Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "High-precision movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

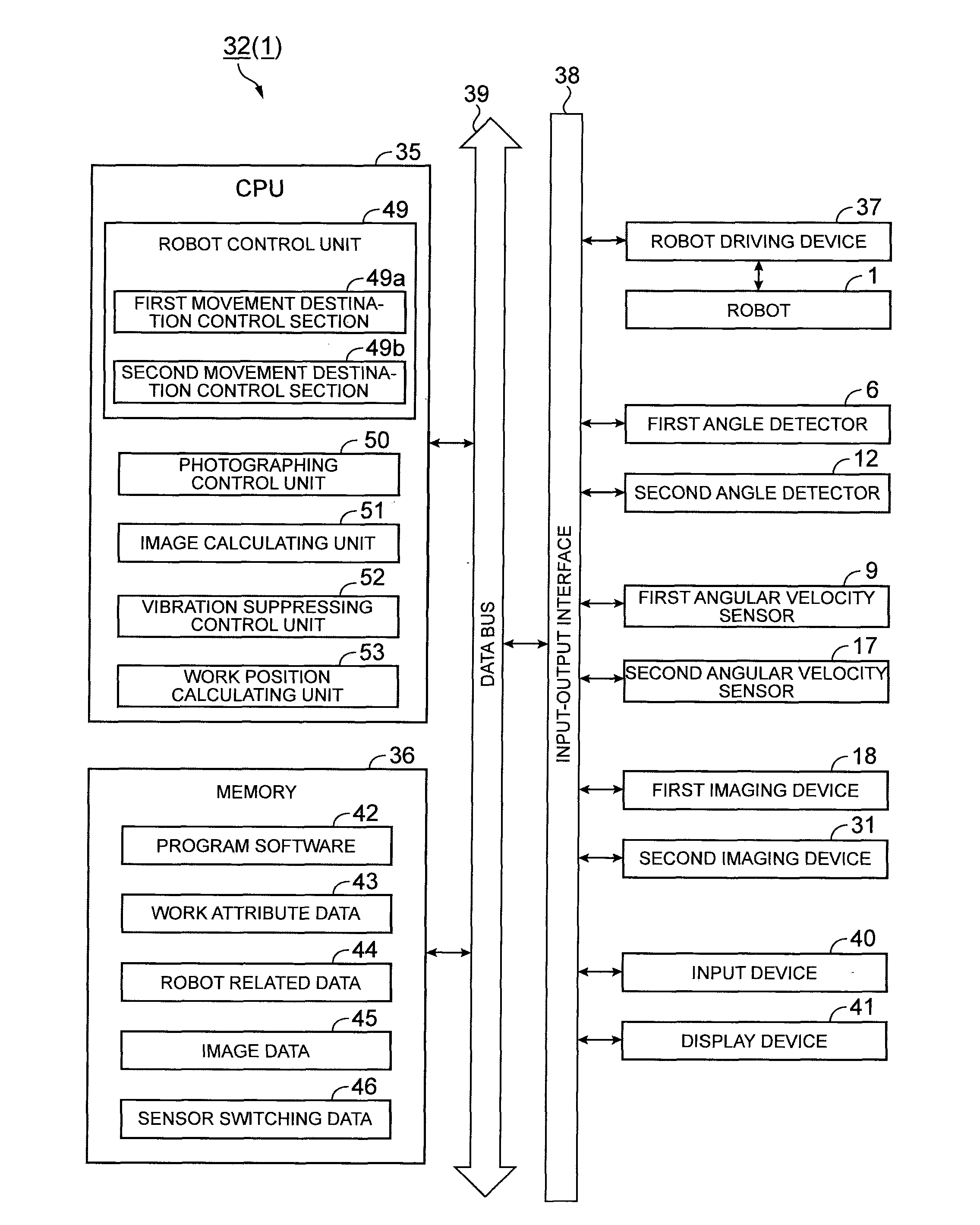

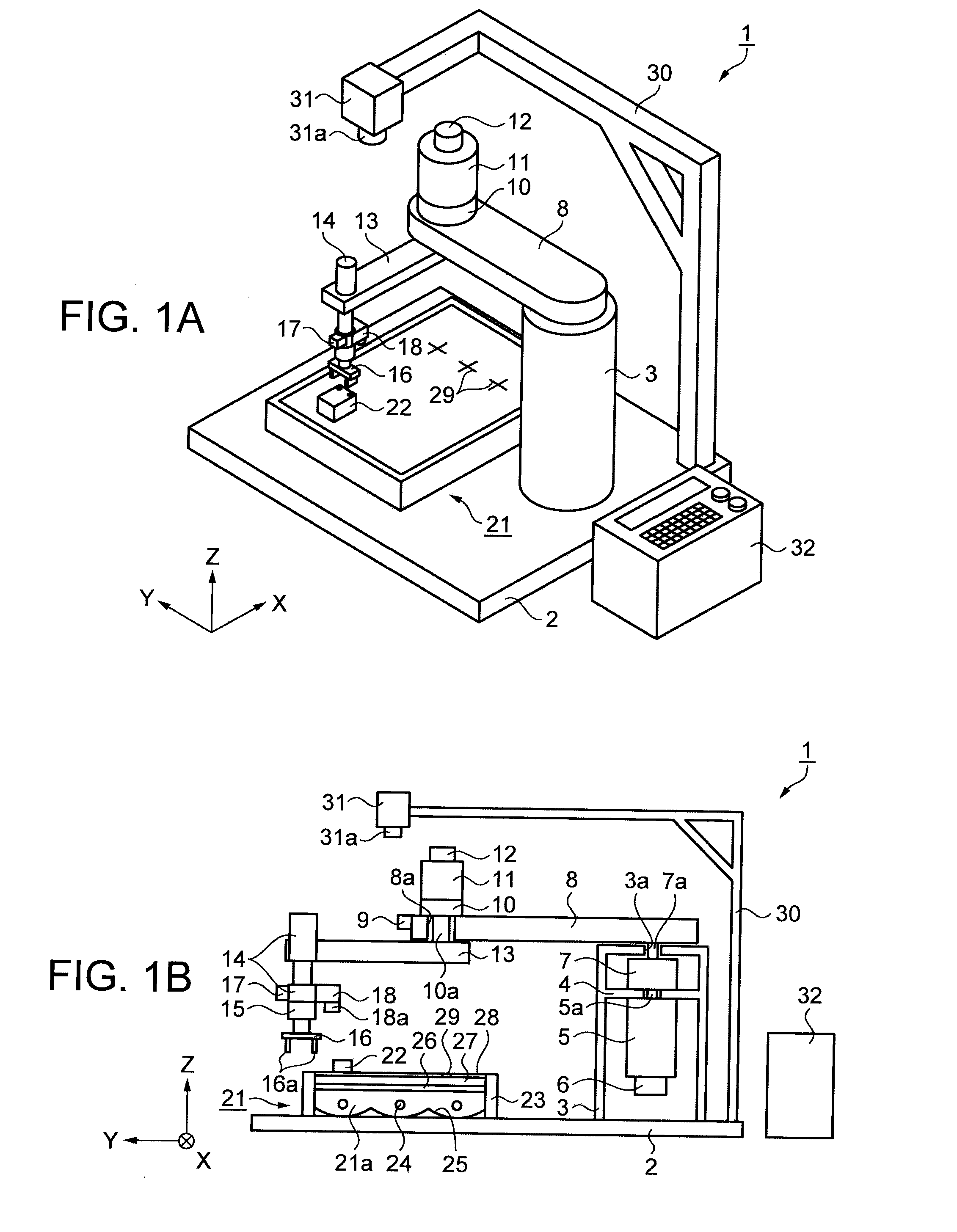

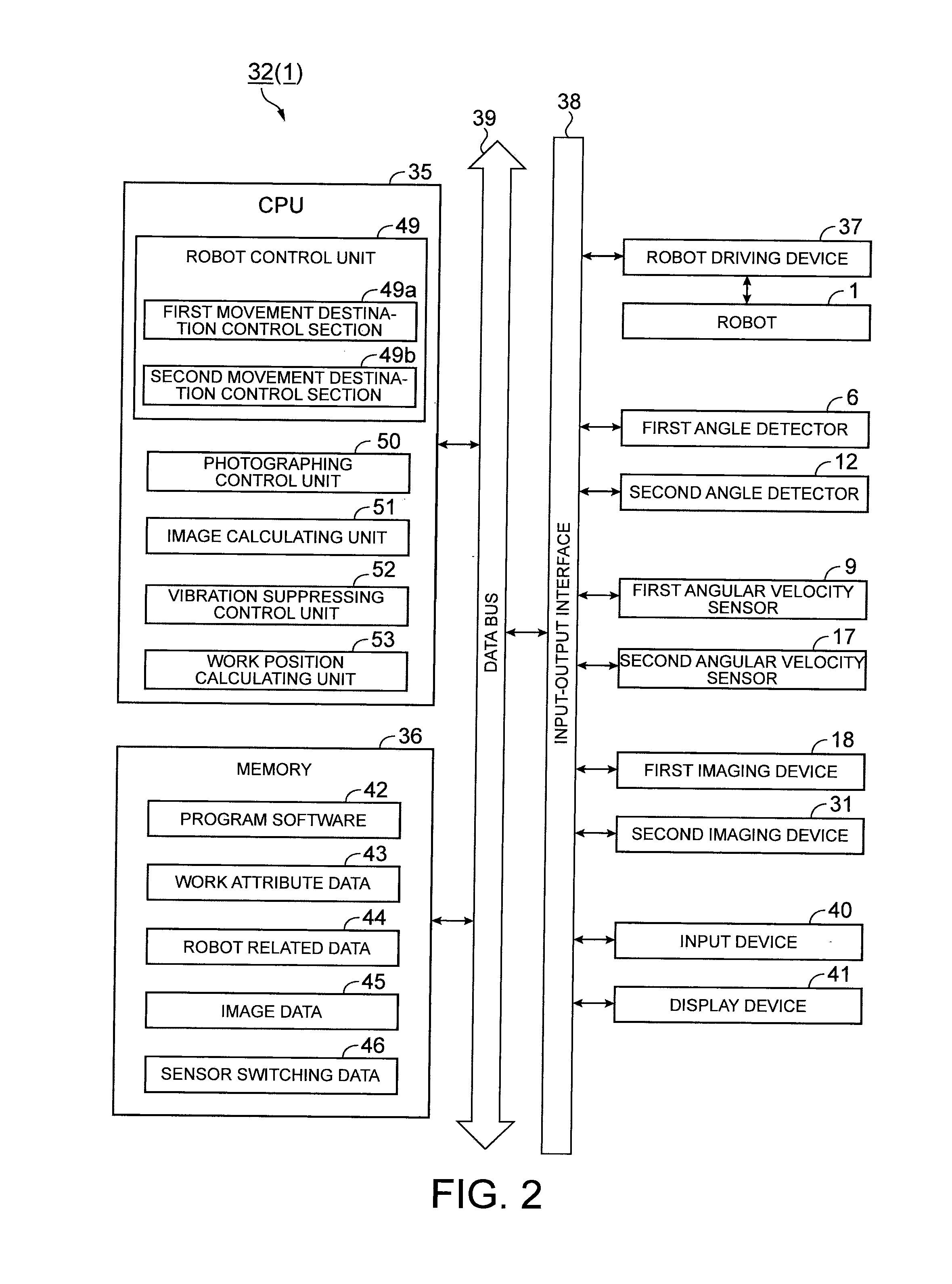

Position control method and robot

ActiveUS20110004343A1Simple configurationQuick controlProgramme-controlled manipulatorTemperatue controlPosition controlRobot

A position control method for controlling a position of a movable portion, includes: performing control of allowing the movable portion to approach a predetermined position by moving the movable portion; and performing control of moving the movable portion to the predetermined position by moving the movable portion and detecting a relative position of the movable portion with respect to the predetermined position by using an imaging unit.

Owner:SEIKO EPSON CORP

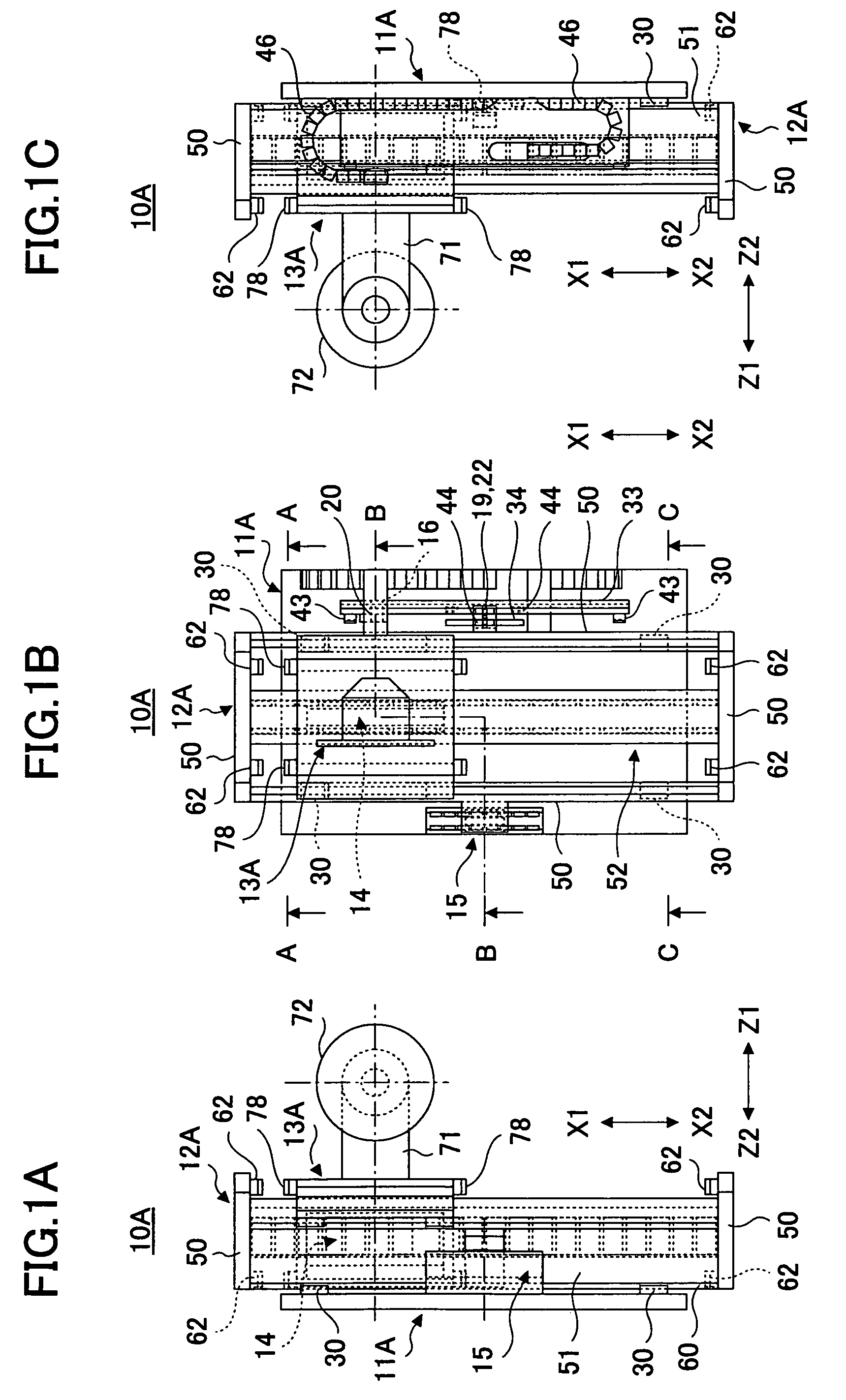

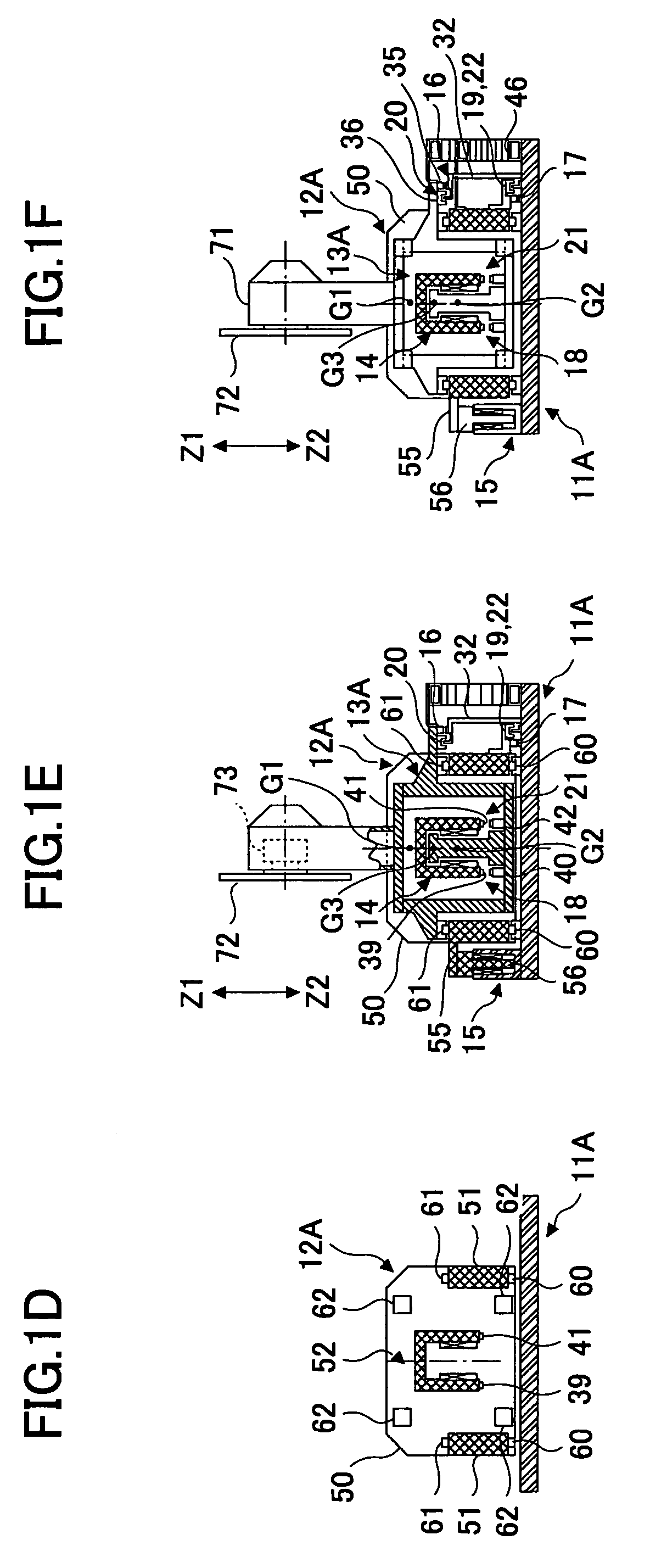

Component feeder

ActiveUS8353424B2Accurately suckImprove accuracyArticle unpackingAdhesivesProduction rateEngineering

A component feeder capable of enhancing productivity is provided by that the component feeder includes a tape feeding device intermittently feeding a component housing tape constituted of a carrier tape having component housing parts formed with predetermined interval to contain respective electronic components, and a cover tape covering the component housing parts to prevent the components from jumping out from the component housing parts while the component housing tape wound on a housing tape reel is sequentially fed to a component extracting position, and an electronic component exposing device exposing the electronic components in the component housing parts to be allowed to be extracted, wherein the tape feeding device is constituted of a first feeding device and a second feeding device, and the electronic component exposing device is provided between the first feeding device and the second feeding device.

Owner:YAMAHA MOTOR CO LTD

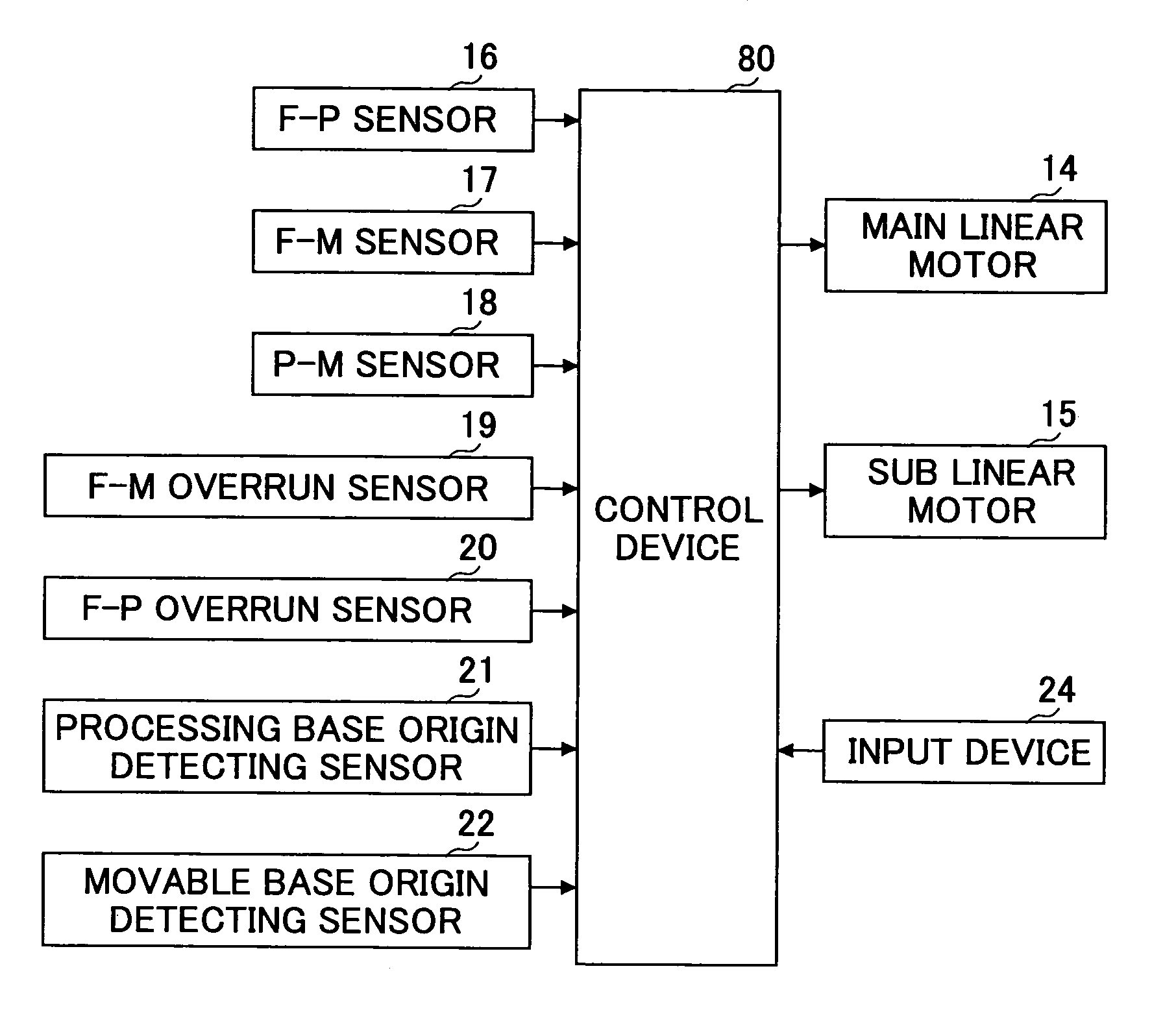

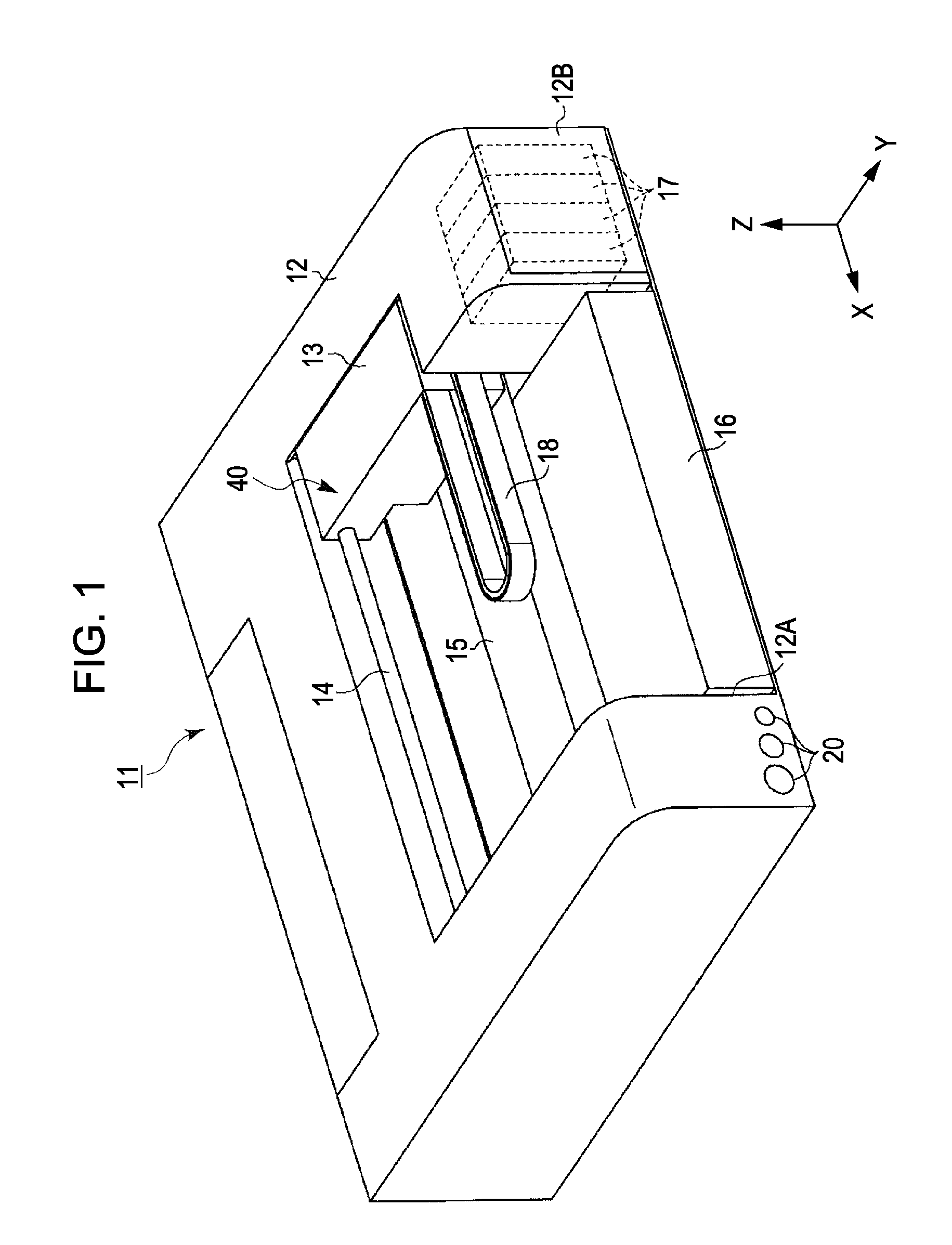

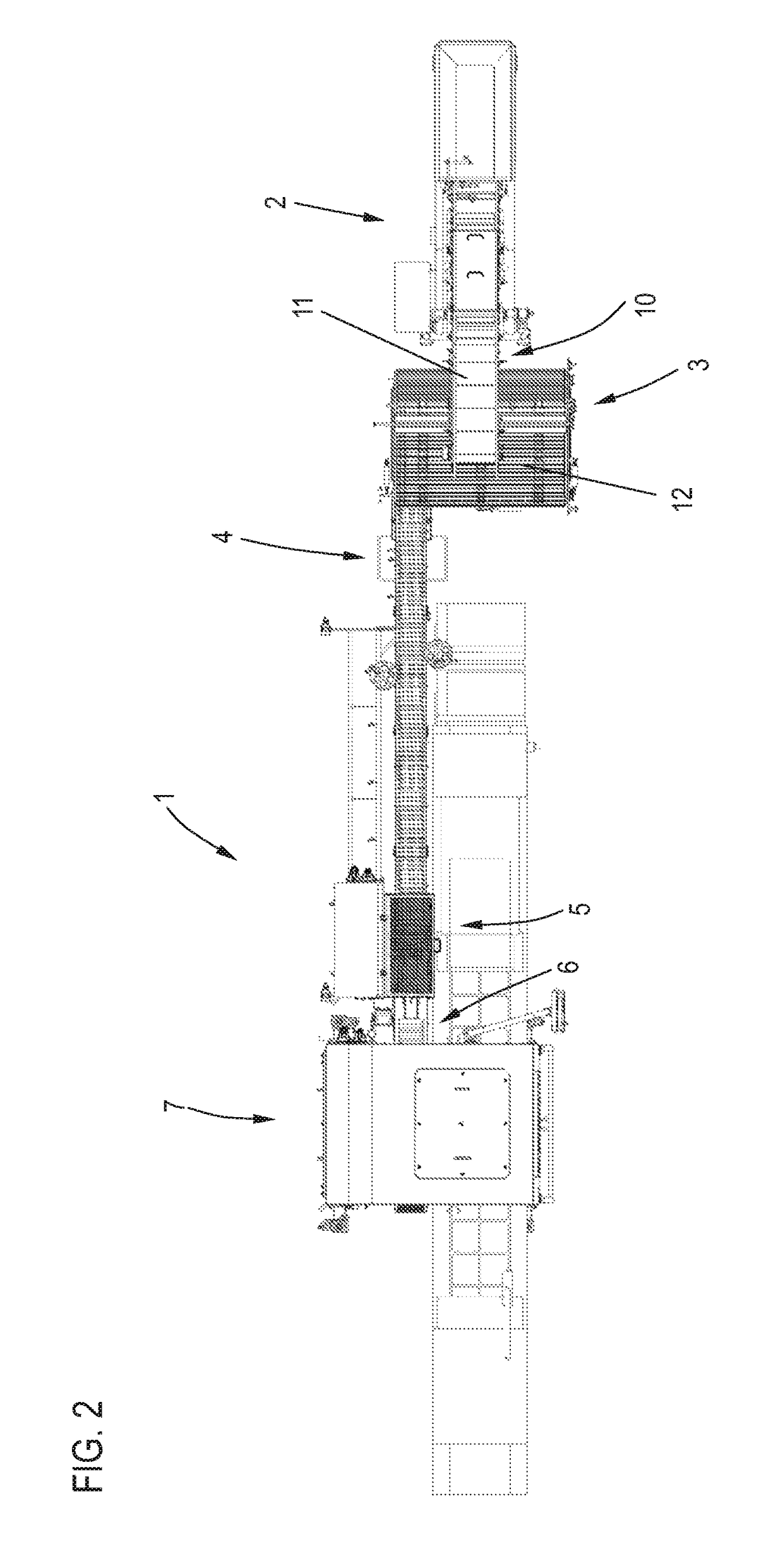

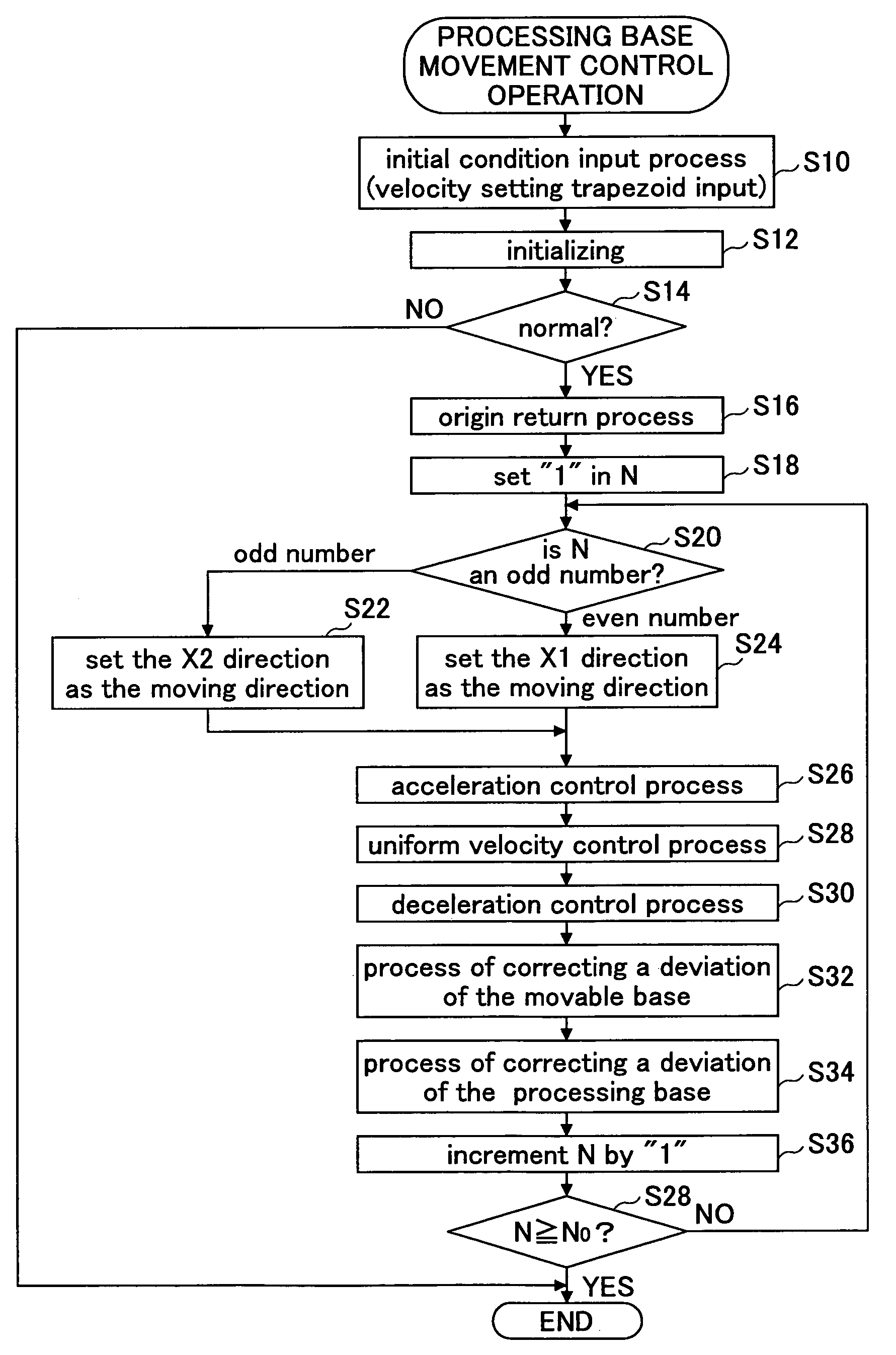

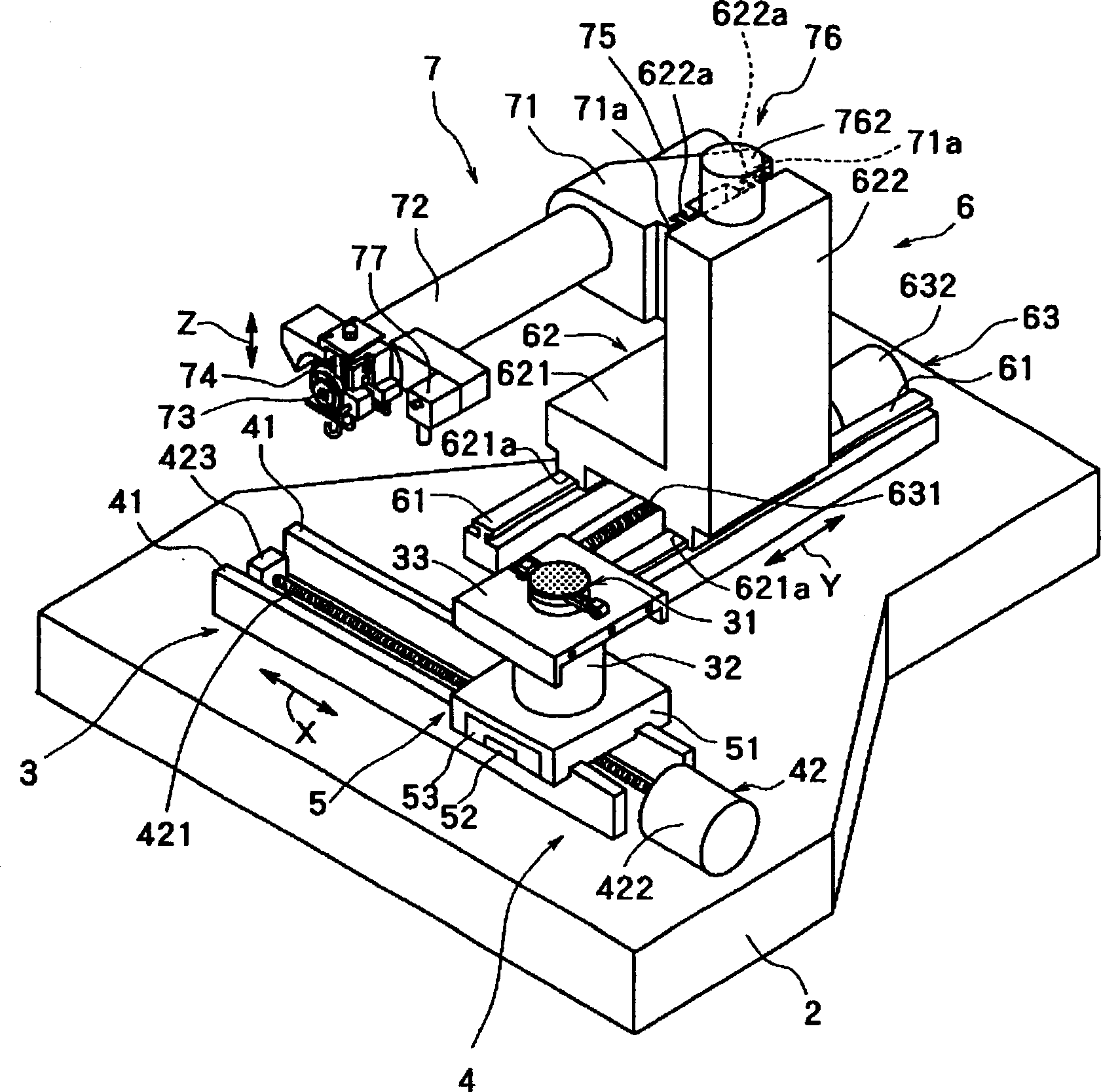

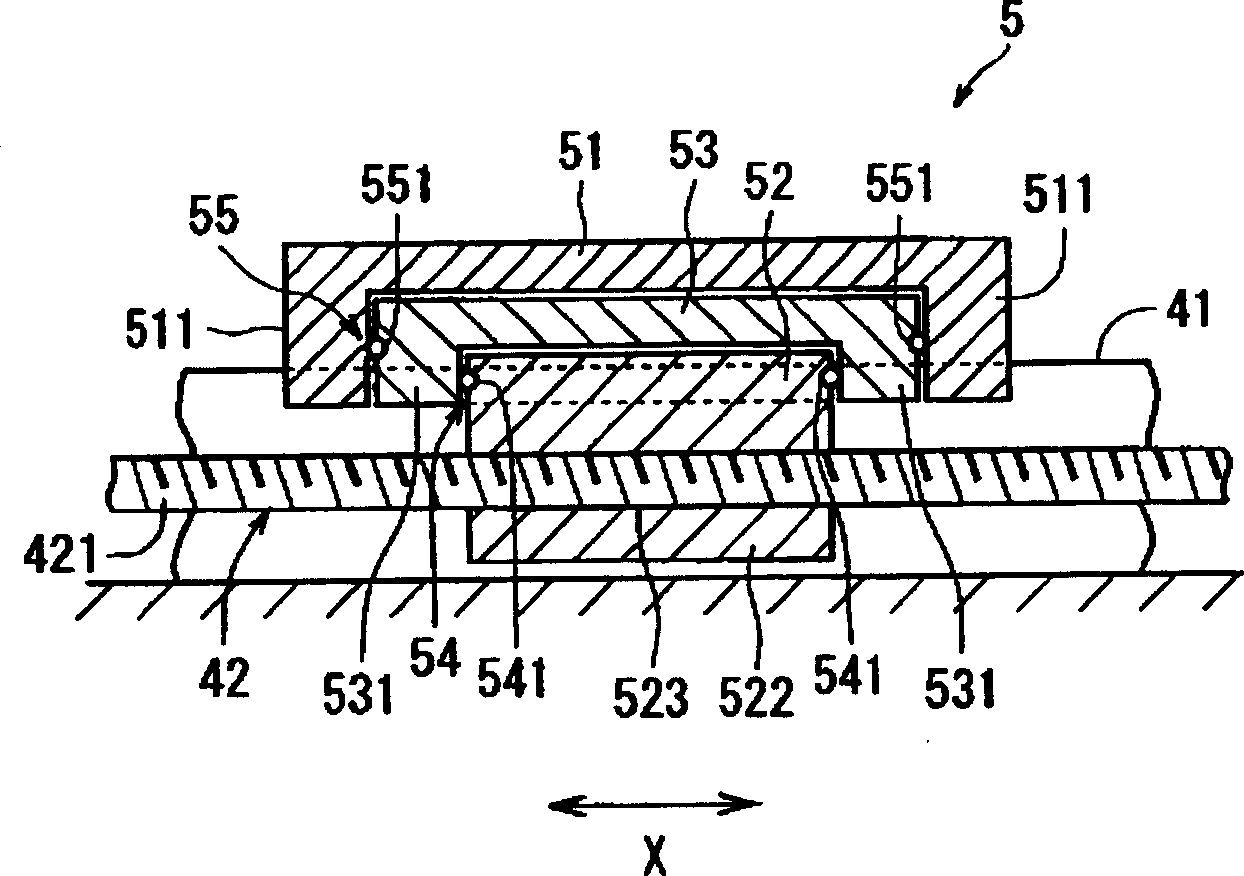

Mover device and semiconductor manufacturing apparatus and method

InactiveUS7187143B2Without undesirable impact and vibration and noiseSmooth movementDC motor speed/torque controlGearingManufactured apparatusEngineering

A mover device and an ion implanter apparatus having a processing base that reciprocates at a high speed without undesirable noise and vibration are provided. The mover device includes: a fixed base; a movable base that is linearly movable with respect to the fixed base; a processing base that is linearly movable with respect to the movable base; a main linear motor that generates a moving force to move the processing base with respect to the movable base, thereby moving the processing base with respect to the fixed base; and a velocity control unit that controls the moving velocity of the processing base with respect to the fixed base. In this mover device, the movable base is moved by virtue of a reaction force caused by the moving force to move the processing base.

Owner:SEN CORP AN SHI & AXCELIS

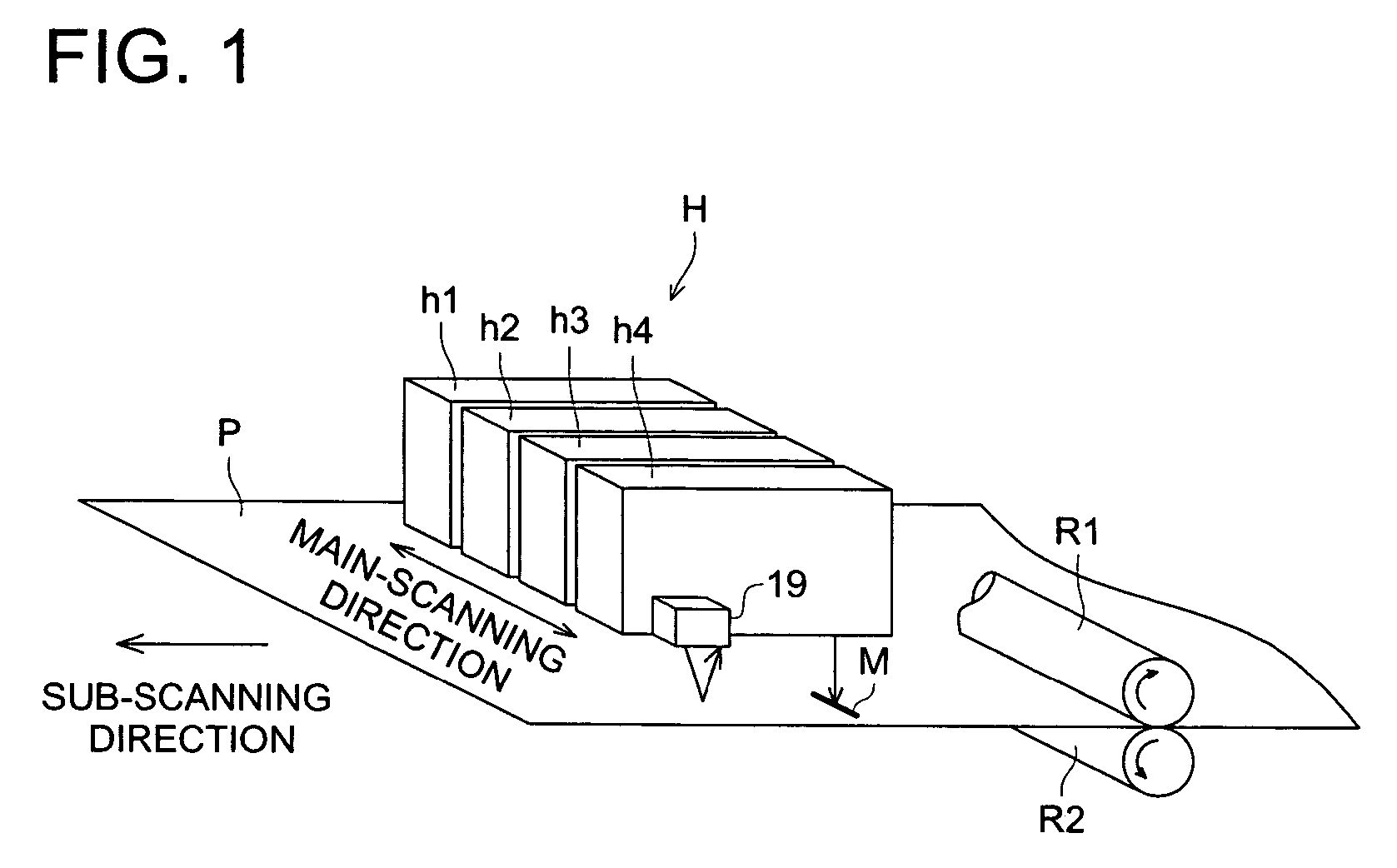

Recording apparatus

ActiveUS20090284556A1High precisionChange in distancePower drive mechanismsOther printing apparatusEmbedded systemRecording head

A recording apparatus includes: a recording head that performs recording on a recording target medium; a driving mechanism that is capable of causing the recording head to move closer to the recording target medium or move away from the recording target medium; and a controlling section that determines driving amount for one driving operation that is performed by the driving mechanism on the basis of results of a comparison made between a first recording head movement direction that is taken or to be taken in the one driving operation and a second recording head movement direction that was taken in another driving operation that is immediately before the one driving operation and thus precedes the one driving operation.

Owner:SEIKO EPSON CORP

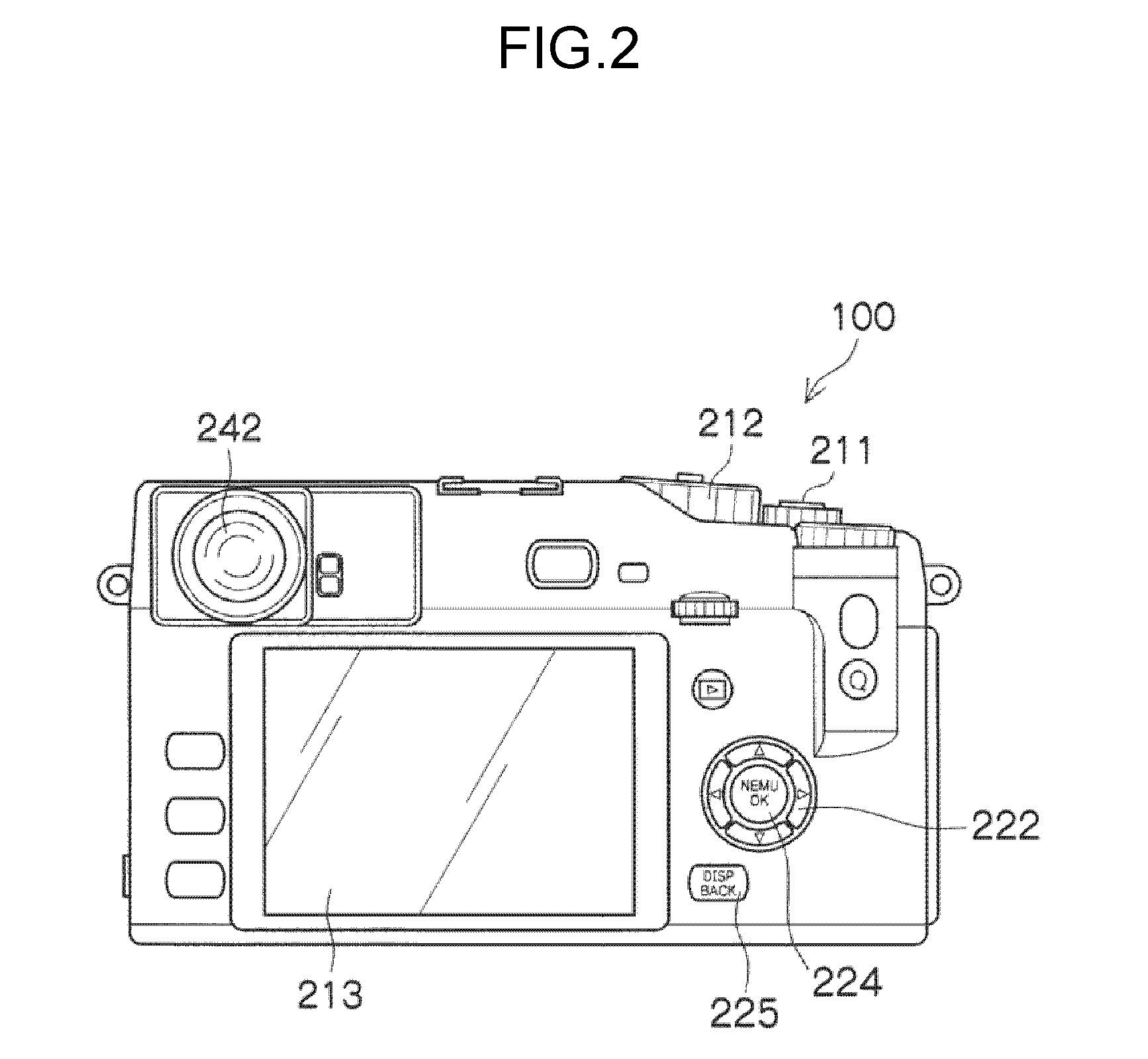

Image processing device, imaging device, image processing method and computer readable medium

ActiveUS20150281560A1High-precision movementTelevision system detailsColor television detailsParallaxImaging processing

An image processing device comprising: a determination section that, based on a factor defining a depth representing a permissible range for acceptable state of focus and on parallax computed by a parallax computation section, determines an operation movement ratio for converting an operation amount, that instructs movement of a focusing lens, into a movement amount of the focusing lens by using a function including the operation movement ratio as a dependent variable and an independent variable determined according to the factor and the parallax; and a control section that controls a movement section to move the focusing lens by an amount equivalent to a movement amount determined based on an operation movement ratio determined by the determination section and the operation amount.

Owner:FUJIFILM CORP

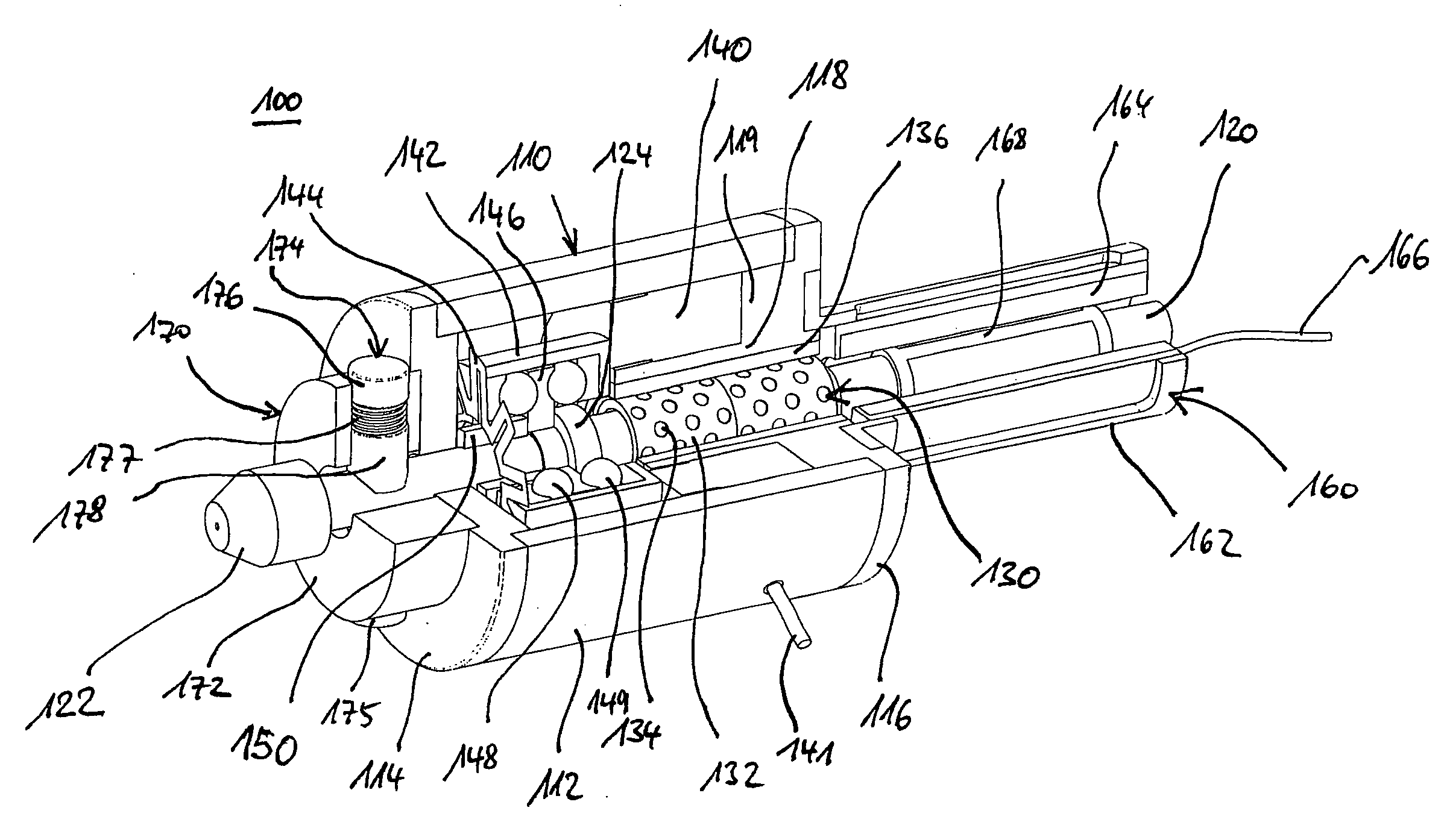

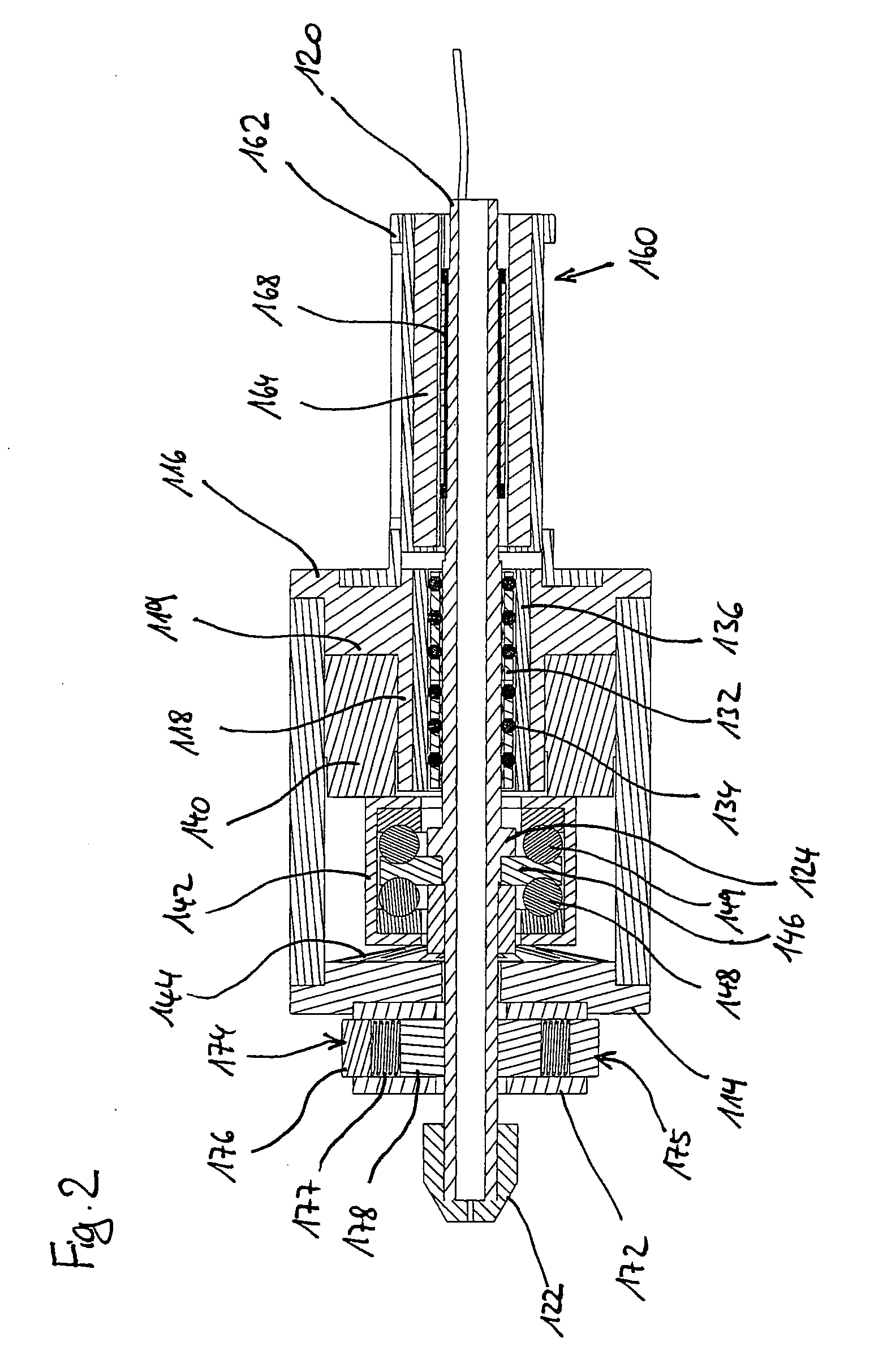

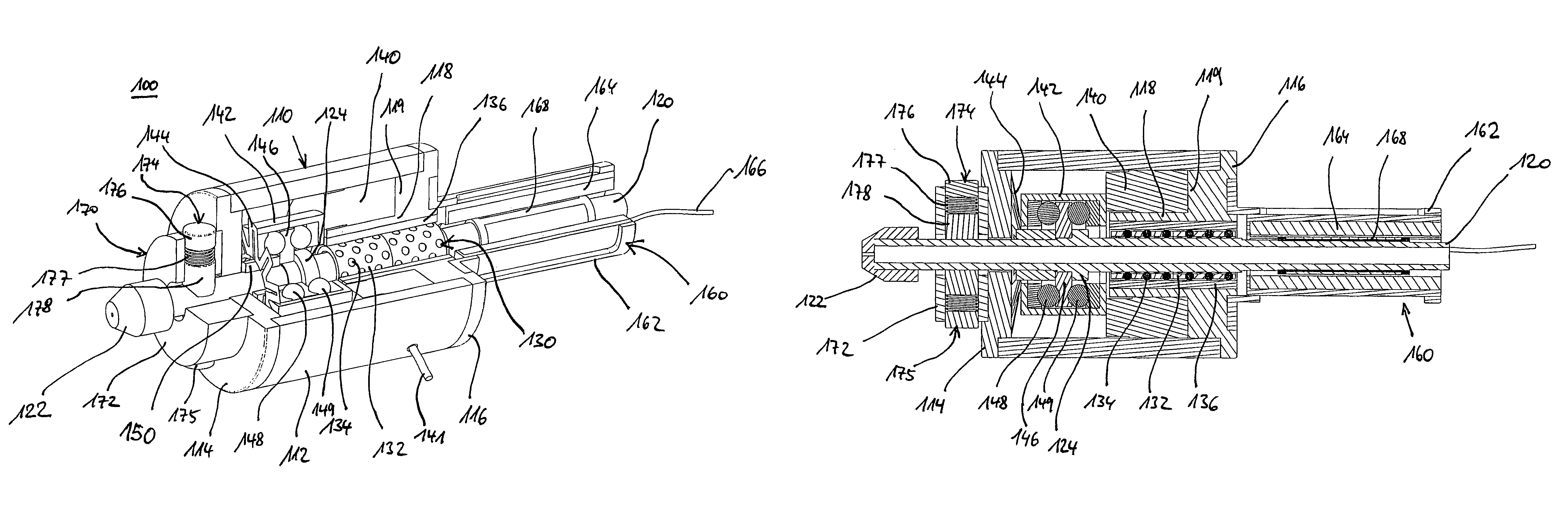

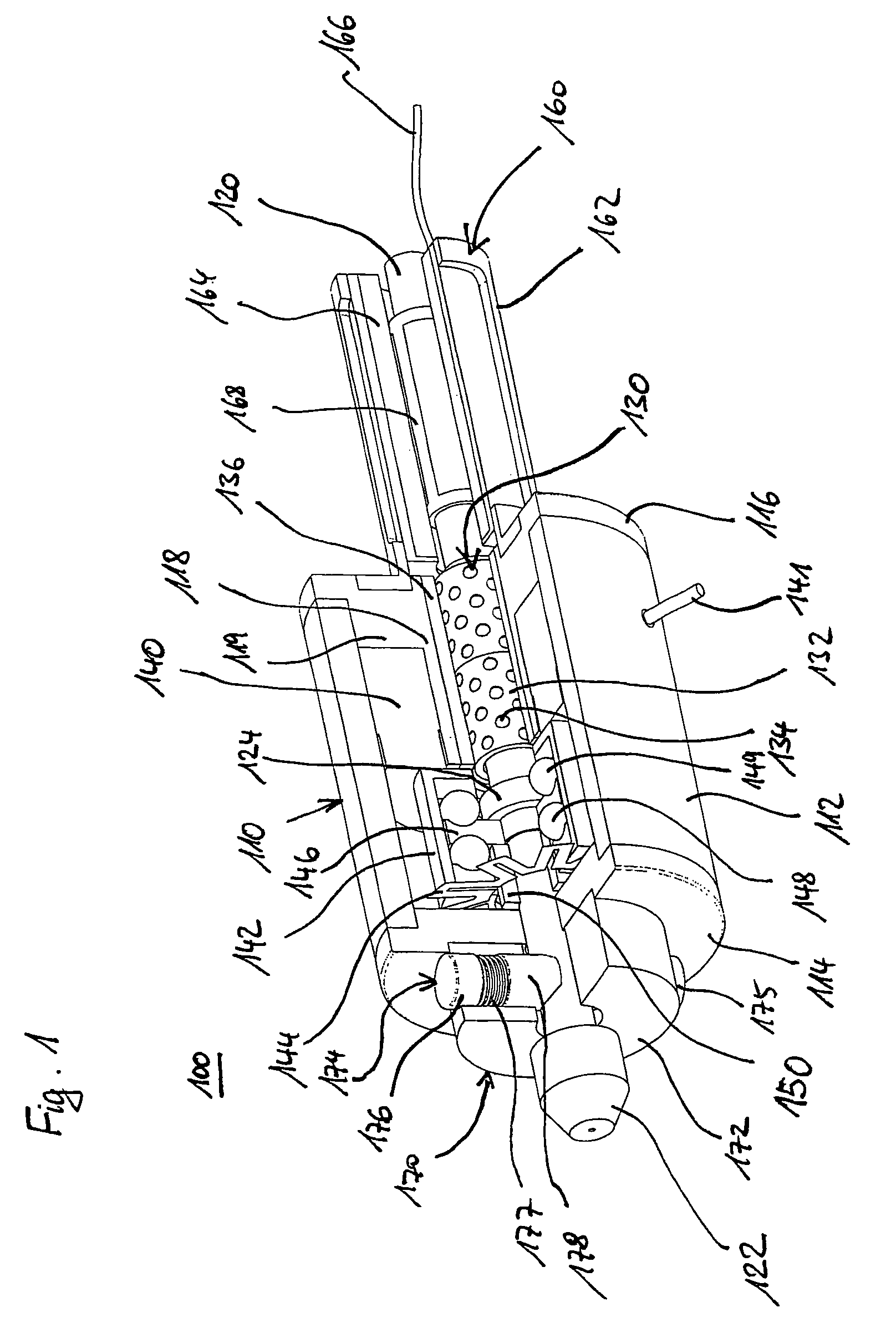

Drive device for erosion tools

ActiveUS20100320172A1Rinse cleanQuality improvementElectrical-based machining electrodesElectric circuitsDrive shaftEngineering

A drive device for erosion tools, having a drive shaft, an electrode holder connected to the drive shaft, an axial drive which works on the drive shaft, a rotational drive which works on the drive shaft as a direct drive in a contactless manner, and a radial bearing. The radial bearing is constructed as a ball track.

Owner:IMM INST FUR MIKROTECHNIK GMBH

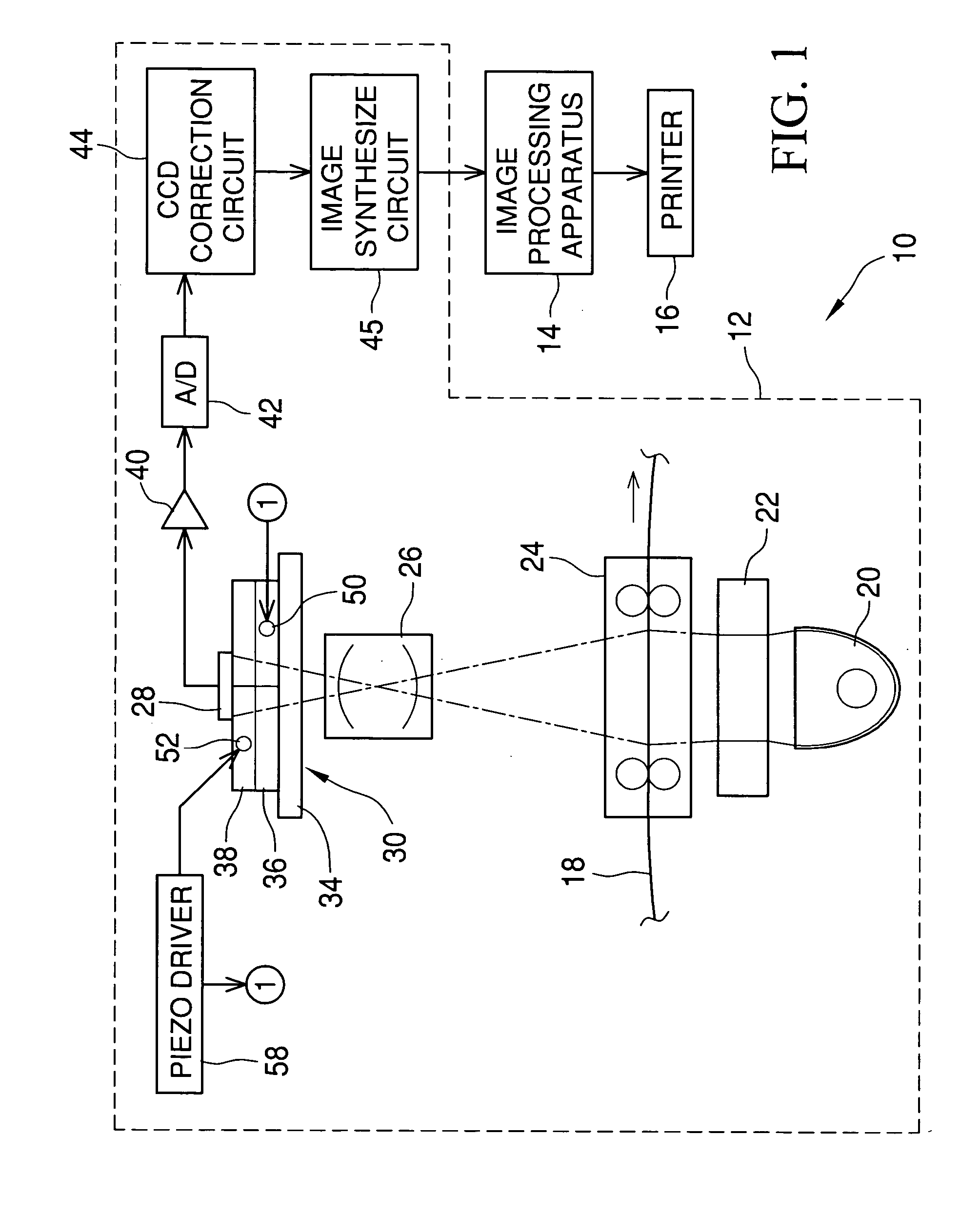

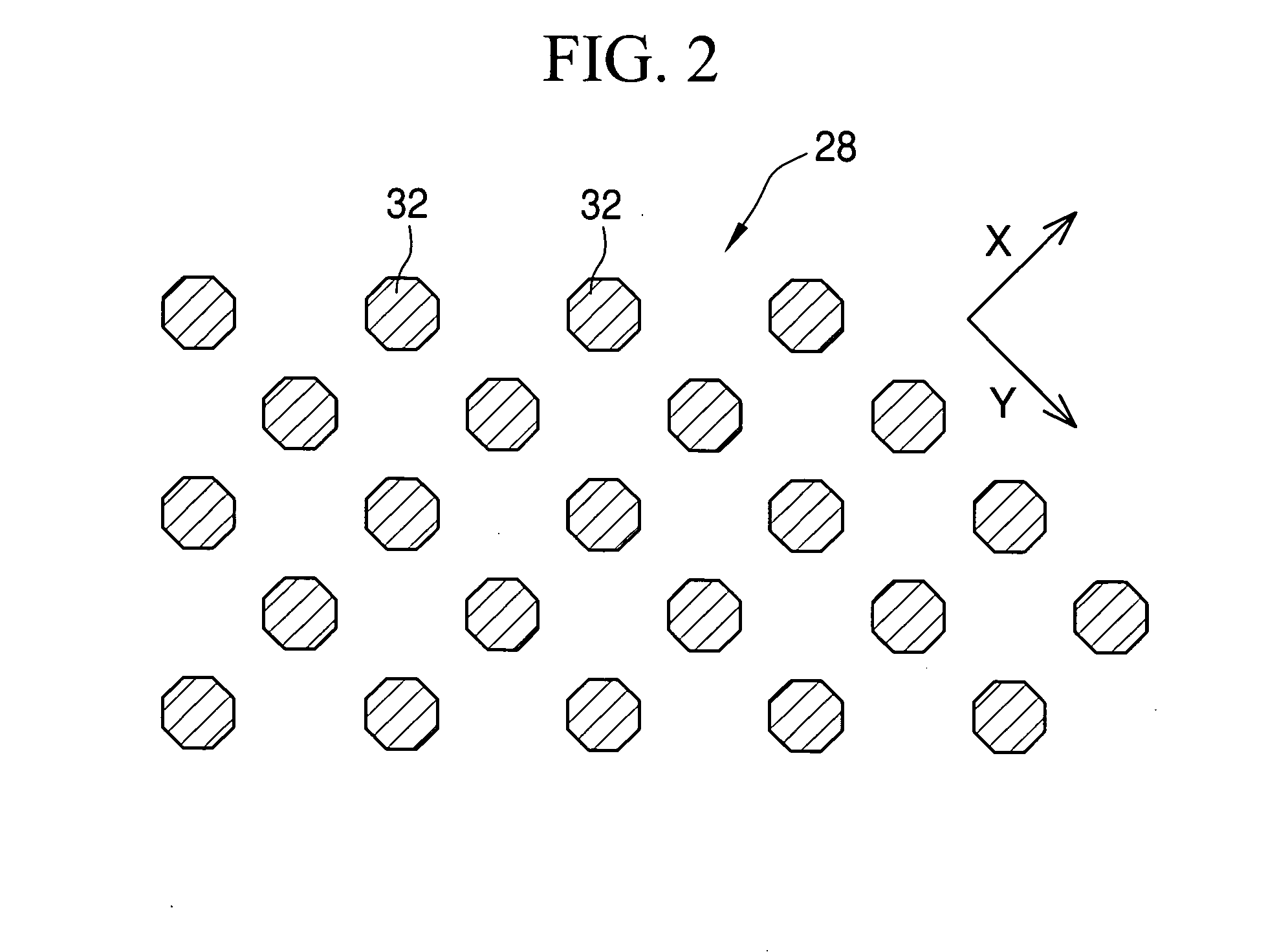

Movement control apparatus, image scan apparatus and image scanning method

InactiveUS20050073728A1High precisionImprove accuracyGeometric image transformationImage data processing detailsPhysicsMovement control

A CCD image sensor is fixed on a Y-direction stage that is supported on an X-direction stage. When a piezo driver supplies voltage to an X-direction piezo element and a Y-direction piezo element, the CCD image sensor is moved in X and Y directions. The X-direction position sensor and the Y-direction position sensor detects the position information of the CCD image sensor in X and Y direction respectively, and send the position information to the piezo driver. The piezo driver sets a target movement of the CCD image sensor, and detects the actual movement of the CCD image sensor from the position information. The piezo driver adjusts the output voltage to the X-direction piezo element and the Y-direction piezo element such that the target movement becomes the same as the actual movement.

Owner:FUJIFILM CORP +1

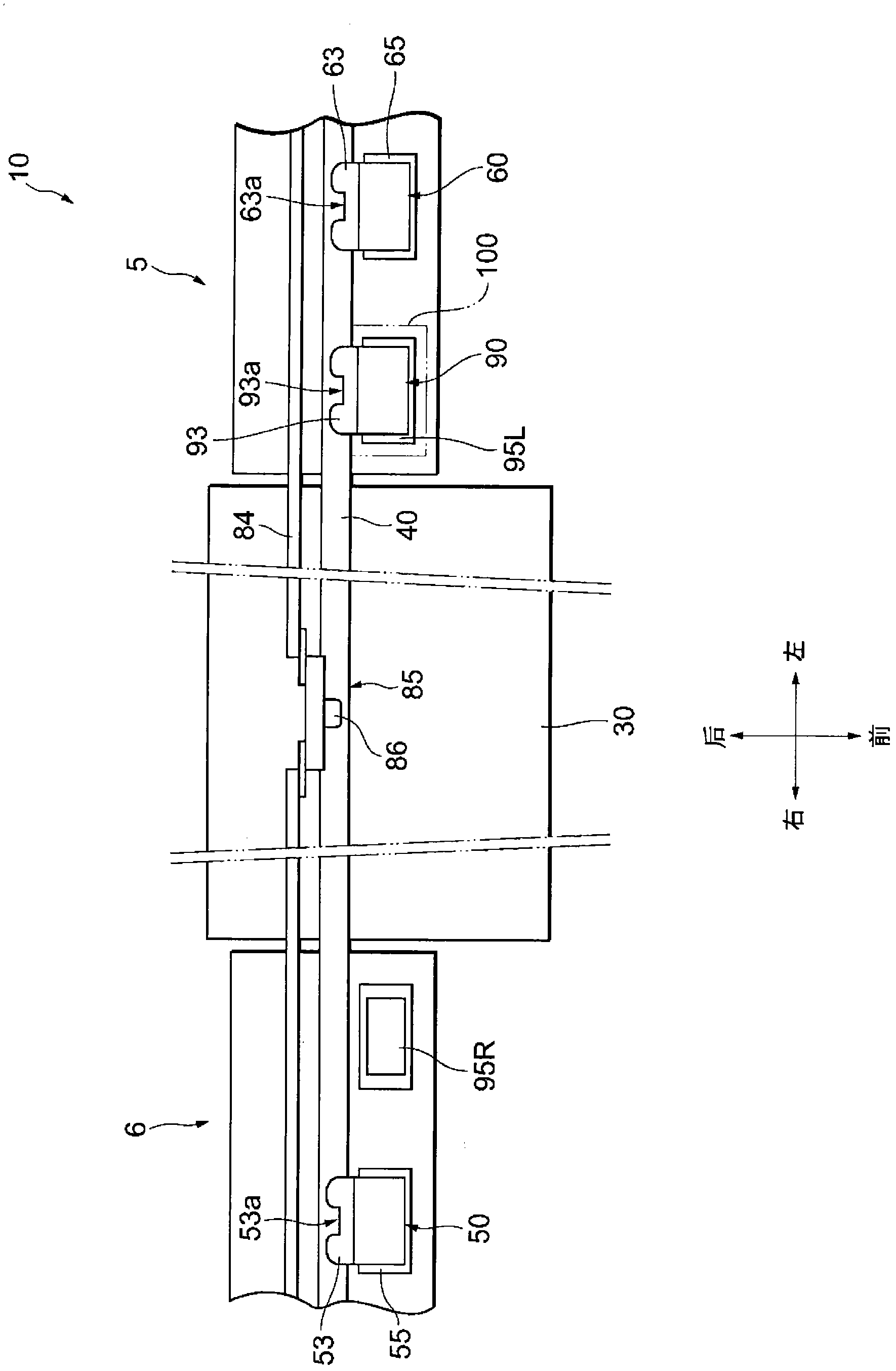

Device and Method for Nondestructive Testing of Pipelines

ActiveUS20090293622A1Improve accuracyHigh-precision movementAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecific gravity measurementNon destructiveEngineering

A device for nondestructive testing of pipelines is designed to move along a pipeline and has at least one measuring unit for acquiring measured data of the pipeline, wherein the device is self-propelled and has at least one functional unit rotatable about a central axis of the device for acquiring measured data and / or for driving the device. In a corresponding method for nondestructive testing of pipelines, the device is moved along the pipeline by a functional unit having drive elements and moving helically along a surface of the pipeline to be covered. The functional unit acquires measured data and the drive elements are forced by a magnetic field generated by the functional unit against the surface of the pipeline.

Owner:ROSEN SWISS

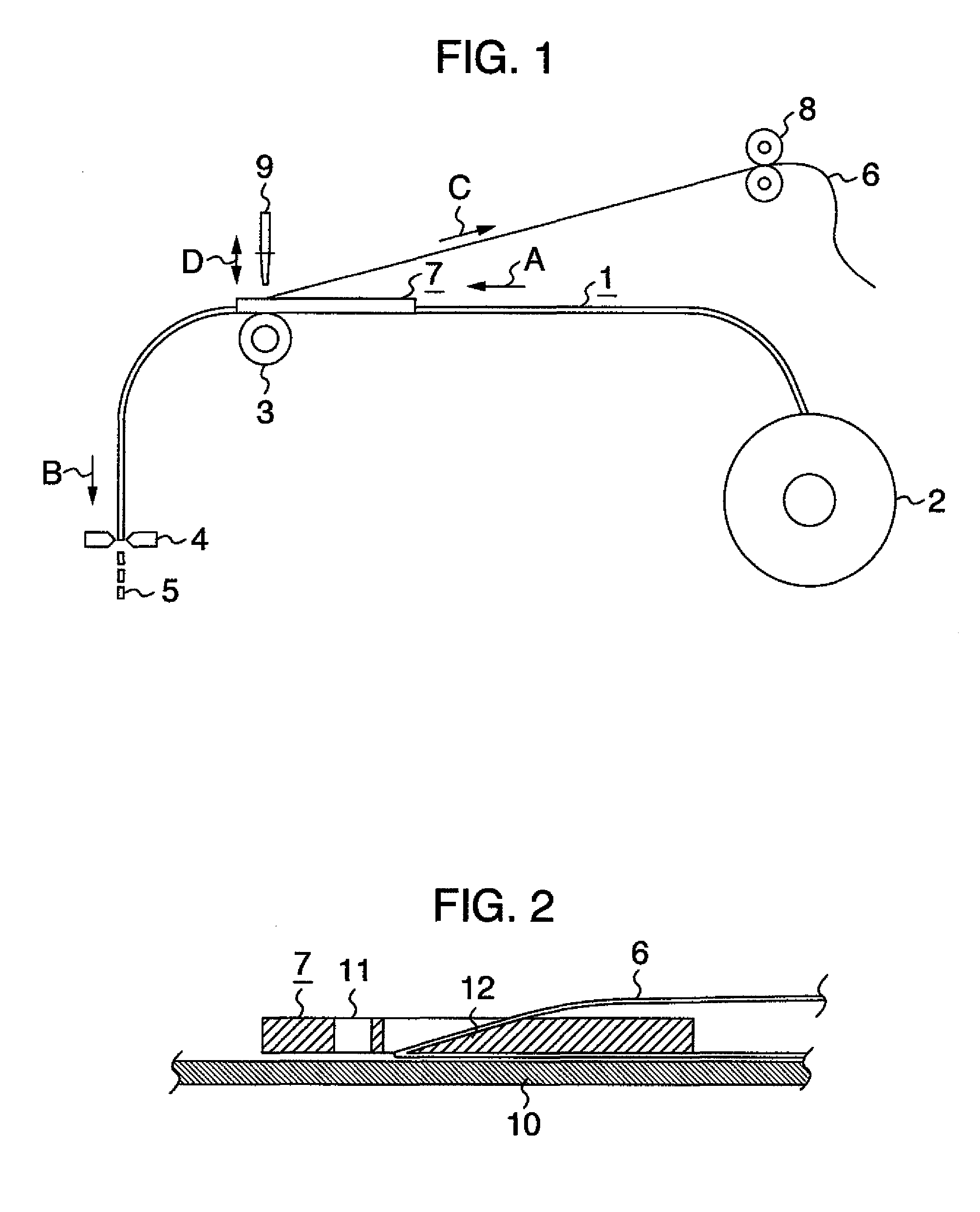

Component feeder

ActiveUS20100186901A1Improve accuracyImprove productivityArticle unpackingAdhesivesProduction rateEngineering

A component feeder capable of enhancing productivity is provided by that the component feeder includes a tape feeding device intermittently feeding a component housing tape constituted of a carrier tape having component housing parts formed with predetermined interval to contain respective electronic components, and a cover tape covering the component housing parts to prevent the components from jumping out from the component housing parts while the component housing tape wound on a housing tape reel is sequentially fed to a component extracting position, and an electronic component exposing device exposing the electronic components in the component housing parts to be allowed to be extracted, wherein the tape feeding device is constituted of a first feeding device and a second feeding device, and the electronic component exposing device is provided between the first feeding device and the second feeding device.

Owner:YAMAHA MOTOR CO LTD

Inkjet recording apparatus and recording medium movement control method

ActiveUS7364251B2Improve reliabilityImprove accuracyOther printing apparatusArticle feedersComputer hardwareEngineering

An inkjet recording apparatus including: a recording head; a recording medium moving section; a position information detecting section synchronized with a movement of the recording medium moving section; a mark recording section for recording a mark on the recording medium; a mark detecting section for detecting the mark recorded; an analog-to-digital conversion section for converting an output signal; and a control section for obtaining a reference mark position of the mark based on a signal outputted from the mark detecting section and the position information detected, and for determining the amount of recording medium movement on the basis of reference detection position of the mark; wherein analog-to-digital conversion is applied to the output signal from the mark detecting section to get a sampling data, in exact timing with an output of position information, and the control section calculates the reference detection position from the sampling data.

Owner:KONICA MINOLTA INC

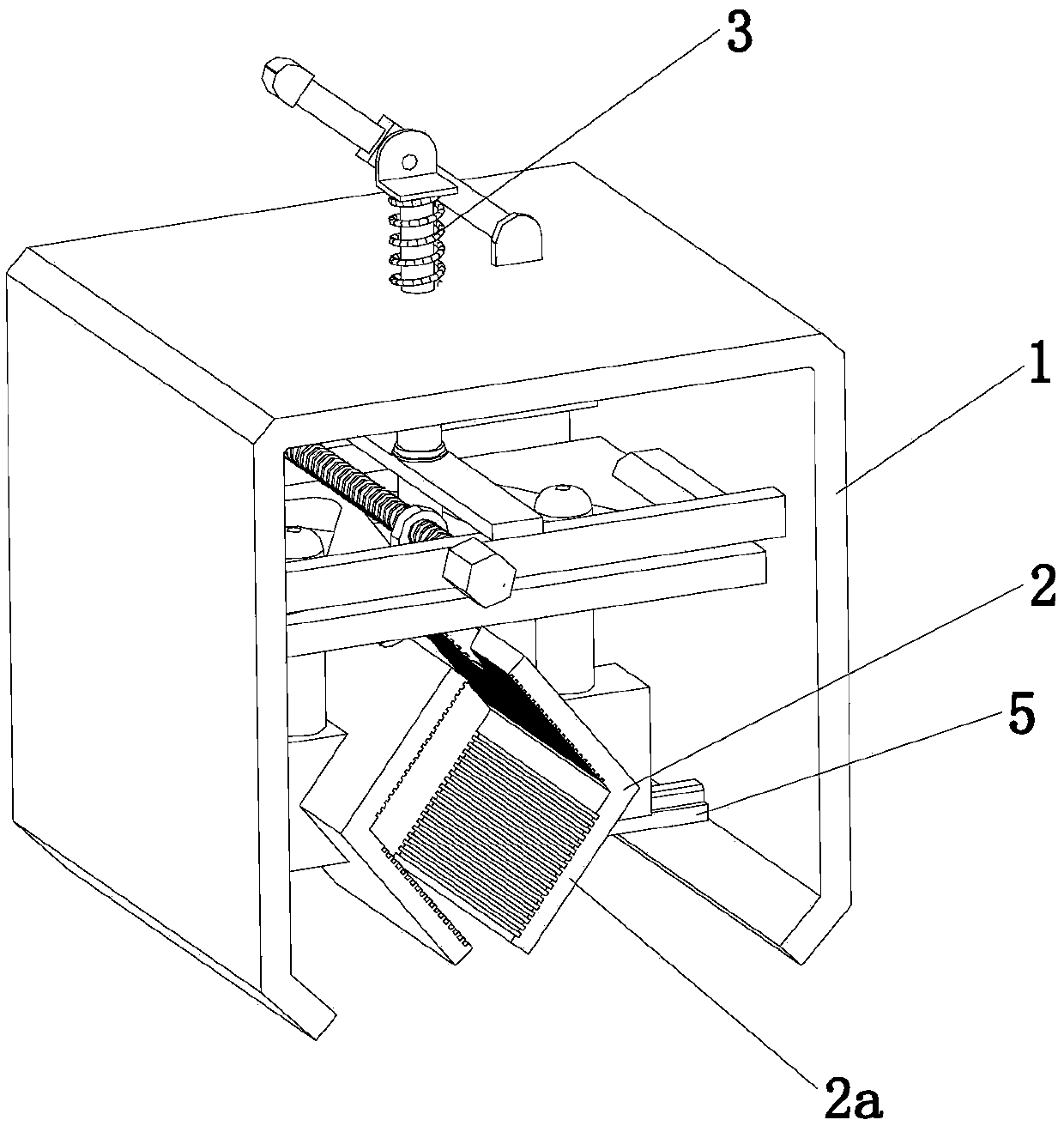

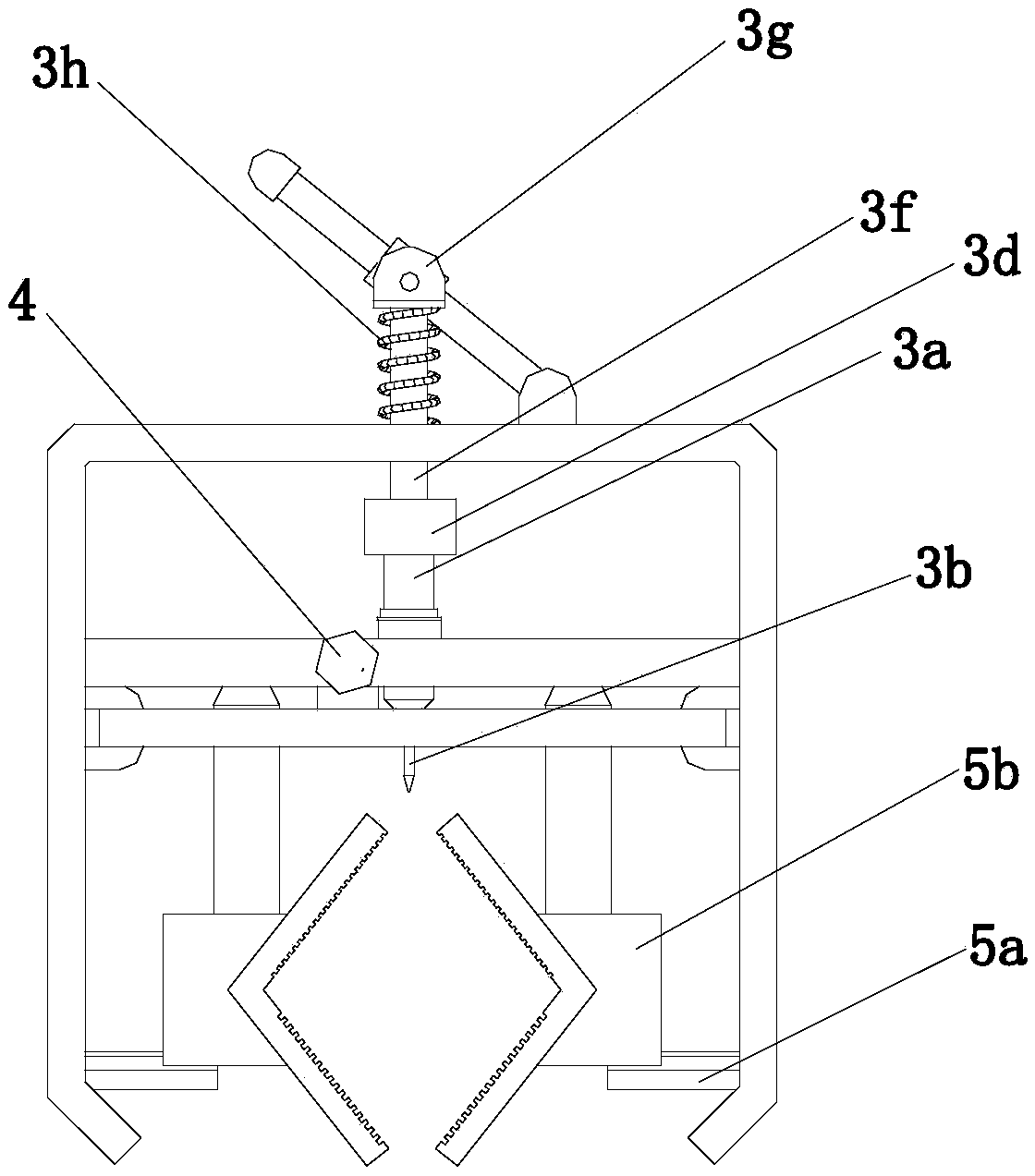

High-voltage electric cable detection device

The invention discloses a high-voltage electric cable detection device, and belongs to the technical field of electric power detection. The high-voltage electric cable detection device comprises a fixing frame, an electric cable clamping assembly and a voltage detection assembly. The fixing frame is of a U-shaped structure, the electric cable clamping assembly comprises a driving component and twoclamping plates, the two clamping plates are of V-shaped structures, antislip layers are arranged on two opposite ends of the two clamping plates, support assemblies are arranged on two sides of thefixing frame, and the two clamping plates are arranged on the two support assemblies. The high-voltage electric cable detection device has the advantages that workers can manually clamp electric cables with different diameters by the aid of the electric cable clamping assembly and can quickly fix or detach the electric cables by the aid of an adjusting head, and accordingly the high-voltage electric cable detection device is high in practicality; the workers can quickly puncture and detect the electric cables by the aid of the voltage detection assembly, accordingly, the time and labor can besaved as compared with the traditional methods, the high-voltage electric cable detection device can bring convenience for the workers, and the detection efficiency of the workers can be improved.

Owner:浙江亘古电缆股份有限公司

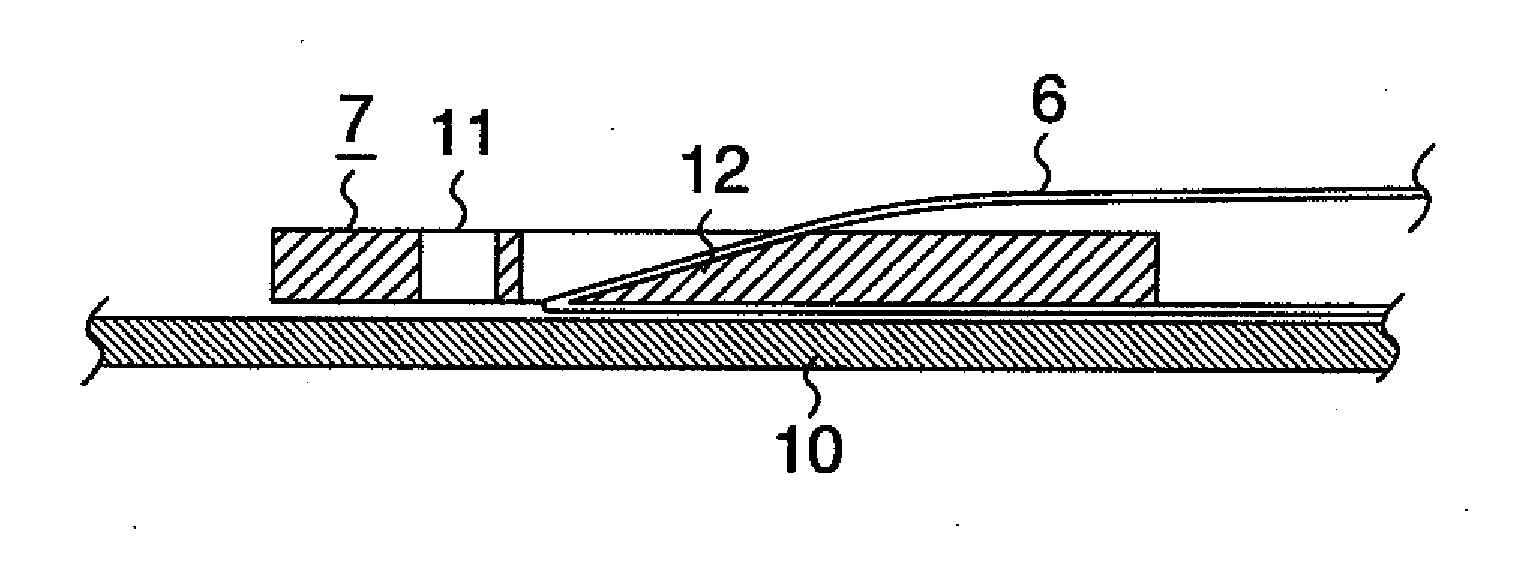

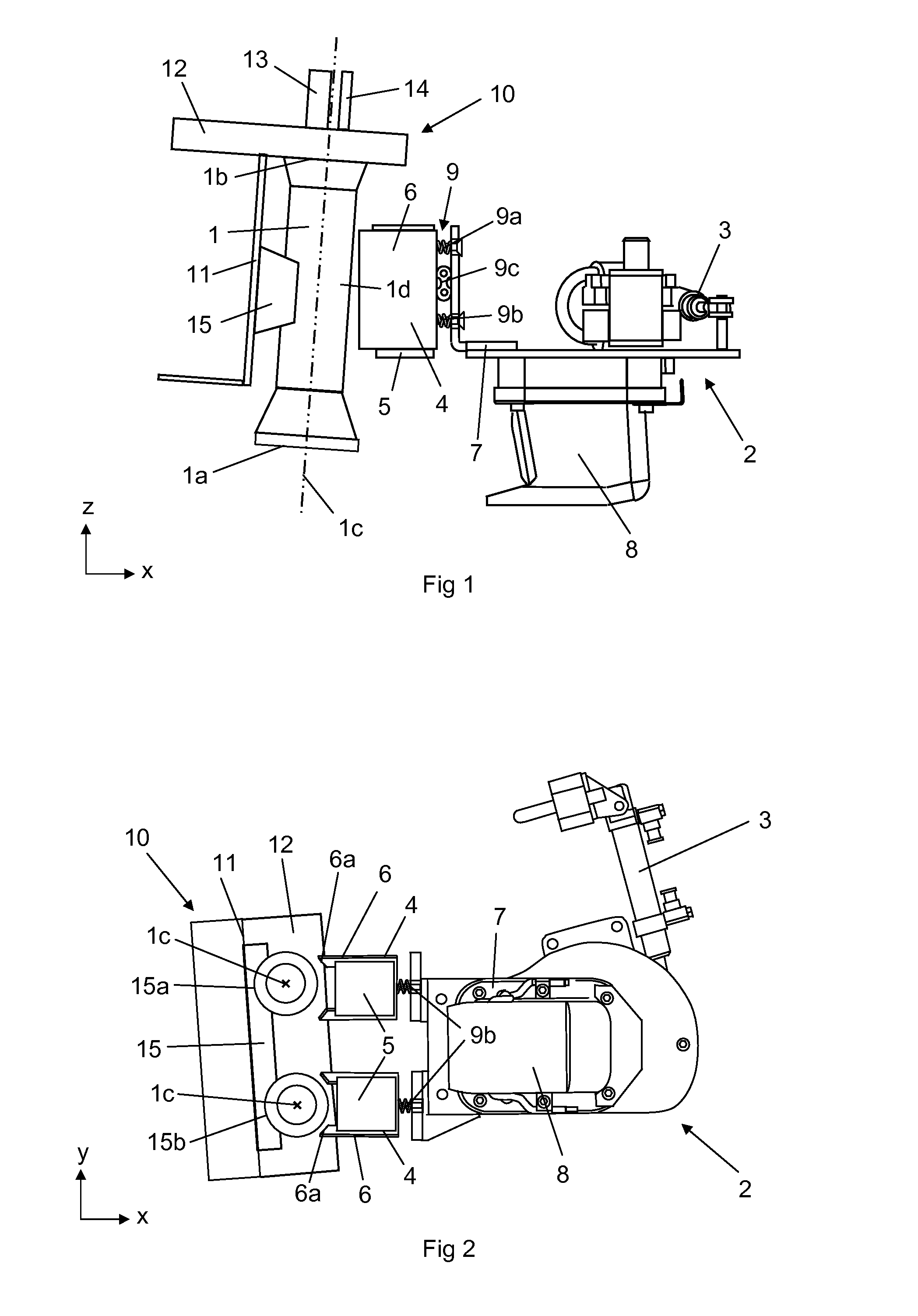

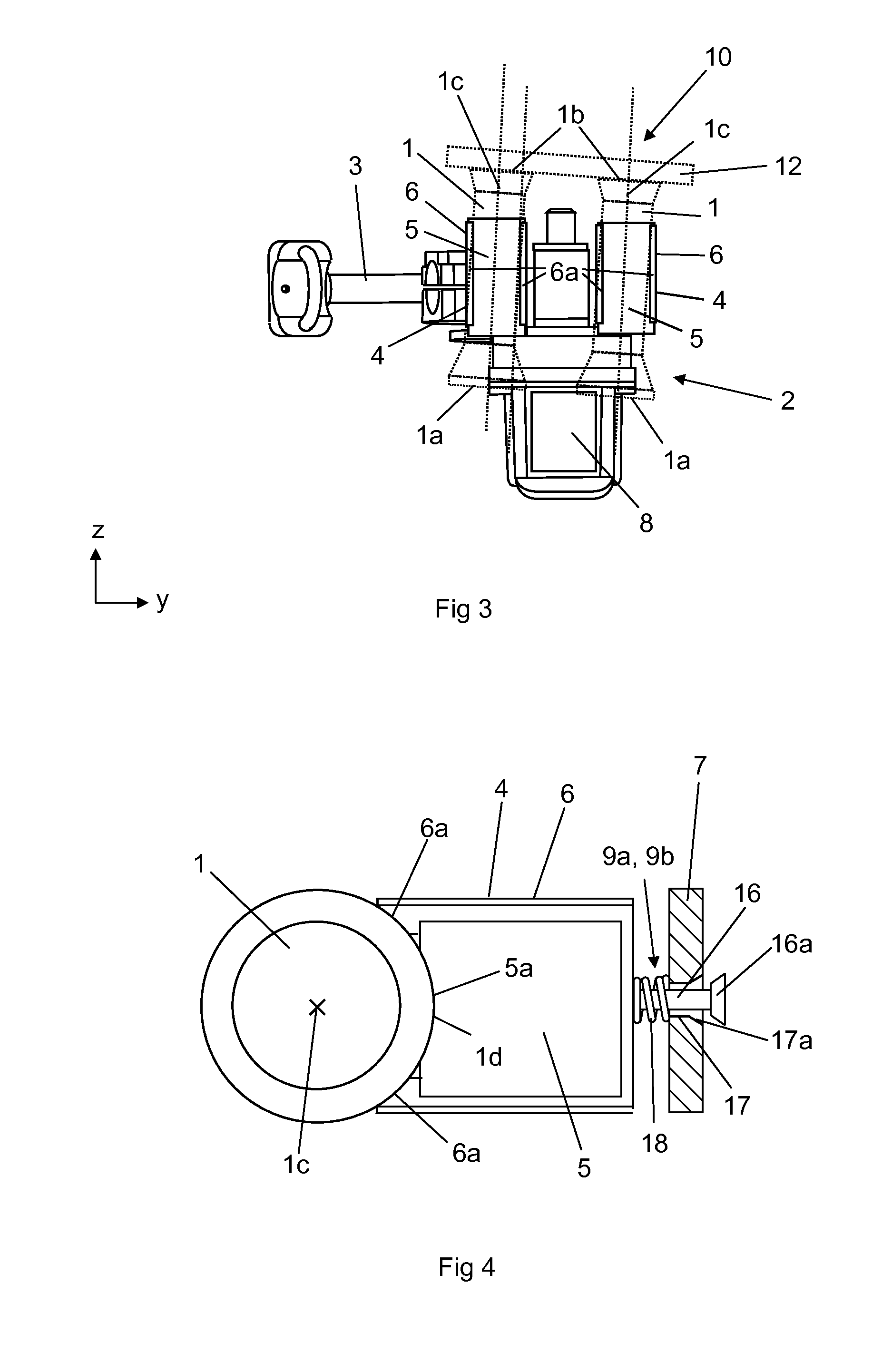

Arrangement for gripping at least one teat cup

ActiveUS20110226184A1Reliable gripping operationEasy to controlMilking devicesEngineeringContact position

An arrangement for gripping at least one teat cup (1). The arrangement includes a storing device (10) adapted to hold the teat cup (1) in a parked position and a gripping device (2) adapted to grip the parked teat cup (1) in the storing device (10). The gripping device (2) includes a contact surface (6a) which is adapted to be moved to a position in which it comes in contact with a contact surface (1d) of the teat cup (1) during a gripping operation of the teat cup (1). The arrangement includes an adjusting part which is able to adjust the position of at least one of said contact surfaces (1d, 6a) in relation to the other contact surface (1d, 6a) from an initial contact position to a grip position in which the gripping device is able to grip the teat cup in the storing device.

Owner:DELAVAL HLDG AB

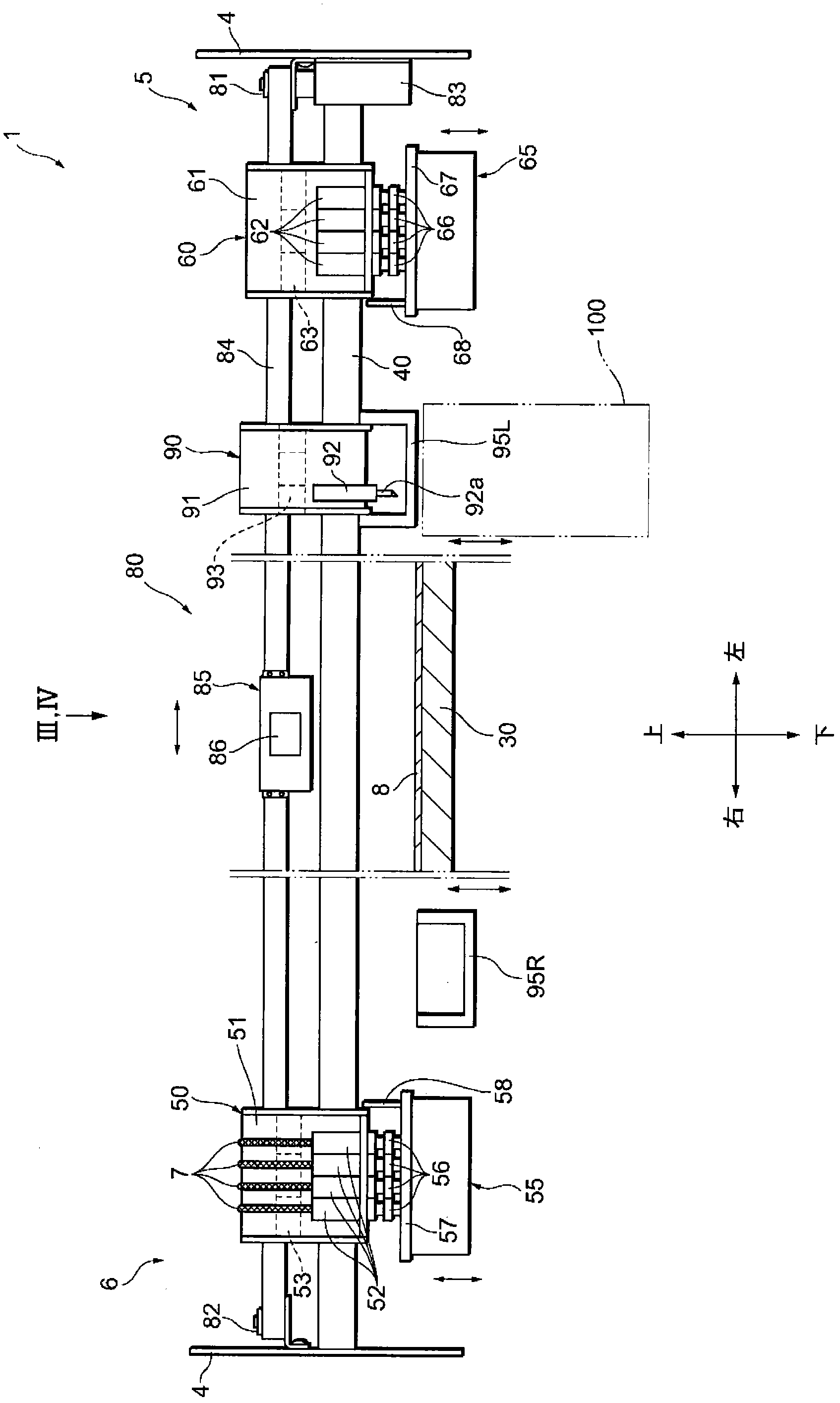

Printer device

InactiveCN102066117AHigh-precision movementSimple structureTypewritersOther printing apparatusEngineeringMechanical engineering

The present invention provides a printer device. The printer device comprises a second printing unit, which has a carriage provided movably in a horizontal direction along a guide rail (40) and a printer head for discharging ink toward a printing sheet; a cutting unit (90), which has a carriage provided movably in a horizontal direction along a guide rail (40) and a cutter holder (92) for cutting the printing sheet into a predetermined shape; a second maintenance device which is capable of holding the second printing unit; a left standby station (95L) which is capable of holding the cutting unit (90); and a vertical movement mechanism (100) which is capable of integrally moving the cutting unit (90) and the left standby station (95L) up and down with respect to a platen (30). When performing printing while moving the printer head in the horizontal direction, the vertical movement mechanism (100) moves the cutting unit (90) and the left standby station (95L) to be positioned below the platen (30).

Owner:MIMAKI ENG

Device for the treatment of individual sausages

ActiveUS9944471B2Improve grouping and placementHigh-precision movementProgramme-controlled manipulatorConveyorsEngineeringConveyor belt

Owner:SINGER & SOHN

Device and method for nondestructive testing of pipelines

ActiveUS8146449B2Minimal weightFriction is causedMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceEngineeringDriven element

Owner:ROSEN SWISS

Traction drive system

ActiveUS8511196B2Without risk of damageReduce the likelihood of injuryProgramme-controlled manipulatorClutchesAbsolute rotationDrive shaft

A traction drive system for an articulated robotic arm. The traction drive system can include an input drive disk, a spider, an array of traction balls, a traction plate, an output drive shaft, a clamping device to load the traction balls, and an absolute rotation position sensor system. The rotation of the output drive shaft can be coupled to the rotation of the input drive disk while the traction balls are frictionally engaged to the drive disk surface and traction plate surface. The rotational connection can be decoupled when the traction balls are not frictionally engaged to the drive disk surface and traction plate surface. A rotational position sensor located in proximity to the traction drive can provide absolute rotational position feedback of the output drive shaft.

Owner:QUANTUM MOTION LLC

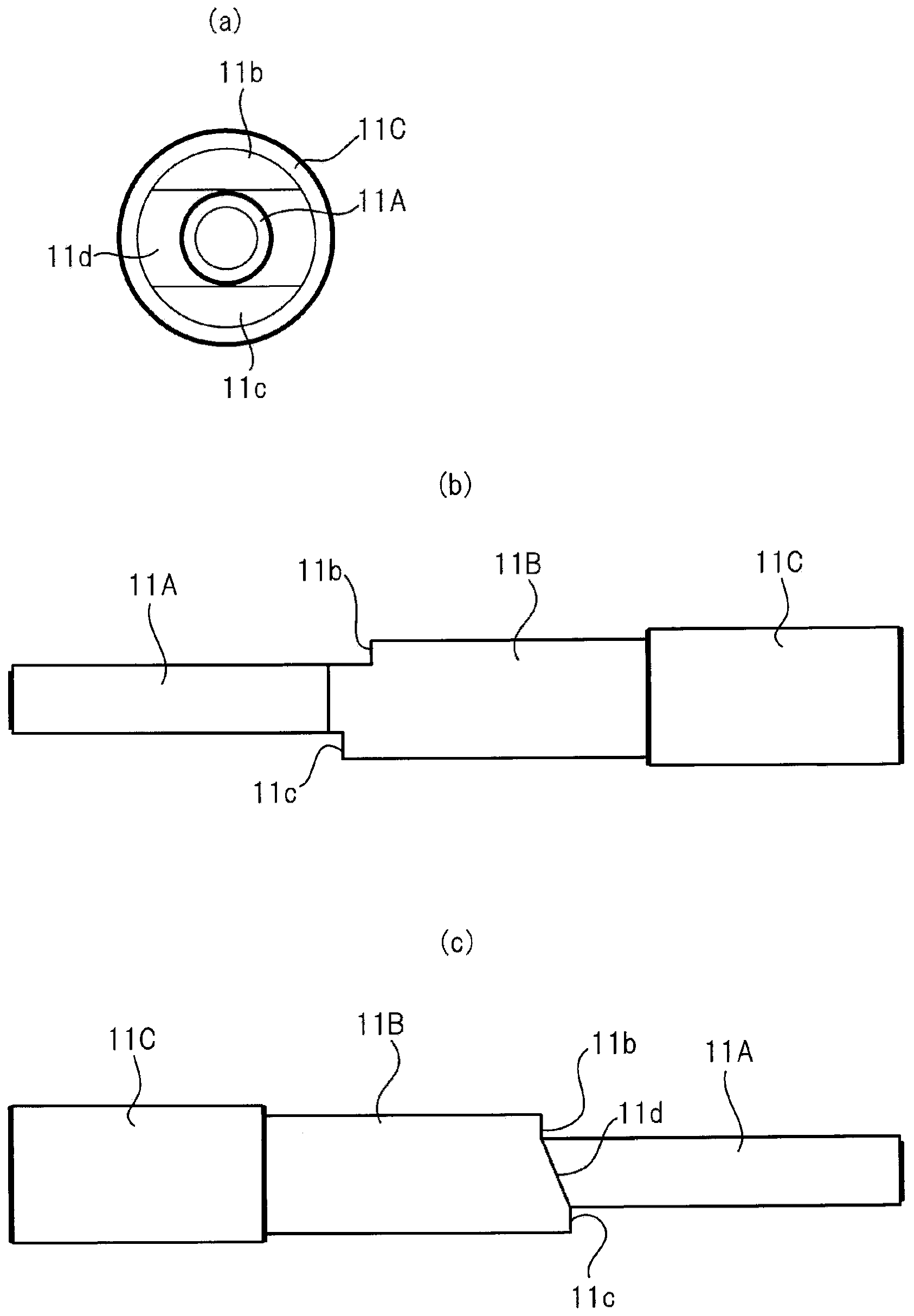

Endoscope device

ActiveCN104111526AHigh-precision movementMiniaturizationTelescopesMountingsTransverse planeEngineering

The invention provides an endoscope device which can be easily made to be miniature and enables the focus distance to be changed in a highly precise manner. The endoscope device comprises a shooting element (23) which shoots an object to be shot through a lens unit including a movable lens (21). The endoscope device is equipped with a rotation component (11) that rotates freely with a rotation shaft (J2) being the center; a motor that drives the rotation component (11) to rotate; a movable lens retaining portion (14) that has a pin (15) abutting against part (11B) of the rotation component (11) and that retains the movable lens (21); and a spring (16) that applied force to the pin (15) toward the rotation component (11). The rotation component (11) includes a cylindrical part (11B) extending in the direction of an optical axis; and a cylindrical part (11A) protruding from the transverse plane of the part (11B) at the side of the object to be shot and thinner than the part (11B). The transverse plane of the part (11B) includes an abut surface (11d) which abuts against the pin (15) and continuously changes, in terms of the height in the direction of the optical axis, along the circumference of the part (11B). The movable lens retaining portion (14) is freely embedded into the part (11A) in a movable manner in the direction of the optical axis.

Owner:FUJIFILM CORP

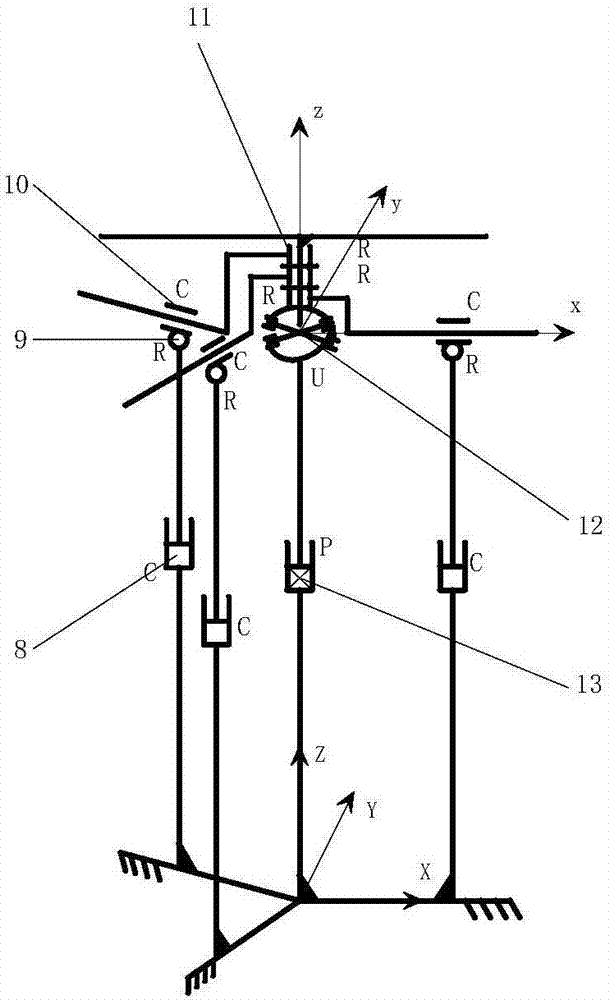

Three-degree-of-freedom position regulating system and method

ActiveCN102785077AHigh-precision movementRealize high-precision movementMetal working apparatusThree degrees of freedomDegrees of freedom

The invention provides a three-degree-of-freedom position regulating system comprising two sets of electric control three- three-degree-of-freedom precise work benches and a control calculating unit, wherein the two sets of electric control three-degree-of-freedom precise work benches are used for implementing three-degree-of-freedom translation within a certain range according to external instructions respectively, and outputting position signals in real time; the control calculating unit is used for receiving position signals of the two sets of electric control three-degree-of-freedom precise work benches respectively, and outputting instruction signals to the first electric control three-degree-of-freedom precise work bench and the second electric control three-degree-of-freedom precise work bench according to the position signals and parameters input by a user; when a workpiece needs to be moved, the control calculating unit sends instructions to the two sets of electric control three-degree-of-freedom precise work benches, so as to drive the two sets of work benches to work toward the same direction by the same distance. The system provided by the invention solves technical problems of the prior art in low movement precision, difficulty in control over movement amount, difficulty in measurement, time-consuming operation, etc., thereby implementing the three-degree-of-freedom high-precision movement of large and medium parts within a certain range.

Owner:TSINGHUA UNIV

Method of controlling mover device

InactiveUS7597531B2Improve impact performanceHigh noiseDC motor speed/torque controlSemiconductor/solid-state device manufacturingEngineeringGenerating unit

Embodiments of the invention are directed to a method of controlling a mover device The method includes generating a moving force from a moving force generating unit to move a processing base with respect to a movable base, thereby moving the processing base with respect to a fixed base as a result of the movement of the processing base with respect to the movable base; moving the movable base on the fixed base in the opposite direction to the moving direction of the processing base by virtue of a reaction force caused by the moving force generated from the moving force generating unit to move the processing base, so that the movable base moves in the opposite direction to the moving direction of the processing base on the fixed base. The method further includes controlling the moving velocity of the processing base with respect to the fixed base.

Owner:SEN CORP AN SHI & AXCELIS

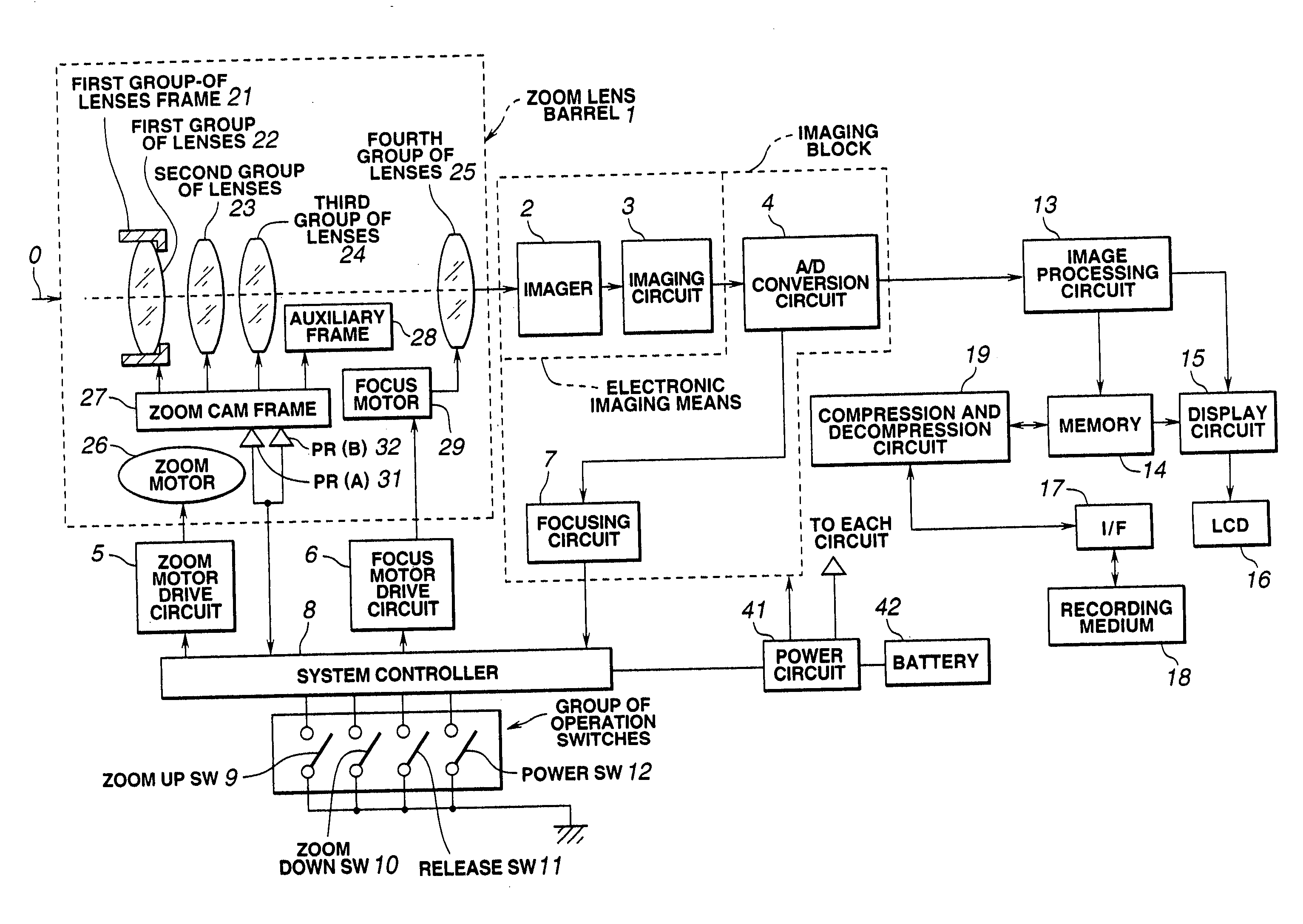

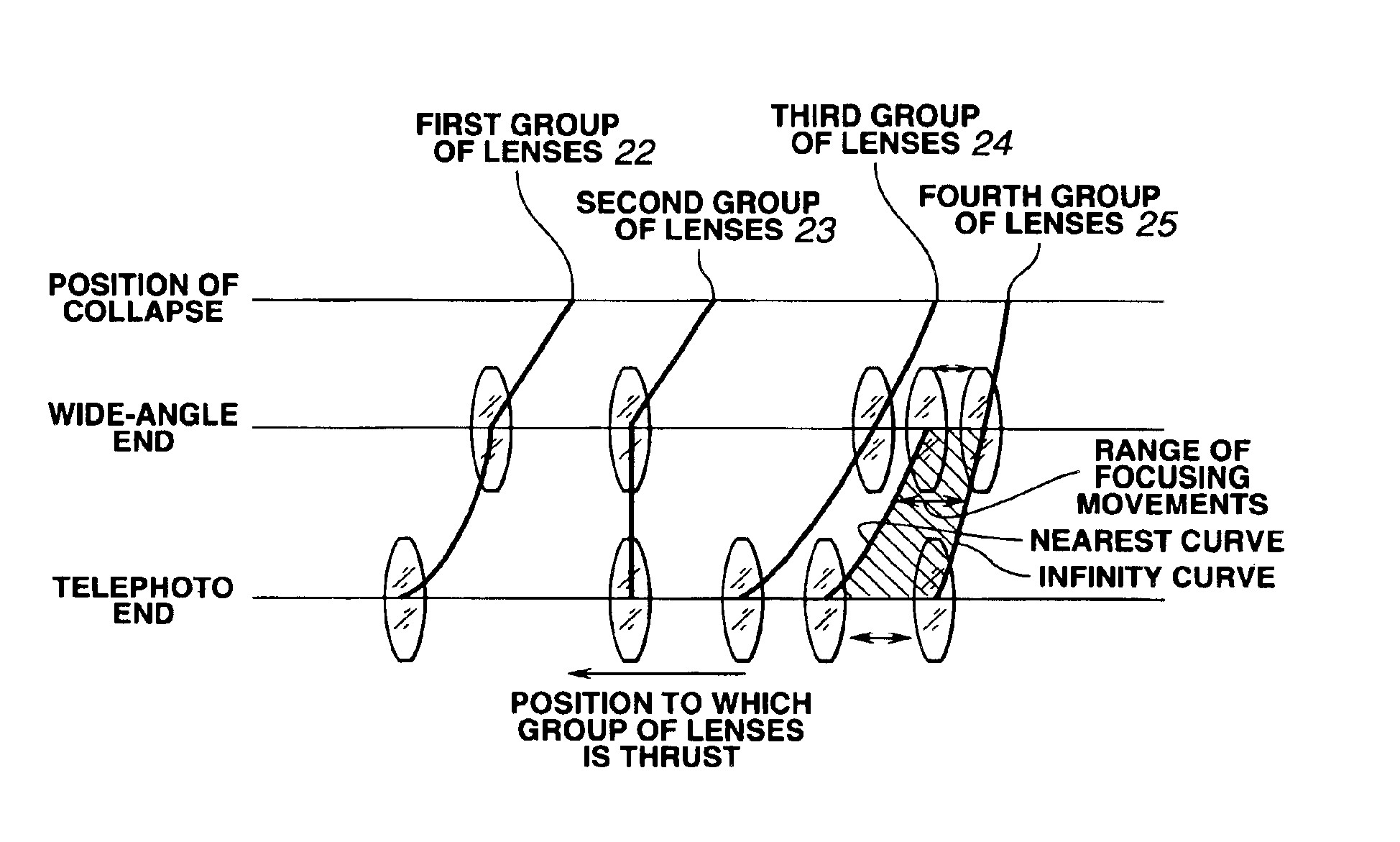

Lens device for a camera with a stepping motor drive optimized for speed and power saving

InactiveUS20050146636A1Reduce power consumptionEffective controlTelevision system detailsPrintersMotor driveComputer science

A lens unit consists of a plurality of lens frames, a stepping motor, and a driving control unit. The plurality of lens frames for holding an imaging optical system lies in a lens barrel and moves over a stowage interval and a zoom interval. The stowage interval is an interval between a position of stowage at which the lens frames are stowed and a ready-to-image position at which imaging is enabled. The zoom interval is an interval over which the ready-to-image position exists and a power varying action is executed. The stepping motor moves the plurality of lens frames. During execution of a thrusting action or storing action, the driving control unit drives and controls the stepping motor in a first driving mode. The thrusting action is executed for moving the plurality of lens frames from the position of stowage to the ready-to-image position. The stowing action is executed for moving the lens frames from any position within the zoom interval to the position of stowage. During execution of a zooming action for moving the lens frames over the zoom interval, the driving control unit drives and controls the stepping motor in a second driving mode in which a lower current is used than in the first driving mode.

Owner:OLYMPUS CORP

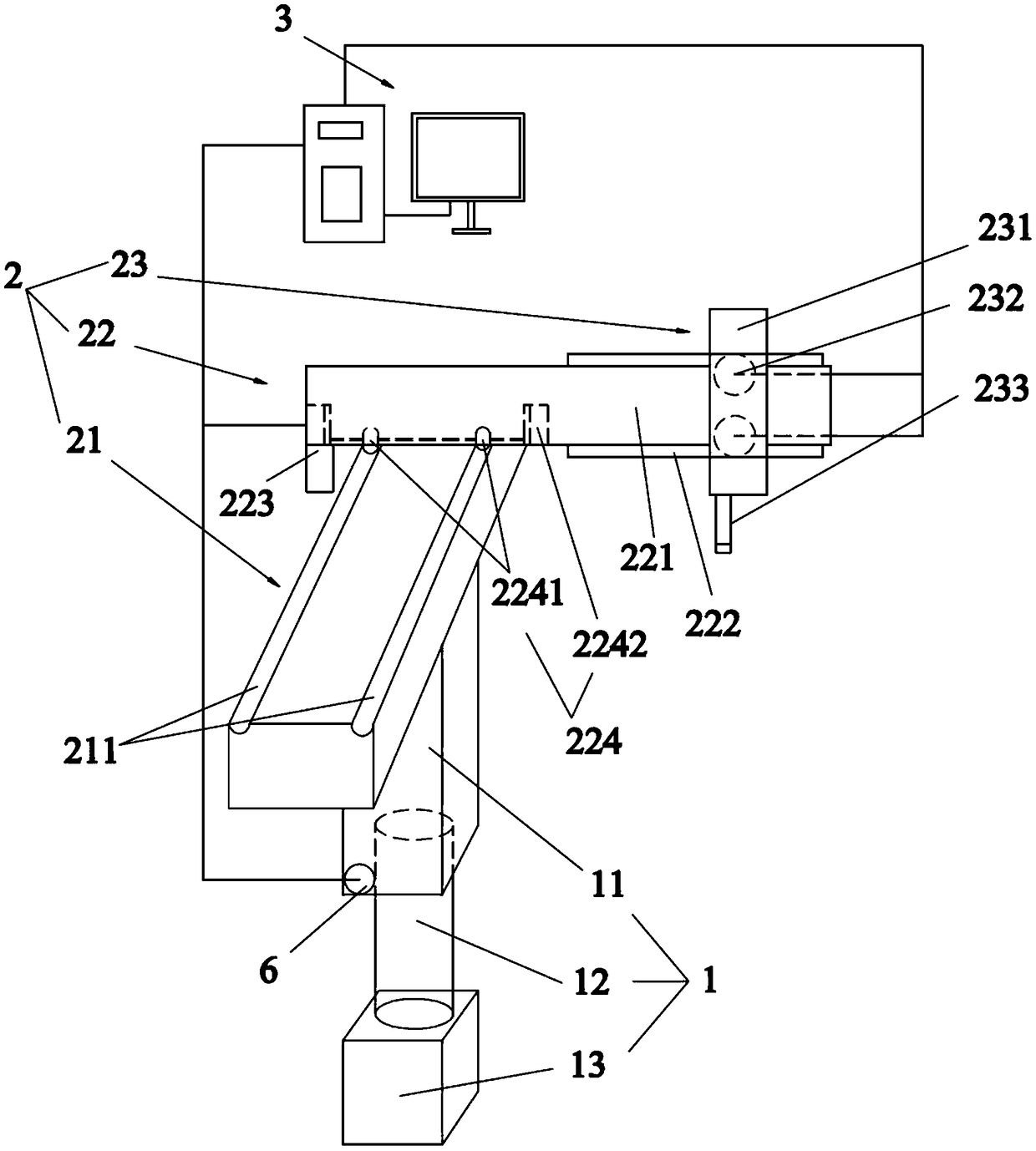

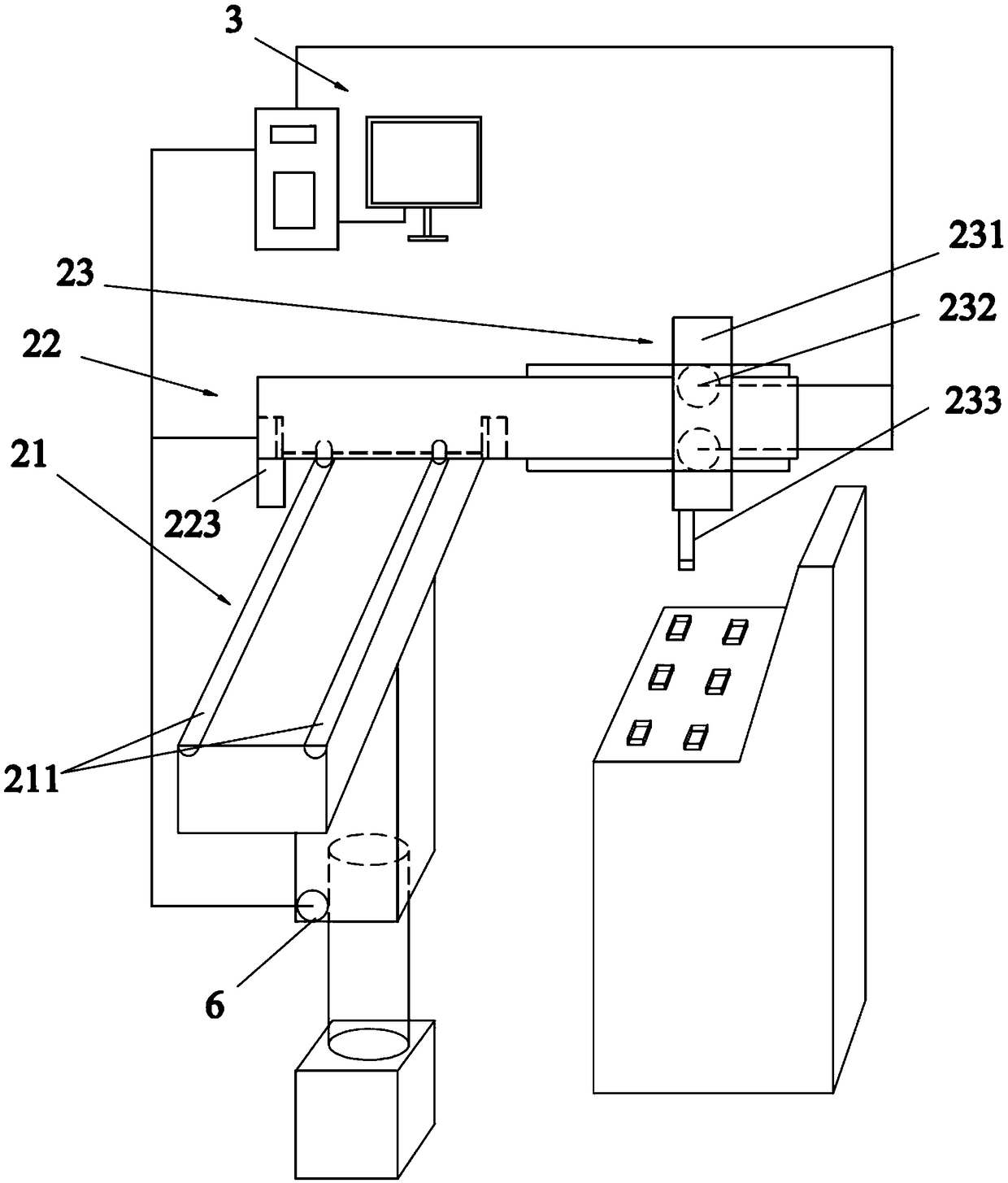

Mechanical arm system and control method of mechanical arm system

InactiveCN109048902AFlexible controlPracticalProgramme-controlled manipulatorGripping headsElectricityEngineering

The invention belongs to the technical field of mechanical arms, and particularly relates to a mechanical arm system. The mechanical arm system comprises a lifting device (1), a plane motion mechanism(2) and a computer (3); the lifting device (1) and the plane motion mechanism (2) are electrically connected with the computer (3), the plane motion mechanism (2) comprises a bearing longitudinal beam (21), a movable cross beam (22) and a replaceable operation part (23), the movable cross beam (22) and the bearing longitudinal beam (21) are in sliding connection, and the operation part (23) is insliding connection with the movable cross beam (22). The mechanical arm system has the expanding and practicability, the mechanical arm can be flexibly controlled to finish corresponding actions, high-precision moving can be achieved, the automatic mechanical operation can be achieved, work efficiency is improved, manual cost is reduced, and in addition, the invention discloses a control method of the mechanical arm system.

Owner:东莞仕达通自动化有限公司

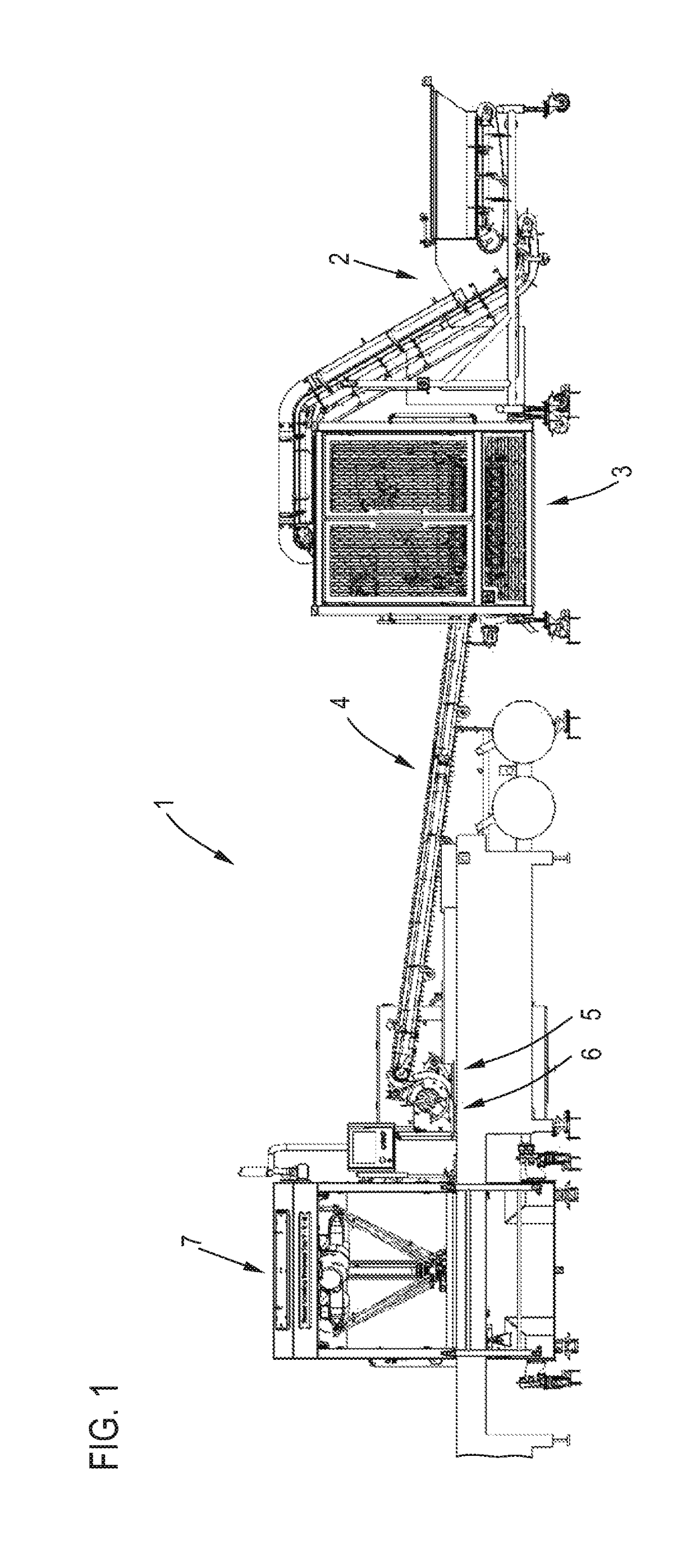

Device for the treatment of individual sausages

ActiveUS20170081133A1Improve grouping and placementHigh-precision movementProgramme-controlled manipulatorConveyorsEngineeringConveyor belt

A device for treating individual sausages, including:a sorting device having an endless conveyor belt traveling around a triangular geometry and having rails or carrier bars, on which belt the sausages, which are loosely deposited onto an ascending run of the belt, are distributed individually into the rails or carrier bars;an endless first conveying device with individual rails or carrier bars to accept the sorted sausages, wherein each individual rail or carrier bar accommodates one sausage;a grouping device, in which the sausages delivered by the first conveying device are combined into groups;a second conveying device with receiving sections, each of which accommodates the sausages of one group, and into which the sausages, lying side by side, are transferred from the grouping device; anda transfer device having a gripper device for gripping a sausage group and for transferring and depositing the sausage group into a receiving container.

Owner:SINGER & SOHN

Chuck workbench moving arrangement

ActiveCN1885520AHigh-precision movementWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingEngineeringMachining

The present invention provides one kind of chuck bench moving mechanism capable of absorbing the vibration of the external screw and supporting the chuck bench with supported machined article to move at high precision. The chuck bench moving mechanism possesses a chuck bench supporting mechanism, a guide track and an external screw. The chuck bench supporting mechanism is provided with a supporting pedestal; several movable pedestals set between the supporting pedestal and the external screw, including one adjacent to the external screw with inner thread fitting the thread in the external screw; and several power transmitting mechanisms set separately between the movable pedestal adjacent to the supporting pedestal and the supporting pedestal and between two adjacent movable pedestals, and with vibration absorbing mechanism to transmit the power in the machining feeding direction.

Owner:DISCO CORP

Recording apparatus

ActiveUS8287065B2Compensate variation in precisionEfficient additionPower drive mechanismsOther printing apparatusEmbedded systemRecording head

A recording apparatus includes: a recording head that performs recording on a recording target medium; a driving mechanism that is capable of causing the recording head to move closer to the recording target medium or move away from the recording target medium; and a controlling section that determines driving amount for one driving operation that is performed by the driving mechanism on the basis of results of a comparison made between a first recording head movement direction that is taken or to be taken in the one driving operation and a second recording head movement direction that was taken in another driving operation that is immediately before the one driving operation and thus precedes the one driving operation.

Owner:SEIKO EPSON CORP

Lens device for a camera with a stepping motor drive optimized for speed and power saving

InactiveUS6867810B1Reduce power consumptionEfficient driveTelevision system detailsPrintersCamera lensMotor drive

A lens unit consists of a plurality of lens frames, a stepping motor, and a driving control unit. The plurality of lens frames for holding an imaging optical system lies in a lens barrel and moves over a stowage interval and a zoom interval. The stowage interval is an interval between a position of stowage at which the lens frames are stowed and a ready-to-image position at which imaging is enabled. The zoom interval is an interval over which the ready-to-image position exists and a power varying action is executed. The stepping motor moves the plurality of lens frames. During execution of a thrusting action or storing action, the driving control unit drives and controls the stepping motor in a first driving mode. The thrusting action is executed for moving the plurality of lens frames from the position of stowage to the ready-to-image position. The stowing action is executed for moving the lens frames from any position within the zoom interval to the position of stowage. During execution of a zooming action for moving the lens frames over the zoom interval, the driving control unit drives and controls the stepping motor in a second driving mode in which a lower current is used than in the first driving mode.

Owner:OLYMPUS CORP

Linear motion guide unit

A slider is composed of four components except for rolling elements. A slider moving relatively to a guide rail is composed of a carriage having raceway grooves, a circulator to make a return passage and insert nuts to fit into through-holes in the circulator. Engaging parts of the carriage makes fit-engagement with holes in the circulator to make snap-fit between the carriage and the circulator to fasten them each other.

Owner:NIPPON THOMPSON

Traction drive system

ActiveUS20100273602A1Reduce reboundReduce rateProgramme-controlled manipulatorClutchesAbsolute rotationRobotic arm

A traction drive system for an articulated robotic arm. The traction drive system can include an input drive disk, a spider, an array of traction balls, a traction plate, an output drive shaft, a clamping device to load the traction balls, and an absolute rotation position sensor system. The rotation of the output drive shaft can be coupled to the rotation of the input drive disk while the traction balls are frictionally engaged to the drive disk surface and traction plate surface. The rotational connection can be decoupled when the traction balls are not frictionally engaged to the drive disk surface and traction plate surface. A rotational position sensor located in proximity to the traction drive can provide absolute rotational position feedback of the output drive shaft.

Owner:QUANTUM MOTION LLC

A Symmetrical Parallel Mechanism Without Singularity

InactiveCN105619389BOvercome inertiaLarge working spaceProgramme-controlled manipulatorMicro-operationThree degrees of freedom

The invention discloses a symmetrical parallel mechanism without singularities. The symmetrical parallel mechanism without the singularities comprises a movable platform, a fixed platform used as a frame, and four kinematic chains connecting the movable platform and the fixed platform, wherein the four kinematic chains comprise a properly constrained chain connecting the central position of the movable platform and the central position of the fixed platform, and three identical kinematic branched chains; the three kinematic branched chains are symmetrically distributed about the centre of the properly constrained chain; the parallel mechanism has three degrees of freedom and four degrees of freedom respectively through addition or no addition of a revolute pair on the properly constrained chain; and the parallel mechanisms with the two degrees of freedom both have the characteristics of symmetrical structure and no singularities. The symmetrical parallel mechanism without the singularities, which is disclosed by the invention, can be applied to the fields of motion simulators, telescope secondary mirror support mechanisms, mechanical wrists, coordinate measuring machines, micro-operation robots, machine tool spindle heads and the like, and has a wide application prospect.

Owner:XIAN UNIV OF TECH

Drive device for erosion tools

ActiveUS8445806B2Rinse cleanQuality improvementElectrical-based machining electrodesElectric circuitsDrive shaftEngineering

A drive device for erosion tools, having a drive shaft, an electrode holder connected to the drive shaft, an axial drive which works on the drive shaft, a rotational drive which works on the drive shaft as a direct drive in a contactless manner, and a radial bearing. The radial bearing is constructed as a ball track.

Owner:IMM INST FUR MIKROTECHNIK GMBH

Supporting device and light exposure device

ActiveCN102484046BStable Position AccuracySuppresses shape changeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight exposureRepeatability

Disclosed are a supporting device and a light exposure device, both of which can achieve the control of an angle of a stage with high repeatability. A spring member (450) is attached to the upper surface of an arm (439c) of a movable member (439) and the lower surface of a substrate support (442), so that the spring member (450), the arm (439c) and the substrate support (442) can move together in the Z-axis direction. In this manner, the change in the form of the spring member (450) can be prevented compared with a case where the spring member (450) is connected to a housing (431), and therefore the accurate positioning of a substrate stage (20) can be achieved stably regardless of the movement of the movable member (439).

Owner:V TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com