Power plant condenser vacuum maintaining unit provided with water chilling unit

A technology of chillers and condensers, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of insufficient unit output, increased coal consumption rate for power supply, and reduced vacuum degree, etc., to achieve high motor efficiency, heat transfer, etc. The effect of high efficiency and high sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

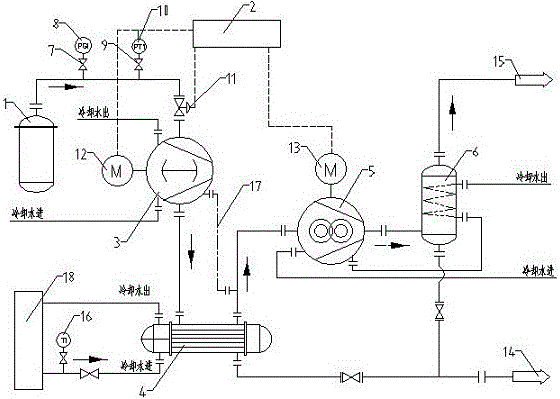

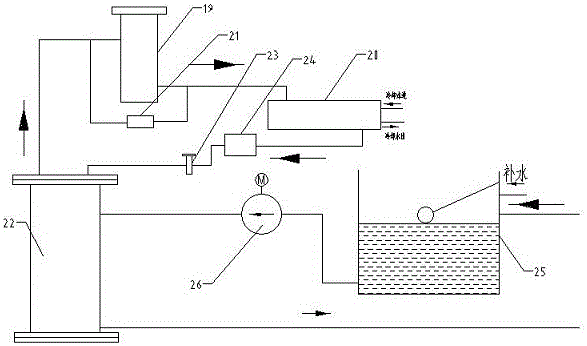

[0032] Examples, as attached figure 1 , attached figure 2 As shown, a power plant condenser vacuum maintenance unit equipped with a chiller unit includes a vacuum pump unit, a cooler 4, a vacuum pipeline, instrument valves, a control system 2 and a chiller 18;

[0033] The vacuum pump unit consists of air-cooled Roots vacuum pump and screw vacuum pump.

[0034] The air inlet of the air-cooled Roots vacuum pump 3 is connected to the condenser 1 through a connecting pipeline, and the connecting pipeline between the air-cooled Roots vacuum pump 3 and the condenser 1 is provided with an intake manual valve 7 and an intake quick disconnect Solenoid valve 9 and automatic valve 11, air intake manual valve 7 are provided with vacuum gauge 8, and intake air quick-break solenoid valve 9 is provided with pressure transmitter 10.

[0035] The air outlet of the air-cooled Roots vacuum pump 3 is connected to the air inlet of the cooler 4 through a connecting pipeline, the air outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com