Novel deep hole blasting charging structure

A technology of deep hole blasting and charging, which is applied in the field of blasting, which can solve the problems of inconvenient shipment and processing, increase the amount of explosives, increase operating costs, etc., and achieve the effects of saving operating costs, good blasting and cutting effects, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

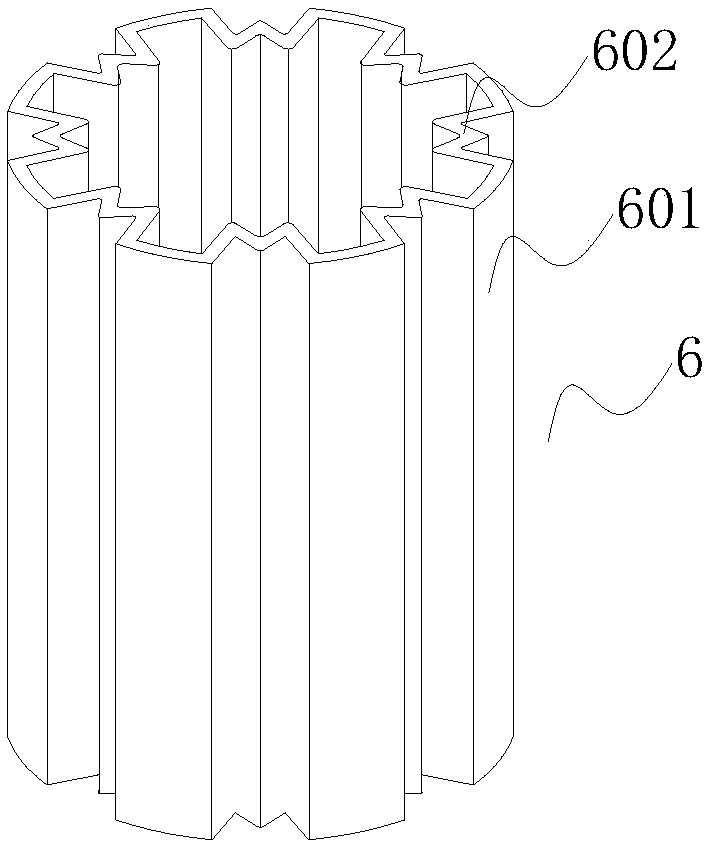

[0022] Implementation 1: see figure 1 , In an embodiment of the present invention, a new type of deep hole blasting charge structure includes a blast hole, and the hole of the blast hole has a packing layer 1; the depth of the packing layer 1 at the hole hole is 2.5-3M. The middle of the packing layer 1 is filled with broken drug packs 101, and the thickness of the broken drug packs 101 accounts for 1 / 6 of the depth of the packing layer 1, and the powder is charged at intervals in the packing layer 1, which can effectively reduce packing and reduce Rock bulk rate; along the direction from top to bottom of the depth of the blast hole, it also includes the blasting water bag 2, the first charge layer 3, the second charge layer 4 and the energy-gathering ring 5 at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com