Three-stage separated efficient horizontal type oil distribution device

A three-stage separation and horizontal oil technology, which is applied to refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problems of reducing heat transfer effect and refrigeration efficiency, so as to reduce the entry of refrigerated oil into the low-pressure system and improve work efficiency , The effect of improving oil separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

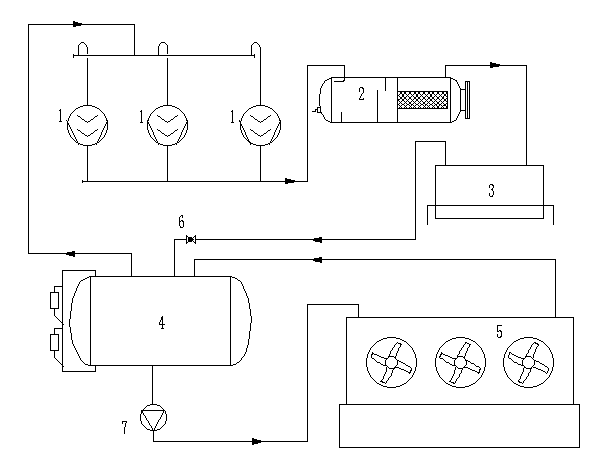

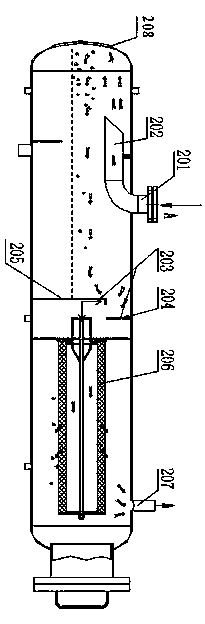

[0012] like Figure 1-2 It shows an embodiment of a three-stage separation type high-efficiency horizontal oil separation device of the present invention: it includes multiple screw compressors 1, and each screw compressor 1 is connected to a horizontal oil separator 2 through an exhaust branch pipe. The inlet and the outlet of the horizontal oil separator 2 are connected to the inlet of the condenser 3 through pipelines, and the outlet of the condenser 3 is connected to a low-pressure circulation barrel 4 through a pipeline, and a throttle is set between the condenser 3 and the low-pressure circulation barrel 4 Valve 6, the bottom of the low-pressure circulation barrel 4 is connected to the evaporator 5 through the fluorine pump 7, the outlet of the evaporator 5 is connected to the low-pressure circulation barrel 4 through a pipeline, and the return pipe of the low-pressure circulation barrel 4 is connected to the compressor 1, horizontal Type oil separator 2 comprises barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com