Screw compressor possessing oil separator and water chilling unit

一种螺杆压缩机、油分离器的技术,应用在压缩机、压缩机、不可逆循环的压缩机器等方向,能够解决油分离效果不佳、油分离效率低、零件数目众多等问题,达到提高安全性和可靠性能、高分油效率、降低制造和安装成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] First of all, it should be noted that the orientation terms such as up, down, front, back, left, right, horizontal and vertical mentioned in this article are relative to the screw compressor with oil separator shown in each drawing. Or its components are defined, they are relative concepts, so they may change accordingly according to their different positions and different usage states. Accordingly, these or other directional terms should not be construed as limiting terms.

[0031] Secondly, it should also be pointed out that for any single technical feature described or implied in the embodiments mentioned herein, or any single technical feature shown or implied in the drawings, these technical features (or their equivalents) can still continue to be combined, so as to obtain more other embodiments of the present invention that may not be directly mentioned herein.

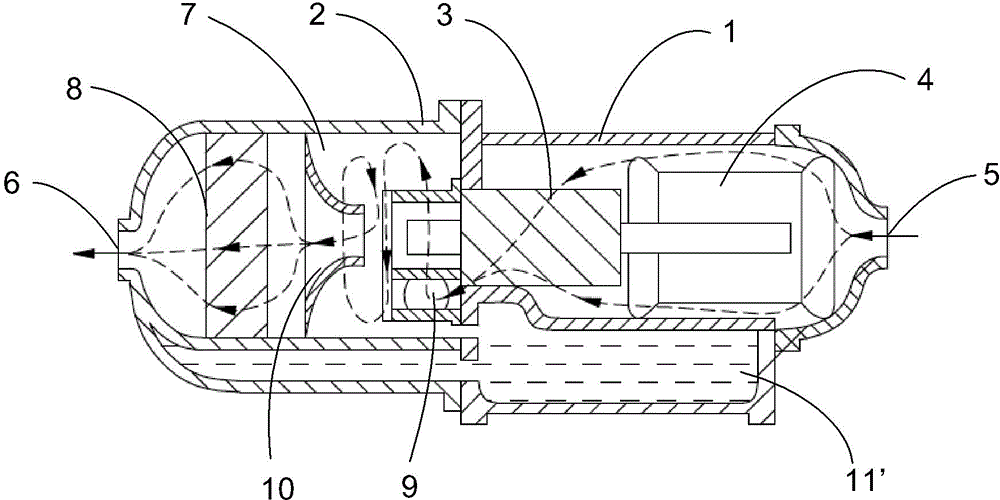

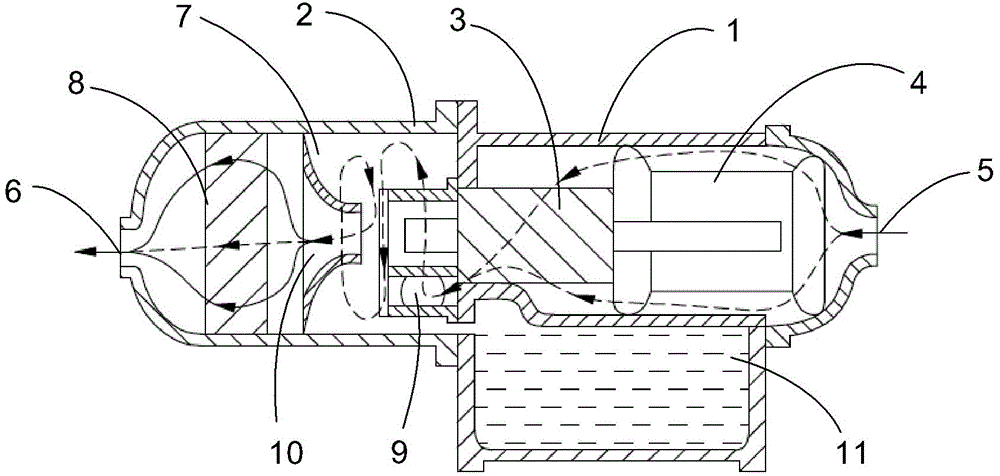

[0032] Please refer to figure 2 , which schematically shows the basic structure of an embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com