Plastic bag crushing and recovering device

A recycling device and plastic bag technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of white pollution, not easy to degrade, not paying attention to the recycling of plastic bags, etc., to expand the crushing range and improve the crushing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

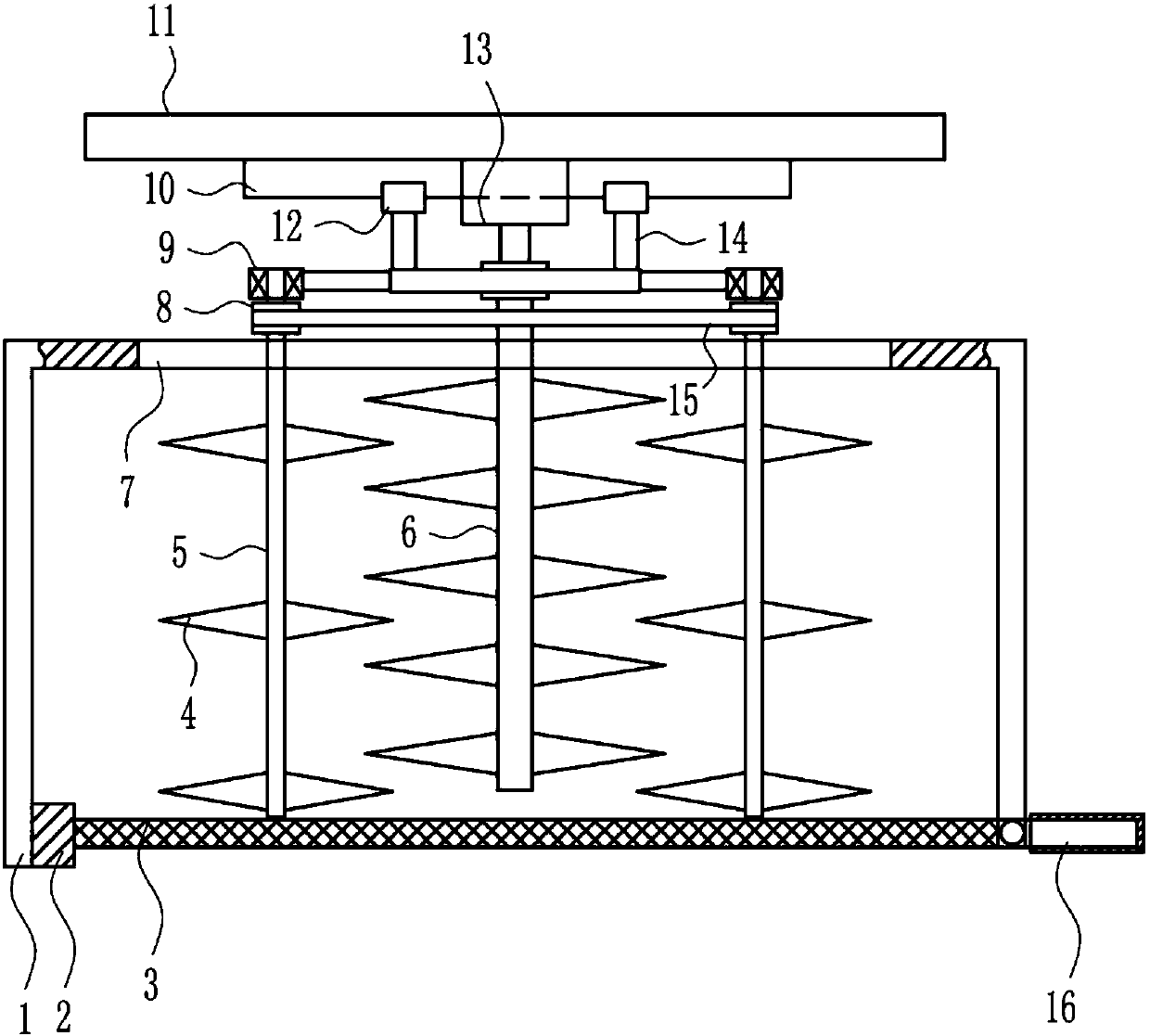

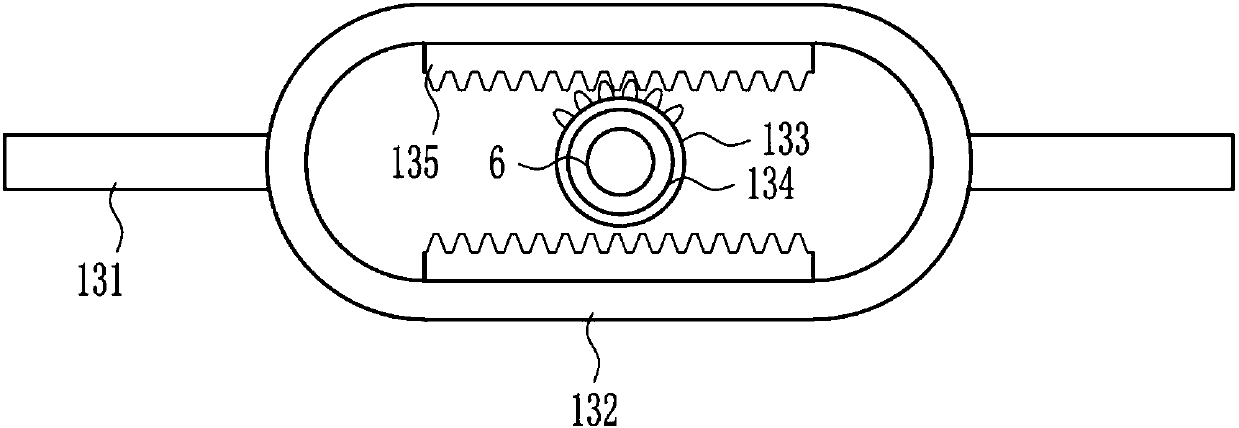

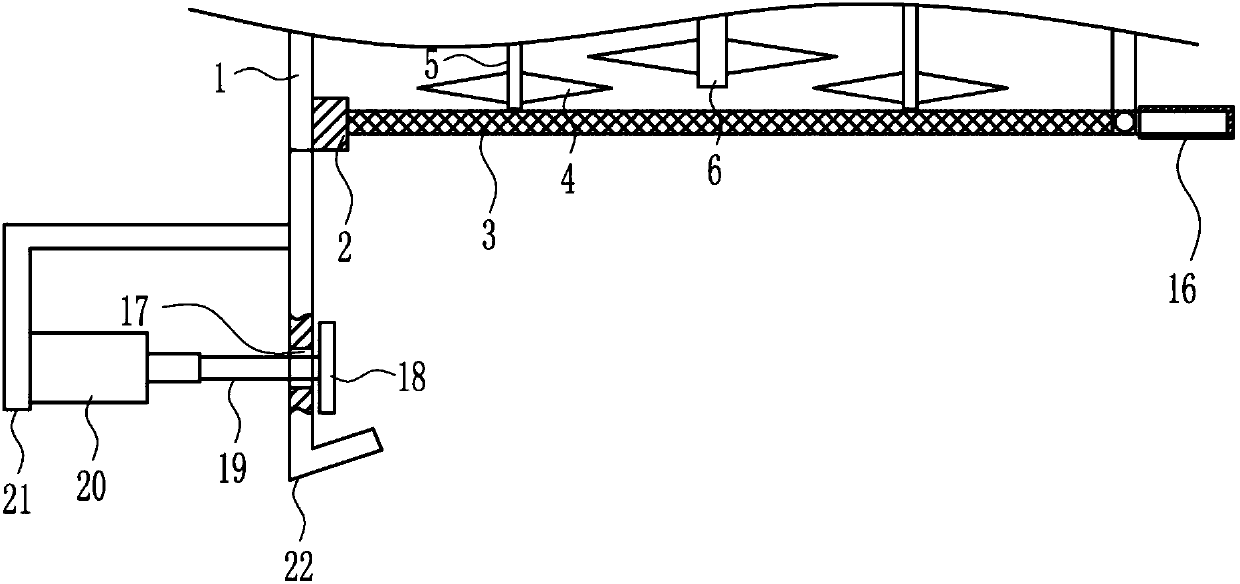

[0031] A plastic bag crushing and recycling device, such as Figure 1-6 As shown, it includes an iron crushing box 1, an electromagnet 2, a mesh plate 3, a crushing knife 4, a first rotating shaft 5, a second rotating shaft 6, an electric wheel 8, a bearing seat 9, a first slide rail 10, a top plate 11, The first slide block 12, linkage 13, pole 14, flat belt 15 and handle 16, a word hole 7 is opened on the top of the iron crushing box 1, and the bottom of the right side of the crushing box is rotatably connected with the net plate 3, and the bottom of the net plate 3 The left end is connected with an electromagnet 2, the right end of the mesh plate 3 is connected with a handle 16, the iron crushing box 1 is provided with a top plate 11, and the bottom of the top plate 11 is provided with a first slide rail 10 and a linkage device 13, the first slide rail 10 Set on the rear side of the linkage device 13, the first slider 12 is symmetrically arranged on the left and right sides o...

Embodiment 2

[0033] A plastic bag crushing and recycling device, such as Figure 1-6 As shown, it includes an iron crushing box 1, an electromagnet 2, a mesh plate 3, a crushing knife 4, a first rotating shaft 5, a second rotating shaft 6, an electric wheel 8, a bearing seat 9, a first slide rail 10, a top plate 11, The first slide block 12, linkage 13, pole 14, flat belt 15 and handle 16, a word hole 7 is opened on the top of the iron crushing box 1, and the bottom of the right side of the crushing box is rotatably connected with the net plate 3, and the bottom of the net plate 3 The left end is connected with an electromagnet 2, the right end of the mesh plate 3 is connected with a handle 16, the iron crushing box 1 is provided with a top plate 11, and the bottom of the top plate 11 is provided with a first slide rail 10 and a linkage device 13, the first slide rail 10 Set on the rear side of the linkage device 13, the first slider 12 is symmetrically arranged on the left and right sides...

Embodiment 3

[0036] A plastic bag crushing and recycling device, such as Figure 1-6 As shown, it includes an iron crushing box 1, an electromagnet 2, a mesh plate 3, a crushing knife 4, a first rotating shaft 5, a second rotating shaft 6, an electric wheel 8, a bearing seat 9, a first slide rail 10, a top plate 11, The first slide block 12, linkage 13, pole 14, flat belt 15 and handle 16, a word hole 7 is opened on the top of the iron crushing box 1, and the bottom of the right side of the crushing box is rotatably connected with the net plate 3, and the bottom of the net plate 3 The left end is connected with an electromagnet 2, the right end of the mesh plate 3 is connected with a handle 16, the iron crushing box 1 is provided with a top plate 11, and the bottom of the top plate 11 is provided with a first slide rail 10 and a linkage device 13, the first slide rail 10 Set on the rear side of the linkage device 13, the first slider 12 is symmetrically arranged on the left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com