Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Expand the range of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

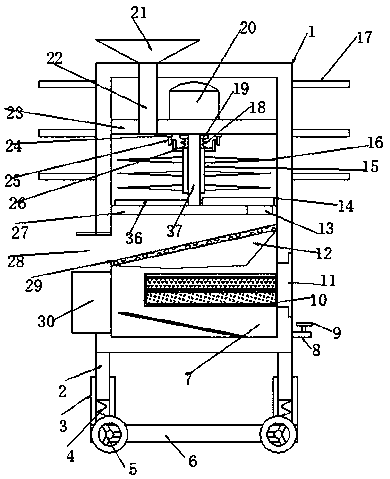

High-efficiency fodder crushing, vibrating and screening device

InactiveCN107486299AExpand the crushing rangeImprove crushing efficiencySievingScreeningElectric machineryMotor shaft

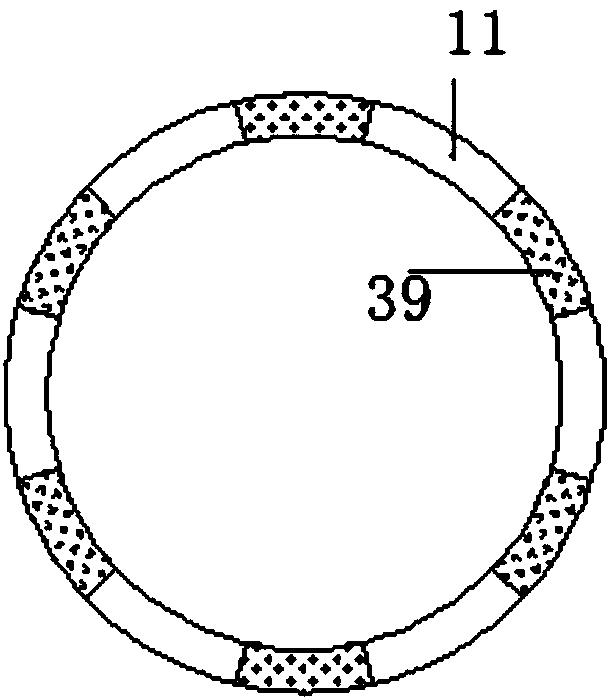

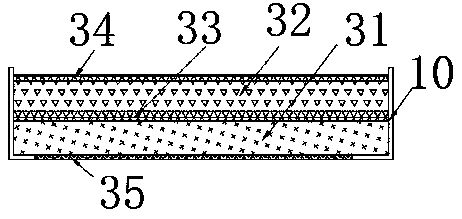

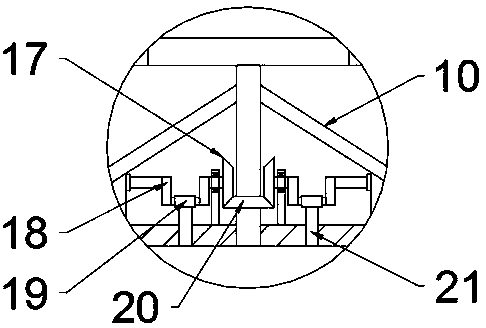

The invention discloses a high-efficiency feed crushing and vibrating screening device, which comprises a base, a slide rail is fixed on the top of the base through a bracket, a crushing box is slidably connected above the slide rail, a screen is arranged at the bottom of the crushing box, and a bottom left corner of the crushing box is connected with a Moving rod; the top of the base is also provided with a fixed seat, the front side wall of the fixed seat is provided with a deceleration motor, the motor shaft at the front end of the deceleration motor is installed with a rotating disc, the top of the front end of the rotating disc is provided with a pin shaft, and the pin shaft is rotatably connected with a connecting rod , the connecting rod is hinged with the moving rod; the left end of the slide rail is fixedly provided with a fixed rod, the top of the front side wall of the fixed rod is hinged with a knocking rod, the bottom of the knocking rod is fixedly provided with a baffle, and the top of the moving rod is provided with a push plate. During the feed grinding process of the present invention, the grinding box moves left and right by rotating the disc, thereby driving the feed to shake; during the grinding process, the knocking rod knocks on the side wall of the grinding box to prevent the feed from sticking to the inner wall of the grinding bucket and avoid screen blockage.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

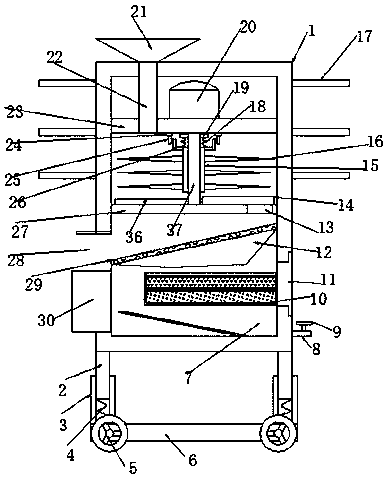

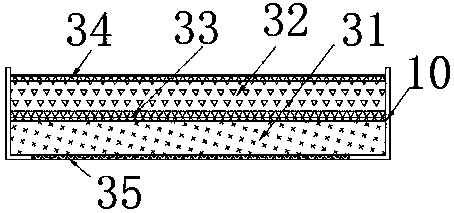

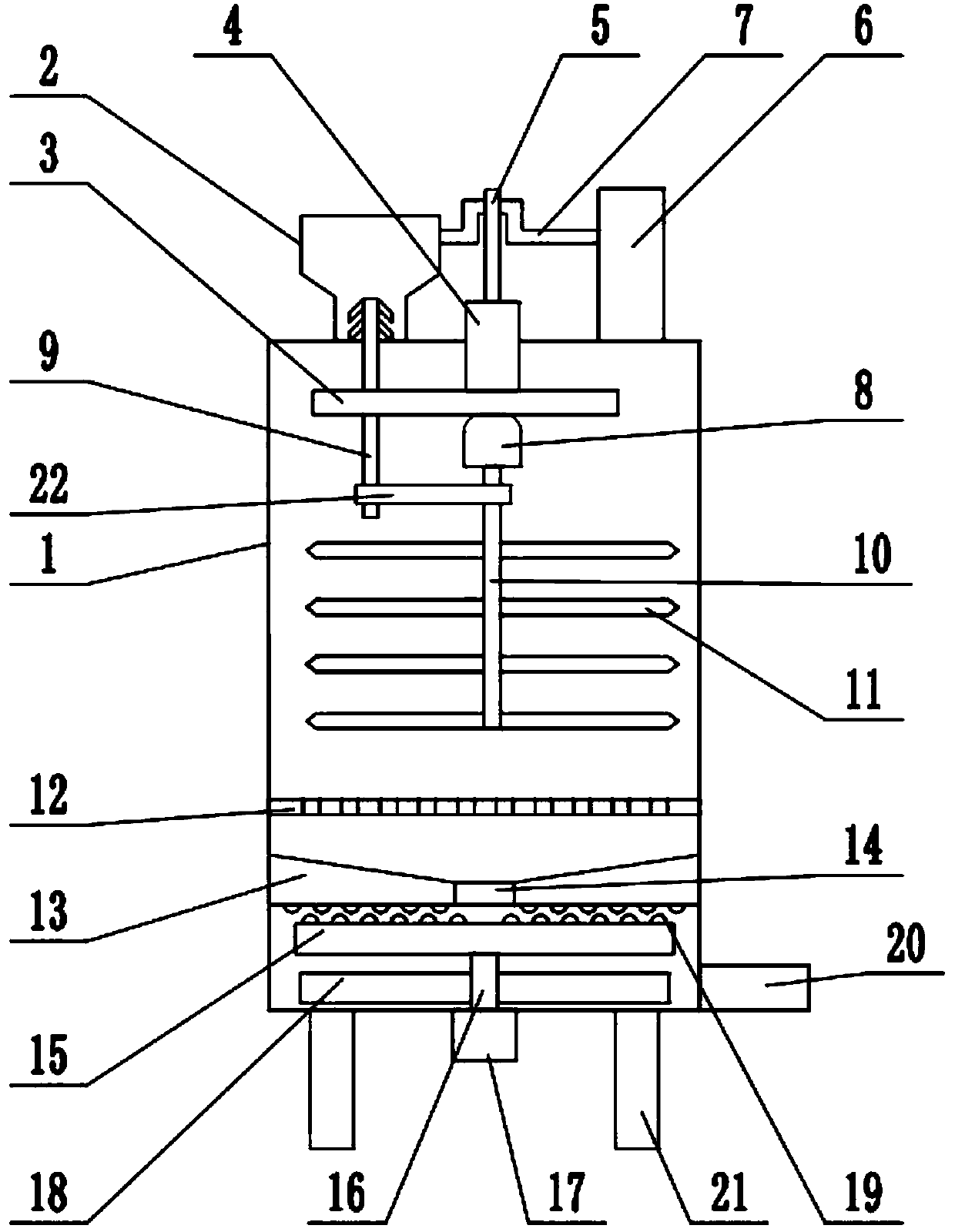

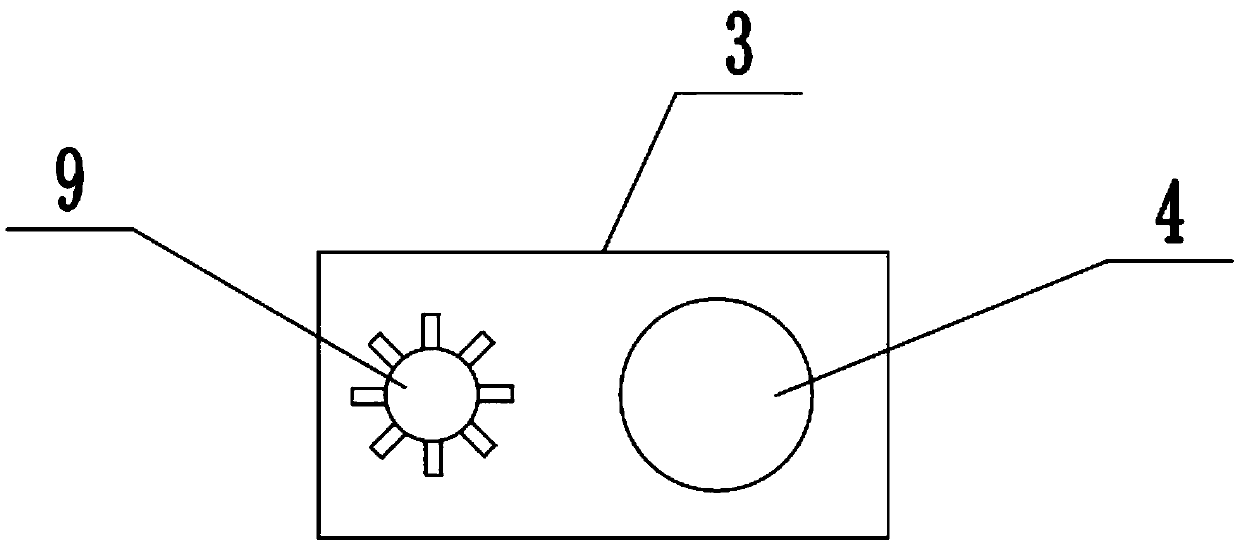

Traditional Chinese medicinal material three-level smashing device

InactiveCN107552211AAchieve three-stage crushingGuaranteed crushing effectNon-rotating vibration suppressionGrain treatmentsThree levelMedicinal herbs

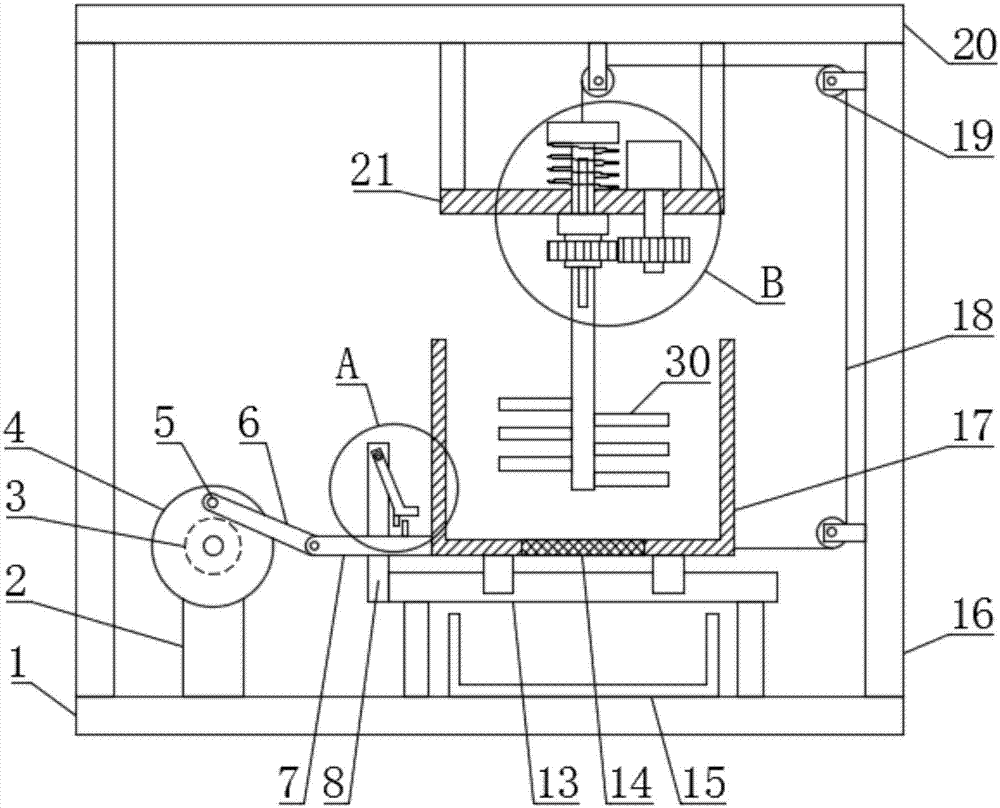

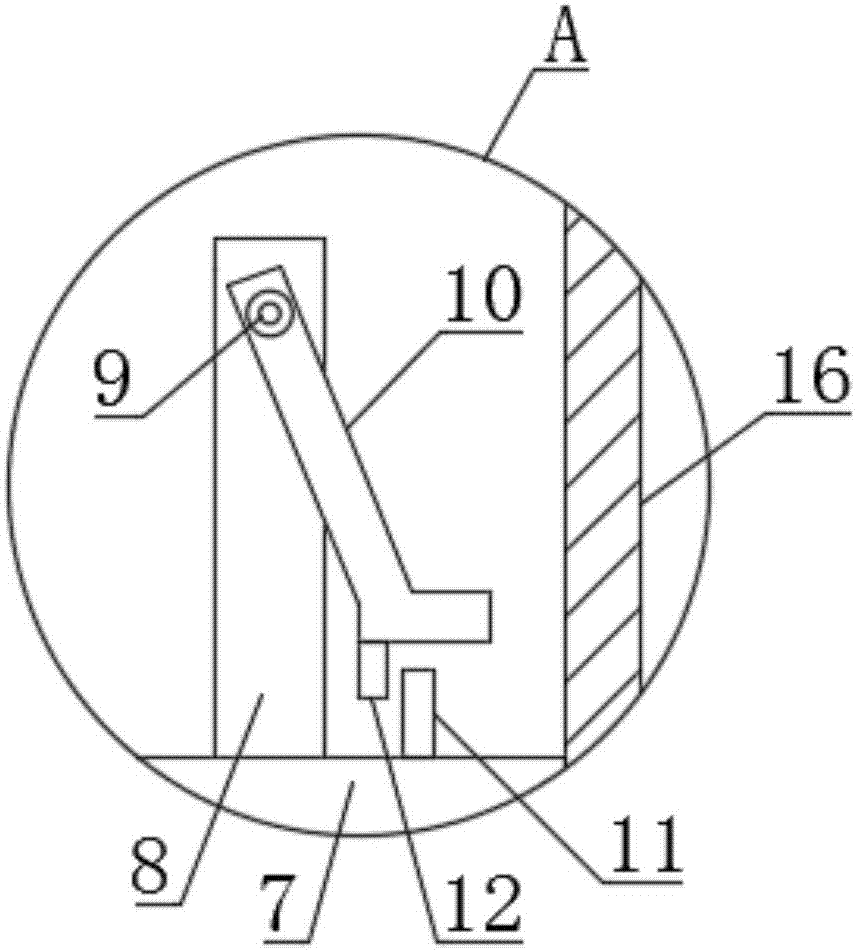

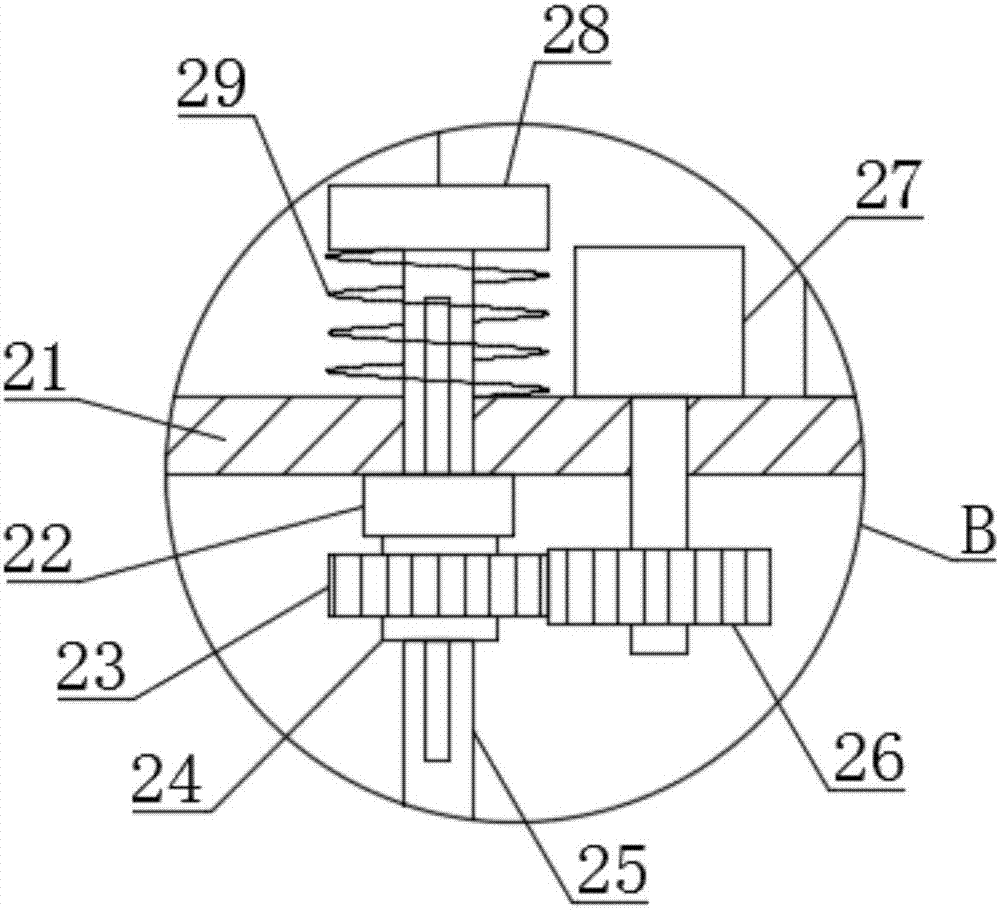

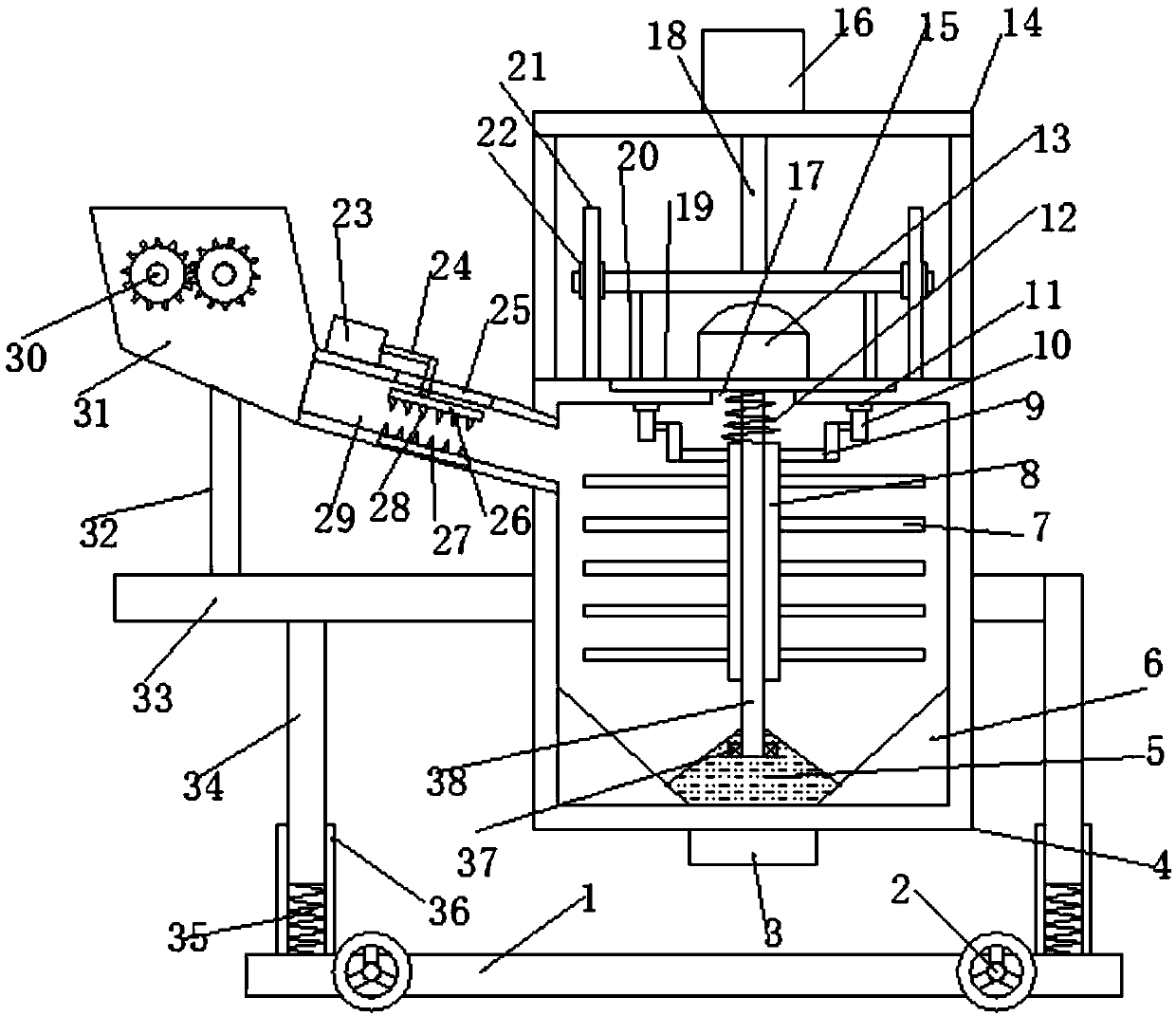

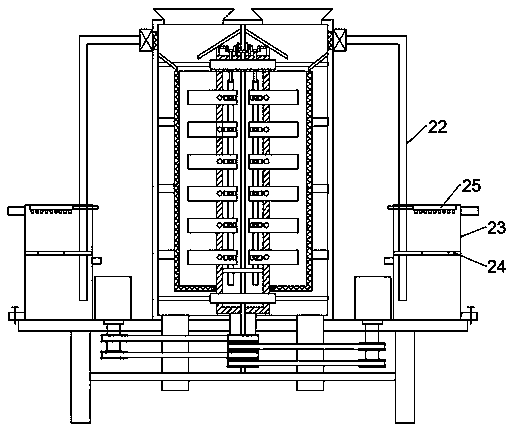

The invention discloses a three-stage crushing device for traditional Chinese medicinal materials, which includes a base and a crushing cylinder. Rollers are arranged on the left and right sides of the base to facilitate the device's transportation. A crushing cylinder is arranged above the base, and a side plate is fixed on the left side of the crushing cylinder. , the side plate and the right side of the support cylinder are provided with outriggers, and the lower end of the outriggers is slidingly provided with shock-absorbing sleeves. The shock-absorbing sleeve is connected and fixed. This shock-absorbing mechanism helps to improve the shock-absorbing effect of the device. The invention has a simple and reasonable structure, is easy to carry, has good shock resistance, and is convenient for discharging materials. It realizes three-stage crushing of materials, thereby ensuring In addition, in the final crushing process, the crushing knife 7 can be moved up and down, thereby increasing the crushing range of the crushing knife, which helps to improve the crushing effect, and has strong practicability.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

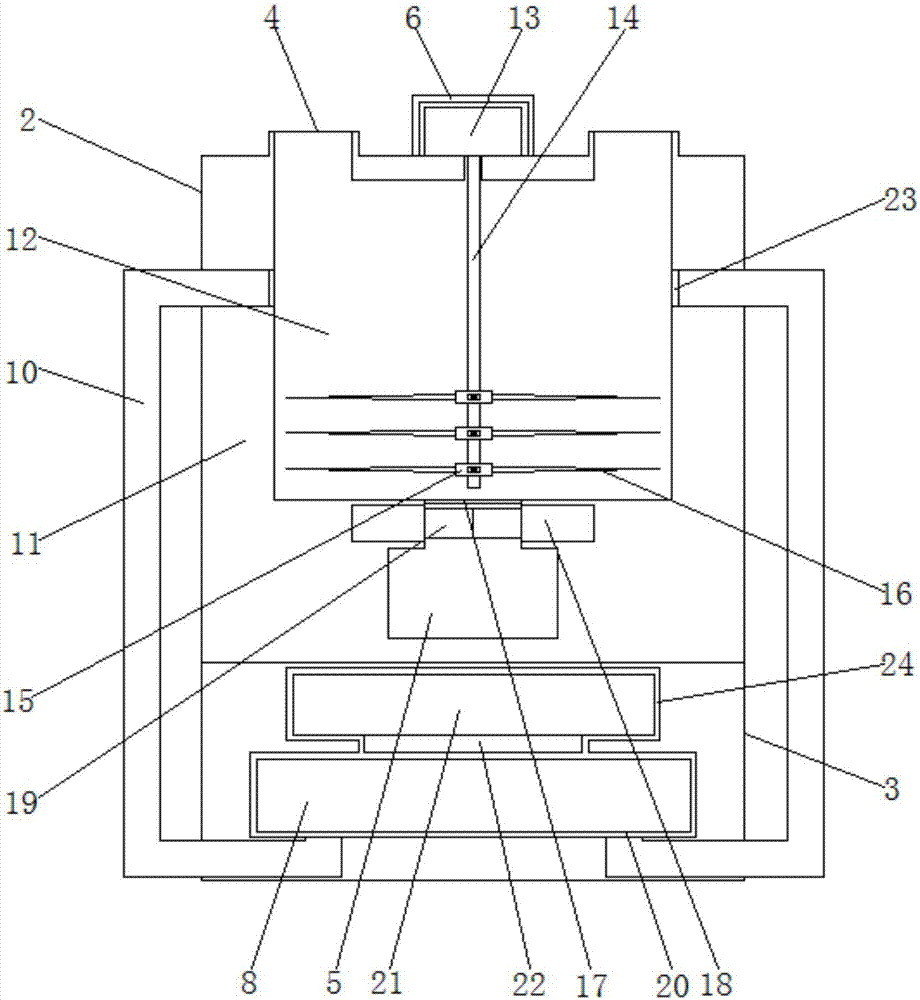

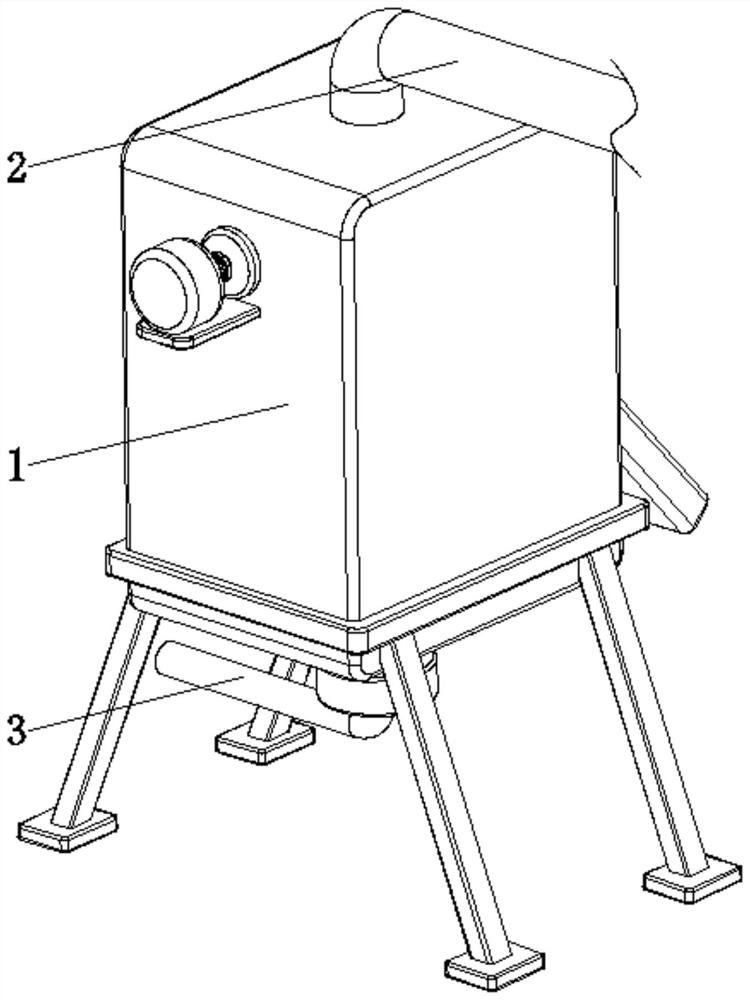

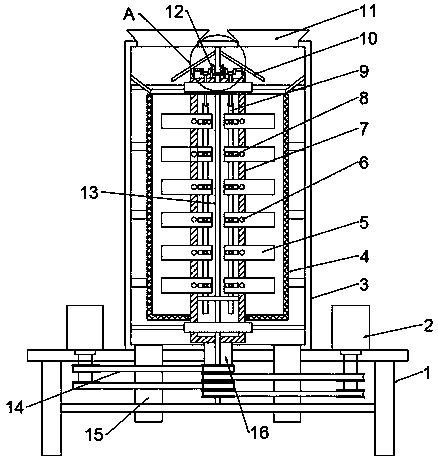

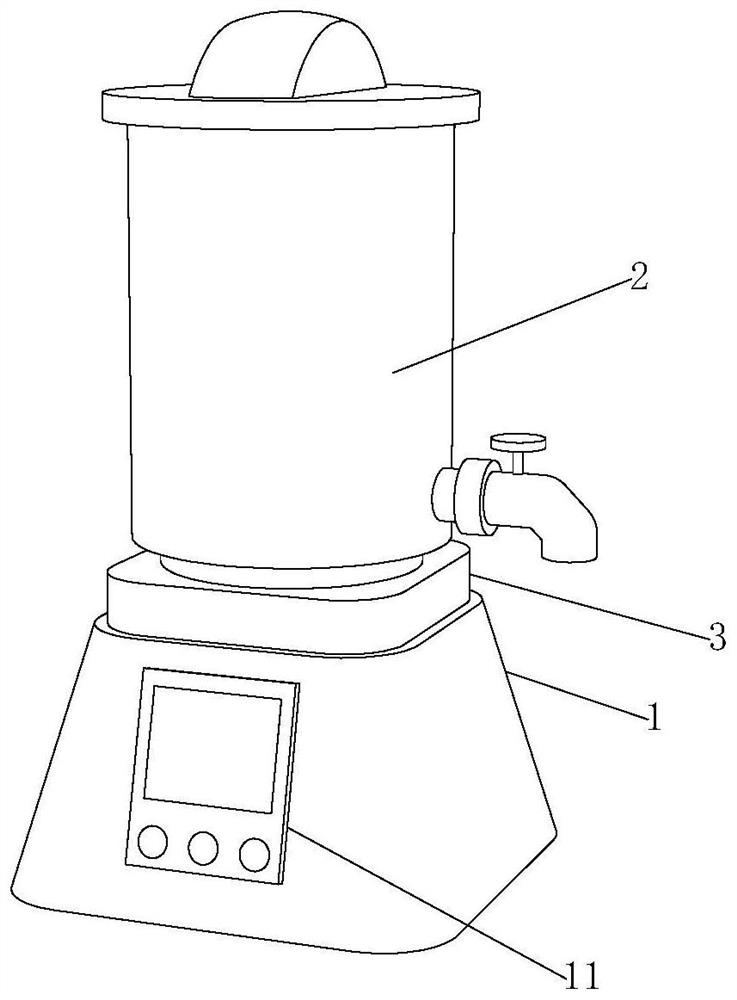

Traditional Chinese medicine crushing machine

ActiveCN107029841AEasy to controlConvenient crushing operationDrying gas arrangementsGrain treatmentsChinese drugMotor protection

The invention discloses a traditional Chinese medicine crushing machine. The traditional Chinese medicine crushing machine comprises a traditional Chinese medicine crushing machine body, wherein the traditional Chinese medicine crushing machine body comprises a traditional Chinese medicine crushing device; a traditional Chinese medicine drying device is fixedly connected to the bottom of the traditional Chinese medicine crushing device; a traditional Chinese medicine charge pipe is fixedly communicated to the top of the traditional Chinese medicine crushing device; an inner shell is arranged in the traditional Chinese medicine crushing device; a traditional Chinese medicine crushing chamber is formed in the inner shell; the bottom of the traditional Chinese medicine charge pipe penetrates through the inner shell and communicates with the traditional Chinese medicine crushing chamber; and a motor protection cover is fixedly connected to the top of the traditional Chinese medicine crushing device. According to the traditional Chinese medicine crushing machine disclosed by the invention, traditional Chinese medicines in the traditional Chinese medicine crushing chamber are filtered through a filter plate, so that the crushing efficiency of the medicines is increased, only the crushed medicines can pass through the filter plate, the crushing force of the medicines is increased, uniform crushing for the traditional Chinese medicines is achieved, the crushing effect of the medicines is improved, the advantage of fine crushing is achieved, and then the problem of influence on a medicine manufacturing process due to the poor crushing effect of an existing traditional Chinese medicine crushing machine is effectively solved.

Owner:DAYA PHARMA HUIZHOU

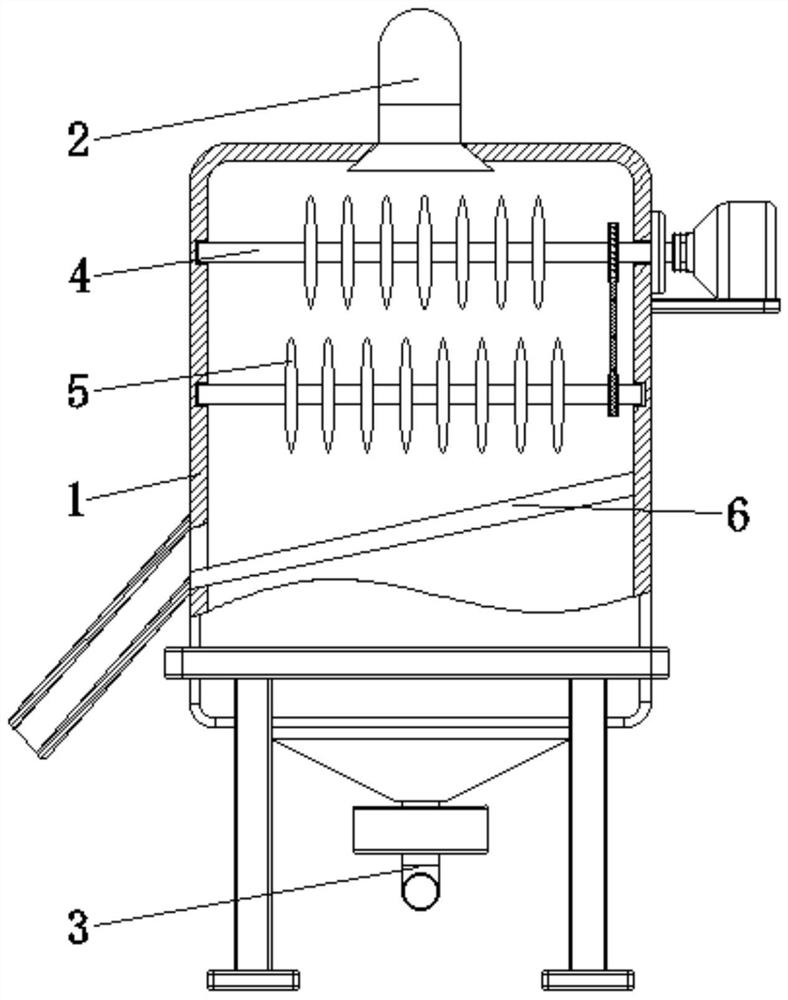

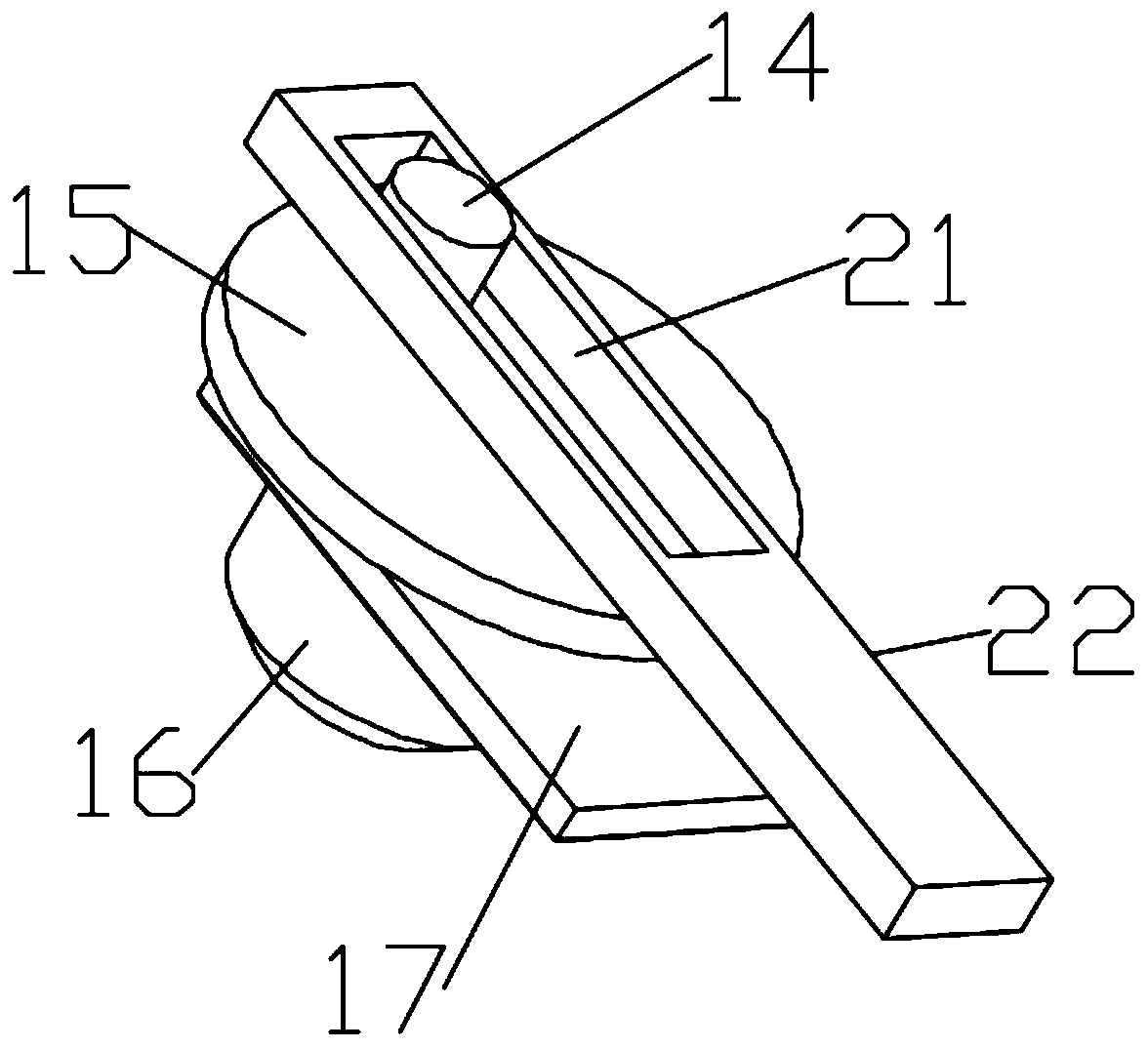

Sewage treatment equipment

InactiveCN112604345AReduce shockAvoid bendingGrain treatmentsStationary filtering element filtersSewage treatmentDrainage tubes

The invention discloses sewage treatment equipment which comprises a treatment box, a water inlet pipe and a drainage pipe, the water inlet pipe is fixed in the center of the top of the treatment box, the drainage pipe is arranged in the center of the bottom of the treatment box, and the water inlet pipe and the drainage pipe are both communicated with the treatment box. The driving rotating shaft is rotatably connected between the two corresponding sides of the inner wall of the treatment box and is close to the top, the crushing devices are fixed to the surface of the driving rotating shaft, the crushing devices are evenly distributed on the surface of the driving rotating shaft and are located at the end of the water inlet pipe, and the filter screen device is fixed to the inner wall of the treatment box and is close to the bottom; and the invention relates to the technical field of sewage treatment. According to the sewage treatment equipment, the purposes of crushing sand balls and preventing blockage are achieved, the sand balls which are bonded into balls can be crushed in time, impact on the equipment is reduced, the service life of the equipment is prolonged, meanwhile, blockage can be prevented, the filtering effect is good, and the using performance is improved.

Owner:刘朝成

Chemical raw material smashing mechanism and smashing and screening device

The invention discloses a chemical raw material smashing mechanism and relates to the technical field of chemical equipment. The chemical raw material smashing mechanism aims at solving the problems that an existing smashing device is single in structure, small in smashing range and long in smashing time. The chemical raw material smashing mechanism comprises a motor, a rotary shaft and smashing blades. An output shaft of the motor is fixedly connected with an L-shaped rod through a coupler. A sleeve is welded and fixed to the end of the short edge of the L-shaped rod. The rotary shaft is connected with the top of a smashing box through a universal bearing, and a bevel gear is mounted on the shaft section, located above the smashing box, of the rotary shaft. An inner bevel gear ring is mounted on a mounting frame, and the multiple smashing blades are mounted on the shaft section, located in the smashing box, of the rotary shaft at intervals from top to bottom. The invention further discloses a smashing device comprising the chemical raw material smashing mechanism. According to the smashing mechanism, smashing can be fuller and more uniform, and the smashing efficiency is improved;and by arranging an incomplete gear, a gear rack, a disc, a lifting lever, a first spring and a third spring, screen meshes can be prevented from being blocked, and the screening efficiency is improved.

Owner:SHANDONG BIO BIOTECH

Breaking refining device used for concrete block reutilization

ActiveCN109277172APlay the role of sievingExpand the range of crushingCocoaGrain treatmentsScreening effectDrive shaft

The invention discloses a breaking refining device used for concrete block reutilization and relates to the technical field of building machines. The breaking refining device comprises a base and a smashing box fixed to the base. A top plate is fixed to the smashing box, and a screen tray is horizontally and rotationally arranged in the smashing box. A spur rack II is transversely installed in thesmashing box in a sliding manner, and the bottom of the spur rack II is connected with a transmission casing pipe in a pivot manner, wherein the transmission casing pipe is fixedly connected with a breaking pressing plate. The transmission casing pipe is fixedly sleeved with a cylindrical spur gear. By means of the breaking refining device, due to relative rotation of the breaking pressing plateand the screen tray, concrete blocks on the screen tray can be rotationally broken, the breaking pressing plate conducts transverse reciprocating motion while rotating, and the breaking range of the concrete blocks is greatly enlarged; the screen tray also has a screening effect, due to the cooperation of a grinding bottom plate and the screen tray, the effect of conducting secondary grinding on the primarily broken concrete blocks is achieved, and the refining degree is greatly promoted; and an arranged smashing blade rotates along with a driving shaft, the concrete grinding effect is greatlyimproved, and the refining degree is higher.

Owner:浏阳市飞宇混凝土有限公司

High-efficiency smashing and grinding integrated machine for traditional Chinese medicinal materials

InactiveCN107321474AIncrease granularityImprove work efficiencyGrain treatmentsFiltrationEngineering

The invention discloses a high-efficiency smashing and grinding integrated machine for traditional Chinese medicinal materials. The high-efficiency smashing and grinding integrated machine comprises a base, a machine body, a smashing box, a grinding roller and a crumb removing mechanism, wherein the machine body is arranged above the base; a shock absorber is arranged between the machine body and the base; and a first crushing roller is arranged at the central position of an inner cavity in the smashing box, second smashing rollers are symmetrically arranged on the two sides of the first grinding roller; an arc-shaped filter plate is arranged at the central position of the bottom of the smashing box; the front end surface of the first smashing roller is coaxially and fixedly provided with a material turning rod; a material turning plate is arranged at the end part of the material turning rod; a discharging plate which is inclined to the left is arranged below the smashing box, a grinding roller is arranged above the left side of the discharging plate; and the crumb removing mechanism is arranged below the discharging plate. The high-efficiency smashing and grinding integrated machine can effectively improve the refining degree of the traditional Chinese medicinal materials, ensures the use effect of the medicinal materials, and can remove iron dust in the medicinal materials and ensures the cleanliness of the medicinal materials.

Owner:吴鑫锋

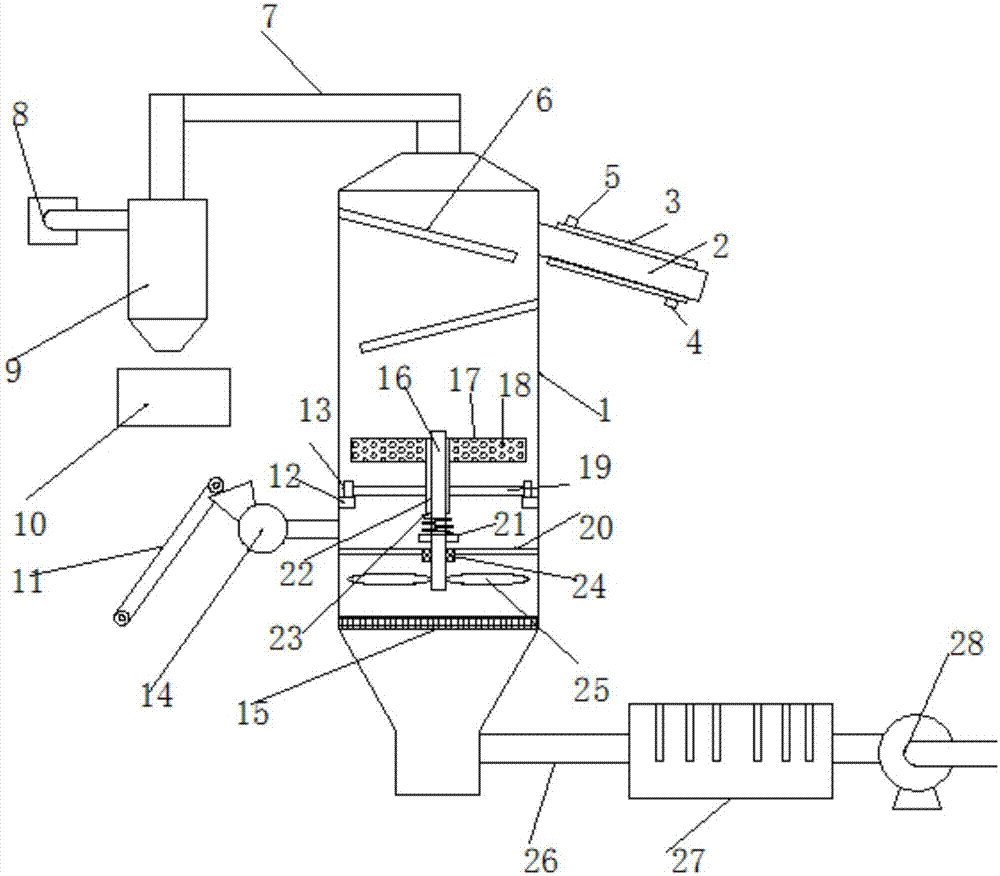

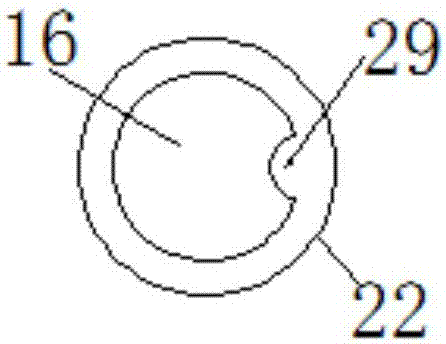

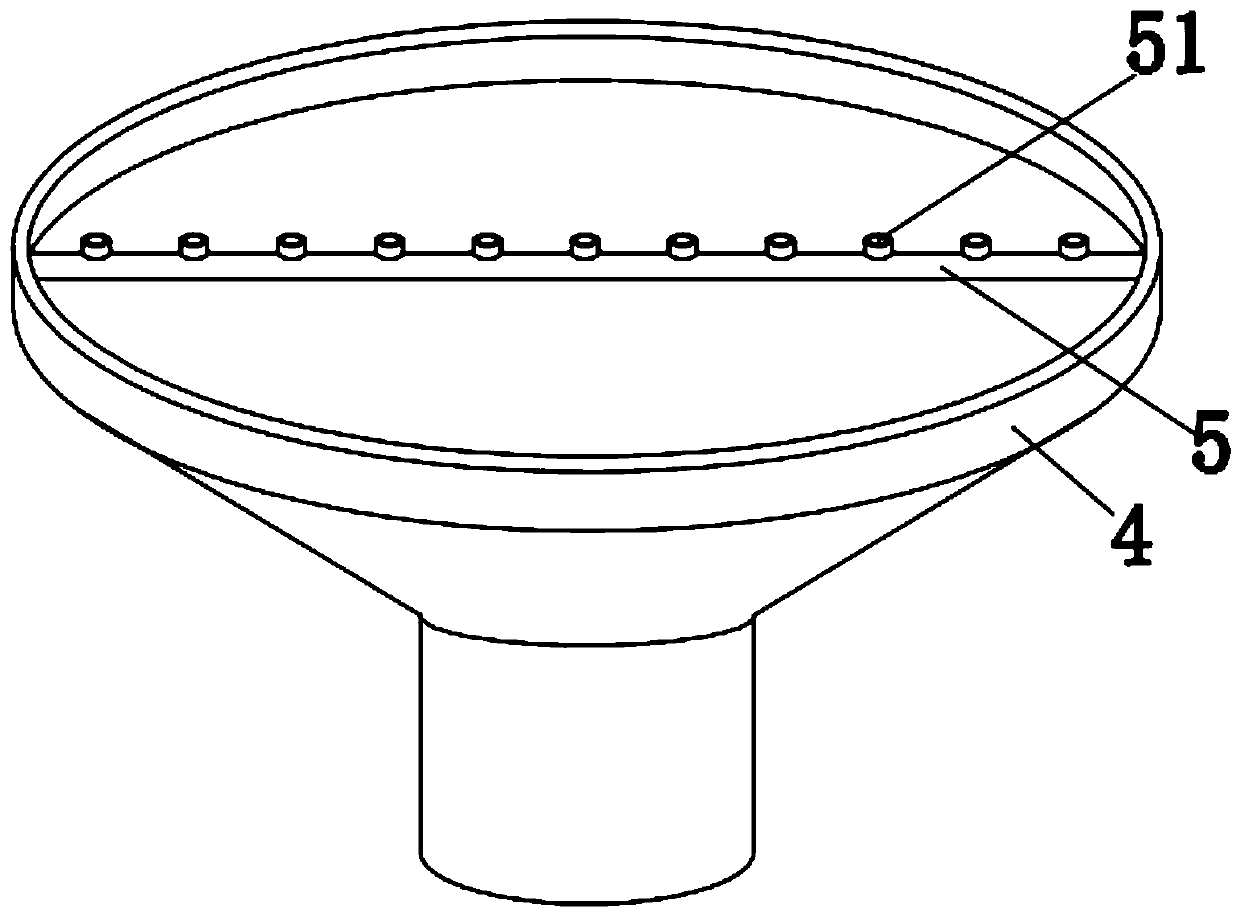

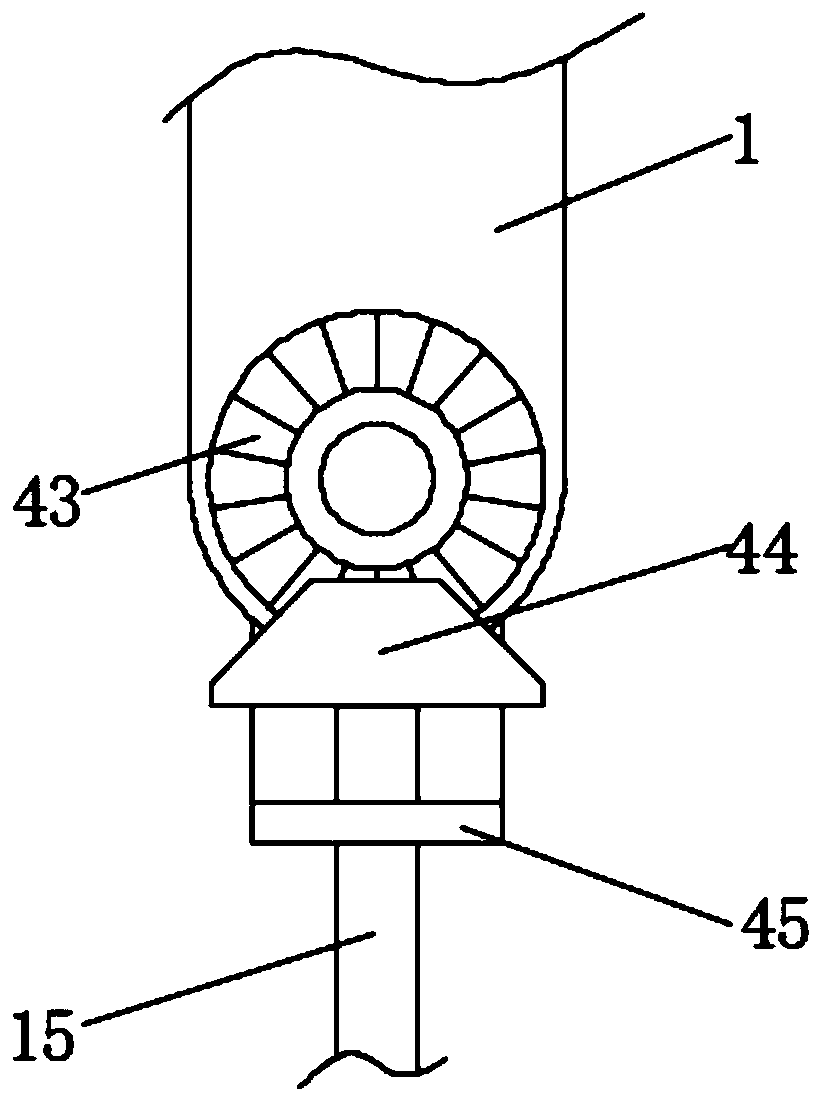

Fluidized bed drying device used for traditional Chinese medicine production and achieving crushing through air flow driving

InactiveCN107576150ADrying helpsHelp break upDrying solid materials with heatGrain treatmentsFluidized bed dryingEngineering

The invention discloses a fluidized bed drying device used for traditional Chinese medicine production and achieving crushing through air flow driving. An air inlet of the lower right end of a fluidized bed is connected with the air outlet end of a heating box through an air inlet pipe. The air inlet end of the heating box is connected with the air outlet end of an air blower. A discharging pipe is arranged on the right upper side of the fluidized bed, and a heat exchange water tank is arranged on the outer side of the discharging pipe. An air outlet at the upper end of the fluidized bed is connected with a cyclone separator through an air outlet pipe, and the air outlet end of the cyclone separator is connected with an exhaust fan. A feeding pipe is arranged on the lower left side of thefluidized bed, and a feeding mechanism is arranged on the left side of the feeding pipe and is a circulating conveyor belt. An air distributing plate is arranged at a lower end opening of the fluidized bed, and air outlets facilitating air outlet are evenly distributed in the air distributing plate. Distributing frames are arranged at an upper end opening of the fluidized bed in a staggered mode.The structure is simple and reasonable, the discharging temperature is decreased, the drying effect on materials is improved, and practicability is high.

Owner:HUNAN HUIXUN ENTERPRISE MANAGEMENT CO LTD

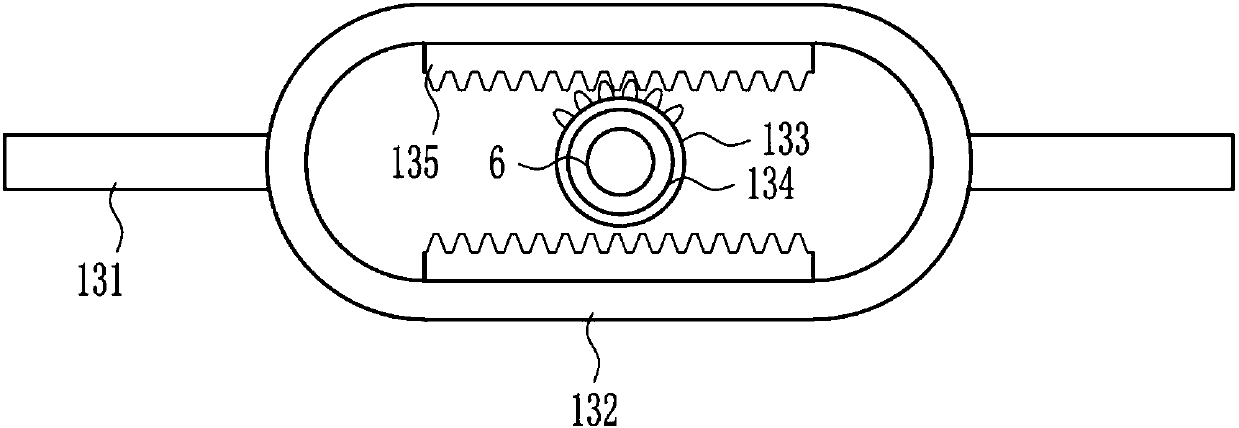

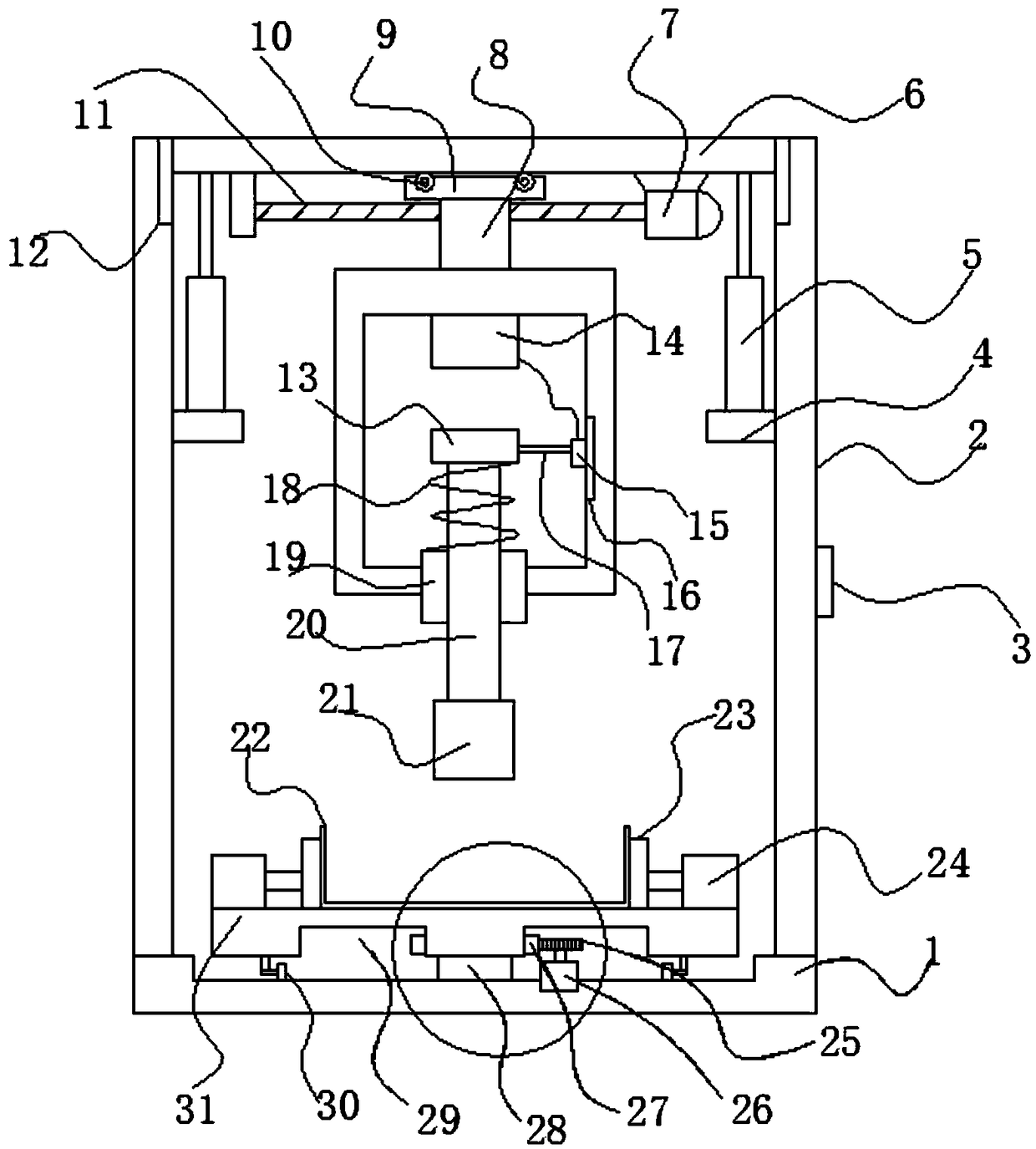

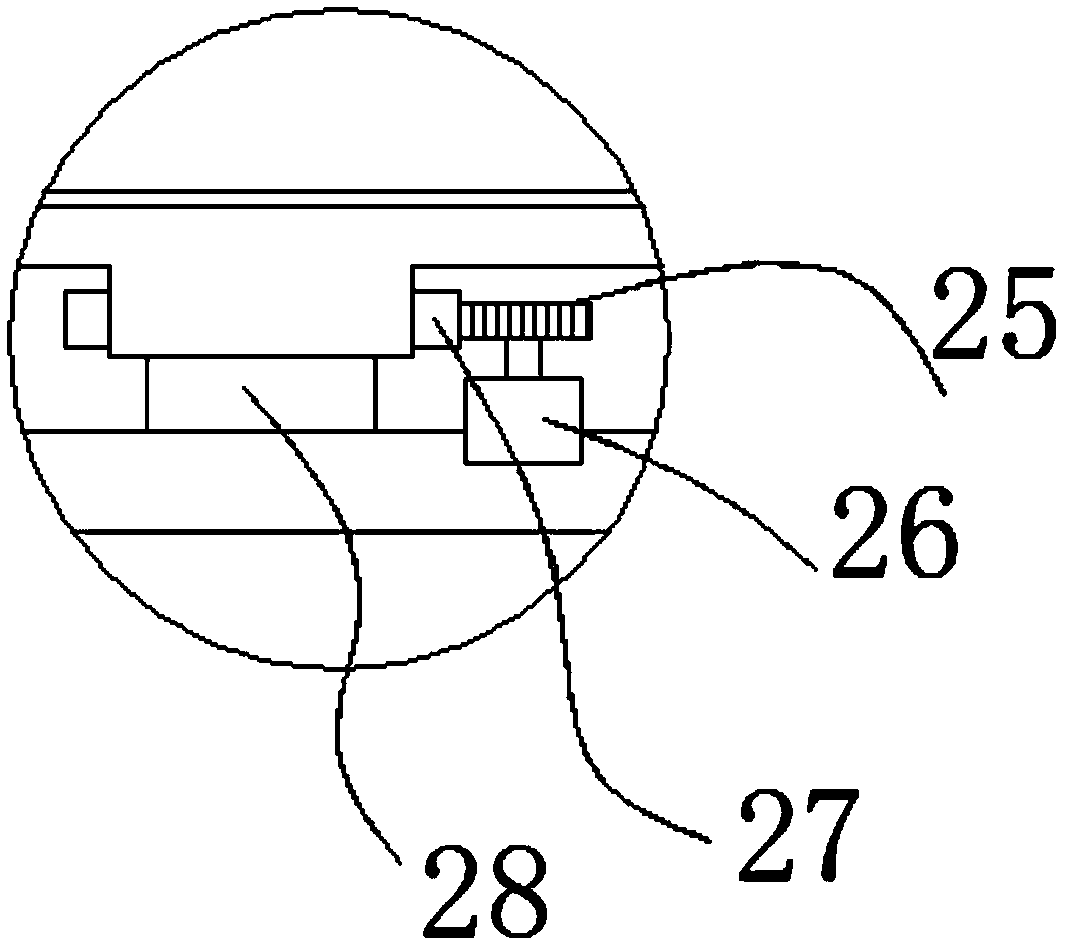

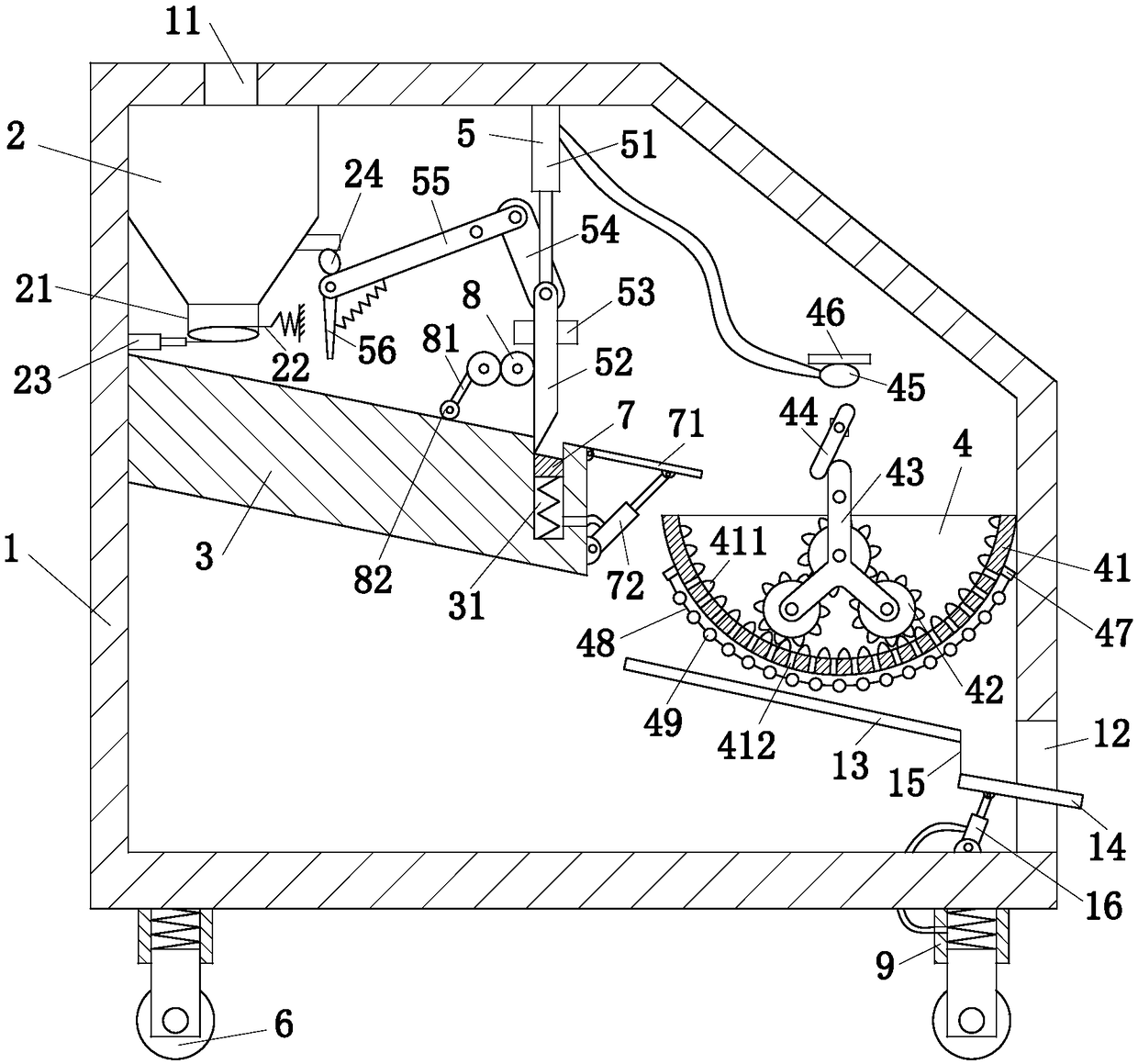

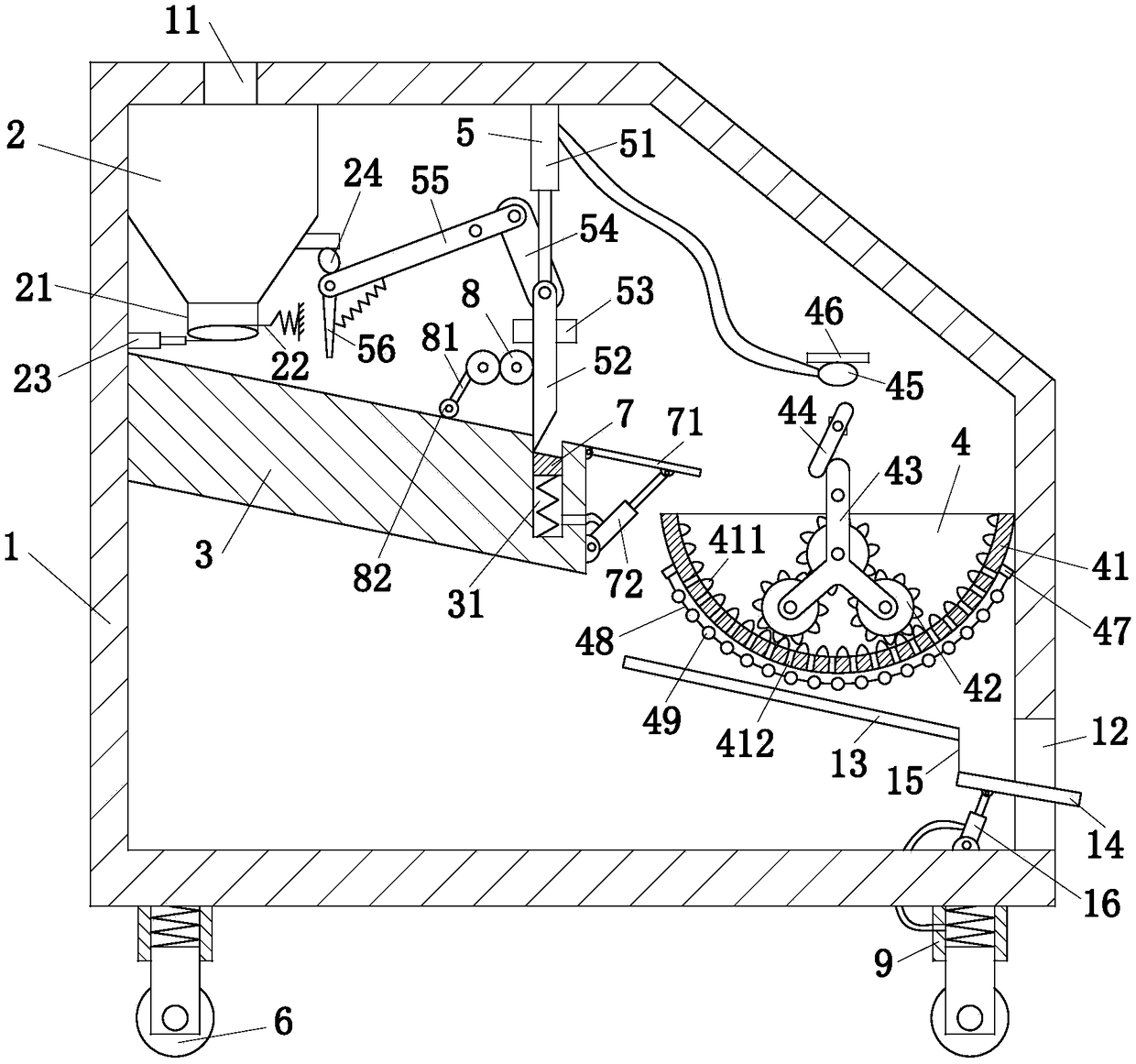

Vertical kitchen waste pulverizing device

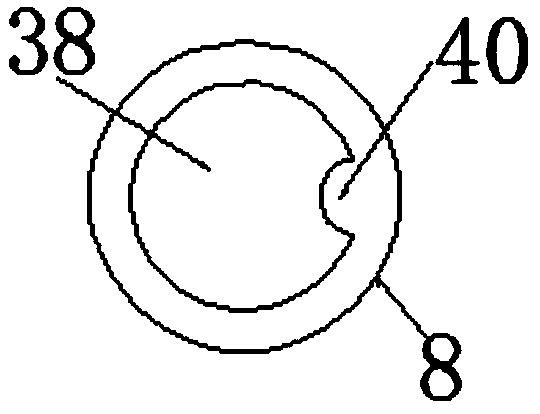

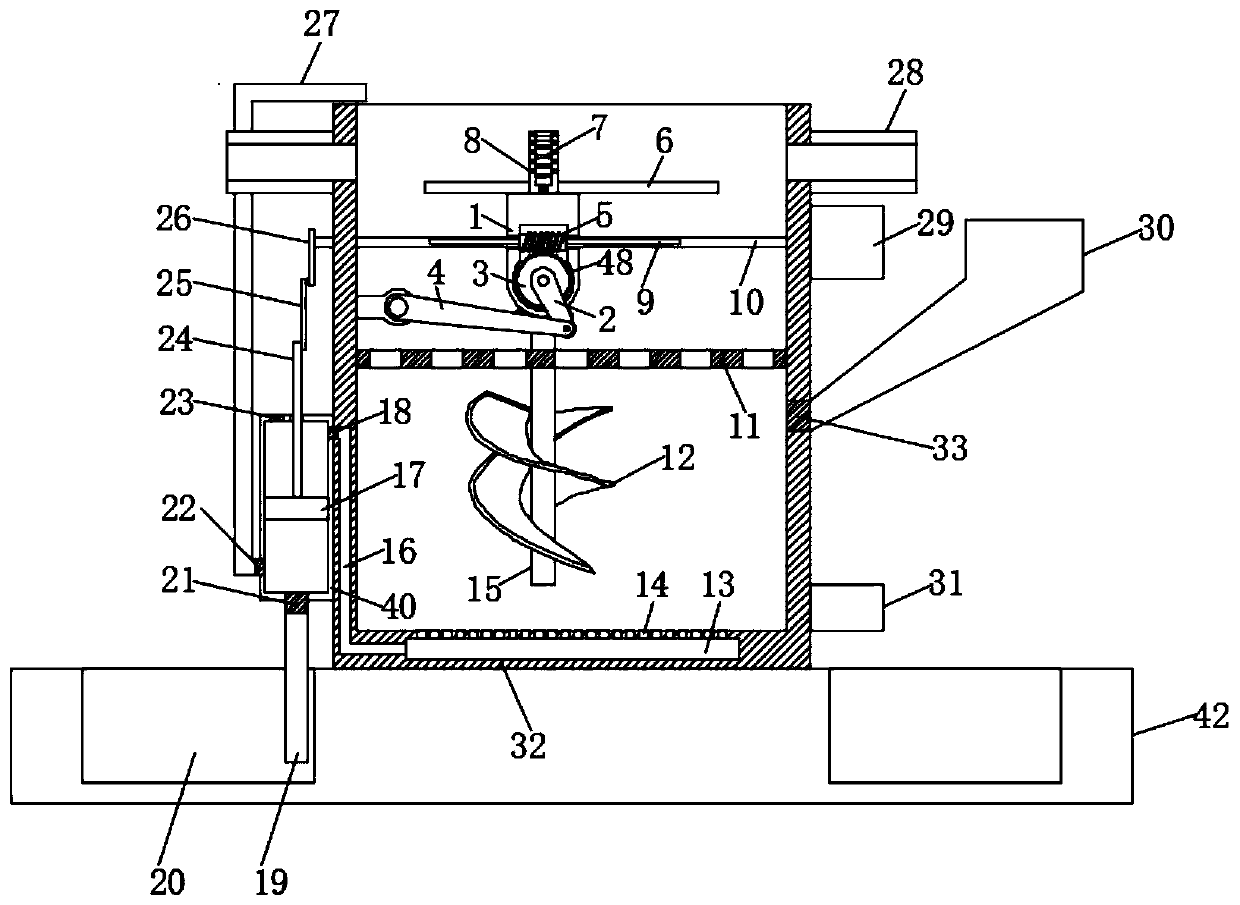

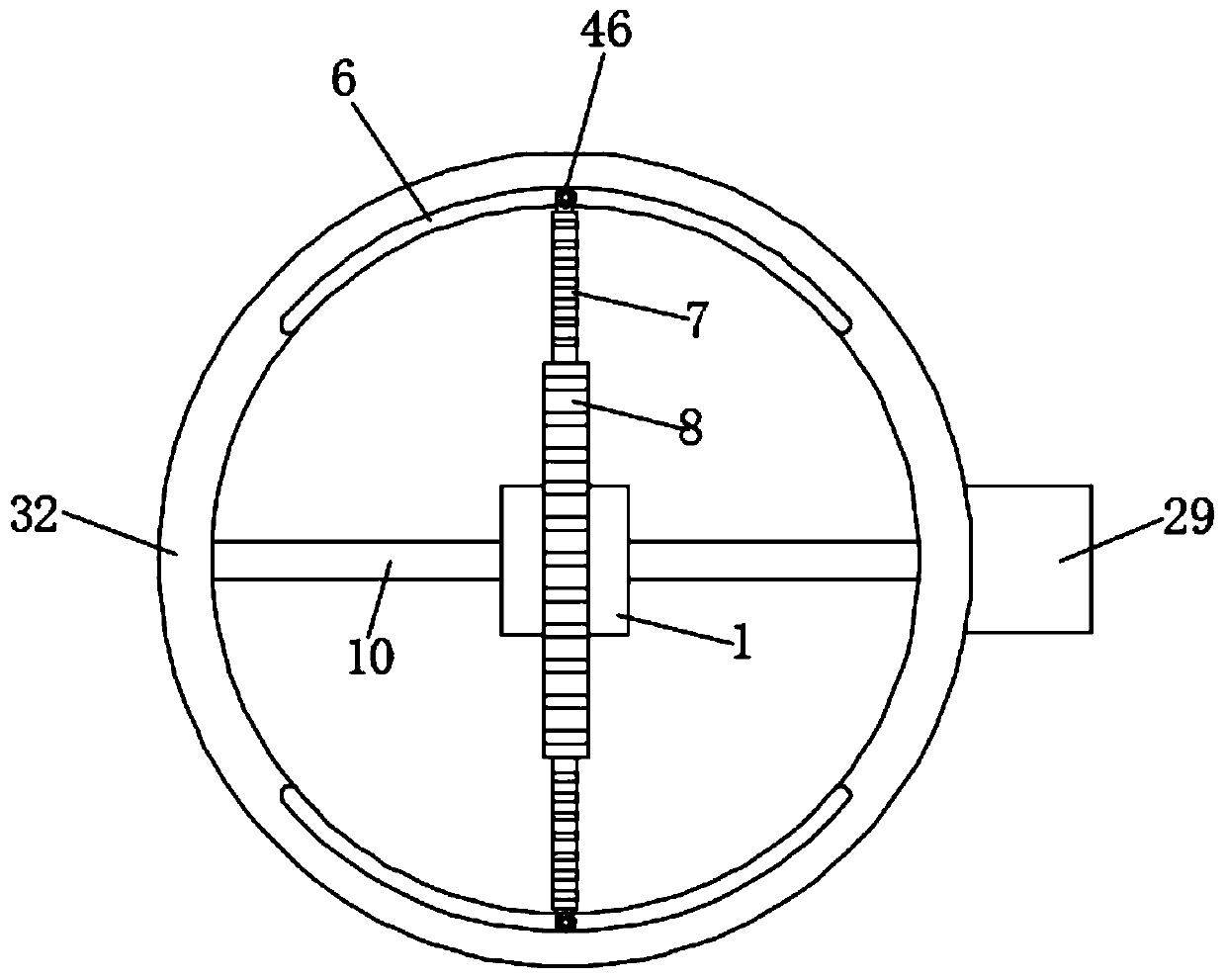

ActiveCN108187888AExpand the range of crushingAchieve recyclingGrain treatmentsFiltration circuitsWater savingDrive shaft

The invention discloses a vertical kitchen waste pulverizing device which comprises a treatment box; a base is arranged below the treatment box; rollers facilitating device carrying are arranged on the left side and the right side of the base; a partition plate is arranged in the treatment box; a driving motor is fixedly arranged in the middle of the upper end of the partition plate; the driving motor is electrically connected with an electric control switch; a driving shaft is arranged at the output end of the driving motor; the driving shaft is slidingly sleeved with a polarization sleeve; alimiting groove is formed in the inner wall in the polarization sleeve; a limiting bulge fitting with the limiting groove is formed on the outer side of the driving shaft; and the limiting groove fits with the limiting bulge to limit relative rotation between the driving shaft and the polarization sleeve. The vertical kitchen waste pulverizing device is convenient to carry; the pulverizing rangeof pulverizing cutters is extended; the vertical kitchen waste pulverizing device contributes to improving the pulverizing effect; recycling of kitchen waste water is achieved by the vertical kitchenwaste pulverizing device, so that the water saving function is played; and with such a vertical structure, the floor area of the vertical kitchen waste pulverizing device is reduced.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

Plastic bag crushing and recovering device

ActiveCN107627494AExpand the range of crushingImprove crushing efficiencySievingScreeningEngineeringElectromagnet

The invention relates to a crushing and recovering device and in particular relates to a plastic bag crushing and recovering device. The invention provides the plastic bag crushing and recovering device. In order to solve the technical problem, the invention provides the plastic bag crushing and recovering device which comprises an iron crushing box, an electromagnet, a screen plate and a crushingcutter and the like. A "-"-shaped hole is formed in the top of the iron crushing box; the screen plate is rotatably connected to the bottom of the right side of the crushing box; the left end of thescreen plate is connected to the electromagnet; the right end of the screen plate is connected to a handle; a top plate is arranged above the iron crushing box; and a first slide rail and a linking device are arranged in the bottom of the top plate. The device provided by the invention achieves the effects of high plastic bag crushing efficiency, resource conservation and recycling and environmental protection, can limit the position of the screen plate to prevent the screen plate from swinging excessively to leak the crushed plastics, and further stir and mix the plastic bags in the crushingbox to more finely and uniformly crushing the plastic bags so as to prevent the plastic bags are left on the screen plate.

Owner:江苏通发环保科技有限公司

Garbage and sludge removing mechanism for river channel treatment

PendingCN110185081AAvoid scatterStrong targetingMechanical machines/dredgersMarine engineeringSludge

The invention discloses a garbage and sludge removing mechanism for river channel treatment. The mechanism comprises a ship body for providing buoyancy, and a through hole for penetrating through theupper end surface of the ship body; a mounting frame is erected above the through hole; a lifting cylinder penetrates through the upper and lower end surfaces of the mounting frame; the upper end of the lifting cylinder is connected with a lifting part for driving the lifting cylinder to move up and down; the lifting part comprises a lifting motor arranged at the top of the lifting cylinder; a lifting shaft is arranged at an output end of the lifting motor; lifting blades for upwards lifting sludge along the lifting cylinder are arranged on the outer side of the lifting shaft; and a cover bodyis arranged in a lower port of the lifting cylinder. The defects in a traditional device are improved; a water spraying crushing mode is designed; the crushing mode is to use ultrahigh impact force of high-pressure water currents to crush the sludge, so that the crushing effect is good; and the cover body can isolate the crushing area from the external to prevent scattering of the sludge to achieve higher pertinence.

Owner:YIKANG TECH CO LTD

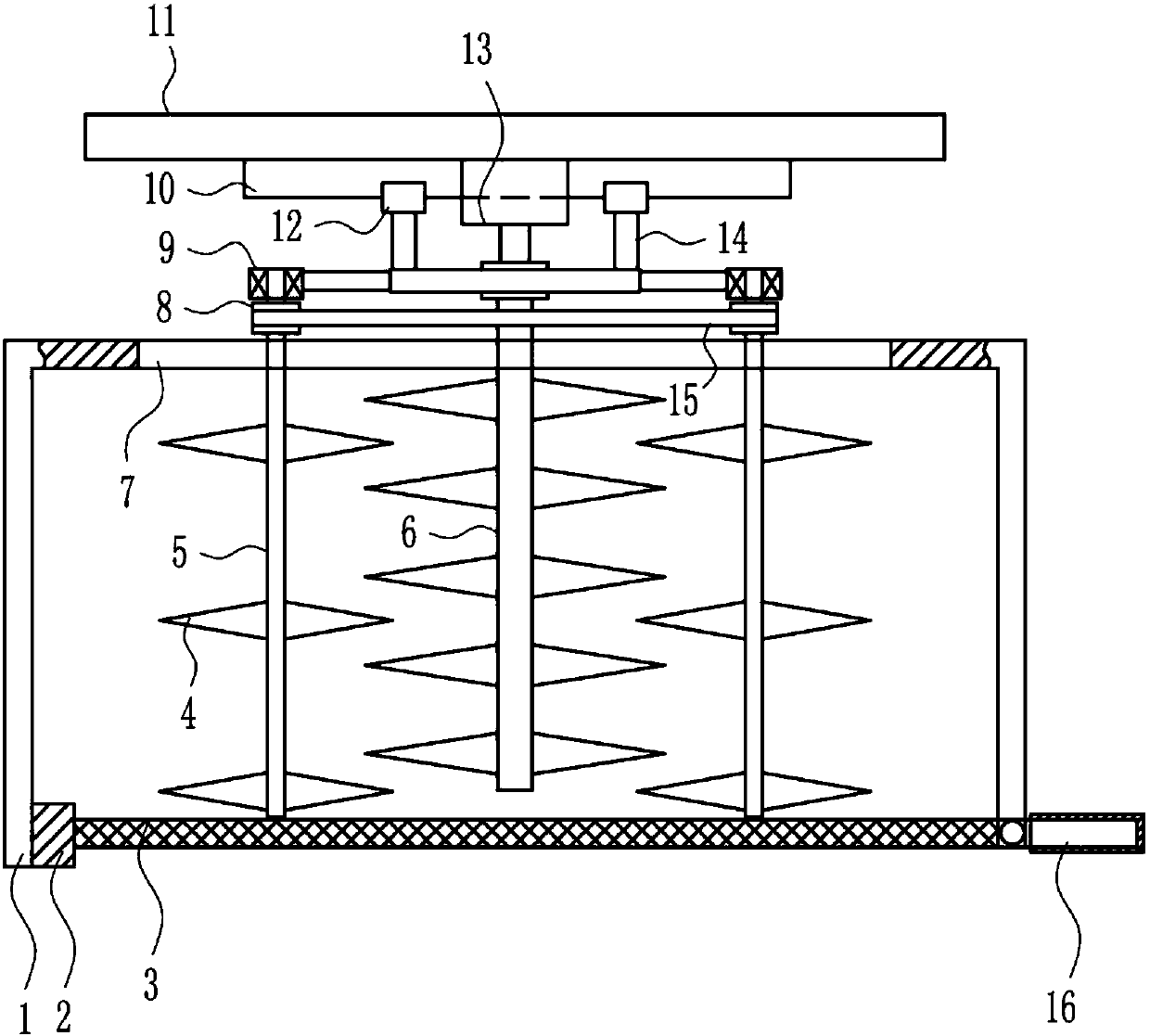

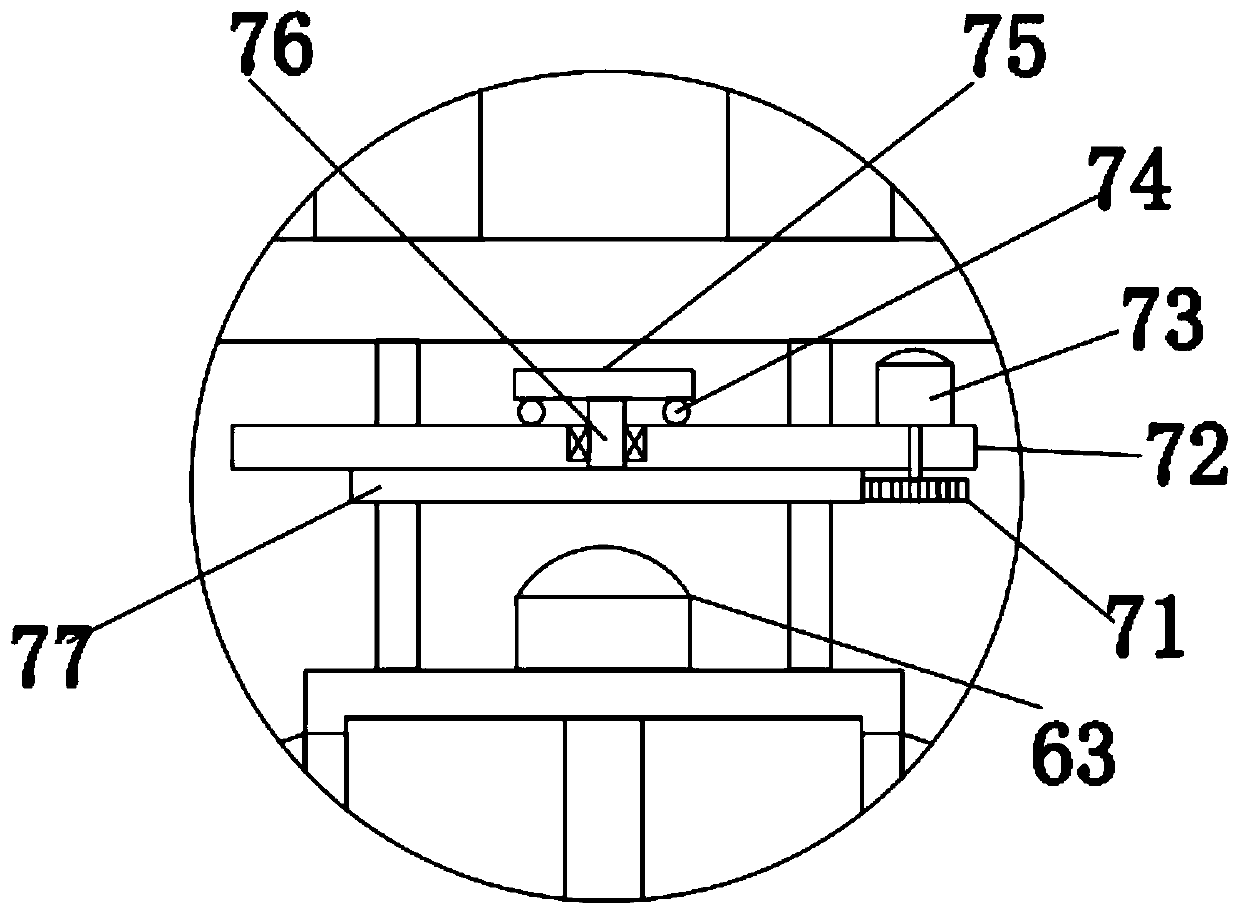

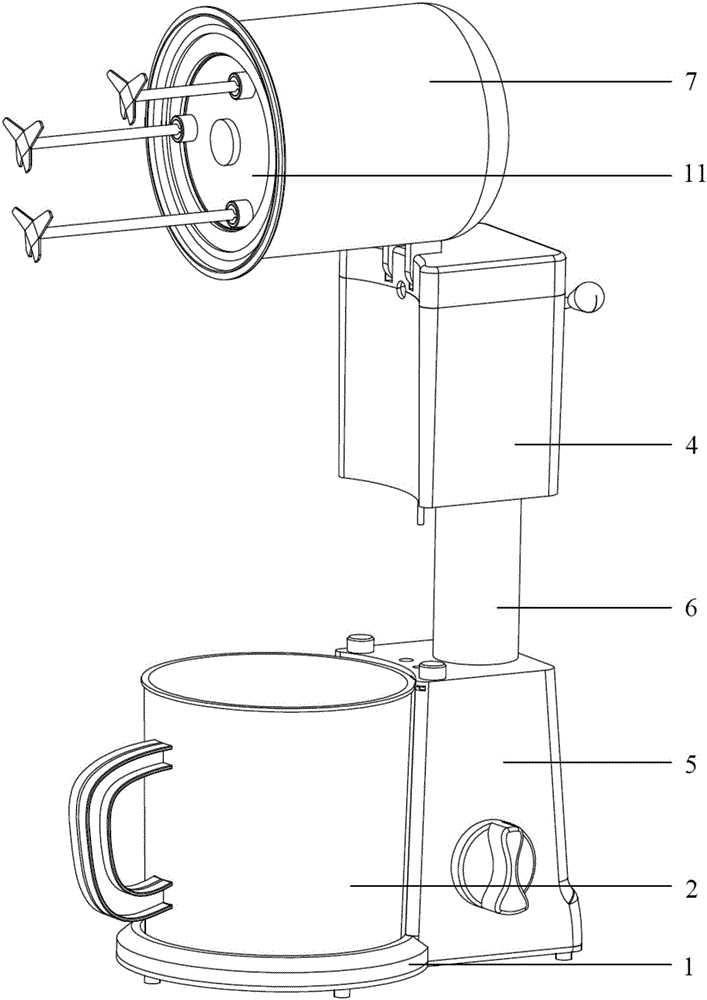

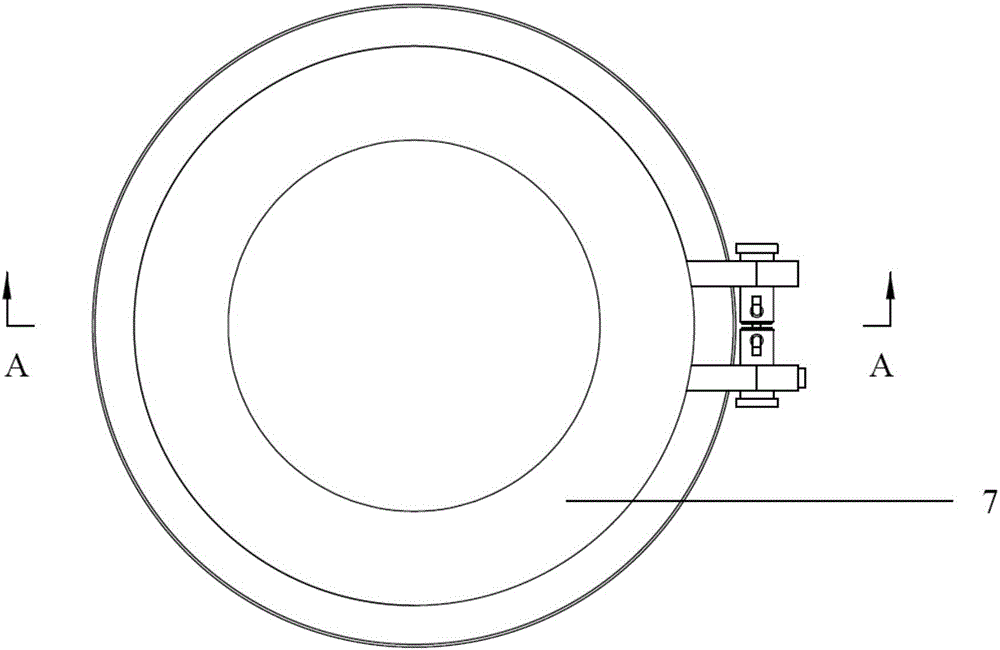

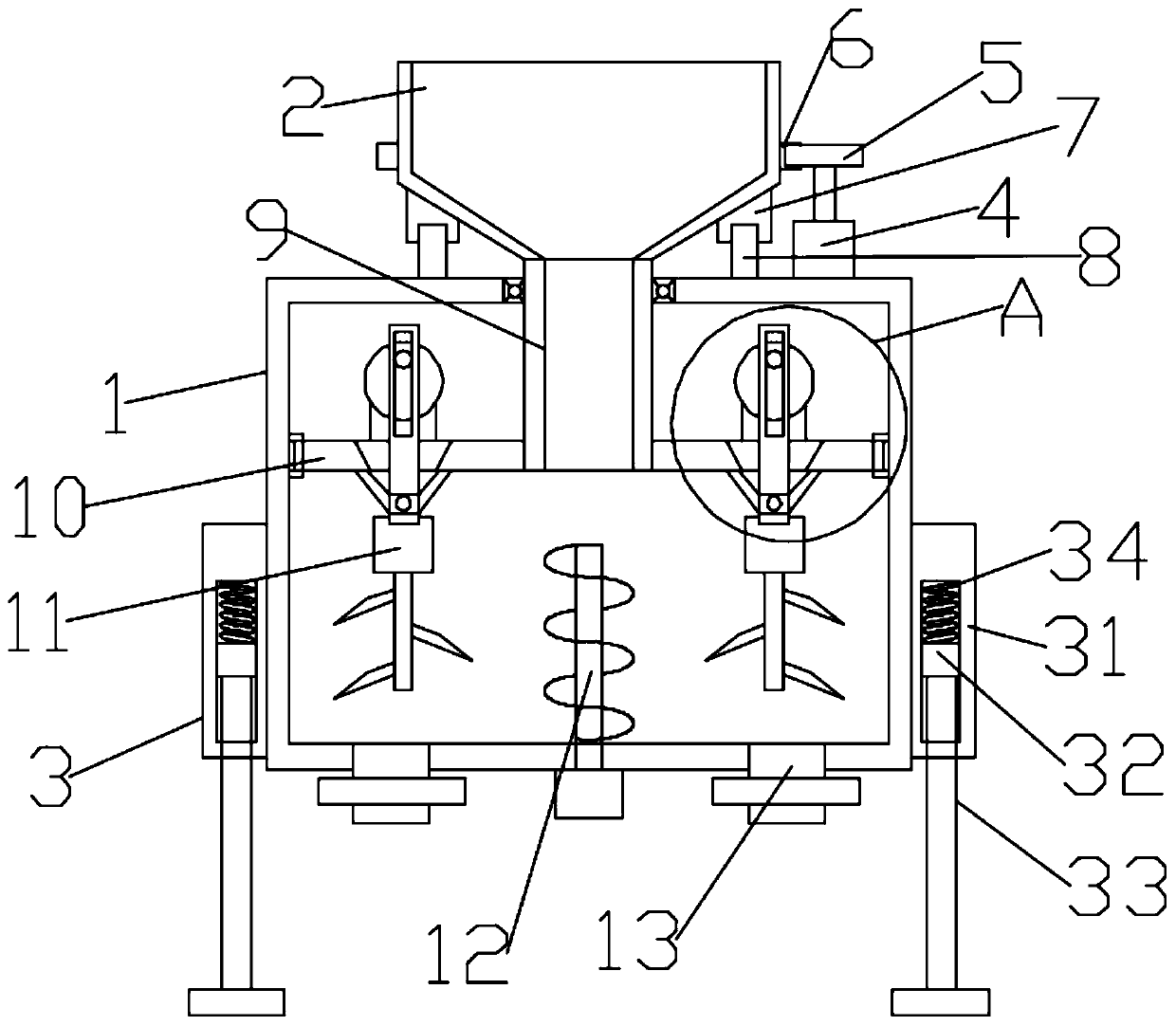

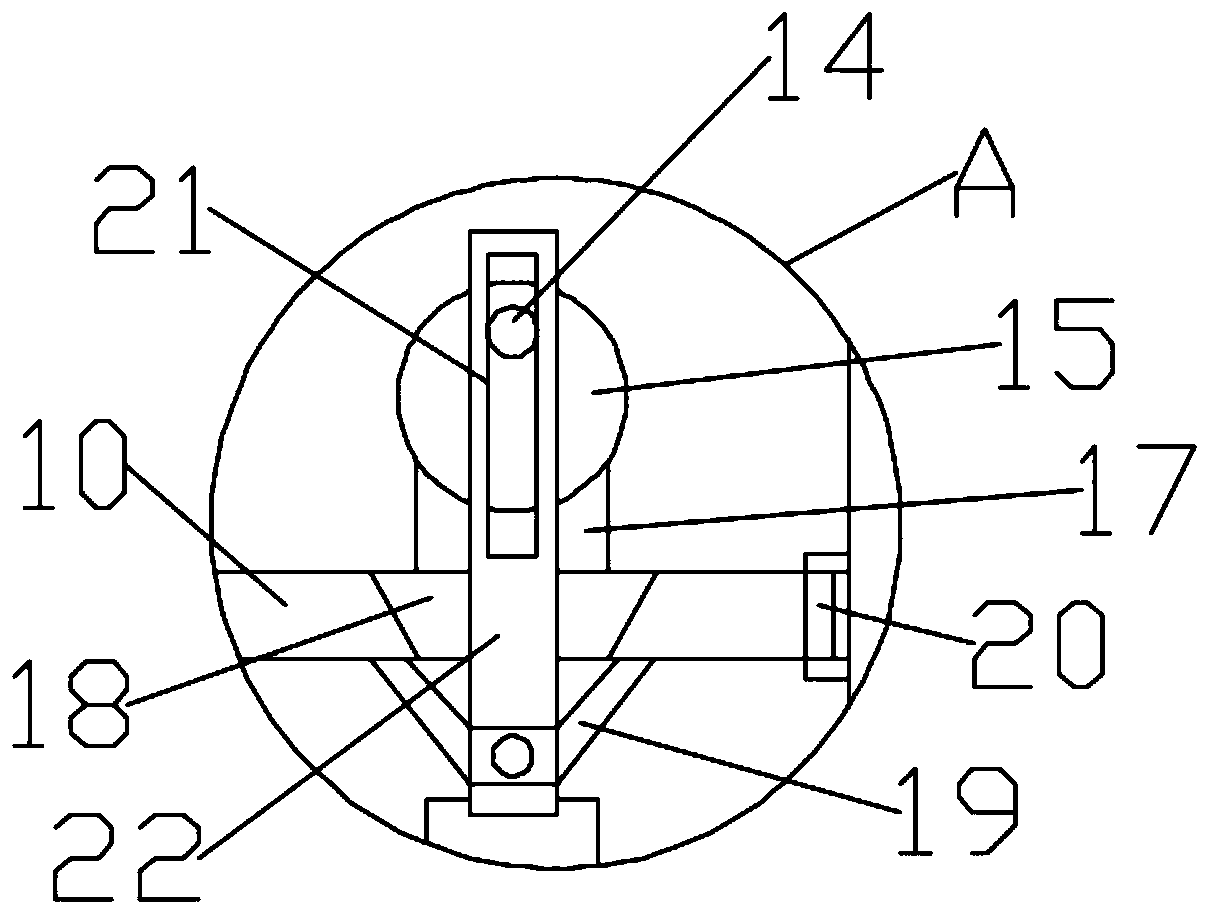

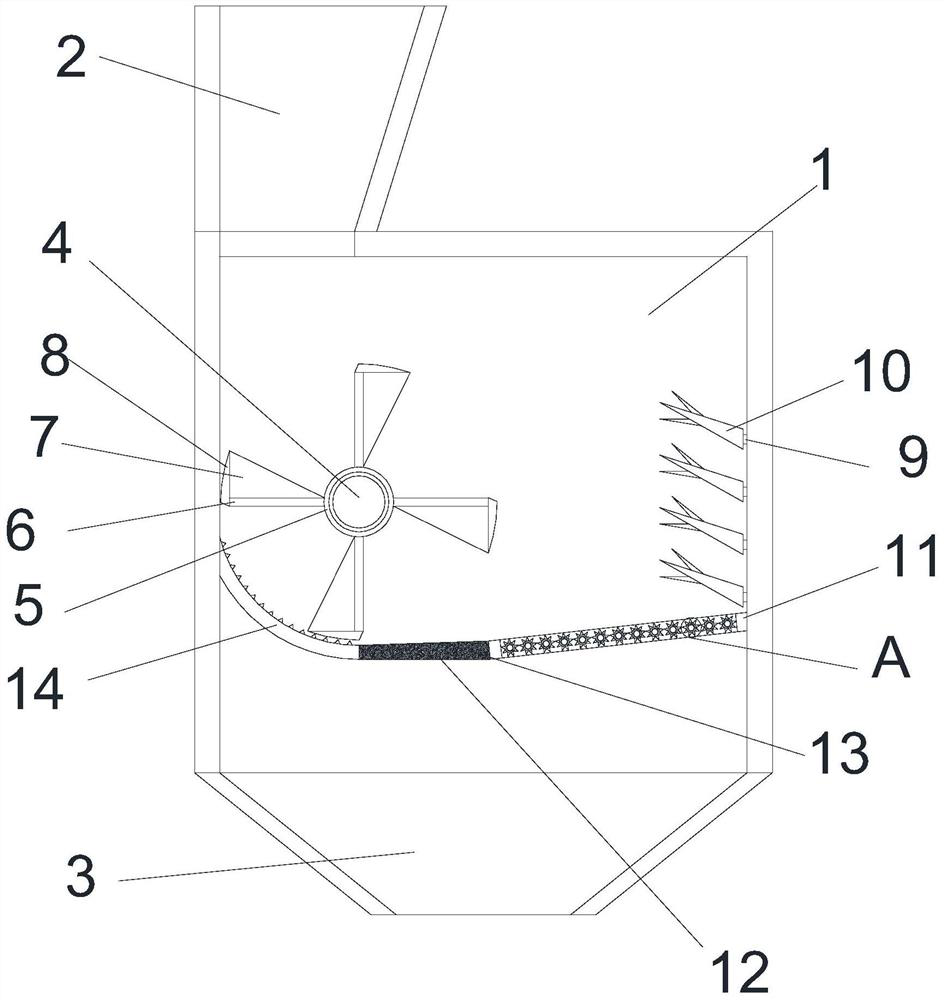

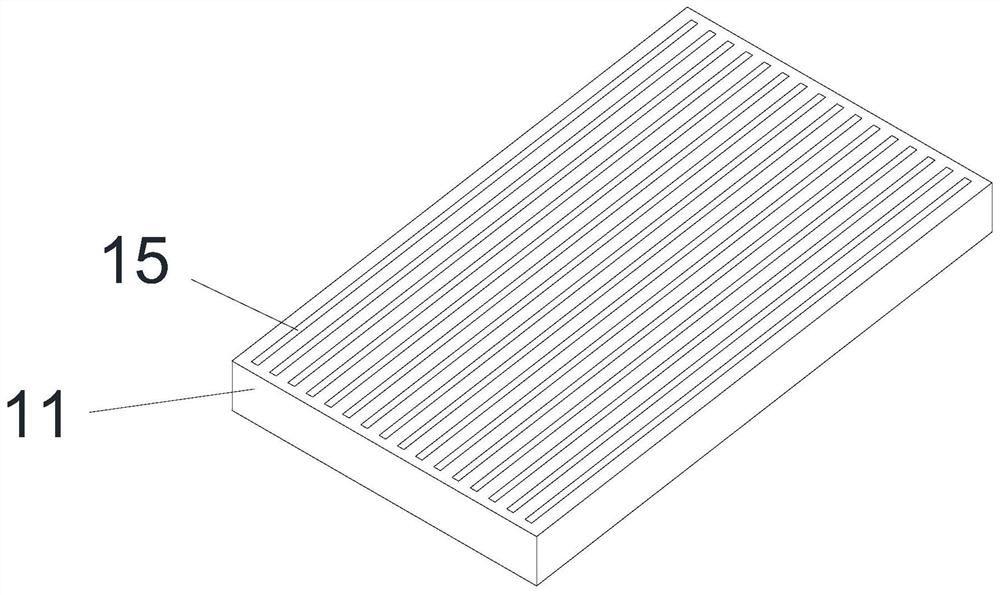

Food mixing machine

ActiveCN105960184AIncrease the probability of collisionImprove stirring efficiencyTransportation and packagingRotary stirring mixersEngineeringMixing effect

A food mixing machine comprises a base (1), a mixing container (2), a support frame (3), and a machine head (7) hinged on the support frame (3). The mixing container (2) and the support frame (3) are respectively arranged on the base (1). The machine head (7) includes a motor (9), a mixing mechanism and a transmission mechanism. The mixing mechanism is in transmission connection with the motor (9) through the transmission mechanism. The mixing mechanism comprises three stirring shafts (12) and a stirring knife (13). The stirring knife (13) is arranged at one end of the stirring shafts (12). The lengths of the stirring shafts (12) are not the same. The mixing machine grinds the food in the mixing container in a full range, so that the mixing effect is more uniform, and the mixing efficiency is greatly enhanced.

Owner:杨伟鸿

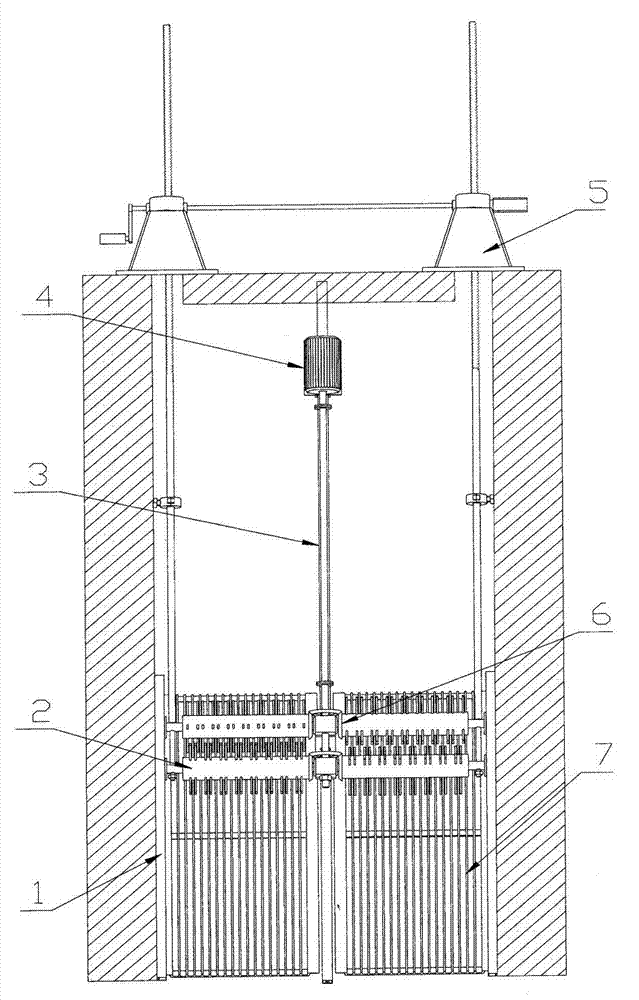

Traditional Chinese medicine crushing and grinding integrated machine capable of conveniently feeding

ActiveCN108672051AExpand the crushing rangeImprove crushing effectCocoaGrain treatmentsEngineeringTraditional Chinese medicine

The invention discloses a traditional Chinese medicine crushing and grinding integrated machine capable of conveniently feeding. The traditional Chinese medicine crushing and grinding integrated machine comprises an outer shell, a material inlet, a crushing shaft, a sieve plate, a material discharge port and supporting legs, wherein the top portion of the outer shell is fixedly connected to the material inlet, an installation plate is arranged inside the outer shell, the upper surface of the installation plate is fixedly connected to a movable column, the upper surface of the outer shell is fixedly connected to a vibration motor, the lower surface of the installation plate is fixedly connected to a crushing motor, the shaft extending end of the crushing motor is fixedly connected to the crushing shaft, crushing blades are distributed on the crushing shaft, the sieve plate is arranged below the crushing shaft, an upper grinding disc is arranged below the sieve plate, and a lower grinding disc is arranged on the lower surface of the upper grinding disc. According to the present invention, the traditional Chinese medicine is crushed by the crushing blades, and the vibration motor drives the crushing blades to move up and down so as to expand the crushing range and improve the crushing effect; the material feeding rotation and the moving up and down are simultaneously performed, such that the clogging of the material inlet by the traditional Chinese medicine can be prevented; and the crushed traditional Chinese medicine particles fall onto the lower grinding disc, and the traditional Chinese medicine is grinded by the grinding disc.

Owner:BOZHOU HUQIAO PHARMA

Electromagnetic building brick crushing device

InactiveCN109499661AAchieve left and right movementExpand the range of crushingGrain treatmentsBrickFriction loss

The invention discloses an electromagnetic building brick crushing device. The electromagnetic building brick crushing device comprises a base and support plates, wherein the support plates are symmetrically arranged on both sides of the upper end of the base, a lifting plate is arranged between the upper ends of the two support plates, a fixed frame is arranged at the lower end of the lifting plate, a guide sleeve is arranged at the lower end of the fixed frame, a sliding rod is in sliding fit with the interior of the guide sleeve, a crushing head is arranged at the lower end of the sliding rod, a mounting block is arranged at the upper end of the sliding rod, an electromagnetic driving mechanism which is used for driving the sliding rod to reciprocate up and down is arranged in the fixedframe, a placing frame is fixed between left and right clamping blocks, and an adjusting mechanism which is used for adjusting the crushing position is arranged on the base and the support plates. The electromagnetic building brick crushing device is improved so as to overcome the defects of the prior art, the crushing head is driven to horizontally move, and the placing frame circumferentially rotates, so that the crushing range is greatly enlarged, and the crushing effect is increased. Additionally, power output of the device is realized by virtue of the electromagnetic driving mechanism, so that the problem of severe friction loss in an existing device is eliminated, and the practicability is high.

Owner:王亮

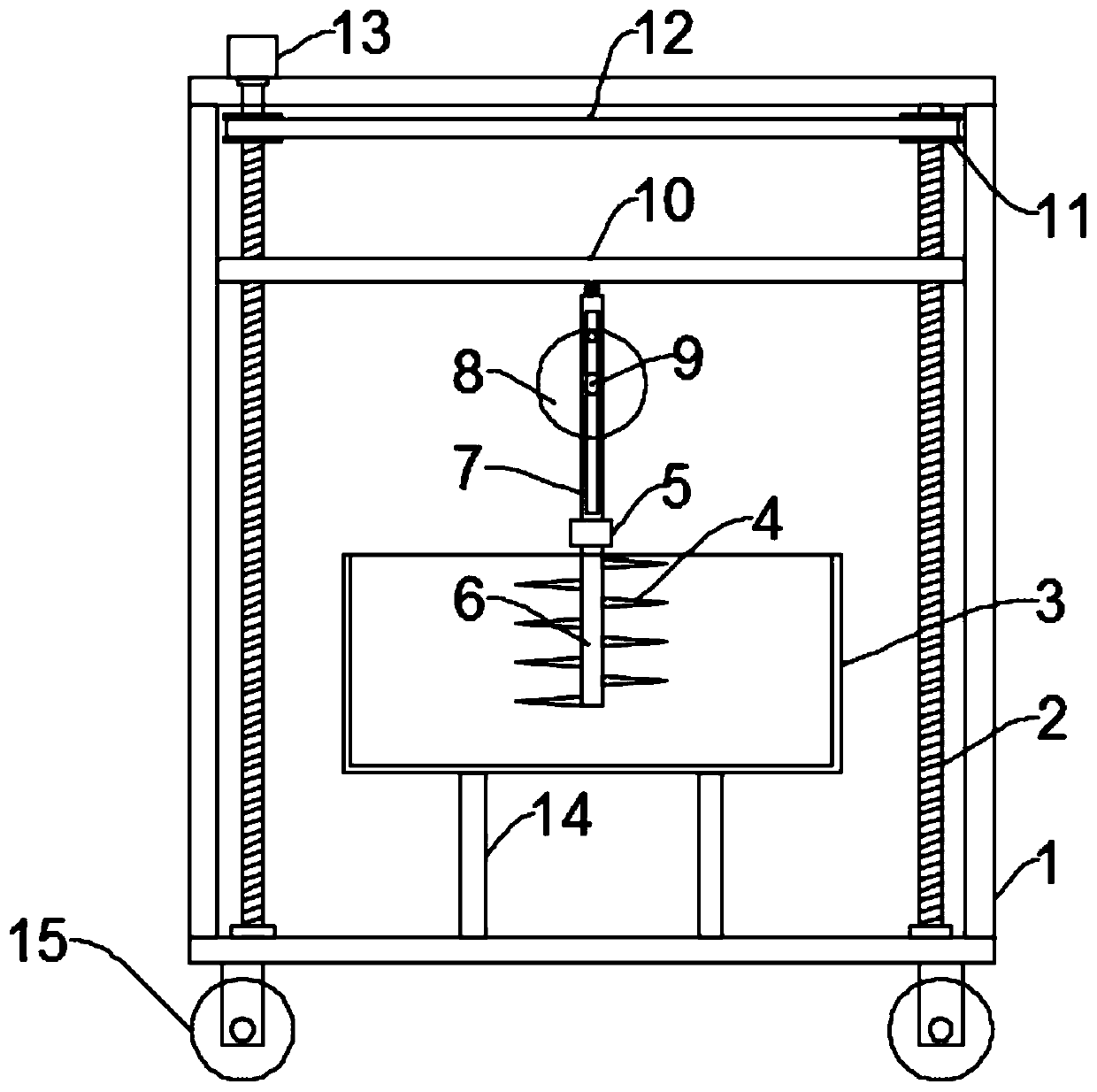

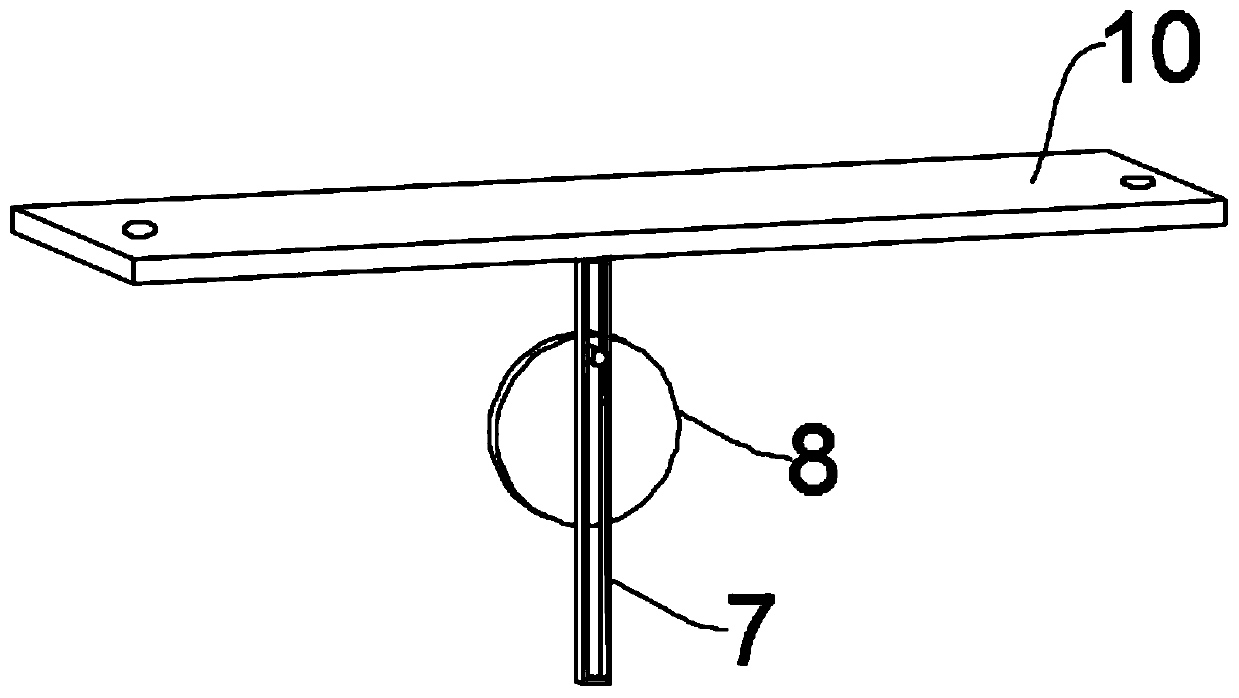

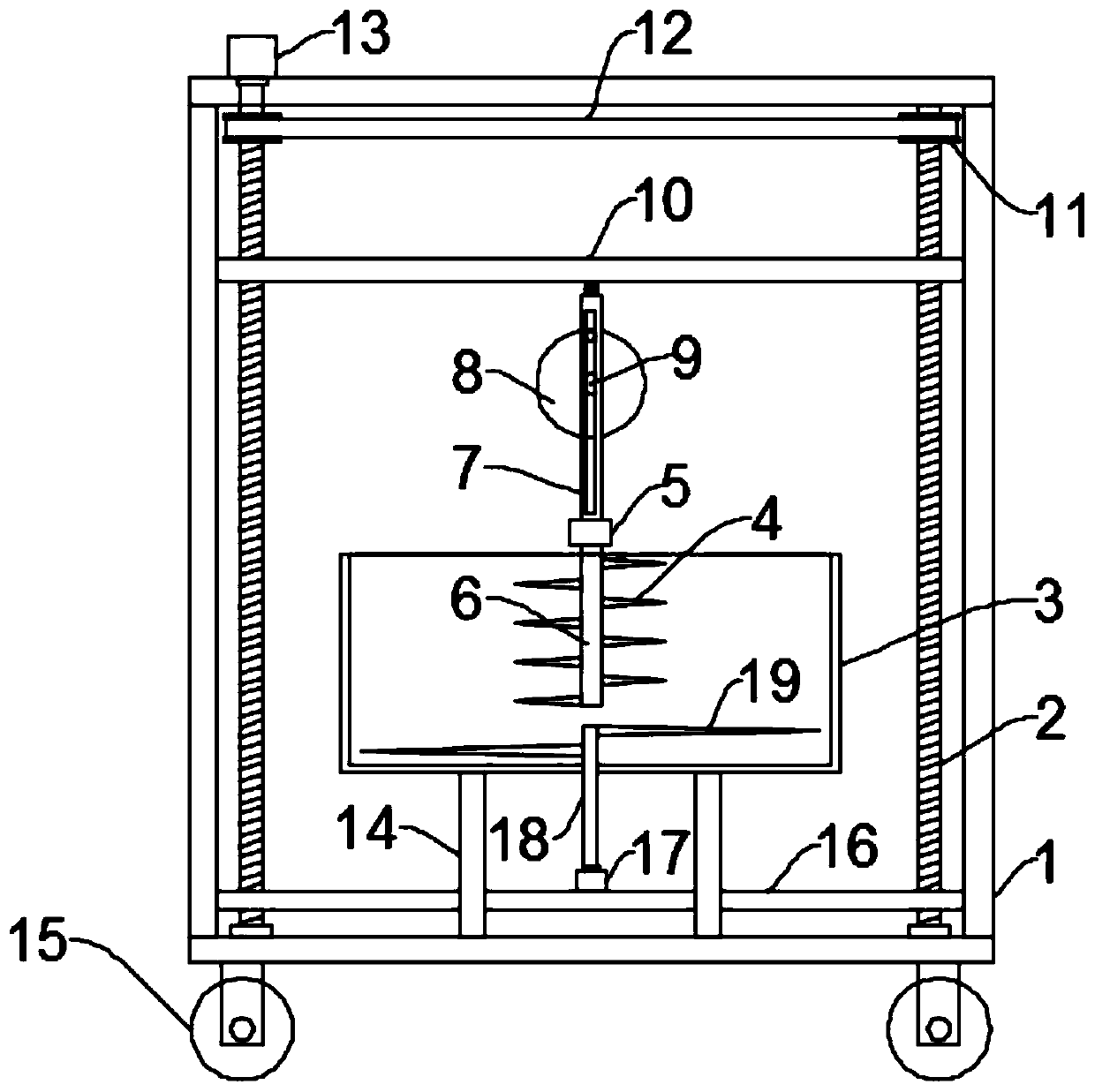

Efficient pulverizing device for crude medicine processing

ActiveCN110665612AExpand the range of crushingCrushed fullyGrain treatmentsMedicinal herbsCircular disc

The invention discloses an efficient pulverizing device for crude medicine processing. The efficient pulverizing device for crude medicine processing comprises a machine frame, a crude medicine frameand a pulverizing unit. The pulverizing unit is arranged in the crude medicine frame. The efficient pulverizing device for crude medicine processing further comprises an adjusting unit. The adjustingunit drives the pulverizing unit to move. The adjusting unit comprises a first installation plate, a second motor, a disc, an oscillating rod and a lifting assembly. The lifting assembly is used for driving the first installation plate to ascend and descend. The efficient pulverizing device for crude medicine processing comprises the pulverizing unit and further comprises the adjusting unit whichdrives the pulverizing unit to move, and the adjusting unit comprises the first installation plate, the second motor, the disc, the oscillating rod and the lifting assembly which is used for driving the first installation plate to ascend and descend. The pulverizing unit pulverizes crude medicine in the crude medicine frame, the second motor drives the disc to rotate, the disc drives the oscillating rod to oscillate in a reciprocating mode through a straight pin, the oscillating rod drives the pulverizing unit to oscillate, and therefore the pulverization range is broadened; when the pulverizing unit oscillates, the angles of first pulverizing blades are continuously changed, and therefore pulverization can be fuller; and the lifting assembly drives the oscillating rod to ascend and descend, and therefore the pulverization range is broadened, and the pulverization efficiency is improved.

Owner:安徽泰恩康制药有限公司

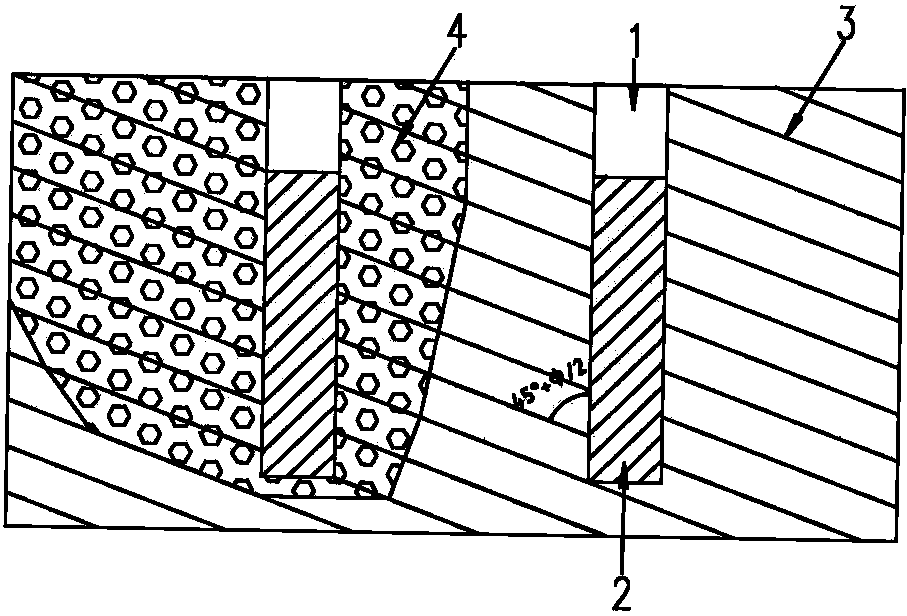

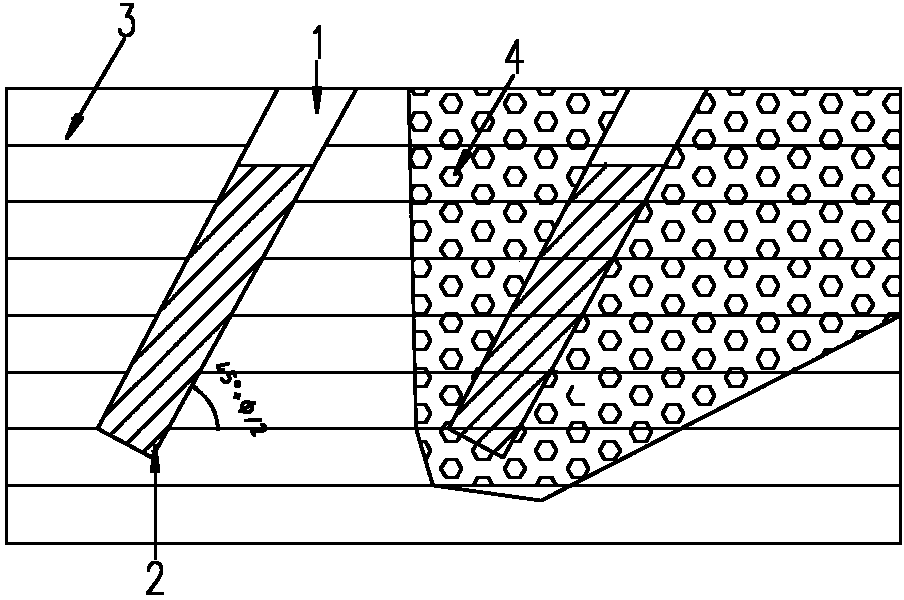

Blasting construction method based on certain angle formed between boreholes and joints

The invention discloses a blasting construction method based on certain angle formed between boreholes and joints. The blasting construction method mainly includes measuring occurrence of trend, inclination and dip angle X of to-be-blasted rock formation to acquire the internal friction angle phi, arranging drilling positions along the trend and the inclination crisscross, drilling holes by a drill with a drill pipe forming the angle of 45-degree +phi / 2+X with the horizontal plane, and performing charging, networking detonation and slag removal and the like. The blasting construction method can utilize the detonation energy of explosives to the utmost extent and prevents secondary breakage of rocks and large rock blocks from obstructing construction machines.

Owner:HOHAI UNIV

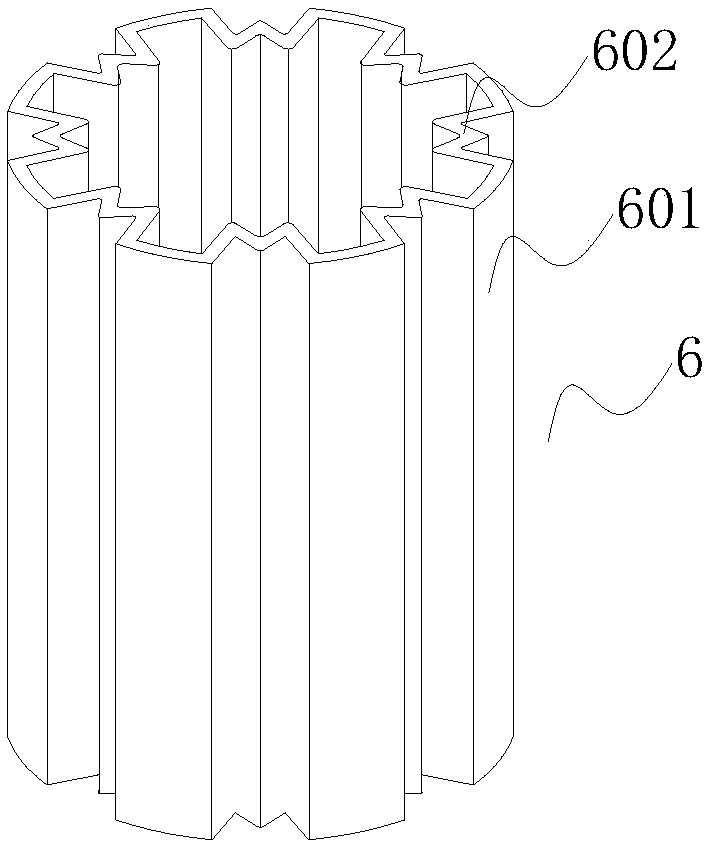

Novel deep hole blasting charging structure

The invention discloses a novel deep hole blasting charging structure which comprises a blast hole. A hole opening of the blast hole is provided with a filling layer, a blasting water bag, a first charging layer, a second charging layer and a hole bottom energy gathering ring are sequentially arranged in the depth direction of the blast hole from top to bottom, the first charging layer comprises afirst explosive column, the first grain is sleeved with a multidirectional M-shaped energy gathering blast charging device, the second charging layer comprises a second explosive column, and the blasting water bag is filled with carbon dioxide. Compared with the prior art, the novel deep hole blasting charging structure is novel in structural design, good in blasting cutting effect, higher in blasting utilization rate, large in breaking range and uniform in blasting block degree, the blast hole bottom energy gathering ring is arranged at the bottom of the blast hole, the depth of the blast hole is reduced, meanwhile, the rock at the bottom of the blast hole can be completely broken, the operation cost is greatly saved, and working efficiency is improved.

Owner:广东矿发节能环保科技有限公司

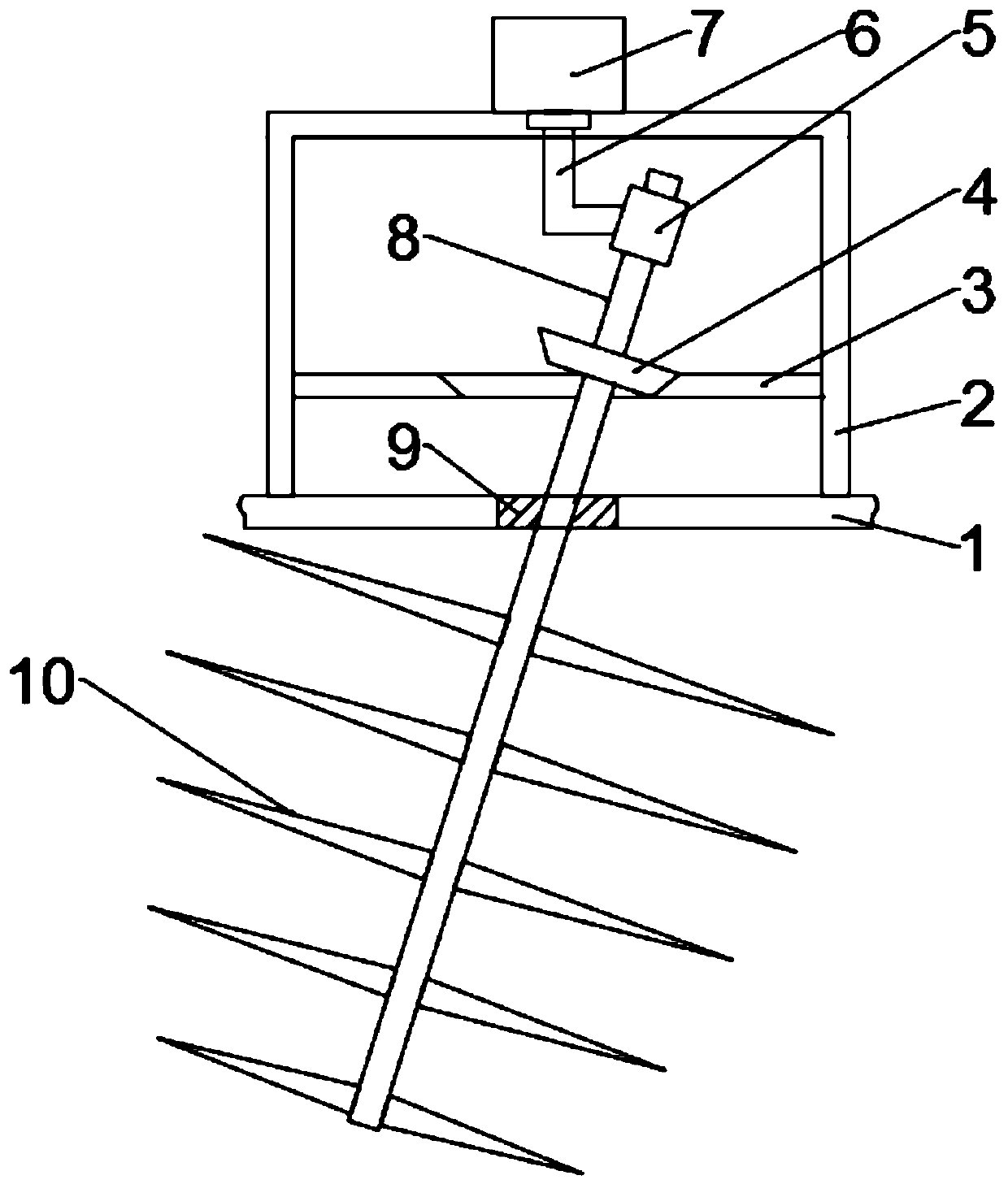

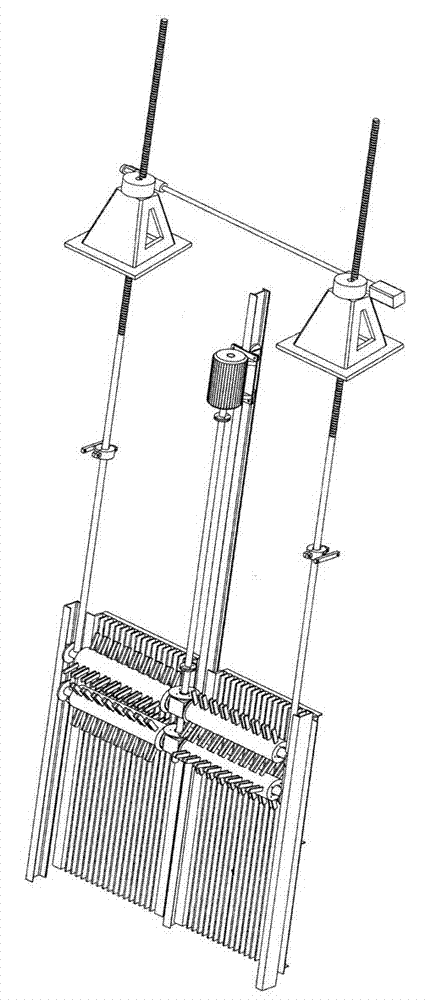

Straw crushing turnover device

ActiveCN109005929AExpand the range of crushingGuaranteed smoothnessCrop conditionersMowersEngineeringMechanical engineering

The invention belongs to the technical field of straw turnover, in particular to a straw crushing turnover device. The device comprises a rack, a feeding hopper, a conveying plate, a crushing unit anda cutting unit, wherein the feeding hopper is located in the rack, the feeding hopper is located under a feeding port; the conveying plate is located under the feeding hopper, the under a feeding port plate is arranged inclined to the left; the crushing unit is located at the right side of the conveying plate, straw on the conveying plate slides rightward along the conveying plate under the action of gravity and falls into the crushing unit to be crushed, the portion, under the crushing unit, of the rack is provided with a discharging port; the cutting unit is located above the conveying plate, the cutting unit is located at the left side of the crushing unit, and the cutting unit is used for cutting the straw on the conveying plate to reduce the size of the straw entering the crushing unit, thereby improving the crushing efficiency. The straw crushing turnover device improves the crushing efficiency, ensures the smoothness of work and improves the utilization rate of energy.

Owner:RUSHAN JINGUO PEANUT PROD +1

A vertical food waste crushing device

ActiveCN108187888BExpand the range of crushingAchieve recyclingGrain treatmentsFiltration circuitsWater savingElectric machine

The invention discloses a vertical kitchen waste pulverizing device which comprises a treatment box; a base is arranged below the treatment box; rollers facilitating device carrying are arranged on the left side and the right side of the base; a partition plate is arranged in the treatment box; a driving motor is fixedly arranged in the middle of the upper end of the partition plate; the driving motor is electrically connected with an electric control switch; a driving shaft is arranged at the output end of the driving motor; the driving shaft is slidingly sleeved with a polarization sleeve; alimiting groove is formed in the inner wall in the polarization sleeve; a limiting bulge fitting with the limiting groove is formed on the outer side of the driving shaft; and the limiting groove fits with the limiting bulge to limit relative rotation between the driving shaft and the polarization sleeve. The vertical kitchen waste pulverizing device is convenient to carry; the pulverizing rangeof pulverizing cutters is extended; the vertical kitchen waste pulverizing device contributes to improving the pulverizing effect; recycling of kitchen waste water is achieved by the vertical kitchenwaste pulverizing device, so that the water saving function is played; and with such a vertical structure, the floor area of the vertical kitchen waste pulverizing device is reduced.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

A traditional Chinese medicine grinder

ActiveCN107029841BEasy to controlConvenient crushing operationDrying gas arrangementsGrain treatmentsCrusherTraditional medicine

The invention discloses a traditional Chinese medicine crushing machine. The traditional Chinese medicine crushing machine comprises a traditional Chinese medicine crushing machine body, wherein the traditional Chinese medicine crushing machine body comprises a traditional Chinese medicine crushing device; a traditional Chinese medicine drying device is fixedly connected to the bottom of the traditional Chinese medicine crushing device; a traditional Chinese medicine charge pipe is fixedly communicated to the top of the traditional Chinese medicine crushing device; an inner shell is arranged in the traditional Chinese medicine crushing device; a traditional Chinese medicine crushing chamber is formed in the inner shell; the bottom of the traditional Chinese medicine charge pipe penetrates through the inner shell and communicates with the traditional Chinese medicine crushing chamber; and a motor protection cover is fixedly connected to the top of the traditional Chinese medicine crushing device. According to the traditional Chinese medicine crushing machine disclosed by the invention, traditional Chinese medicines in the traditional Chinese medicine crushing chamber are filtered through a filter plate, so that the crushing efficiency of the medicines is increased, only the crushed medicines can pass through the filter plate, the crushing force of the medicines is increased, uniform crushing for the traditional Chinese medicines is achieved, the crushing effect of the medicines is improved, the advantage of fine crushing is achieved, and then the problem of influence on a medicine manufacturing process due to the poor crushing effect of an existing traditional Chinese medicine crushing machine is effectively solved.

Owner:DAYA PHARMA HUIZHOU

Concrete pile head crushing device

InactiveCN108532598AAchieve looseningAvoid accumulationBulkheads/pilesThreaded pipeElectric machinery

The invention discloses a concrete pile head crushing device. The device comprises a machine body, a movable base and supporting arms, wherein the movable base is arranged at the bottom of the machinebody, rolling wheels are installed at four corners of the bottom of the movable base, and the supporting arms are welded on the two sides of the upper surface of the movable base; a rotating shaft ishorizontally arranged at the upper part of the machine body, and the machine body is characterized in that the left end of the rotating shaft is rotationally connected with the supporting arms on theleft side, and the right end of the rotating shaft penetrates through the supporting arms on the right side and extends to the right side of the machine body; and a first servo motor is arranged on the right upper portion of the machine body, the right end of the rotating shaft is welded with an output shaft of the first servo motor, the rotating shaft is provided with two first bevel gears withthe same size, an inner threaded pipe is vertically arranged below the rotating shaft, and the lower end of the inner threaded pipe is connected with a screw rod in a rotating mode. According to the device, the design is reasonable, the pile head which can be crushed is quickly realized, time and labor are saved, the construction difficulty is lowered, the life safety of constructors is guaranteed, and the device is suitable for popularization.

Owner:张显

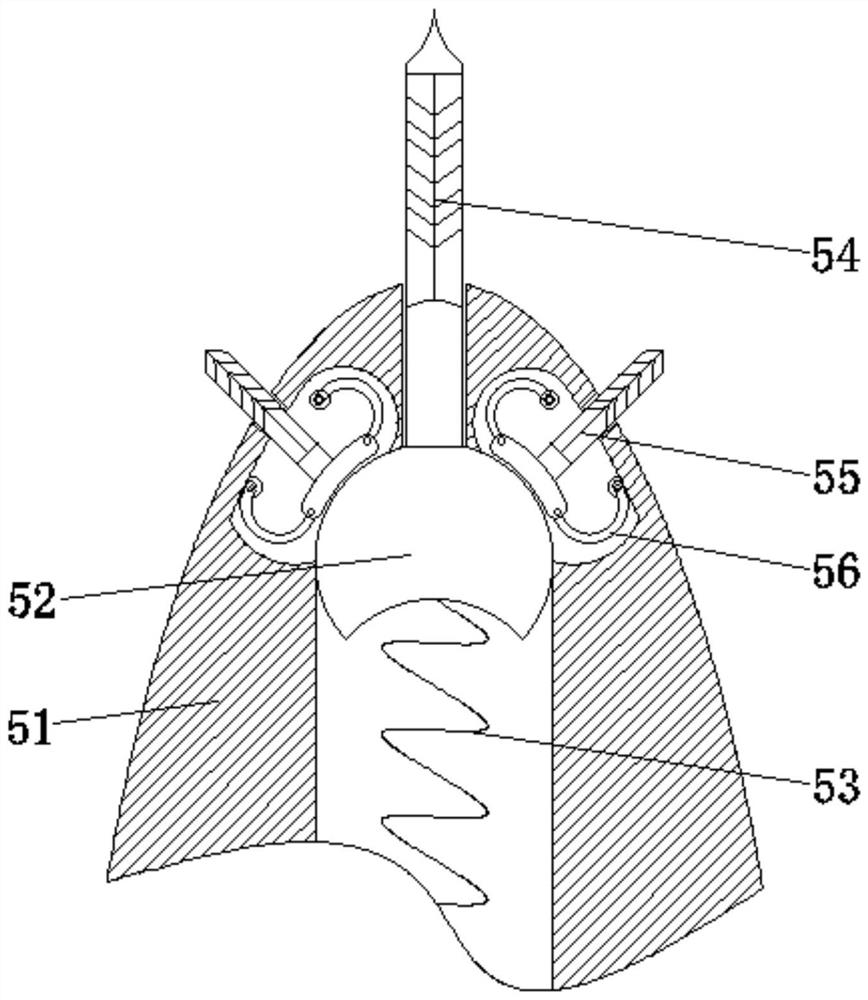

Smashing device for traditional Chinese medicine machining

InactiveCN111013775ACrushed fullyExpand the range of crushingGrain treatmentsElectric machineryEngineering

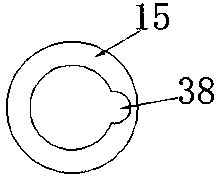

The invention relates to the field of traditional Chinese medicine machining, and particularly discloses a smashing device for traditional Chinese medicine machining. The smashing device comprises a smashing box and a feeding assembly arranged at the top of the smashing box. A rotating disc in linkage with the feeding assembly is further rotationally arranged inside the smashing box. A first driving motor for driving the feeding assembly and the rotating disc to rotate synchronously is further installed on the top plate of the smashing box. Two smashing assemblies are symmetrically arranged atthe bottom face of the rotating disc, two swing assemblies are arranged on the upper surface of the rotating disc, and the two swing assemblies drive the two smashing assemblies to swing respectively. According to the smashing device, the first driving motor is used for driving the rotating disc to rotate, and in cooperation with the swinging smashing assemblies, traditional Chinese medicine in an inner cavity in the lower portion of the smashing box can be sufficiently smashed.

Owner:韩明智

Fertility improvement method for saline and alkaline rice field

ActiveCN108834465AAccelerate the rate of decayQuick conversionSoil lifting machinesSoil-working methodsBiotechnologySprayer

The invention belongs to the technical field of straw returning to fields and particularly relates to a fertility improvement method for a saline and alkaline rice field. The method includes the following steps that harvested rice straw is conveyed to a spraying chamber, and a mixed solution of clean water and a decomposition assistant agent is sprayed out; the rice straw on which the mixed solution is sprayed is put into a feeding hopper of a straw returning machine, and a plow is installed in front of the straw returning machine; a diesel is used for driving the straw returning machine to move in the saline and alkaline rice field, and the straw returning machine smashes the rice straw and then sprinkles the smashed rice straw into the saline and alkaline rice field; a biological fungicide solution storage box is arranged in the straw returning machine, biological fungicide solutions fall on the surfaces of the smashed straw when the rice straw is smashed by the straw returning machine, and therefore biological fungicides are fully in contact with the straw; a nitrogenous fertilizer solution storage tank is suspended behind the straw returning machine; an oxygen tank is arrangedat the bottom of the straw returning machine, and an oxygen sprayer is positioned behind the plow. Fast conversion of the straw into soil nutrients is facilitated, and the soil fertility is improved.

Owner:黑龙江万丰德肥料有限公司

Multifunctional hydraulic gravel breaking hammer and manufacturing method thereof

PendingCN107971062AExpand the range of crushingPrecise positioningSoil-shifting machines/dredgersGrain treatmentsSmall armsEngineering

Owner:宣城市安工大工业技术研究院有限公司

Vertical shaft multistage board hammer sand making machine

InactiveCN109126996AAvoid health effectsExpand the range of crushingUsing liquid separation agentGrain treatmentsGear wheelDrive motor

The invention discloses a vertical shaft multistage board hammer sand making machine, and belongs to the technical field of the sand making equipment. The problems that the board hammer cannot beat gravels between the adjacent board hammers in the crushing since the board hammers of the existing vertical shaft board hammer are fixedly arranged at intervals and the crushing range is relatively small are solved. The sand making machine comprises a rack, a main case, a metal screen drum, a driving motor, a board hammer rotor and aboard hammers; an umbrella-shaped baffle plate is fixedly arrangedabove the board hammer rotor through an outer ring board, a fixed rod penetrates through the center of the board hammer rotor, and a driving mechanism is arranged between the board hammer rotor and the umbrella-shaped baffle plate; the driving mechanism comprises a first bevel gear, a second bevel gear, a crankshaft and a connecting rod, and further comprises a dust collection device. By arrangingthe board hammer rotor, the fixed rod and the driving mechanism, the board hammers are driven to swing up and down through the cooperation of the board hammer rotor, the fixed rod and the driving mechanism, the crushing range is enlarged, the crushing speed is higher, and the crushing efficiency is improved; a dust collection device is provided, and the dust is discharged after being sufficientlywashed, and the environment and the health of the worker cannot be influenced.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

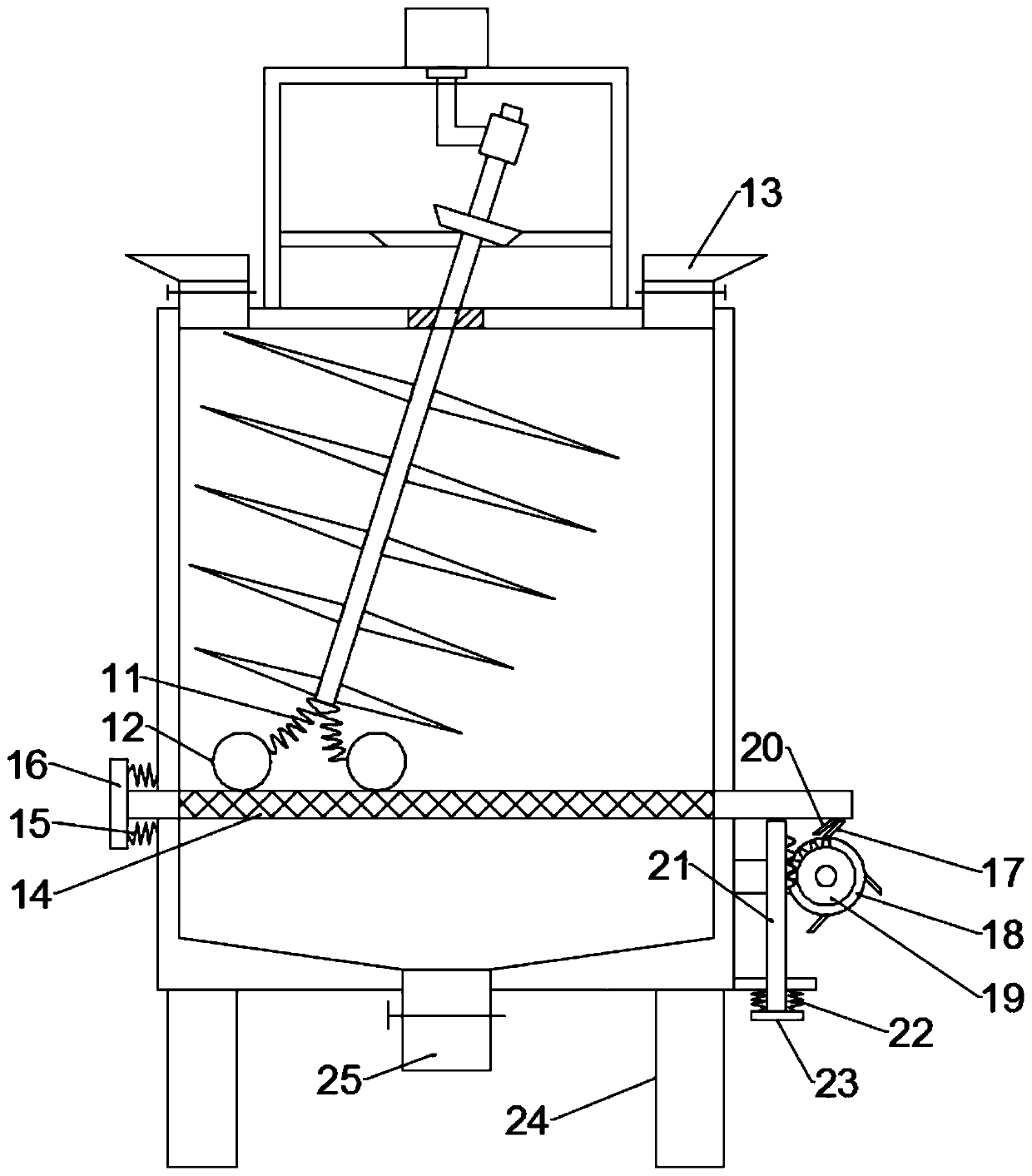

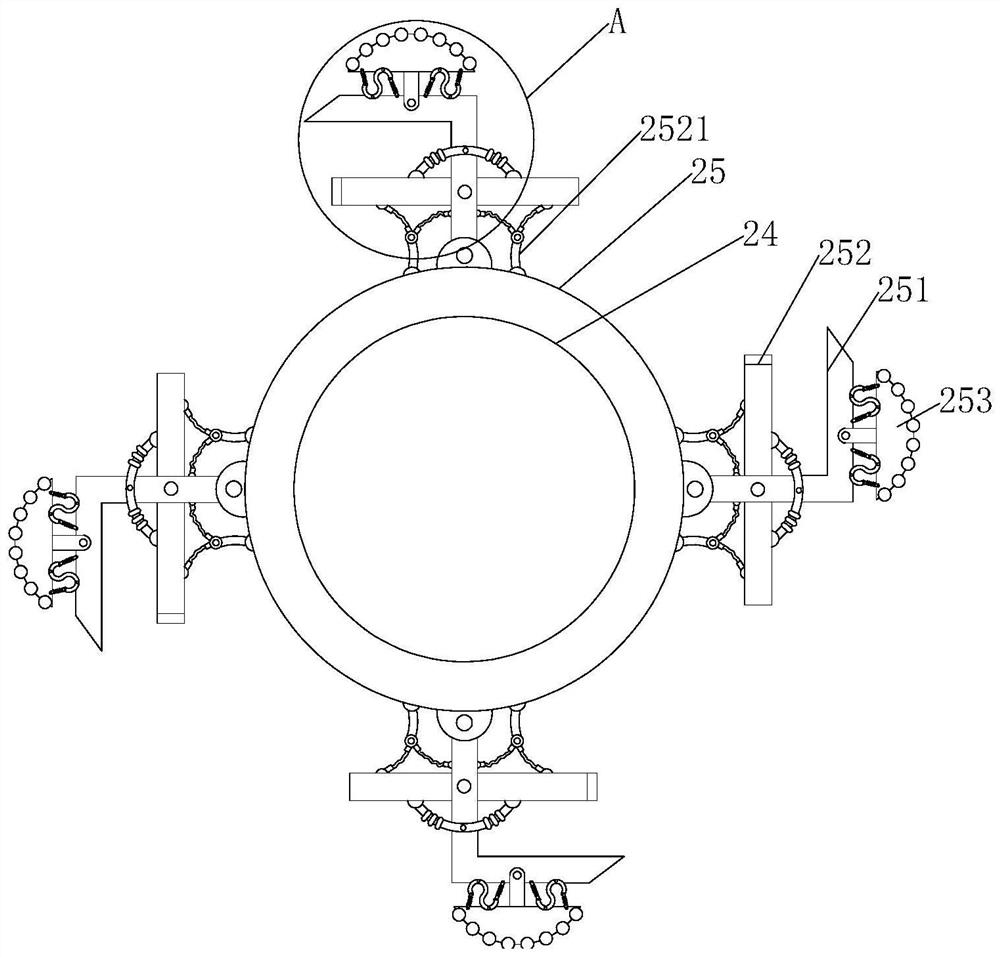

Water circulation cleaning treatment device of raw material straw for biogas production

ActiveCN110093258AExpand the range of crushingImprove crushing efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsWater resourcesBiogas production

The invention discloses a water circulation cleaning treatment device of raw material straw for biogas production. The water circulation cleaning treatment device comprises a base and a barrel body which is fixedly connected with the upper end of the base, wherein arc grooves formed in opposite inner walls of the barrel body; the barrel body is provided with a double-layer plate which is arrangedin the axis center; the front side and the rear side of the double-layer plate are connected with single-layer plates in a sliding manner; the double-layer plate is elastically connected with the inner wall of the double-layer plate through a spring; one end, away from the double-layer plate, of each of the single-layer plates is fixedly connected with a corresponding rolling wheel; the rolling wheels are connected with the inner walls of the arc grooves in a sliding manner; the lower end of the double-layer plate is fixedly connected with a mounting plate; and a device groove is formed in oneside, positioned on the front side, of the mounting plate. According to the water circulation cleaning treatment device disclosed by the invention, the straw is crushed, so that the reaction efficiency of the straw in a biogas production device is improved, and water is recycled when the straw is cleaned at the same time, so that water resources can be reduced.

Owner:盐城市圣和给水设备有限公司

Separating and filtering device for extracting plant flower perfume

ActiveCN114247200AGuaranteed to be completely brokenExpand the range of crushingSolid solvent extractionGrain treatmentsAgricultural engineeringStructural engineering

The invention discloses a separation and filtration device for extracting plant flower perfume, and relates to the technical field of plant flower perfume extraction, the separation and filtration device comprises an extraction, separation and filtration device main body, the outer surface of the extraction, separation and filtration device main body is provided with a control screen, and the control screen is internally provided with a wall breaking extraction device; and a separating and filtering device is arranged outside the wall-breaking extraction device. According to the wall-breaking extraction device, a wall-breaking extraction device is installed, a motor works to drive a rotating shaft and a clamping seat to rotate, a wall-breaking rotating shaft is clamped with the clamping seat through a clamping column and then rotates along with the clamping seat, and an L-shaped blade and a Z-shaped blade are matched with each other to conduct wall-breaking treatment on plant flower perfume in a residue filter screen in the rotating process of the wall-breaking rotating shaft, so that plant perfume fully flows out; the elastic connector and the movable rod are matched with each other, so that the Z-shaped blade has a certain elastic movement space in the rotating process, the crushing range of the Z-shaped blade is enlarged, it is guaranteed that plants are completely crushed, and waste is reduced.

Owner:浙江鸣怡生物科技有限公司

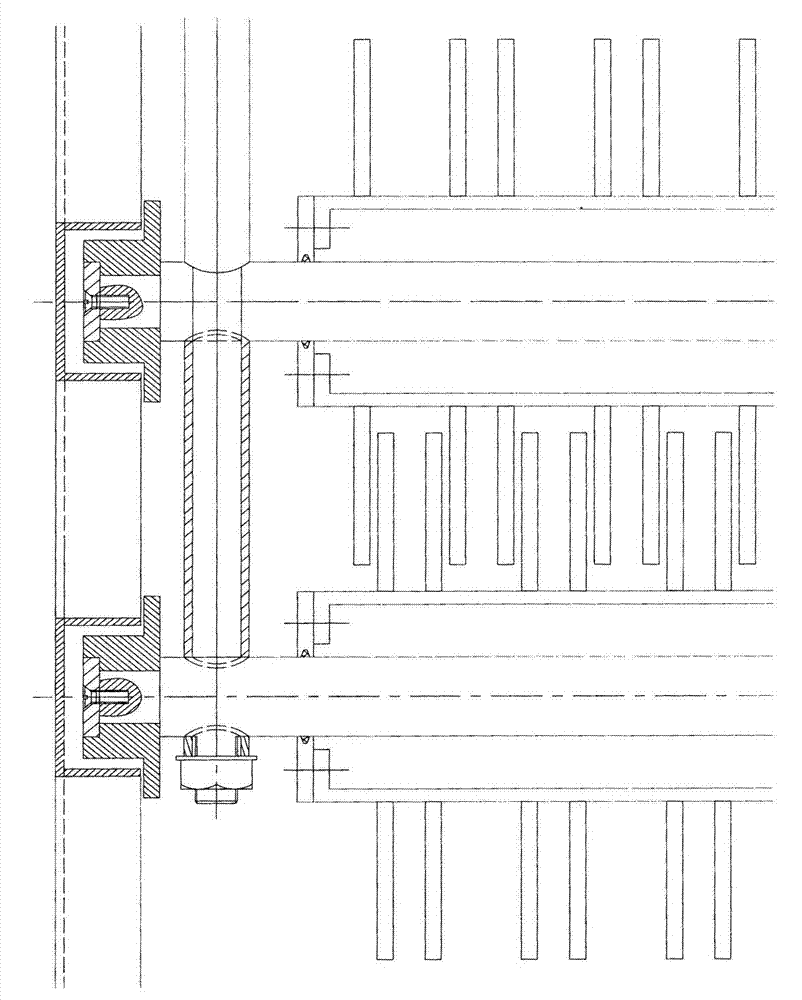

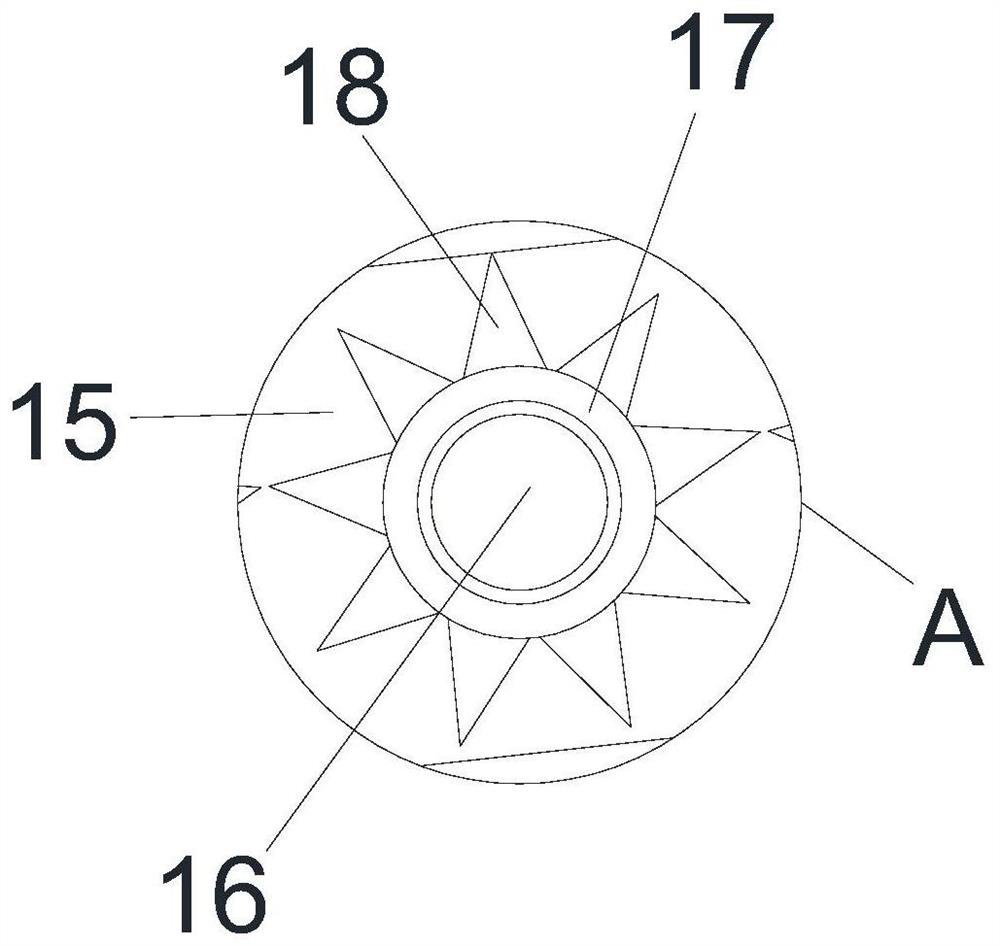

Mobile smash-type grid sewage removing machine

InactiveCN103111108AExpand the range of crushingAvoid cloggingStationary filtering element filtersEngineeringSewage

The invention discloses a mobile smash-type grid sewage removing machine, which comprises a water-through grid fixedly arranged in the grid room and hoists arranged on the upper part of the two side walls of the grid room. The mobile smash-type grid sewage removing machine is characterized in that the water-through grid is composed of right and left grids symmetrically arranged at the two sides of the center guide rail; a rotating drum-type breaking device moving up and down along the slideway located on the two sides of the grid room is arranged on the upstream face side of the water-through grid, and the rotating drum-type breaking device is driven by the hoist and is used for crushing sundries; the rotating drum-type breaking device is composed of two sets of transmission devices arranged up and down respectively and two sets of breaking rotating drums arranged up and down respectively at the two sides of the upper and lower transmission devices in a horizontal and symmetrical manner; and the two breaking rotating drums which are opposite up and down and which are located at the same side of the transmission device rotate in opposite directions.

Owner:胡建国

Powder block crushing device

InactiveCN112387388ACompletely brokenExpand the range of crushingGrain treatmentsDrive shaftElectric machinery

The invention discloses a powder block crushing device, and relates to the technical field of raw material crushing. The powder block crushing device comprises an equipment box, a feeding limiting annular plate is fixedly mounted on the left side of the top of the equipment box, a discharging limiting plate is fixedly mounted on the bottom wall surface of the equipment box, and driving shafts arearranged on the front and rear side wall surfaces of the inner side of the equipment box; and the rear ends of the driving shafts penetrate through the rear side wall surface of the equipment box to be mutually and fixedly connected with the output shaft of an external driving motor. According to the powder block crushing device, powder blocks are conveyed to a material conveying plate through a material transmitting plate, powder of qualified specifications after crushing can seep downwards through a filtering screen to fall onto the discharging limiting plate and is conveyed outwards throughthe discharging limiting plate, after crushing, unqualified raw material blocks enter a pocket plate again for repeated operation through cooperation of rotation of the pocket plate and inclined arrangement of the material conveying plate and a repeated arc plate, so that the raw materials can be effectively crushed, and the situation that the raw materials cannot be effectively crushed due to too large or too small force is avoided.

Owner:羊彬

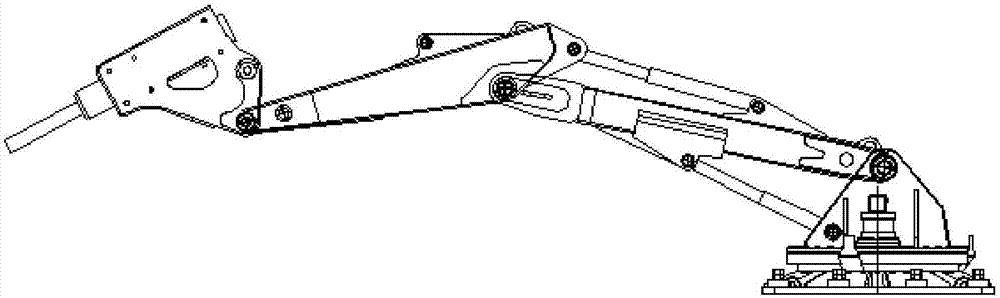

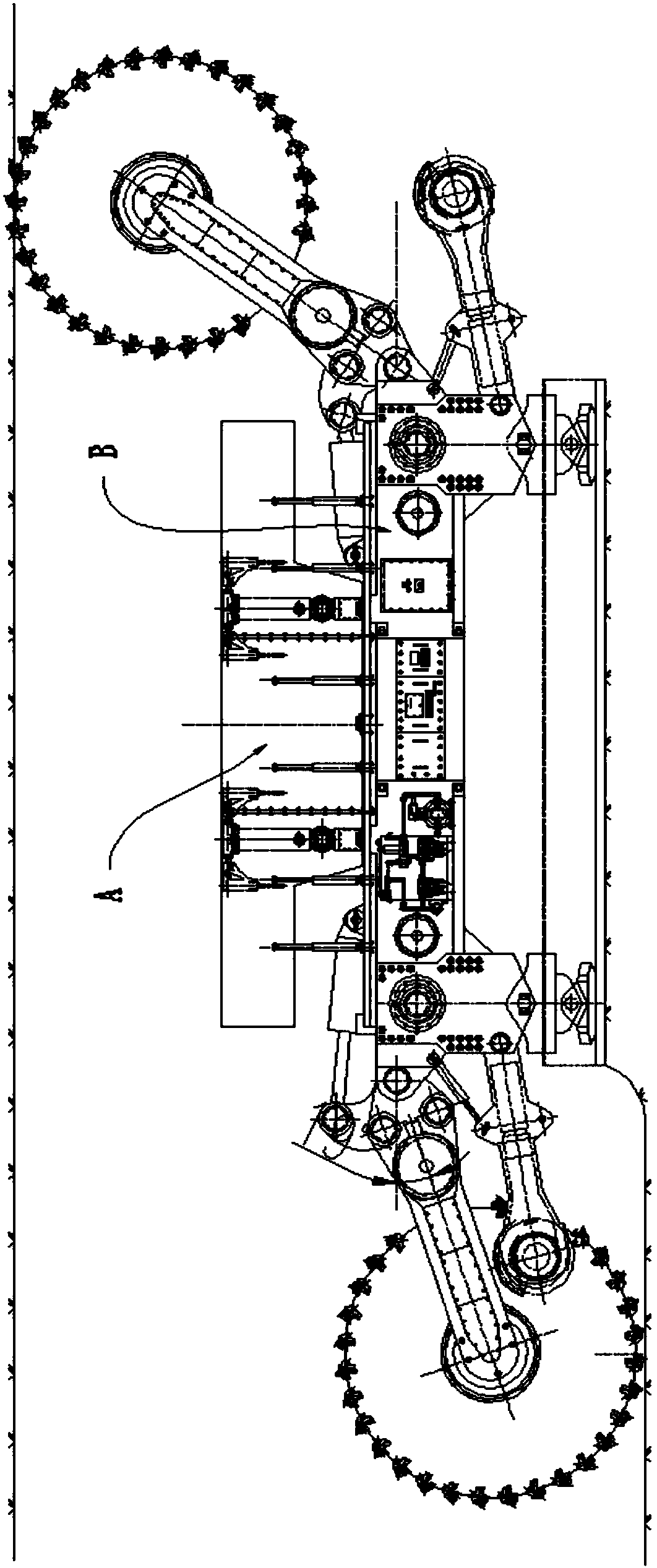

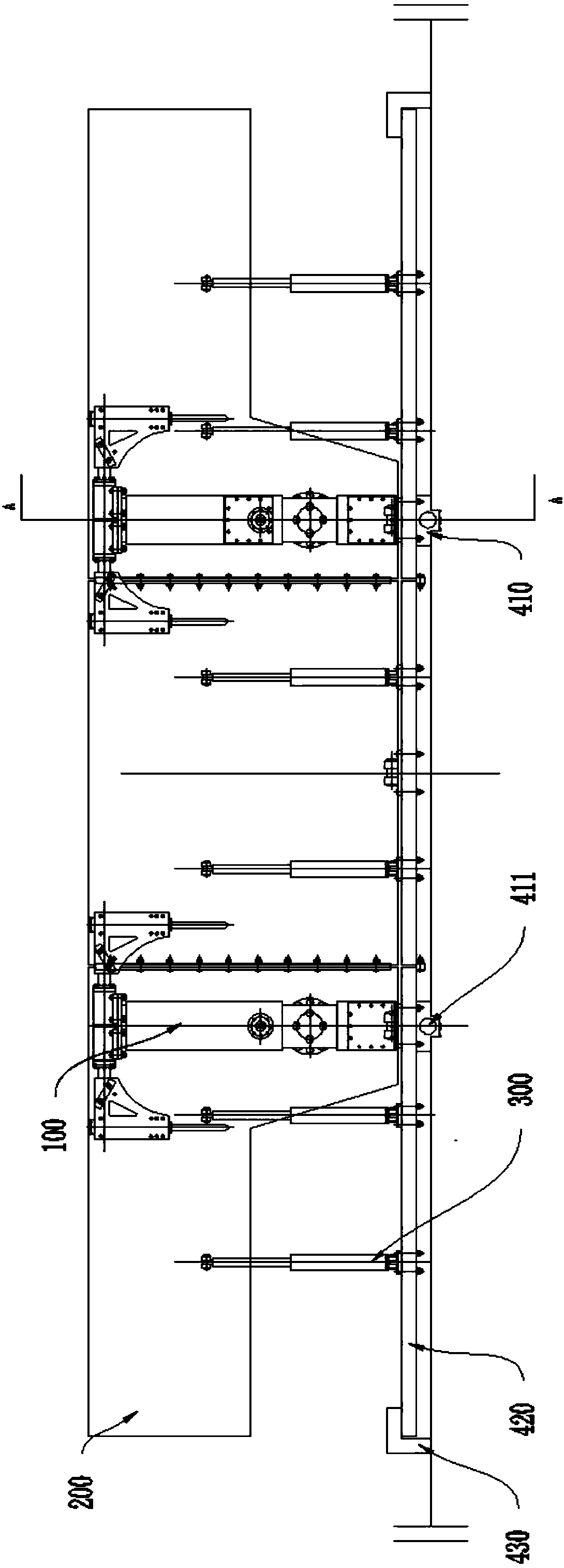

Coal wall side crushing device of coal mining machine with large mining height

ActiveCN107597242AExpand the range of crushingEfficient crushingGrain treatmentsMining engineeringCantilever

The invention discloses a coal wall side crushing device of a coal mining machine with the large mining height. Each crushing mechanism (100) comprises a main frame (110), a large swing oil cylinder (120), small swing oil cylinders (130), a cantilever (140) and crushing hammers (150). Output flanges I (121) of the large swing oil cylinders are connected to the lower ends of the main frames. The cantilevers are connected to the right ends of the main frames. The small swing oil cylinders are mounted on the right sides of the cantilevers. The crushing hammers are connected with output flanges II(131) of the small swing oil cylinders. The coal wall side crushing device further comprises a gangue blocking device (200) and height-adjustment oil cylinders (300). The gangue blocking device is connected to the cylinder walls of the large swing oil cylinders through flanges (122). Piston rods (310) of the height-adjustment oil cylinders are hinged to the gangue blocking device. Cylinder barrels (320) of the height-adjustment oil cylinders are hinged to a fixed seat mechanism (400) located at the upper end of a rack of the coal mining machine. The bottom of the gangue blocking device is hinged to the fixed seat mechanism. The coal wall side crushing device can crush large chunks of coal rock collapsing on the coal rock side wall efficiently, the crushing range is large, the crushing position is accurate, and adjustment is easy.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com