Multifunctional hydraulic gravel breaking hammer and manufacturing method thereof

A multifunctional, breaking hammer technology, applied in the field of robots, can solve the problems that the breaking hammer cannot quickly capture the force point and impact direction of the crushed object, and the working efficiency of the hydraulic breaking hammer is low, so as to improve the working efficiency of breaking, avoid shaking, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0036] Example 1

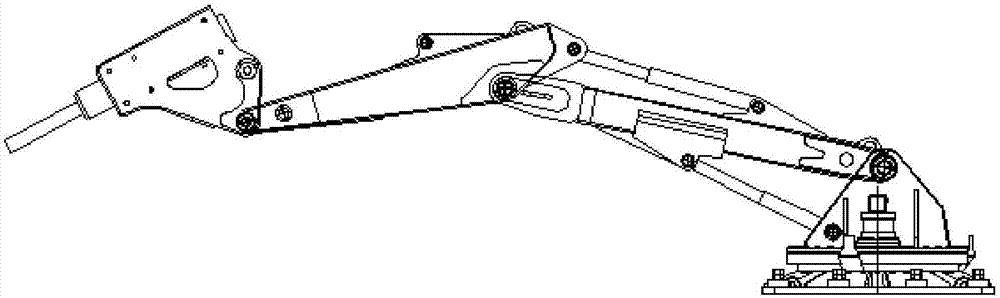

[0037] Such as Figure 1 to Figure 3 As shown, the multifunctional hydraulic rock breaking hammer of this embodiment includes a plane luffing mechanism 1 and a rotating mechanism 2. The plane luffing mechanism 1 includes a boom 110, a boom cylinder 120, a small arm 130, a forearm cylinder 140, a rocker 150, a connecting rod 160, a hydraulic hammer cylinder 170, and a hydraulic hammer 180. The hydraulic hammer 180 adopts a full hydraulic mechanism; The slewing mechanism 2 includes a base 210 and a slewing seat 220, wherein the bottom of the boom 110 is fixed on the slewing seat 220, the cylinder block of the boom cylinder 120 is fixed on the slewing seat 220, the piston rod is hinged with the boom 110, and the arm 130 The middle is hinged to the front end of the boom 110, the cylinder body of the forearm cylinder 140 is hinged to the middle of the boom 110, the piston rod is hinged to the upper end of the forearm 130, and the lower end of the forearm 130 is hin...

Example Embodiment

[0042] Example 2

[0043] The manufacturing method of the multifunctional hydraulic rock crushing hammer of this embodiment includes the following specific steps:

[0044] Step S101. Ingredients: Weigh and mix the components of the big arm or the forearm according to mass percentages, where the component mass percentages are: C: 0.19%, Mn: 0.59%, Si: 0.25%, Co: 0.5% , Cr: 1.4%, V: 1.13%, Ni: 1.02%, S: 0.020%, P: 0.020%, the balance is Fe; the blank of the big arm or forearm passes through the first stage: room temperature~560℃: the blank Heat from room temperature to 560℃, heating time is 60min; second stage: 560℃~780℃: heat the billet from 560℃ to 780℃, control heating time to 20min, hold 80min; third stage: 780℃~1200℃ : Heat the billet from 780°C to 1200°C, control the heating time to 70min, keep the temperature for 45min; the fourth stage: 1200°C~1350°C: Heat the billet from 1200°C to 1350°C, control the heating time to 20min, keep the temperature for 40min, heat treatment Aft...

Example Embodiment

[0049] Example 3

[0050] The manufacturing method of the multifunctional hydraulic rock crushing hammer of this embodiment includes the following specific steps:

[0051] Step S101. Ingredients: Weigh and mix the components of the big arm or the forearm according to mass percentages, where the component mass percentages are: C: 0.20%, Mn: 0.75%, Si: 0.35%, Co: 0.6% , Cr: 1.47%, V: 1.03%, Ni: 1.22%, S: 0.020%, P: 0.020%, the balance is Fe; the blank of the big arm or forearm passes the first stage: room temperature ~ 560℃: the blank Heat from room temperature to 560℃, heating time is 45min; second stage: 560℃~780℃: heat the billet from 560℃ to 780℃, control the heating time to 20min, hold 65min; third stage: 780℃~1200℃ : Heat the billet from 780°C to 1200°C, control the heating time to 65min, hold 40min; the fourth stage: 1200°C~1350°C: Heat the billet from 1200°C to 1350°C, control the heating time to 20min, hold 40min, heat treatment After the blank, there are almost no system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com