Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve oil separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature throttling refrigerator with mixed media and switchable gas resources

InactiveCN1712864ARelieve stressAvoid cooling effectCompression machinesFiberRefrigeration compressor

A low-temp throttle refrigerator with switchable gas tank and mixed working medium is composed of refrigerating compressor, switchable gas tank with high-and low-pressure electromagnetic valves, oil-gas separator, and fine oil-gas separator containing fibrous filtering core. Its advantages are high reliability and safety, high oil separating efficiency, and long service life.

Owner:XI AN JIAOTONG UNIV

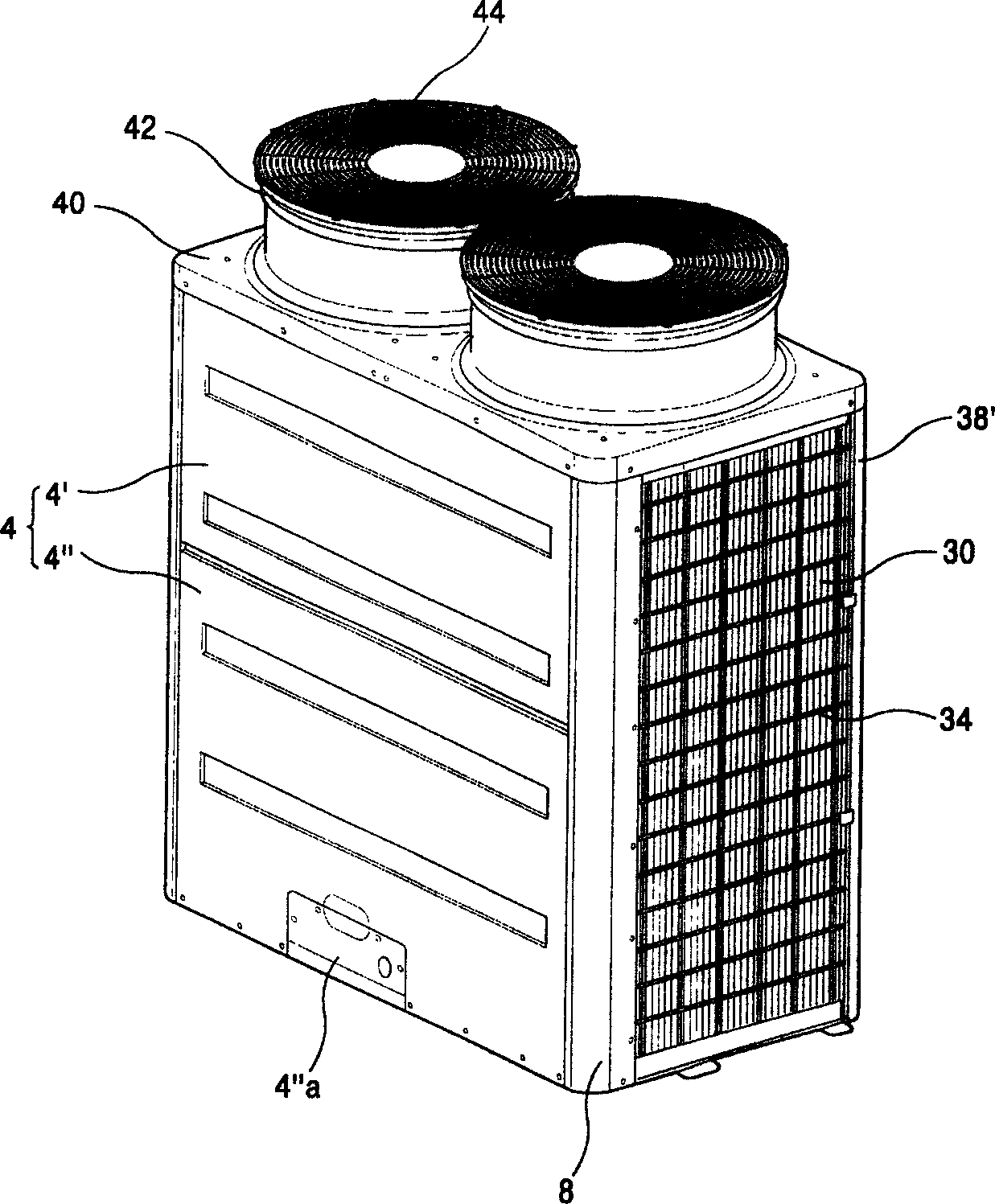

Condenser and refrigeration system

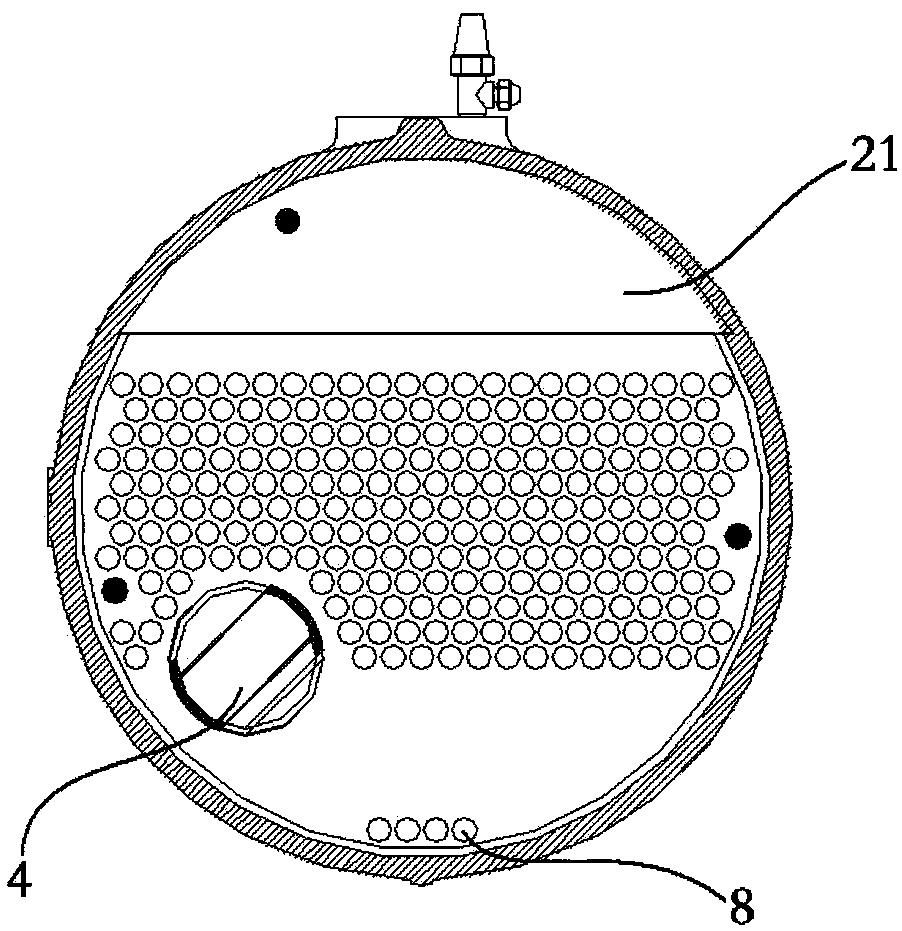

PendingCN107062709AImprove oil separation efficiencyImprove separation efficiencyEvaporators/condensersPhysicsRefrigerant

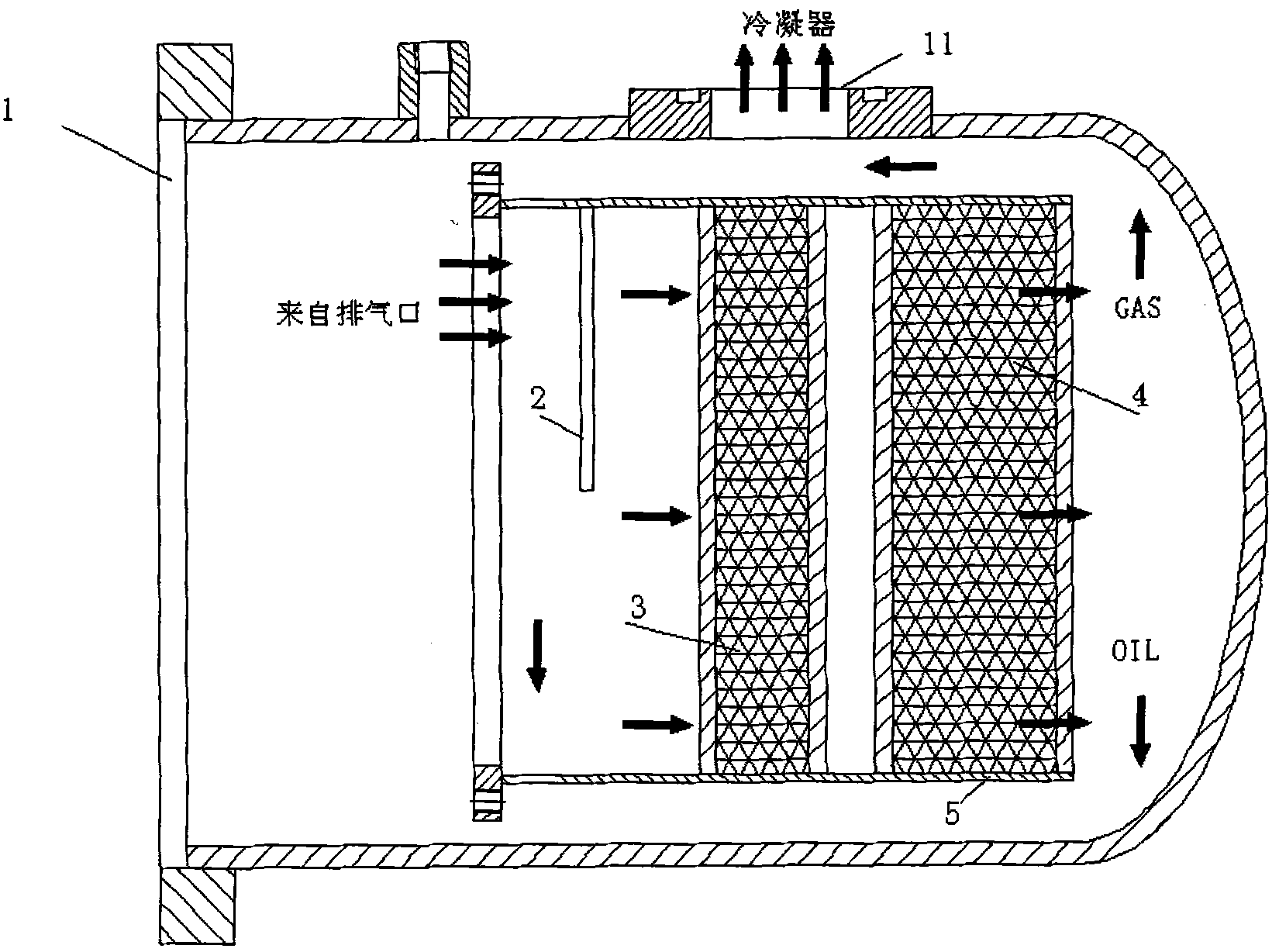

The invention discloses a condenser and a refrigeration system. The condenser comprises a shell, a condensation tube bundle and an oil separation device. The oil separation device comprises an inner separation plate and an oil separation structure. The shell is divided by the inner separation plate into a condensation chamber and an oil separation chamber located above the condensation chamber. The condensation tube bundle is arranged in the condensation chamber in the front-back direction. The shell is provided with a refrigerant inlet communicated with the oil separation chamber and a refrigerant outlet communicated with the condensation chamber. The oil separation structure comprises a baffle plate, a filtering screen, a refrigerant communicating opening and an oil return opening, and the baffle plate and the filtering screen are arranged in the oil separation chamber. A refrigerant enters the oil separation chamber through the refrigerant inlet and sequentially passes through the baffle plate and the filtering screen, oil in the refrigerant is separated, and the separated refrigerant enters the condensation chamber through the refrigerant communicating opening to be condensed; and the condensed refrigerant flows out of the refrigerant outlet, and separated oil liquid flows out of the oil separation chamber through the oil return opening. According to the condenser and the refrigeration system, the oil separation efficiency of the refrigerant is high.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

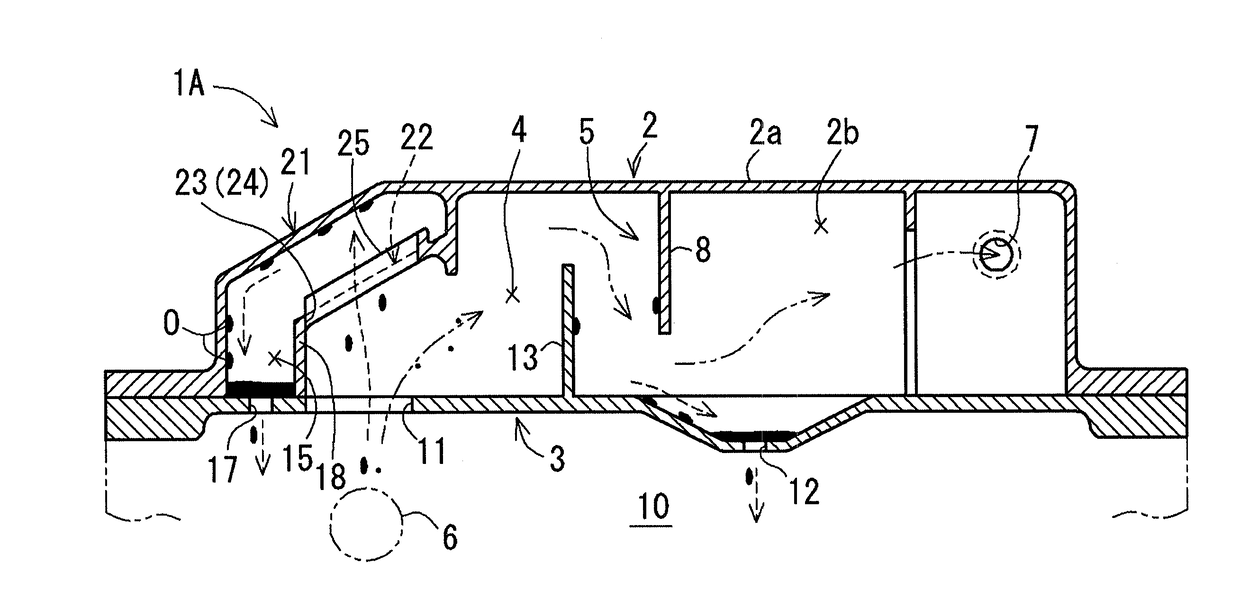

Oil mist separator

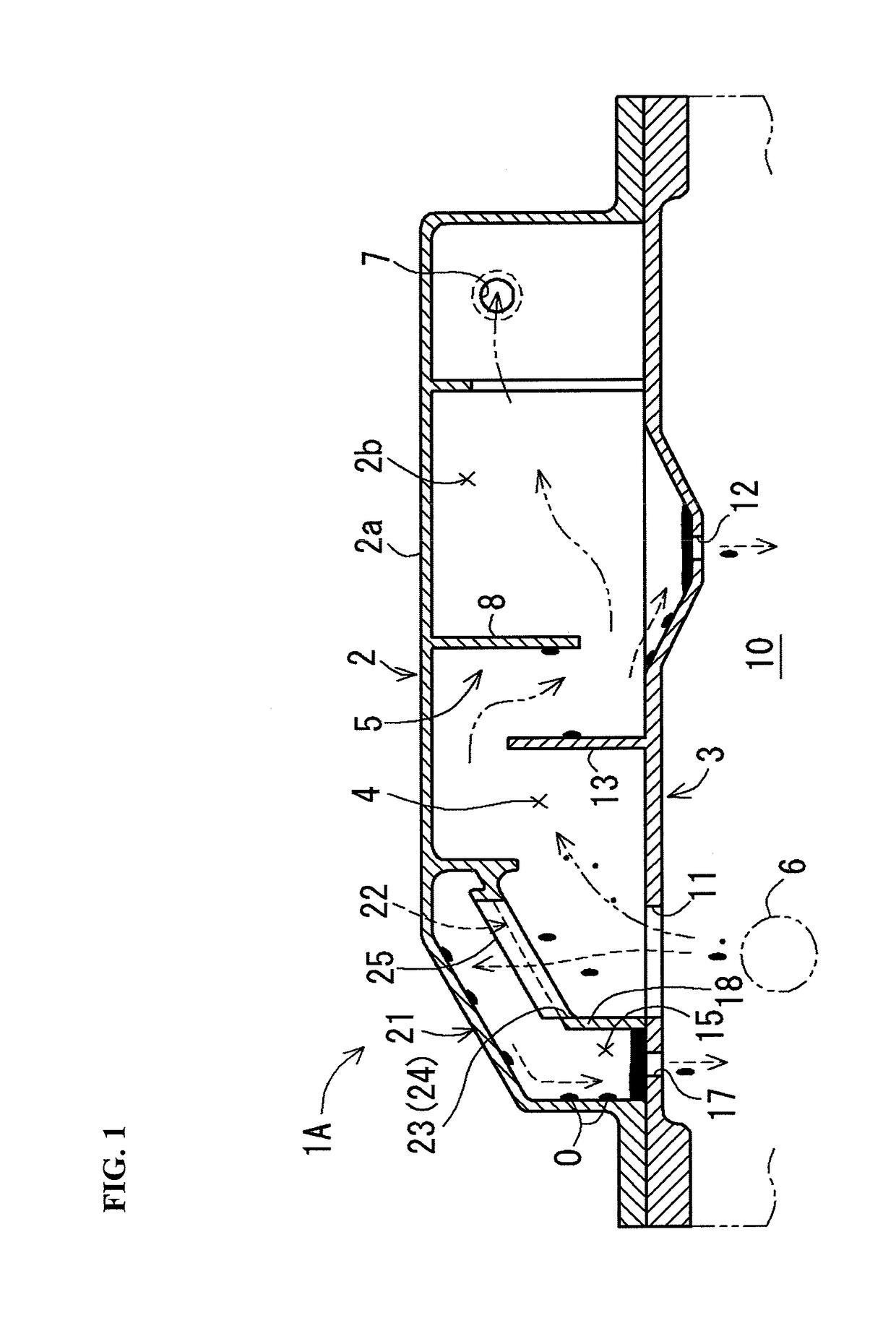

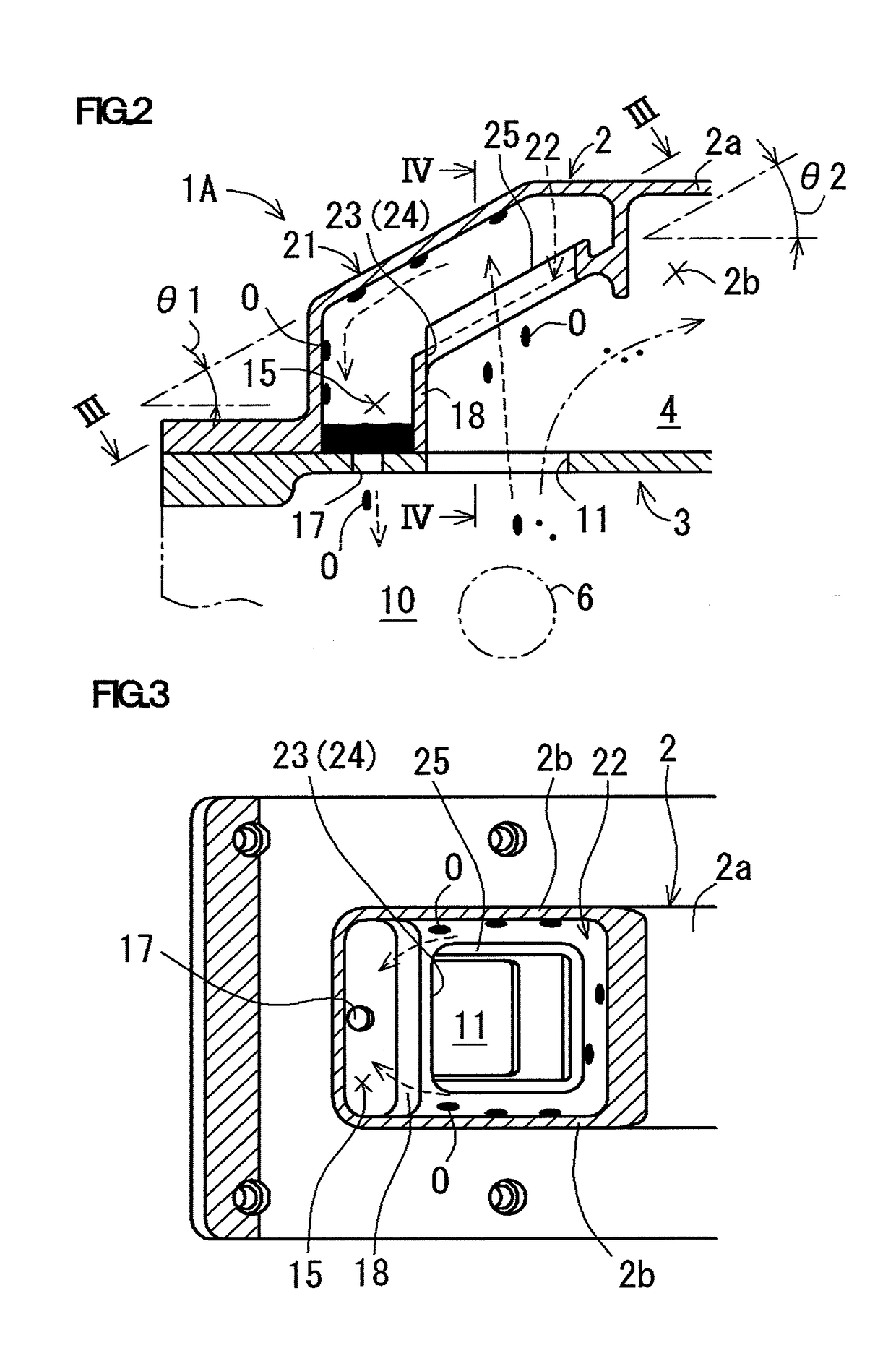

ActiveUS20180207565A1Improve oil separation efficiencyImprove the installation effectDispersed particle filtrationMachines/enginesAirflowEngineering

The oil mist separator separates oil from blow-by gas which flows through a gas flow passage. A chamber, which is partitioned from the gas flow passage including a gas introduction port, is provided between a cylinder head cover and a baffle plate. A first guide wall, which extends with a downward inclination toward the chamber so as to cover the gas introduction port and the chamber, is provided above the gas introduction port and the chamber. A drain hole for discharging the oil within the chamber is formed in the baffle plate.

Owner:TOYOTA BOSHOKU KK

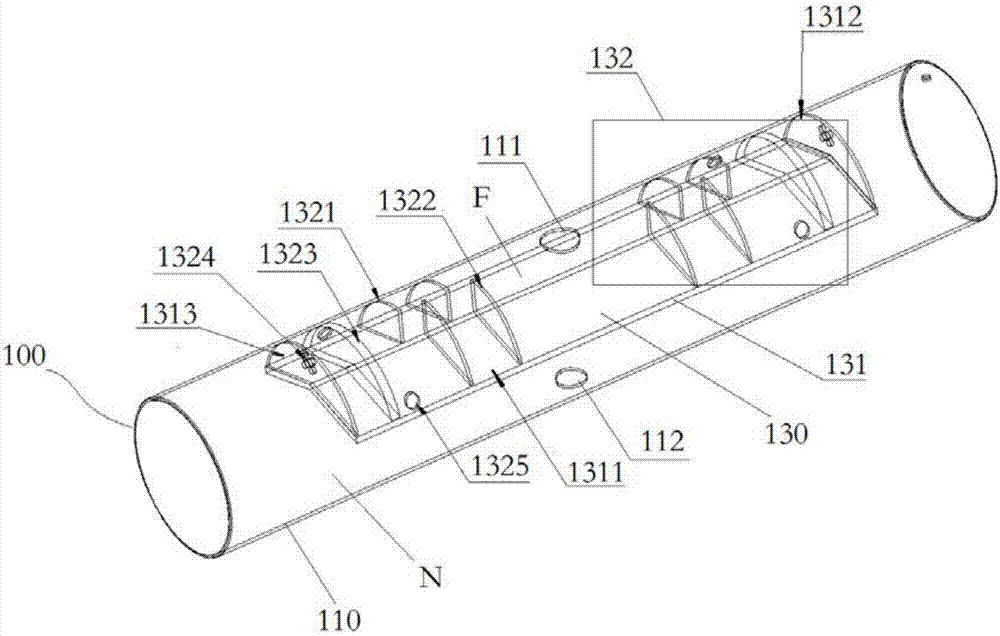

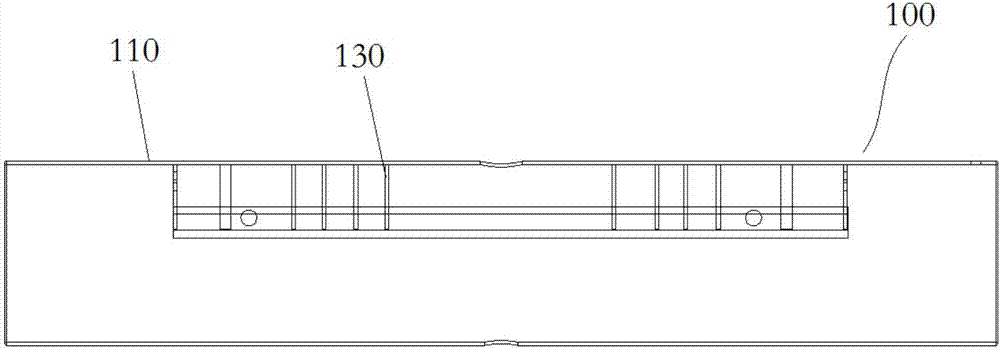

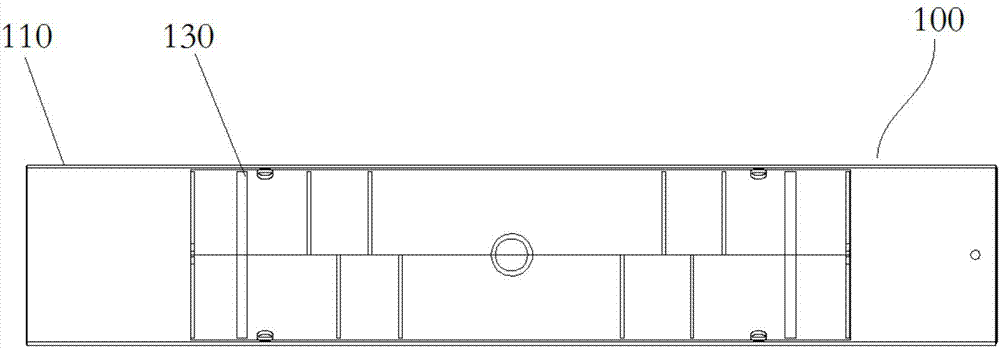

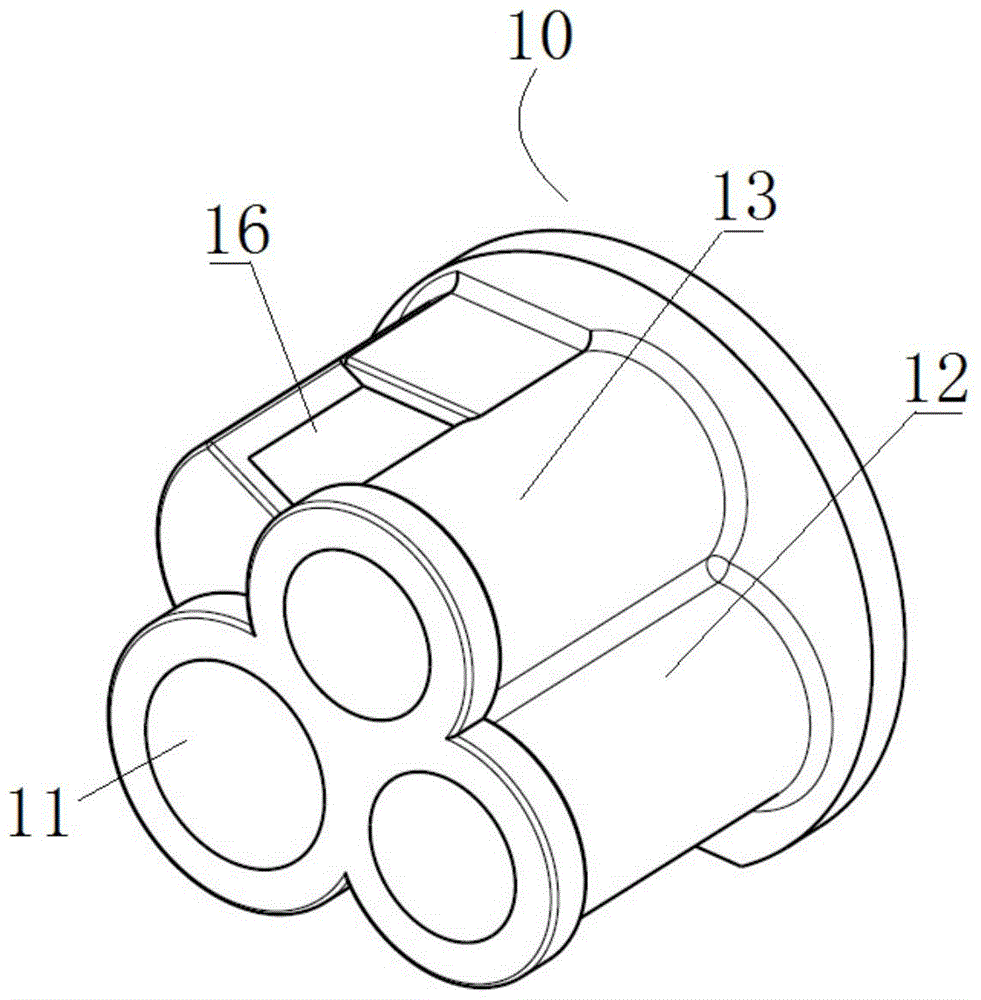

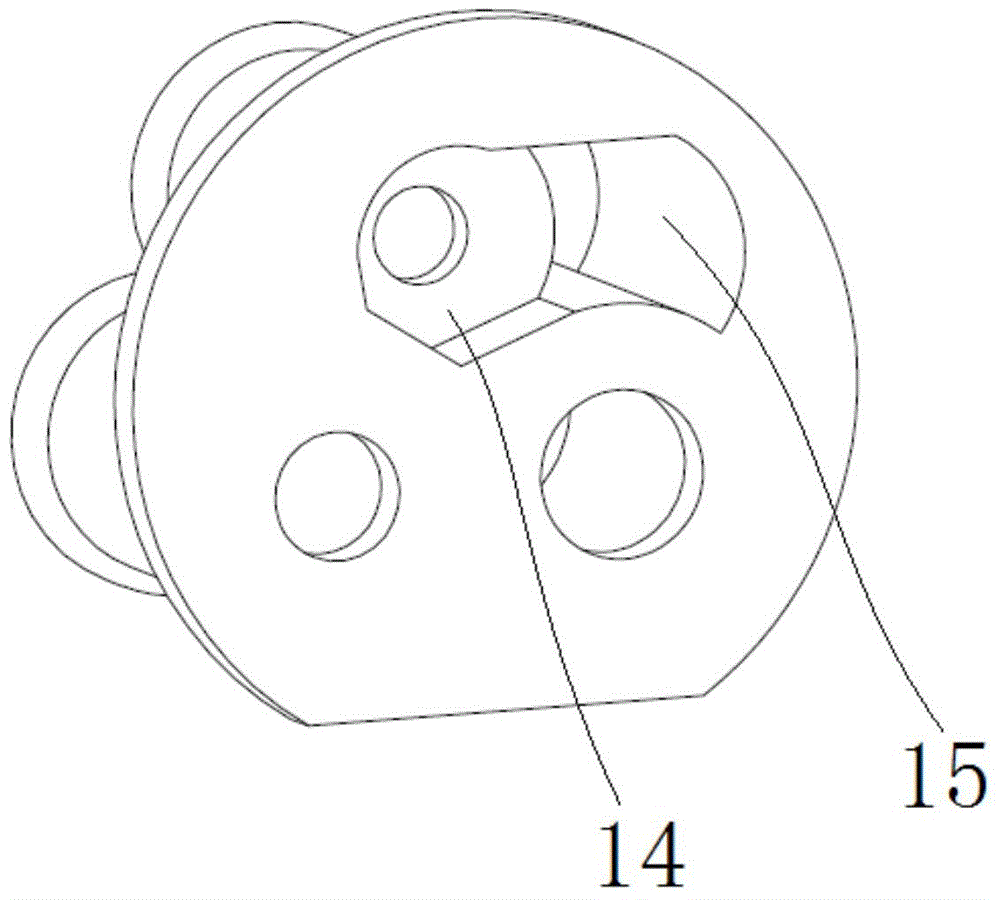

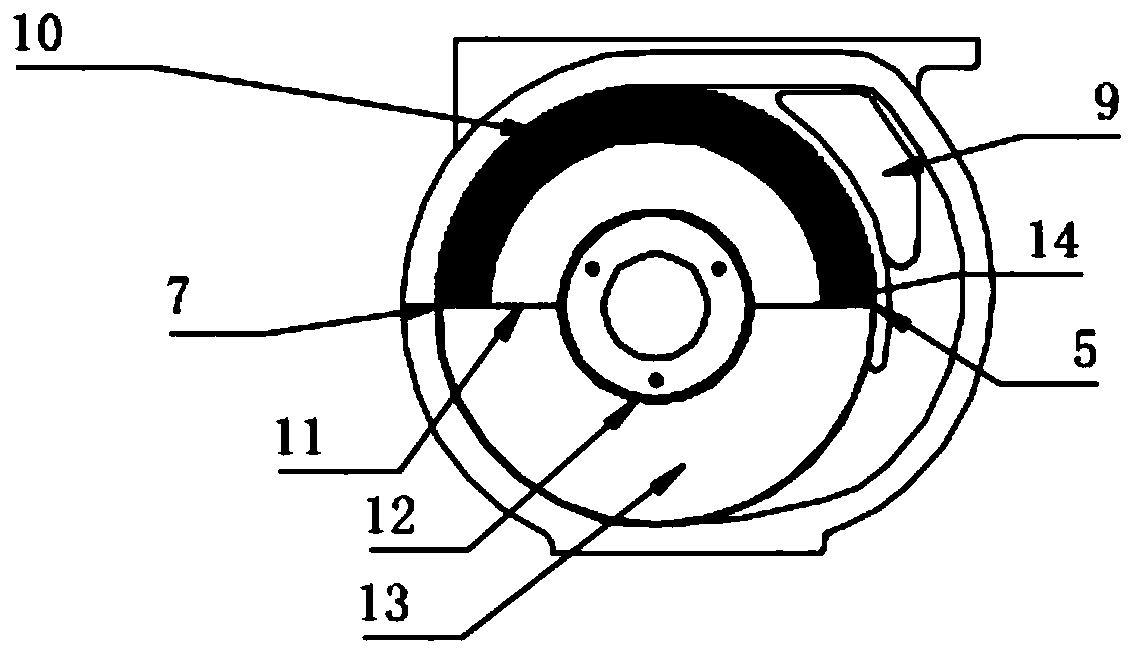

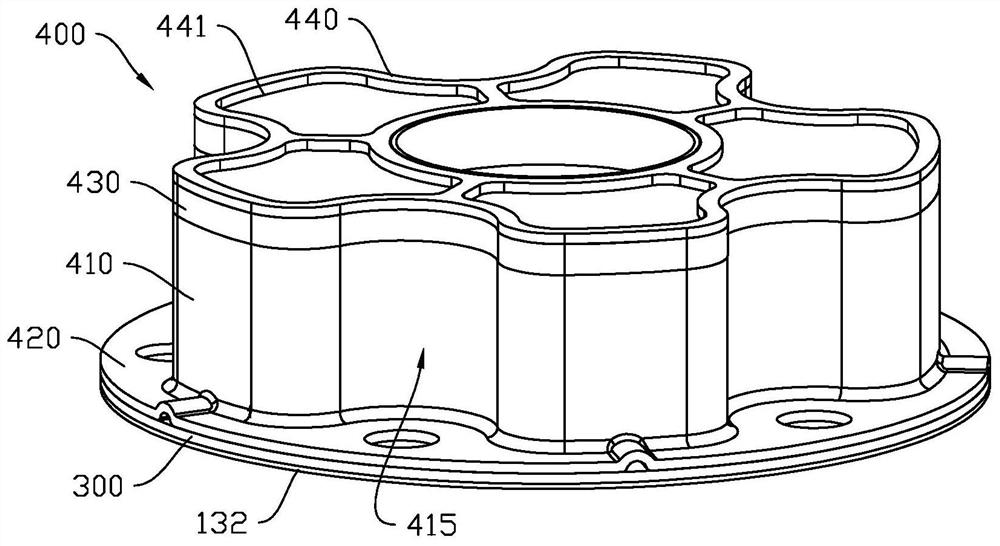

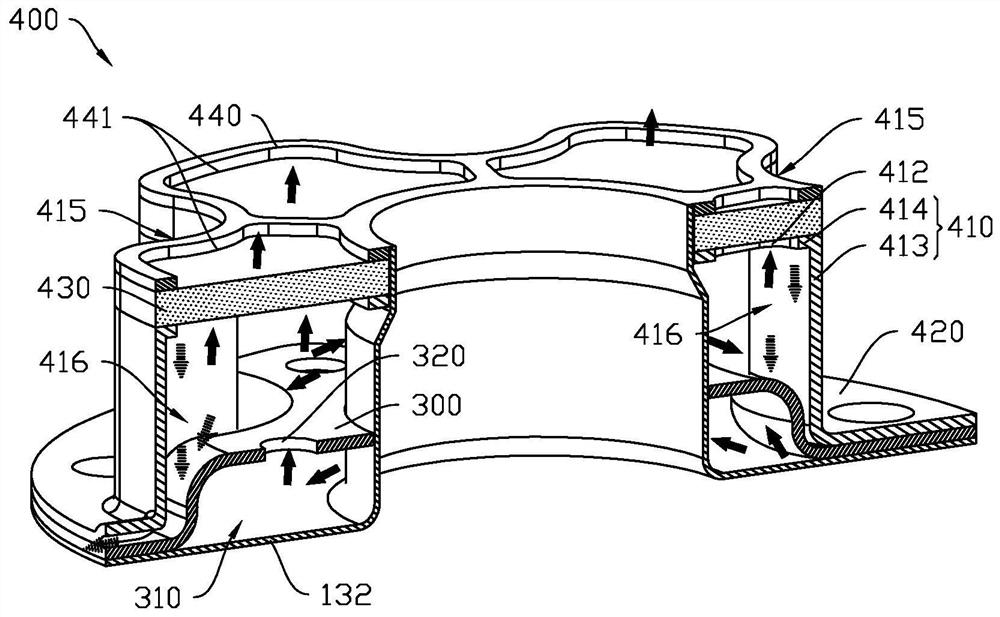

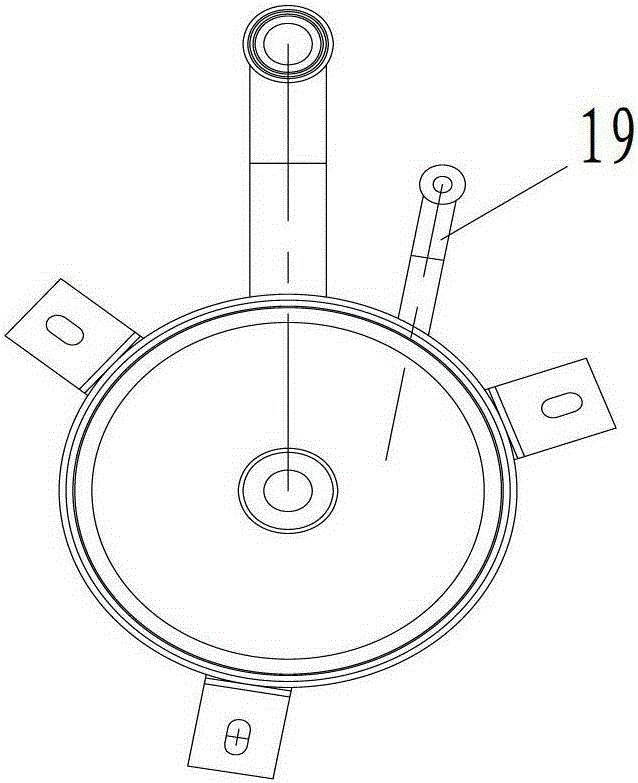

Oil distributing barrel, screw compressor and air conditioner device

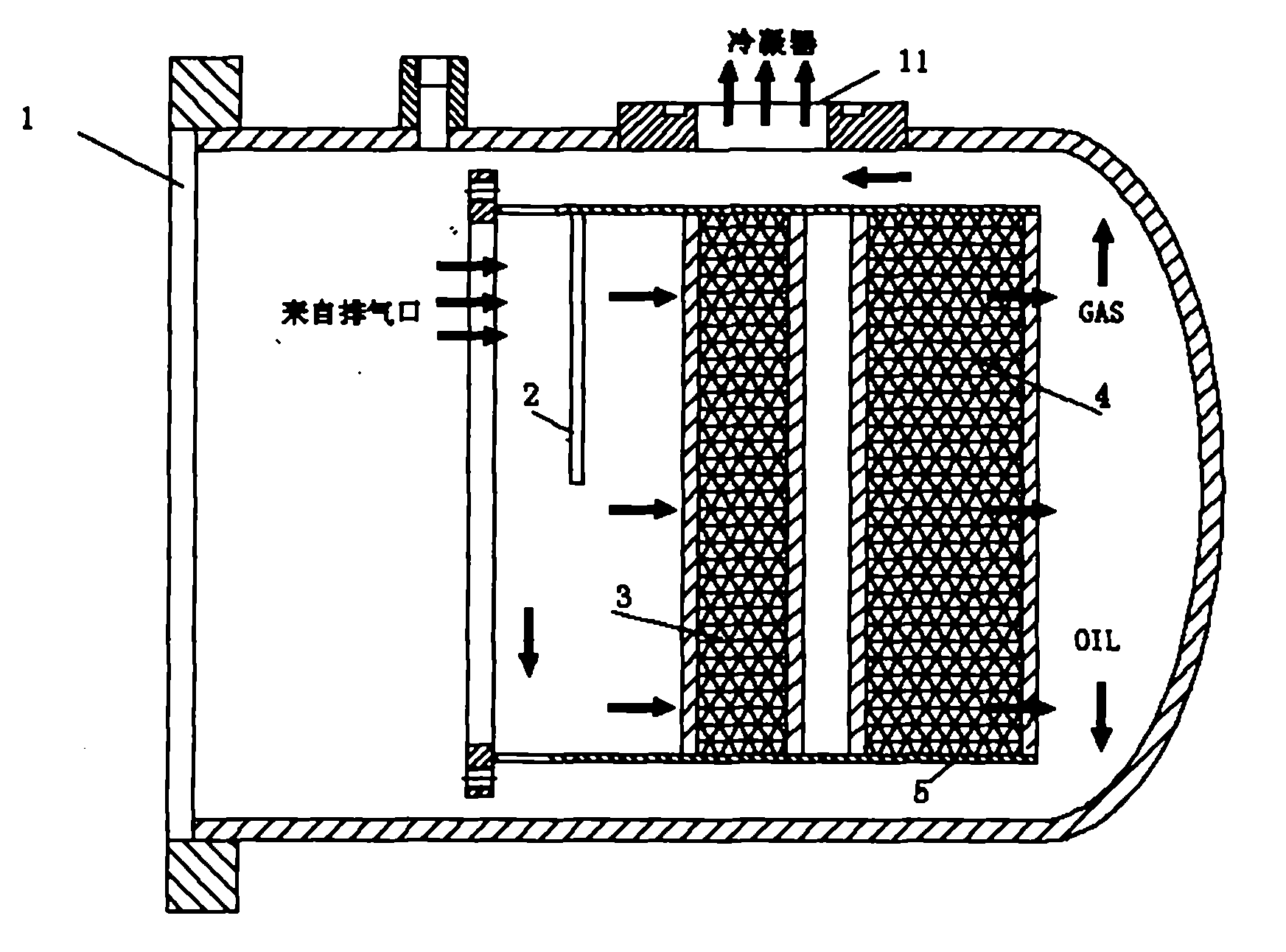

PendingCN105840519AImprove oil separation efficiencyStable oil circulationRotary/oscillating piston pump componentsLiquid fuel engine componentsGas compressorExhaust pipe

The invention discloses an oil distributing barrel, a screw compressor and an air conditioner device. The oil distributing barrel comprises a barrel body with a vent, a primary oil filtering net installed inside the barrel body, an exhaust pipe located inside the barrel body, and a secondary oil filtering net installed at the vent, wherein a first cavity is formed between the primary oil filtering net and the end of the barrel body; and one end of the exhaust pipe penetrates through the primary oil filtering net to enter the first cavity. The oil distributing efficiency is improved through two times of filtering, so that the oil distributing efficiency of the compressor is increased, the oil circulation stability of the compressor is maintained, the load of a unit to return oil for the compressor is reduced, and the characteristics of simple structure and low cost are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

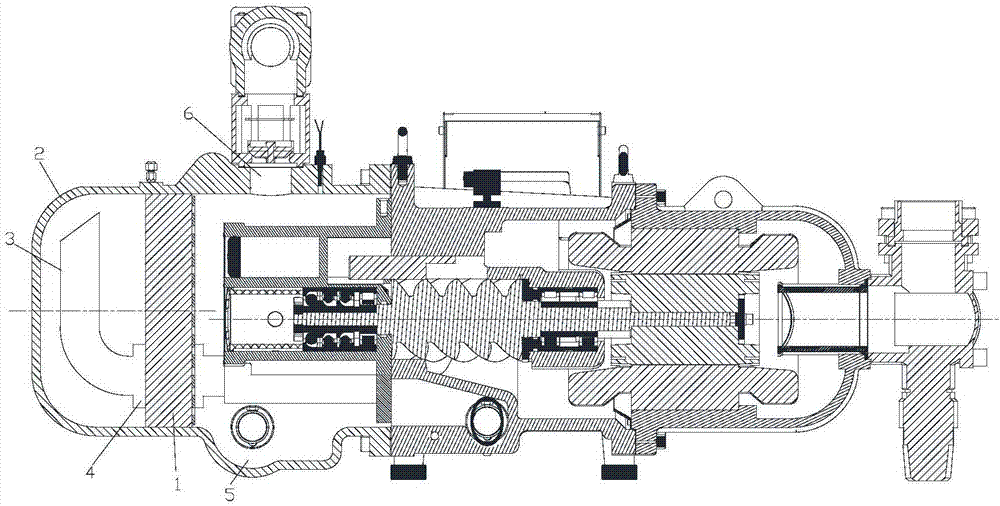

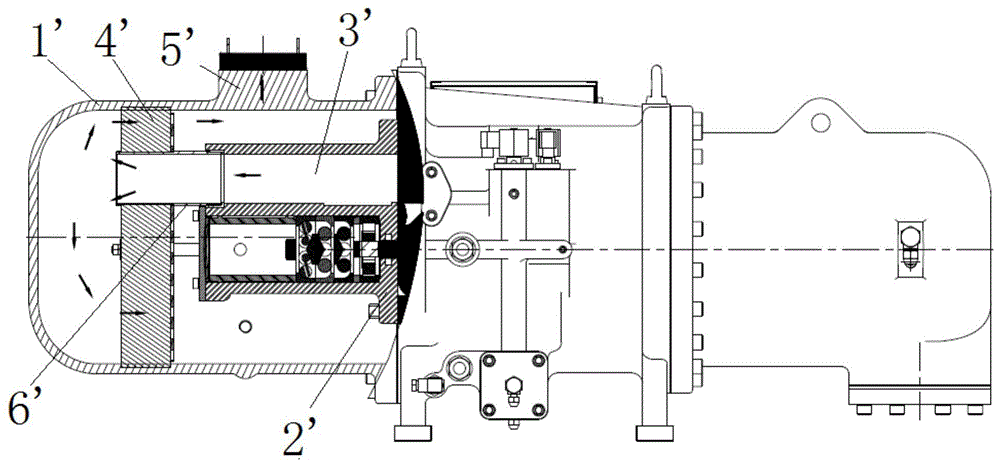

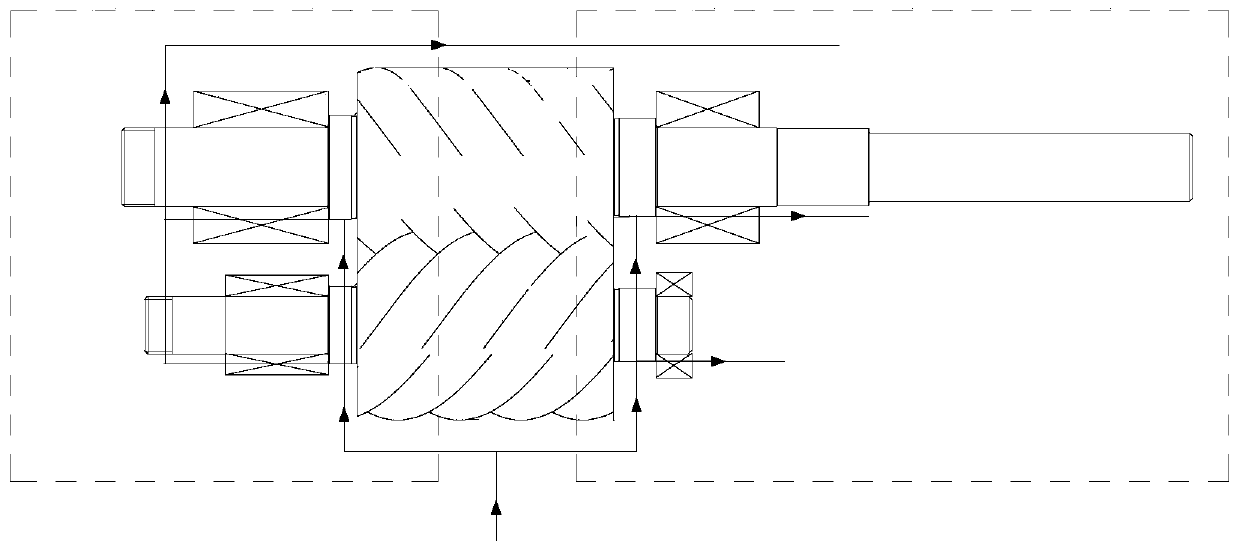

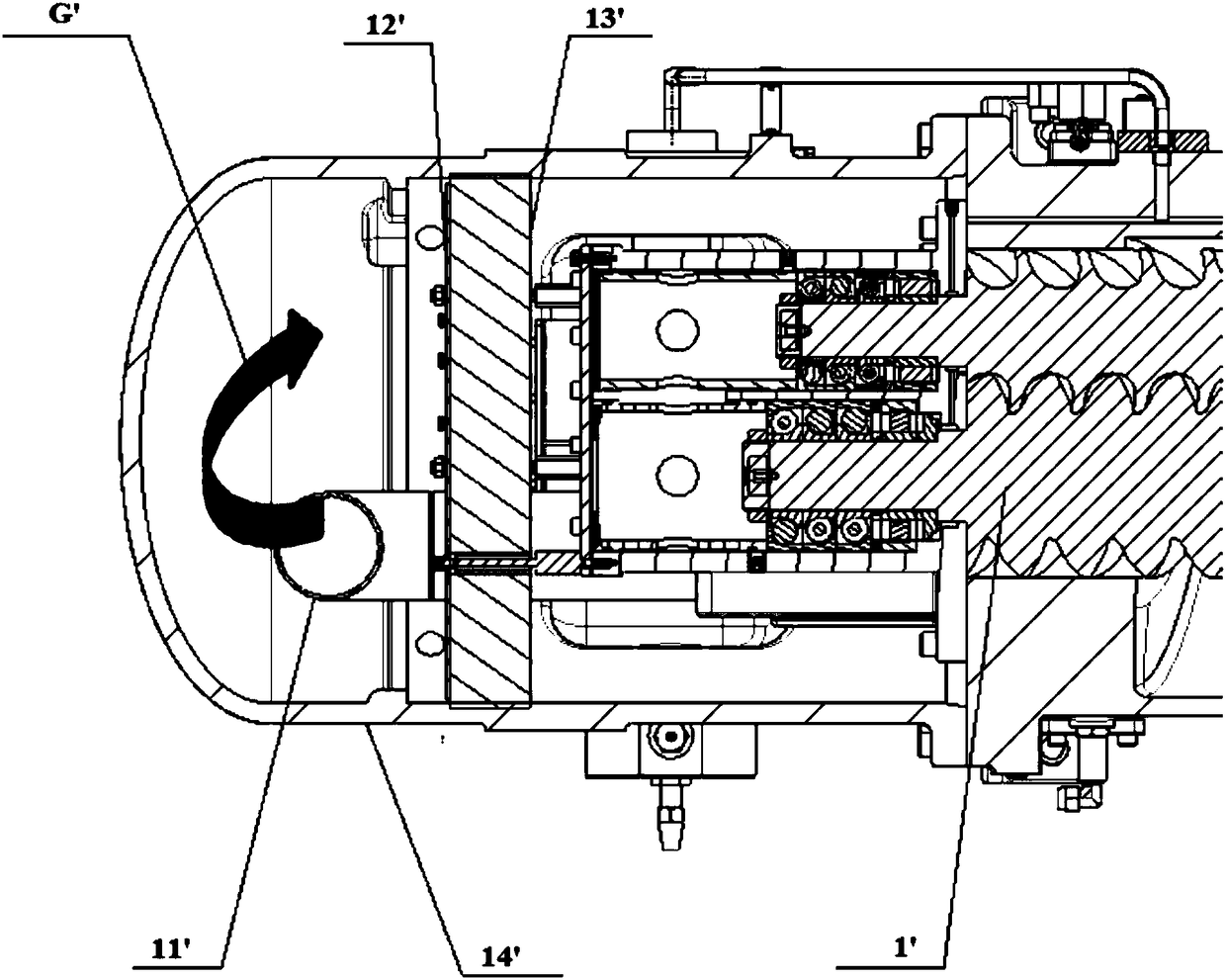

Screw compressor possessing oil separator and water chilling unit

ActiveCN105090041AEasy to recycleImprove oil separation efficiencyRotary/oscillating piston combinations for elastic fluidsCompressorThermodynamicsOil separation

The present invention relates to a screw compressor having an oil separator, comprising: a compressor housing with an inlet for a refrigerant gas flow to flow in; an oil separator housing connected to the compressor housing in a fastened and sealed manner and having an outlet for the refrigerant gas flow to flow out; a compressing assembly disposed within the compressor housing and close to the inlet for compressing the refrigerant gas flow; an electric motor for driving the compressing assembly; and an oil supply device for supplying a freezing oil to the compressing assembly; the screw compressor further comprises an oil separator, the oil separator is disposed within the oil separator housing and comprises a first separator and a second separator, wherein the second separator is disposed close to the outlet, and the first separator is disposed between the compressing assembly and the second separator.

Owner:CARRIER CORP

Oil distributing device for air conditioner

InactiveCN1752670AImprove oil separation efficiencySimple structureRefrigeration componentsEngineeringCentrifugal force

The present invention discloses an oil separator of air conditioner. It includes external shell which is used for forming appearance, refrigerant discharge tube which is extended into the interior of external shell, one side of said refrigerant discharge tube is equipped with an oil-separating fan, the oil-separating fan is set in the interior of external shell, and can be rotated to produce vortex flow, the refrigerant in the external shell interior can be passed through the refrigerant discharge tube and discharged, the side face of the external shell is equipped with refrigerant supply tube, said refrigerant supply tube can supply refrigerant to the interior of the external shell, the oil-separating fan can be rotated by utilizing refrigerant discharged from refrigerant supply tube so as to separate the lubricating oil from refrigerant.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

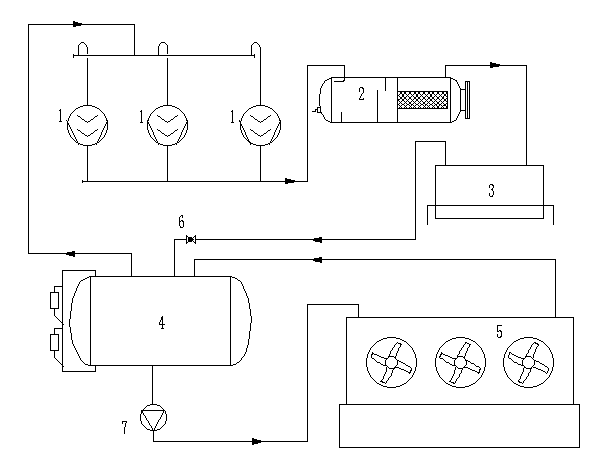

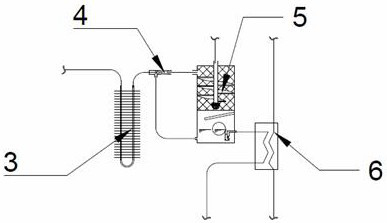

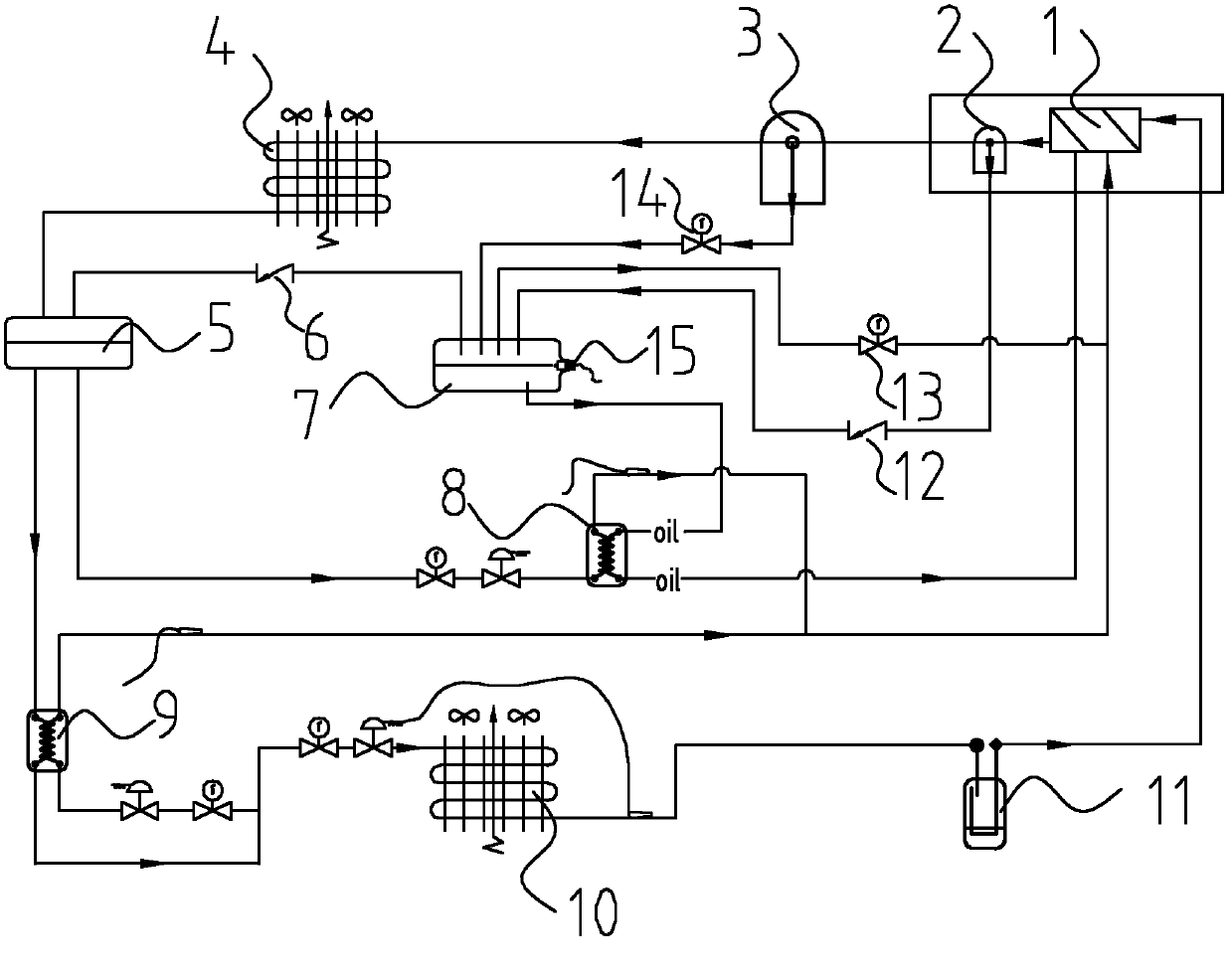

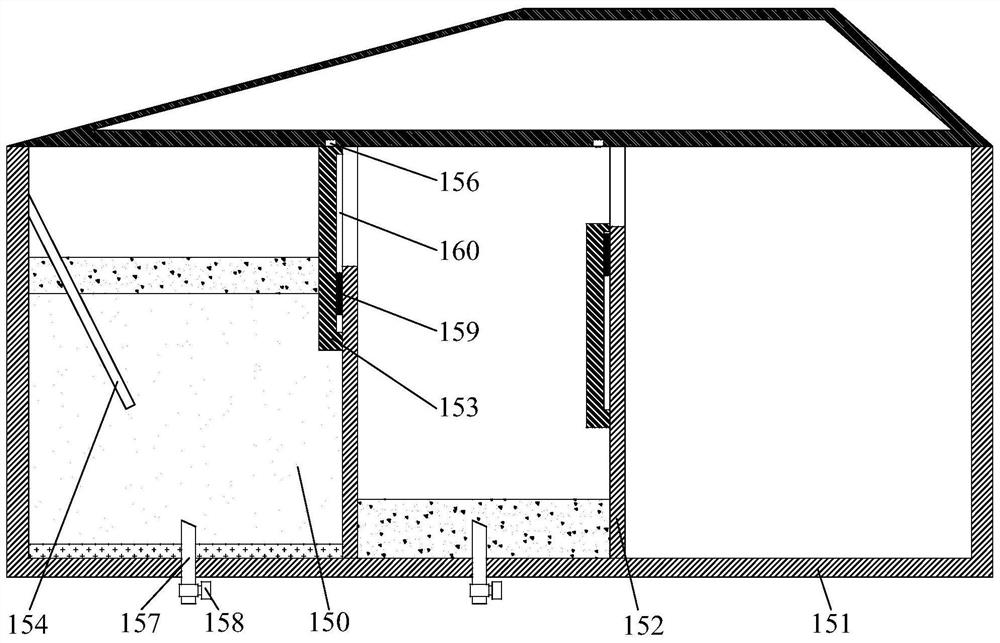

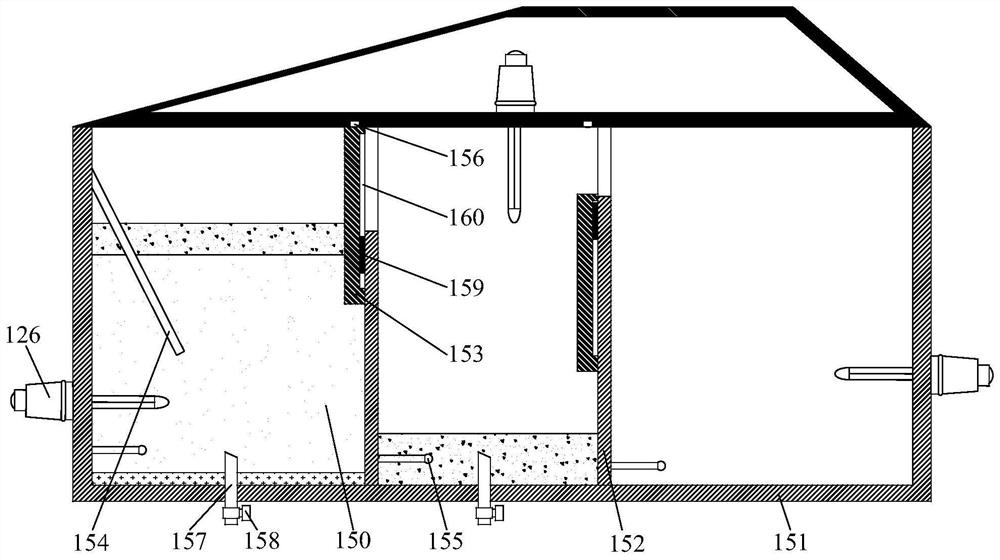

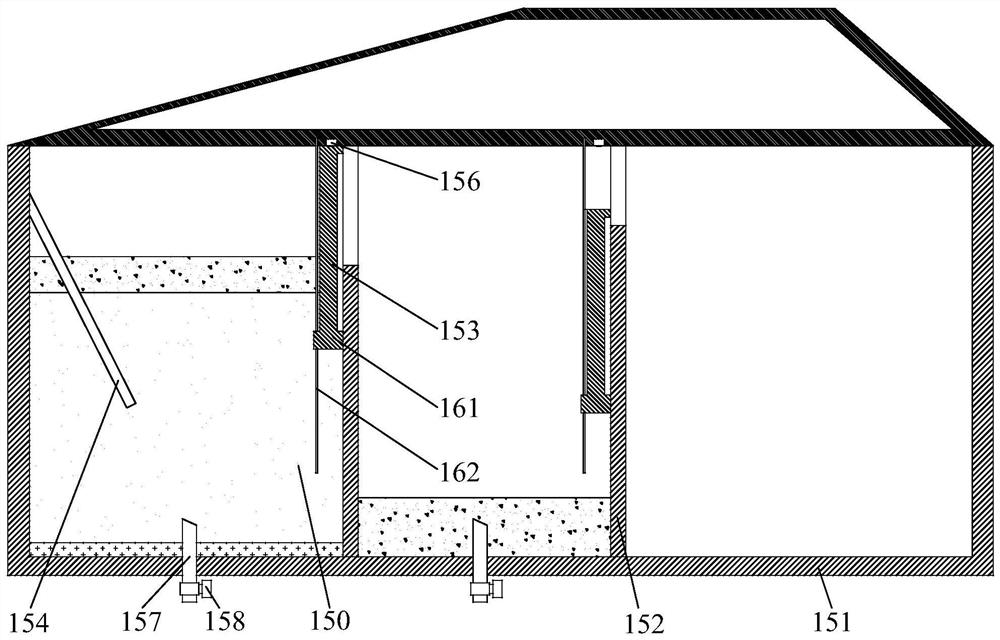

Three-stage separated efficient horizontal type oil distribution device

InactiveCN104006588AImprove work efficiencyReduce entryRefrigeration componentsOil separationEngineering

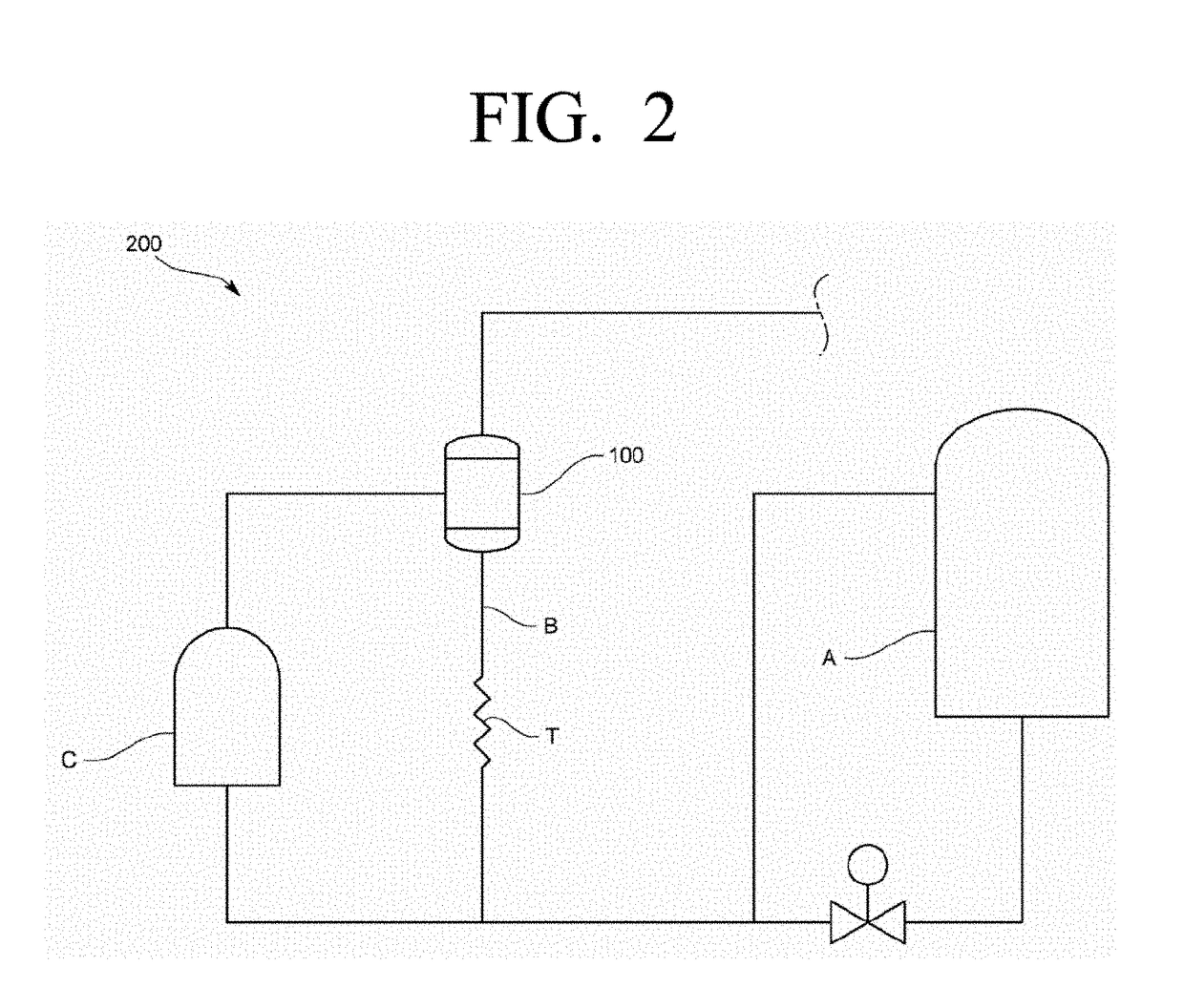

The invention discloses a three-stage separated efficient horizontal type oil distribution device which comprises multiple screw compressors. Each screw compressor is connected with an inlet of a horizontal type oil separator through an exhaust branch, an outlet of the horizontal type oil separator is connected with an inlet of a condenser through a pipe, an outlet of the condenser 3 is connected with a low-pressure circulating bucket through a pipe, a throttle valve is arranged between the condenser and the low-pressure circulating bucket, the bottom of the low-pressure circulating bucket is connected with an evaporator through a fluorine pump, an outlet of the evaporator is connected with the low-pressure circulating bucket through a pipe, and a return air pipe of the low-pressure circulating bucket is connected with the compressors. The three-stage separated efficient horizontal type oil distribution device has the advantages of improving the oil distribution efficiency, achieving 10 PPM, effectively decreasing frozen oil entering a low-pressure system and accordingly improving the working efficiency of a parallelly connected compressor unit.

Owner:SIFANG TECH GRP CO LTD

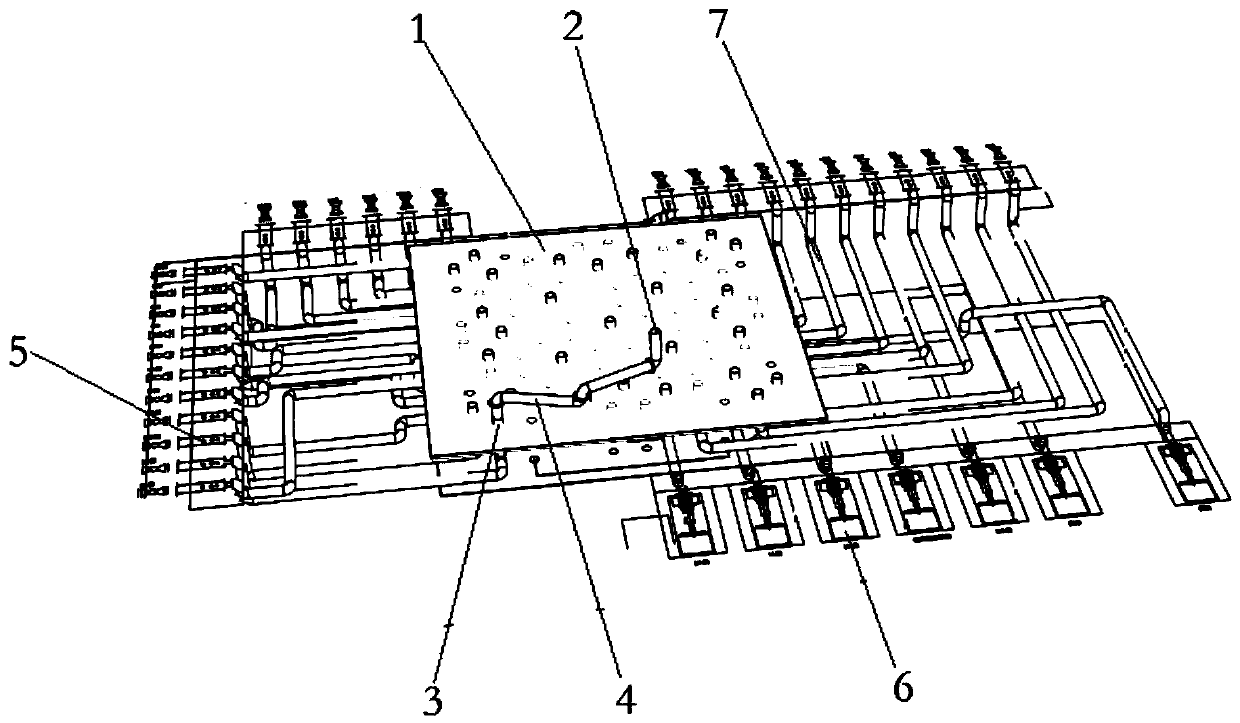

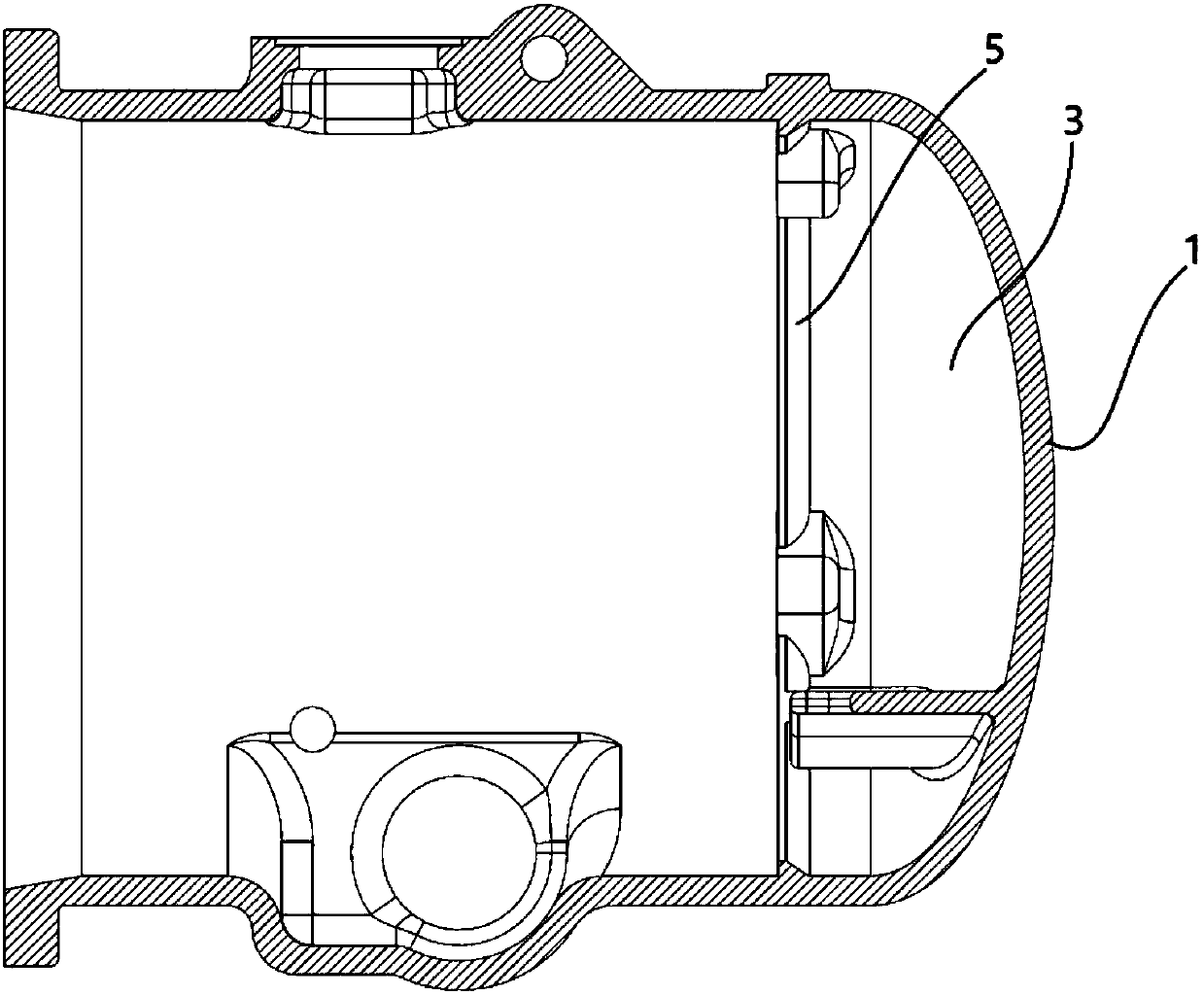

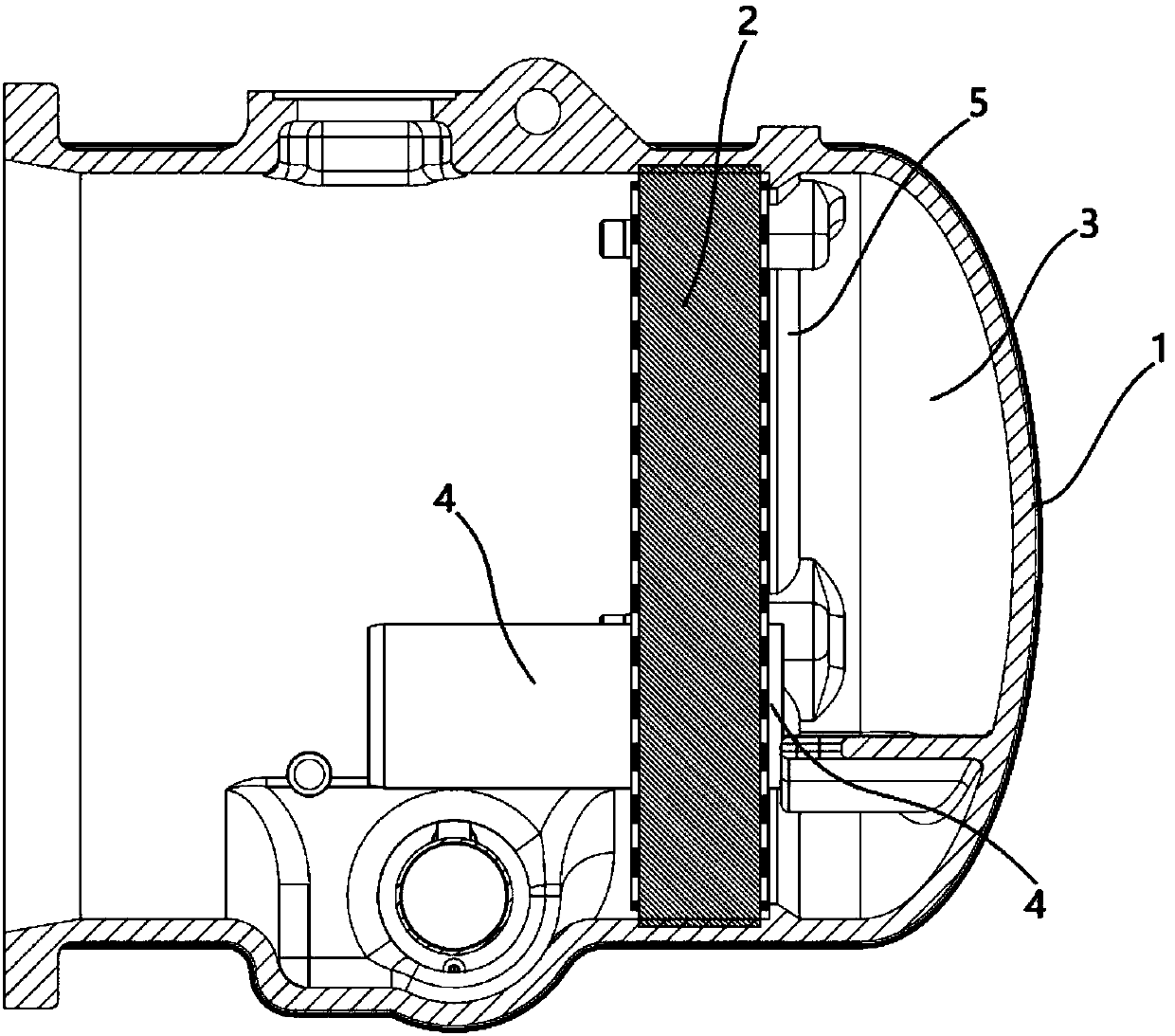

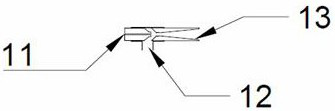

Exhaust structure of compressor and compressor

PendingCN107956699AAvoid sweepingImprove oil separation efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsThermodynamicsOil separation

The invention discloses an exhaust structure of a compressor and the compressor. The exhaust structure of the compressor comprises an oil separation filter net (1), an oil separation barrel (2) and anexhaust pipe (3); and the exhaust pipe (3) extends into a cavity formed by the oil separation filter net (1) and the oil separation barrel (2), and is upwards bent in the cavity. The exhaust structure of the compressor can prevent refrigerant gas, exhausted by the exhaust pipe, from sweeping bottom oil drops to improve the oil separation efficiency.

Owner:GREE ELECTRIC APPLIANCES INC

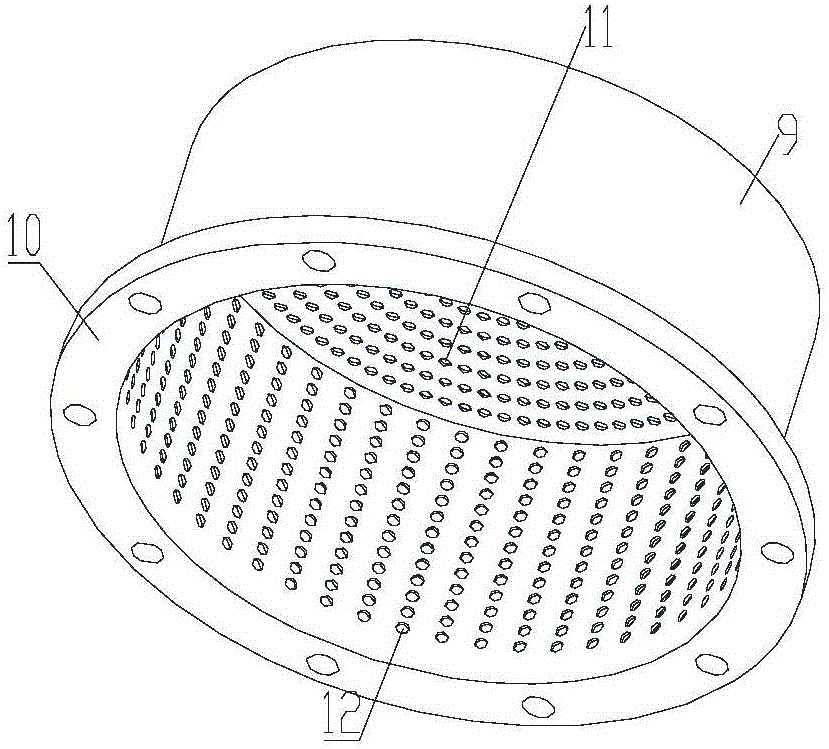

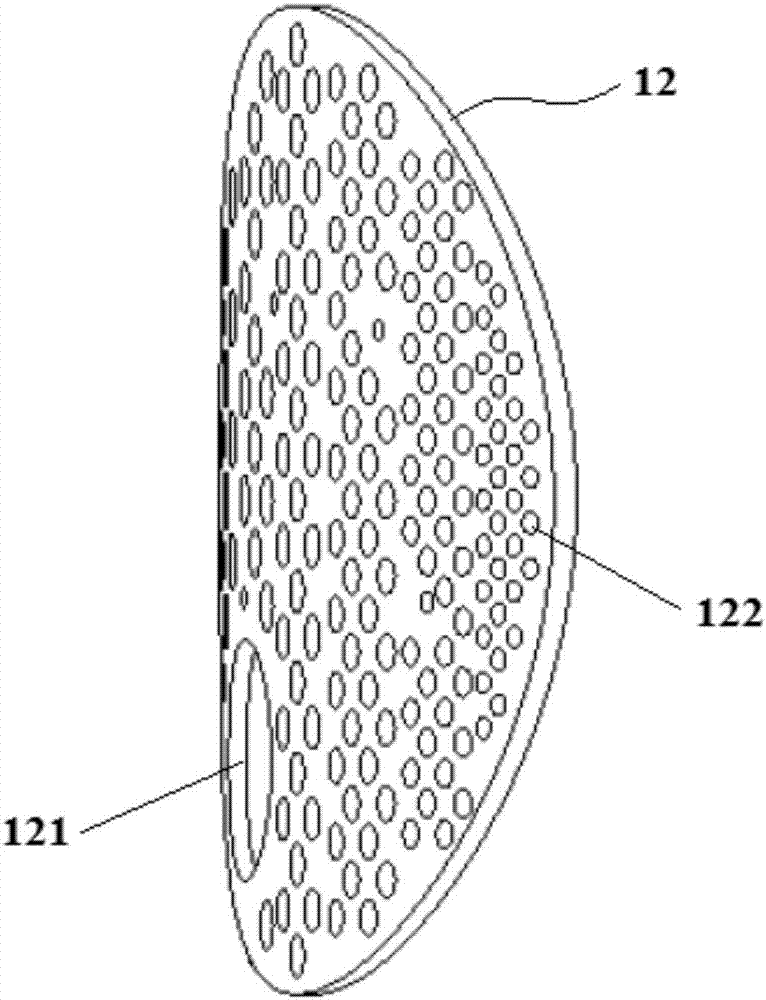

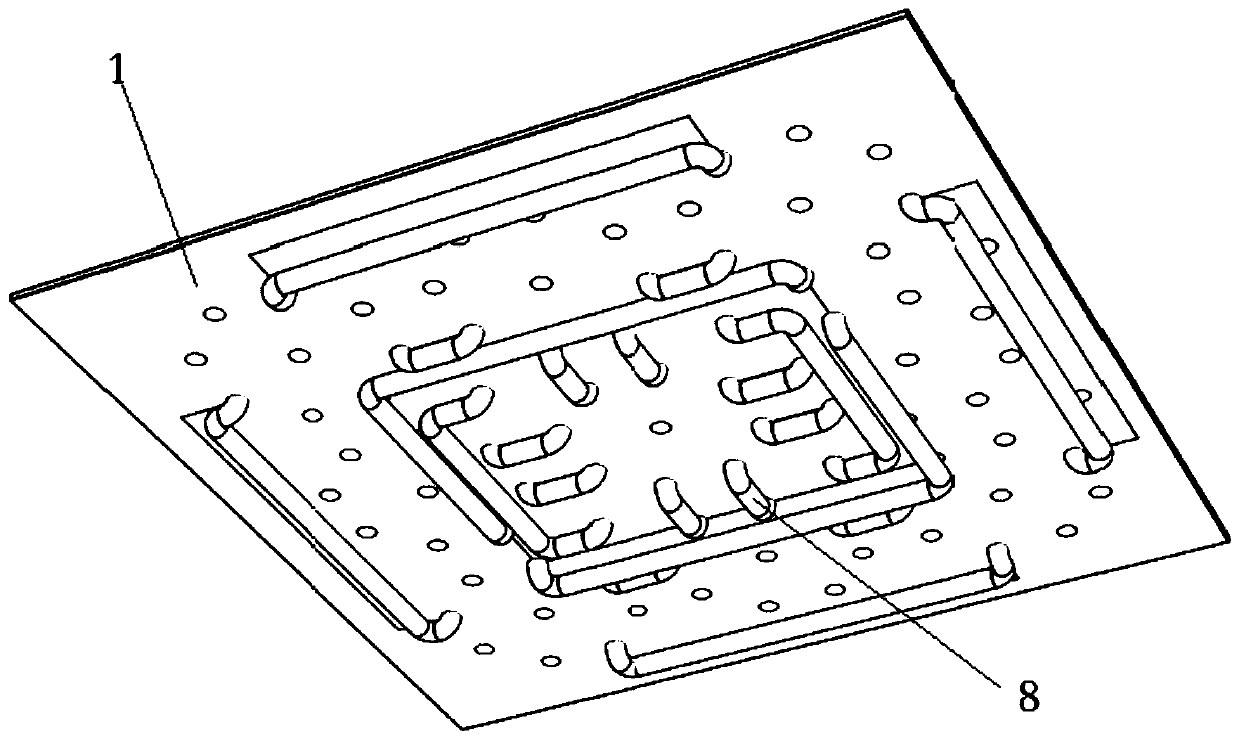

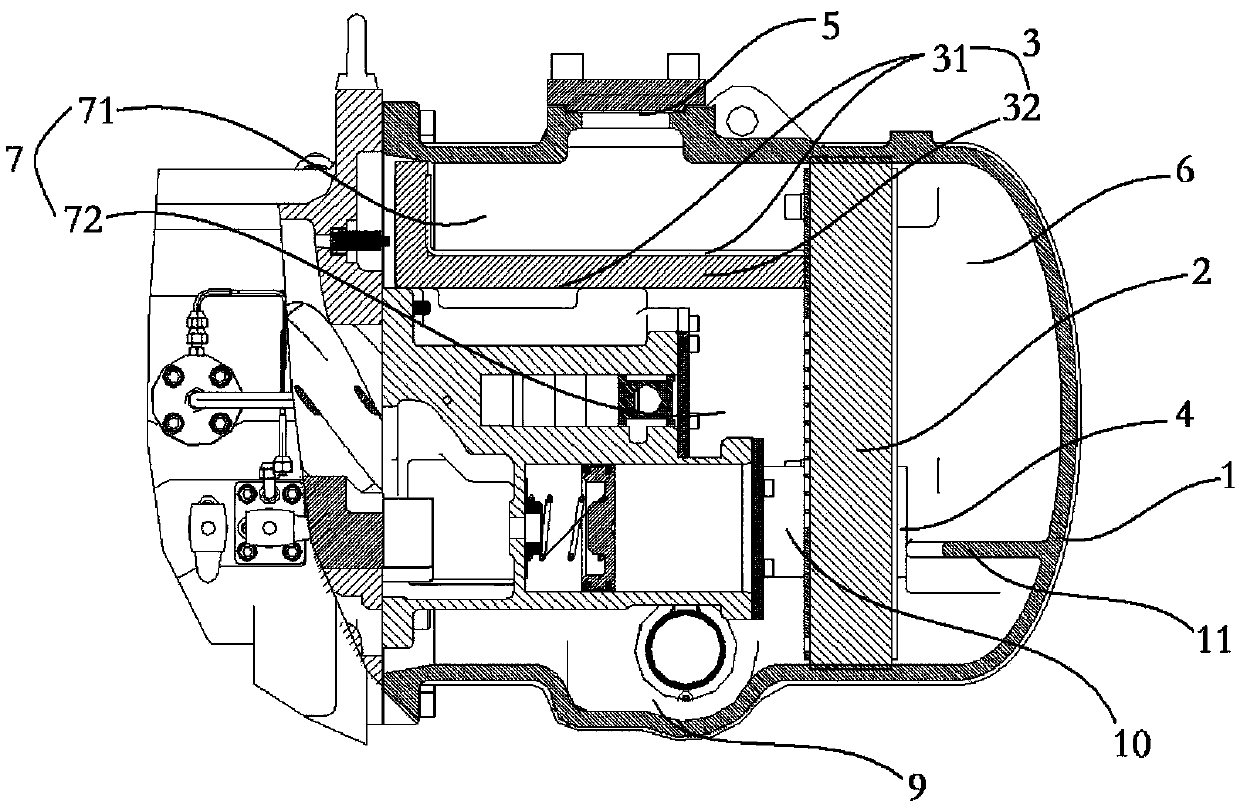

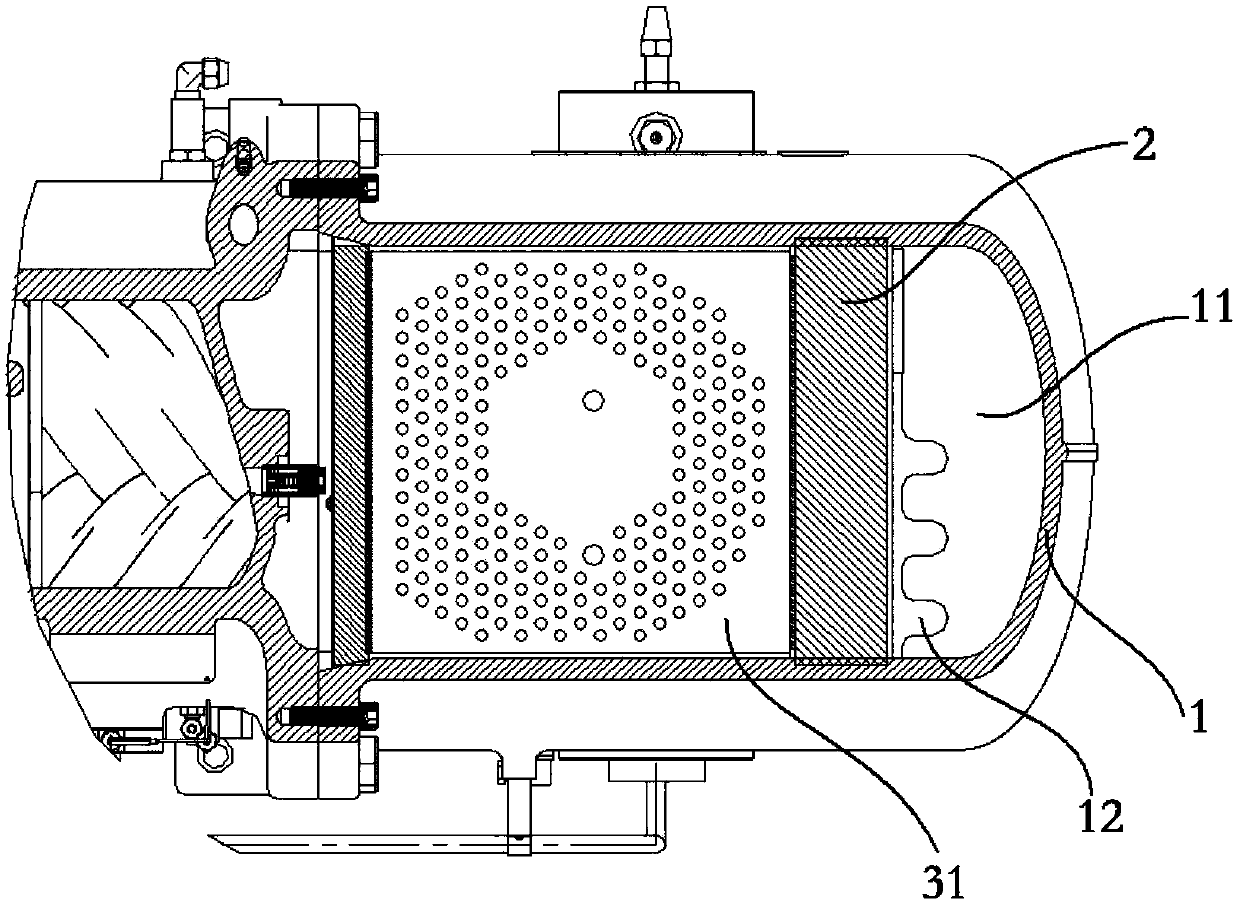

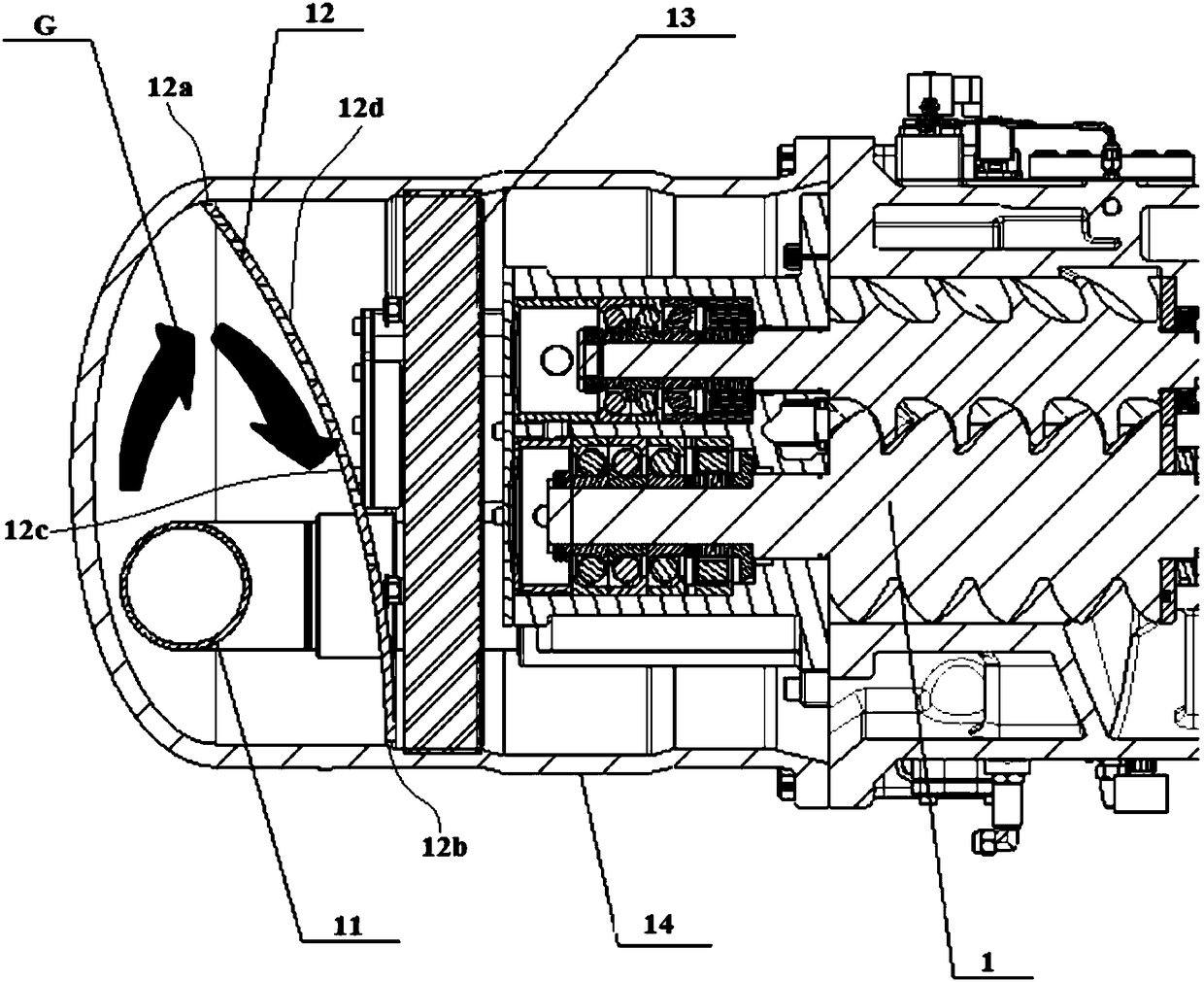

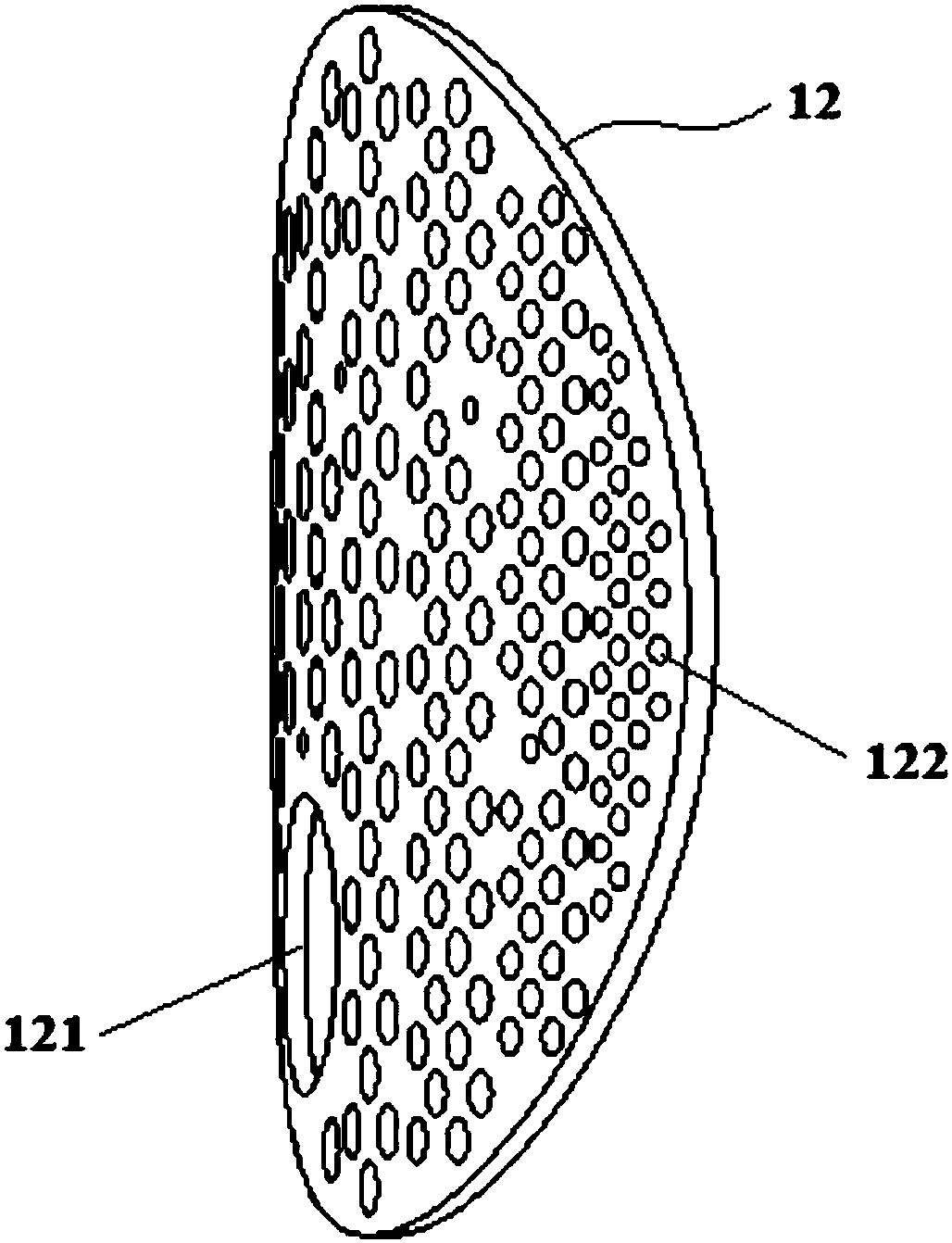

Oil-gas separation device, compressor and air conditioner system

ActiveCN106949063ASolve uneven distributionIncrease the utilization areaRotary/oscillating piston pump componentsLiquid fuel engine componentsOil separationEngineering

The invention relates to the technical scheme of air conditioners, in particular to an oil-gas separation device, a compressor and an air conditioner system. The oil-gas separation device comprises a perforated plate and a filter net; multiple vent holes which penetrate through a first plate surface and a second plate surface, which are opposite, of the perforated plate are formed in the perforated plate; an air stream emitted from a vent pipe can flow from the side of the first plate surface to the side of the second plate surface through the plurality of vent holes, and flow to the filter net; and besides, the first plate surface is a curve surface which is convex to the side of the filter net, so that the air stream which flows towards the perforated plate from the vent pipe can flow along the first plate surface under guiding of the first plate surface. According to the oil-gas separation device, the air stream is guided to flow along the first plate surface by utilizing the curve surface shape of the first plate surface of the perforated plate, so that the problem in the prior art that the air stream is distributed nonuniformly when impacting on the perforated plate because the perforated plate is flat can be effectively solved; and the utilization area of the filter net is increased, so that oil separation efficiency is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

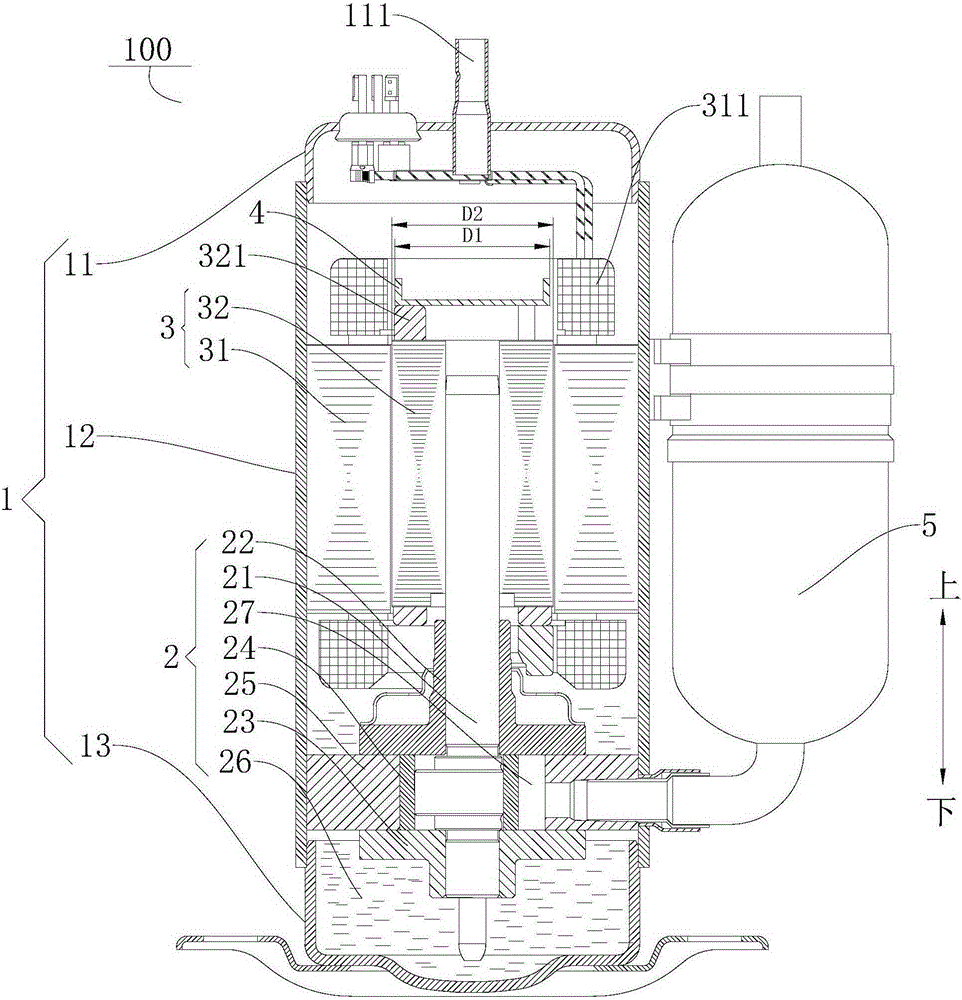

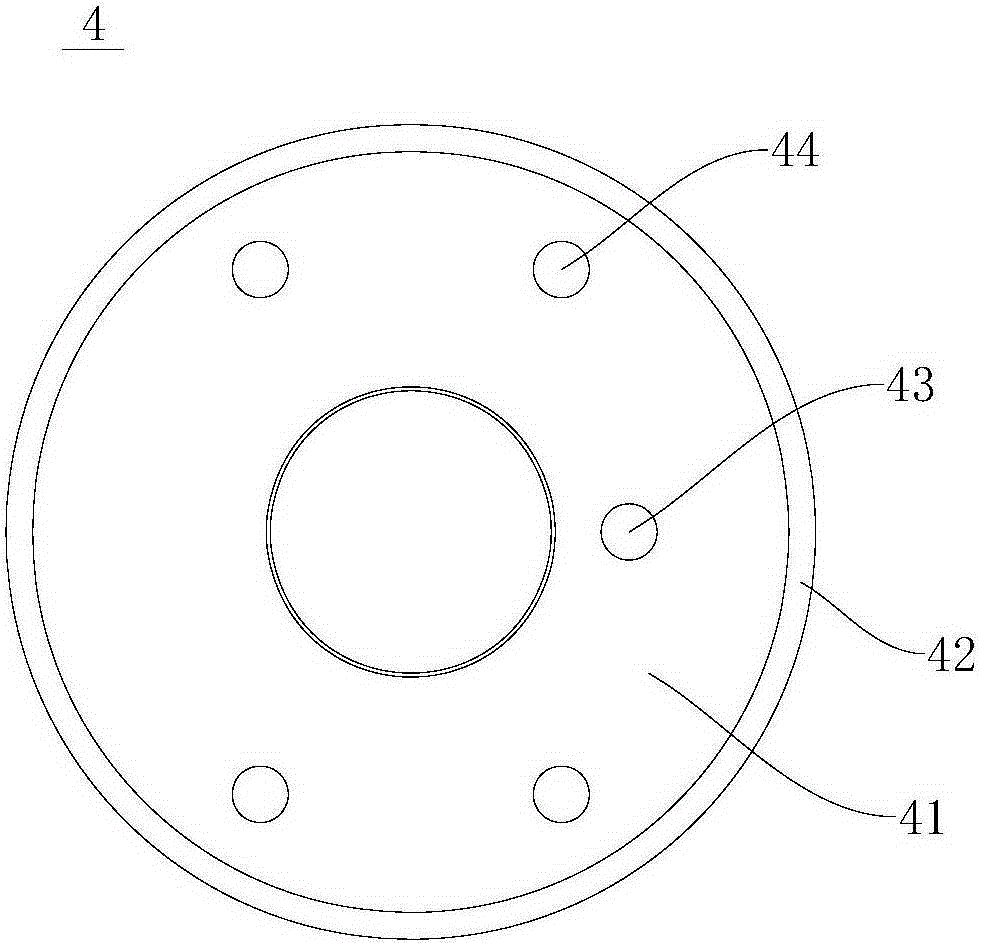

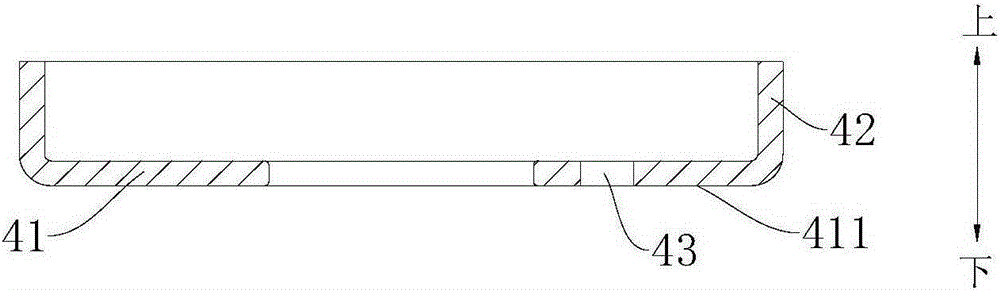

Rotation compressor

InactiveCN105275819AGuaranteed performanceImprove reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsOil separationMechanical engineering

The invention discloses a rotation compressor. The rotation compressor comprises a shell, a compression mechanism, a motor assembly and an oil separation assembly. The shell is provided with an exhaust port. The compression mechanism is arranged in the shell and provided with a compression cavity. The motor assembly is arranged in the shell and comprises a rotor and a stator. The motor assembly is located between the compression mechanism and the exhaust port, and an exhaust channel is defined jointly by the motor assembly and the compression mechanism. One end of the exhaust channel is communicated with the compression cavity, and the other end of the exhaust channel is communicated with the exhaust port. The oil separation assembly is arranged in the exhaust channel and provided with a fluid collision face suitable for being impacted by fluid in the exhaust channel. According to the rotation compressor, the possibility that refrigerating machine oil in the rotation compressor enters a heat exchanger can be reduced, the heat exchange capability of the heat exchanger is guaranteed, and the heat exchange efficiency is improved. Meanwhile, the phenomenon that abrasion is increased due to the fact that the interior of the rotation compressor is lack of refrigerating machine oil can be prevented, and therefore the performance of the compressor is guaranteed, and reliability of working of the compressor is improved.

Owner:ANHUI MEIZHI PRECISION MFG

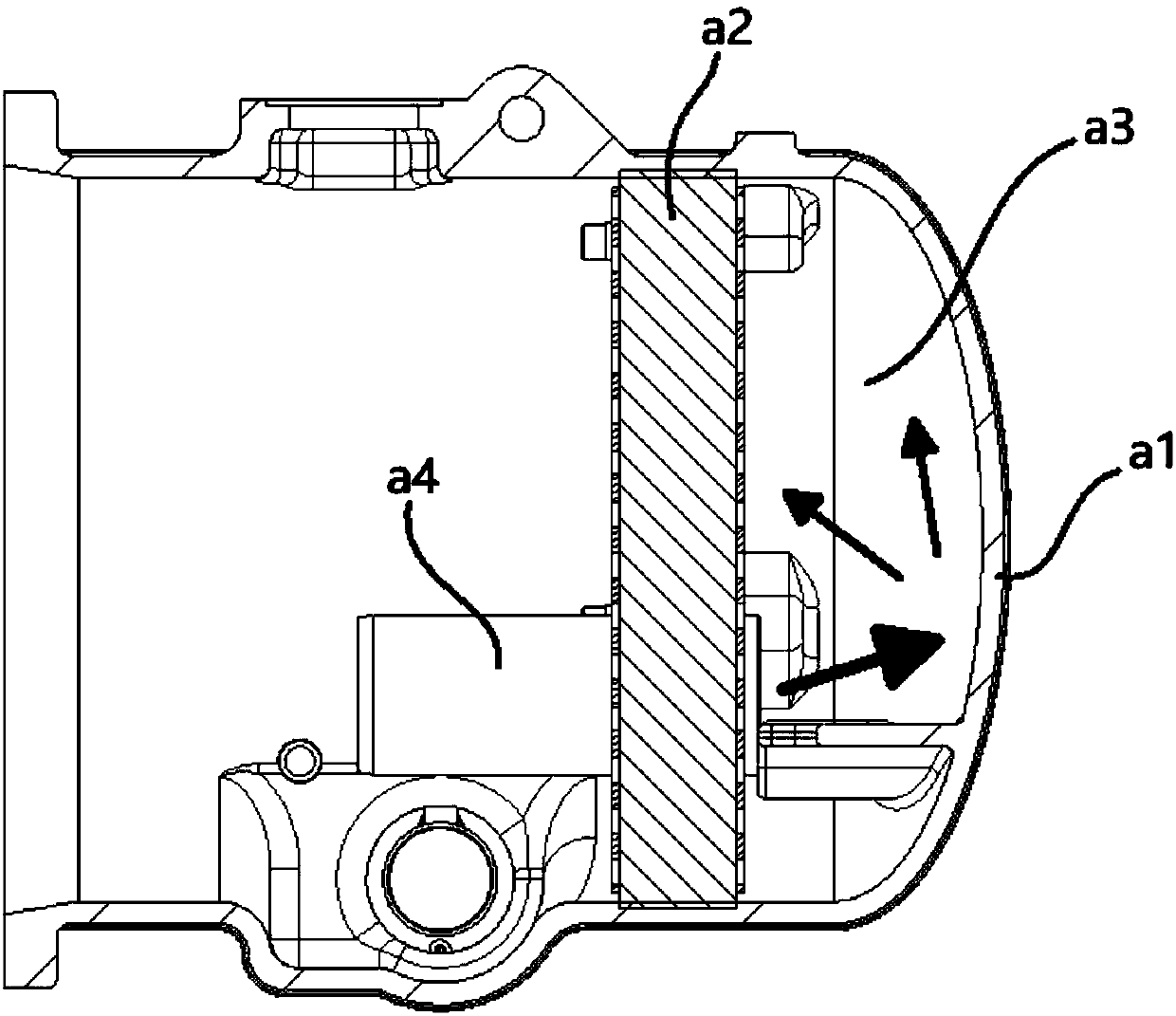

Exhaust bearing block, screw compressor and air conditioning unit

InactiveCN104963870AImprove oil separation efficiencyReduce vibrationRotary/oscillating piston pump componentsLiquid fuel engine componentsGas compressorOil separation

The invention relate to an exhaust bearing block, a screw compressor and an air conditioning unit, wherein the exhaust bearing block comprises an exhaust cavity, an exhaust hole is formed in the exhaust cavity, the exhaust cavity is configured to have a plurality of turning structures, exhaust air flow can change directions for a plurality of times in the exhaust cavity, and finally is exhausted from the exhaust hole, the opening of the exhaust hole is designed in such a way that under the condition that the exhaust bearing block is covered by a shell, gas exhausted from the exhaust hole has components flowing in a rotating manner along the inner wall of the shell and around the axis of the shell. The exhaust bearing block can play the role of improving the oil separation efficiency from multiple aspects, including centrifugal effect, uniform flow field, impacting separation and the like.

Owner:GREE ELECTRIC APPLIANCES INC +1

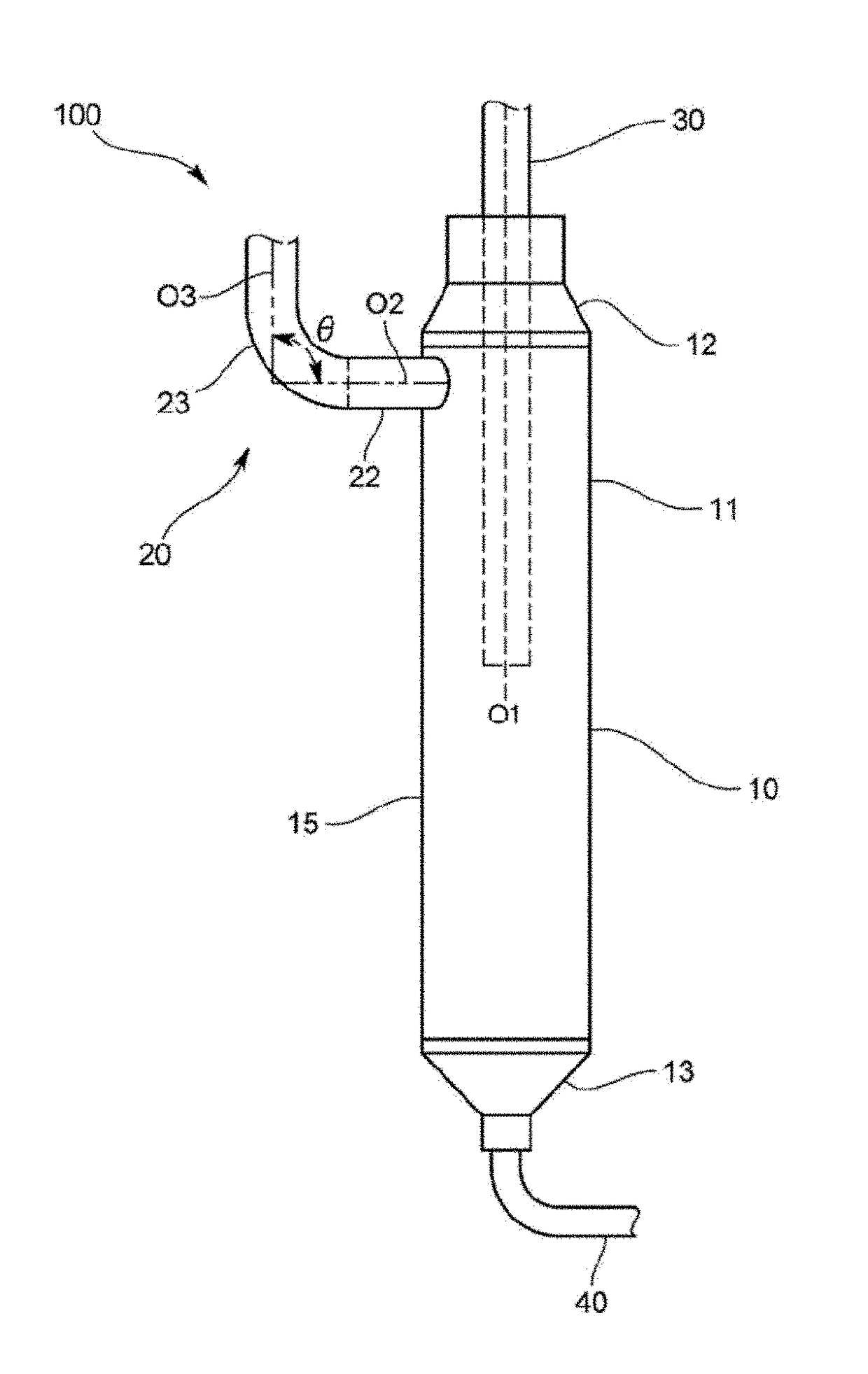

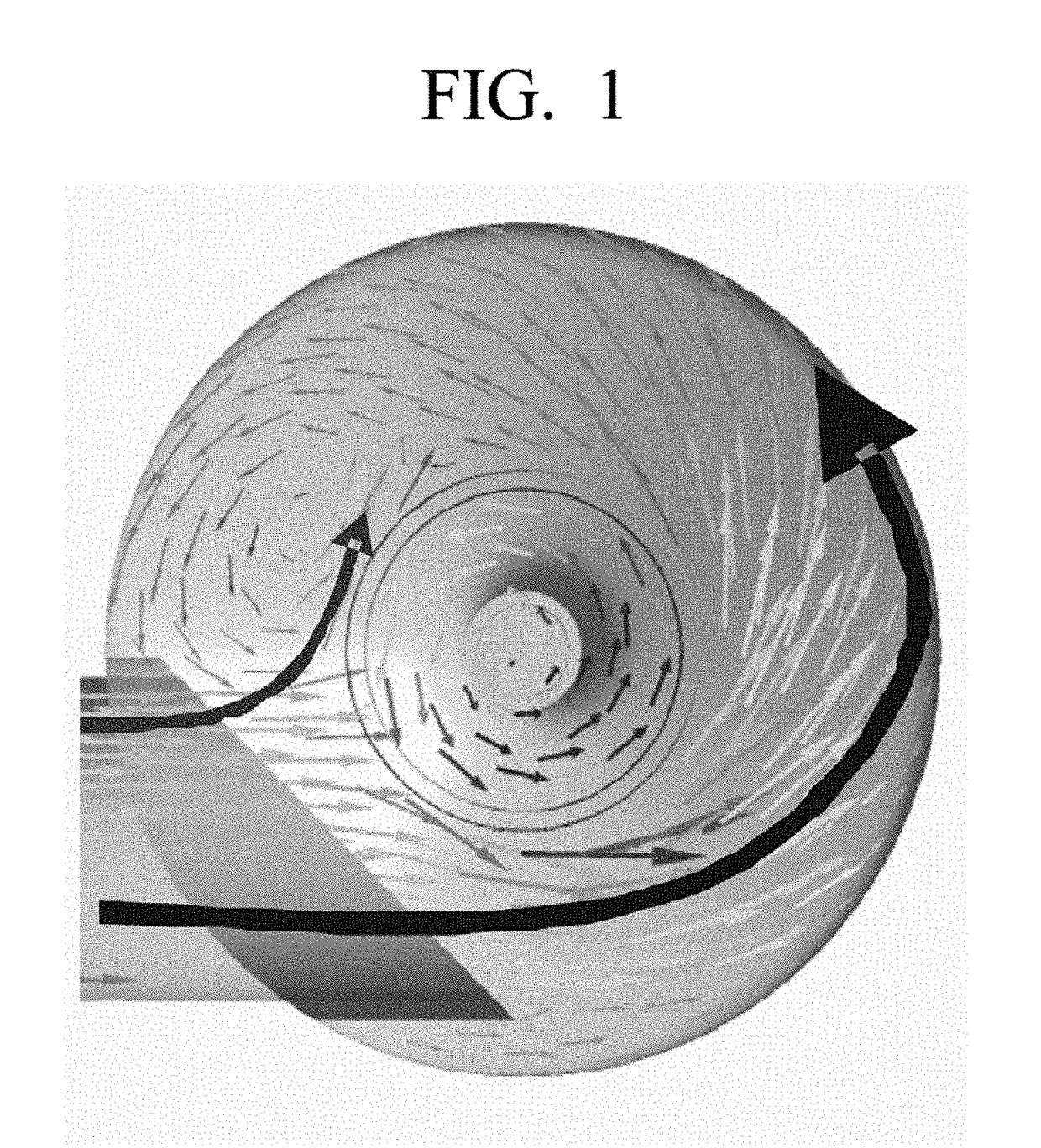

Oil separator

ActiveUS20170184331A1Avoid separationImprove oil separation efficiencyCompression machines with reversible cycleRefrigeration componentsEngineeringMechanical engineering

An oil separator includes a container having an inner circumferential surface of a cylindrical shape; an inlet pipe that penetrates through from an outside of the container to an inside of the container, comprises an inlet port through which the oil-containing refrigerant is introduced to the container; and a refrigerant discharge pipe that is provided coaxially with a central axis of the container in a top of the container, projects from the top of the container toward a bottom of the container, and comprises a discharge port which is disposed below the inlet port and allows oil removed refrigerant to be discharged. The oil-containing refrigerant flowing out of the inlet port of the inlet pipe is not branched by the refrigerant discharge pipe, and forms a single flow flowing in one direction along an outer circumferential surface of the refrigerant discharge pipe and the inner circumferential surface of the container.

Owner:SAMSUNG ELECTRONICS CO LTD

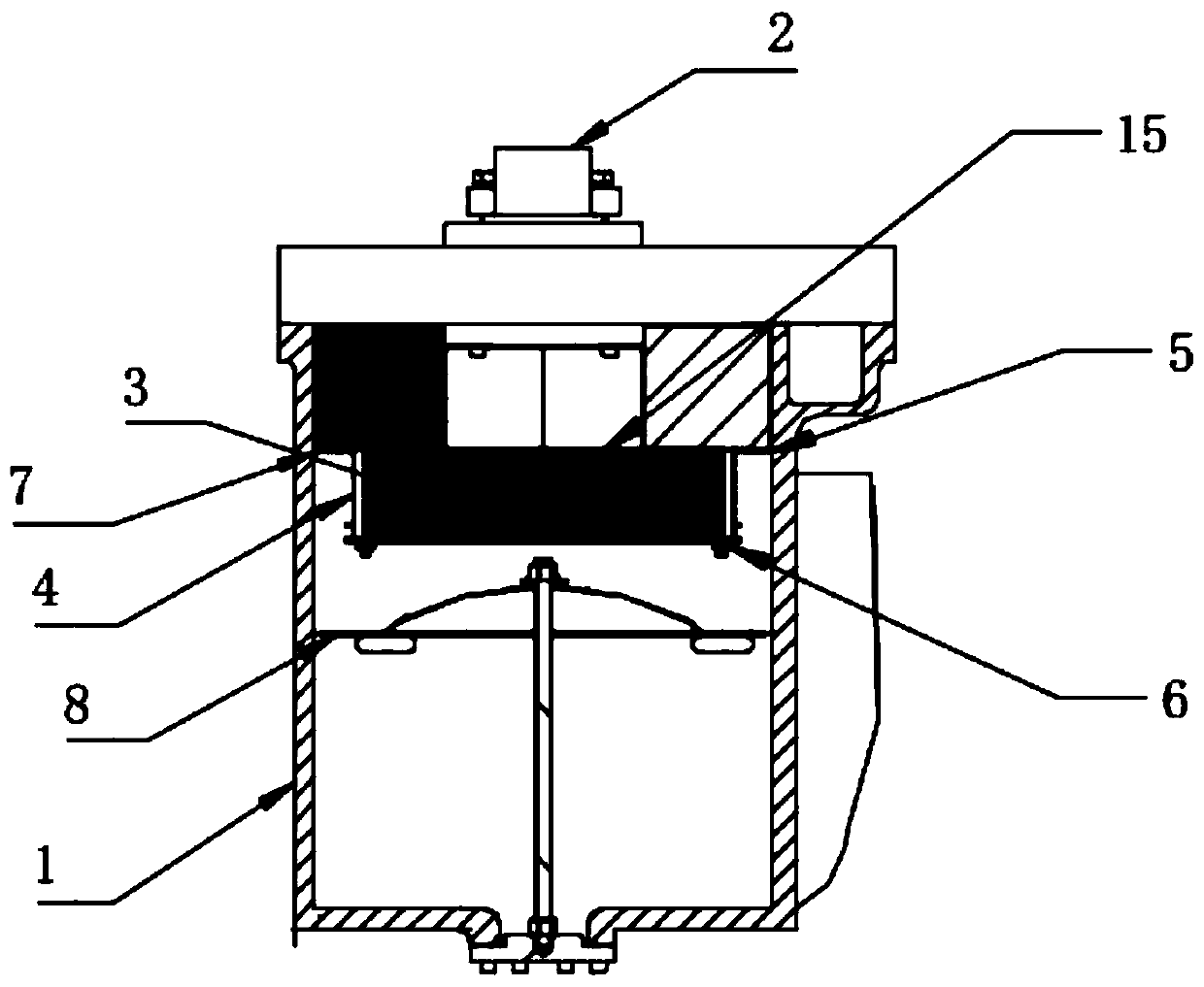

Oil separator in compressor

InactiveCN102116297AEfficient separationImprove oil separation efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsOil separationPetroleum engineering

The invention relates to an oil separator in a compressor. The oil separator comprises an oil separating shell; one side of the oil separating shell is provided with a hole which is connected with a condensor; and the oil separating shell is internally fixedly provided with an oil drum. The oil separator is characterized in that the front end of the oil drum is provided with a baffle plate; one end of the baffle plate is connected with the inner wall of the oil drum, and a distance is arranged between the other end of the baffle plate and the correspondng inner wall of the oil drum; the rear side of the baffle plate is provided with a first filter screen which is connected with the inner wall of the oil drum; and a second filter screen which is connected with the inner wall of the oil drum is arranged apart from the first filter screen. The invention has the beneficiall effects that the oil separator has higher oil separating efficiency than that of the traditional oil separation and secondary oil separation, and the lubricating oil carried by exhaust air can be effectively separated, thus the systematic design is simplified, and the cost is saved.

Owner:SHANGHAI HANBELL PRECISE MASCH CO LTD

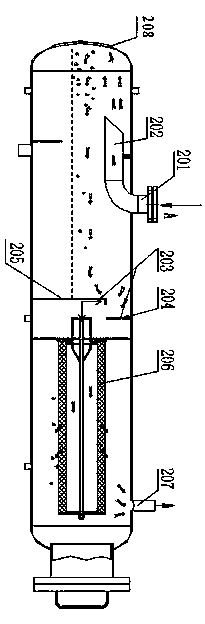

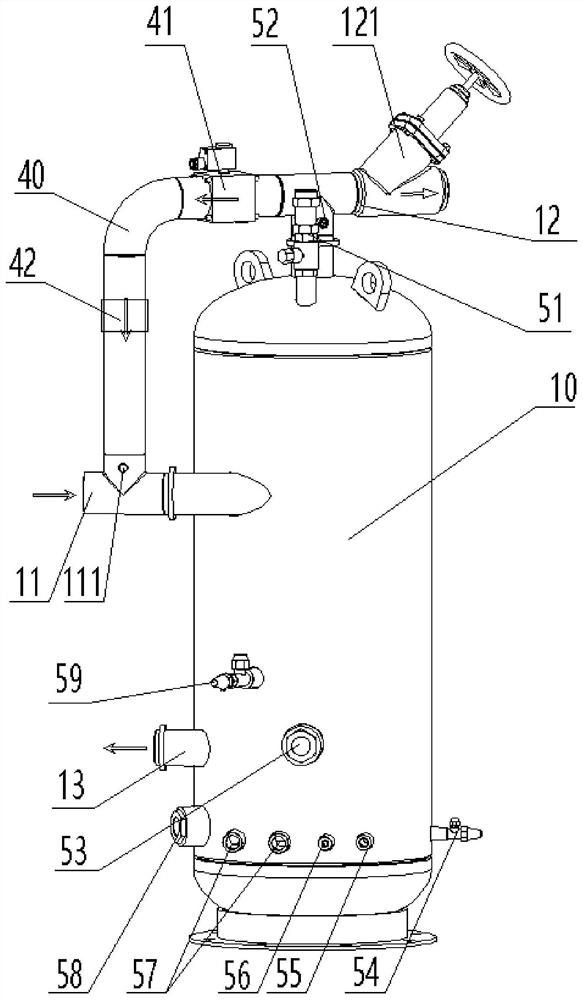

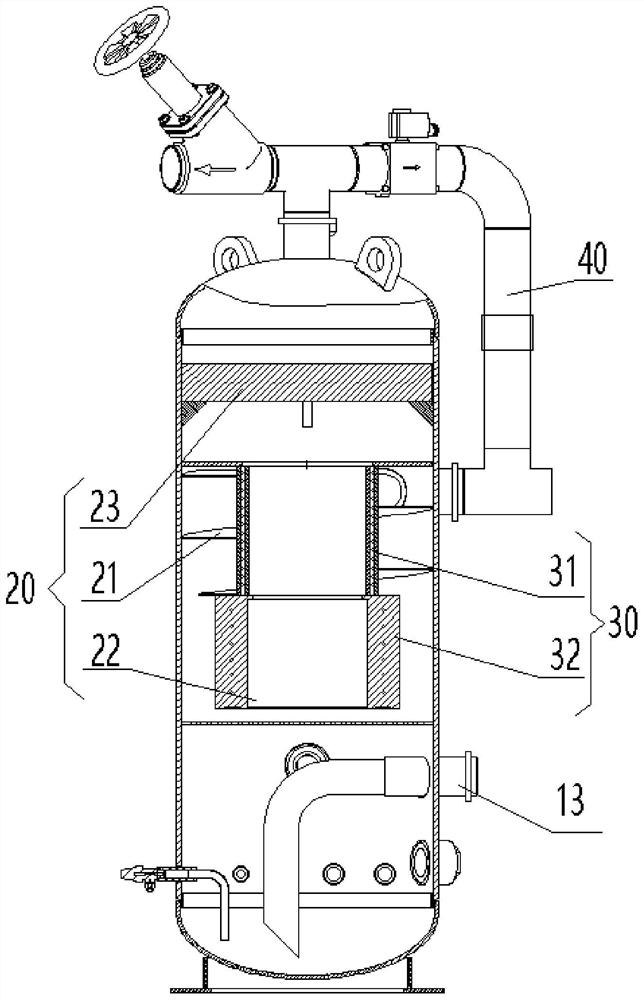

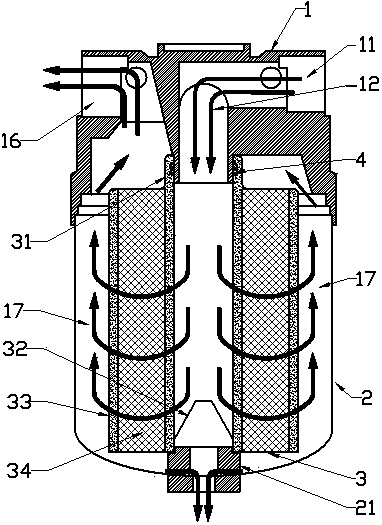

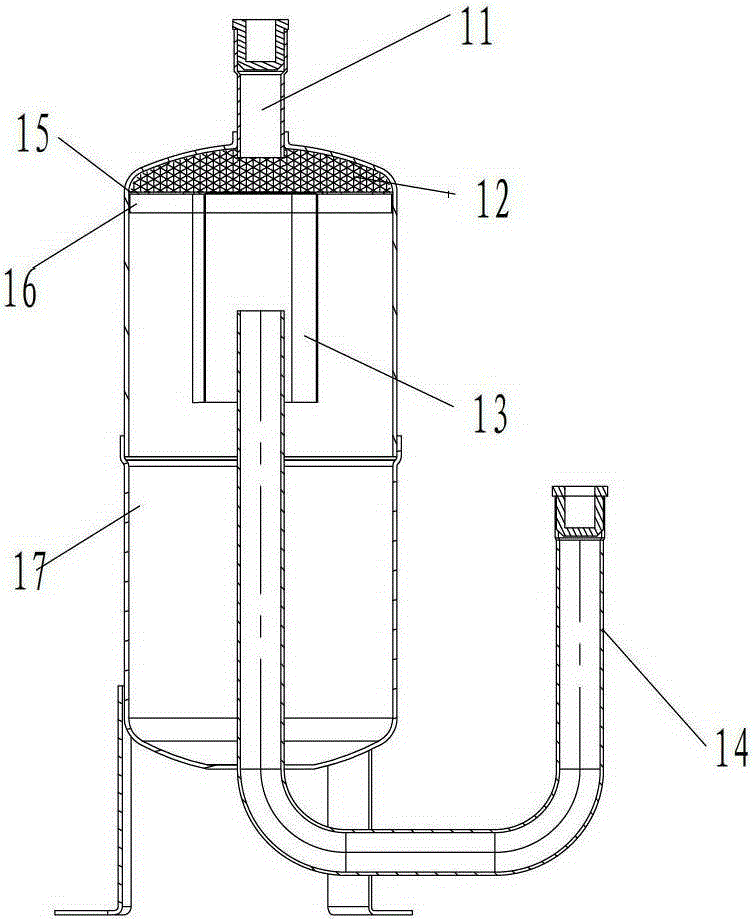

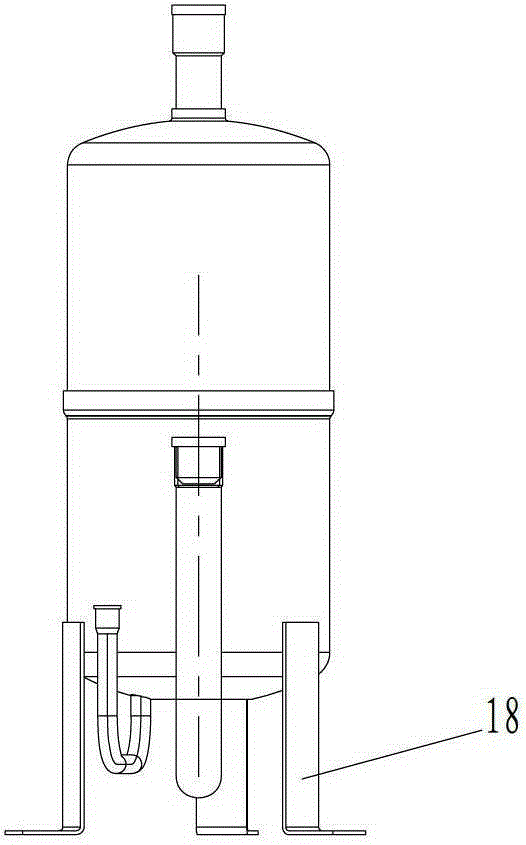

Built-in vertical oil separator for compressor

PendingCN111255658AEfficient use ofEfficient separationPositive displacement pump componentsPositive-displacement liquid enginesOil separationEngineering

The invention relates to a built-in vertical oil separator for a compressor. The built-in vertical oil separator comprises a barrel body, and an initial air vent and a diversion channel are formed inthe upper part of the barrel body. One end of the initial air vent is connected with the diversion channel, and the other end of the initial air vent is connected with an air vent of the compressor. The diversion channel is connected with a first metal filter screen through a porous screen plate, and a second metal filter screen is arranged under the diversion channel and the first metal filter screen. An umbrella type oil and gas separation baffle plate is arranged under the second metal filter screen. Through four times of oil separation and a layer of oil and gas separation baffle plate, efficient oil and gas separation can be achieved, exhaust gas with very low oil content is provided for a refrigeration system, and the overall efficiency of a system is improved.

Owner:福州市虚谷技术有限公司

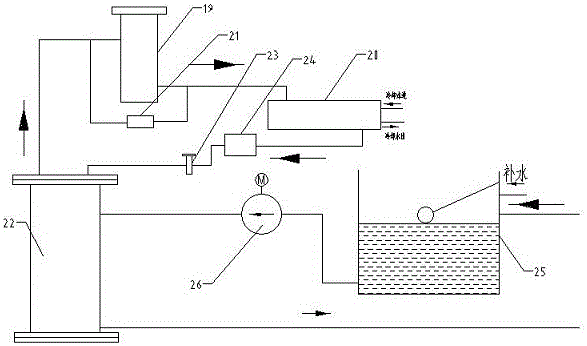

Power plant condenser vacuum maintaining unit provided with water chilling unit

InactiveCN105953601AStable vacuum effectGood effectSteam/vapor condensersAutomatic controlChilled water

The invention discloses a power plant condenser vacuum maintenance unit equipped with a chiller, which includes a vacuum pump set and a chiller; the chiller includes a compressor, the inlet of the compressor is connected with the refrigerant outlet of the evaporator, and the compressor The outlet of the condenser is connected to the refrigerant inlet of the condenser; the refrigerant outlet of the condenser is connected to the refrigerant inlet of the evaporator through a filter and an expansion valve in turn; the compressor is controlled by a pressure controller; the evaporator The chilled water inlet is connected with a water pump; the device of the invention has the advantages of stable vacuum unit efficiency, high vacuum degree, energy saving and high efficiency, high oil separation efficiency of the chiller, high heat transfer efficiency and safe and stable automatic control operation.

Owner:SHENZHEN SEP INVESTMENT

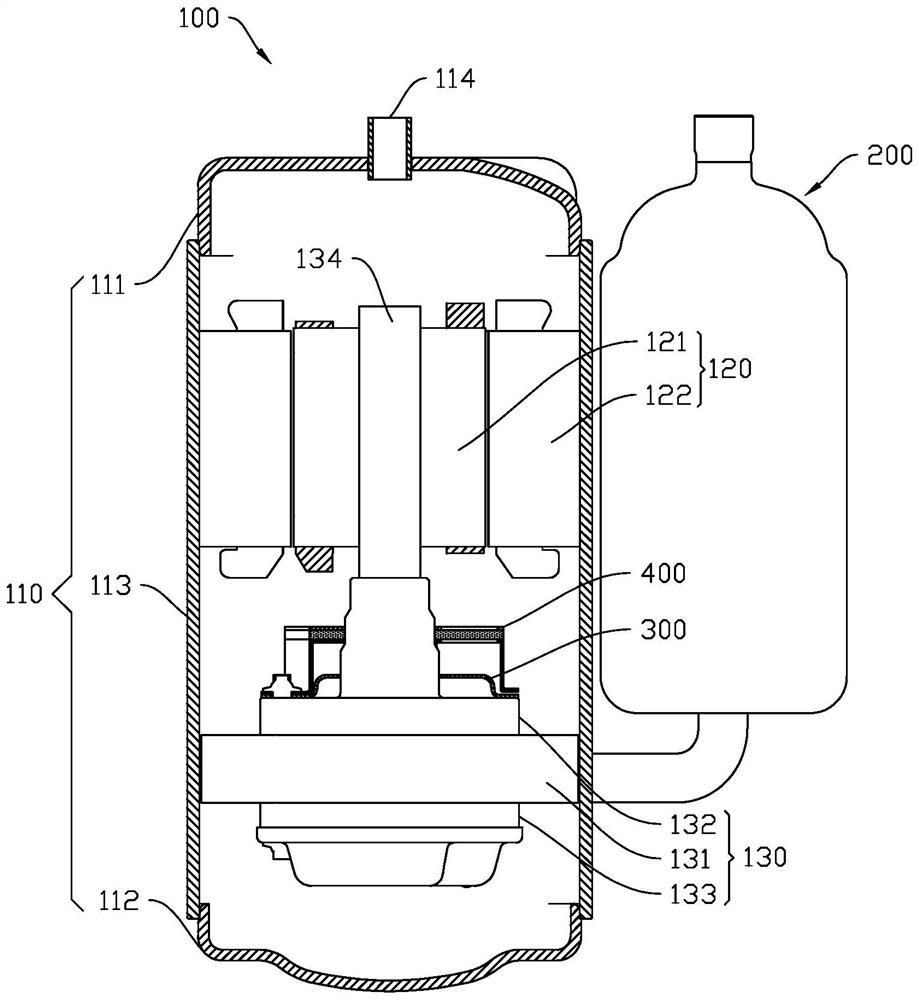

Compressor and refrigeration equipment

ActiveCN114017339AEasy to installImprove reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsOil separationRefrigerant

The invention discloses a compressor and refrigeration equipment. The compressor comprises a pump body assembly, a silencer and an oil separation structure. The silencer is provided with a discharge port; the oil separation structure comprises an oil separation shell and a filter screen, the oil separation shell is connected with the silencer or the pump body assembly, the oil separation shell covers the air outlet side of the exhaust port and forms a containing cavity, the oil separation shell is provided with an exhaust hole communicating the containing cavity with the interior of a shell of the compressor, and the filter screen is connected with the oil separation shell and covers the exhaust hole. An oil-gas mixture discharged from the discharge port has enough time to diffuse in the containing cavity, when the oil-gas mixture is discharged through the exhaust hole, the filter screen is stably installed on the oil separation shell and is not prone to deformation and damage, the filter screen filters refrigerant oil and only allows a gaseous refrigerant to pass through, and therefore effective separation of the refrigerant oil and the gaseous refrigerant is achieved, and the oil output is reduced and the reliability of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

Oil separator, control method of oil separator and air conditioning unit

PendingCN111947354AIncrease temperatureReduce freezing oil contentCompressorMechanical apparatusOil separationAir conditioning

The invention provides an oil separator, a control method of the oil separator and an air conditioning unit. The oil separator comprises an oil separation barrel, an oil separation assembly and a heating assembly; the oil separation barrel is provided with a gas inlet and a gas outlet, and the oil separation assembly is arranged in the oil separation barrel and used for separating a gas-oil mixture entering from the gas inlet; the heating assembly is arranged on the oil separation assembly and used for heating the gas-oil mixture. According to the technical scheme, in the gas-oil mixture separation process, if the exhaust temperature of a compressor is too low, the gas-oil mixture in the separation process can be heated through the heating assembly, the temperature of the gas-oil mixture is increased, a liquid refrigerant in the gas-oil mixture is evaporated, the emulsified refrigerant oil content is effectively reduced, and oil and gas can be separated in production. meanwhile, the problem that a refrigerant easily carries lubricating oil and deposits in the oil separation barrel at a low exhaust temperature can be effectively avoided, so that the oil separation efficiency is improved, and normal oil supply of the unit is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

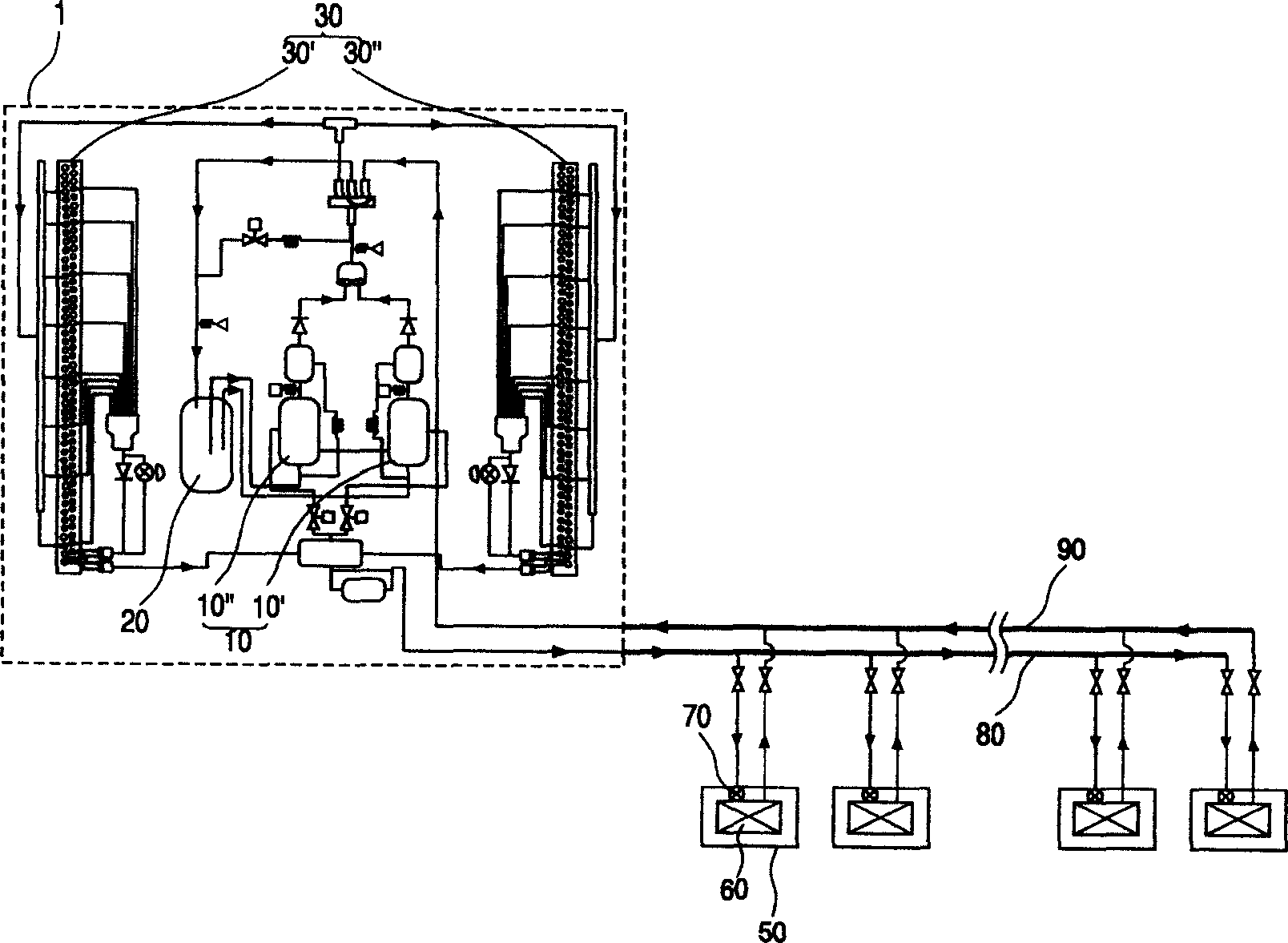

Integrated oil distribution system with pipelines in pump room being centralized

ActiveCN110217748AImprove securityImprove reliabilityLiquid transferring devicesPipe fittingOil distribution

The invention provides an integrated oil distribution system with pipelines in a pump room being centralized. The integrated oil distribution system comprises a horizontal oil distribution plate whichis arranged in the pump room and a storage tank for storing oil which is arranged on the oil distribution plate; the storage tank is arranged at the periphery of the oil distribution plate and is connected with oil supply equipment outside the oil distribution plate through external connection pipelines; an oil pump is arranged on the oil distribution plate; the oil inlet end of the oil pump is connected with the storage tank through an adapter pipe fitting; the oil outlet end of the oil pump is connected with oil outlet equipment of the pump room through the external connection pipelines; the oil distribution plate is internally provided with embedded pipe fittings; and connecting joints for connecting with the adapter pipe fitting are arranged at the two ends of the embedded pipe fittings. By concentrating the external connection pipelines on the oil distribution plate, the problem of winding and pollution caused by a too long hose in a hose oil distribution system is solved, and the safety and reliability of the oil distribution system are improved.

Owner:JIALI GRAIN & OIL TIANJIN

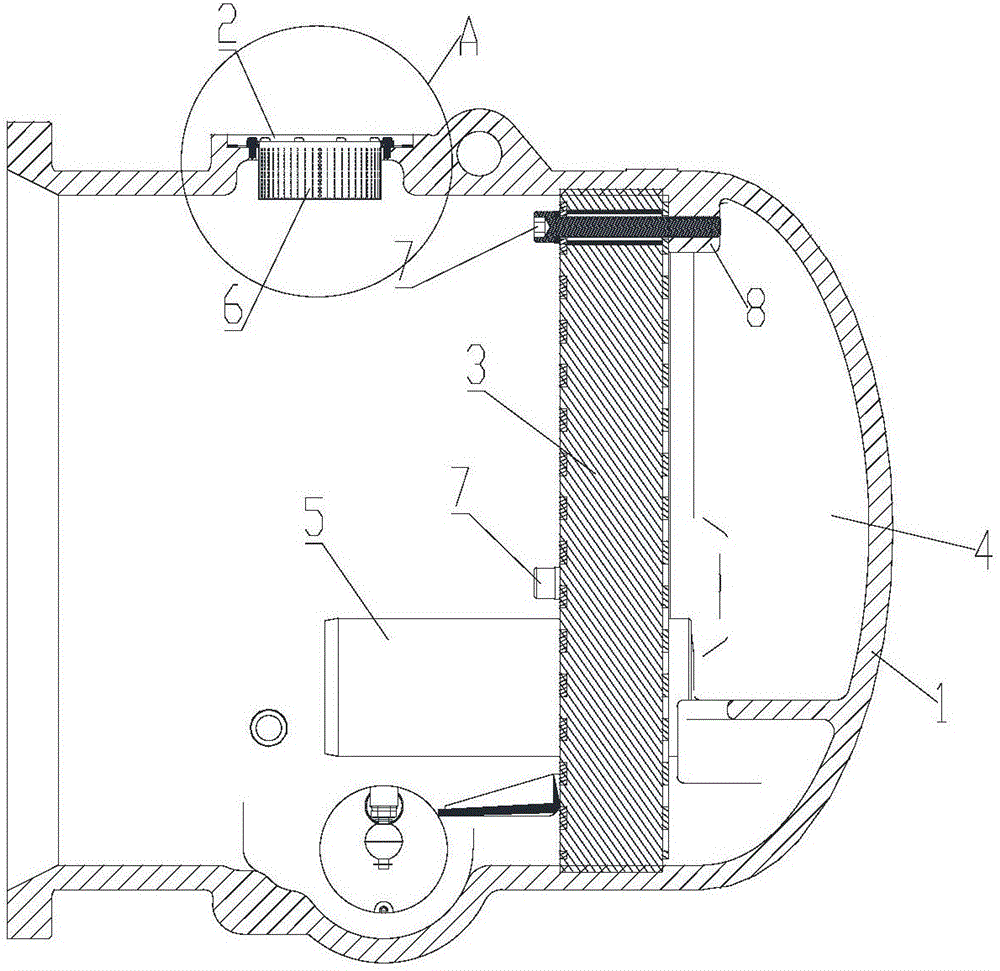

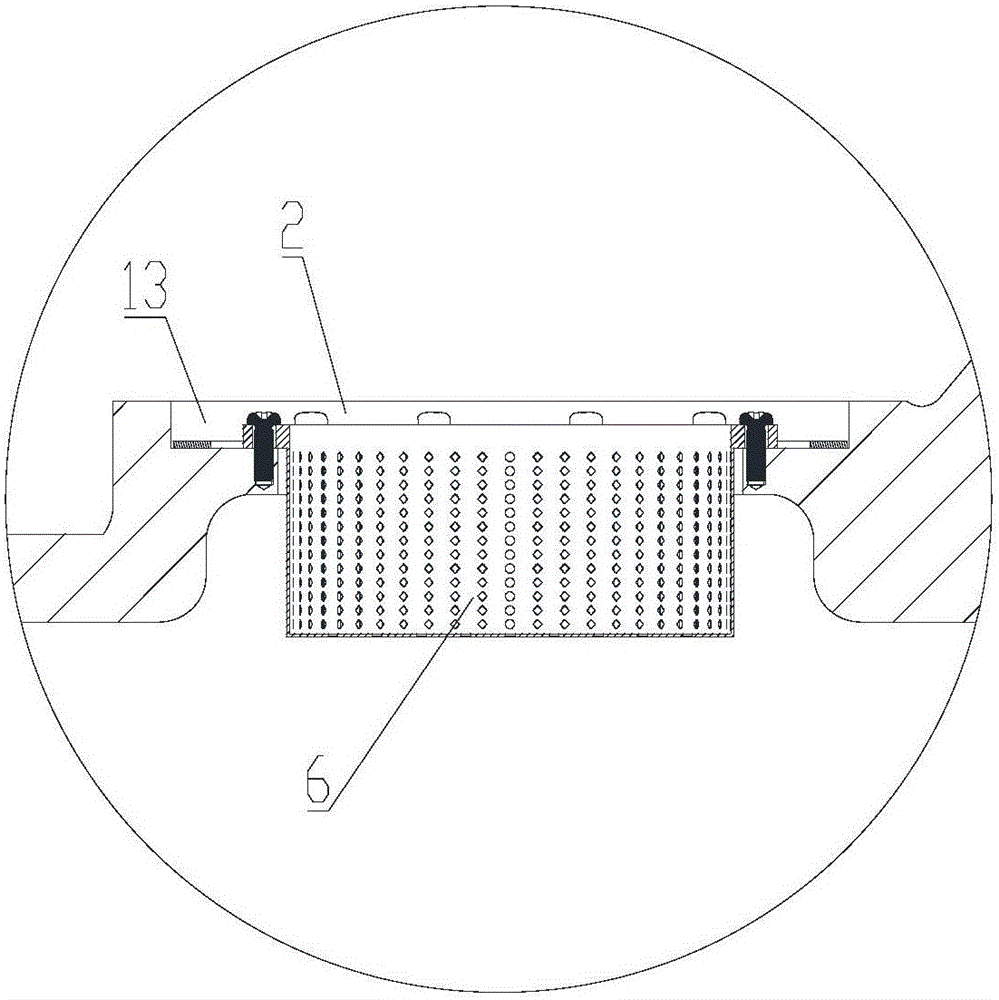

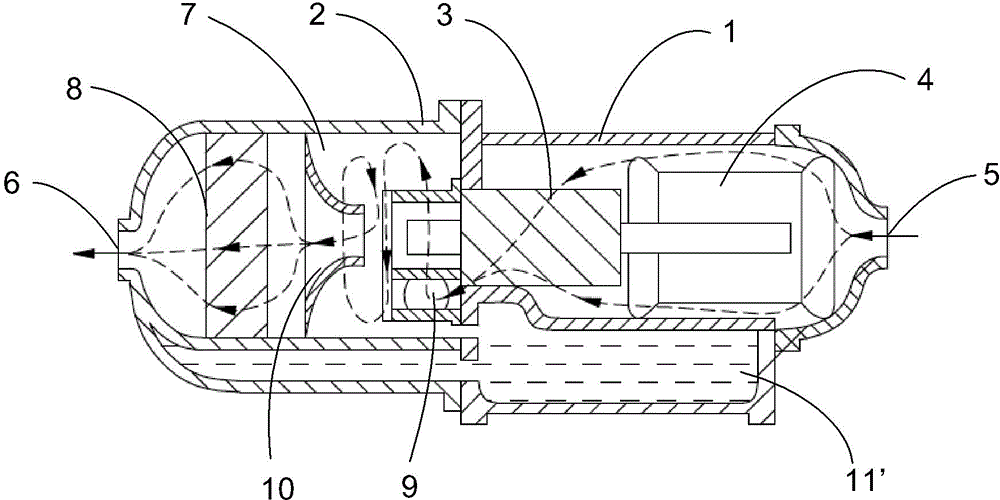

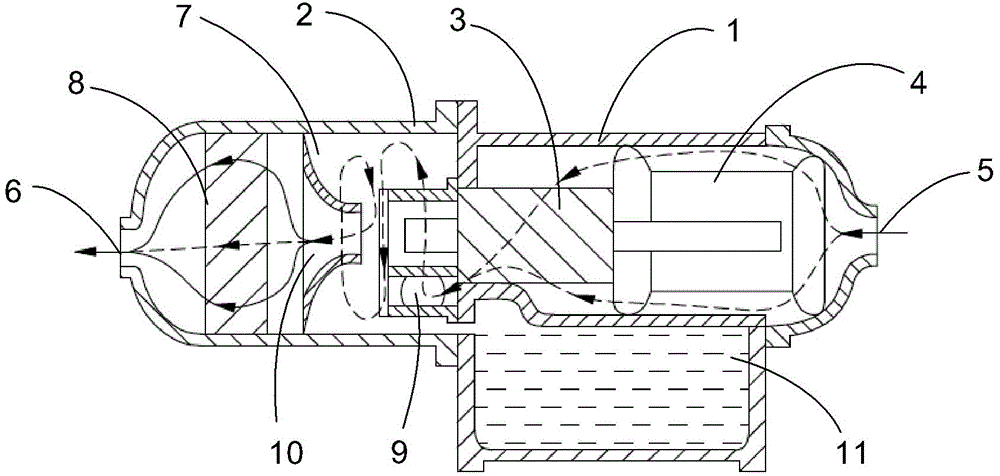

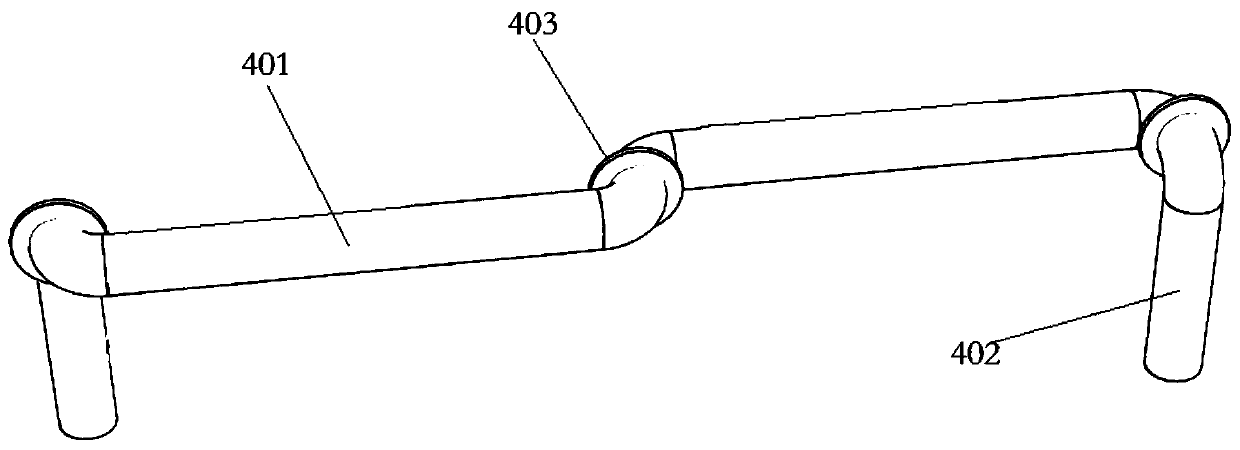

Oil separation bucket, screw compressor and air conditioner

PendingCN107917082AImprove oil separation efficiencyImprove efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsOil separationAir compressor

The invention relates to an oil separation bucket, a screw compressor and an air conditioner. The oil separation bucket comprises an end cap, an oil separation filter screen arranged in the oil separation bucket, and a separation cavity formed between the oil separation filter screen and the end cap. The side, close to the oil separation filter screen, of the separation cavity is provided with a flow guiding ring which is used for guiding gas discharged through an exhaust pipe of the compressor to the oil separation filter screen. By arranging the flow guiding ring on the side, close to the oil separation filter screen, of the separation cavity of the oil separation bucket, on the one hand, a mixed gas of a coolant and refrigerant oil is more uniform through the flow guiding ring, and on the other hand, the mixed gas which flows along the inner wall of the oil separation bucket originally flows to the center of the oil separation bucket, so that the oil separation efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

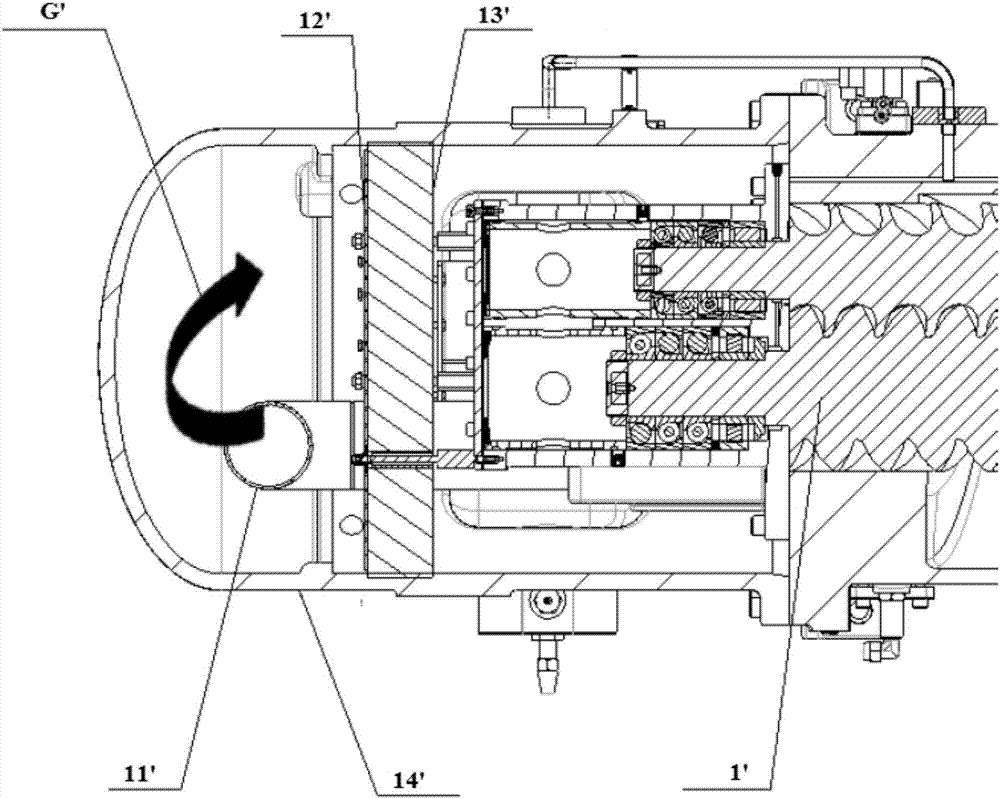

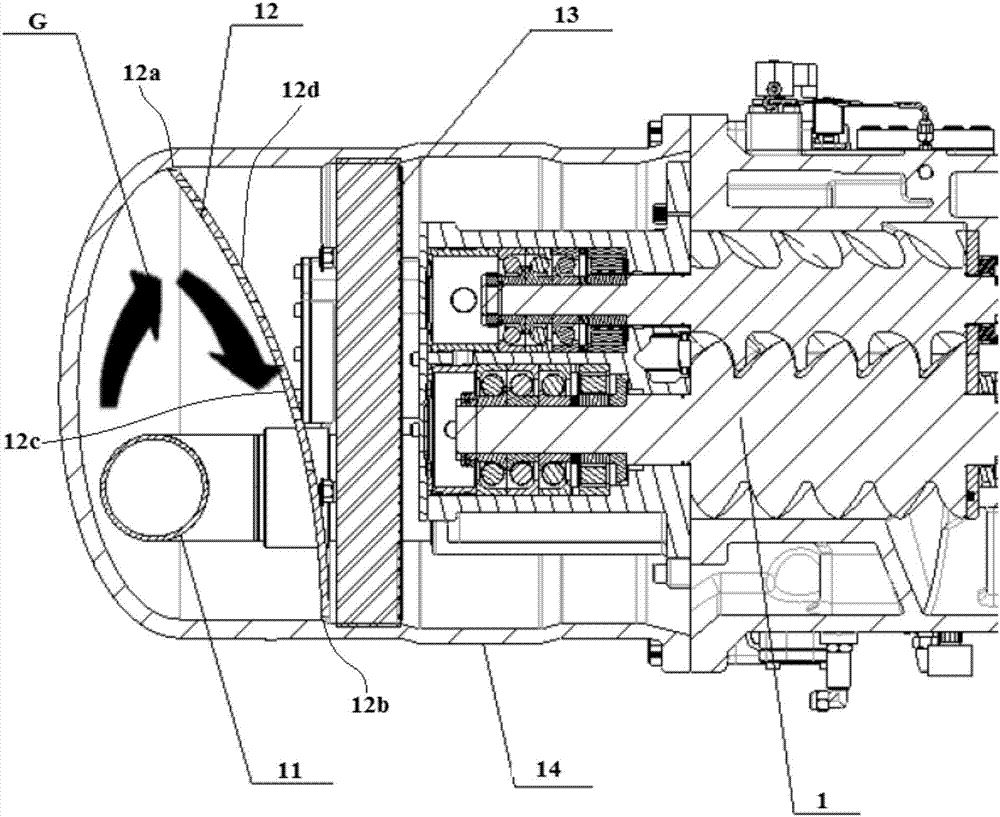

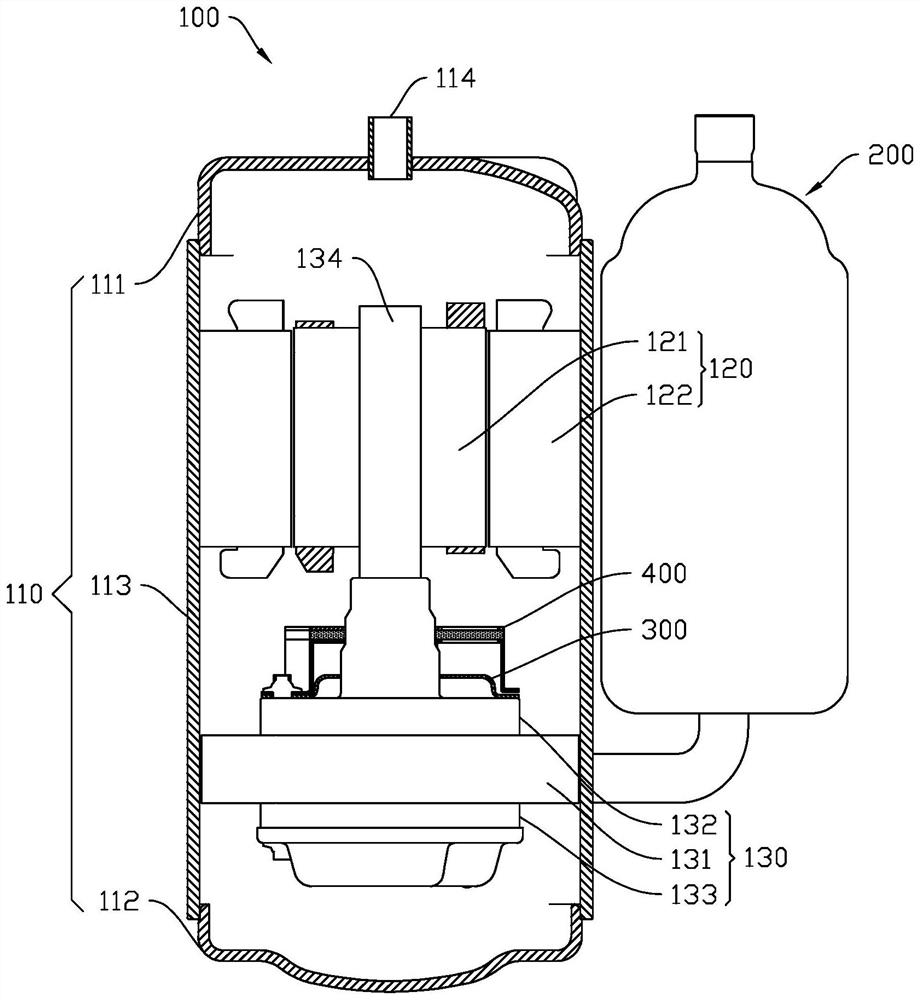

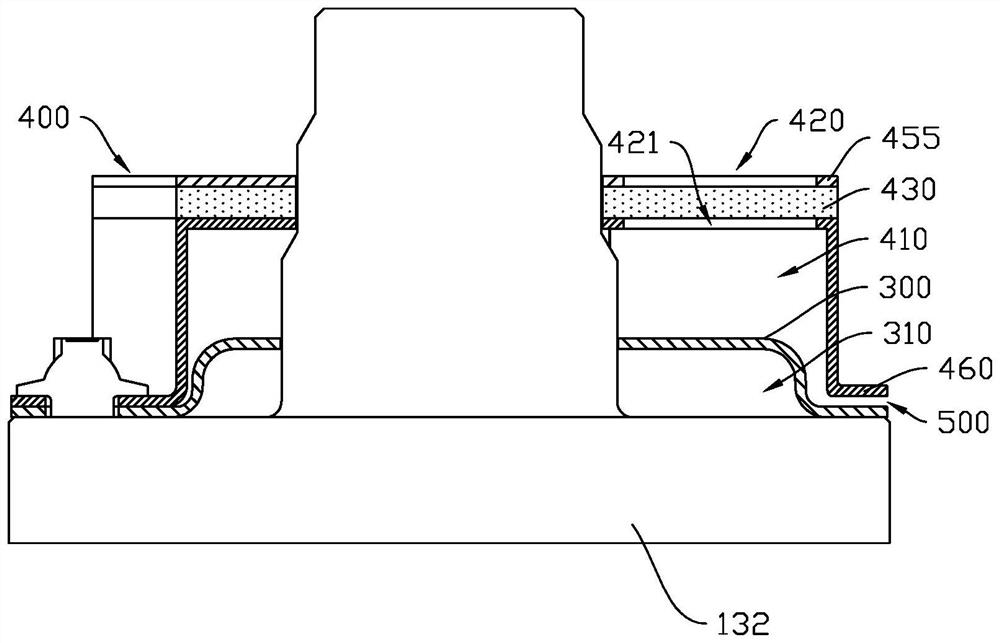

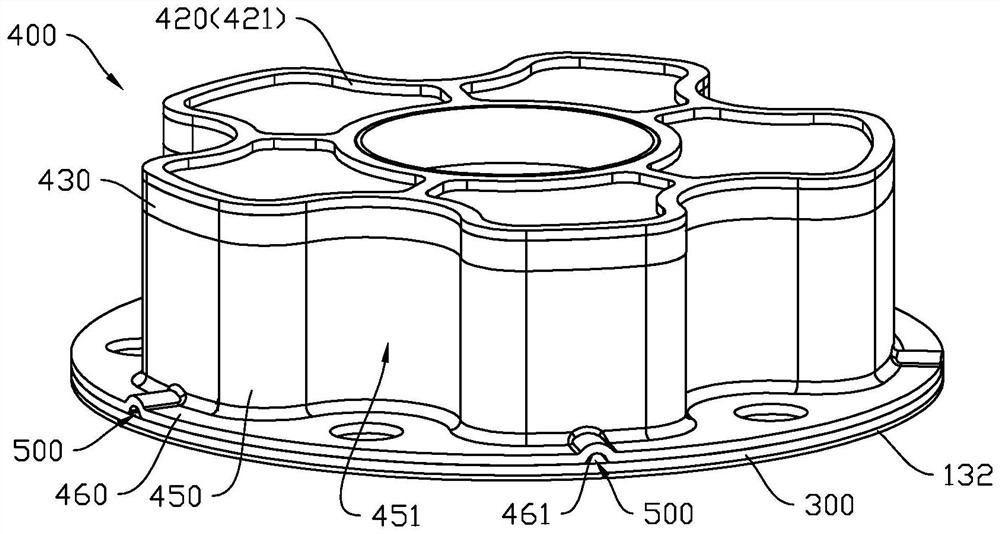

An oil separation device, a screw compressor and an air conditioning system

ActiveCN106678046BReduce cloggingExtend effective lifeRotary/oscillating piston pump componentsLiquid fuel engine componentsGas compressorOil separation

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Multifunctional integrated oil-mud-water separation device

PendingCN113087184ASpeed up poolingEasy to separateWater/sewage treatment by centrifugal separationWater contaminantsOil separationSewage

The invention discloses a multifunctional integrated oil-mud-water separation device, which comprises a bottom plate, wherein the top end of the bottom plate is fixedly connected with a device shell, and the interior of the device shell is fixedly connected with an oil separation tank. The device shell is arranged, the oil separation tank is arranged in the device shell, a piston is slidably connected to the inner side of the oil separation tank, sewage in the oil separation tank is centrifuged through a centrifugal rotating disc on the inner side of the piston, collection of oil in the sewage is accelerated, and finally the oil enters the oil separation tank through an oil discharge pipe under pushing of the piston, so that separation of an oil layer is accelerated, and the oil separation efficiency is improved; and an electric valve is arranged, after the oil layer is separated, the electric valve at the bottom end of a blow-off pipe is opened, sewage obtained after oil separation in the oil separation tank enters a mud-water separation box through a blow-off hose and a connecting pipe, mud and water are separated through a filter pressing membrane plate in the mud-water separation box, and then the mud-water separation effect is achieved.

Owner:陕西诺金油气工程服务有限公司

Compressor and refrigeration equipment

PendingCN113958503AImprove oil separation efficiencyReduce oil outputRotary/oscillating piston pump componentsLiquid fuel engine componentsOil separationRefrigerant

The invention discloses a compressor and refrigeration equipment. The compressor comprises a pump body assembly, a silencer and an oil separation structure, wherein the pump body assembly is provided with an exhaust port, the silencer covers the exhaust port and is provided with a discharge port, the oil separation structure covers the air outlet side of the discharge port and forms a containing cavity, the oil separation structure is provided with an exhaust channel and a filtering piece located in the exhaust channel, an oil discharge channel is arranged at the joint of the silencer or the pump body assembly and the oil separation structure, and the oil discharge channel communicates with the containing cavity and the interior of a shell of the compressor. According to the compressor and the refrigeration equipment, the oil separation structure is arranged, a mixture discharged from the discharge port is diffused into the containing cavity and is discharged out of the oil separation structure after passing through the filtering piece of the exhaust channel, so that refrigeration oil and a gaseous refrigerant in the mixture are effectively separated, moreover, the refrigeration oil separated in the containing cavity can flow back to the joint under the action of gravity and flows back to an oil pool of the compressor through the oil discharge channel in time, so that the backflow speed of the refrigeration oil is increased, and the operation reliability of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

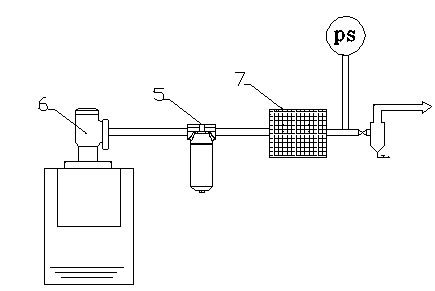

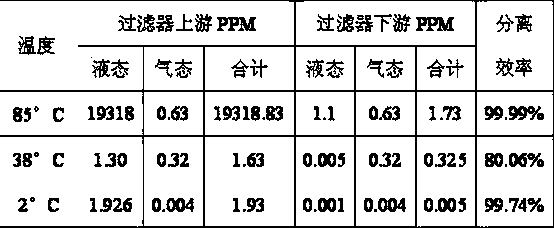

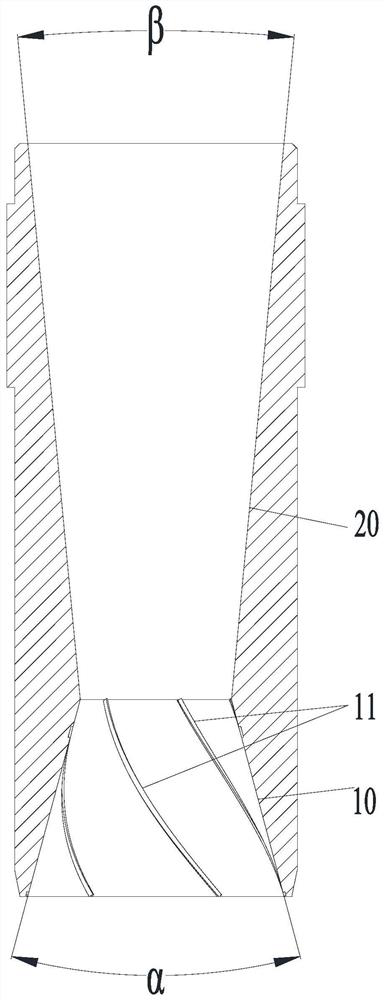

Precise oil-gas separation device and application of precise oil-gas separation device in screw-type compressor

InactiveCN103527488ALow input costImprove oil separation efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsFiberInlet channel

The invention relates to a precise oil-gas separation device and application of the precise oil-gas separation device in a screw-type compressor. The precise oil-gas separation device comprises an upper cover, a barrel body and a filtering core, wherein the upper cover is provided with an air inlet and an air inlet channel which are isolated from each other as well as an air outlet and an air outlet channel which are isolated from each other; the filtering core is hollowly tubular; a condensation fiber net is arranged on the inner wall / outer wall of the hollowly tubular filtering core; a foldable type filtering layer is clamped between the inner wall and the outer wall of the hollowly tubular filtering core; the upper cover is connected with the barrel body through threads; the filtering core is positioned between the upper cover and the barrel body; the bottom of the filtering core is positioned on an oil outlet seat at the bottom of the barrel body; a pipe neck of the filtering core is sleeved on a vertical downward section of the air inlet channel of the upper cover. The precise oil-gas separation device has the advantages that (1) the oil separation rate of the precise oil-gas separation device can reach 99.74% to 99.99%, so that the oil separation efficiency is high and the investment cost of user equipment is lowered; (2) the oil content of compressed air discharged from the screw-type compressor on which the precise oil-gas separation device is mounted is commonly decreased from 3PPM / M<3> to a range within 0.001PPM / M<3> to 0.002PPM / M<3>. Thus, the screw-type compressor can be used for replacing an oilless compressor or is directly used as a low-pressure compressor.

Owner:德哈哈压缩机(上海)有限公司

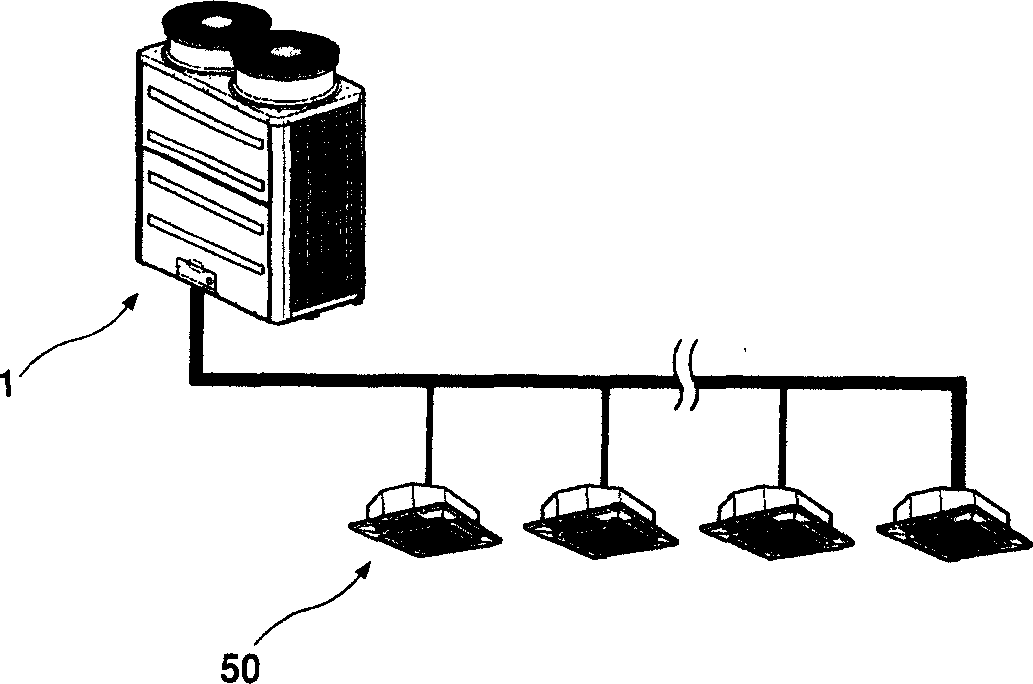

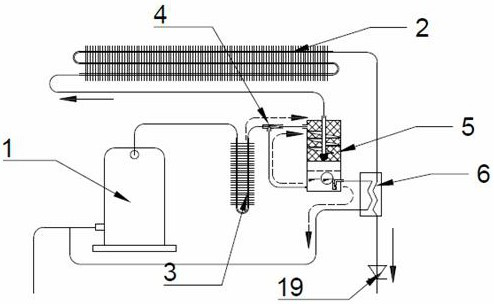

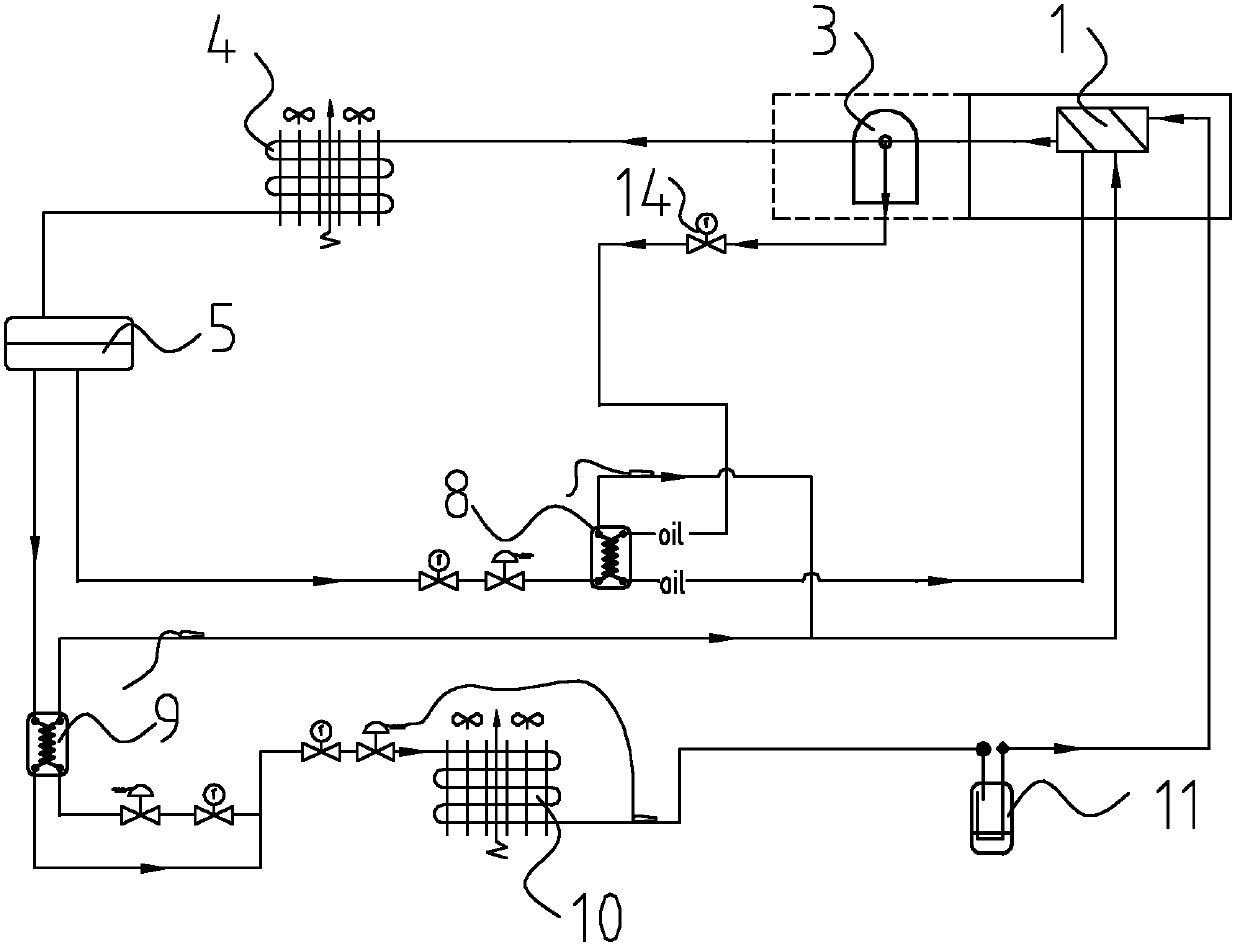

An air conditioner host with oil separation function, an air conditioner system and an oil separation method

ActiveCN111059806BIncrease the installation distanceImprove oil separation efficiencyMechanical apparatusFluid circulation arrangementOil separationAir conditioning

An air-conditioning host with oil separation function, an air-conditioning system, and an oil separation method, comprising a compressor, an ejector connected to the compressor, an oil separator connected to the ejector, and the oil separator The connected condenser is characterized in that a precooler is provided between the ejector and the air outlet of the compressor, and a subcooler is provided between the oil separator and the air inlet of the compressor. The device also includes the main engine of the fluorine pump and the inner unit of the air conditioner. The pre-cooler is set between the compressor and the centrifugal oil separator to supplement the first stage of ordinary oil for rough treatment, and the centrifugal oil separator is then subjected to fine treatment to improve oil separation. Efficiency solves the problem of difficult oil throwing, and lengthens the installation distance of indoor and outdoor units.

Owner:JIANGSU OLYWELL ENVIRONMENTAL EQUIP CO LTD

oil separator

InactiveCN103591741BImprove oil separation efficiencyWith oil storage functionRefrigeration componentsOil separationAir conditioning

The invention provides an oil separator. The oil separator comprises a cylinder body, an air inlet pipe, an air outlet pipe and an oil return pipe. The top of the cylinder body is provided with a first through hole, and the bottom of the cylinder body is provided with a second through hole; the air inlet pipe and the air outlet pipe extend inside the cylinder body through the first through hole and the second through hole respectively; the bottom of the cylinder body is provided with a third through hole, and the oil return pipe extends inside the cylinder body through the third through hole. The oil separator also comprises a filtering device and an oil retaining device which are sequentially arranged inside the cylinder body from top to bottom, the filtering device is arranged at the air outlet end of the air inlet pipe, and the air outlet pipe extends inside the oil retaining device. According to the above structure of the oil separator, the filtering device and the oil retaining device achieve double oil separation, so that the oil separation efficiency is higher and meanwhile the oil storage function can be obtained. By means of a vertical type structure, the oil separator has relatively large capacities, thereby being applicable to large air conditioning systems.

Owner:GREE ELECTRIC APPLIANCES INC

Compressor with lubricating oil self-cooling function and air conditioning system

PendingCN110332113ATroubleshoot access to air conditioning systemsReduce trafficCompressorRotary piston pumpsGas compressorEngineering

The invention provides a compressor with a lubricating oil self-cooling function and an air conditioning system. The compressor comprises a compressor body and further comprises a heat exchange channel, wherein a cooling oil path is arranged in the compressor body; and the heat exchange channel is arranged in a gas suction cavity of the compressor body. By the adoption of the compressor with the lubricating oil self-cooling function and the air conditioning system, high-temperature lubricating oil can preferentially pass through the gas suction cavity for being cooled under the flow guiding action of the heat exchange channel, bearings can be cooled after the high-temperature lubricating oil is cooled, and the problem that the temperature of the lubricating oil for the bearings in the compressor is too high can be effectively solved; furthermore, the problem that in the prior art, the compressor structure is complex due to the additional arrangement of an oil cooling device can be solved; meanwhile, the flow rate of the lubricating oil for the bearings in the compressor can be reduced under the premise that the bearings can be sufficiently cooled when the temperature of the lubricating oil is low enough, and then the energy efficiency of the compressor and the oil separating efficiency can be compressor can be improved; and the problem that the lubricating oil enters the air conditioning system can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

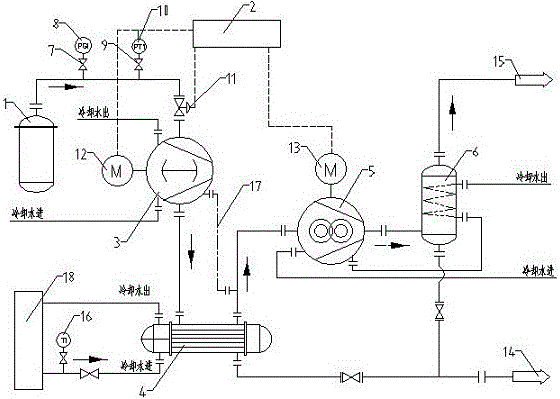

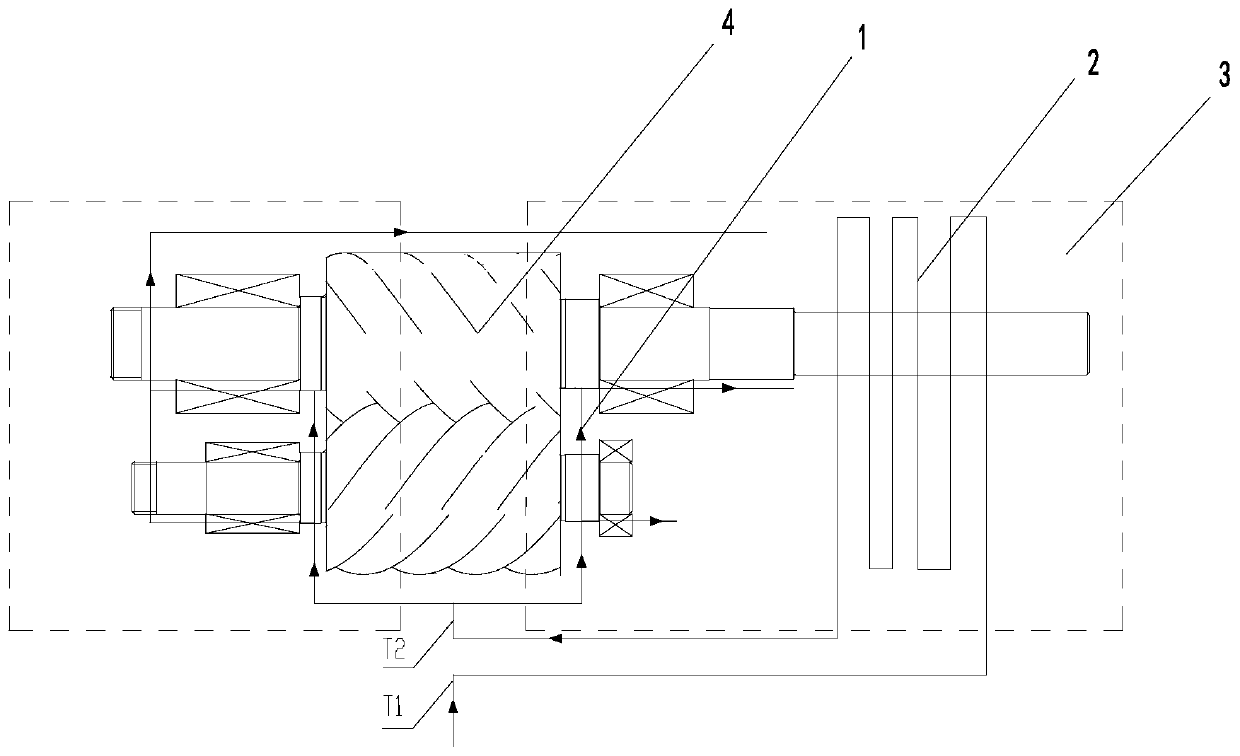

Screw compressor refrigerating system and refrigerating method thereof

ActiveCN102353167BImprove oil separation efficiencyAvailableCompression machines with non-reversible cycleRefrigeration componentsSuper coolingVapor–liquid separator

The invention discloses a screw compressor refrigerating system and a refrigerating method thereof. The screw compressor refrigerating system comprises a compressor, an internal oil separator, an external oil separator, a condenser, a liquid reservoir, an oil cooling heat exchanger, a super-cooling heat exchanger, an evaporator, a gas liquid separator, an oil reservoir, a low-oil-level alarm and a time delay unit, wherein a refrigeration oil outlet of the internal oil separator is connected with an inlet of the oil reservoir; an oil outlet of the external oil separator passes through an electromagnetic valve B and then is connected with the oil reservoir; and the low-oil-level alarm is arranged on the oil reservoir. Oil separation is realized by arranging the external oil separator, the internal oil separator has an oil separation function without any modification of the compressor, and refrigeration oil which cannot be separated by using the internal oil separator is secondarily separated in the external oil separator, so that oil separation efficiency is improved, and the internal compressor is available in a special working condition.

Owner:PANASONIC APPLIANCES REFRIGERATION SYST DALIAN CO LTD

Oil and gas separation units, compressors and air conditioning systems

ActiveCN106949063BSolve uneven distributionIncrease the utilization areaRotary/oscillating piston pump componentsLiquid fuel engine componentsOil separationEngineering

The invention relates to the technical scheme of air conditioners, in particular to an oil-gas separation device, a compressor and an air conditioner system. The oil-gas separation device comprises a perforated plate and a filter net; multiple vent holes which penetrate through a first plate surface and a second plate surface, which are opposite, of the perforated plate are formed in the perforated plate; an air stream emitted from a vent pipe can flow from the side of the first plate surface to the side of the second plate surface through the plurality of vent holes, and flow to the filter net; and besides, the first plate surface is a curve surface which is convex to the side of the filter net, so that the air stream which flows towards the perforated plate from the vent pipe can flow along the first plate surface under guiding of the first plate surface. According to the oil-gas separation device, the air stream is guided to flow along the first plate surface by utilizing the curve surface shape of the first plate surface of the perforated plate, so that the problem in the prior art that the air stream is distributed nonuniformly when impacting on the perforated plate because the perforated plate is flat can be effectively solved; and the utilization area of the filter net is increased, so that oil separation efficiency is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Oil-water mixture oil separation tank and oil separation system for swill separation

ActiveCN110975336BAchieve multiple separationsReduce moisture contentLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesOil separationSwitching signal

The invention discloses an oil-water mixture oil separation tank for swill separation and an oil separation system thereof. The oil-water mixture oil trap for swill separation includes a box body, a partition, a suspension plate, a buffer plate, a touch switch, a drain pipe, a water valve, and a material inlet and outlet controller. The partition divides the box into multiple oil-separating spaces, and two adjacent oil-separating spaces communicate through the upper space of the partition. The suspension board moves to cover the upper space of the corresponding partition, and the density of the suspension board is between the oil density and the water density. The touch switch is located above the corresponding suspension board, and the suspension board can press against the corresponding touch switch, so that the touch switch generates a switch signal. One end of each drainage pipe is arranged in the oil separation space, and the other end is located outside the box. The water valve is used to open or close the corresponding drain pipe. When the input and output controller generates a switch signal by touching the pressure switch, it drives the corresponding water valve to open the corresponding drain pipe. The invention can reduce the water content and improve the purity of oil-water separation.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Exhaust pipe structure and compressor

ActiveCN106762671BLarge runnerAdded collision separation processRotary/oscillating piston pump componentsLiquid fuel engine componentsThermodynamicsOil separation

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com