Precise oil-gas separation device and application of precise oil-gas separation device in screw-type compressor

A technology of screw compressor and separation device, which is applied to parts of pumping devices for elastic fluid, pump parts of rotary piston type/oscillating piston type, mechanical equipment, etc., and can solve the problem of high cleanliness requirements of compressed air , to achieve the effect of reducing input cost and high oil separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

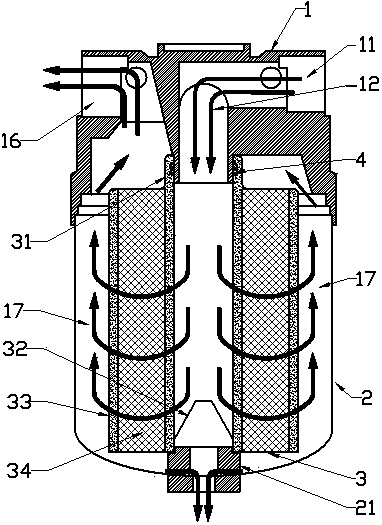

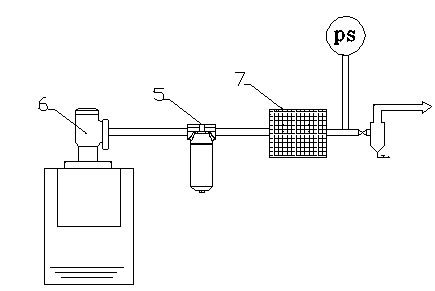

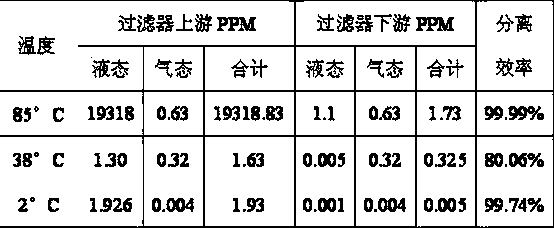

[0012] The specific implementation will be described in detail below in conjunction with the accompanying drawings: Figure 1 ~ Figure 2 One embodiment of the invention is shown. In the figure, a precision oil-gas separation device includes: an upper cover 1, a cylinder body 2, and a filter element 3; the upper cover is provided with an air inlet 11, an air inlet channel 12, an air outlet 16, and an air outlet channel 17 that are mutually isolated , the air inlet 11 is located on one side of the upper cover 1, the air inlet channel 12 is L-shaped, enters the upper cover 1 horizontally through the air inlet, and bends vertically downward at the center of the upper cover 1, and the air outlet 16 is located on the upper cover 1 On the side opposite to the air inlet, the air outlet channel 17 surrounds the vertically downward section of the air inlet channel 12 and communicates with the air outlet 16. The filter element 3 is in the shape of a hollow tube, and the two ends of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com