Batch steel pipe pressure test device

A pressure test, steel pipe technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of high construction cost, waste of human resources and material resources, low construction efficiency, etc., to avoid temporary welding and reduce main materials. The effect of high consumption and pressure test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

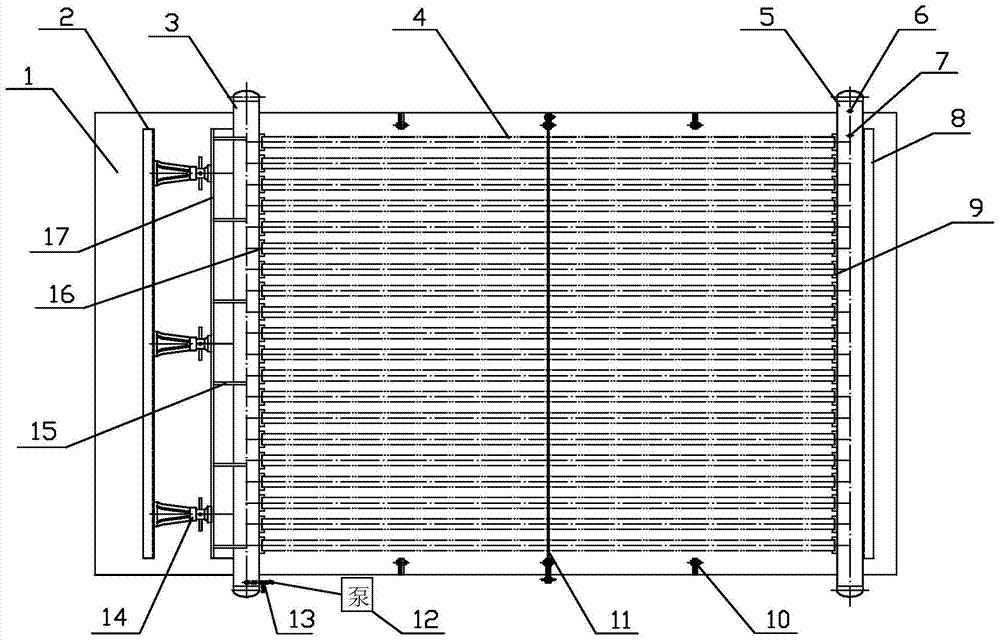

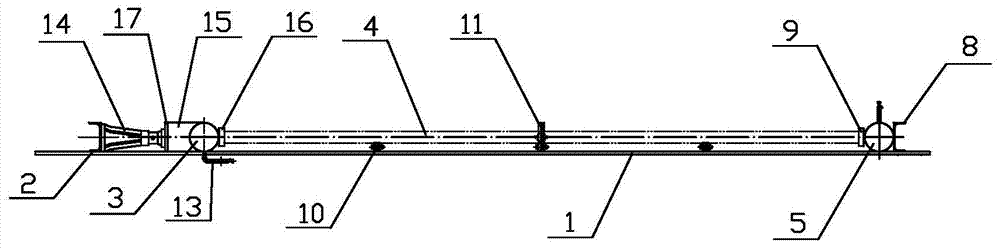

[0026] like Figure 1 to Figure 11 As shown, the batch steel pipe pressure test device of the present invention includes a pressure test bench 1 , a pressure test manifold, a jacking clamping device, a pressure test tube positioning device, and a pressure test pump 12 .

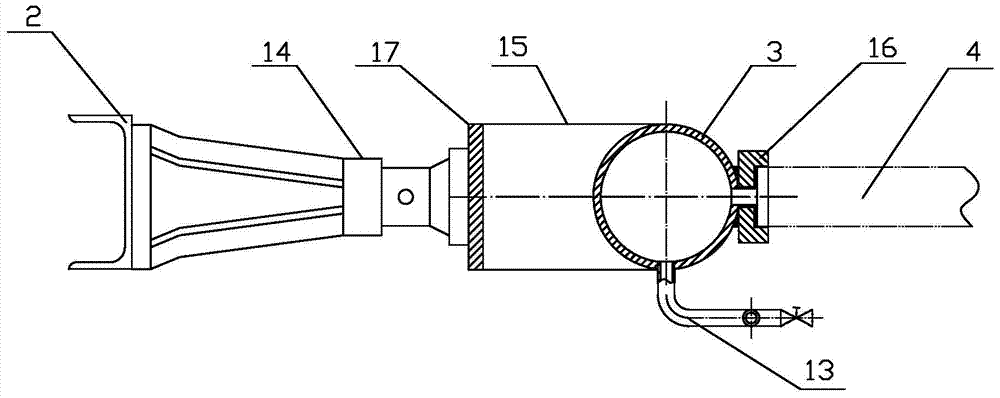

[0027] The pressure test manifold includes manifold I3 and manifold II5 respectively arranged on both sides of the pressure test platform 1 and oppositely arranged, the pressure test platform 1 is a base steel plate, and the main bodies of the manifold I3 and manifold II5 are seamless steel pipes. Both ends are welded and sealed with oval heads. On the inner side of the confluence pipe I3, there is a row of nozzles I20 that penetrate the wall of the confluence pipe I3 and are arranged equidistantly. The positions correspond to each other. The nozzle I20 and the nozzle II are formed by drilling, and the nozzle I20 and the nozzle II are round holes of Φ15mm. A pressure test socket I16 connected to the manif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com