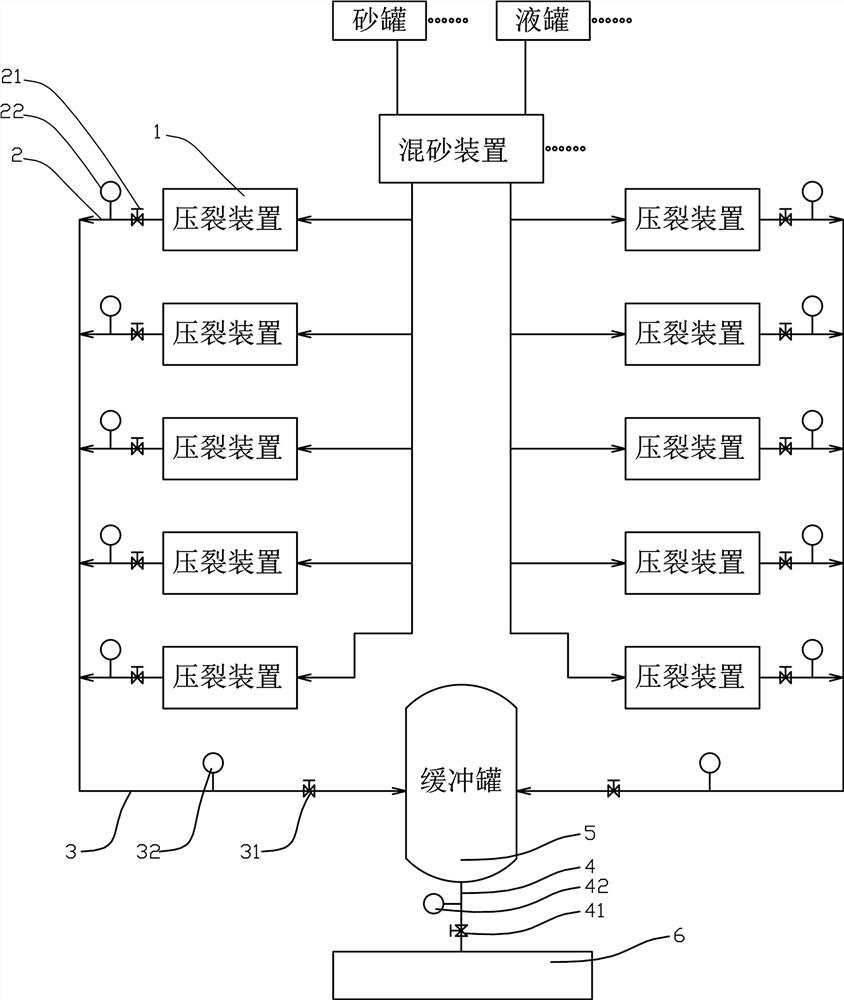

[0044] like figure 1 , 4 Among them, a method for quickly locating a pressure test fault in a fracturing system includes the following steps:

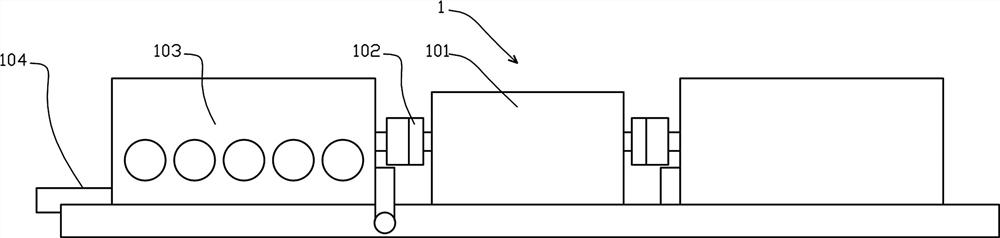

[0045] S01. The discharge pipeline 104 of each fracturing device 1 is connected to the trunk pipeline 3 through the branch pipeline 2, and the trunk pipeline 3 is connected to the bus pipeline 4. The branch pipeline 2 is provided with a branch valve 21 and a branch pressure sensor 22. A trunk valve 31 and a trunk pressure sensor 32 are provided on the trunk pipeline 3, and a bus valve 41 and a bus pressure sensor 42 are provided on the bus pipeline 4;

[0046] Close the bus valve 41, and the main controller sends a signal to make a part of the branch controllers control the output pressure of the fracturing device 1;

[0047] The bus pressure sensor 42 outputs a pressure signal, and the main controller receives the pressure signal and compares it with a preset pressure value;

[0048] S02, regrouping, the main controller gives a sig...

Embodiment 2

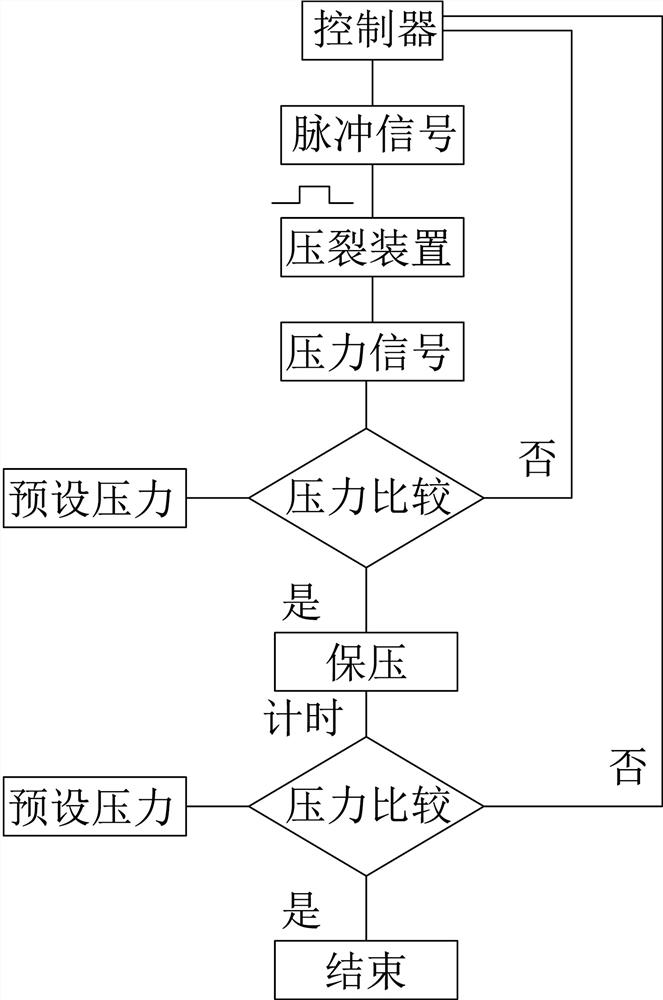

[0064] The preferred solution is as image 3 In the above, after the fault location is determined, the pressure test verification is carried out on a single fracturing device 1, and the specific steps are as follows:

[0065] S001, closing the valve of the discharge pipeline 104 of the fracturing device 1;

[0066] S002. The controller outputs a pulse signal to drive the motor of the fracturing device 1 to rotate to increase the pressure of the discharge pipeline 104, and the pressure sensor of the discharge pipeline 104 outputs a pressure signal; the pulse signal is within a preset period of time The pulse signal, the duration is 0.1~2 seconds;

[0067] The pulse signal is used as the command signal of the motor inverter, and the motor inverter controls the rotation of the motor;

[0068] S003. The controller receives the pressure signal and compares it with the preset pressure value. If it reaches the pressure, it maintains the pressure. If it does not, it outputs the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com